Study on the similarity of elasticity and ideal plasticity response of thin plate under impact loading

-

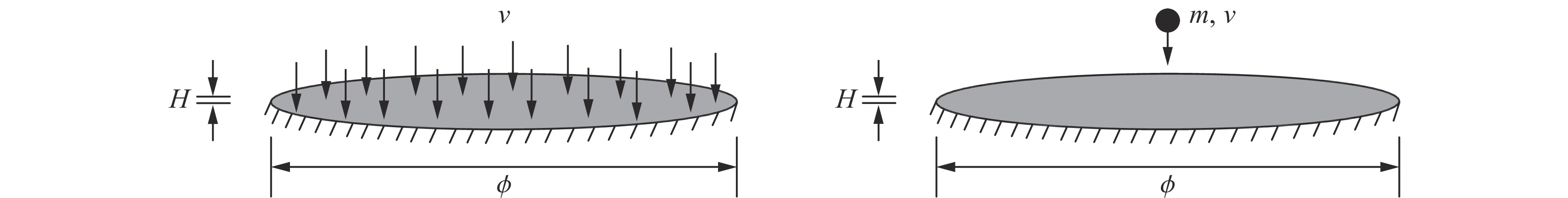

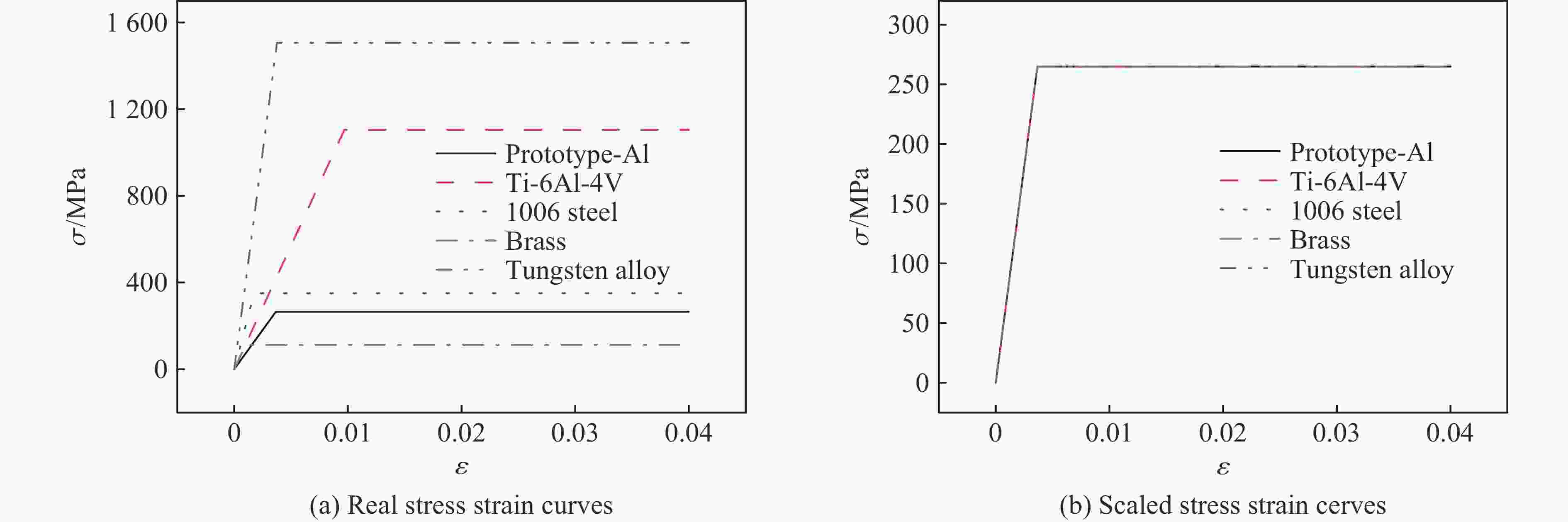

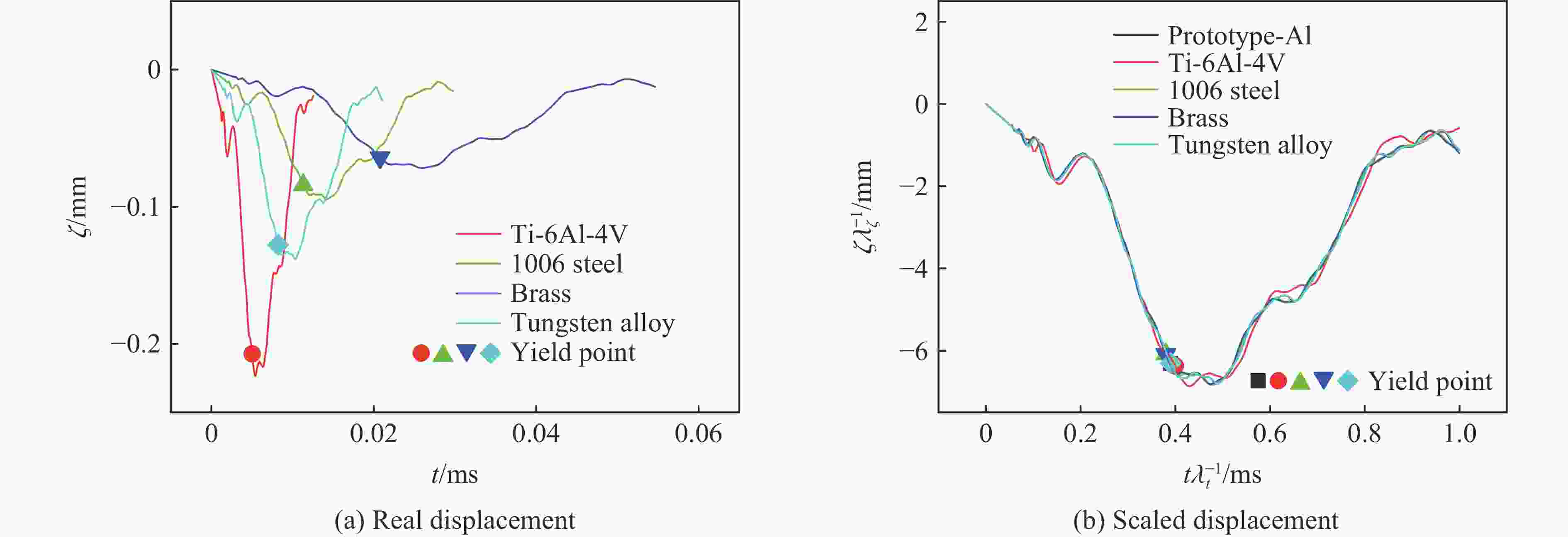

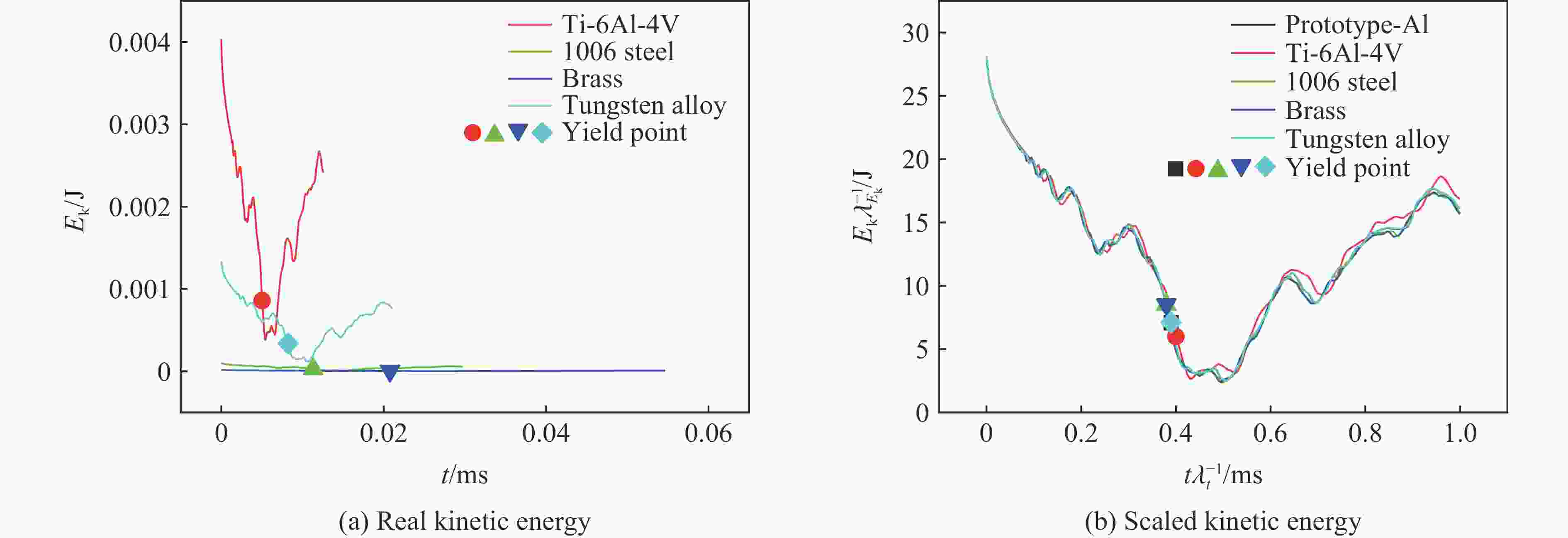

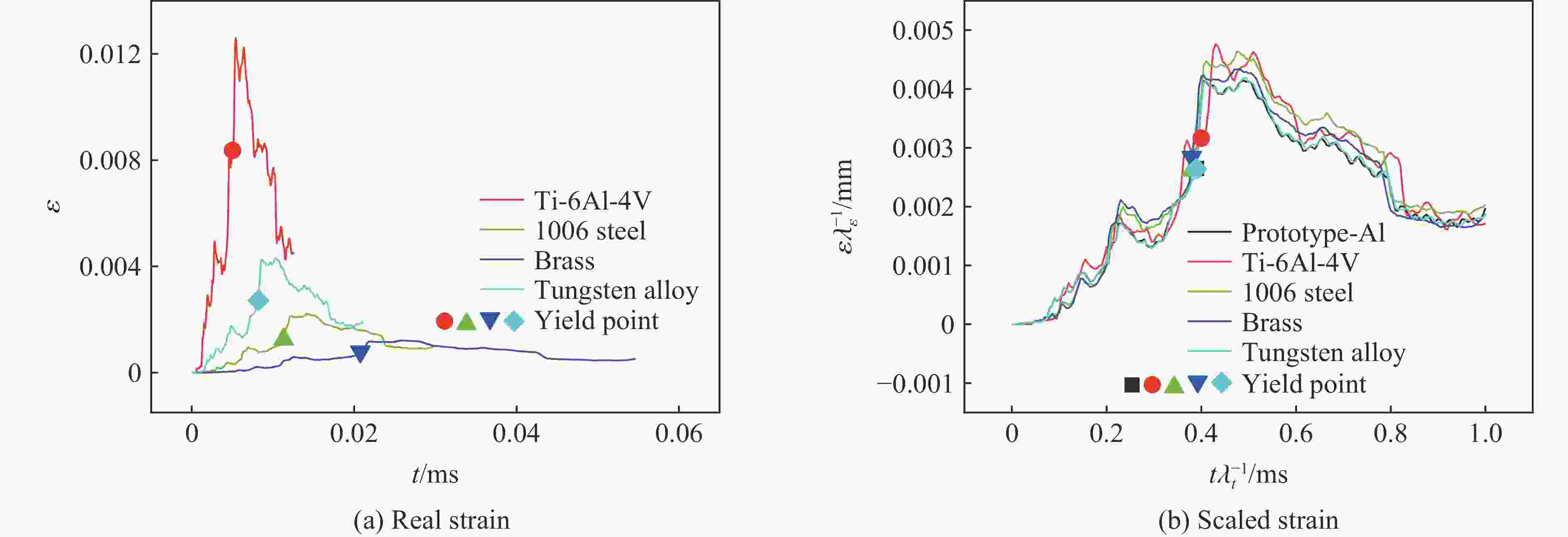

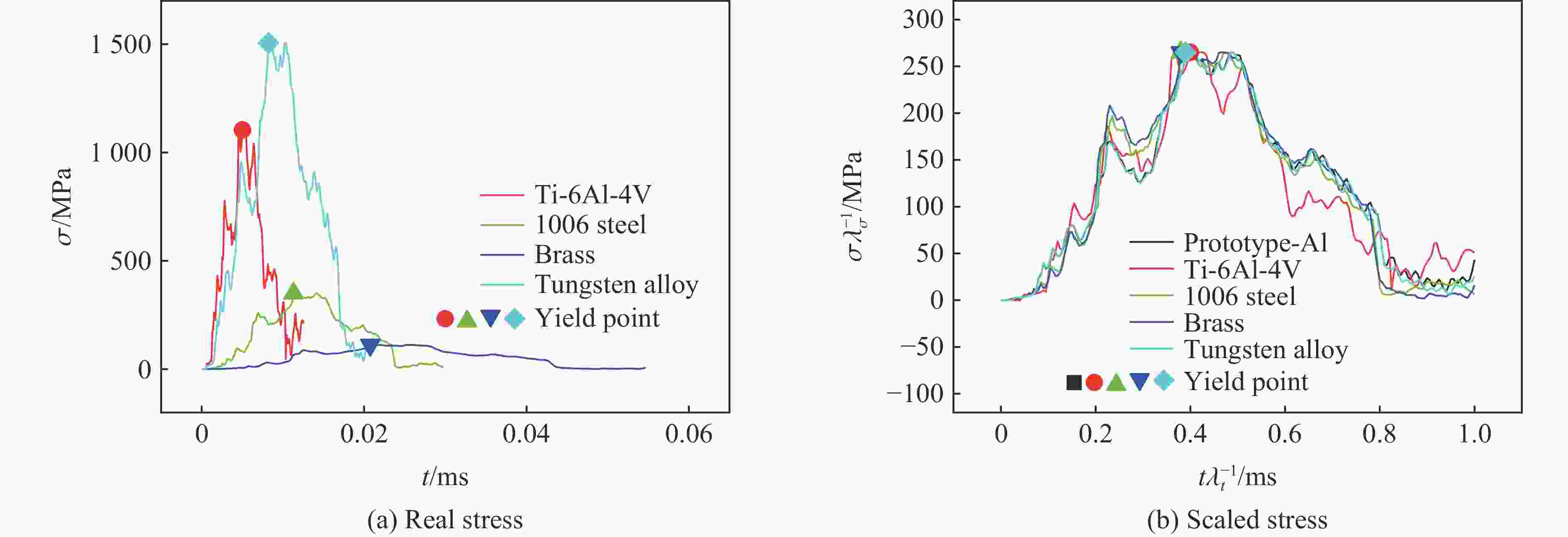

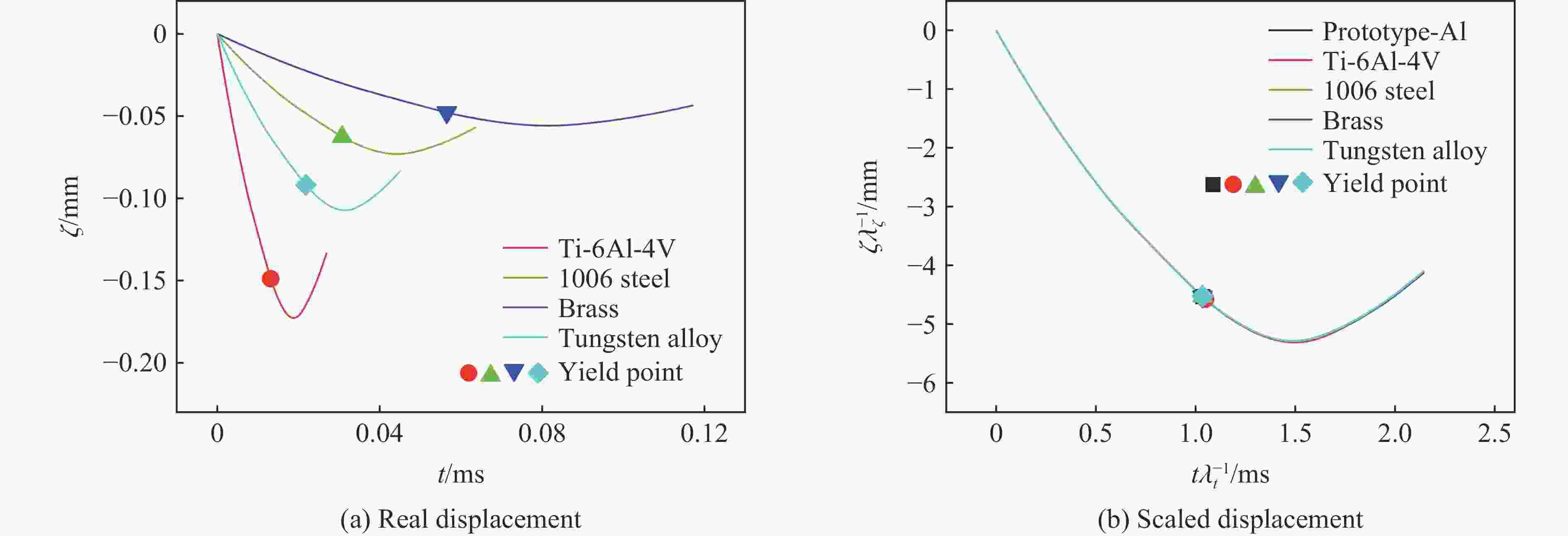

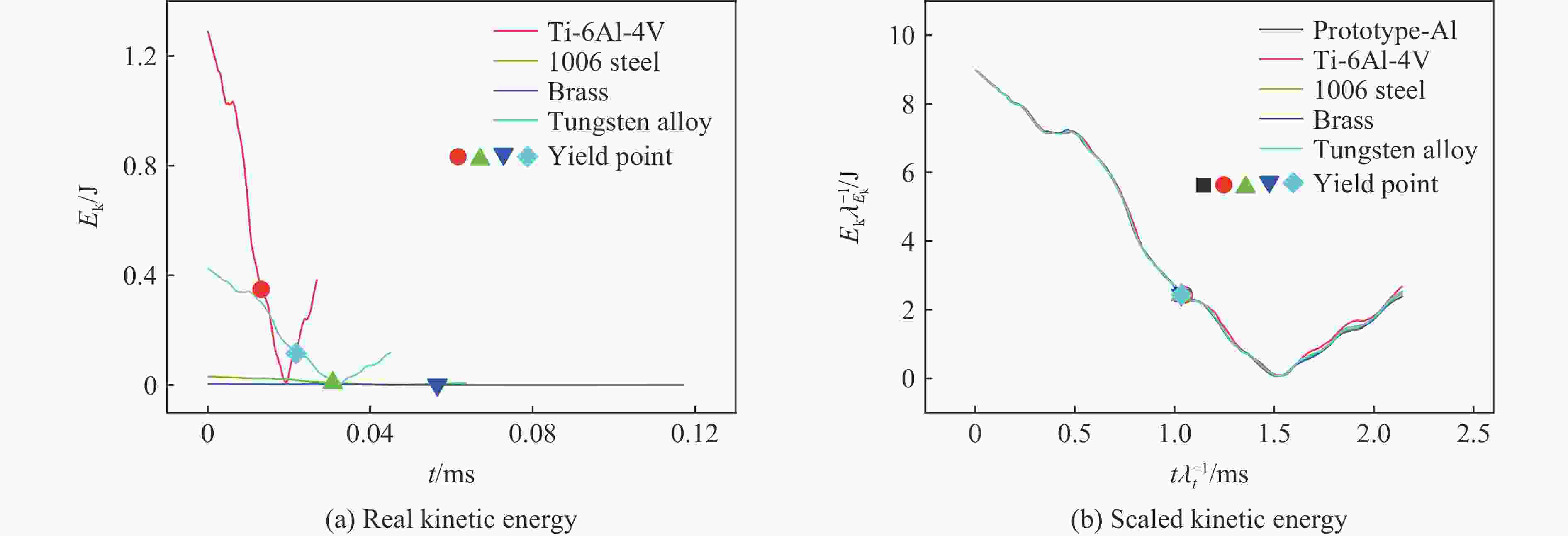

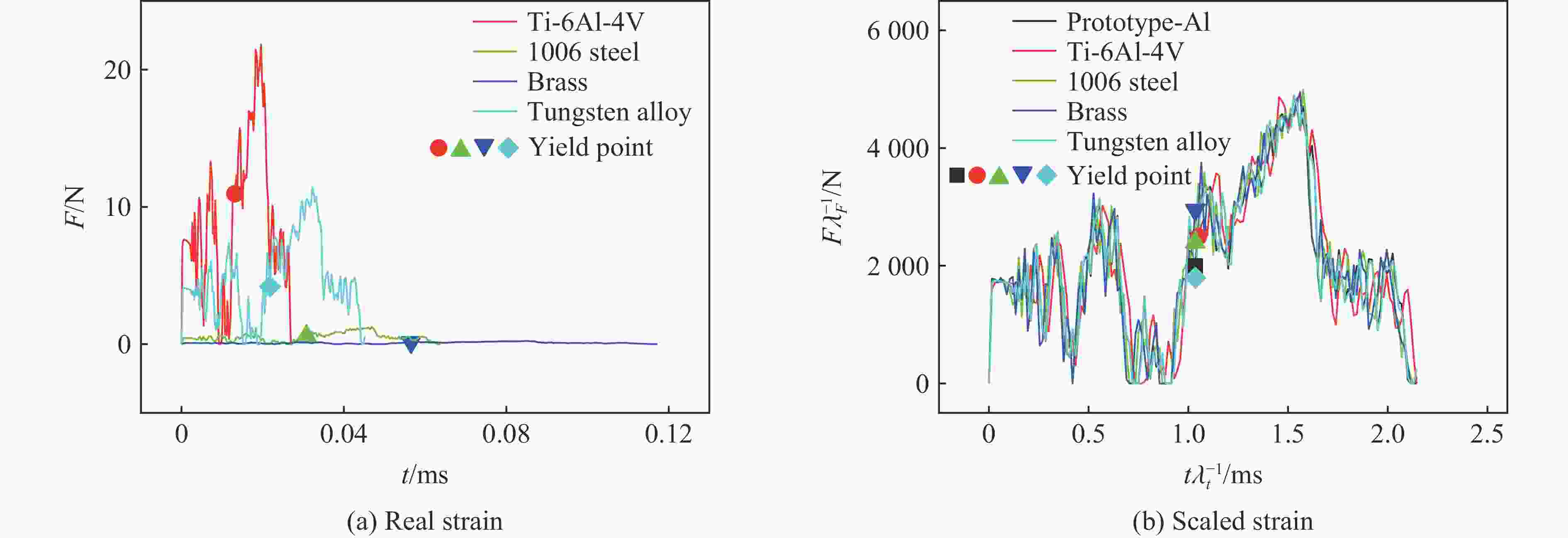

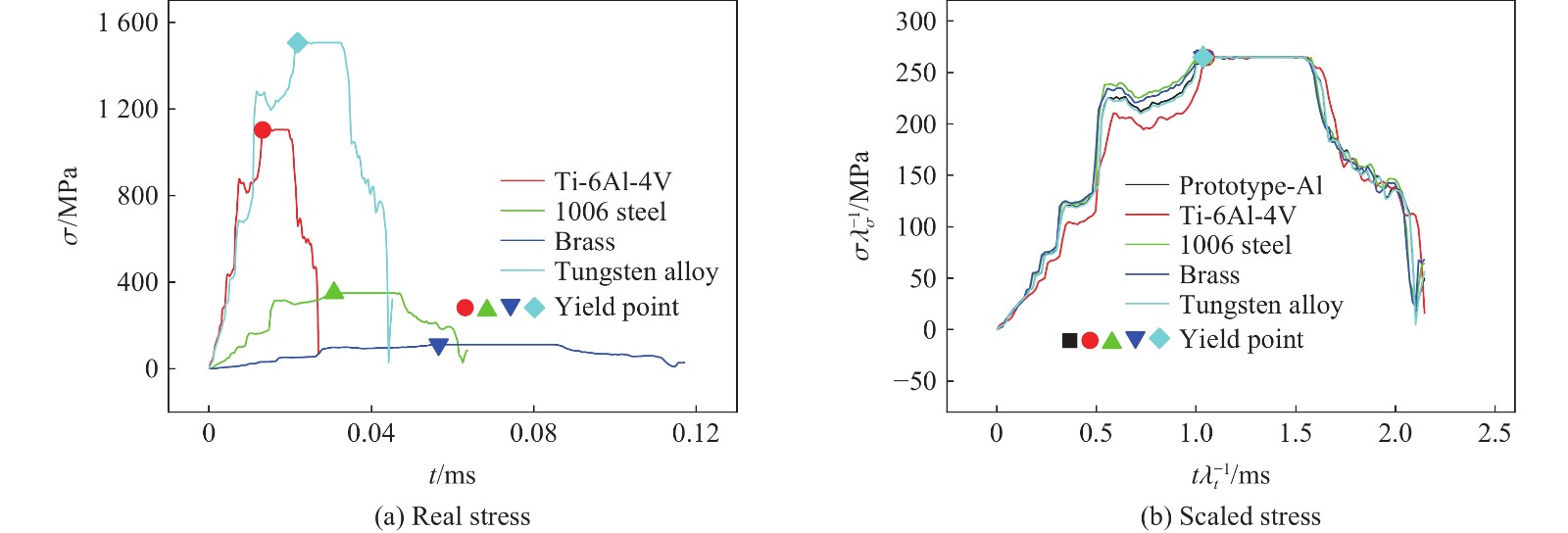

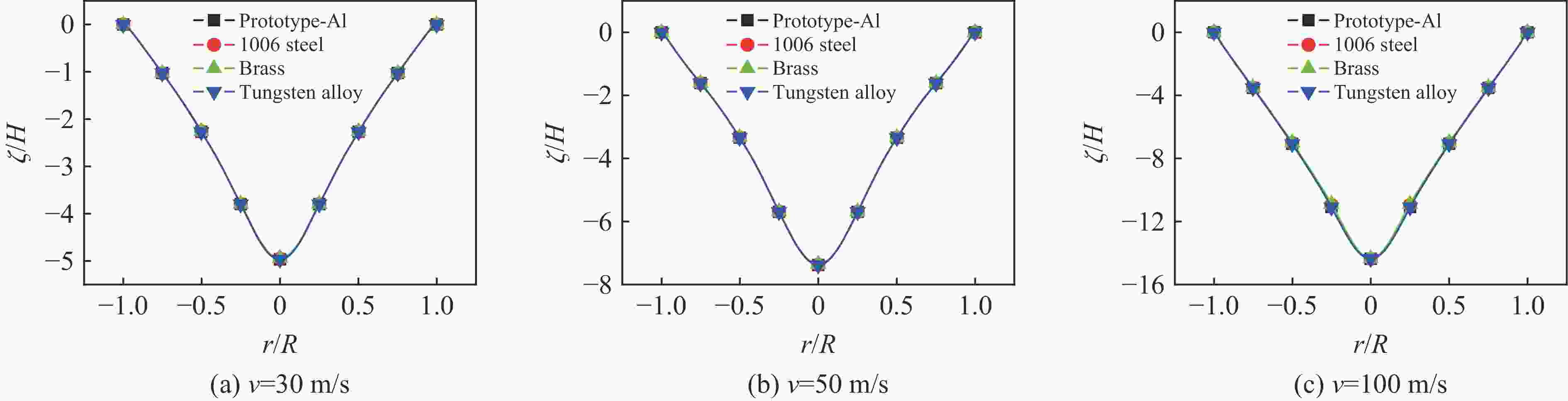

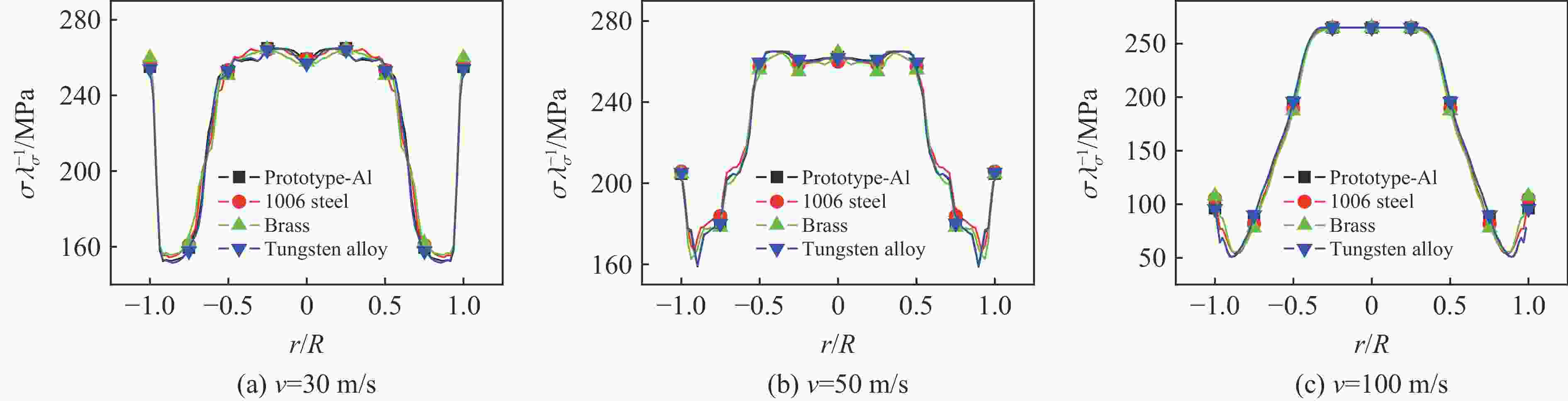

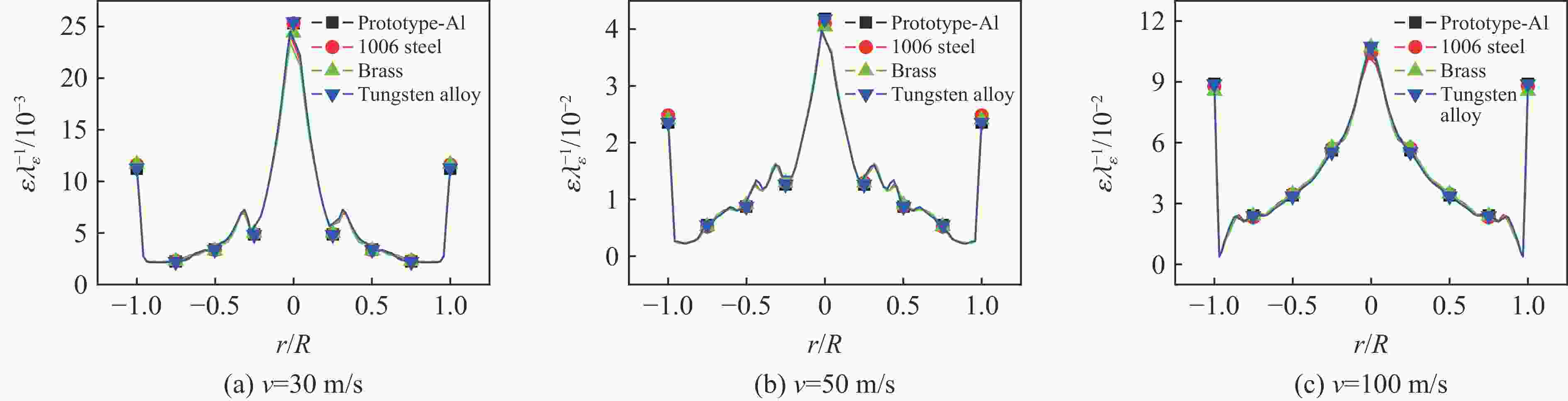

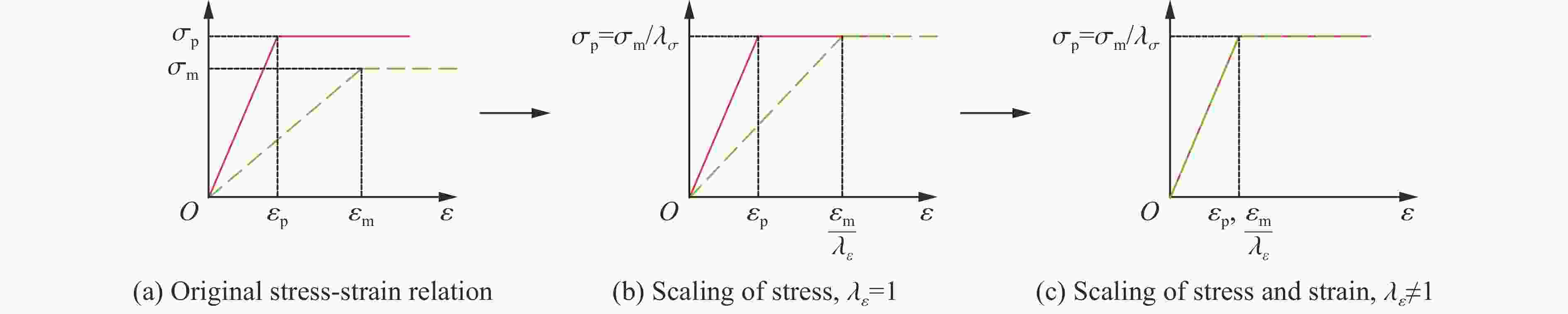

摘要: 对于比例模型和原型使用不同弹塑性材料的冲击相似性问题,由于弹性和塑性阶段材料特性的差别及其在不同变形阶段的弹性塑性共存现象,将导致原有的结构冲击相似性理论失效。基于薄板冲击问题的理论模型,采用方程分析方法重新推导了材料线弹性以及理想刚塑性共存时的冲击响应的相似律。提出了一种能够同时考虑弹性变形和塑性变形的结构缩放响应相似性分析的厚度补偿方法,并利用数值分析验证了提出方法的适用性。分析结果表明,使用厚度补偿方法得到的比例模型结构响应能够准确地预测原型结构的冲击响应。Abstract: For the impact similarity problem of the scaled model and the prototype usually have different materials with elastic and plastic properties, the differences of material properties and the coexistence of elastoplastic in different deformation stages will lead to the failure of the previous impact similarity theory. Based on the theory of the thin plate impact problem, the similarity law of impact response was derived by using the method of equation similarity analysis for the material with the linear elastic and ideal rigid-plastic properties. The basic equations of the thin plate structure, such as the energy conservation equation and the strain-displacement equation, were analyzed using equation similarity analysis methods, and the similarity scaling factor of the ideal elastic-plastic thin plate structure was derived. Based on the equation similarity analysis methods, a thickness compensation method that can simultaneously consider the similarity of elastic deformation and plastic deformation was proposed. For the impact similarity problem of the scaled model and the prototype using different ideal elastoplastic materials, this method can be used to calculate the geometric sizes and load conditions of the scaled model through the material properties when the response of the scaled model is similar to that of the prototype. Two finite element models of circular plate mass impact and circular plate velocity impact were established.The geometric sizes and load conditions of the scaled model were calculated through the thickness compensation method when the prototype uses aluminum alloy and the scaled model uses different materials such as steel, brass, etc. The applicability of the thickness compensation method was verified by the response of prototype and scaled model. The results show that the structural response of the scaled model obtained by the thickness compensation method can accurately predict the impact response of the prototype, even though the scale model and the scale model use different materials.

-

变量 缩放因子 变量 缩放因子 长度,$ L $ $ \lambda ={L}_{\mathrm{m}}/{L}_{\mathrm{p}} $ 位移,$ \delta $ $ {\lambda }_{\delta }=\lambda $ 密度,$ \rho $ $ {\lambda }_{\rho }={\rho }_{\mathrm{m}}/{\rho }_{\mathrm{p}} $ 应力,$ \sigma $ $ {\lambda }_{\sigma }={\lambda }_{\rho }{\lambda }_{v}^{2} $ 速度,$ v $ $ {\lambda }_{v}={v}_{\mathrm{m}}/{v}_{\mathrm{p}} $ 应变,$ \varepsilon $ $ {\lambda }_{\varepsilon }=1 $ 质量,$ m $ $ {{\lambda }_{m}={\lambda }_{\rho }\lambda }^{3} $ 应变率,$ \dot{\varepsilon } $ $ {\lambda }_{\dot{\varepsilon }}={\lambda }_{v}/\lambda $ 时间,$ t $ $ {\lambda }_{t}=\lambda /{\lambda }_{v} $ 力,$ F $ $ {{\lambda }_{F}={\lambda }_{\rho }\lambda }^{2}{\lambda }_{v}^{2} $ 加速度,$a$ ${\lambda }_{a}={\lambda }_{v}^{2}/\lambda$ 能量,${E}_{{\rm{n}}}$ ${ {\lambda }_{ {E}_{{\rm{n}}} }={\lambda }_{\rho }\lambda }^{3}{\lambda }_{v}^{2}$ 注:在表中,比例模型与原型相关的物理量分别用下标m和p表示,$ {\lambda }_{K}={K}_{\mathrm{m}}/{K}_{\mathrm{p}} $表示缩比模型和原型相关物理量的比值,例如${\lambda }_{v}={v}_{\mathrm{m} }/{v}_{\mathrm{p} }$表示比例模型和原型速度的比值,比例模型和原型的几何缩放系数$ \mathrm{\lambda }={L}_{\mathrm{m}}/{L}_{\mathrm{p}} $。 表 2 理想弹塑性薄板结构冲击载荷作用下缩放因子

Table 2. Scaling factors of theideal elastic-plastic thin-plates under impact loading

变量 缩放因子 变量 缩放因子 x, y $ {\lambda }_{x}={\lambda }_{y}={\left({L}_{x}\right)}_{\mathrm{m}}/{\left({L}_{x}\right)}_{\mathrm{p}} $ t $ {\lambda }_{t}={\lambda }_{\zeta }/{\lambda }_{{v}_{\textit{z}}} $ z $ {\lambda }_{\textit{z}}={\lambda }_{x}{\left({\lambda }_{{\sigma }_{\mathrm{Y}}}/{\lambda }_{E}\right)}^{1/2} $ χ, η $ {\lambda }_{\chi }={\lambda }_{\eta }={\lambda }_{x}{\lambda }_{{\sigma }_{\mathrm{Y}}}/{\lambda }_{E} $ $ \rho $ $ {\lambda }_{\rho }={\rho }_{\mathrm{m}}/{\rho }_{\mathrm{p}} $ ζ $ {\lambda }_{\zeta }={\lambda }_{x}{\left({\lambda }_{{\sigma }_{\mathrm{Y}}}/{\lambda }_{E}\right)}^{1/2} $ m $ {{\lambda }_{m}=\mathrm{\lambda }}_{\rho }{\lambda }_{x}{\lambda }_{y}{\lambda }_{\textit{z}} $ $ {v}_{\textit{z}} $ $ {\lambda }_{{v}_{\textit{z}}}={\lambda }_{{\sigma }_{\mathrm{Y}}}{\left({\lambda }_{\rho }{\lambda }_{E}\right)}^{-1/2} $ E $ {\lambda }_{E}={E}_{\mathrm{m}}/{E}_{\mathrm{p}} $ $ {F}_{\textit{z}} $ $ {\lambda }_{{F}_{\textit{z}}}={\lambda }_{M}{\lambda }_{{A}_{\textit{z}}} $ $ {\sigma }_{\mathrm{Y}} $ ${\lambda }_{ {\sigma }_{\mathrm{Y} } }={\left({\sigma }_{{\rm{Y}}}\right)}_{\mathrm{m} }/{\left({\sigma }_{\mathrm{Y} }\right)}_{\mathrm{p} }$ $ {a}_{\textit{z}} $ ${\lambda }_{ {a}_{\textit{z} } }= {\lambda }_{ {v}_{\textit{z} } } ^{2}/{\lambda }_{\zeta }$ $ {\sigma }_{x},{\sigma }_{y} $ $ {\lambda }_{{\sigma }_{x}}={\lambda }_{{\sigma }_{y}}={\lambda }_{{\sigma }_{\mathrm{Y}}} $ $ {\varepsilon }_{x}{,\varepsilon }_{y} $ $ {\lambda }_{{\varepsilon }_{x}}{,\lambda }_{{\varepsilon }_{y}}={\lambda }_{{\sigma }_{\mathrm{Y}}}/{\lambda }_{E} $ $ {\tau }_{xy} $ $ {\lambda }_{{\tau }_{xy}}={\lambda }_{{\sigma }_{\mathrm{Y}}} $ $ {\gamma }_{xy} $ ${\lambda }_{ {\gamma }_{xy} }={\lambda }_{ {\sigma }_{{\rm{Y}}} }/{\lambda }_{E}$ 表 3 圆板材料属性

Table 3. Material properties of circular plate

材料 密度/(kg·m−3) 弹性模量/GPa 屈服强度/MPa 原型铝 2.70 72.4 265 Ti-6Al-4V 4.43 114 1104 1006钢 7.89 200 350 黄铜 8.52 110 112 钨合金 17.0 400 1506 表 4 模型缩放系数

Table 4. Scaling factors of themodels

$ {\lambda }_{x} $ 模型材料 $ {\lambda }_{\rho } $ $ {\lambda }_{E} $ $ {\lambda }_{\sigma } $ ${\lambda }_{\varepsilon }$ $ {\lambda }_{\textit{z}} $ $ {\lambda }_{{v}_{\textit{z}}} $ $ {\lambda }_{t} $ 1 原型铝 1 1 1 1 1 1 1 1/50 Ti-6Al-4V 1.64 1.57 4.17 2.65 0.0325 2.59 0.0126 1/50 1006钢 2.92 2.76 1.32 0.48 0.0138 0.46 0.0298 1/50 黄铜 3.16 1.52 0.42 0.28 0.0106 0.19 0.0547 1/50 钨合金 6.30 5.52 5.68 1.03 0.0203 0.96 0.0211 -

[1] CASABURO A, PETRONE G, FRANCO F, et al. A review of similitude methods for structural engineering [J]. Applied Mechanics Reviews, 2019, 71(3): 030802. DOI: 10.1115/1.4043787. [2] COUTINHO C P, BAPTISTA A J, RODRIGUES J D. Reduced scale models based on similitude theory: a review up to 2015 [J]. Engineering Structures, 2016, 119: 81–94. DOI: 10.1016/j.engstruct.2016.04.016. [3] JONES N. Structural impact [M]. 2nd ed. New York: Cambridge University Press, 2011. [4] ALVES M, OSHIRO R E. Scaling impacted structures when the prototype and the model are made of different materials [J]. International Journal of Solids and Structures, 2006, 43(9): 2744–2760. DOI: 10.1016/j.ijsolstr.2005.03.003. [5] 秦健, 张振华. 原型和模型不同材料时加筋板冲击动态响应的相似预报方法 [J]. 爆炸与冲击, 2010, 30(5): 511–516. DOI: 10.11883/1001-1455(2010)05-0511-06.QIN J, ZHANG Z H. A scaling method for predicting dynamic responses of stiffened plates made of materials different from experimental models [J]. Explosion and Shock Waves, 2010, 30(5): 511–516. DOI: 10.11883/1001-1455(2010)05-0511-06. [6] MAZZARIOL L M, OSHIRO R E, ALVES M. A method to represent impacted structures using scaled models made of different materials [J]. International Journal of Impact Engineering, 2016, 90: 81–94. DOI: 10.1016/j.ijimpeng.2015.11.018. [7] SADEGHI H, DAVEY K, DARVIZEH R, et al. A scaled framework for strain rate sensitive structures subjected to high rate impact loading [J]. International Journal of Impact Engineering, 2019, 125: 229–245. DOI: 10.1016/j.ijimpeng.2018.11.008. [8] WANG S, XU F, DAI Z. Suggestion of the DLV dimensionless number system to represent the scaled behavior of structures under impact loads [J]. Archive of Applied Mechanics, 2020, 90(4): 707–719. DOI: 10.1007/s00419-019-01635-9. [9] 王帅, 徐绯, 代震, 等. 结构冲击畸变问题的直接相似方法研究 [J]. 力学学报, 2020, 52(3): 774–786. DOI: 10.6052/0459-1879-19-327.WANG S, XU F, DAI Z, et al. A direct scaling method for the distortion problems of structural impact [J]. Chinese Journal of Theoretical and Applied Mechanics, 2020, 52(3): 774–786. DOI: 10.6052/0459-1879-19-327. [10] MAZZARIOL L M, ALVES M. Similarity laws of structures under impact load: geometric and material distortion [J]. International Journal of Mechanical Sciences, 2019, 157−158: 633–647. DOI: 10.1016/j.ijmecsci.2019.05.011. [11] WANG S, XU F, ZHANG X Y, et al. Suggestion of a framework of similarity laws for geometric distorted structures subjected to impact loading [EB/OL]. Preprint (2020-02-25) [2020-10-09]. https://www.preprints.org/manuscript/202002.0394/v1. DOI: 10.20944/preprints202002.0394.v1. [12] WU J J. Prediction of the dynamic characteristics of an elastically supported full-size flat plate from those of its complete-similitude scale model [J]. Computers & Structures, 2006, 84(3−4): 102–114. DOI: 10.1016/j.compstruc.2005.09.033. [13] COUTINHO C P, BAPTISTA A J, RODRIGES J D. Modular approach to structural similitude [J]. International Journal of Mechanical Sciences, 2018, 135: 294–312. DOI: 10.1016/j.ijmecsci.2017.11.005. [14] REDDY J N. Theory and analysis of elastic plates and shells [M]. 2nd ed. London: CRC Press, 2007. [15] 张培信. 能量理论结构力学 [M]. 上海: 上海科学技术出版社, 2010. -

下载:

下载: