Study on explosion-resistance performance of concrete-filled steel tubular columns considering the influence of elevated temperatures

-

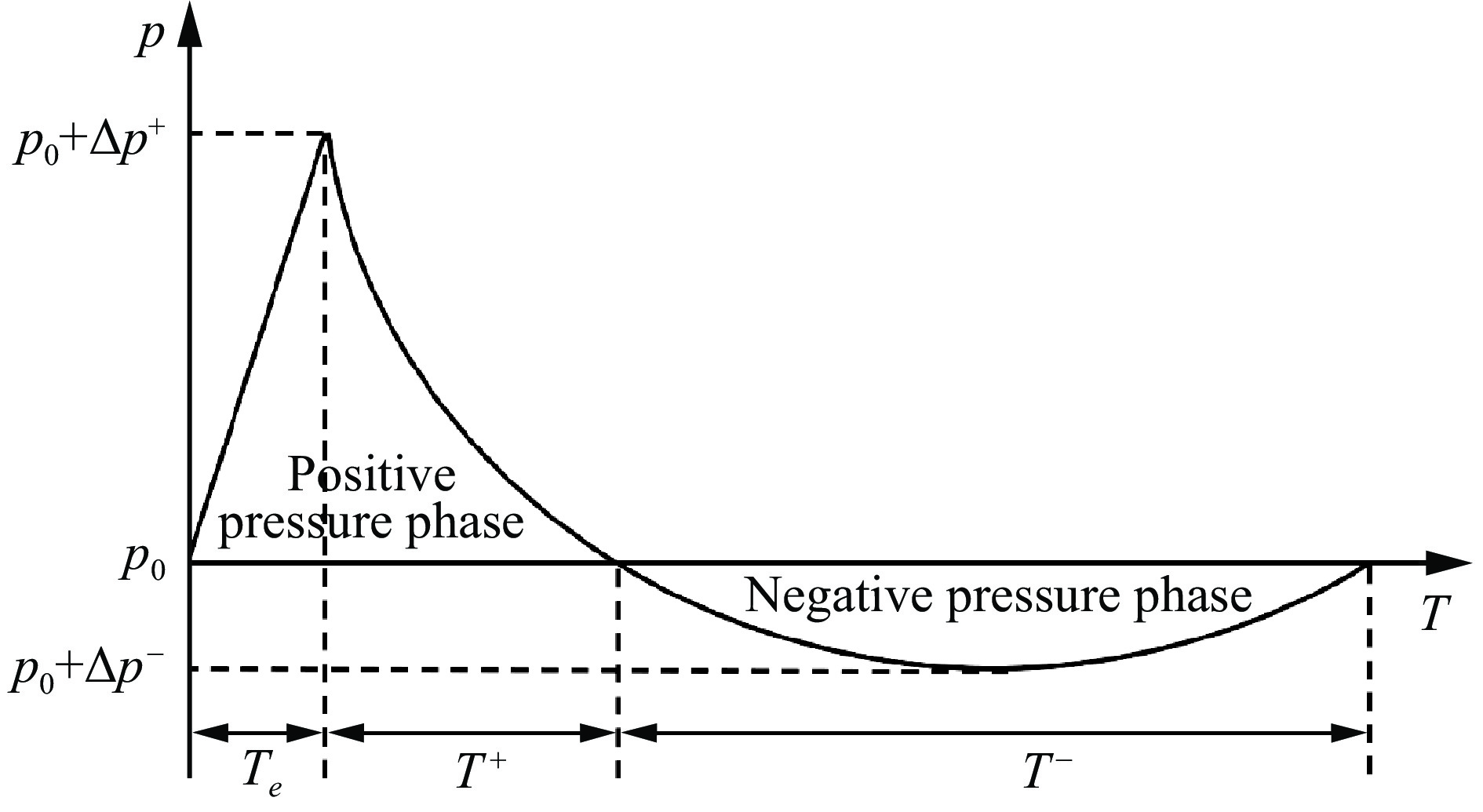

摘要: 火灾与爆炸通常相伴发生,对工程结构安全造成了严重威胁。为研究高温下钢管混凝土柱抗爆性能,采用ABAQUS有限元软件建立了ISO 834标准火灾作用下钢管混凝土柱抗爆模型。在验证有限元模型可靠性基础上,首先分析了标准火灾作用下钢管混凝土柱抗爆工作机理;其次重点研究了受火时间、材料强度、含钢率以及爆炸当量对构件在标准火灾下抗爆性能的影响。研究结果表明:火灾作用下两端固结的钢管混凝土柱受爆炸荷载时,柱两端首先发生剪切破坏,随后整体发生受弯破坏;随着受火时间增加,钢管耗能占比降低,混凝土塑性变形逐渐成为主要耗能机制;混凝土强度、爆炸当量与轴压比对钢管混凝土柱高温下抗爆性能影响明显,当混凝土立方体抗压强度从30 MPa增加到50 MPa,常温与受火90 min构件抗爆性能分别提高约21%与42%。Abstract: Fire and explosion often occur together that seriously threatens the safety of engineering structures. In order to investigate the explosion resistance of concrete-filled steel tubular (CFST) columns at elevated temperatures, the finite element (FE) model of explosion resistance performance for circular CFST columns at elevated temperatures was established using the ABAQUS software. The fire and blast loads were simulated using ISO 834 standard fire and ConWep model, respectively. In the model, the static implicit and dynamic explicit analysis was coupled using “Restart” and “Import” commands and the strain-rate effect was considered. The experiment results of related literatures, including the temperature field, fire resistance duration and explosion resistance of CFST columns, were used to verify the feasibility of the method. Based on the validated FE models, the explosion mechanism of CFST columns subjected to standard fire was analyzed, including the failure modes, full-range analysis, development of stress and strain, interaction between steel tube and concrete and energy consumption. The influence of duration time, material strength, steel ratio and explosion equivalent on the explosion resistance were studied. The maximum mid-span deflection (Δpeak) was employed to quantitatively analyze the explosion-resistance performance of the CFST columns. The results show that shear failure firstly occurs at both fixed ends, and then the whole column presents flexural failure mode when subjected to explosion load under fire condition. With the increase of duration time, the proportion of energy consumption of steel tube decreases, and plastic deformation of concrete gradually becomes the main energy consumption mechanism. The concrete strength, explosion equivalent and axial load ratio have significant influence on the explosion resistance of CFST at high temperatures. After 0 min and 90 min fire duration, the explosion resistance is improved by approximately 21% and 42% respectively when the concrete cubic compressive strength increases from 30 MPa to 50 MPa.

-

表 1 高温下钢材力学性能指标折减系数[11]

Table 1. Reduction coefficient of mechanical properties of steel under various temperatures[11]

温度/℃ Es(T)/Es0 fy(T)/fy0 fp(T)/fy0 温度/℃ Es(T)/Es0 fy(T)/fy0 fp(T)/fy0 温度/℃ Es(T)/Es0 fy(T)/fy0 fp(T)/fy0 20 1.000 1.000 1.000 500 0.600 0.780 0.360 1000 0.045 0.040 0.025 100 1.000 1.000 1.000 600 0.310 0.470 0.180 1100 0.023 0.020 0.013 200 0.900 1.000 0.807 700 0.130 0.230 0.075 1200 0.000 0.000 0.000 300 0.800 1.000 0.613 800 0.090 0.110 0.050 400 0.700 1.000 0.420 900 0.067 0.060 0.038 注:表中Es0、fy0与fp0分别为钢材在常温下的弹性模量、屈服强度与比例极限。 表 2 试验与模拟位移比值

Table 2. Ratio of experimental to numerical deformation

试件 位移/mm 模拟值/试验值 模拟值 试验值 S2 27.9 25.2 1.11 S10 136.5 119.9 1.14 13-T1-5CF 180.7 173.1 1.04 13-T2-5CF 251.5 279.0 0.90 表 3 典型构件详细参数

Table 3. Detailed parameters of typical specimens

构件编号 W/kg R/m Z/(m·kg−1/3) t0/min F-00 500 4 0.5 0 F-30 30 F-60 60 F-90 90 注:W为爆炸当量;R为物体与爆心的距离;Z为比例距离;t0为受火时间。 -

[1] SONG L, IZZUDDIN B A, ELNASHAI A S, et al. An integrated adaptive environment for fire and explosion analysis of steel frames: Part I: analytical models [J]. Journal of Constructional Steel Research, 2000, 53(1): 63–85. DOI: 10.1016/S0143-974X(99)00040-1. [2] IZZUDDIN B A, SONG L, ELNASHAI A S, et al. An integrated adaptive environment for fire and explosion analysis of steel frames: Part II: verification and application [J]. Journal of Constructional Steel Research, 2000, 53(1): 87–111. DOI: 10.1016/S0143-974X(99)00041-3. [3] LIEW J Y R, CHEN H. Explosion and fire analysis of steel frames using fiber element approach [J]. Journal of Structural Engineering, 2004, 130(7): 991–1000. DOI: 10.1061/(ASCE)0733-9445(2004)130:7(991). [4] CHEN H, LIEW J Y. Explosion and fire analysis of steel frames using mixed element approach [J]. Journal of Engineering Mechanics, 2005, 131(6): 606–616. DOI: 10.1061/(ASCE)0733-9399(2005)131:6(606). [5] 方秦, 赵建魁, 陈力. 爆炸与火荷载联合作用下钢梁耐火极限的数值分析 [J]. 土木工程学报, 2010, 43(S2): 62–68. DOI: 10.15951/j.tmgcxb.2010.s2.031.FANG Q, ZHAO J K, CHEN L. Numerical simulation of fire resistance of steel beams subjected to blast and fire [J]. China Civil Engineering Journal, 2010, 43(S2): 62–68. DOI: 10.15951/j.tmgcxb.2010.s2.031. [6] 赵建魁, 方秦, 陈力, 等. 爆炸与火荷载联合作用下RC梁耐火极限的数值分析 [J]. 天津大学学报(自然科学与工程技术版), 2015, 48(10): 873–880. DOI: 10.11784/tdxbz201312027.ZHAO J K, FANG Q, CHEN L, et al. Numerical analysis of fire resistance of RC beams subjected to explosion and fire load [J]. Journal of Tianjin University (Science and Technology), 2015, 48(10): 873–880. DOI: 10.11784/tdxbz201312027. [7] ZHAI C C, CHEN L, XIANG H B, et al. Experimental and numerical investigation into RC beams subjected to blast after exposure to fire [J]. International Journal of Impact Engineering, 2016, 97: 29–45. DOI: 10.1016/j.ijimpeng.2016.06.004. [8] 陈万祥, 郭志昆, 邹慧辉, 等. 标准火灾后钢管RPC柱抗近距离爆炸荷载的试验研究 [J]. 工程力学, 2017, 34(1): 180–191. DOI: 10.6052/j.issn.1000-4750.2015.07.0537.CHEN W X, GUO Z K, ZOU H H, et al. Near-field blast-resistant test of reactive powder concrete filled steel tubular column after exposure to standard fire [J]. Engineering Mechanics, 2017, 34(1): 180–191. DOI: 10.6052/j.issn.1000-4750.2015.07.0537. [9] 邹慧辉, 陈万祥, 郭志昆, 等. 火灾后钢管RPC柱抗爆动力响应数值模拟研究 [J]. 振动与冲击, 2019, 38(21): 155–163,171. DOI: 10.13465/j.cnki.jvs.2019.21.022.ZOU H H, CHEN W X, GUO Z K, et al. Numerical simulation for anti-blast dynamic response of fire-damaged RPC-filled steel tube columns [J]. Journal of Vibration and Shock, 2019, 38(21): 155–163,171. DOI: 10.13465/j.cnki.jvs.2019.21.022. [10] RUAN Z, CHEN L, FANG Q. Numerical investigation into dynamic responses of RC columns subjected for fire and blast [J]. Journal of Loss Prevention in the Process Industries, 2015, 34: 10–21. DOI: 10.1016/j.jlp.2015.01.009. [11] British Standard Institution. Design of steel structures: part 1−2: general rules-structural fire design: EN 1993-1-2: 2005 [S]. London: British Standard Institution, 2005. [12] LIE T T, KODUR V K R. Fire resistance of steel columns filled with bar-reinforced concrete [J]. Journal of Structural Engineering, 1996, 122(1): 30–36. DOI: 10.1061/(ASCE)0733-9445(1996)122:1(30). [13] HONG S, VARMA A H. Analytical modeling of the standard fire behavior of loaded CFT columns [J]. Journal of Constructional Steel Research, 2009, 65(1): 54–69. DOI: 10.1016/j.jcsr.2008.04.008. [14] LI M H, ZONG Z H, LIU L, et al. Experimental and numerical study on damage mechanism of CFDST bridge columns subjected to contact explosion [J]. Engineering Structures, 2018, 159: 265–276. DOI: 10.1016/j.engstruct.2018.01.006. [15] CHEN L, FANG Q, JIANG X Q, et al. Combined effects of high temperature and high strain rate on normal weight concrete [J]. International Journal of Impact Engineering, 2015, 86: 40–56. DOI: 10.1016/j.ijimpeng.2015.07.002. [16] 刘发起. 三面受火的矩形钢管混凝土柱抗火性能研究 [D]. 哈尔滨: 哈尔滨工业大学, 2010. DOI: 10.7666/d.D264694.LIU F Q. Fire resistance of concrete filled RHS columns under three-surface fire loading [D]. Harbin: Harbin Institute of Technology, 2010. DOI: 10.7666/d.D264694. [17] 韩林海. 钢管混凝土结构——理论与实践 [M]. 3版. 北京: 科学出版社, 2016.HAN L H. Concrete filled steel tubular structures—theory and practice [M]. 3rd ed. Beijing: Science Press, 2016. [18] DING J, WANG Y C. Realistic modelling of thermal and structural behaviour of unprotected concrete filled tubular columns in fire [J]. Journal of Constructional Steel Research, 2008, 64(10): 1086–1092. DOI: 10.1016/j.jcsr.2007.09.014. [19] 李国强, 瞿海雁, 杨涛春, 等. 钢管混凝土柱抗爆性能试验研究 [J]. 建筑结构学报, 2013, 34(12): 69–76. DOI: 10.14006/j.jzjgxb.2013.12.010.LI G Q, QU H Y, YANG T C, et al. Experimental study of concrete-filled steel tubular columns under blast loading [J]. Journal of Building Structures, 2013, 34(12): 69–76. DOI: 10.14006/j.jzjgxb.2013.12.010. [20] RITCHIE C B, PACKER J A, SEICA M V et al. Behaviour and analysis of concrete-filled rectangular hollow sections subject to blast loading [J]. Journal of Constructional Steel Research, 2018, 147: 340–359. DOI: 10.1016/j.jcsr.2018.04.027. [21] ALBRIFKANI S, WANG Y C. Explicit modelling of large deflection behaviour of restrained reinforced concrete beams in fire [J]. Engineering Structures, 2016, 121: 97–119. DOI: 10.1016/j.engstruct.2016.04.032. [22] WANG R, HAN L H, ZHAO X L, et al. Experimental behavior of concrete filled double steel tubular (CFDST) members under low velocity drop weight impact [J]. Thin-Walled Structures, 2015, 97: 279–295. DOI: 10.1016/j.tws.2015.09.009. [23] ZHAO H, WANG R, HOU C C, et al. Performance of circular CFDST members with external stainless steel tube under transverse impact loading [J]. Thin-Walled Structures, 2019, 145: 106380. DOI: 10.1016/j.tws.2019.106380. -

下载:

下载: