Multi-scale simulation study on characteristics of free surface velocity curve in ductile metal spallation

-

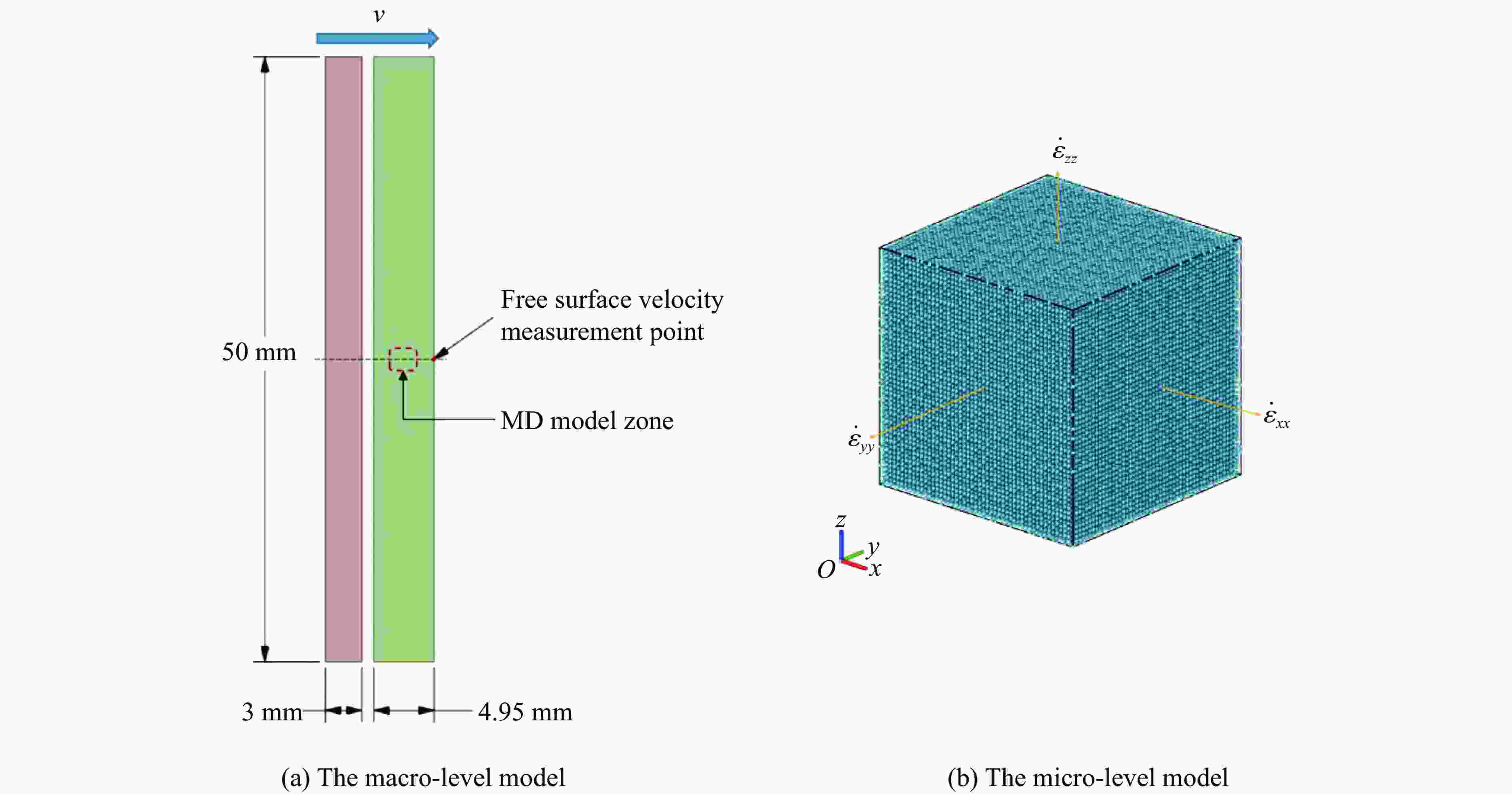

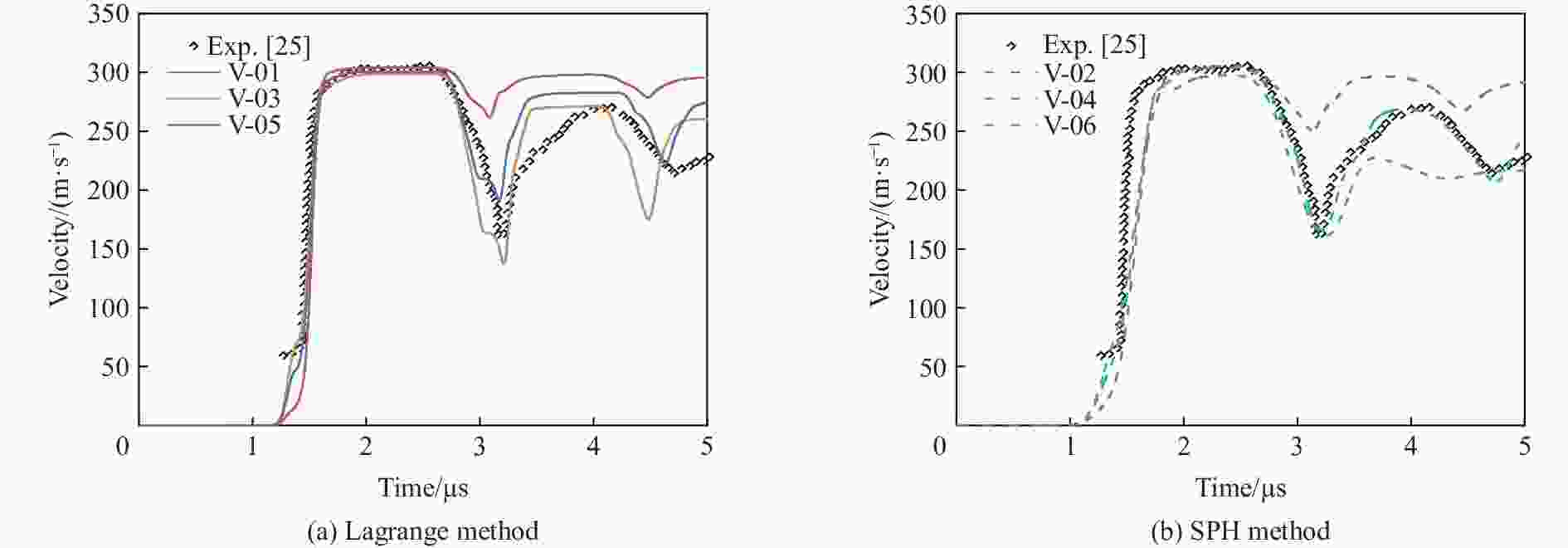

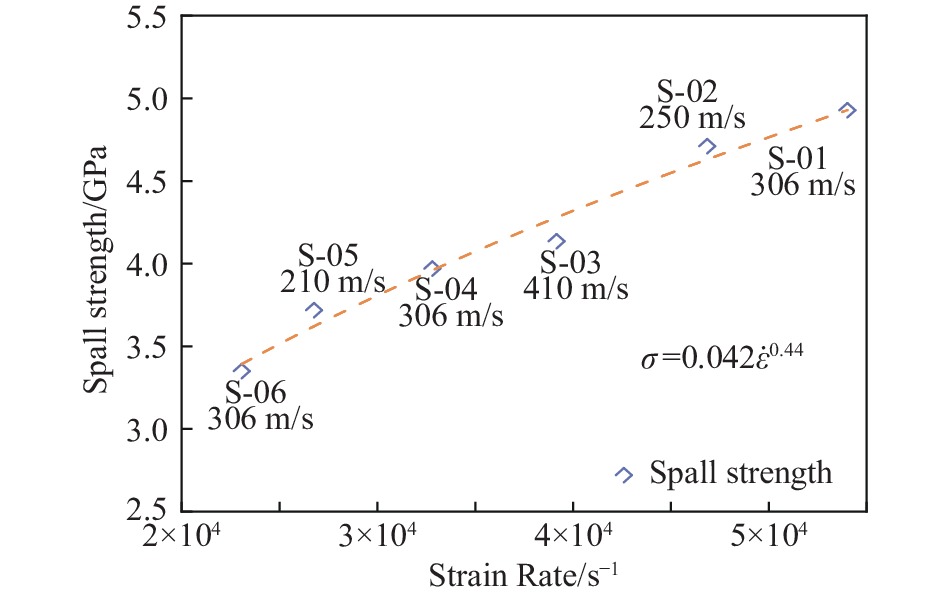

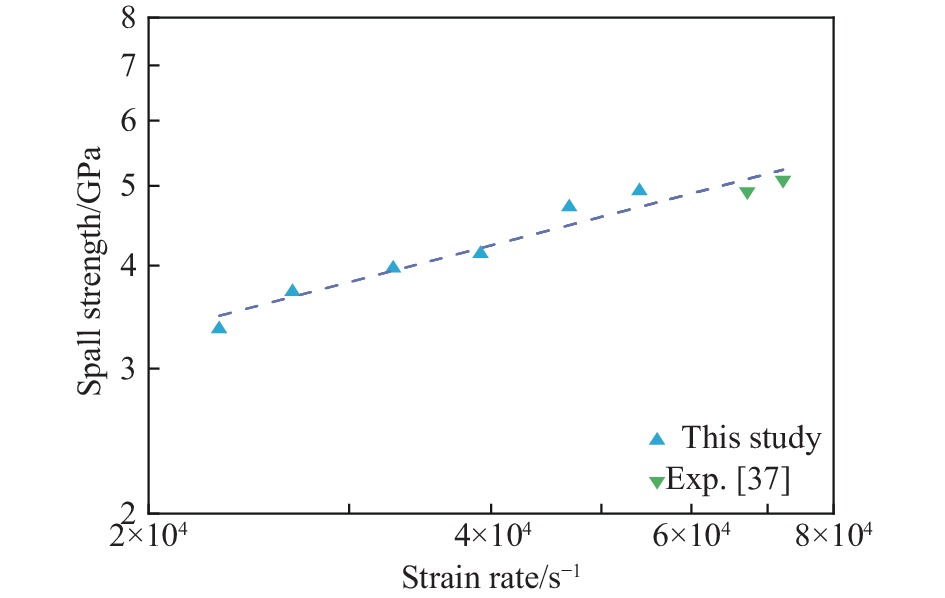

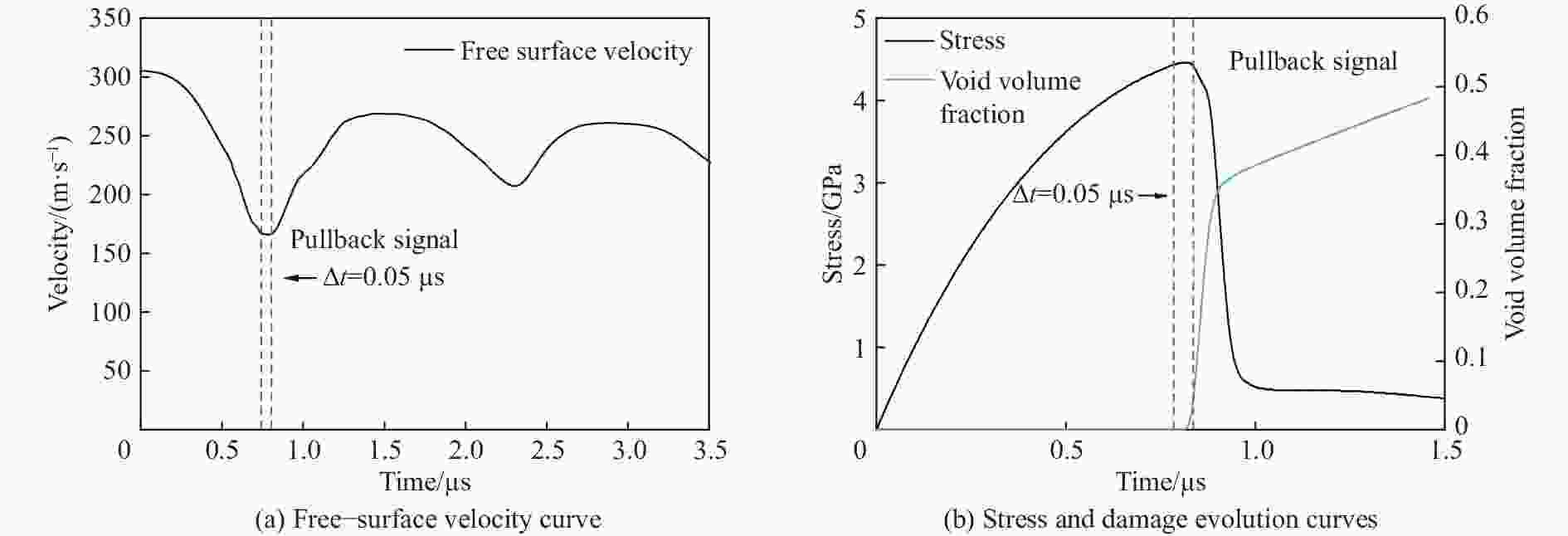

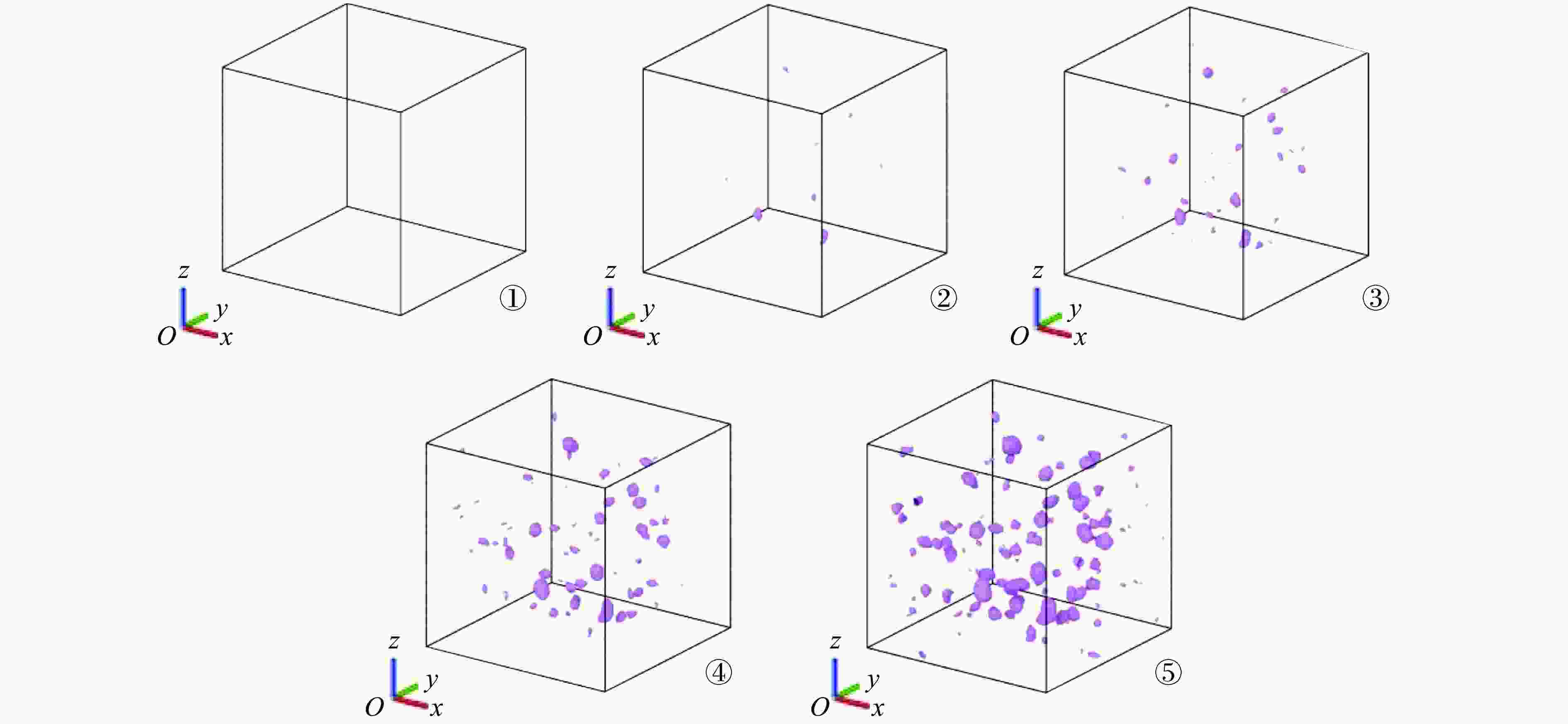

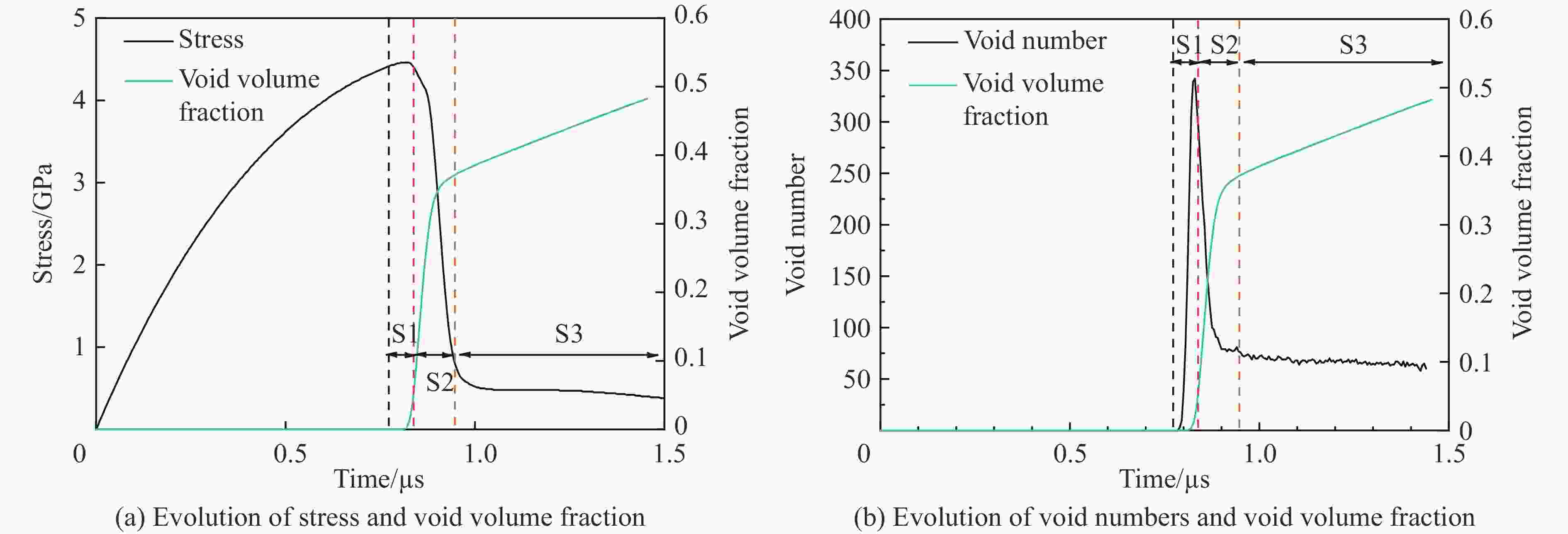

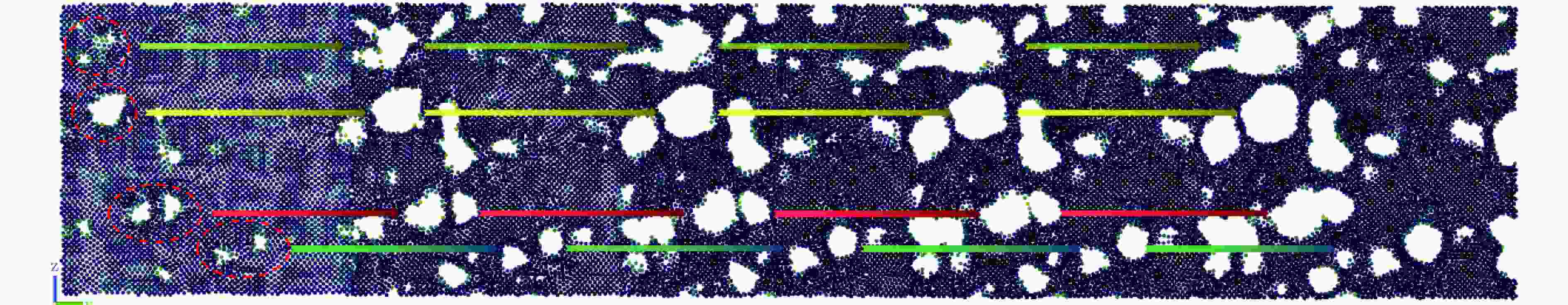

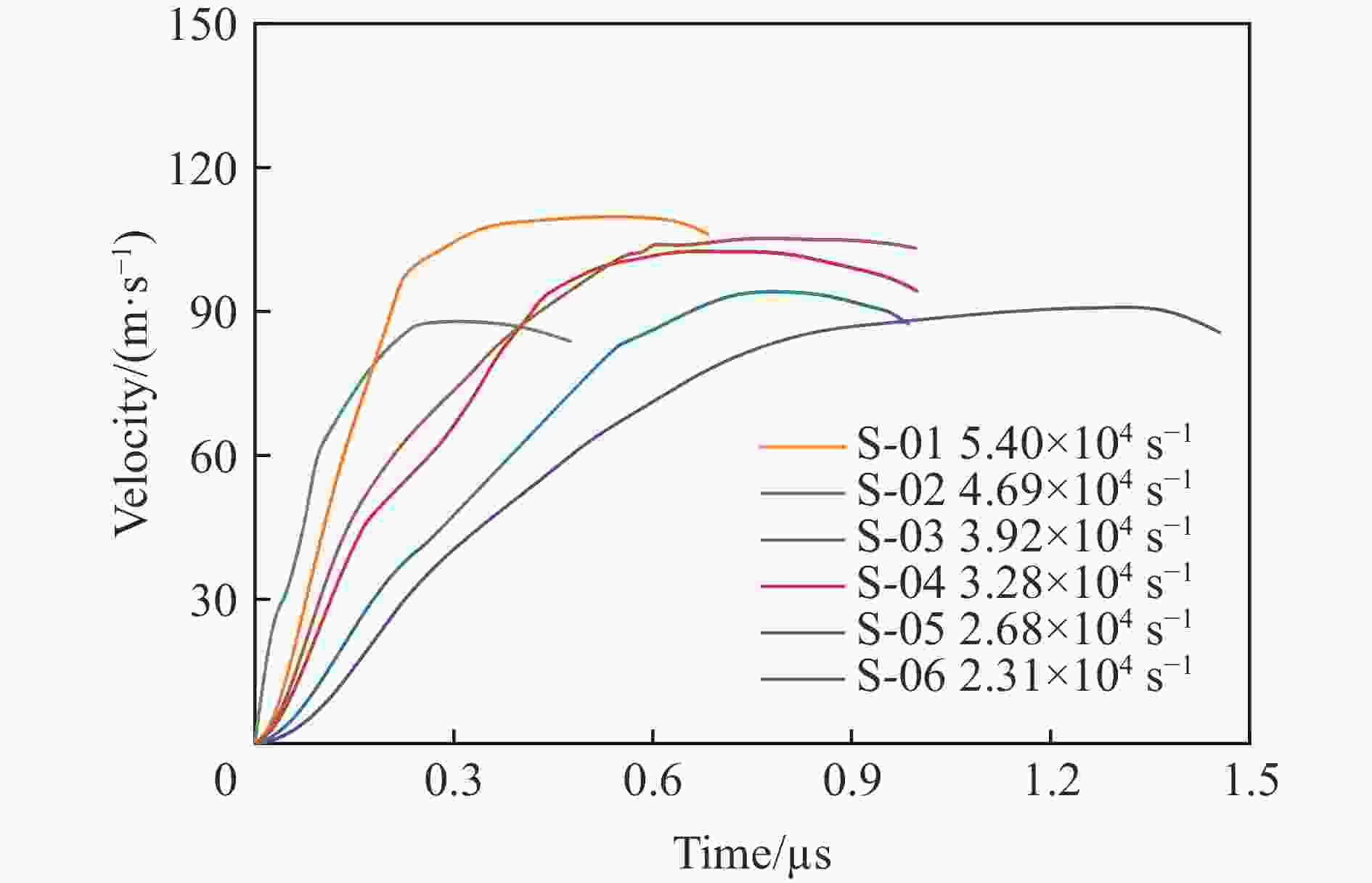

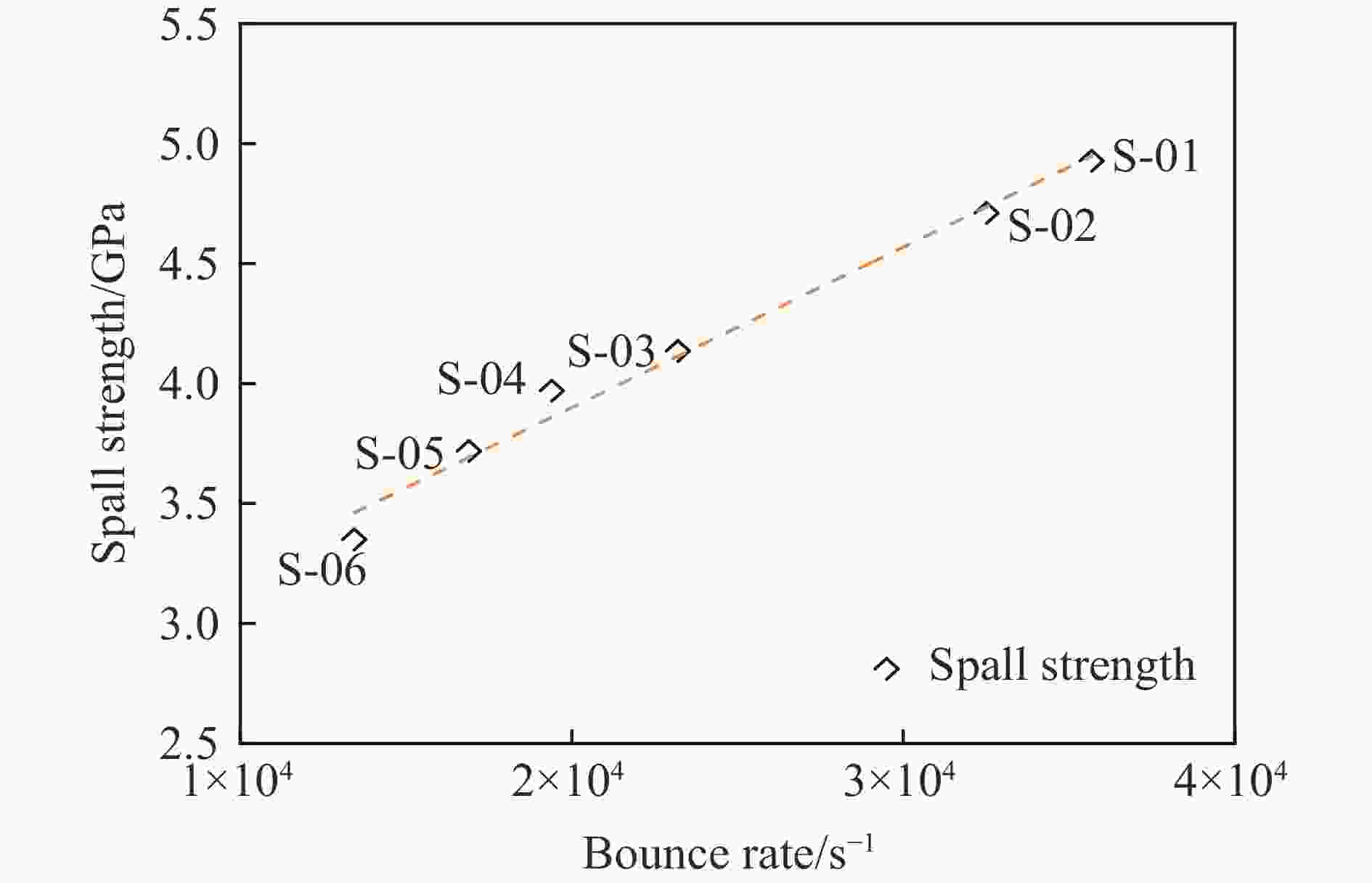

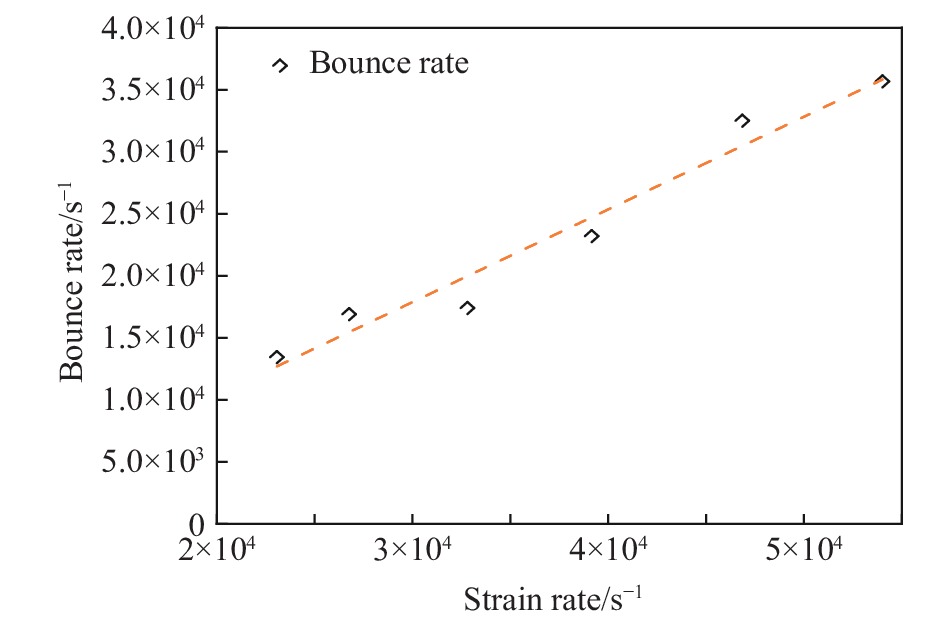

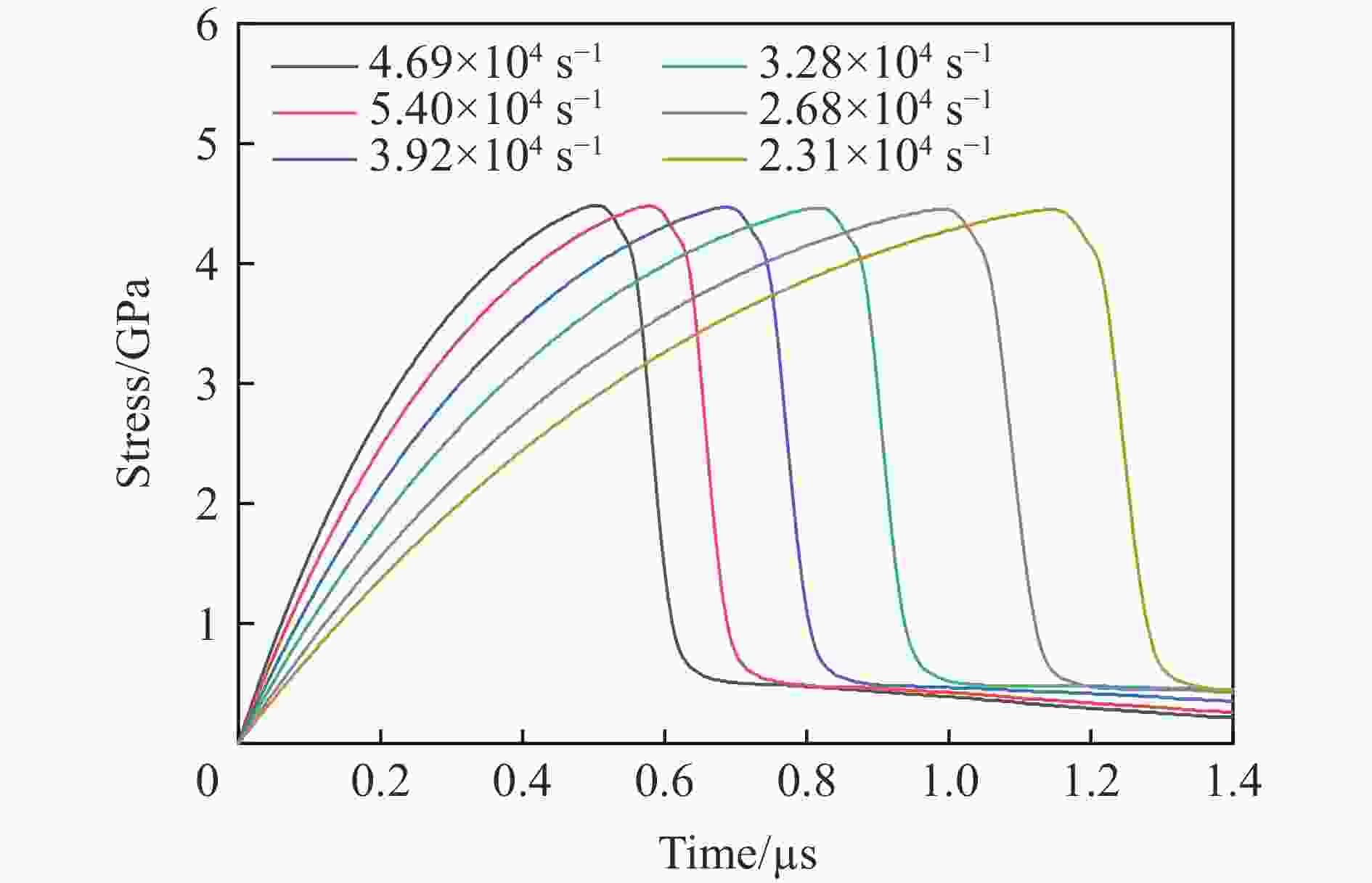

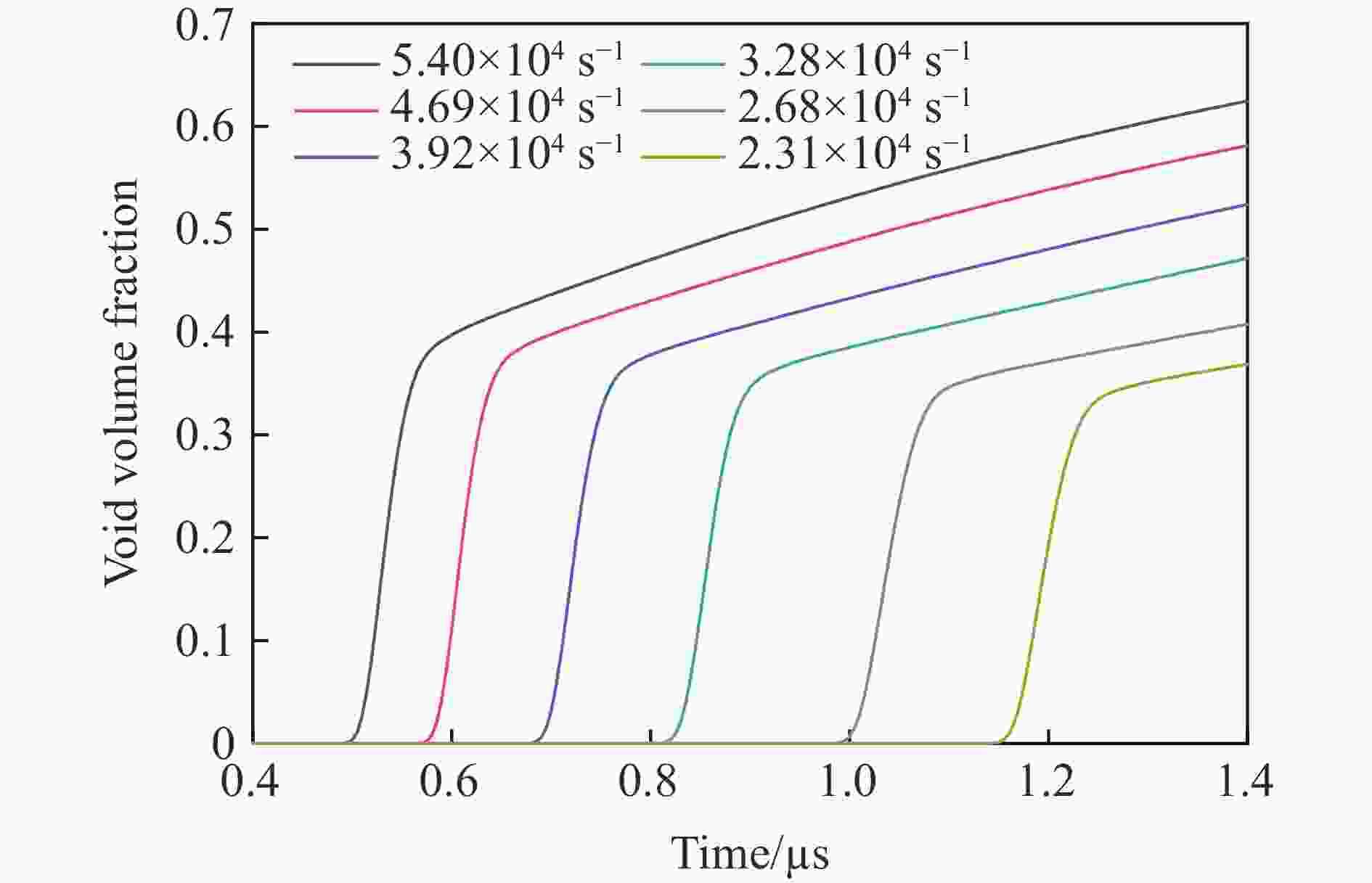

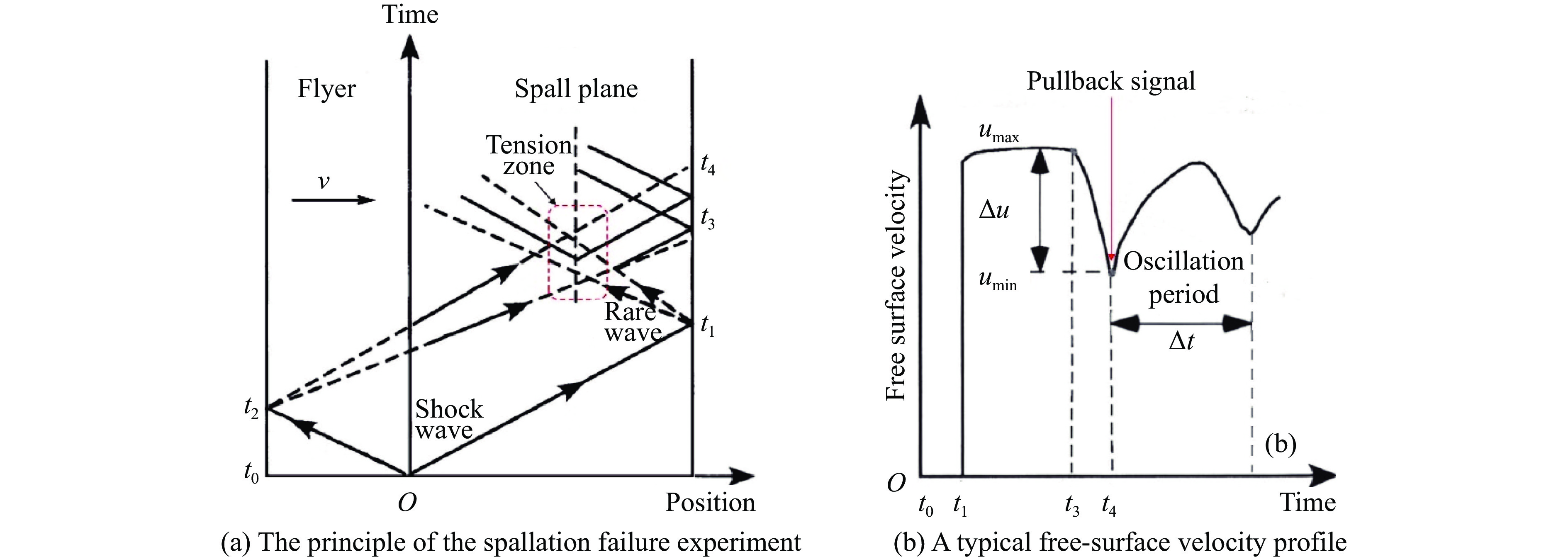

摘要: 以延性金属钽为研究对象,对钽在平板撞击下的层裂行为进行了多尺度下的数值模拟研究,从微观视角对自由面速度曲线上的典型特征进行了新的解读。在宏观尺度,对比分析了光滑粒子流体动力学法(smootfied particle hydrodynamics, SPH)与Lagrange网格法以及几种本构模型的模拟结果及其适用性。通过与实验数据的对比表明,Steinberg-Cochran-Guinan本构模型在层裂模拟中与实验数据吻合较好,通过改变加载条件获得了不同应变率下的自由面速度曲线,分析了不同应变率下的自由面速度曲线中的典型特征。在微观尺度,采用分子动力学方法获得层裂区域内损伤演化情况,揭示了宏观尺度自由面速度曲线典型特征所蕴含的物理内涵。分析表明,层裂表现为材料内部微孔洞形核、长大和聚集的损伤演化过程,自由面速度曲线上的典型特征与层裂区域的损伤演化过程存在密切关联。Pullback信号是层裂区域内微孔洞形核的宏观表征;自由面速度曲线的下降幅值在一定程度上反映了微孔洞的形核条件,由此计算得到的层裂强度实际上是微孔洞的形核强度。此外,Pullback信号后的速度回跳速率反映了微损伤演化的速率。Abstract: The spallation characteristics of ductile tantalum metal under planar plate impact was analyzed through a multi-scale perspective. And the typical characteristics of the free-surface velocity curve on the macro-scale were interpreted from the micro-scale to reveal the physical meanings corresponding to these typical characteristics. On the macro-scale, the spallation behaviors of the ductile tantalum metal under planar-plate impact were numerically simulated through the smooth particle hydrodynamics (SPH) and Lagrange methods, and the free-surface velocity curves of the tantalum during spallation were obtained. In addition, the free-surface velocity curves obtained by the Johnson-Cook model, Steinberg-Cochran-Guinan model and Zerilli-Armstrong model were compared in the numerical simulations. Comparison with the experimental data shows that the Steinberg-Cochran-Guinan constitutive model has a better performance in the macro-level simulation. The free-surface velocity curves at different strain rates were obtained by changing the loading conditions, and the typical characteristics of the free-surface velocity curves at different strain rates were discussed. Results show that there is an exponential relationship between spall strength and strain rate, and the spall strength obtained from the simulation has a good agreement with the experimental data. On the micro-scale, the damage evolution in the spallation region was obtained by molecular dynamics simulation conducted in the LAMMPS software, and the loading strain rate was consistent with that on the macro-scale. The micro-scale simulation reveals the physical connotation of the typical characteristics of the macro-scale free-surface velocity curve. Micro-scale analysis shows that spallation is the response of damage evolution of nucleation, growth, and aggregation of voids. From the multi-scale perspective analysis, the typical characteristics on the free-surface velocity curve are closely related to the damage evolution in the spallation area: the pullback signal is a macroscopic response of the void nucleation in the spall area; the decline amplitude of the free-surface velocity curve reflects the void nucleation condition, and the spall strength reflects the nucleation strength of the voids. What’s more, the velocity rises to the first peak beyond the minima after the pullback signal reflects the rate of damage evolution. The multi-scale perspective analysis is helpful to fully understand the physical mechanism of the spallation under planar-plate impact.

-

表 1 Mie-Grüneisen状态方程参数

Table 1. Parameters for Mie-Grüneisen equation of state

材料 ρ0 /(kg·m−3) c0/(m·s−1) S1 γ Ta 16690 3340 1.20 1.67 表 2 Johnson-Cook模型参数

Table 2. Parameters for the Johnson-Cook model

材料 A/MPa B/MPa n C m Ta 142 164 0.31 0.057 0.88 表 3 Zerilli-Armstrong模型参数

Table 3. Parameters for the Zerilli-Armstrong model

材料 C0/MPa k1/(MPa·m−3/2) C2/MPa C3/K−1 C4/K−1 C5/MPa n Ta 1125 10 178 5.35×10−3 0.327×10−3 310 0.44 表 4 Steinberg-Cochran-Guinan模型参数

Table 4. Parameters for the Steinberg-Cochran-Guinan model

材料 G0/GPa Y0/GPa Ymax/GPa β n $ {G}_{\rm{p}}^{'} $ $ {G}_{\rm{T}}^{'} $/(MPa ·K−1) Tm0/K Ta 69 0.77 1.10 10 0.1 1.005 −8.97 4340 表 5 用于验证的模型编号及参数设置

Table 5. Model number and parameter settings for validation

模型编号 飞片厚度/mm 样片厚度/mm 强度模型 方法 V-01 3 4.95 JC Lagrange V-02 3 4.95 JC SPH V-03 3 4.95 ZA Lagrange V-04 3 4.95 ZA SPH V-05 3 4.95 SCG Lagrange V-06 3 4.95 SCG SPH 表 6 不同应变率下平面撞击层裂模型参数与结果

Table 6. Parameters of planar plate impact simulations and results under various strain rates

模型编号 飞片厚度/mm 样片厚度/mm 加载速度/(m·s−1) p/GPa $ {\dot{\varepsilon }}_{\rm{s}} $/s−1 $ {\sigma }_{\rm{spall}} $/GPa $ {\dot{\varepsilon }}_{\rm{r}} $/s−1 S-01 2 4.95 306 8.84 5.40×104 4.92 3.57×104 S-02 2 4.95 250 7.05 4.69×104 4.70 3.25×104 S-03 3 4.95 410 12.25 3.92×104 4.14 2.32×104 S-04 3 4.95 306 8.84 3.28×104 3.97 1.74×104 S-05 3 4.95 210 6.19 2.68×104 3.71 1.69×104 S-06 4 4.95 306 8.84 2.31×104 3.34 1.34×104 表 7 不同计算公式得到的层裂强度

Table 7. Spall strengths obtained by different formulas

模型编号 $ {\sigma }_{\rm{spall}} $/GPa $ {\sigma }_{\rm{spall}}^{\left(1\right)} $/GPa $ {\sigma }_{\rm{spall}}^{\left(2\right)} $/GPa S-01 4.92 5.25 5.36 S-02 4.71 5.02 5.32 S-03 4.13 4.40 4.48 S-04 3.97 4.23 4.32 S-05 3.72 3.96 4.07 S-06 3.35 3.57 3.58 -

[1] LU K. The future of metals [J]. Science, 2010, 328(5976): 319–320. DOI: 10.1126/science.1185866. [2] 裴晓阳, 彭辉, 贺红亮, 等. 延性金属层裂自由面速度曲线物理涵义解读 [J]. 物理学报, 2015, 64(3): 034601. DOI: 10.7498/aps.64.034601.PEI X Y, PENG H, HE H L, et al. Discussion on the physical meaning of free surface velocity curve in ductile spallation [J]. Acta Physica Sinica, 2015, 64(3): 034601. DOI: 10.7498/aps.64.034601. [3] CURRAN D R, SEAMAN L, SHOCKEY D A. Dynamic failure of solids [J]. Physics Reports, 1987, 147(5): 253–388. DOI: 10.1016/0370-1573(87)90049-4. [4] ANTOUN T, SEAMAN L, CURRAN D R, et al. Spall fracture [M]. New York: Springer, 2003: 199−200. [5] THOMAS S A, HAWKINS M C, MATTHES M K, et al. Dynamic strength properties and alpha-phase shock Hugoniot of iron and steel [J]. Journal of Applied Physics, 2018, 123(17): 175902. DOI: 10.1063/1.5019484. [6] 陈永涛, 唐小军, 李庆忠, 等. 纯铁材料的冲击相变与“反常”层裂 [J]. 爆炸与冲击, 2009, 29(6): 637–641. DOI: 10.11883/1001-1455(2009)06-0637-05.CHEN Y T, TANG X J, LI Q Z, et al. Phase transition and abnormal spallation in pure iron [J]. Explosion and Shock Waves, 2009, 29(6): 637–641. DOI: 10.11883/1001-1455(2009)06-0637-05. [7] 翟少栋, 李英华, 彭建祥, 等. 平面碰撞与强激光加载下金属铝的层裂行为 [J]. 爆炸与冲击, 2016, 36(6): 767–773. DOI: 10.11883/1001-1455(2016)06-0767-07.ZHAI S D, LI Y H, PENG J X, et al. Spall behavior of pure aluminum under plate-impactand high energy laser shock loadings [J]. Explosion and Shock Waves, 2016, 36(6): 767–773. DOI: 10.11883/1001-1455(2016)06-0767-07. [8] KOLLER D D, HIXSON R S, III G T G, et al. Influence of shock-wave profile shape on dynamically induced damage in high-purity copper [J]. Journal of Applied Physics, 2005, 98(10): 103518. DOI: 10.1063/1.2128493. [9] LIU M B, LIU G R. Smoothed particle hydrodynamics (SPH): an overview and recent developments [J]. Archives of Computational Methods in Engineering, 2010, 17(1): 25–76. DOI: 10.1007/s11831-010-9040-7. [10] 张凤国, 刘军, 王裴, 等. 三角波强加载下延性金属多次层裂破坏问题 [J]. 爆炸与冲击, 2018, 38(3): 659–664. DOI: 10.11883/bzycj-2016-0279.ZHANG F G, LIU J, WANG P, et al. Multi-spall in ductile metal under triangular impulse loading [J]. Explosion and Shock Waves, 2018, 38(3): 659–664. DOI: 10.11883/bzycj-2016-0279. [11] 种涛, 唐志平, 谭福利, 等. 纯铁相变和层裂损伤的数值模拟 [J]. 高压物理学报, 2018, 32(1): 014102. DOI: 10.11858/gywlxb.20170528.CHONG T, TANG Z P, TAN F L, et al. Numerical simulation of phase transition and spall of iron [J]. Chinese Journal of High Pressure Physics, 2018, 32(1): 014102. DOI: 10.11858/gywlxb.20170528. [12] GLAM B, STRAUSS M, ELIEZER S, et al. Shock compression and spall formation in aluminum containing helium bubbles at room temperature and near the melting temperature: Experiments and simulations [J]. International Journal of Impact Engineering, 2014, 65(3): 1–12. DOI: 10.1016/j.ijimpeng.2013.10.010. [13] LIBERSKY L D, PETSCHEK A G. Smooth particle hydrodynamics with strength of materials [C]// TREASE H E, FRITTS M F, CROWLEY W P. Advances in the Free-Lagrange Method Including Contributions on Adaptive Gridding and the Smooth Particle Hydrodynamics Method. Berlin: Springer Berlin Heidelberg, 1991, 248−257. DOI: 10.1007/3-540-54960-9_58. [14] 徐志宏, 汤文辉, 罗永. 光滑粒子模拟方法在超高速碰撞现象中的应用 [J]. 爆炸与冲击, 2006, 26(1): 53–58. DOI: 10.11883/1001-1455(2006)01-0053-06.XU Z H, TANG W H, LUO Y. Applications of the smoothed particle hydrodynamics method to hypervelocity impact simulations [J]. Explosion and Shock Waves, 2006, 26(1): 53–58. DOI: 10.11883/1001-1455(2006)01-0053-06. [15] ZHOU C E, LOU K Y, LIU G R. Three-dimensional penetration simulation using smoothed particle hydrodynamics [J]. International Journal of Computational Methods, 2007, 04(04): 671–691. DOI: 10.1142/S0219876207000972. [16] 贺年丰, 任国武, 陈永涛, 等. 爆轰加载下金属锡层裂破碎数值模拟 [J]. 爆炸与冲击, 2019, 39(4): 042101. DOI: 10.11883/bzycj-2017-0354.HE N F, REN G W, CHEN Y T, et al. Numerical simulation on spallation and fragmentation of tin under explosive loading [J]. Explosion and Shock Waves, 2019, 39(4): 042101. DOI: 10.11883/bzycj-2017-0354. [17] 席涛, 范伟, 储根柏, 等. 超高应变率载荷下铜材料层裂特性研究 [J]. 物理学报, 2017, 66(4): 040202. DOI: 10.7498/aps.66.040202.XI T, FAN W, CHU G B, et al. Spall behavior of copper under ultra-high strain rate loading [J]. Acta Physica Sinica, 2017, 66(4): 040202. DOI: 10.7498/aps.66.040202. [18] RAWAT S, RAOLE P M. Molecular dynamics investigation of void evolution dynamics in single crystal iron at extreme strain rates [J]. Computational Materials Science, 2018, 154(11): 393–404. DOI: 10.1016/j.commatsci.2018.08.010. [19] YANG X, ZENG X, WANG J, et al. Atomic-scale modeling of the void nucleation, growth, and coalescence in Al at high strain rates [J]. Mechanics of Materials, 2019, 135(8): 98–113. DOI: 10.1016/j.mechmat.2019.05.005. [20] CHEN J, FENSIN S J. Associating damage nucleation and distribution with grain boundary characteristics in Ta [J]. Scripta Materialia, 2020, 187(11): 329–334. DOI: 10.1016/j.scriptamat.2020.06.035. [21] 王云天, 曾祥国, 杨鑫. 高应变率下温度对单晶铁中孔洞成核与生长影响的分子动力学研究 [J]. 物理学报, 2019, 68(24): 246102. DOI: 10.7498/aps.68.20190920.WANG Y T, ZENG X G, YANG X. Molecular dynamics simulation of effect of temperature on void nucleation and growth of single crystal iron at a high strain rate [J]. Acta Physica Sinica, 2019, 68(24): 246102. DOI: 10.7498/aps.68.20190920. [22] HAHN E N, GERMANN T C, RAVELO R, et al. On the ultimate tensile strength of tantalum [J]. Acta Materialia, 2017, 126(3): 313–328. DOI: 10.1016/j.actamat.2016.12.033. [23] WANG H, GAO N, Lü G H, et al. Effects of temperature and point defects on the stability of C15 Laves phase in iron: A molecular dynamics investigation [J]. Chinese Physics B, 2018, 27(6): 066104. DOI: 10.1088/1674-1056/27/6/066104. [24] DANIAN C, CHUNLEI F, SHUGANG X, et al. Study on constitutive relations and spall models for oxygen-free high-conductivity copper under planar shock tests [J]. Journal of Applied Physics, 2007, 101(6): 063532. DOI: 10.1063/1.2711405. [25] CZARNOTA C, JACQUES N, MERCIER S, et al. Modelling of dynamic ductile fracture and application to the simulation of plate impact tests on tantalum [J]. Journal of the Mechanics & Physics of Solids, 2008, 56(4): 1624–1650. DOI: 10.1016/j.jmps.2007.07.017. [26] MARSH S P. LASL shock Hugoniot data [M]. Berkeley: University of California Press, 1980: 75−78. [27] JOHNSON G R, COOK W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures [J]. Engineering Fracture Mechanics, 1985, 21(1): 31–48. DOI: 10.1016/0013-7944(85)90052-9. [28] STEINBERG D J, COCHRAN S G, GUINAN M W. A constitutive model for metals applicable at high-strain rate [J]. Journal of Applied Physics, 1980, 51(3): 1498–1504. DOI: 10.1063/1.327799. [29] ZERILLI F J, ARMSTRONG R W. Dislocation-mechanics-based constitutive relations for material dynamics calculations [J]. Journal of Applied Physics, 1987, 61(5): 1816–1825. DOI: 10.1063/1.338024. [30] 樊雪飞. 药型罩材料性能对双模毁伤元成型影响研究[D]. 南京: 南京理工大学, 2017: 19−22. [31] GRADY D E. The spall strength of condensed matter [J]. Journal of the Mechanics and Physics of Solids, 1988, 36(3): 353–384. DOI: 10.1016/0022-5096(88)90015-4. [32] 邸德宁, 陈小伟. 碎片云SPH方法数值模拟中的材料失效模型 [J]. 爆炸与冲击, 2018, 38(5): 948–956. DOI: 10.11883/bzycj-2017-0328.DI D N, CHEN X W. Material failure models in SPH simulation of debris cloud [J]. Explosion and Shock Waves, 2018, 38(5): 948–956. DOI: 10.11883/bzycj-2017-0328. [33] 陈大年, 俞宇颖, 尹志华, 等. 对于层裂强度传统测定方法有效性的讨论 [J]. 工程力学, 2006, 23(1): 62–68. DOI: 10.3969/j.issn.1000-4750.2006.01.013.CHEN D N, YU Y Y, YIN Z H, et al. On the validity of the traditional methodology of spall strength measurement [J]. Engineering Mechanics, 2006, 23(1): 62–68. DOI: 10.3969/j.issn.1000-4750.2006.01.013. [34] DALTON D A, BREWER J L, BERNSTEIN A C, et al. Laser-induced spallation of aluminum and Al alloys at strain rates above 2×106s−1 [J]. Journal of Applied Physics, 2008, 104(1): 013526. DOI: 10.1063/1.2949276. [35] RAVELO R, GERMANN T C, GUERRERO O, et al. Shock-induced plasticity in tantalum single crystals: Interatomic potentials and large-scale molecular-dynamics simulations [J]. Physical Review B, 2013, 88(13): 134101. DOI: 10.1103/PhysRevB.88.134101. [36] PLIMPTON S. Fast parallel algorithms for short-range molecular dynamics [J]. Journal of Computational Physics, 1995, 117(1): 1–19. DOI: 10.1006/jcph.1995.1039. [37] 张林. 延性材料冲击响应: 动态损伤与断裂、结构相变的新模型[D]. 绵阳: 中国工程物理研究院, 2005: 68−69. [38] KANEL G I. Dynamic strength of materials [J]. Fatigue and Fracture of Engineering Materials and Structures, 1999, 22(11): 1011–1020. DOI: 10.1046/j.1460-2695.1999.00246.x. [39] ZUREK A K, THISSELL W R, JOHNSON J N, et al. Micromechanics of spall and damage in tantalum [J]. Journal of Materials Processing Technology, 1996, 60(1-4): 261–267. DOI: 10.1016/0924-0136(96)02340-0. [40] KANEL G I, RAZORENOV S V, BOGATCH A, et al. Simulation of spall fracture of aluminum and magnesium over a wide range of load duration and temperature [J]. International Journal of Impact Engineering, 1997, 20(6): 467–478. DOI: 10.1016/S0734-743X(97)87435-0. -

下载:

下载: