Experimental research on the law of flame spreading in the charge bed of a central ignition tube

-

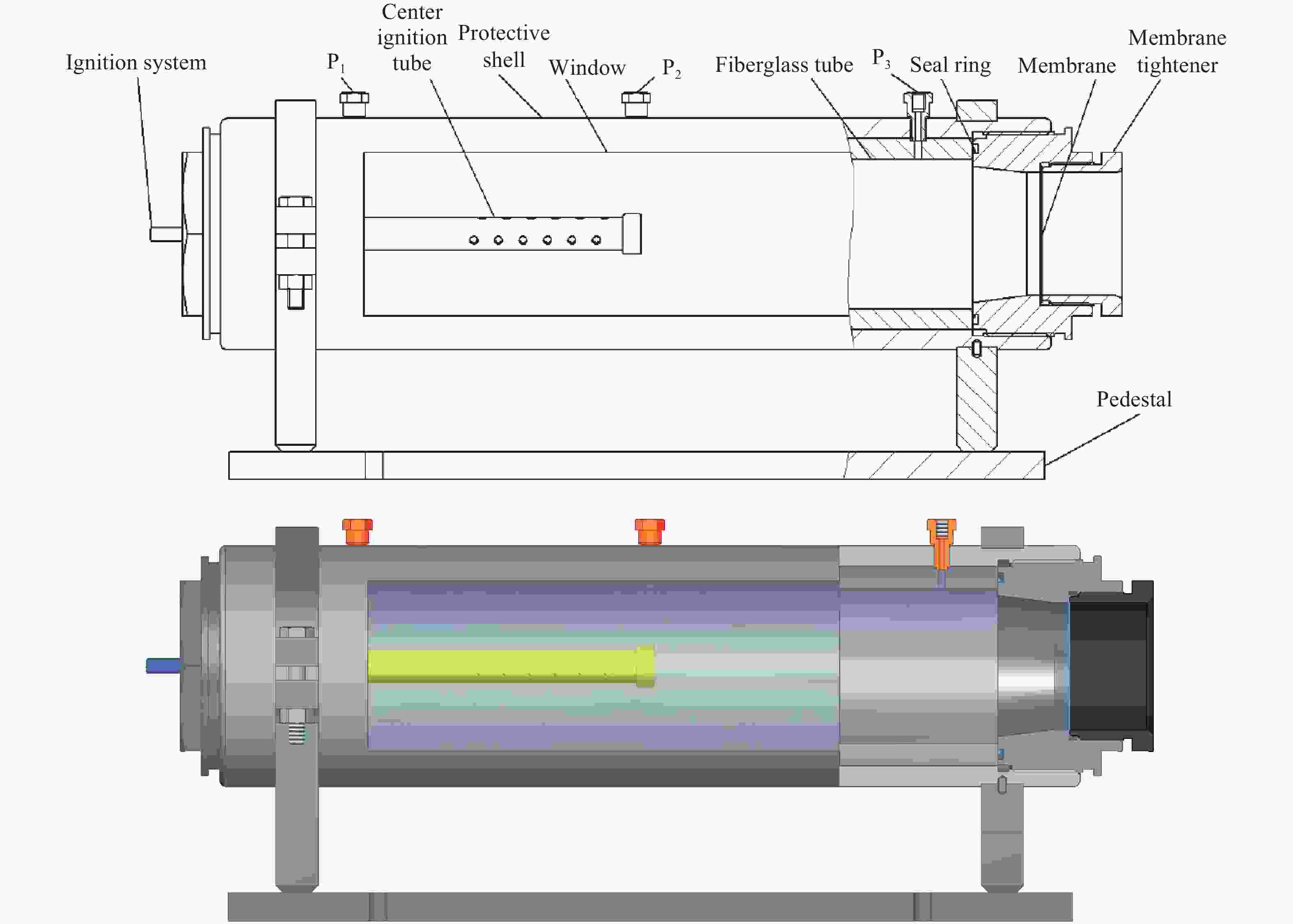

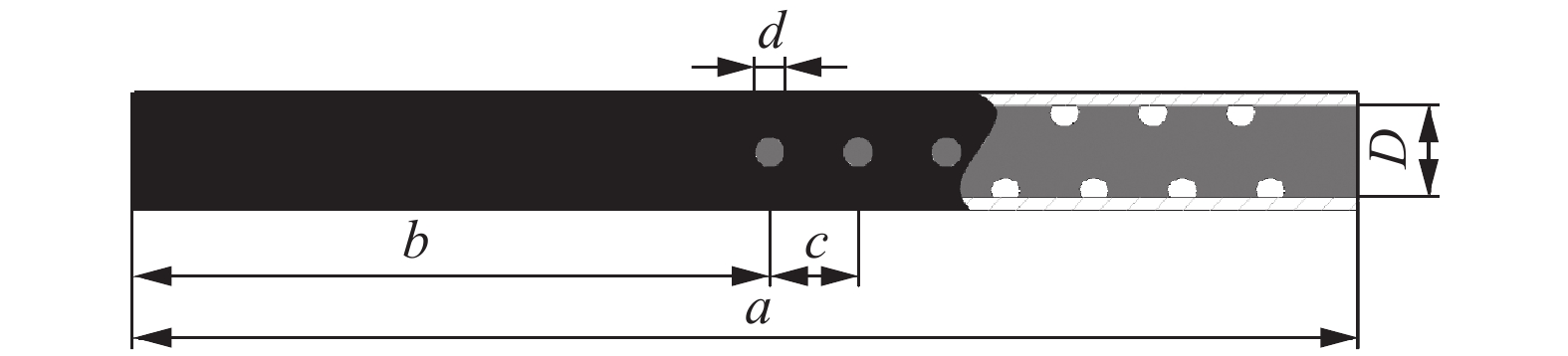

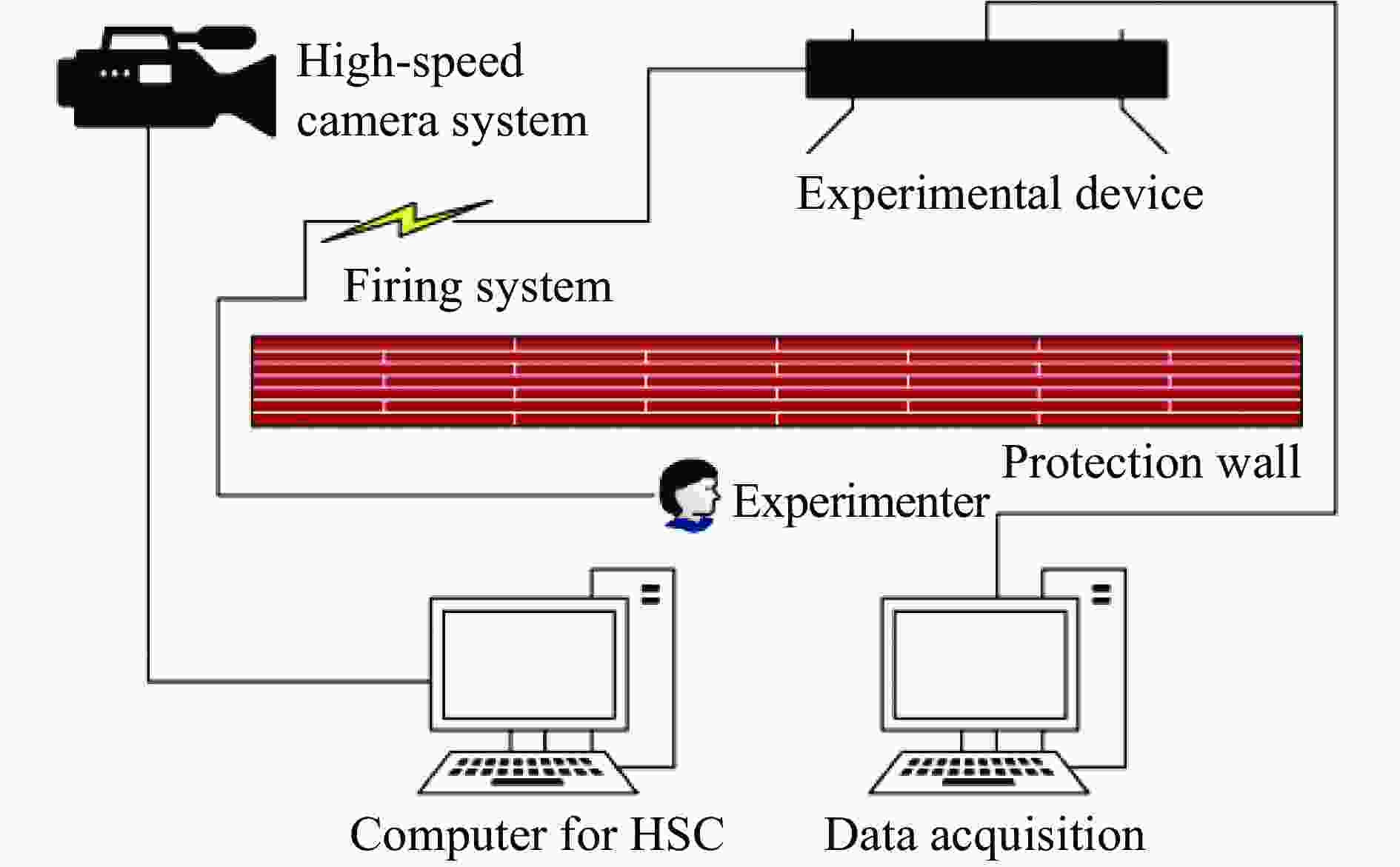

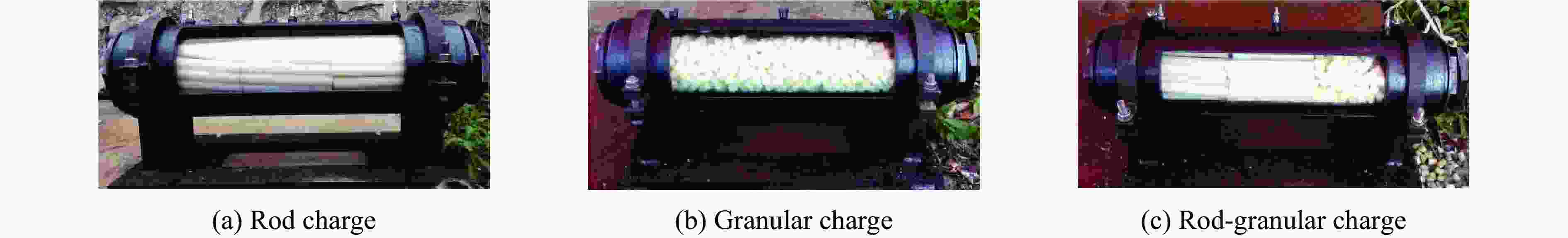

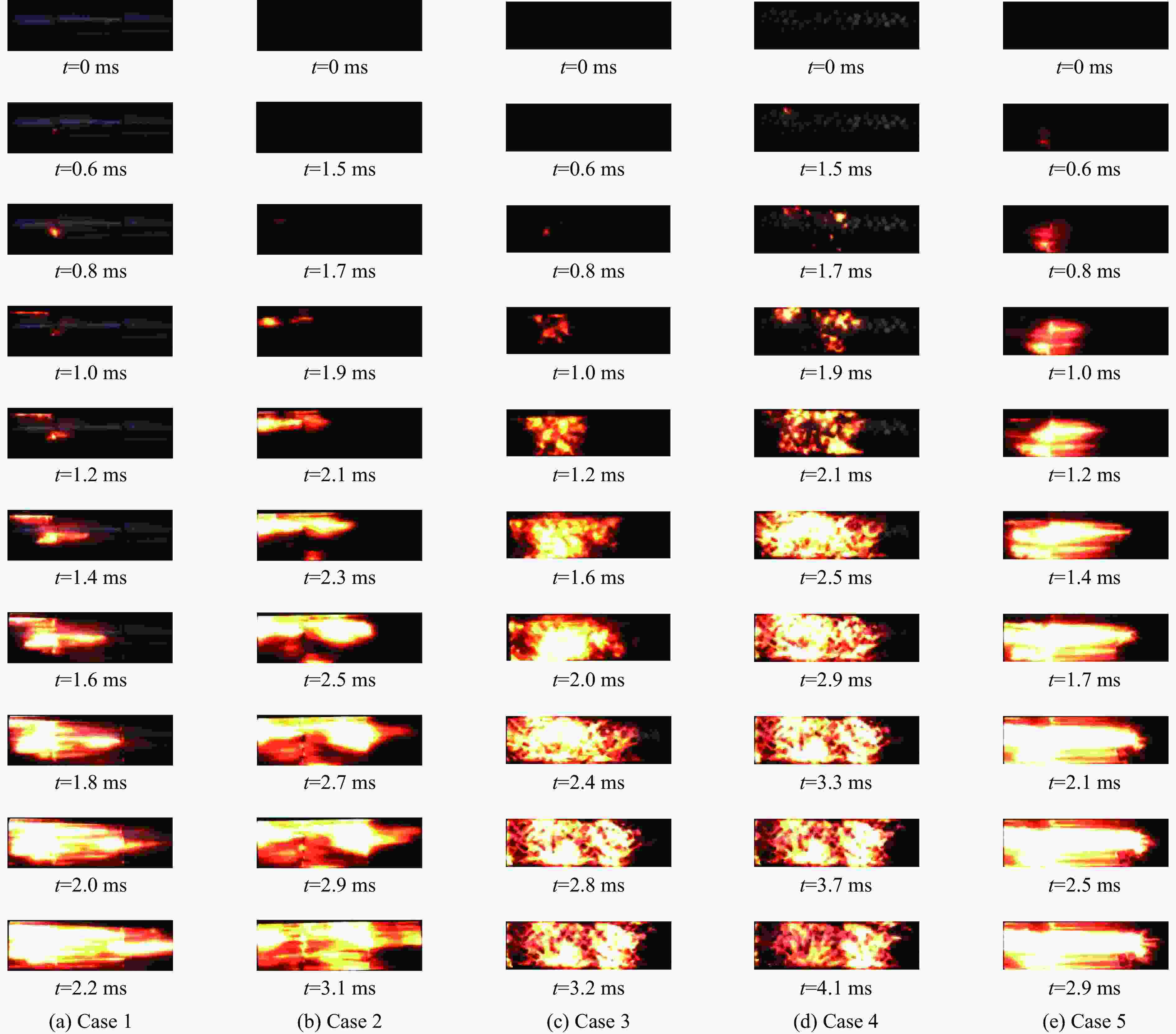

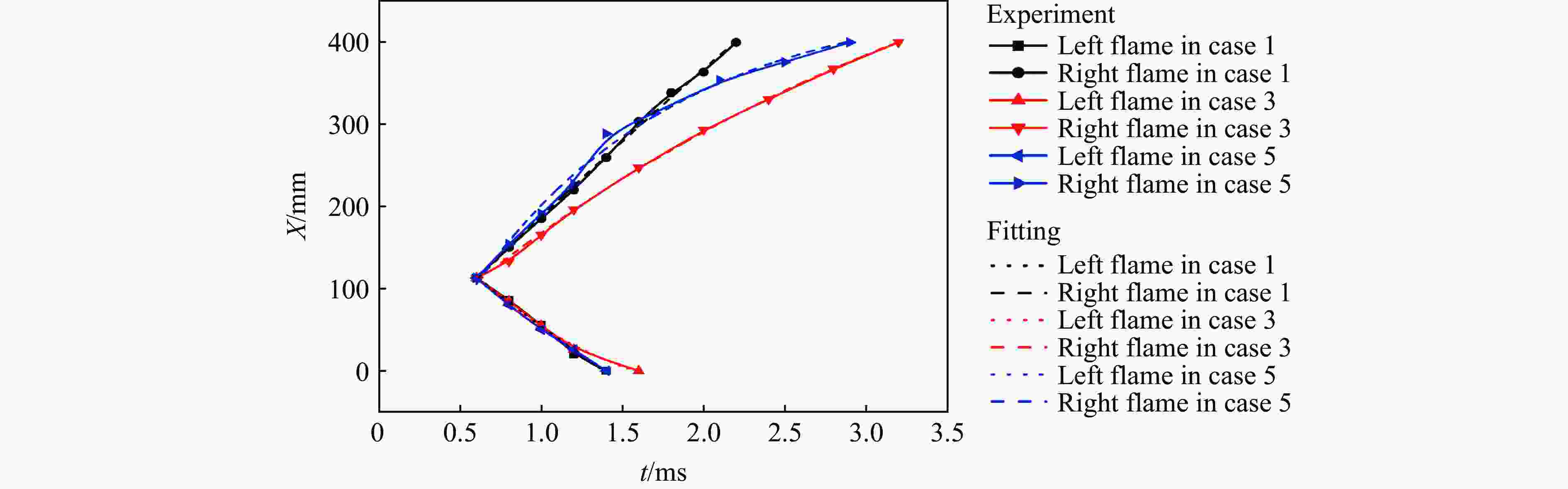

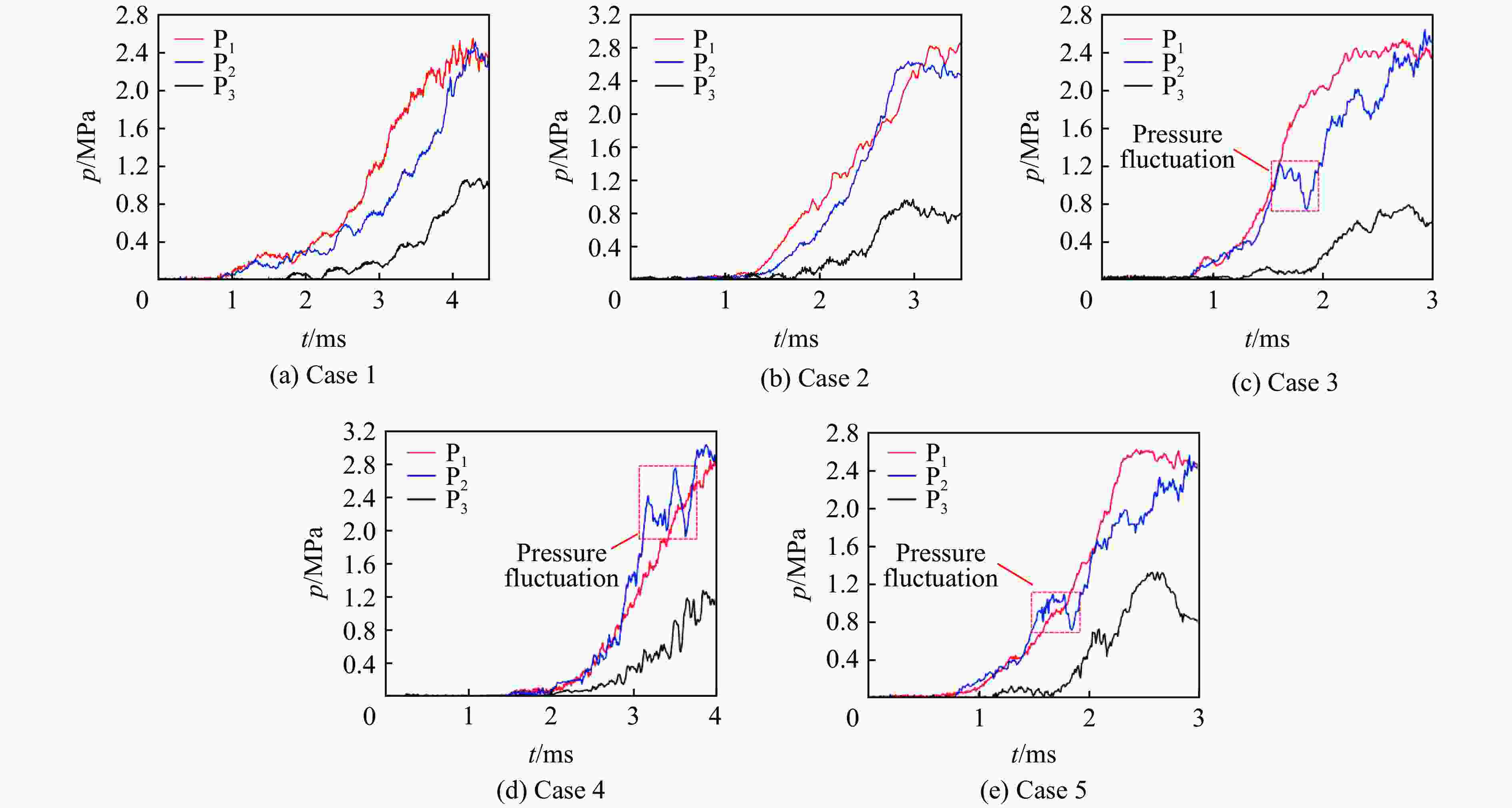

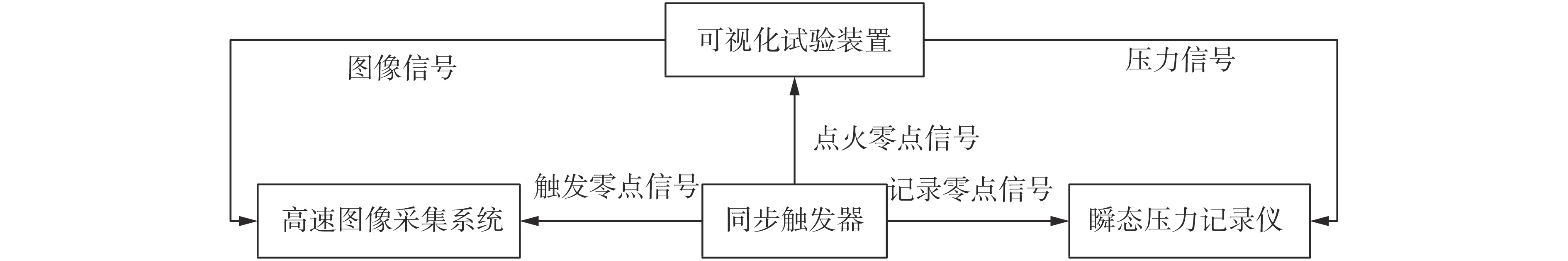

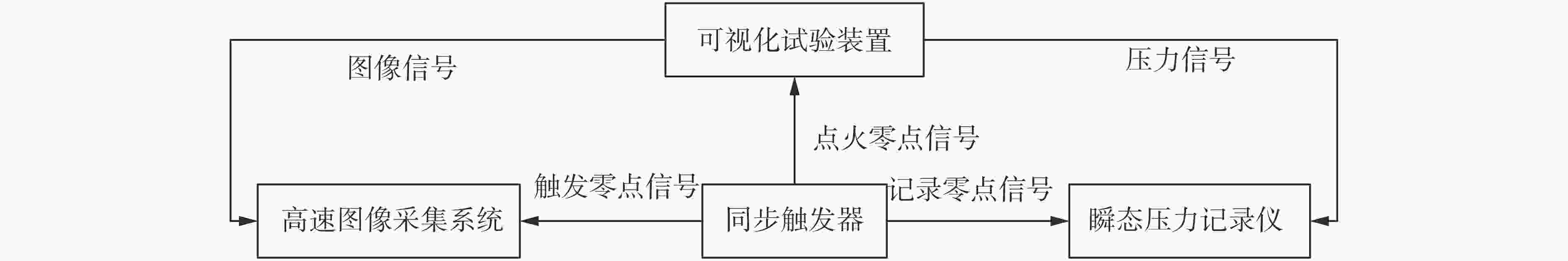

摘要: 为了研究中心点火管火焰在药床中的传播规律,设计了可视化模拟试验平台,开展了不同点火药量、不同装药结构的中心点传火试验。采用高速图像采集系统记录了中心点火管火焰在药床中的传播过程,采用瞬态压力记录仪记录膛内压力的时空变化。结果表明,点火药量为20 g时,出火时间为0.6 ms;点火药量为30 g时,出火时间为1.5 ms;杆状装药床的传火时间平均为2.2 ms,粒状装药床的传火时间平均为3.4 ms,而杆粒混装药床的传火时间为3.1 ms。可见,点火药量对药床出火时间影响显著,较大的点火药量导致药床出火时间延长;不同装药床结构传火性能差异较大,单一杆状装药床传火性能优于单一粒状装药和杆粒混装药床,并且粒状装药床易形成气体壅塞,膛内会出现明显的压力波动现象;根据火焰传播时序位置点,利用一阶指数衰减函数拟合建立了火焰传播过程数学模型,拟合优度大于0.98。Abstract: In order to investigate the development of flame spreading in the charge bed of a central ignition tube, a visualized ignition experiment platform was designed, and experiments were carried out with different ignition charge masses and charge structures. A high-speed image acquisition system was used to record the propagation process of ignition flame in the propellant bed at 10000 frames per second, and a transient pressure recorder was used to obtain the variation of pressure with time and position in the chamber. In addition, a synchronous trigger was used to connect the high-speed image acquisition system, the transient pressure recorder and the ignition system of the experimental platform, giving the system a trigger zero point, which is convenient for the statistical analysis of subsequent experimental phenomena. The experimental results show that the time of flame-appearing from the ignition tube into the combustion chamber is 0.6 ms when the mass of the black powder is 20 g. However, the time increases to 1.5 ms when the mass of the black powder is 30 g. The average flame-spreading time of the stick charge structure is 2.2 ms, the average flame-spreading time of the granular charge structure is 3.4 ms, and the average flame-spreading time of the mixed charge structure is 3.1 ms. The results indicate that the mass of the black powder in an ignition tube has a significant effect on the time of flame-appearing from the ignition tube, and the higher black powder mass lead to the longer flame-appearing time. The performances of flame-spreading in different charge bed structures are quite different. The performance of flame-spreading in the stick charge structures is better than that in the granular charge structures and mixed charge structures. In addition, the pressure fluctuations will appear in the chamber due to gas choking in the granular charge structures. A mathematical model of the flame-spreading process was established by fitting the first-order exponential decay function according to the time sequence of the position of flame, and the goodness of fit is greater than 0.98.

-

表 1 各方案装填参数

Table 1. Charging parameters in each case

方案 电底火 点火药量/g 仿真发射药装药结构 仿真发射药量/kg 仿真发射药装填密度/(g·cm−3) 1 3# 20 单一杆状发射药 2.7 0.58 2 3# 30 单一杆状发射药 2.7 0.58 3 3# 20 单一粒状发射药 3.0 0.64 4 3# 30 单一粒状发射药 3.0 0.64 5 3# 20 杆状-粒状混装发射药 1.8(杆状),0.9(粒状) 0.58 表 2 各方案传火时间

Table 2. Flame speeding time of each case

方案 tL/ms tR/ms tt/ms 1 0.8 1.6 2.4 2 0.6 1.4 2.0 3 1.0 2.6 3.6 4 1.0 2.2 3.2 5 0.8 2.3 3.1 表 3 方案1、3、5火焰传播位置函数拟合系数

Table 3. Exponential decay function coefficients in cases 1, 3 and 5

方案 火焰传播方向 A/mm t1/ms X0/mm 1 左 960.73748 5.48834 −746.77192 右 −2140.67126 10.28158 2129.96097 3 左 337.19979 0.96082 −65.56418 右 −670.86944 3.58306 675.19170 5 左 449.90302 1.92159 −216.47406 右 −567.63017 1.26204 458.43930 表 4 各方案的最高压力和破膜压力

Table 4. The highest pressure and membrane-broken pressure in each case

方案 最高压力/MPa 破膜压力/MPa 1 2.51 0.98 2 2.82 0.96 3 2.53 0.85 4 2.91 1.00 5 2.63 1.10 -

[1] 金志明, 翁春生. 高等内弹道学 [M]. 北京: 高等教育出版社, 2003: 237−239. [2] 翁春生, 王浩. 计算内弹道学 [M]. 北京: 国防工业出版社, 2006: 95−97. [3] 王升晨, 周彦煌, 刘千里, 等. 膛内多相燃烧理论及应用 [M]. 北京: 兵器工业出版社, 1994: 84−86. [4] ACHARYA R. Effect of different flash-tube vent-hole patterns on interior ballistic processes of ignition cartridge of 120-mm mortar system [J]. International Journal of Energetic Materials and Chemical Propulsion, 2008, 7(5): 383–397. DOI: 10.1615/IntJEnergeticMaterialsChemProp.v7.i5.30. [5] HOUIM R W, KUO K K. Understanding interior ballistic processes in a flash tube [J]. Journal of Applied Mechanics, 2010, 77(5): 051403. DOI: 10.1115/1.4001285. [6] MOORE J D, ACHARYA R, FERRARA P J. Effect of flash-tube vent-hole patterns on the combustion product discharge rate [J]. International Journal of Energetic Materials and Chemical Propulsion, 2009, 8(3): 199–220. DOI: 10.1615/IntJEnergeticMaterialsChemProp.v8.i3.30. [7] JIANG S P, RUI X T, HONG J, et al. Numerical simulation of impact breakage of gun propellant charge [J]. Granular Matter, 2011, 13(5): 611. DOI: 10.1007/s10035-011-0276-1. [8] 张瑞华, 芮筱亭, 赵宏立, 等. 基于离散单元法的发射装药挤压破碎模拟实验 [J]. 爆炸与冲击, 2021, 41(6): 062301. DOI: 10.11883/bzycj-2020-0157.ZHANG R H, RUI X T, ZHAO H L, et al. Simulational experiment on compression and fracture of propellant charge based on the discrete element method [J]. Explosion and Shock Waves, 2021, 41(6): 062301. DOI: 10.11883/bzycj-2020-0157. [9] 陈言坤, 罗兴柏, 甄建伟, 等. 发射药动态力学性能的研究进展 [J]. 含能材料, 2013, 21(5): 675–680. DOI: 10.3969/j.issn.1006-9941.2013.05.023.CHEN Y K, LUO X B, ZHEN J W, et al. Review on dynamical mechanical properties of propellants [J]. Chinese Journal of Energetic Materials, 2013, 21(5): 675–680. DOI: 10.3969/j.issn.1006-9941.2013.05.023. [10] 王浩, 梁世超, 张莺, 等. 火焰在传火管装药床中的传输特性研究 [J]. 爆炸与冲击, 1999, 19(1): 66–71.WANG H, LIANG S C, ZHANG Y, et al. Study of flame propagation characteristics in fire transfering tube [J]. Explosion and Shock Waves, 1999, 19(1): 66–71. [11] 王珊珊, 张玉成, 王浩, 等. 大长径比点火管高密实火药床点传火过程两相流的数值模拟 [J]. 爆炸与冲击, 2013, 33(4): 444–448. DOI: 10.11883/1001-1455(2013)04-0444-05.WANG S S, ZHANG Y C, WANG H, et al. Two-phase flow in ignition process of consolidated charge bed within a large length-to-diameter ratio igniter tube [J]. Explosion and Shock Waves, 2013, 33(4): 444–448. DOI: 10.11883/1001-1455(2013)04-0444-05. [12] 王珊珊, 王浩, 黄明, 等. 药床透气性对大长径比点传火管点传火性能的影响研究 [J]. 弹道学报, 2013, 25(4): 95–99. DOI: 10.3969/j.issn.1004-499X.2013.04.019.WANG S S, WANG H, HUANG M, et al. Research on influence of charge permeability on ignition characteristics on large length-diameter ratio igniter tube [J]. Journal of Ballistics, 2013, 25(4): 95–99. DOI: 10.3969/j.issn.1004-499X.2013.04.019. [13] 韩博, 张晓志, 邢浴仁, 等. 大口径火炮发射装药点传火模拟试验装置的研究 [J]. 兵工学报, 2008, 29(3): 262–265. DOI: 10.3321/j.issn:1000-1093.2008.03.002.HAN B, ZHANG X Z, XING Y R, et al. Research on simulation testing device of the ignition system for large caliber propellant charging [J]. Acta Armamentarii, 2008, 29(3): 262–265. DOI: 10.3321/j.issn:1000-1093.2008.03.002. [14] 程诚, 张小兵. 某制导炮弹二维两相流内弹道性能分析与数值模拟研究 [J]. 兵工学报, 2015, 36(1): 58–63. DOI: 10.3969/j.issn.1000-1093.2015.01.009.CHENG C, ZHANG X B. Two-dimensional numerical simulation on two-phase flow interior ballistic performance of a guided projectile [J]. Acta Armamentarii, 2015, 36(1): 58–63. DOI: 10.3969/j.issn.1000-1093.2015.01.009. [15] MIURA H, MATSUO A, NAKAMURA Y. Three-dimensional simulation of pressure fluctuation in a granular solid propellant chamber within an ignition stage [J]. Propellants, Explosives, Pyrotechnics, 2011, 36(3): 259–267. DOI: 10.1002/prep.201000058. [16] JANG J S, Oh S H, ROH T S. Development of three-dimensional numerical model for combustion-flow in interior ballistics [J]. Journal of Mechanical Science and Technology, 2016, 30(4): 1631–1637. DOI: 10.1007/s12206-016-0319-y. [17] JENARO G, OTON-MARTINEZ R A, MORATILLA D, et al. Analysis of pressure waves generation in gun combustion chambers during the propellant ignition process [J]. Propellants, Explosives, Pyrotechnics, 2016, 41(2): 228–237. DOI: 10.1002/prep.201500173. [18] JARAMAZ S, MICKOVIĆ D, ELEK P. Two-phase flows in gun barrel: theoretical and experimental studies [J]. International Journal of Multiphase Flow, 2011, 37(5): 475–487. DOI: 10.1016/j.ijmultiphaseflow.2011.01.003. [19] COLLETTI A, BOYER E, KUO K K, et al. Characterization of black-powder igniter jets into a granular bed through analysis of condensed-phase product deposition and regions of penetration [J]. International Journal of Energetic Materials and Chemical Propulsion, 2010, 9(6): 505–522. DOI: 10.1615/IntJEnergeticMaterialsChemProp.2011001422. -

下载:

下载: