Peridynamic damage simulation of composite structures subjected to fragment clusters

-

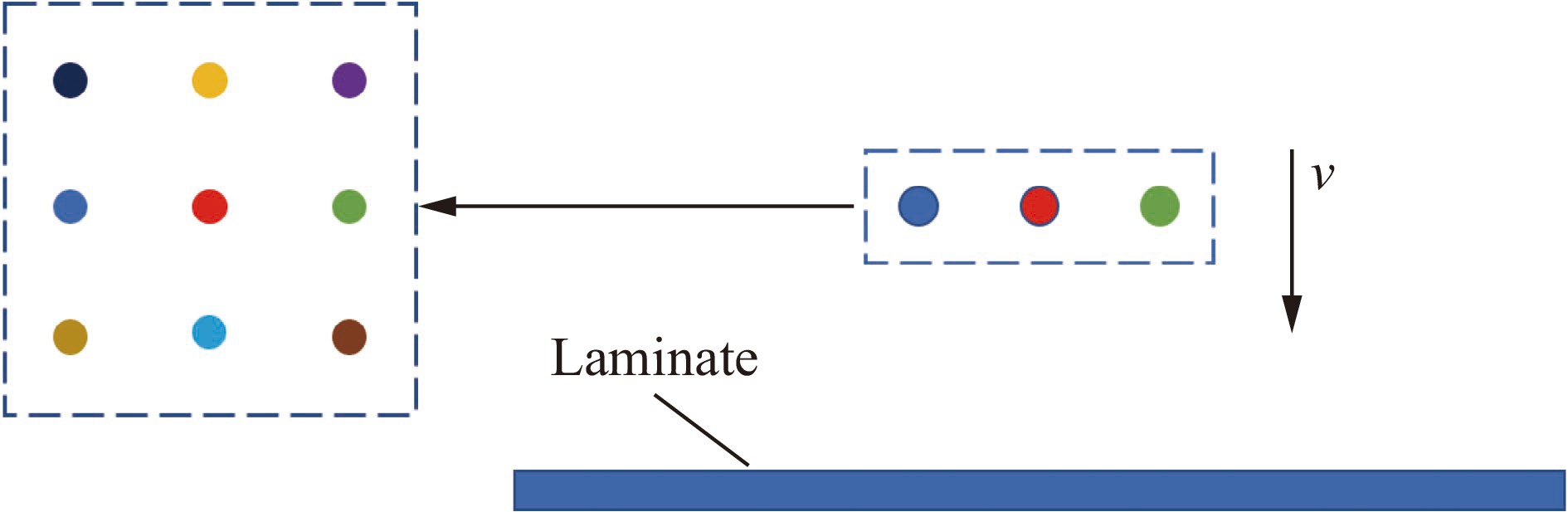

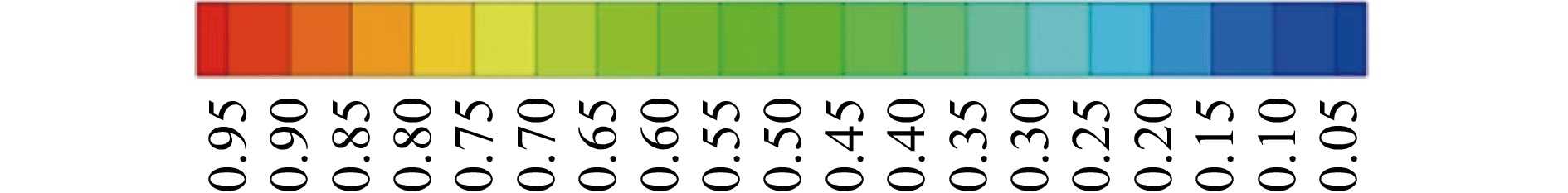

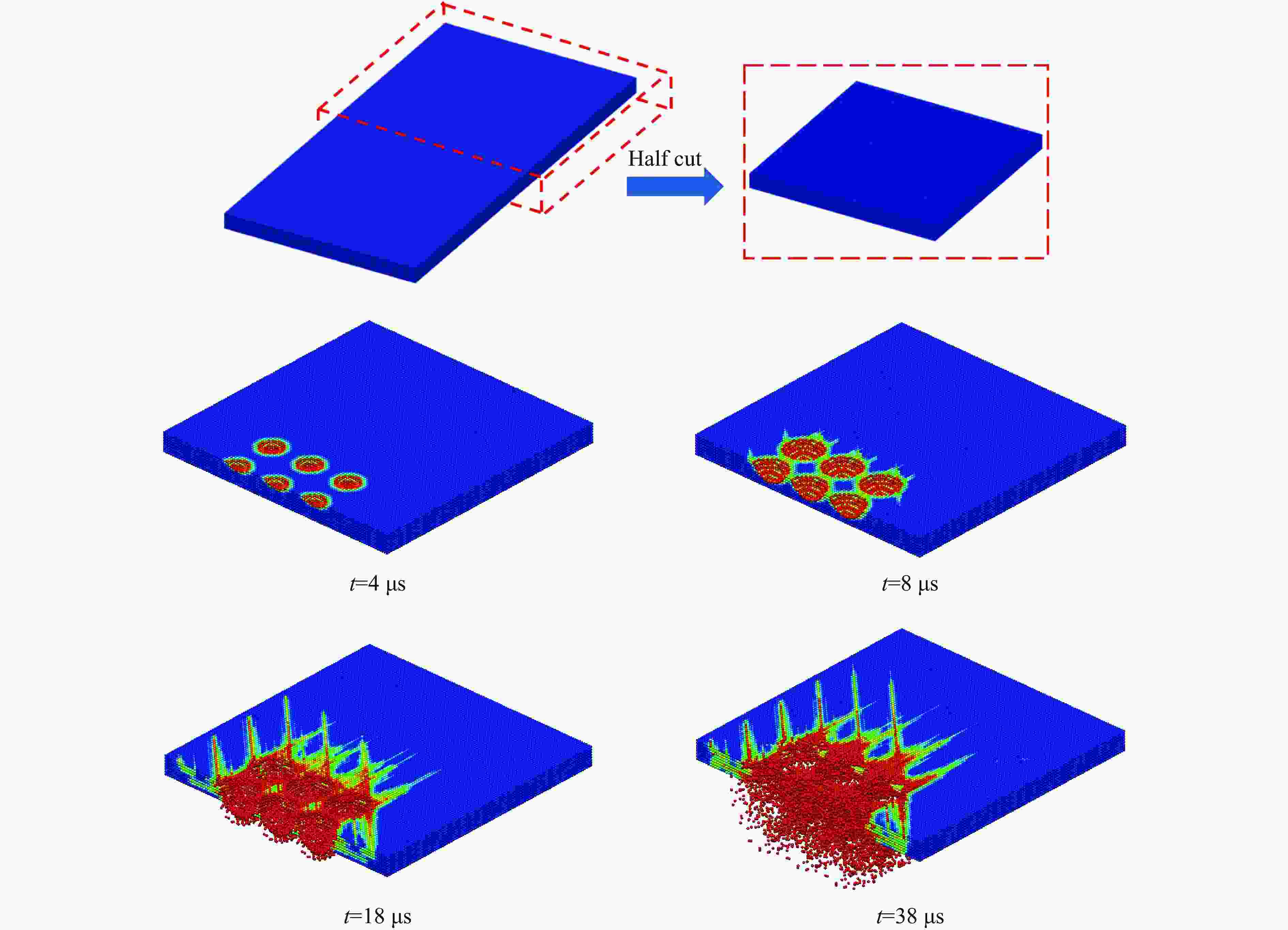

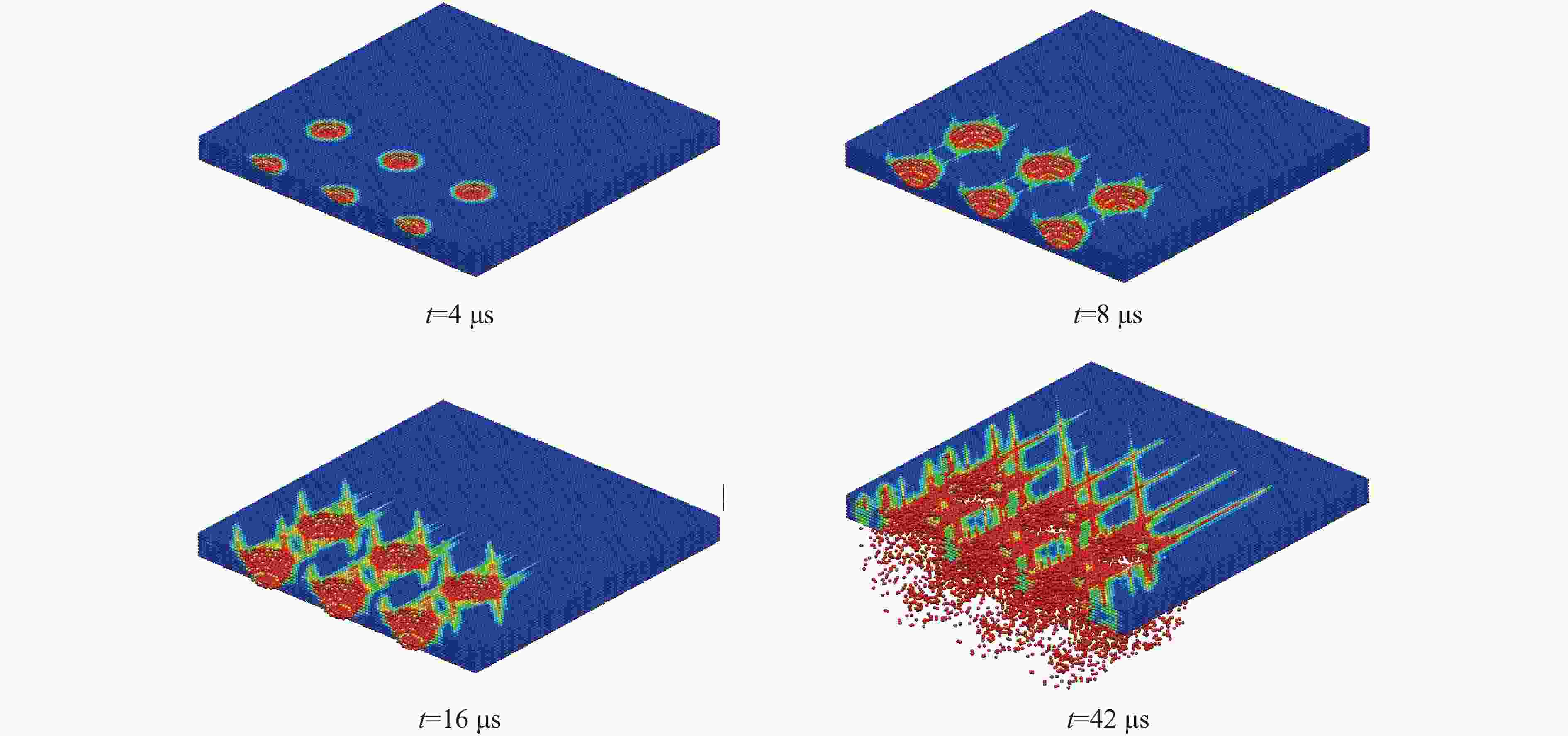

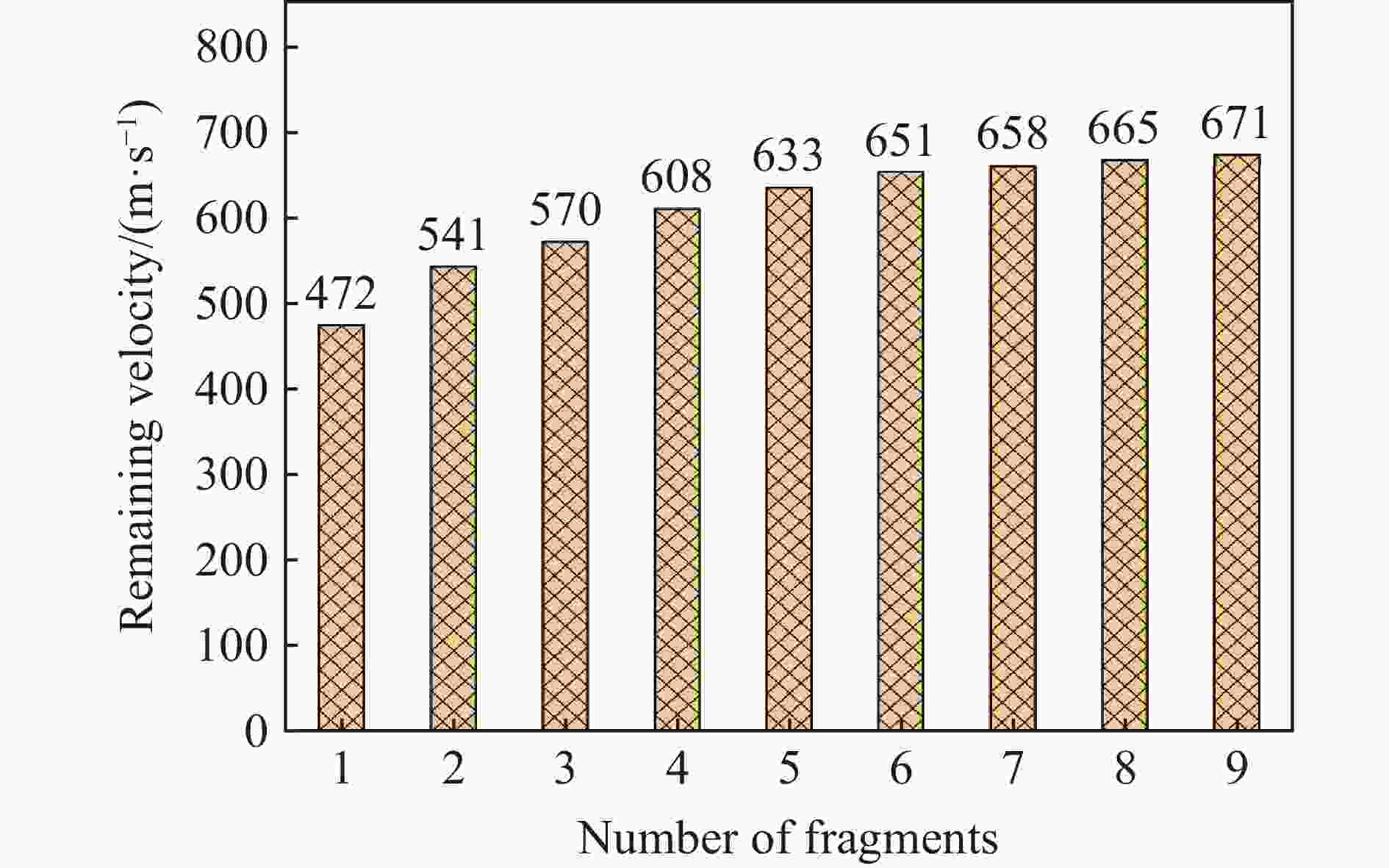

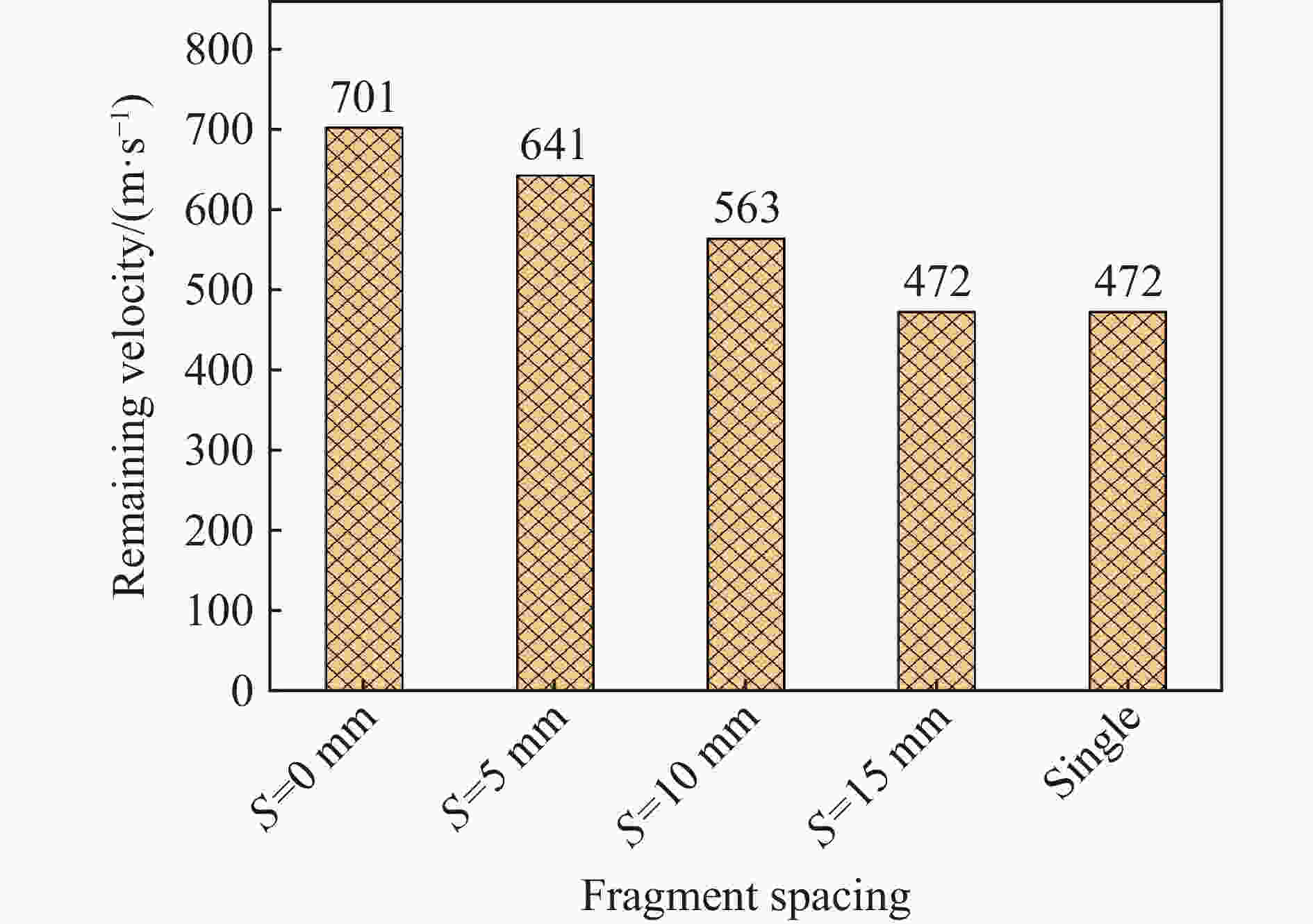

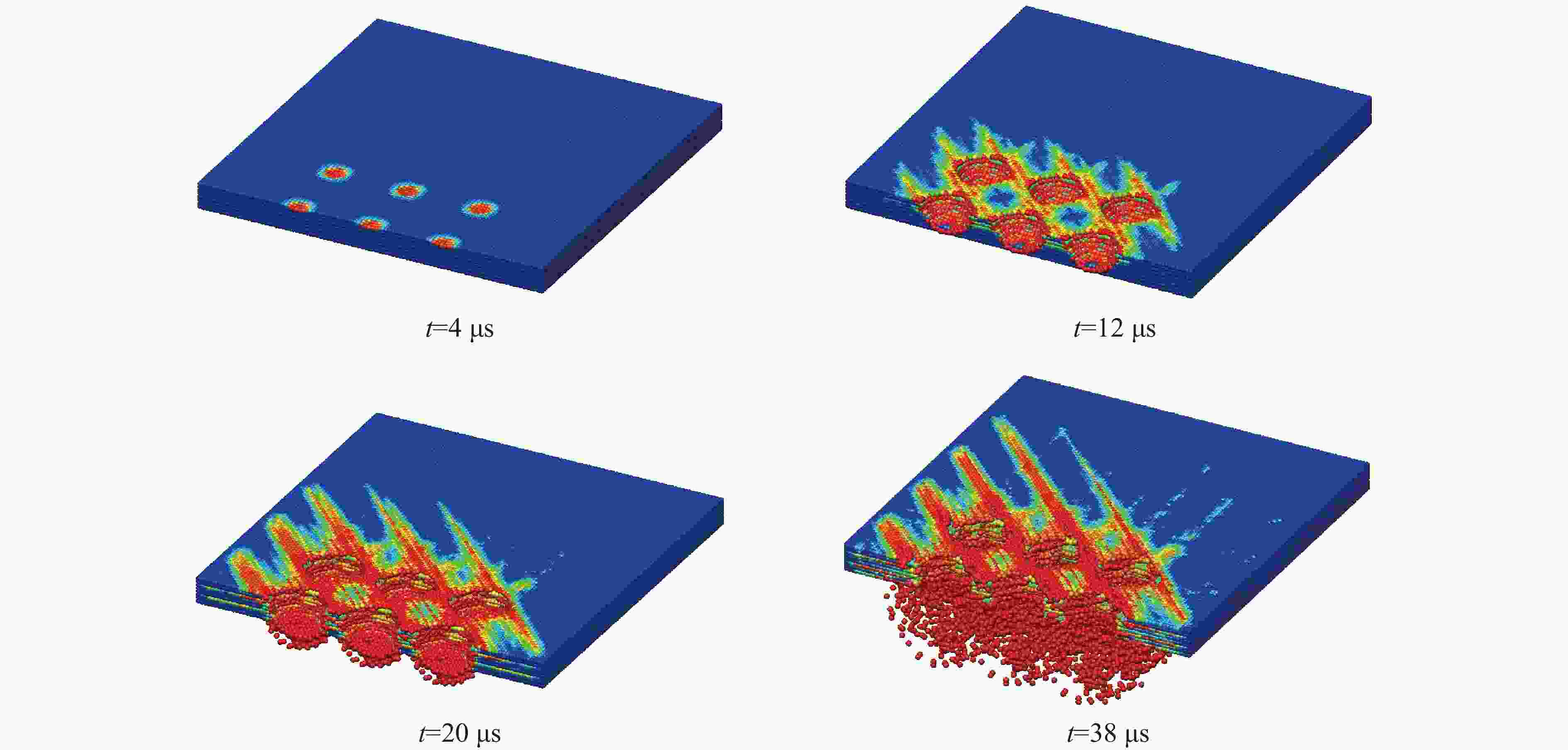

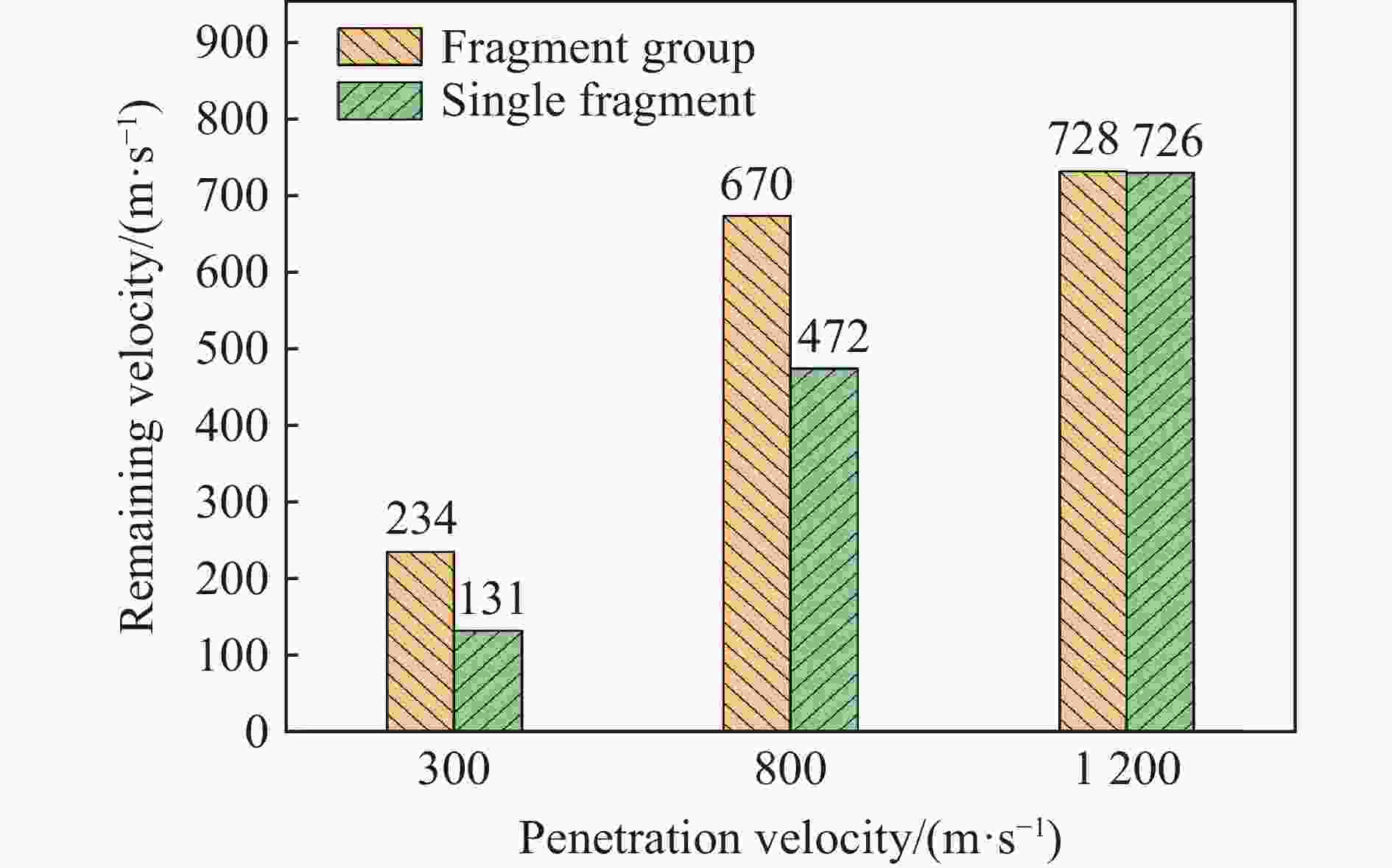

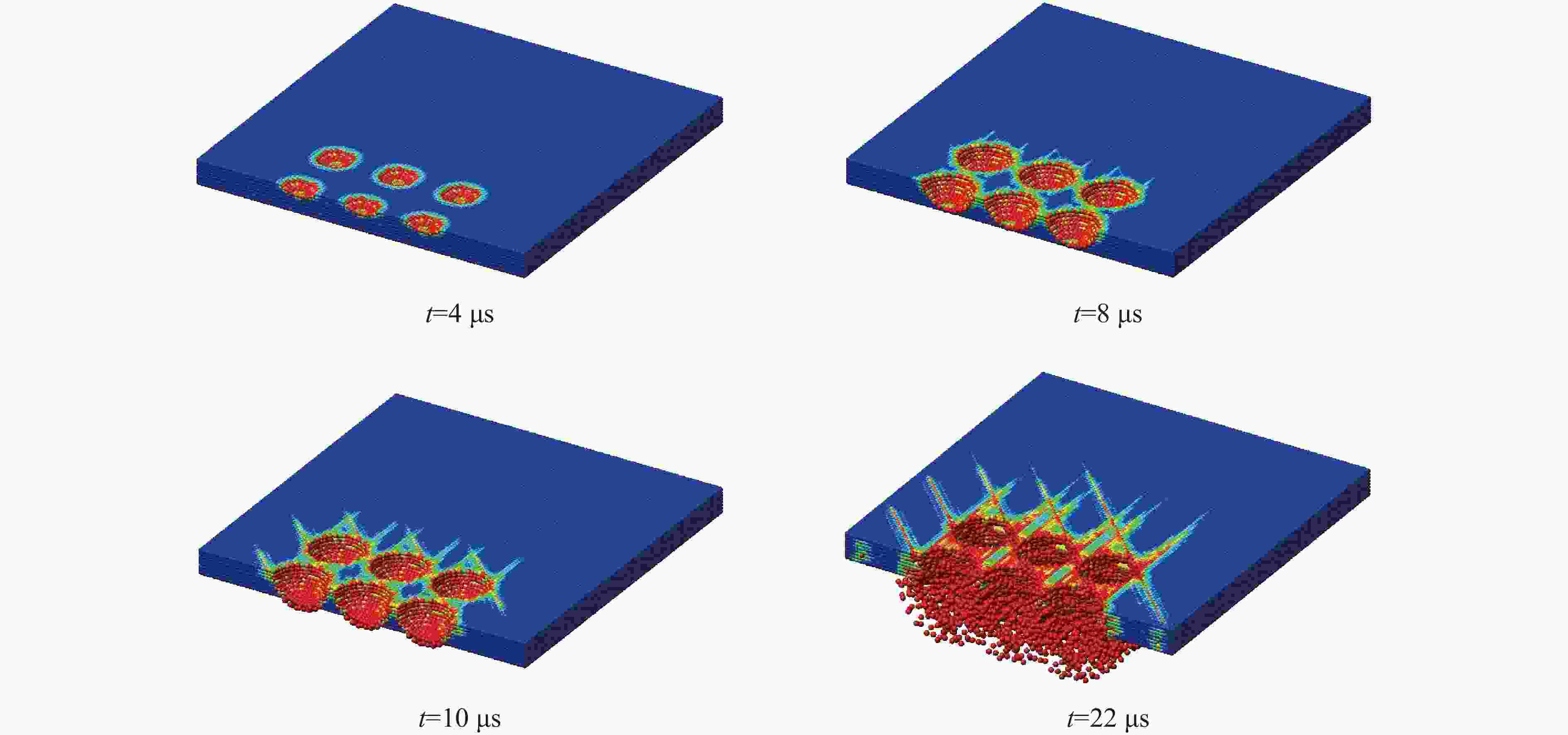

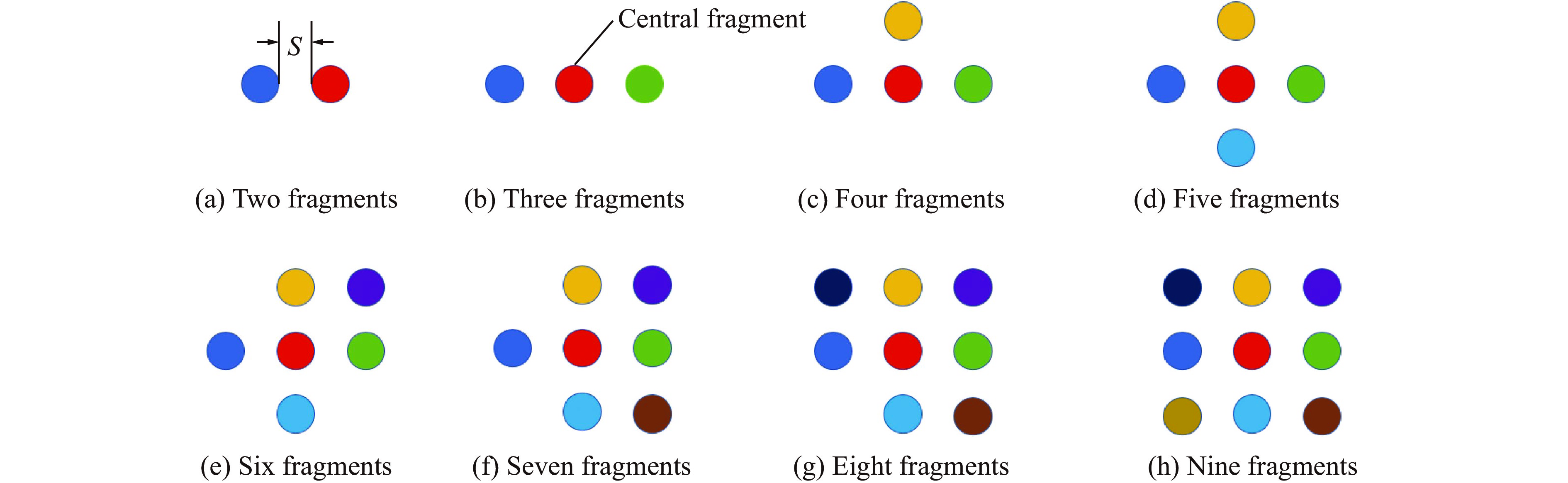

摘要: 采用一种新兴的无网格法——近场动力学理论,模拟复合材料结构在破片群载荷作用下的损伤情况。根据复合材料结构受到载荷的特性,总结破片群冲击作用下复合材料结构损伤特性,分析其破坏过程,研究破片群增强效应,并对破片速度、破片数量、破片群间距对侵彻能力增强效应的影响进行分析。结果表明:层合板结构在高速破片群侵彻作用下损伤模式多样,与破片数量、速度、间距相关;破片数量的增加,对破片群侵彻能力增强效应明显;破片间距与破片群侵彻能力增强效应负相关,破片间距减小,破片群损伤效应提高;破片速度直接决定穿透时间,破片速度的提高使得穿透时间缩短,应力波的叠加效应不足以影响破片群的侵彻能力。Abstract: In recent years, as a hot area of computational mechanics, peridynamic has attracted the attention of researchers. The peridynamic theory attempts to unify the mathematical models of continuum, cracks, and particles into one framework, which is essentially a mechanical model independent of the scope of continuum mechanics. The governing equation of peridynamic adopts the spatial integral form, and the continuity of the field function is no longer required. Compared with the traditional methods based on continuum mechanics, this method has a great advantage in dealing with discontinuity problems, such as crack propagation and other fracture problems. In this paper, the peridynamic method was used to study the damage characteristics of composite structures under the impact of a fragment group and to analyze the enhancement effect on the penetration ability during the destruction process. Through a self-programmed peridynamic model, the penetration process of a fragment group into a composite laminate was simulated to explore the influence of the fragment velocity, fragment number and fragment spacing on the penetration ability enhancement. The results show that the damage modes of the laminate structure under the action of high-velocity fragment group penetration are diverse and related to the number, velocity and spacing of the fragments. The increase in the fragment number has a significant effect on the penetration ability of the fragments. The fragment spacing is negatively correlated with the enhancement effect. When the fragment spacing decreases, the damage effect increases. The fragment velocity directly determines the penetration time, and the increase in the fragment velocity decreases the penetration time. The superimposition effect of the stress waves is not enough to affect the penetration ability of the fragment group.

-

Key words:

- composites /

- peridynamics /

- fragment clusters /

- fragment number /

- fragment spacing

-

表 1 层合板材料性能参数

Table 1. Material properties of the laminate

参数 含义 数值 单位 E1 x方向弹性模量 125 GPa E2 y方向弹性模量 7.6 GPa E3 z方向弹性模量 7.6 GPa ν12 面内泊松比 0.344 ν13 面外泊松比 0.344 ν23 面外泊松比 0.46 G12 xy平面剪切模量 4.32 GPa G13 xz平面剪切模量 4.32 GPa G23 yz平面剪切模量 3.23 GPa ρ 密度 1678 kg/m3 Xt 纵向拉伸强度 2200 MPa Xc 纵向压缩强度 1100 MPa Yt 横向拉伸强度 50 MPa Yc 横向压缩强度 200 MPa 表 2 破片间距

$S=1\;{\rm{mm}}$ 时,在破片群侵彻下层合板的损伤模式Table 2. Damage modes of the laminate subjected to fragment group penetration when the fragment spacing

$S=1\;{\rm{mm}}$ v/(m·s−1) 基体损伤 剪切损伤 迎弹面 迎弹面 迎弹面 背弹面 300

800

1 200

表 3 破片间距

$S=10\;{\rm{mm}}$ 时,在破片群侵彻下层合板的损伤模式Table 3. Damage modes of the laminate subjected to fragment group penetration when the fragment spacing

$S=10\;{\rm{mm}}$ v/(m·s−1) 基体损伤 剪切损伤 迎弹面 背弹面 迎弹面 背弹面 300

800

1 200

-

[1] RIEDEL W, NAHME H, WHITE D M, et al. Hypervelocity impact damage prediction in composites: Part Ⅱ: experimental investigations and simulations [J]. International Journal of Impact Engineering, 2006, 33(1): 670–680. DOI: 10.1016/j.ijimpeng.2006.09.052. [2] 王晓强, 朱锡, 梅志远, 等. 超高分子量聚乙烯纤维增强层合厚板抗弹性能实验研究 [J]. 爆炸与冲击, 2009, 29(1): 29–34. DOI: 10.11883/1001-1455(2009)01-0029-06.WANG X Q, ZHU X, MEI Z Y, et al. Ballistic performances of ultra-high molecular weight polyethylene fiber-reinforced thick laminated plates [J]. Explosion and Shock Waves, 2009, 29(1): 29–34. DOI: 10.11883/1001-1455(2009)01-0029-06. [3] WAMBUA P, VANGRIMDE B, LOMOV S, et al. The response of natural fibre composites to ballistic impact by fragment simulating projectiles [J]. Composite Structures, 2007, 77(2): 232–240. DOI: 10.1016/j.compstruct.2005.07.006. [4] 李典, 侯海量, 朱锡, 等. 破片群侵彻纤维增强层合板破坏机理及穿甲能力等效方法 [J]. 兵工学报, 2018, 39(4): 707–716. DOI: 10.3969/j.issn.1000-1093.2018.04.010.LI D, HOU H L, ZHU X, et al. Study of the failure mechanism of fiber reinforced composite laminates subjected to fragment cluster penetration and the equivalent method for armor piercing ability of fragment cluster [J]. Acta Armamentarii, 2018, 39(4): 707–716. DOI: 10.3969/j.issn.1000-1093.2018.04.010. [5] SILLING S A. Reformulation of elasticity theory for discontinuities and long-range forces [J]. Journal of the Mechanics and Physics of Solids, 2000, 48(1): 175–209. DOI: 10.1016/S0022-5096(99)00029-0. [6] 李典, 侯海量, 戴文喜, 等. 爆炸冲击波和破片联合作用下玻璃纤维夹芯复合结构毁伤特性实验研究 [J]. 兵工学报, 2017, 38(5): 877–885. DOI: 10.3969/j.issn.1000-1093.2017.05.006.LI D, HOU H L, DAI W X, et al. Experimental investigation on damage of glassfiber sandwich structure under explosion and fragment loadings [J]. Acta Armamentarii, 2017, 38(5): 877–885. DOI: 10.3969/j.issn.1000-1093.2017.05.006. [7] 姜翠香. 裂纹损伤舰船结构的断裂及止裂研究 [D]. 武汉: 华中科技大学, 2004: 1−3.JIANG C X. Research on fracture and crack arrest in ship structrue [D]. Wuhan: Huazhong University of Science and Technology, 2004: 1−3. [8] 姚熊亮. 舰船结构振动冲击与噪声 [M]. 北京: 国防工业出版社, 2007: 144−146. [9] 赵国志. 穿甲工程力学 [M]. 北京: 兵器工业出版社, 1992: 52−53. [10] 侯海量, 朱锡, 谷美邦, 等. 破片模拟弹侵彻钢板的有限元分析 [J]. 海军工程大学学报, 2006, 18(3): 78–83; 88. DOI: 10.3969/j.issn.1009-3486.2006.03.019.HOU H L, ZHU X, GU M B, et al. Investigation on penetration of steel plate by fragment simulated projectile using finite element method [J]. Journal of Naval University of Engineering, 2006, 18(3): 78–83; 88. DOI: 10.3969/j.issn.1009-3486.2006.03.019. [11] 侯海量, 朱锡, 李伟, 等. 低速大质量球头弹冲击下薄板穿甲破坏机理数值分析 [J]. 振动与冲击, 2008, 27(1): 40–45. DOI: 10.13465/j.cnki.jvs.2008.01.004.HOU H L, ZHU X, LI W, et al. Numerical analysis of perforation mechanism for a thin plate subjected to impact by hemispherical-nosed projectiles with low velocity [J]. Journal of Vibration and Shock, 2008, 27(1): 40–45. DOI: 10.13465/j.cnki.jvs.2008.01.004. -

下载:

下载: