Experimental study on the effect of loading angle on crack propagation in bedding shale

-

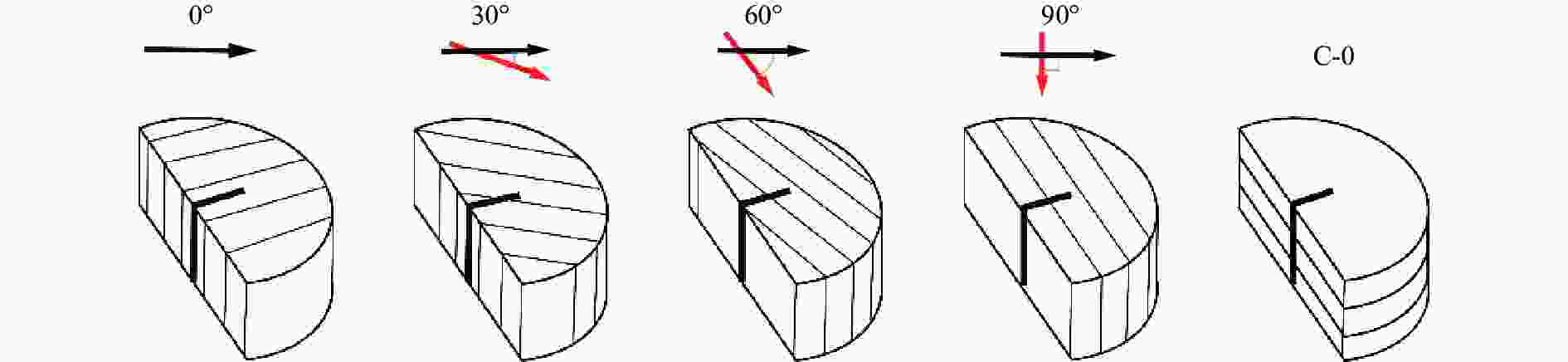

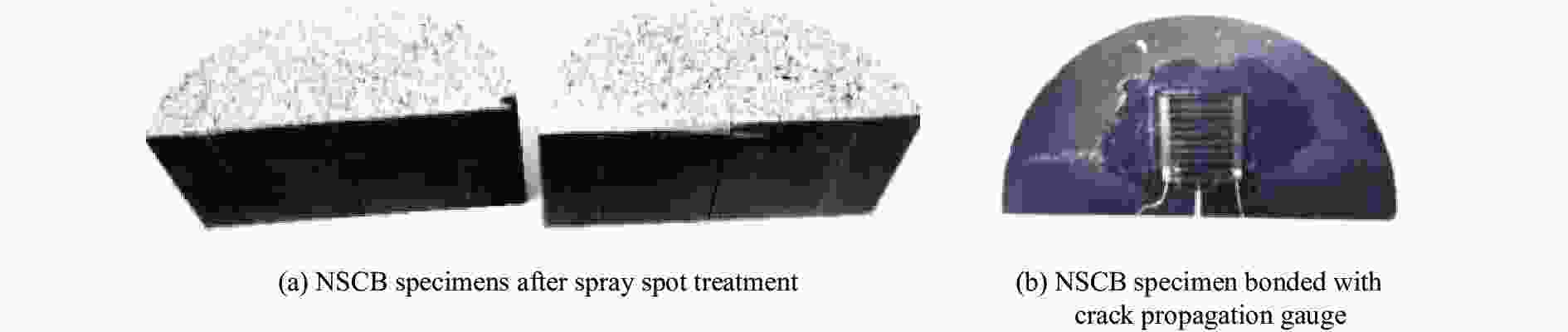

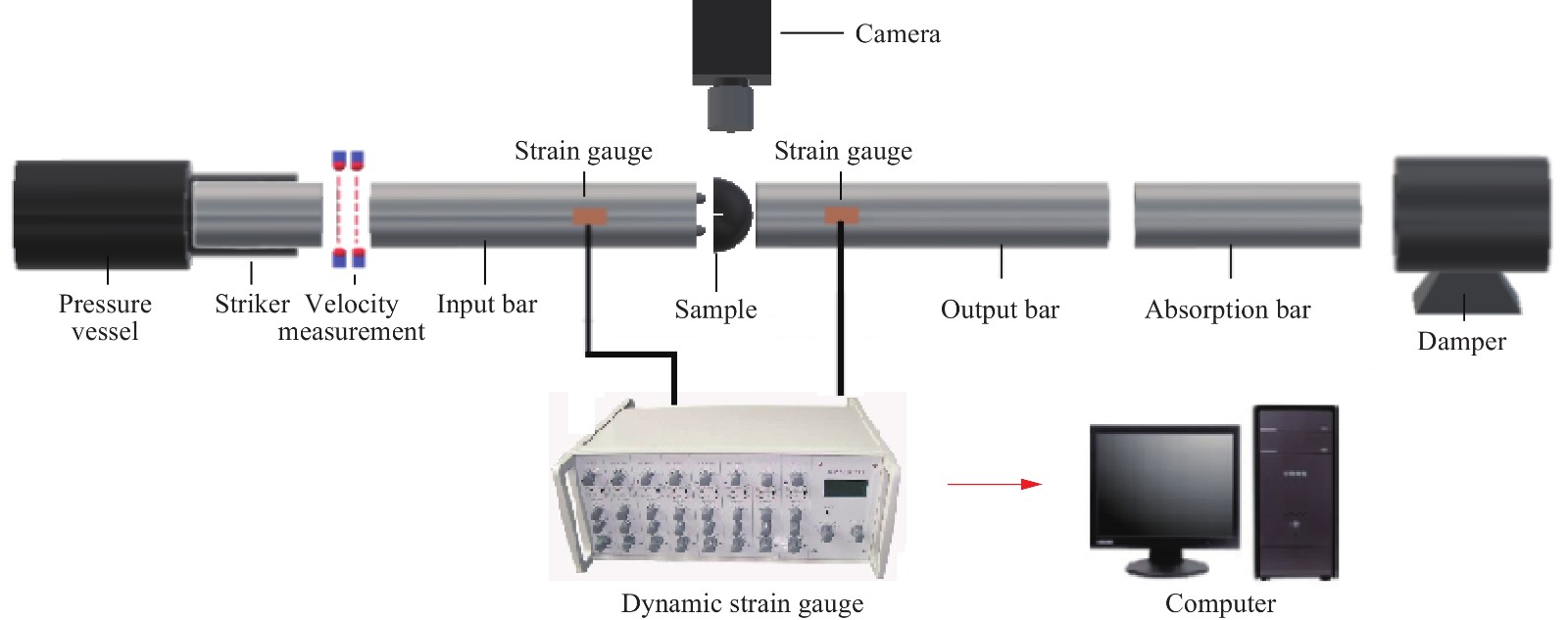

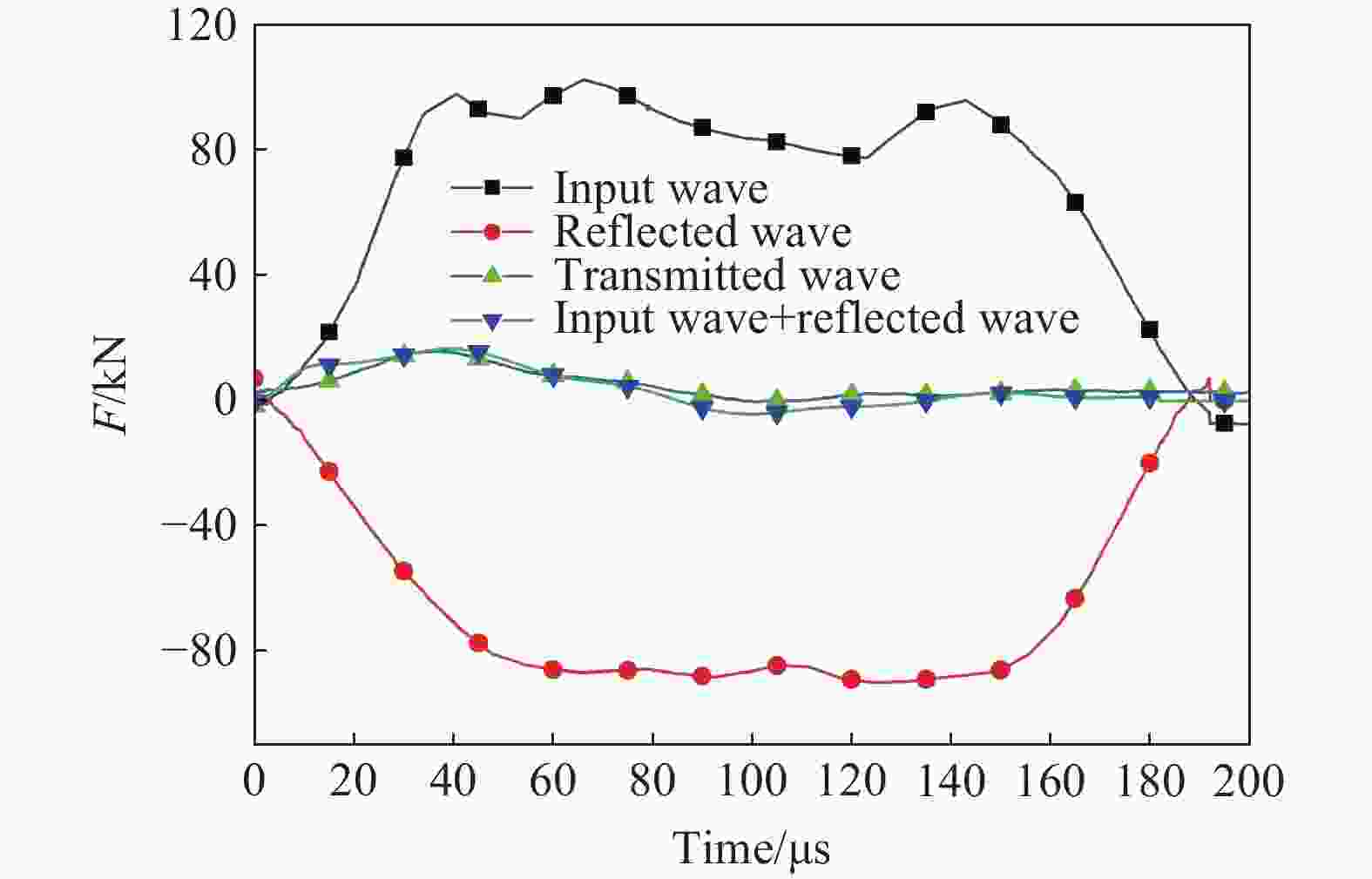

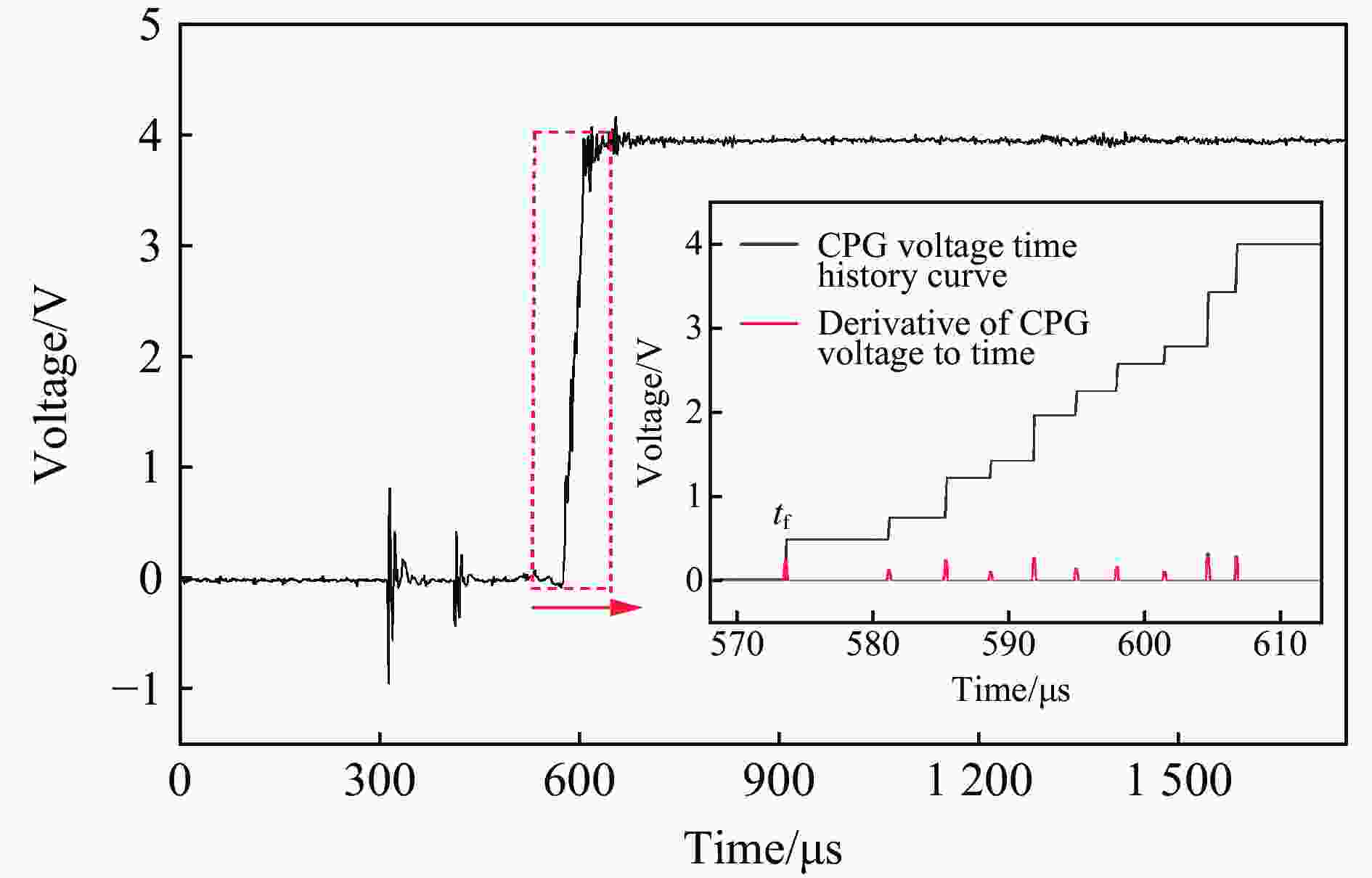

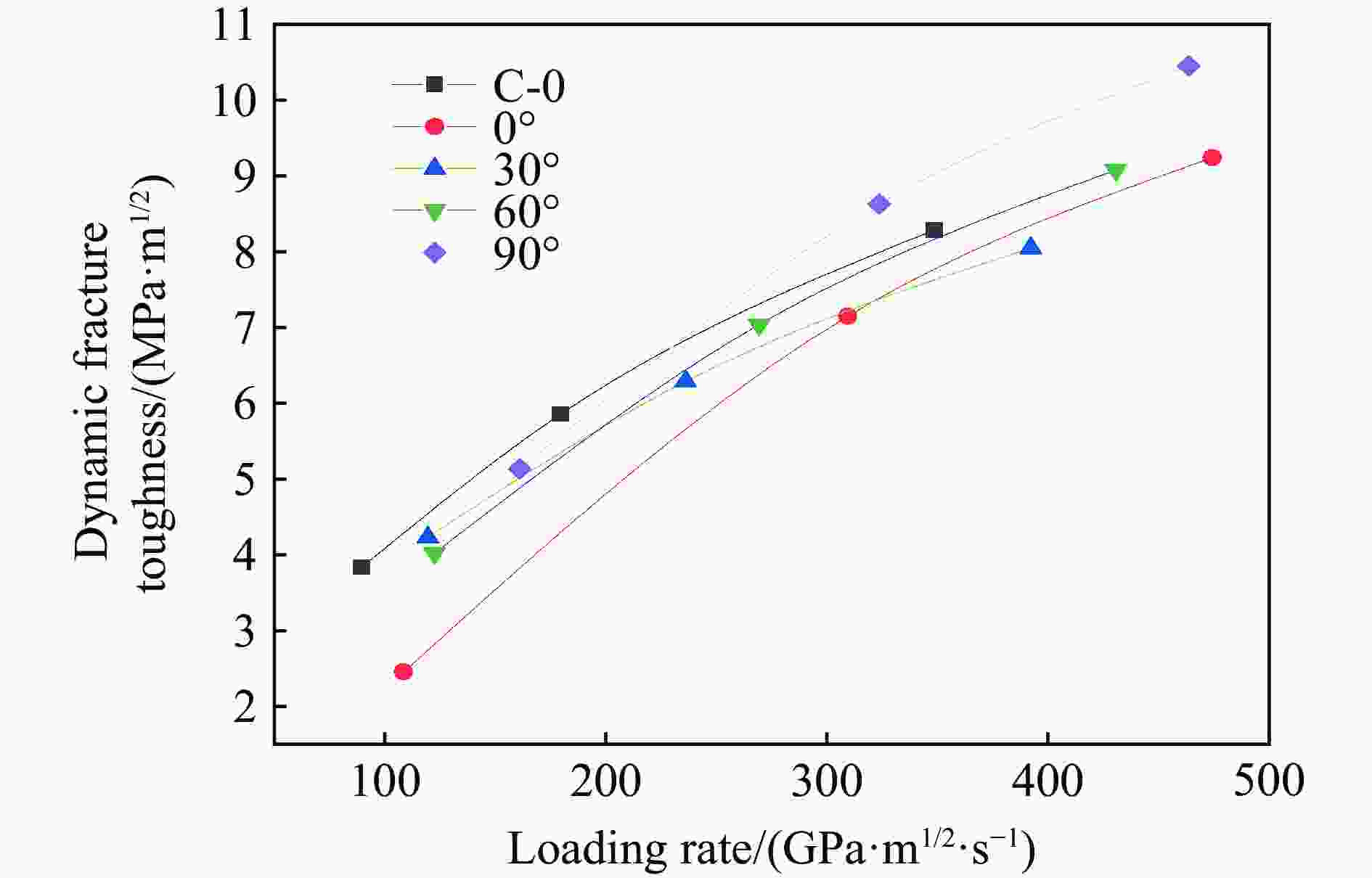

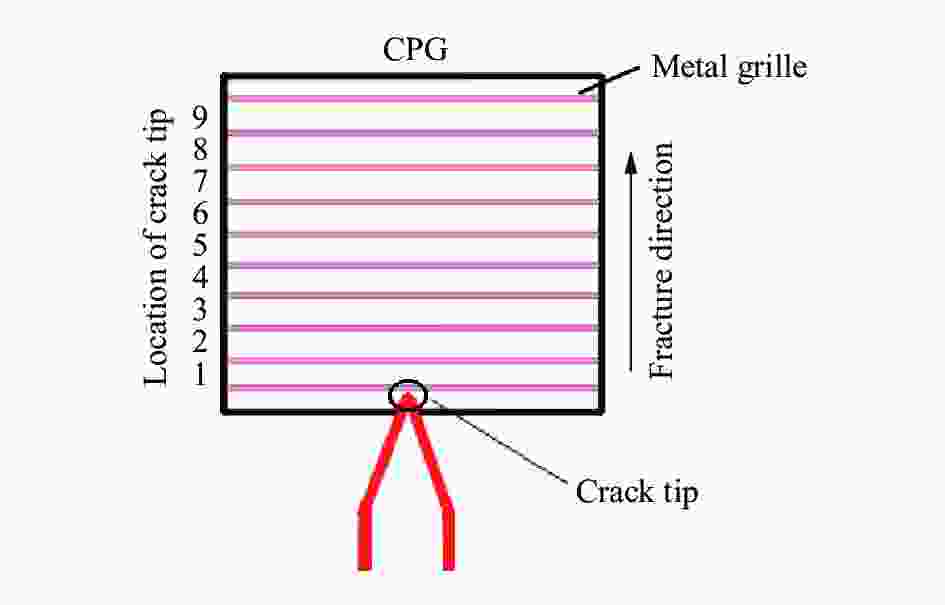

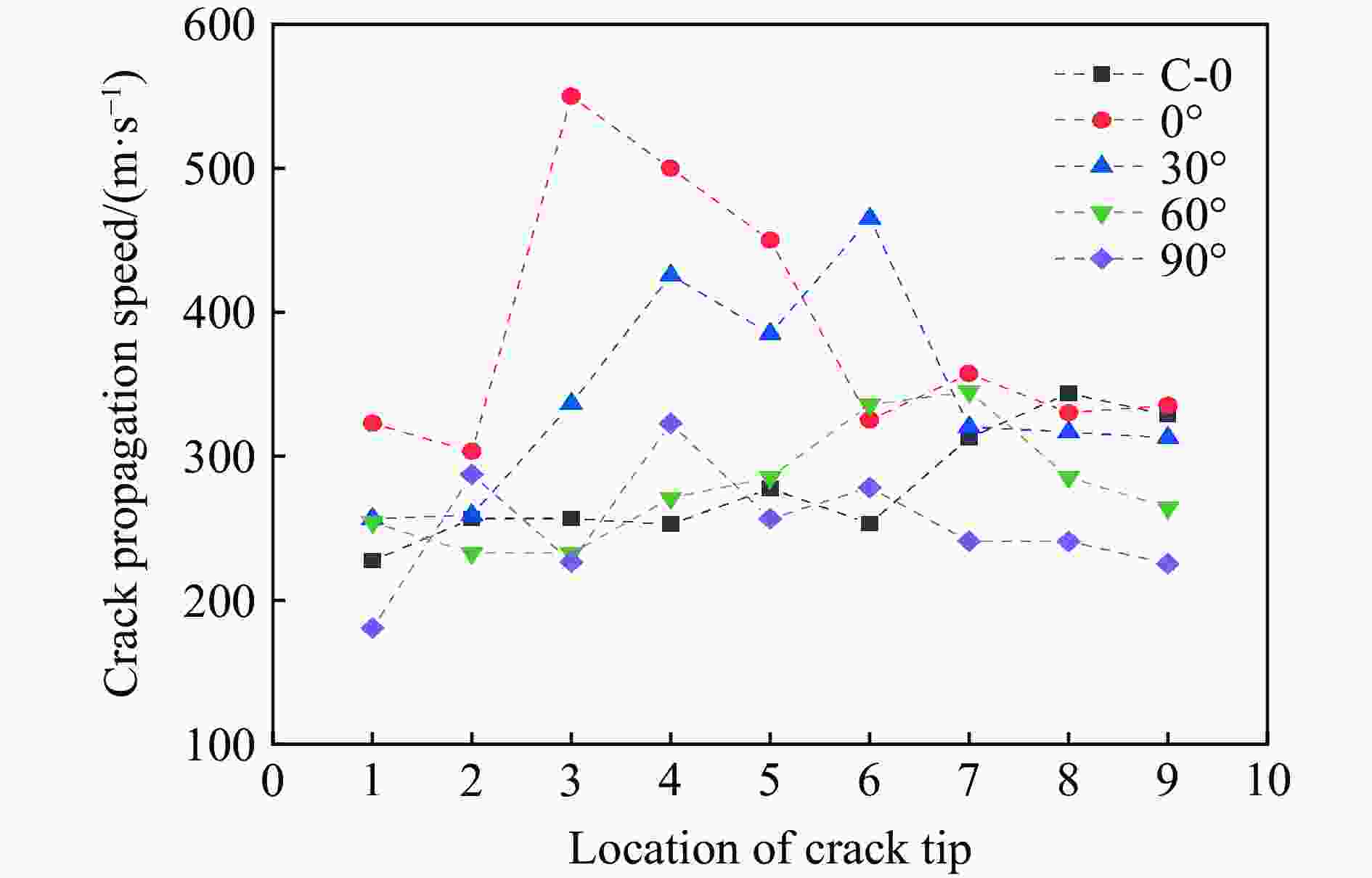

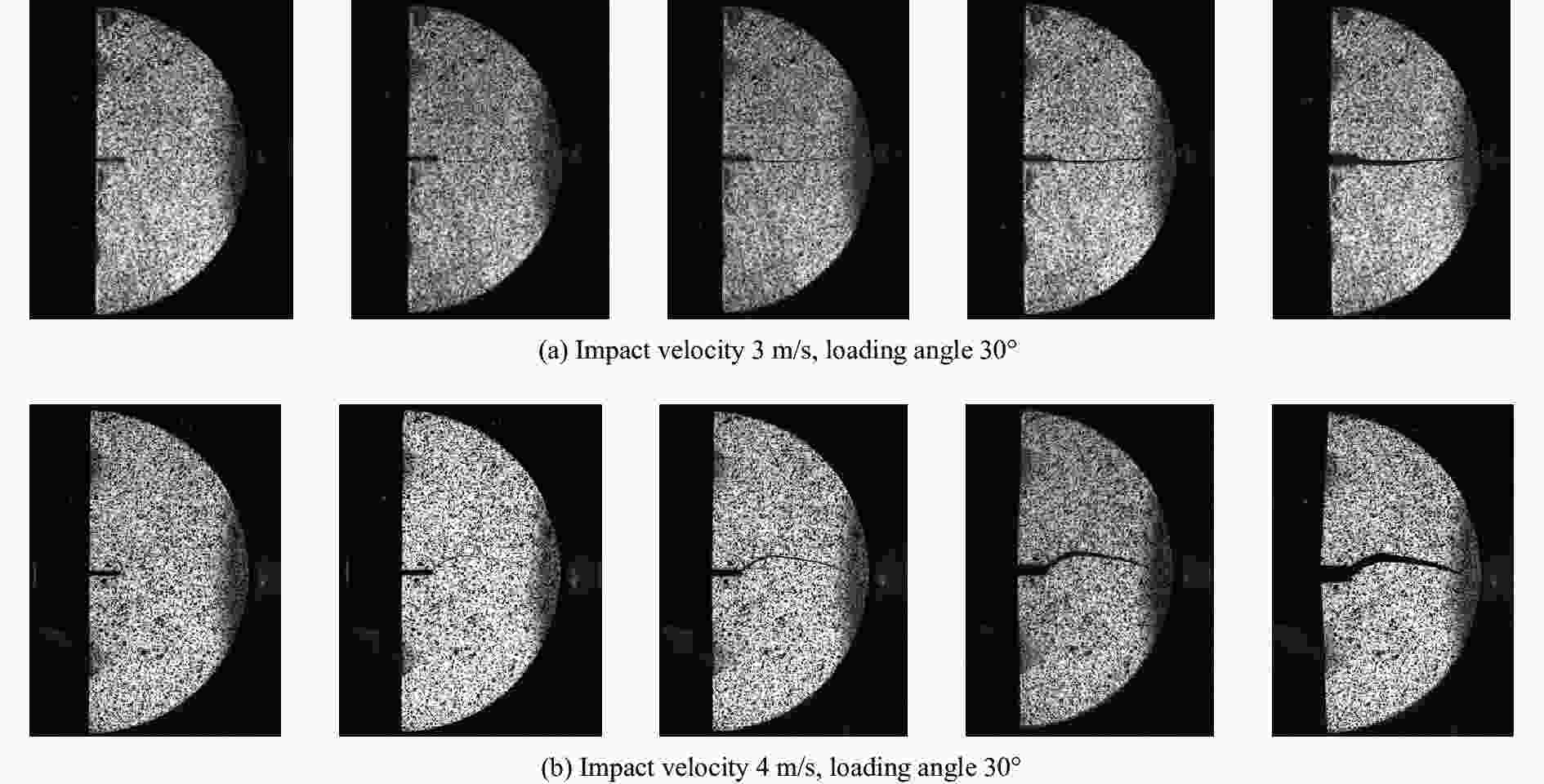

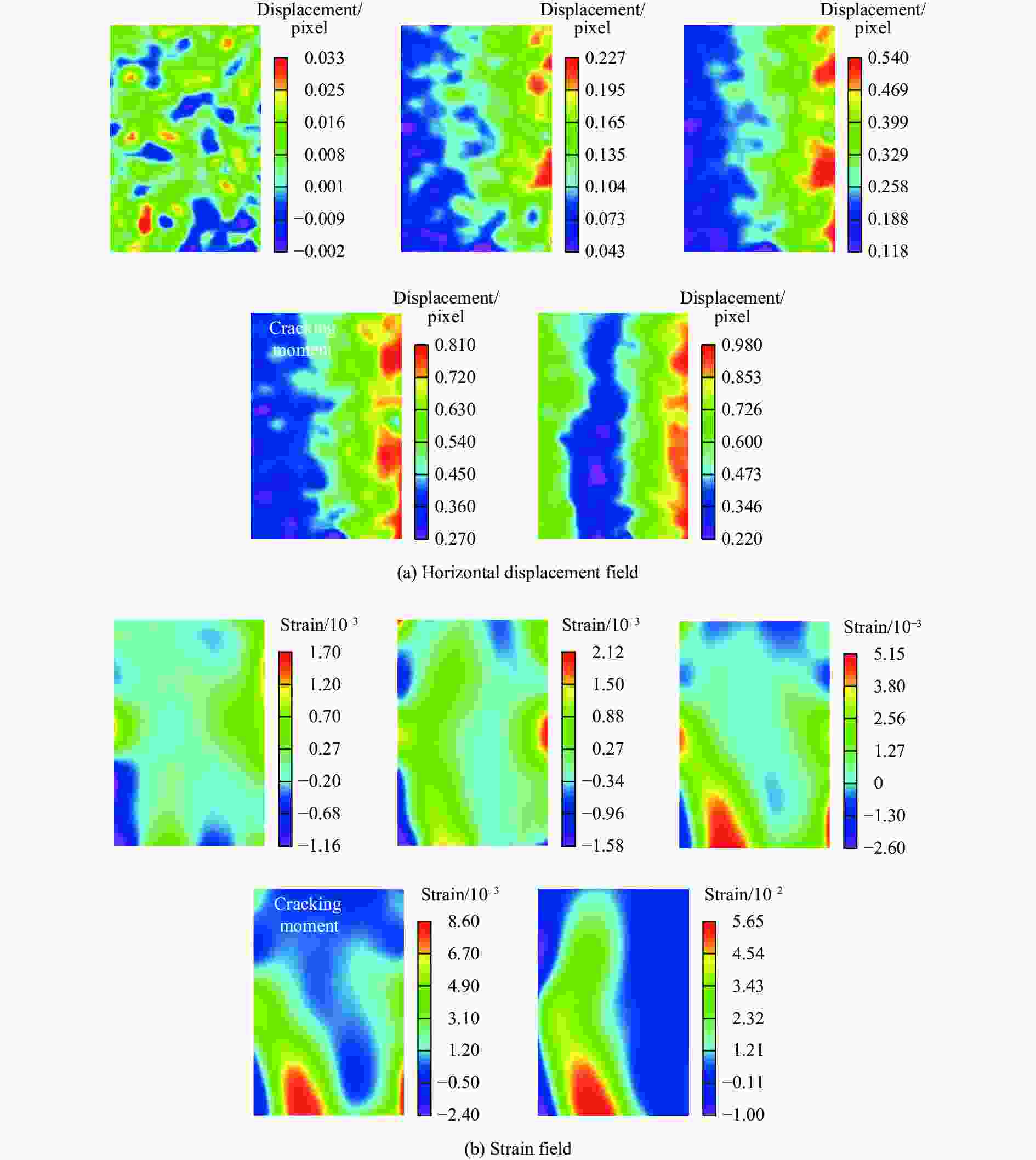

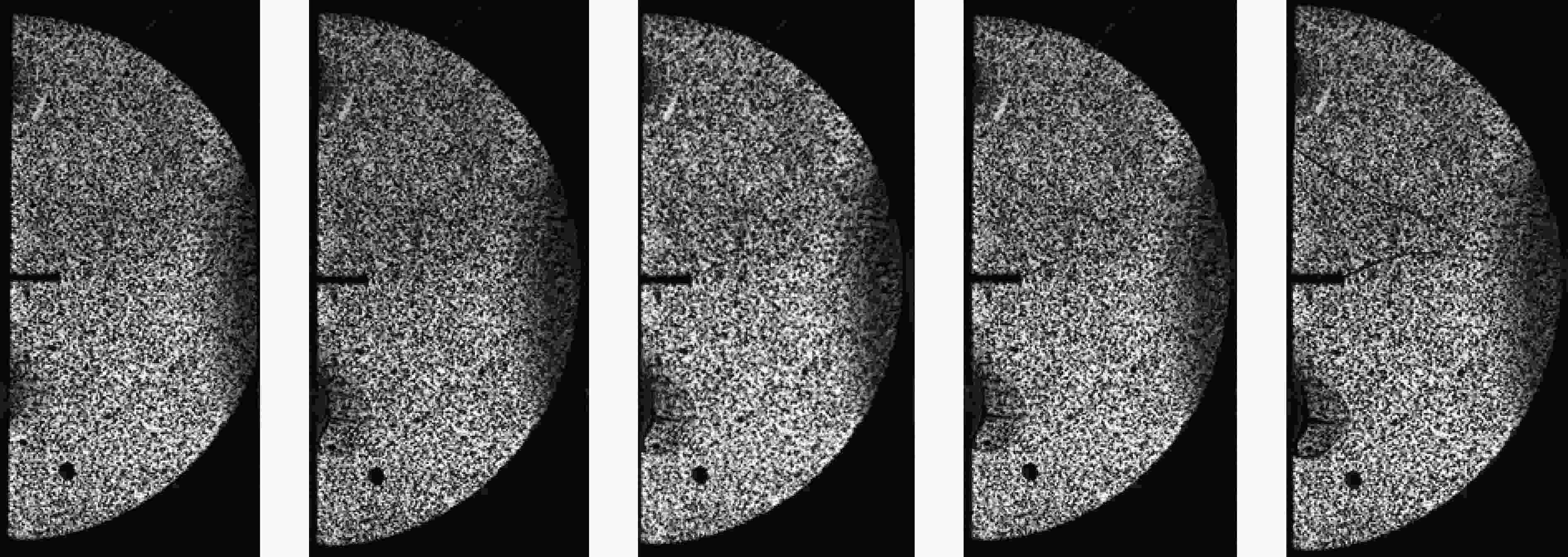

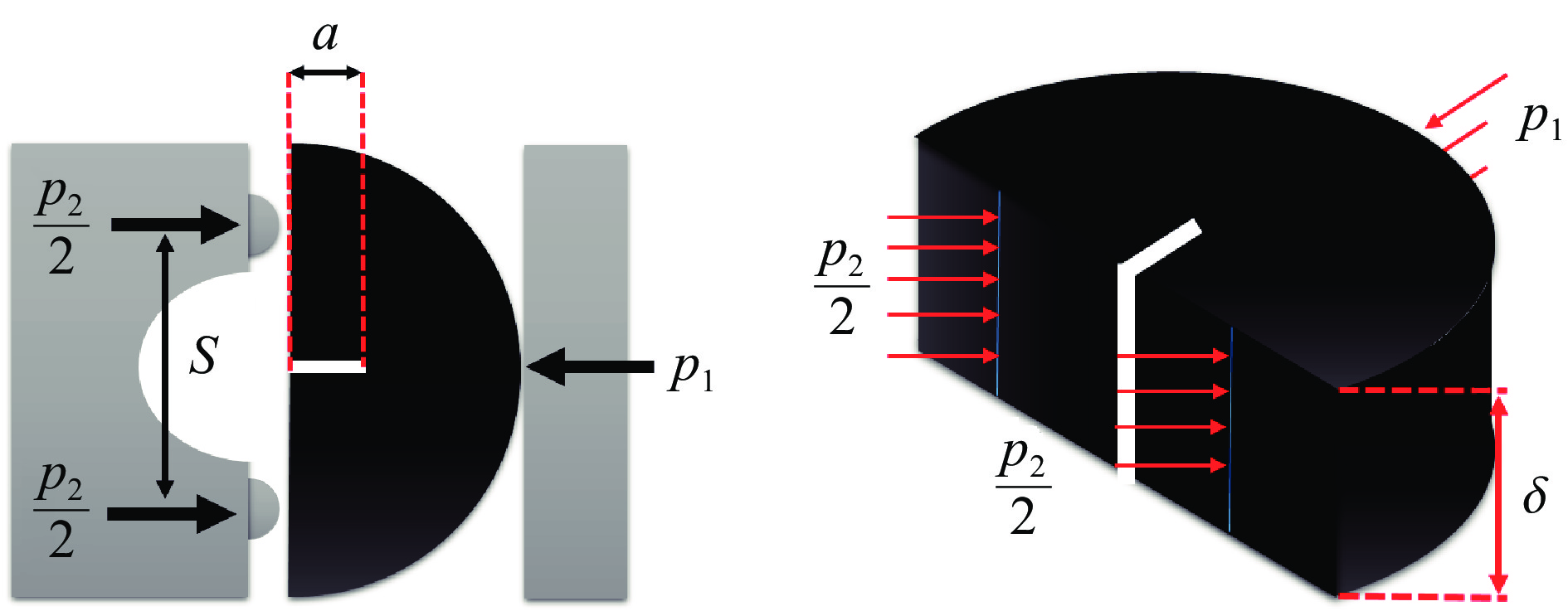

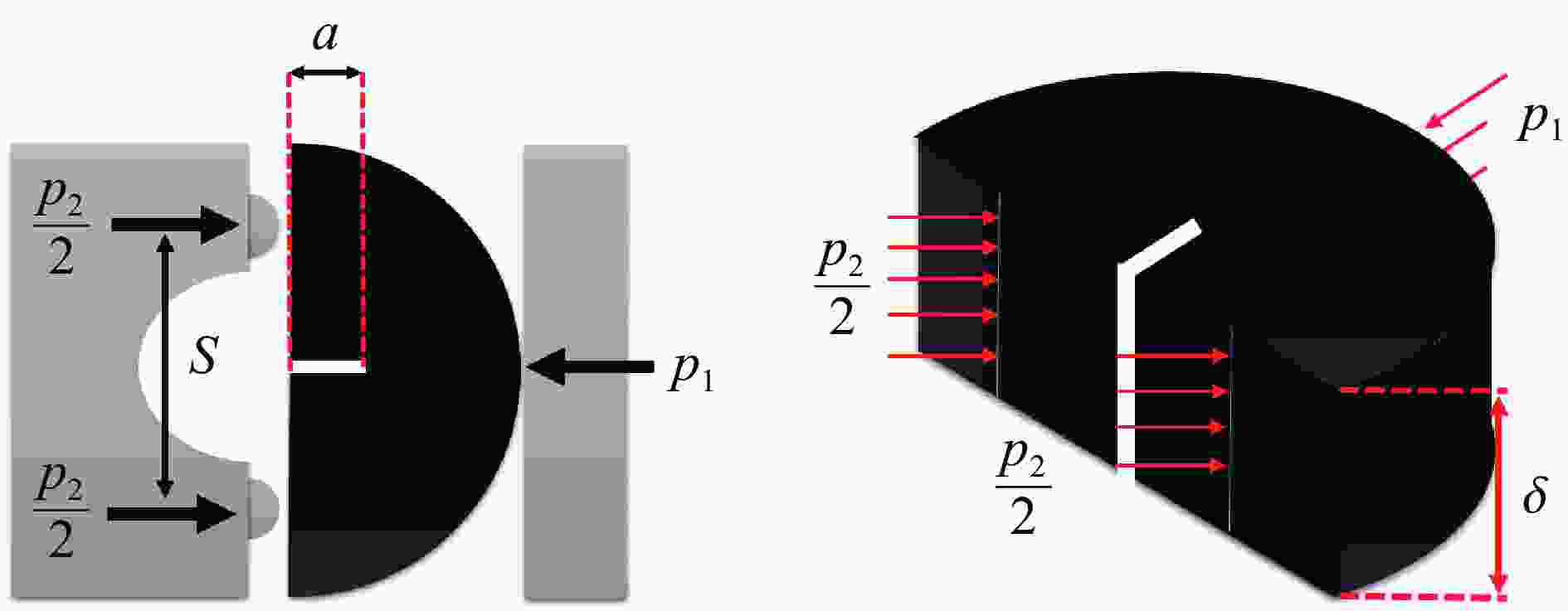

摘要: 采用分离式霍普金森压杆(SHPB)系统对页岩进行冲击实验,研究层理角度对页岩动态断裂过程的影响,在裂尖设置裂纹扩展计,借助高速摄影和数字图像相关(DIC)技术对页岩中心切槽半圆盘弯曲(NSCB)试件断裂的全过程进行研究,得到了不同加载角度下页岩的动态起裂韧度、裂纹扩展速度、断裂过程中应变场和水平位移场的变化规律。实验发现:不同加载角度下,页岩的动态起裂韧度具有显著的各向异性,加载角度与动态起裂韧度呈正相关;加载角度对试样的裂纹扩展速度具有显著影响,与裂纹扩展速度呈负相关;当冲击速度较低时,切槽方向是裂纹扩展的优势方向,而当冲击速度较高时,试样会产生沿层理弱面的次生裂纹,次生裂纹对试样的断裂具有显著影响。Abstract: The dynamic fracture of rock materials is a basic problem in the field of rock mechanics, while the dynamic fracture mechanism of shale is more complex due to its anisotropic characteristics. In order to study the effect of bedding angle on dynamic fracture process of shale, a split Hopkinson pressure bar (SHPB) system was used to carry out impact tests on notched semi-circular bend (NSCB) specimens of shale. Additionally, a crack propagation gauge (CPG) was set at the crack tip, and the whole fracture process of the shale NSCB specimen was studied with the help of a high-speed photography system and the digital image correlation (DIC) method. The loading rate and Mode-I dynamic fracture toughness of the shale NSCB samples were obtained by the method recommended by the International Society for Rock Mechanics (ISRM). And the crack initiation time and crack propagation speed of the shale NSCB samples can be accurately obtained by CPG. It is found from the experimental results that the Mode-I dynamic fracture toughness of the shale NSCB samples has significant anisotropy, and the loading angle has a positive correlation with the Mode-I dynamic fracture toughness. Although the crack propagation of the C-0sample is not affected by the bedding, its crack propagation needs to cut through the shale matrix, hence the C-0 and 90° shale specimens have a high Mode-I dynamic fracture toughness. When the impact velocity is low, the bending stress on the dangerous section affects the fracture direction of the shale specimen, but with less effect on the bedding. The crack propagation path finally closes to the notch direction. With the increase of impact velocity, stress concentration and micro cracks may exist along the weak plane of bedding due to its relatively low strength. With the increase of impact velocity, the cracks between the weak planes of bedding begin to extend, and the failure planes along the direction of bedding and notch occurred simultaneously.

-

表 1 页岩基本力学性质

Table 1. Mechanical properties of shale

层理方向 单轴抗压强度/MPa 密度/(g·cm−3) 弹性模量/GPa 泊松比 纵波波速/(m·s−1) 平行层理 97.34 2.43 17.62 0.29 4 217 垂直层理 108.21 2.46 26.34 0.32 4 592 表 2 页岩动态起裂韧度

Table 2. Dynamic initiation toughness of shale

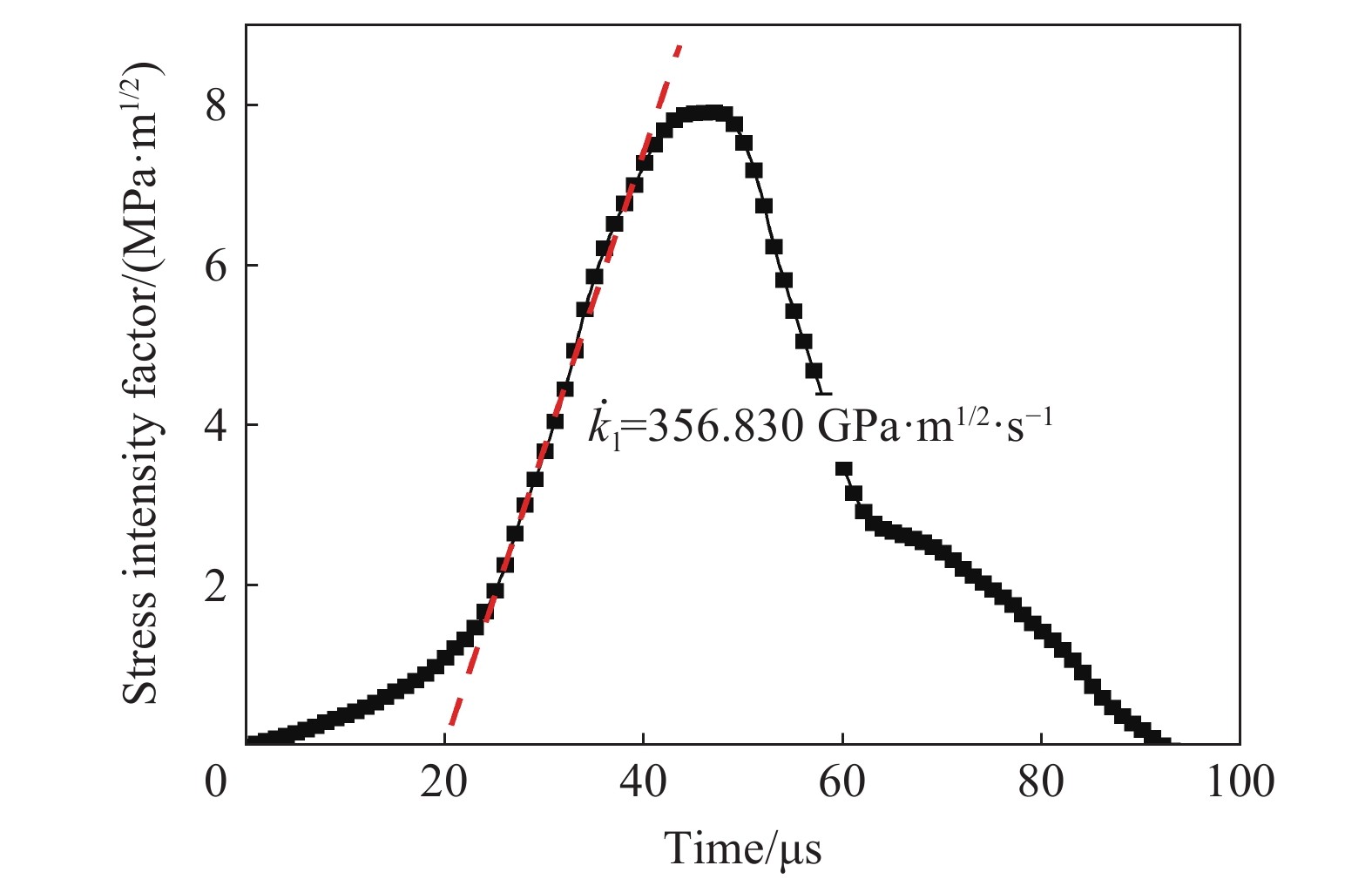

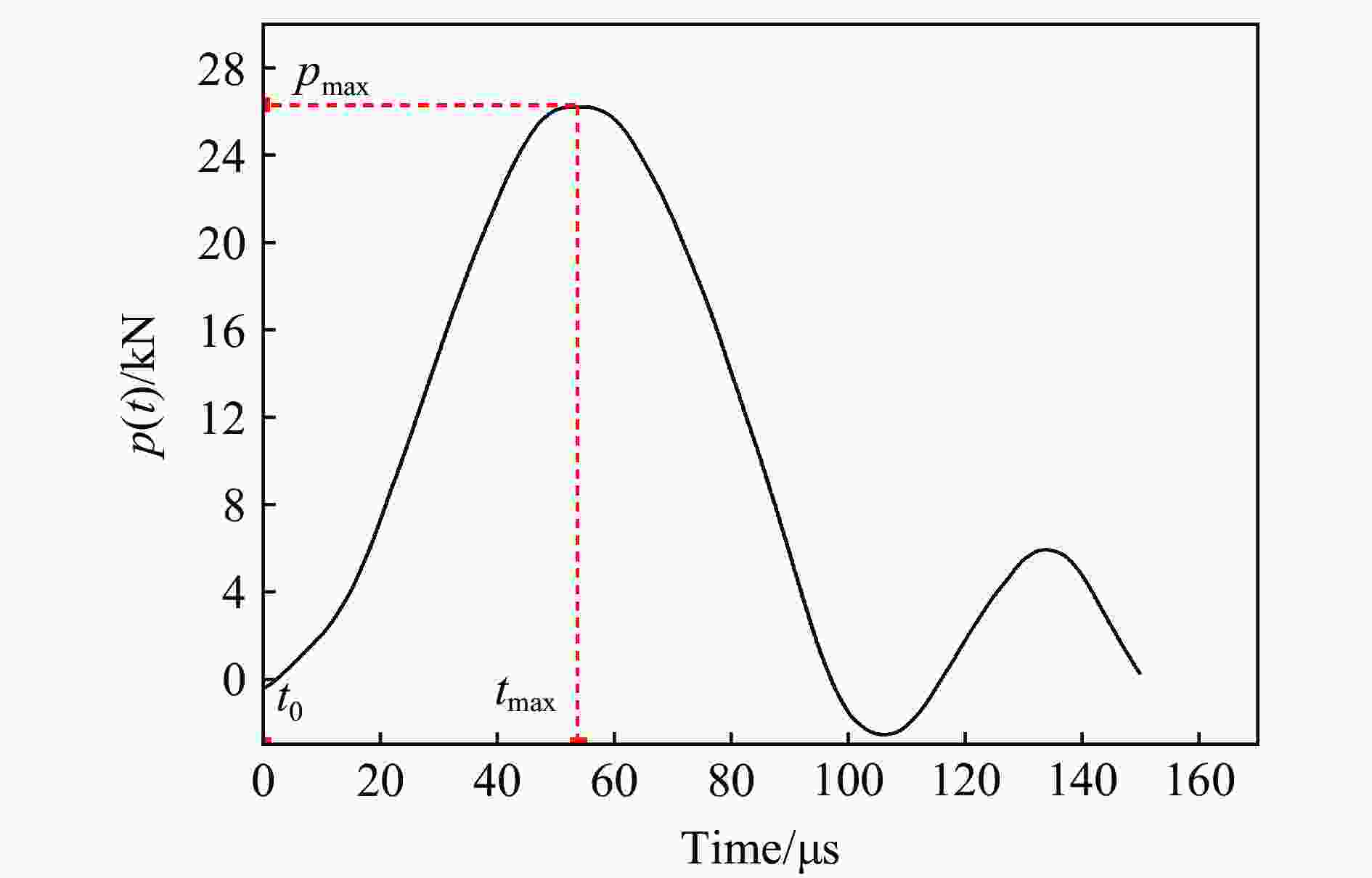

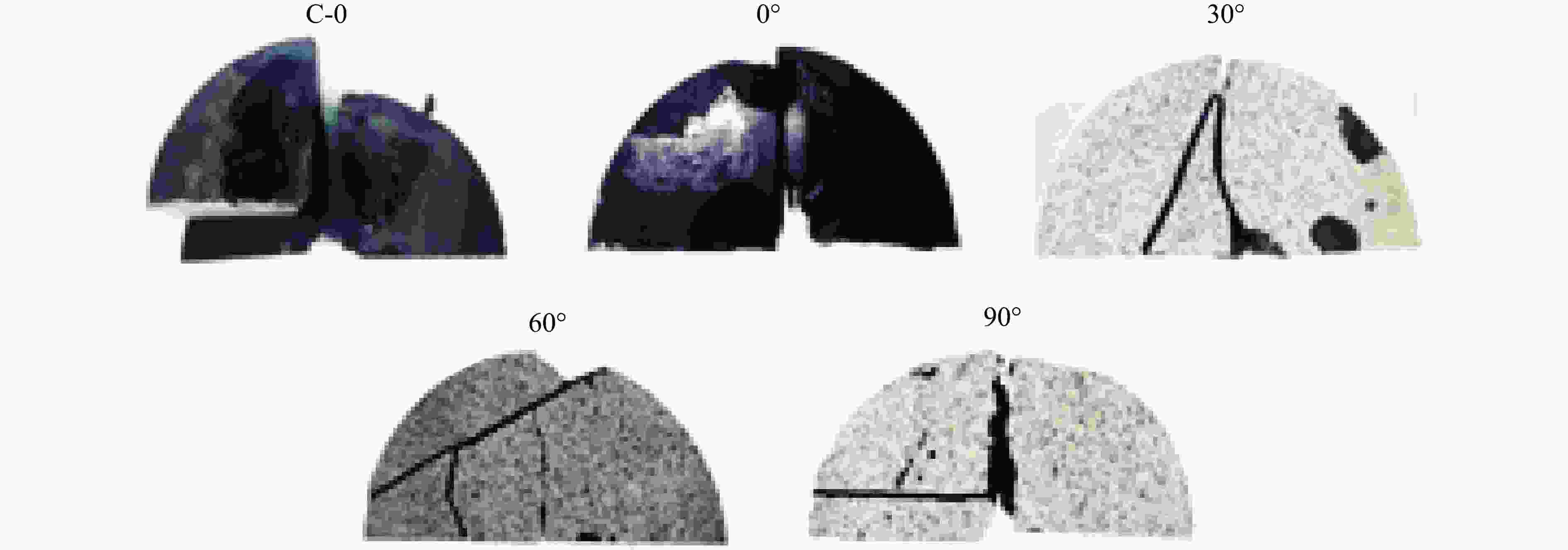

加载角度 冲击速度/(m·s−1) 起裂时刻/μs 加载力峰值对应时刻/μs 加载率/(GPa·m1/2·s−1) 动态起裂韧度/(MPa·m1/2) 裂纹扩展速度/(m·s−1) C-0 3 551.3 493.8 89.335 3.83 278.49 4 538.1 527.9 179.391 5.85 296.43 5 551.5 525.3 348.482 8.28 382.26 0° 3 554.7 524.6 108.322 2.45 335.30 4 571.8 538.3 309.285 7.14 383.71 5 524.9 518.4 474.167 9.23 445.16 30° 3 570.3 547.2 119.442 4.23 312.21 4 519.2 489.6 235.974 6.28 392.52 5 563.4 523.4 392.154 8.04 415.17 60° 3 554.9 535.2 122.36 4.02 264.50 4 577.4 521.7 269.242 7.03 350.02 5 576.1 549.3 430.563 9.07 382.35 90° 3 578.8 554.3 160.947 5.13 225.66 4 533.2 507.6 323.626 8.62 331.74 5 569.4 513.8 463.592 10.44 367.53 表 3 页岩NSCB试样的典型破坏路径

Table 3. Typical failure pathes of shale NSCB samples

冲击速度/(m·s−1) 加载角度 C-0 0° 30° 60° 90° 3

4

5

-

[1] 张金川, 徐波, 聂海宽, 等. 中国页岩气资源勘探潜力 [J]. 天然气工业, 2008(6): 136–140. DOI: 10.3787/j.issn.1000-0976.2008.06.040.ZHANG J C, XU B, NIE H K, et al. Exploration potential of shale gas resources in China [J]. Natural Gas Industry, 2008(6): 136–140. DOI: 10.3787/j.issn.1000-0976.2008.06.040. [2] 陈军斌. 页岩气储层液体火药高能气体压裂增产关键技术研究[M]. 北京: 科学出版社地质分社, 2017. [3] YANG G L, BI J J, MA L N. Dynamic compression damage energy consumption and fractal characteristics of shale [J]. Shock and Vibration, 2019(3): 1–7. DOI: 10.1155/2019/5792841. [4] 李德建, 祁浩, 李春晓, 等. 含层理面煤试样的巴西圆盘劈裂实验及数值模拟研究 [J]. 矿业科学学报, 2020, 5(2): 150–159. DOI: 10.19606/j.cnki.jmst.2020.02.003.LI D J, QI H, LI C X, et al. Brazilian disc splitting tests and numerical simulations on coal samples containing bedding planes [J]. Journal of Mining Science and Technology, 2020, 5(2): 150–159. DOI: 10.19606/j.cnki.jmst.2020.02.003. [5] 邓华锋, 王伟, 李建林, 等. 层状砂岩各向异性力学特性试验研究 [J]. 岩石力学与工程学报, 2008, 37(1): 112–120. DOI: 10.13722/j.cnki.jrme.2017.1205.DENG H F, WANG W, LI J L, et al. Experimental study on anisotropic characteristics of bedded sandstone [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 37(1): 112–120. DOI: 10.13722/j.cnki.jrme.2017.1205. [6] 王聪聪, 李江腾, 林杭, 等. 板岩单轴压缩各向异性力学特征 [J]. 中南大学学报(自然科学版), 2019, 47(11): 3759–3764. DOI: 10.11817/j.issn.1672-7207.2016.11.020.WANG C C, LI J T, LI K, et al. Anisotropic mechanical characteristics of slat in uniaxial compression [J]. Journal of Central South University (Science and Technology), 2019, 47(11): 3759–3764. DOI: 10.11817/j.issn.1672-7207.2016.11.020. [7] 衡帅, 杨春和, 张保平, 等. 页岩各向异性特征的试验研究 [J]. 岩土力学, 2015, 36(3): 609–616. DOI: 10.16285/j.rsm.2015.03.001.HENG S, YANG C H, ZHANG B P, et al. Experimental research on anisotropic properties of shale [J]. Rock and Soil Mechanics, 2015, 36(3): 609–616. DOI: 10.16285/j.rsm.2015.03.001. [8] HUANG D, LI B, MA W Z, et al. Effects of bedding planes on fracture behavior of sandstone under semi-circular bending test [J]. Theoretical and Applied Fracture Mechanics, 2020, 108: 102625. DOI: 10.1016/j.tafmec.2020.102625. [9] 何柏, 谢凌志, 李凤霞, 等. 龙马溪页岩各向异性变形破坏特征及其机理研究 [J]. 中国科学: 物理学 力学 天文学, 2017, 47(11): 114611. DOI: 10.1360/sspma2016-00534.HE B, XIE L Z, LI F X, et al. Anisotropic mechanism and characteristics of deformation and failure of Longmaxi shale [J]. Scientia Sinica Physica, Mechanica & Astronomica, 2017, 47(11): 114611. DOI: 10.1360/sspma2016-00534. [10] 衡帅, 杨春和, 郭印同, 等. 层理对页岩水力裂缝扩展的影响研究 [J]. 岩石力学与工程学报, 2015, 34(2): 228–237. DOI: 10.13722/j.cnki.jrme.2015.02.002.HENG S, YANG C H, GUO Y T, et al. Influence of bedding planes on hydraulic fracture propagation in shale formations [J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(2): 228–237. DOI: 10.13722/j.cnki.jrme.2015.02.002. [11] 李玉琳. 龙马溪组层状页岩宏细观破坏行为及模型研究[D]. 北京: 中国矿业大学(北京), 2019: 49–73.LI Y L. Investigation on macroscopic and microscopic failure behavior and model study of layered Longmaxi shale [D]. Beijing: China University of Mining and Tachnology (Beijing), 2019: 49–73. [12] ZHOU Y X, XIA K, LI X B, et al. Suggested methods for determining the dynamic strength parameters and mode-I fracture toughness of rock materials [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 49: 105–112. DOI: 10.1016/j.ijrmms.2011.10.004. [13] 赵文峰, 张盛, 王猛, 等. 用两种ISRM推荐圆盘试样测试岩石断裂韧度的试验研究 [J]. 实验力学, 2020, 35(4): 702–711. DOI: 10.7520/1001-4888-18-216.ZHAO W F, ZHANG S, WANG M, et al. Experimental study on testing rock fracture toughness with two types of disc specimens recommended by ISRM [J]. Journal of Experimental Mechanics, 2020, 35(4): 702–711. DOI: 10.7520/1001-4888-18-216. [14] 宋耀. 不同加载率条件下花岗岩动态断裂及损伤机理试验研究[D]. 北京: 中国矿业大学(北京), 2019: 87–95.SONG Y. Experimental study on dynamic fracture and damage mechanism of granite under different loading rates [D]. Beijing: China University of Mining and Tachnology (Beijing), 2019: 87–95. [15] YANG G L, LI X G, BI J J, et al. Dynamic crack initiation toughness of shale under impact loading [J]. Energies, 2019, 12(9): 1636. DOI: 10.3390/en12091636. [16] SHI X S, YAO W, LIU D A, et al. Experimental study of the dynamic fracture toughness of anisotropic black shale using notched semi-circular bend specimens [J]. Engineering Fracture Mechanics, 2019, 205: 136–151. DOI: 10.1016/j.engfracmech.2018.11.027. [17] 赵子江, 刘大安, 崔振东, 等. 半圆盘三点弯曲法测定页岩断裂韧度(K Ⅰ C)的实验研究 [J]. 岩土力学, 2018, 39(S1): 258–266. DOI: 10.16285/j.rsm.2018.0571.ZHAO Z J, LIU D A, CUI Z D, et al. Experimental study of determining fracture toughness K Ⅰ C of shale by semi-disc three-point bending [J]. Rock and Soil Mechanics, 2018, 39(S1): 258–266. DOI: 10.16285/j.rsm.2018.0571. [18] 曹富, 杨丽萍, 李炼, 等. 压缩单裂纹圆孔板(SCDC)岩石动态断裂全过程研究 [J]. 岩土力学, 2017, 38(6): 1573–1582; 1588. DOI: 10.16285/j.rsm.2017.06.005.CAO F, YANG L P, LI L, et al. Research on whole dynamic fracture process of rock using single cleavage drilled compression (SCDC) specimen [J]. Rock and Soil Mechanics, 2017, 38(6): 1573–1582; 1588. DOI: 10.16285/j.rsm.2017.06.005. [19] GAO G, HUANG S, XIA K, et al. Application of digital image correlation (DIC) in dynamic notched semi-circular bend (NSCB) tests [J]. Experimental Mechanics, 2015, 55(1): 95–104. DOI: 10.1007/s11340-014-9863-5. [20] 潘兵, 吴大方, 夏勇. 数字图像相关方法中散斑图的质量评价研究 [J]. 实验力学, 2010, 25(2): 120–129.PAN B, WU D F, XIA Y. Study of speckle pattern quality assessment used in digital image correlation [J]. Journal of Experimental Mechanics, 2010, 25(2): 120–129. [21] ZHANG Q B, ZHAO J. Quasi-static and dynamic fracture behaviour of rock materials: phenomena and mechanisms [J]. International Journal of Fracture, 2014, 189: 1–32. DOI: 10.1007/s10704-014-9959-z. [22] 周妍, 张财贵, 王启智. 用圆孔内单边裂纹平台巴西圆盘和实验-数值-解析法确定砂岩的动态起裂和扩展韧度 [J]. 振动与冲击, 2017, 36(5): 37–47. DOI: 10.13465/j.cnki.jvs.2017.05.007.ZHOU Y, ZHANG C G, WANG Q Z. Determination of dynamic initiation toughness and dynamic propagation toughness of sandstone [J]. Journal of Vibration and Shock, 2017, 36(5): 37–47. DOI: 10.13465/j.cnki.jvs.2017.05.007. [23] 岳中文, 胡庆文, 陈彪. 爆生裂纹与层理缺陷相互作用的实验研究 [J]. 振动与冲击, 2017, 36(12): 99–104. DOI: 10.13465/j.cnki.jvs.2017.12.017.YUE Z W, HU Q W, CHEN B. An experimental study of the interaction between the blast-indused crack and the bedding defect [J]. Journal of Vibration and Shock, 2017, 36(12): 99–104. DOI: 10.13465/j.cnki.jvs.2017.12.017. [24] 王雁冰, 吴后为, 孔骥, 等. 含预制双层理的半圆盘模型冲击试验 [J]. 中国矿业, 2020, 29(11): 198–205.WANG Y B, WU H W, KONG J, et al. Impact test of half-disc model with prefabricated double bedding [J]. China Mining Magazine, 2020, 29(11): 198–205. [25] 岳中文, 宋耀, 陈彪, 等. 冲击载荷下层状岩体动态断裂行为的模拟试验研究 [J]. 振动与冲击, 2017, 36(12): 223–229. DOI: 10.13465/j.cnki.jvs.2017.12.036.YUE Z W, SONG Y, CHEN B, et al. A study on the behaviors of dynamic fracture in layered rock under impact loading [J]. Journal of Vibration and Shock, 2017, 36(12): 223–229. DOI: 10.13465/j.cnki.jvs.2017.12.036. -

下载:

下载: