Comparative study of numerical simulations of projectile penetration into metal targets

-

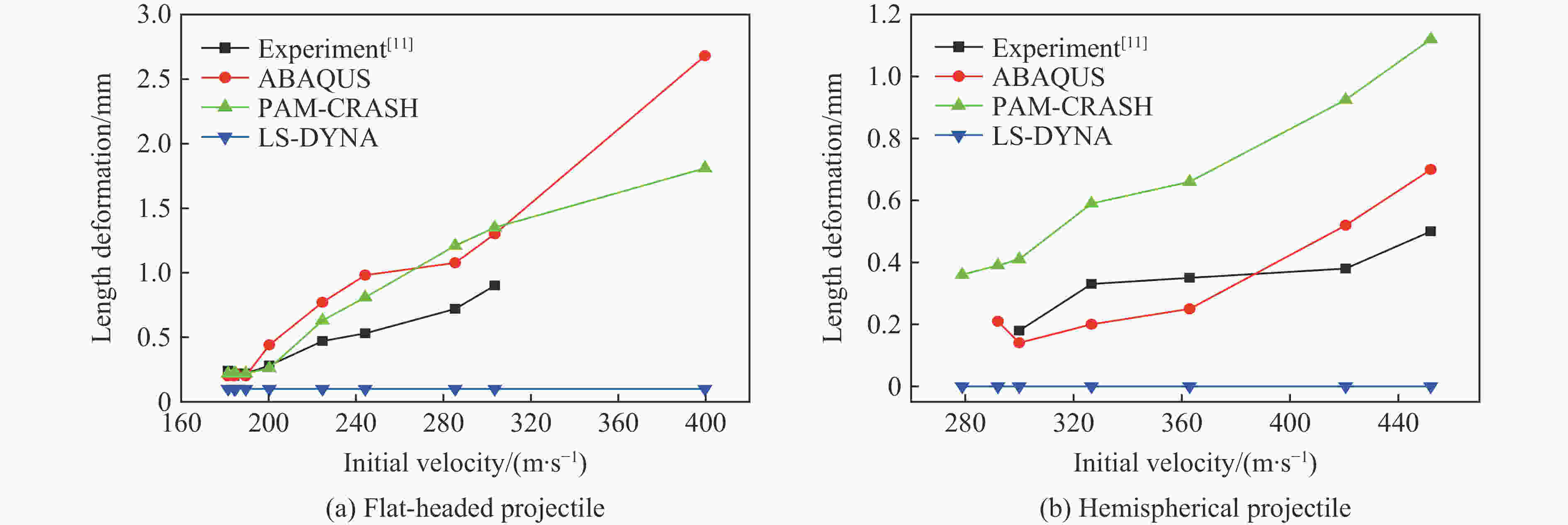

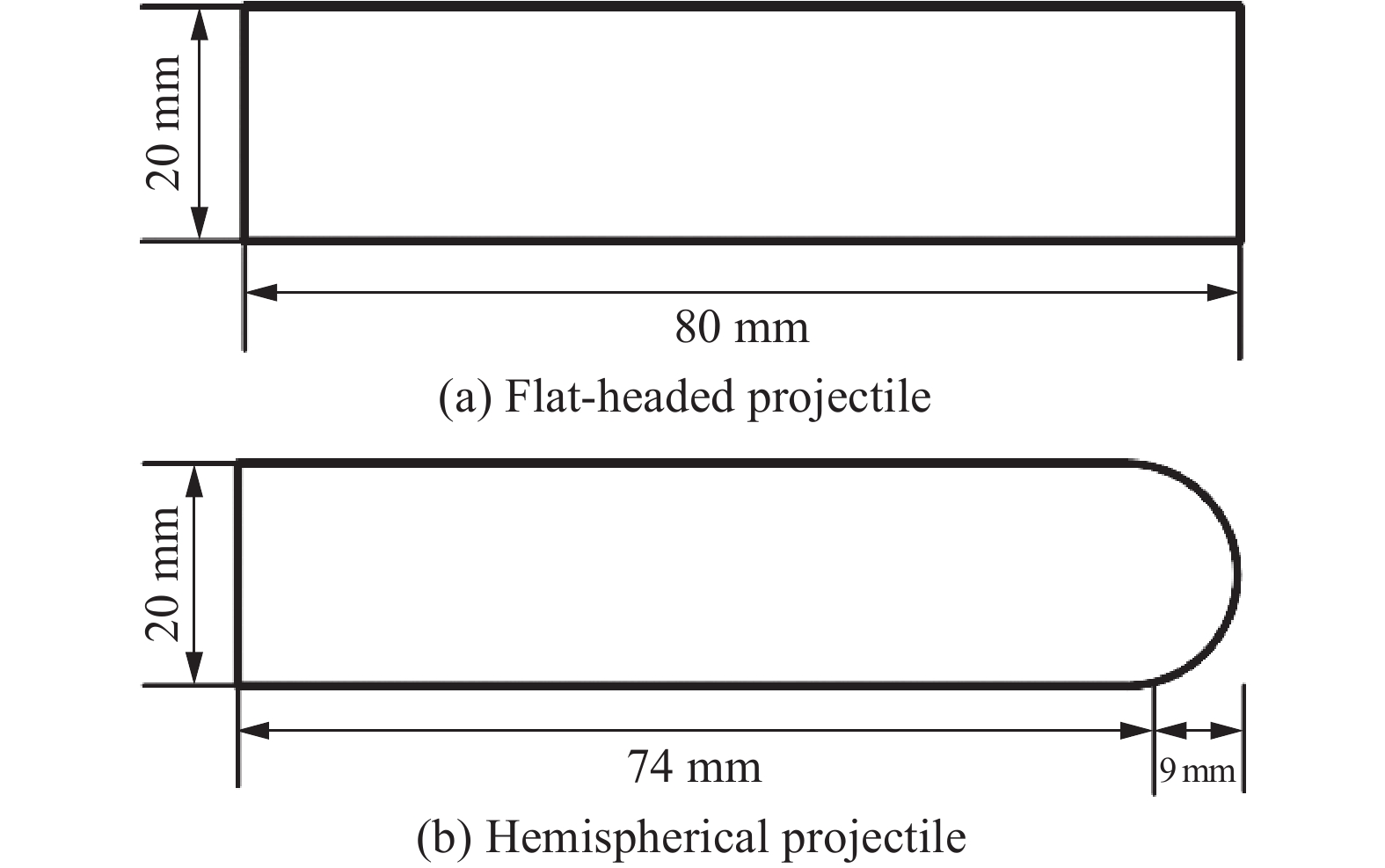

摘要: 数值模拟是研究靶板侵彻问题的重要手段。为对相关软件的选取提供参考,采用当前广泛使用的3种有限元软件(LS-DYNA、ABAQUS、PAM-CRASH)对同一个靶板侵彻实验进行了数值模拟,并比较了各模拟软件的优缺点。研究结果表明:3种软件的模拟结果与实验结果均基本一致;对平头形弹体侵彻的模拟效果普遍优于对半球形弹体的模拟效果;在弹体剩余速度、冲塞块速度2个方面,3种有限元软件的数值模拟结果与实验结果大致吻合。其中,ABAQUS和PAM-CRASH对上述特征量的模拟结果更接近实验结果,平均相对误差普遍小于15%,且PAM-CRASH多数模拟结果误差都小于10%;而在弹体变形量上,3种软件的模拟结果均与实验结果相差较大。此外,LS-DYNA在模拟时的鲁棒性较好,模拟结果较稳定,PAM-CRASH对参数设置最敏感,ABAQUS在计算时间和效果上较平衡。Abstract: Numerical simulation is an important method to study the penetration into targets. Distinct results may be acquired if different kinds of software are adopted. In this paper, three kinds of commonly-used softwares (LS-DYNA, ABAQUS and PAM-CRASH) were adopted to simulate the same series of penetration experiments. The simulation results were analyzed and the advantages and disadvantages of each kind of software were compared. The purpose of this work is to help the researchers and engineers to select the most suitable software. The results in this paper demonstrate that the calculation results of the three kinds of software are basically consistent with the experimental results. The simulation results of the flat-headed projectile are generally better than those of the hemispherical projectile. The residual velocity of the projectile and the plug velocity were simulated well using all of the three kinds of software. The calculated velocities by ABAQUS and PAM-CRASH are closer to the experimental results, and the average relative errors are generally lower than 15%. Moreover, the errors from most calculation results by PAM-CRASH are even less than 10%. However, for the deformation of the projectile, the calculation results of the three kinds of software are quite different from the experimental ones. There are other differences in the performance of the three kinds of software. For example, the ballistic limits calculated by ABAQUS and LS-DYNA are higher than the experimental results, while those by PAM-CRASH are lower. ABAQUS is most likely to report errors but is balanced by calculation time and effects. LS-DYNA has a low error rate and good robustness. The change of model parameters (such as mesh density, friction coefficient, contact stiffness, viscous damping coefficient, etc.) has little effect on its calculation results. PAM-CRASH is greatly affected by model parameters. The conclusion of this paper is based on the following conditions: the target material is Weldox 460E steel, the projectile is ARNE tool steel, and the impact velocity range is 180-450 m/s. However, it is also of guiding significance for the penetration problem simulation of other materials in this velocity range.

-

Key words:

- target /

- projectile penetration /

- LS-DYNA /

- ABAQUS /

- PAM-CRASH

-

图 11 采用LS-DYNA模拟初始速度为399.6 m/s的平头形弹体侵彻钢靶时,靶板网格单元尺寸对平头形弹体剩余速度和靶板冲塞块速度的影响

Figure 11. Influences of target mesh size on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the flat-headed projectile with the initial velocity of 399.6 m/s into the steel target

图 12 采用LS-DYNA模拟初始速度为200.4 m/s的平头形弹体侵彻钢靶时,靶板网格单元尺寸对平头形弹体剩余速度和靶板冲塞块速度的影响

Figure 12. Influences of target mesh size on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the flat-headed projectile with the initial velocity of 200.4 m/s into the steel target

图 13 采用LS-DYNA模拟初始速度为224.7 m/s的平头形弹体侵彻钢靶时,靶板网格单元尺寸对平头形弹体剩余速度和靶板冲塞块速度的影响

Figure 13. Influences of target mesh size on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the flat-headed projectile with the initial velocity of 224.7 m/s into the steel target

图 14 采用LS-DYNA模拟初始速度为452.0 m/s的平头形弹体侵彻钢靶时,靶板网格单元尺寸对半球形弹体弹体剩余速度和靶板冲塞块速度的影响

Figure 14. Influences of target mesh size on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the hemispherical projectile with the initial velocity of 452.0 m/s into the steel target

图 15 采用LS-DYNA模拟初始速度为300.0 m/s的平头形弹体侵彻钢靶时,靶板网格单元尺寸对半球形弹体弹体剩余速度和靶板冲塞块速度的影响

Figure 15. Influences of target mesh size on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the hemispherical projectile with the initial velocity of 300.0 m/s into the steel target

图 16 采用LS-DYNA模拟初始速度为244.2 m/s的平头形弹体侵彻钢靶时,摩擦因数对平头形弹体剩余速度和靶板冲塞块速度的影响

Figure 16. Influences of friction coefficient on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the flat-headed projectile with the initial velocity of 244.2 m/s into the steel target

图 17 采用LS-DYNA模拟初始速度为362.9 m/s的半球形弹体侵彻钢靶时,摩擦因数对弹体剩余速度和靶板冲塞块速度的影响

Figure 17. Influences of friction coefficient on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the hemispherical projectile with the initial velocity of 362.9 m/s into the steel target

图 18 采用LS-DYNA模拟初始速度为285.4 m/s的平头形弹体侵彻钢靶时,惩罚刚度缩放因数(SLSFAC)对弹体剩余速度和靶板冲塞块速度的影响

Figure 18. Influences of penalty stiffness scaling factors (SLSFACs) on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the flat-headed projectile with the initial velocity of 285.4 m/s into the steel target

图 19 采用LS-DYNA模拟初始速度为326.7 m/s的半球形弹体侵彻钢靶时,惩罚刚度缩放因数对弹体剩余速度和靶板冲塞块速度的影响

Figure 19. Influences of penalty stiffness scaling factor on the projectile residual velocity and target plug velocity simulatedby LS-DYNA for penetration of the hemispherical projectile with the initial velocity of 326.7 m/s into the steel target

图 20 采用LS-DYNA模拟初始速度为244.2 m/s的平头形弹体侵彻钢靶时,黏性阻尼因数(VDC)对弹体剩余速度和靶板冲塞块速度的影响

Figure 20. Influences of viscous damping coefficient (VDC) on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the flat-headed projectile with the initial velocity of 244.2 m/s into the steel target

图 21 采用LS-DYNA模拟初始速度为420.6 m/s的半球形弹体侵彻钢靶时,黏性阻尼因数对弹体剩余速度和靶板冲塞块速度的影响

Figure 21. Influences of viscous damping coefficient on the projectile residual velocity and target plug velocity simulated by LS-DYNA for penetration of the hemispherical projectile with the initial velocity of 420.6 m/s into the steel target

表 1 弹体剩余速度平均相对误差对比分析

Table 1. Comparative analysis of the average relative error of the residual projectile velocity

对比量 弹体形状 平均相对误差/% LS-DYNA ABAQUS PAM-CRASH 剩余速度 平头形 19.64 16.34 16.62 半球形 23.13 21.56 11.58 剩余速度(不含弹道

极限附近初速度)平头形 8.37 4.07 3.71 半球形 4.06 5.40 2.82 表 2 弹体变形量平均相对误差对比分析

Table 2. Comparison of the average relative error of the projectile deformation

对比量 弹体形状 平均相对误差/% LS-DYNA ABAQUS PAM-CRASH 直径 平头形 18.51 48.00 半球形 22.32 87.91 长度 平头形 30.19 22.35 半球形 19.85 96.00 表 3 冲塞块速度平均相对误差对比分析

Table 3. Comparison of the average relative error of plug velocity

对比量 弹体形状 平均相对误差/% LS-DYNA ABAQUS PAM-CRASH 剩余速度 平头形 21.82 14.84 7.15 半球形 15.49 16.11 5.30 剩余速度

(不含弹道附近初速度)平头形 13.19 2.67 3.31 半球形 10.51 8.94 4.07 表 4 靶板最大变形量平均相对误差对比分析

Table 4. Comparison of the average relative error of maximum deformation of the target

对比量 弹体形状 平均相对误差% LS-DYNA ABAQUS PAM-CRASH 靶板最大变形量 平头形 41.26 22.25 19.58 半球形 21.35 28.45 11.99 表 5 主要有限元模型参数对LS-DYNA数值模拟结果的影响

Table 5. Influences of main finite element parameters on the numerical simulation results of LS-DYNA

影响因素 弹体形状 弹体剩余速度 冲塞块速度 网格密度 平头形弹体 影响较大 影响较大 半球形弹体 无影响 有一定影响 摩擦因数 平头形弹体 无影响 无影响 半球形弹体 无影响 无影响 惩罚刚度缩放因数 平头形弹体 无影响 无影响 半球形弹体 无影响 有一定影响 黏性阻尼因数 平头形弹体 无影响 无影响 半球形弹体 无影响 有一定影响 表 6 主要有限元模型参数对ABAQUS数值模拟结果的影响

Table 6. Influences of main finite element parameters on the numerical simulation results of ABAQUS

影响因素 弹体形状 弹体剩余速度 冲塞块速度 网格密度 平头形弹体 影响较大 影响较大 半球形弹体 有一定影响 有一定影响 摩擦因数 平头形弹体 有一定影响 有一定影响 半球形弹体 影响较大 影响较大 分析步方式 平头形弹体 无影响 无影响 半球形弹体 有一定影响 有一定影响 沙漏控制方式 平头形弹体 有一定影响 有一定影响 半球形弹体 有一定影响 有一定影响 表 7 主要有限元模型参数对PAM-CRASH数值模拟结果的影响

Table 7. Influence of main finite element parameters on the numerical simulation results of PAM-CRASH

影响因素 弹体形状 弹体剩余速度 冲塞块速度 网格密度 平头形弹体 有一定影响 有一定影响 半球形弹体 影响较大 影响较大 摩擦因数 平头形弹体 有一定影响 影响较大 半球形弹体 有一定影响 有一定影响 滑动界面惩罚比例因子 平头形弹体 影响较大 影响较大 半球形弹体 影响较大 影响较大 接触刚度 半球形弹体 影响较大 影响较大 平头形弹体 影响较大 影响较大 表 8 不同软件计算时长比较

Table 8. Comparison of the calculation time of different software

弹体形状 单元数 节点数 软件 计算所耗时间/h 平头形 981 810 1 012 037 LS-DYNA ~28.5 981 810 1 012 037 ABAQUS ~38.0 272 954 289 114 PAM-CRASH ~14.0 半球形 982 107 1 012 345 LS-DYNA ~29.0 982 107 1 012 345 ABAQUS ~40.0 375 741 395 789 PAM-CRASH ~17.5 -

[1] RUSINEK A, RODRÍGUEZ-MARTÍNEZ J A, ARIAS A, et al. Influence of conical projectile diameter on perpendicular impact of thin steel plate [J]. Engineering Fracture Mechanics, 2008, 75(10): 2946–2967. DOI: 10.1016/j.engfracmech.2008.01.011. [2] IQBAL M A, CHAKRABARTI A, BENIWAL S, et al. 3D numerical simulations of sharp nosed projectile impact on ductile targets [J]. International Journal of Impact Engineering, 2010, 37(2): 185–195. DOI: 10.1016/j.ijimpeng.2009.09.008. [3] IQBAL M A, GUPTA P K, DEORE V S, et al. Effect of target span and configuration on the ballistic limit [J]. International Journal of Impact Engineering, 2012, 42: 11–24. DOI: 10.1016/j.ijimpeng.2011.10.004. [4] BØRVIK T, HOPPERSTAD O S, BERSTAD T, et al. Perforation of 12 mm thick steel plates by 20 mm diameter projectiles with flat, hemispherical and conical noses: Part Ⅱ: numerical simulations [J]. International Journal of Impact Engineering, 2002, 27(1): 37–64. DOI: 10.1016/S0734-743X(01)00035-5. [5] BØRVIK T, HOPPERSTAD O S, BERSTAD T, et al. Numerical simulation of plugging failure in ballistic penetration [J]. International Journal of Solids and Structures, 2001, 38(34/35): 6241–6264. DOI: 10.1016/S0020-7683(00)00343-7. [6] DEY S, BØRVIK T, HOPPERSTAD O S, et al. On the influence of fracture criterion in projectile impact of steel plates [J]. Computational Materials Science, 2006, 38(1): 176–191. DOI: 10.1016/j.commatsci.2006.02.003. [7] DEY S, BØRVIK T, HOPPERSTAD O S, et al. On the influence of constitutive relation in projectile impact of steel plates [J]. International Journal of Impact Engineering, 2007, 34(3): 464–486. DOI: 10.1016/j.ijimpeng.2005.10.003. [8] FLORES-JOHNSON E A, SALEH M, EDWARDS L. Ballistic performance of multi-layered metallic plates impacted by a 7.62-mm APM2 projectile [J]. International Journal of Impact Engineering, 2011, 38(12): 1022–1032. DOI: 10.1016/j.ijimpeng.2011.08.005. [9] BØRVIK T, LANGSETH M, HOPPERSTAD O S, et al. Ballistic penetration of steel plates [J]. International Journal of Impact Engineering, 1999, 22(9/10): 855–886. DOI: 10.1016/S0734-743X(99)00011-1. [10] BØRVIK T, LEINUM J R, SOLBERG J K, et al. Observations on shear plug formation in Weldox 460E steel plates impacted by blunt-nosed projectiles [J]. International Journal of Impact Engineering, 2001, 25(6): 553–572. DOI: 10.1016/S0734-743X(00)00069-5. [11] BØRVIK T, LANGSETH M, HOPPERSTAD O S, et al. Perforation of 12 mm thick steel plates by 20 mm diameter projectiles with flat, hemispherical and conical noses: Part Ⅰ: experimental study [J]. International Journal of Impact Engineering, 2002, 27(1): 19–35. DOI: 10.1016/S0734-743X(01)00034-3. [12] DEY S, BØRVIK T, HOPPERSTAD O S, et al. The effect of target strength on the perforation of steel plates using three different projectile nose shapes [J]. International Journal of Impact Engineering, 2004, 30(8/9): 1005–1038. DOI: 10.1016/j.ijimpeng.2004.06.004. [13] 李晓杰, 张程娇, 王小红, 等. 水的状态方程对水下爆炸影响的研究 [J]. 工程力学, 2014, 31(8): 46–52. DOI: 10.6052/j.issn.1000-4750.2013.03.0180.LI X J, ZHANG C J, WANG X H, et al. Numerical study on the effect of equations of state of water on underwater explosions [J]. Engineering Mechanics, 2014, 31(8): 46–52. DOI: 10.6052/j.issn.1000-4750.2013.03.0180. [14] 彭霞锋. 高氮合金钢的动态压缩实验及动态本构关系 [D]. 成都: 西南交通大学, 2009. DOI: 10.7666/d.y1572808.PENG X F. Dynamical compression experiment and dynamical constitutive law of high nitrogen steel [D]. Chengdu, China: Southwest Jiaotong University, 2009. DOI: 10.7666/d.y1572808. [15] CALDER C A, GOLDSMITH W. Plastic deformation and perforation of thin plates resulting from projectile impact [J]. International Journal of Solids and Structures, 1971, 7(7): 863–868. DOI: 10.1016/0020-7683(71)90096-5. [16] 肖新科, 王要沛. ABAQUS有限元程序中Jonson-Cook断裂准则与原始模型的差异及对比分析 [J]. 南阳理工学院学报, 2018, 10(6): 38–42. DOI: 10.3969/j.issn.1674-5132.2018.06.008.XIAO X K, WANG Y P. The difference between the built-in Jonson-Cook fracture criterion in Abaqus finite element program and the original criterion as well as a comparative analysis [J]. Journal of Nanyang Institute of Technology, 2018, 10(6): 38–42. DOI: 10.3969/j.issn.1674-5132.2018.06.008. [17] 时党勇, 李裕春, 张胜民. 基于ANSYS/LS-DYNA 8.1进行显式动力分析 [M]. 北京: 清华大学出版社, 2005: 139−160. -

下载:

下载: