Explosion characteristics of oil shale dust in a confined space

-

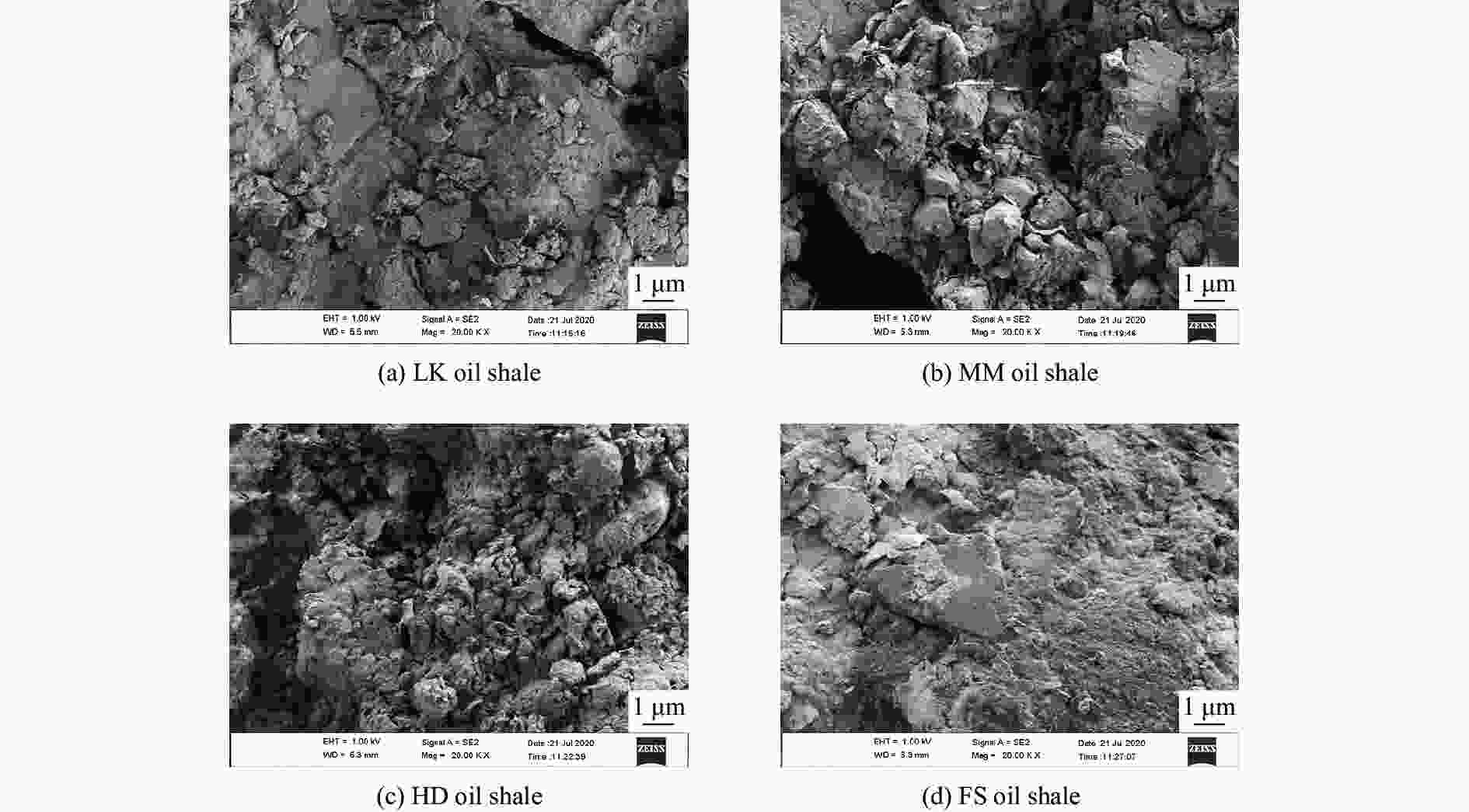

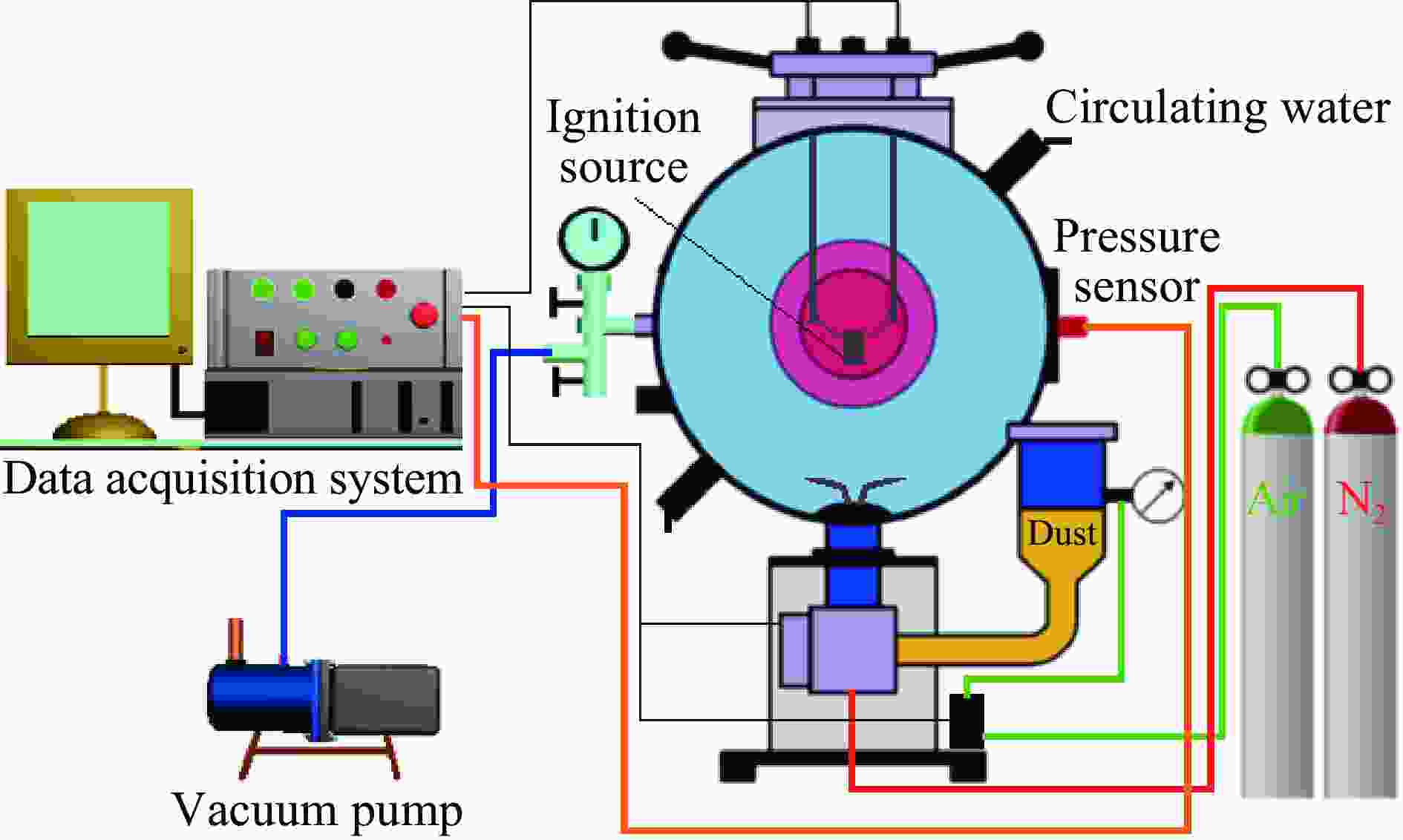

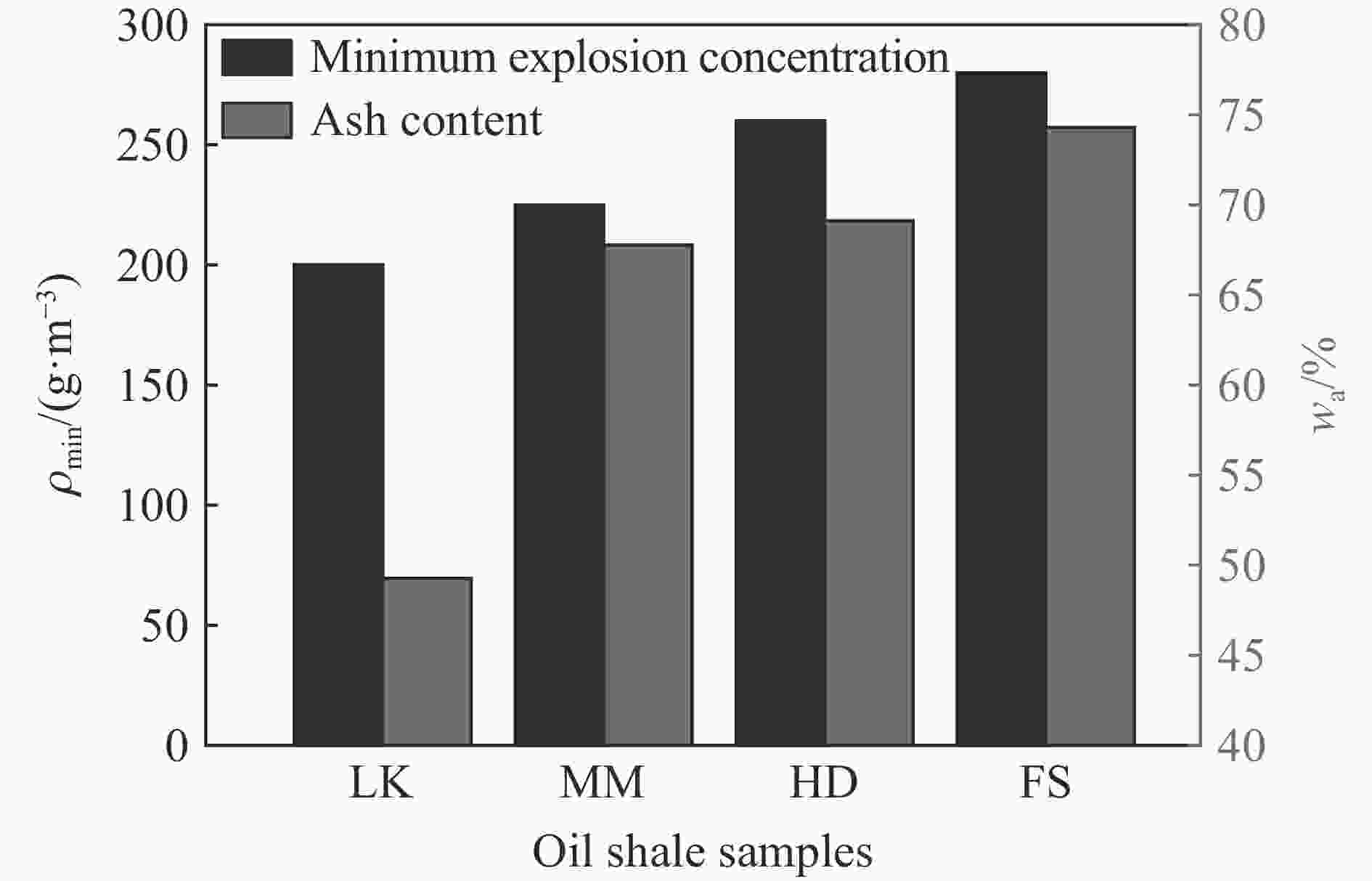

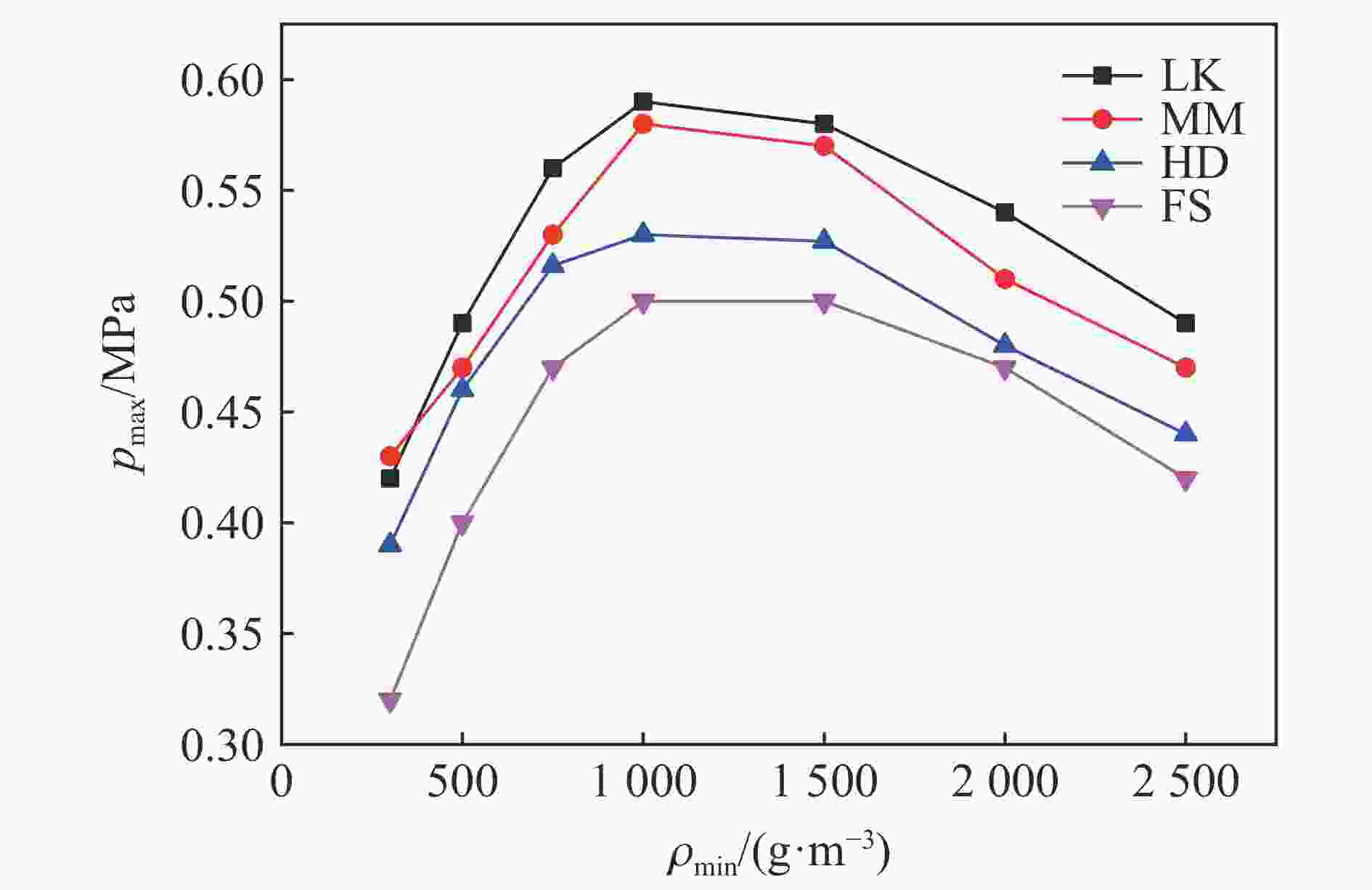

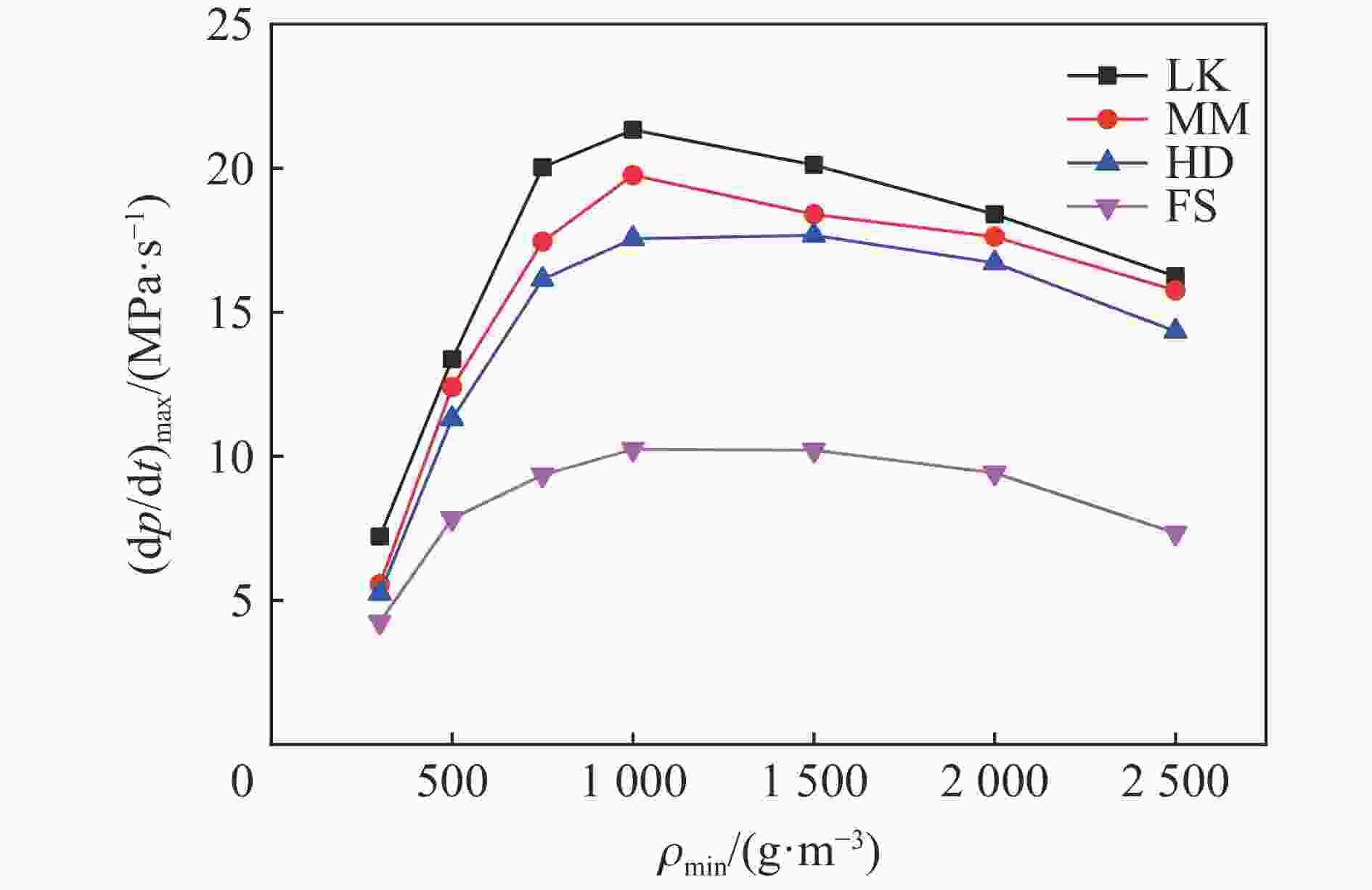

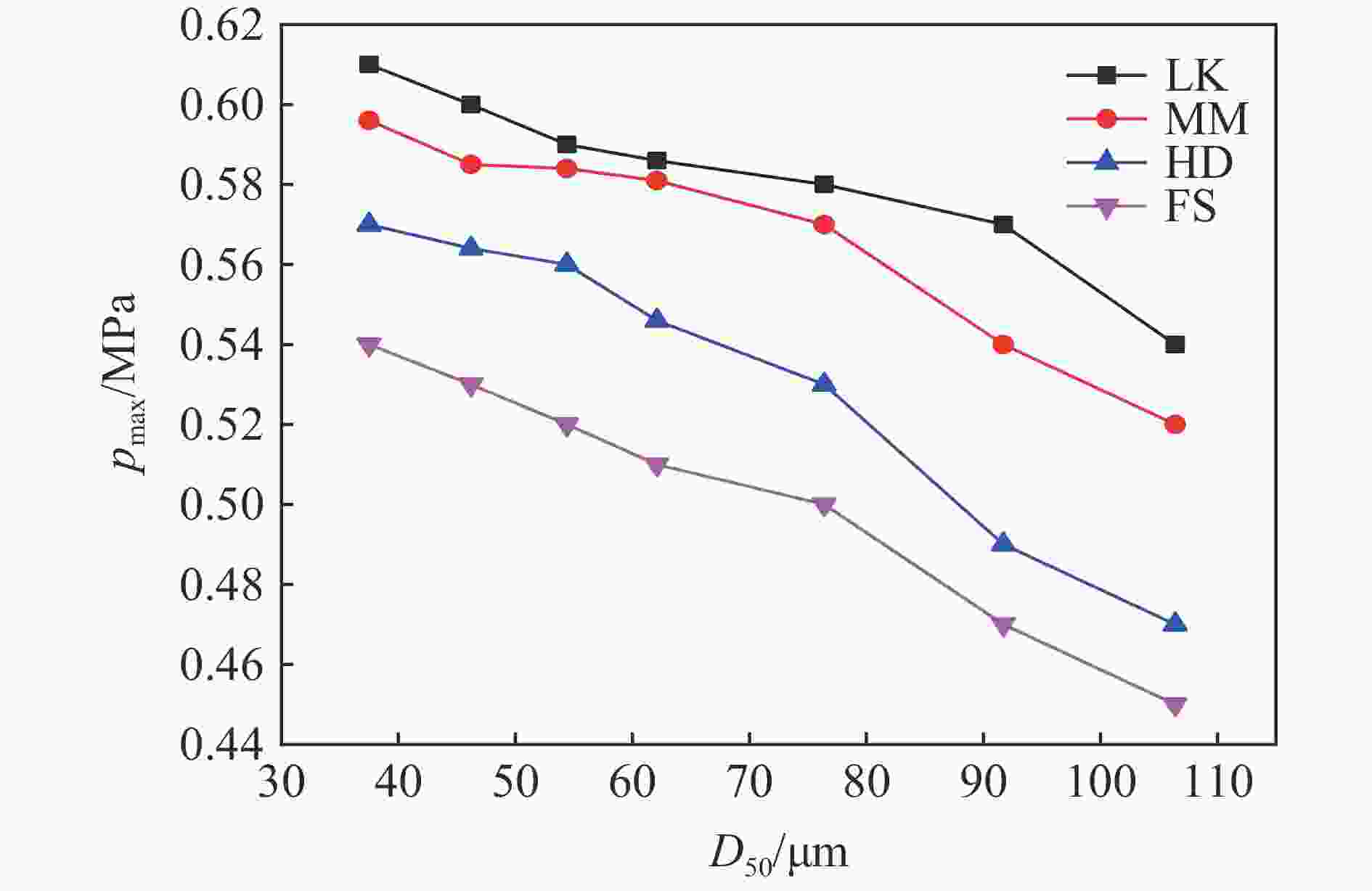

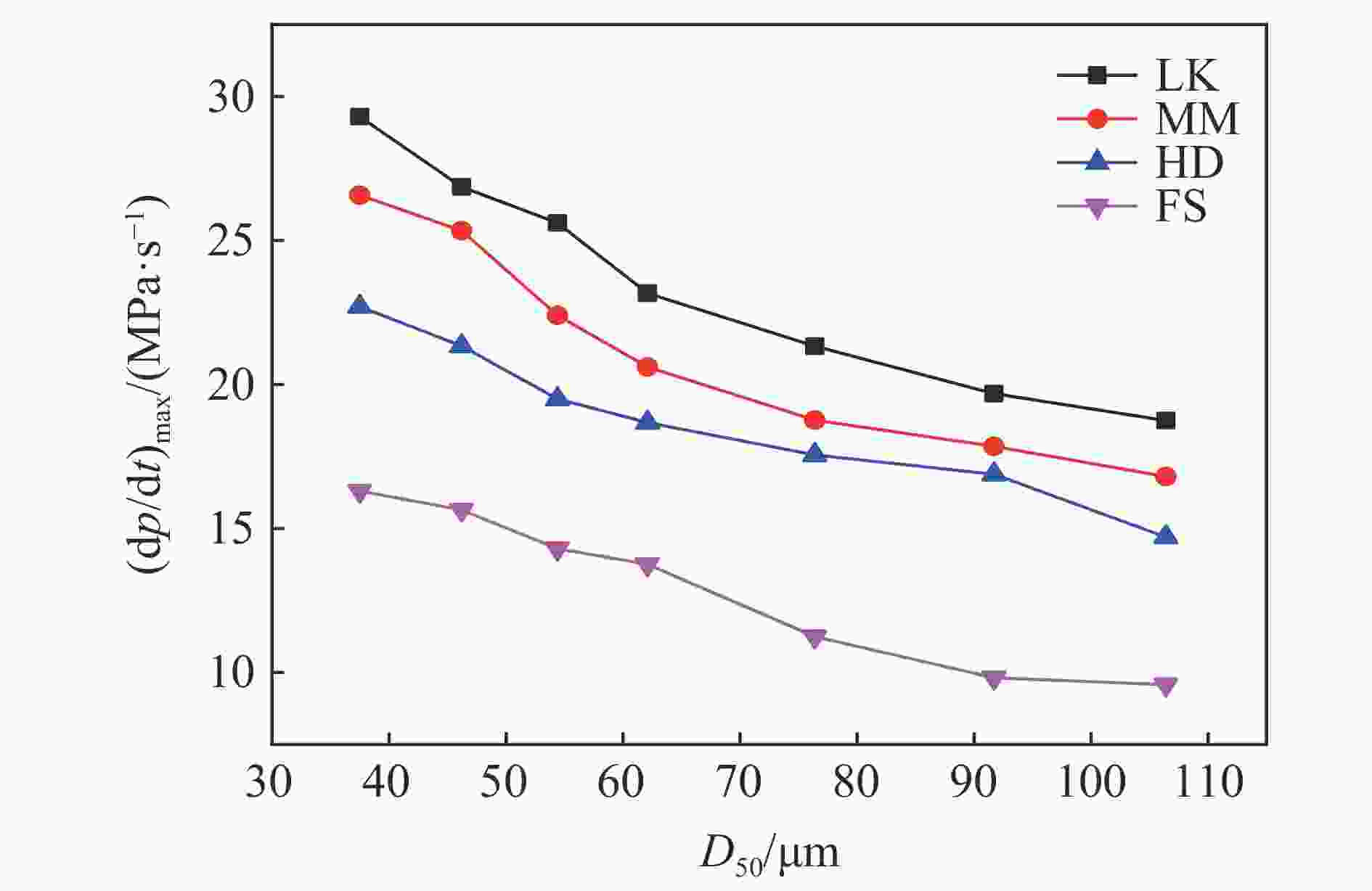

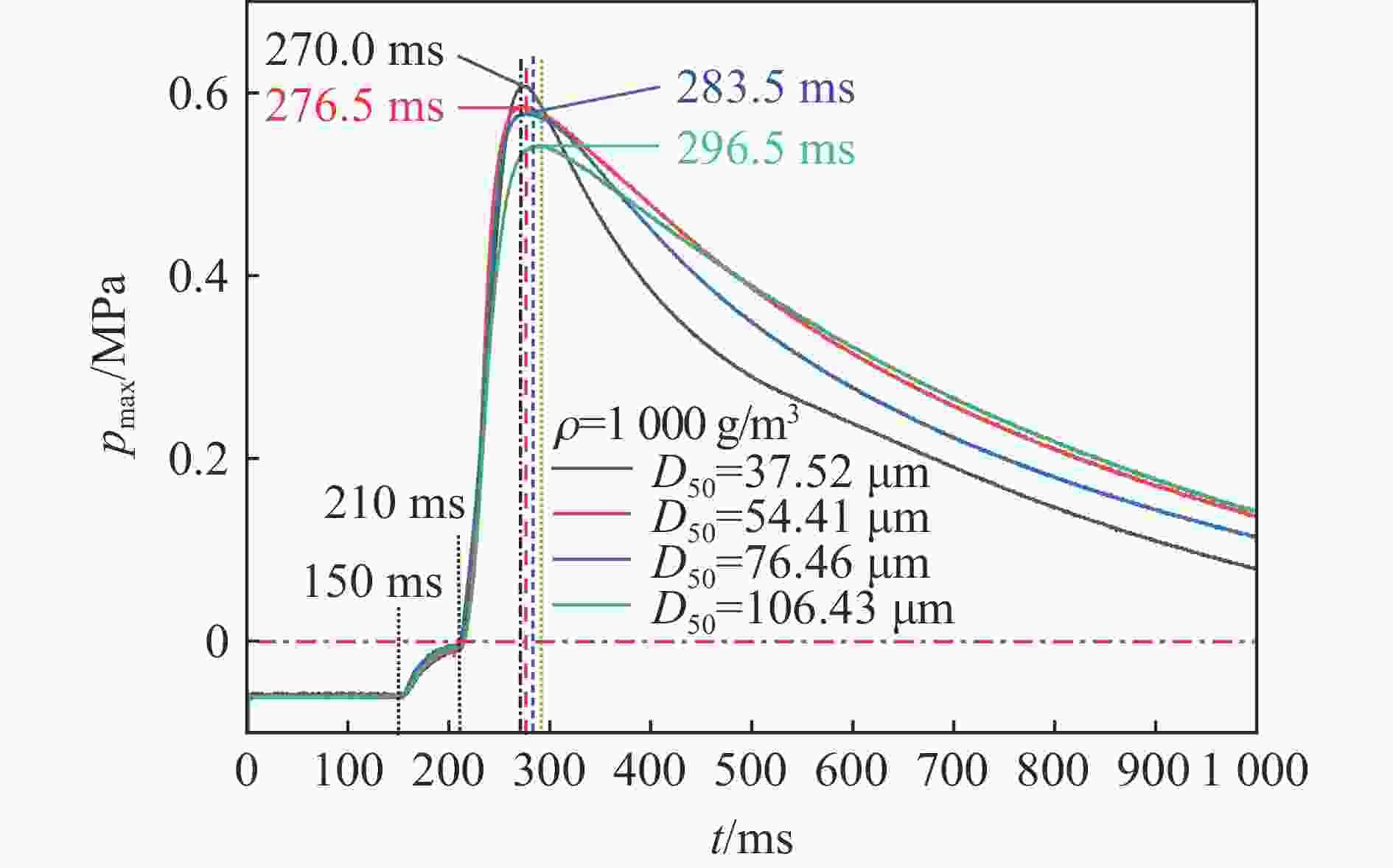

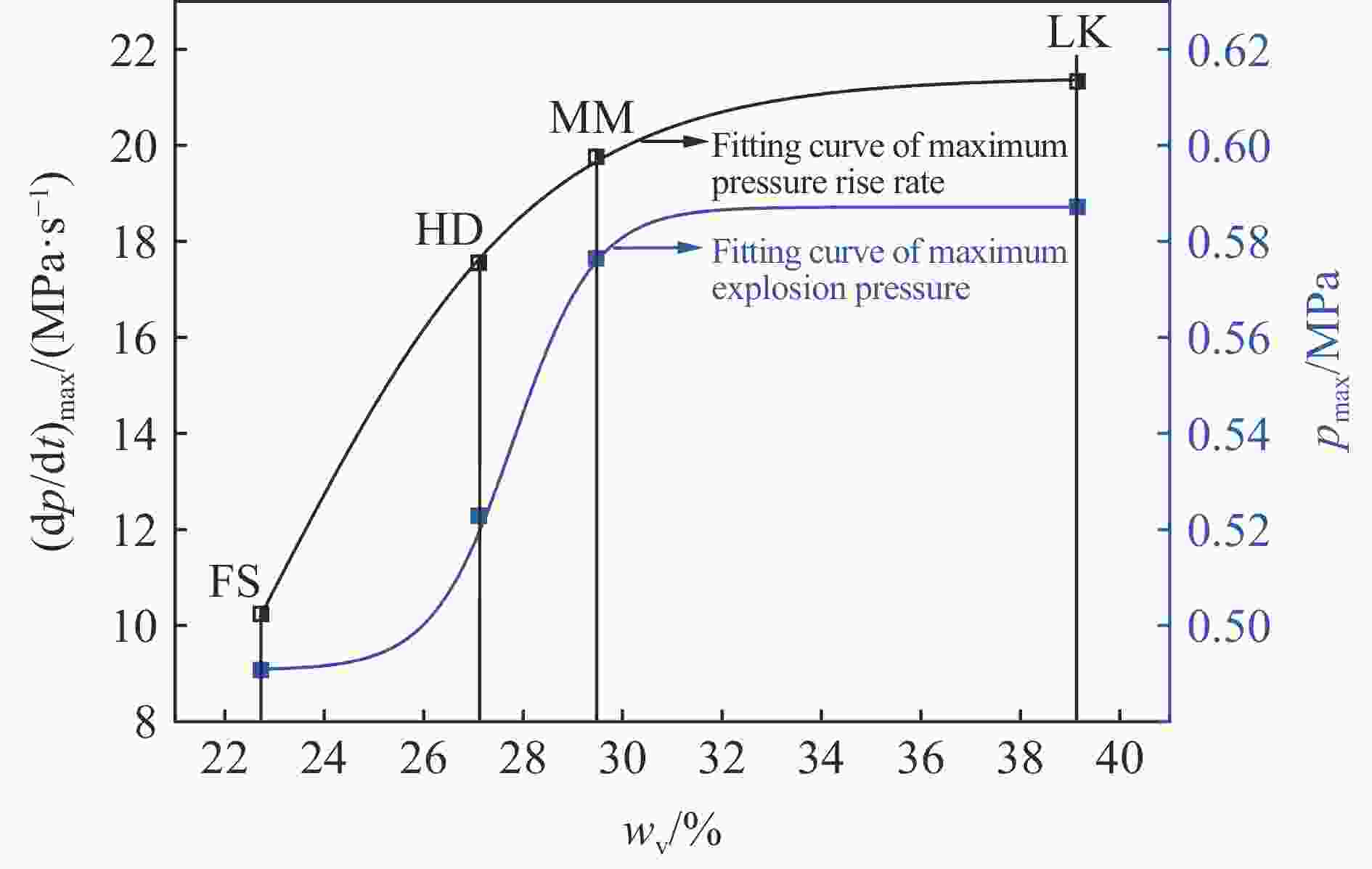

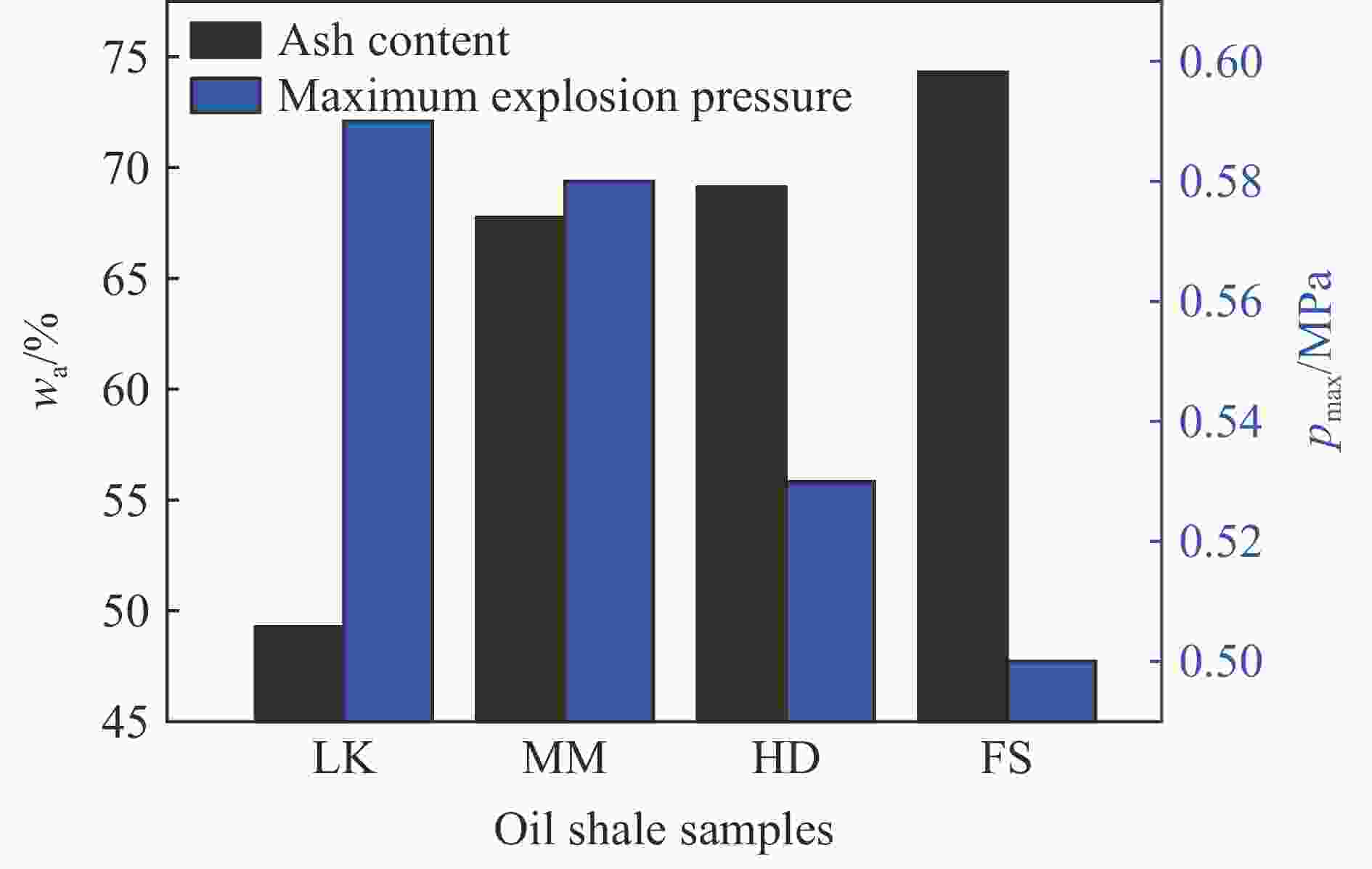

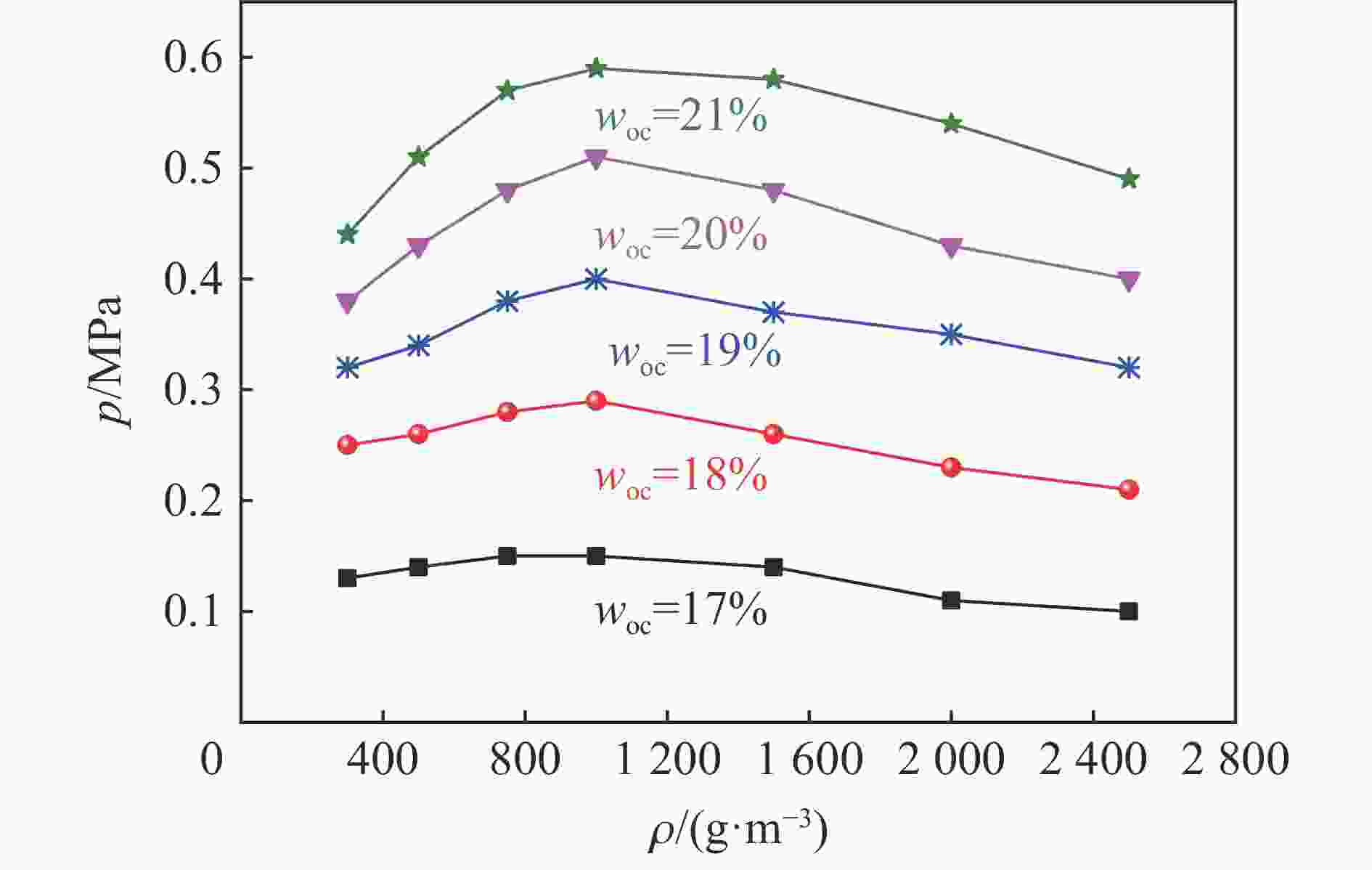

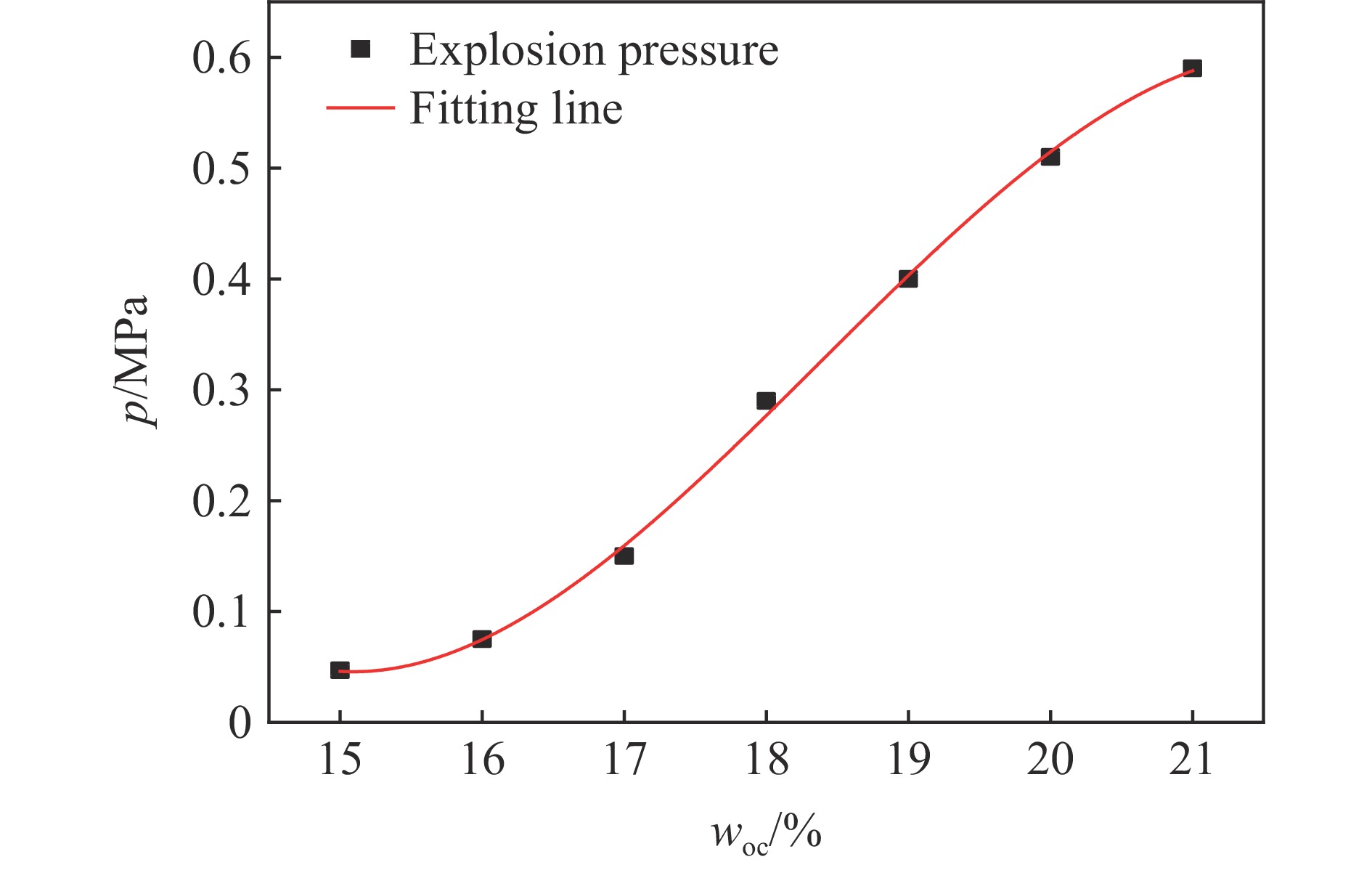

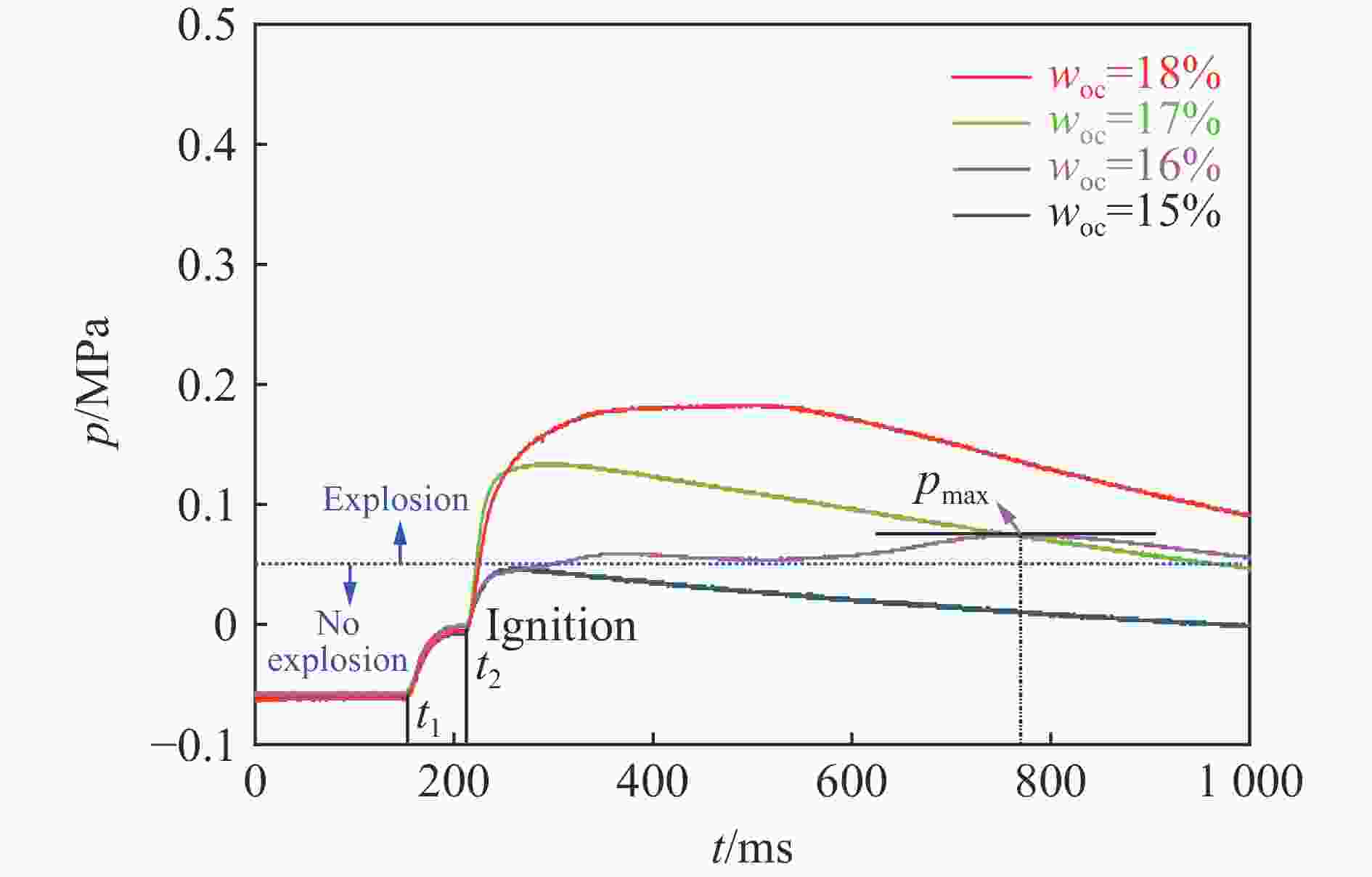

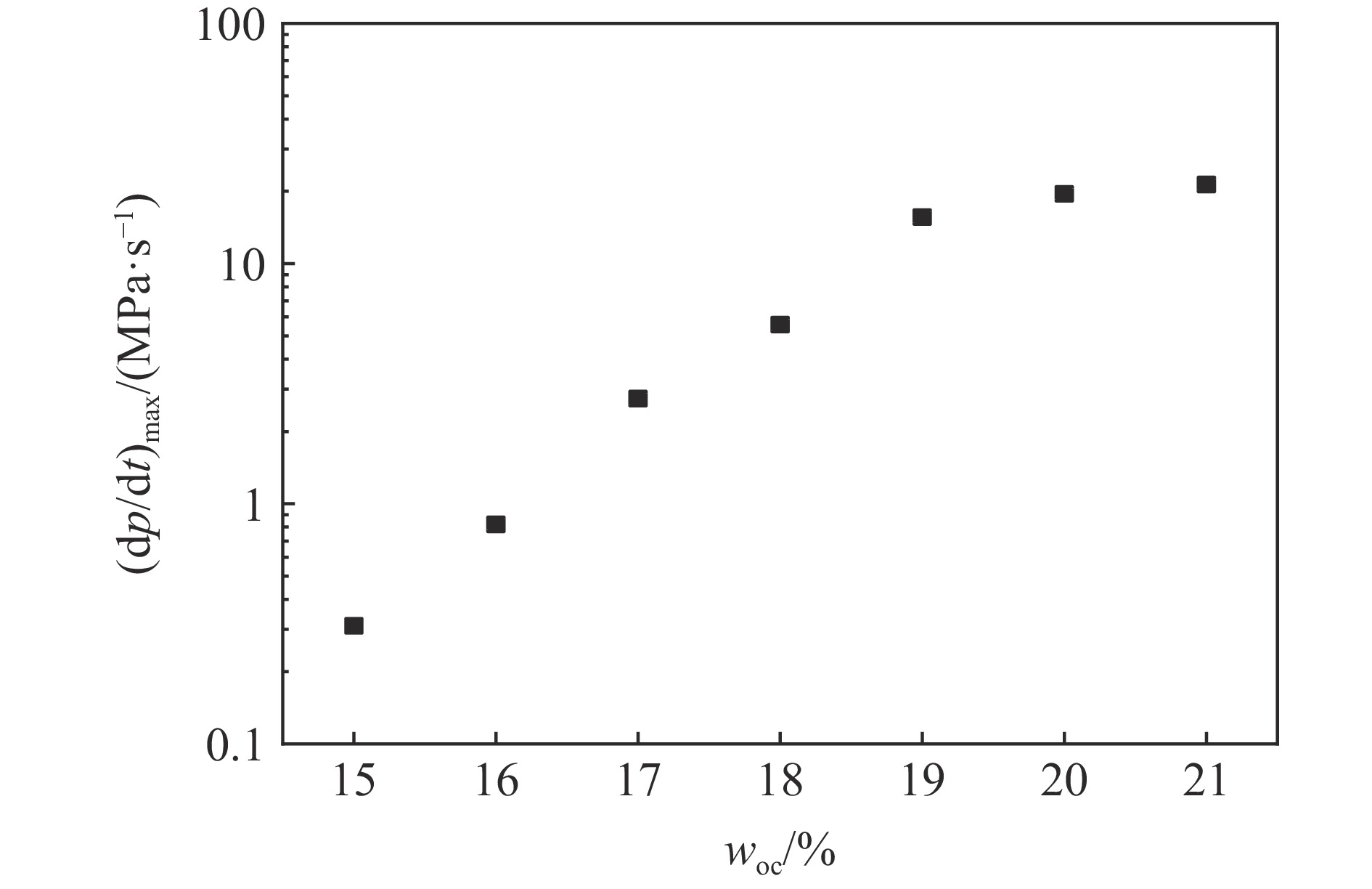

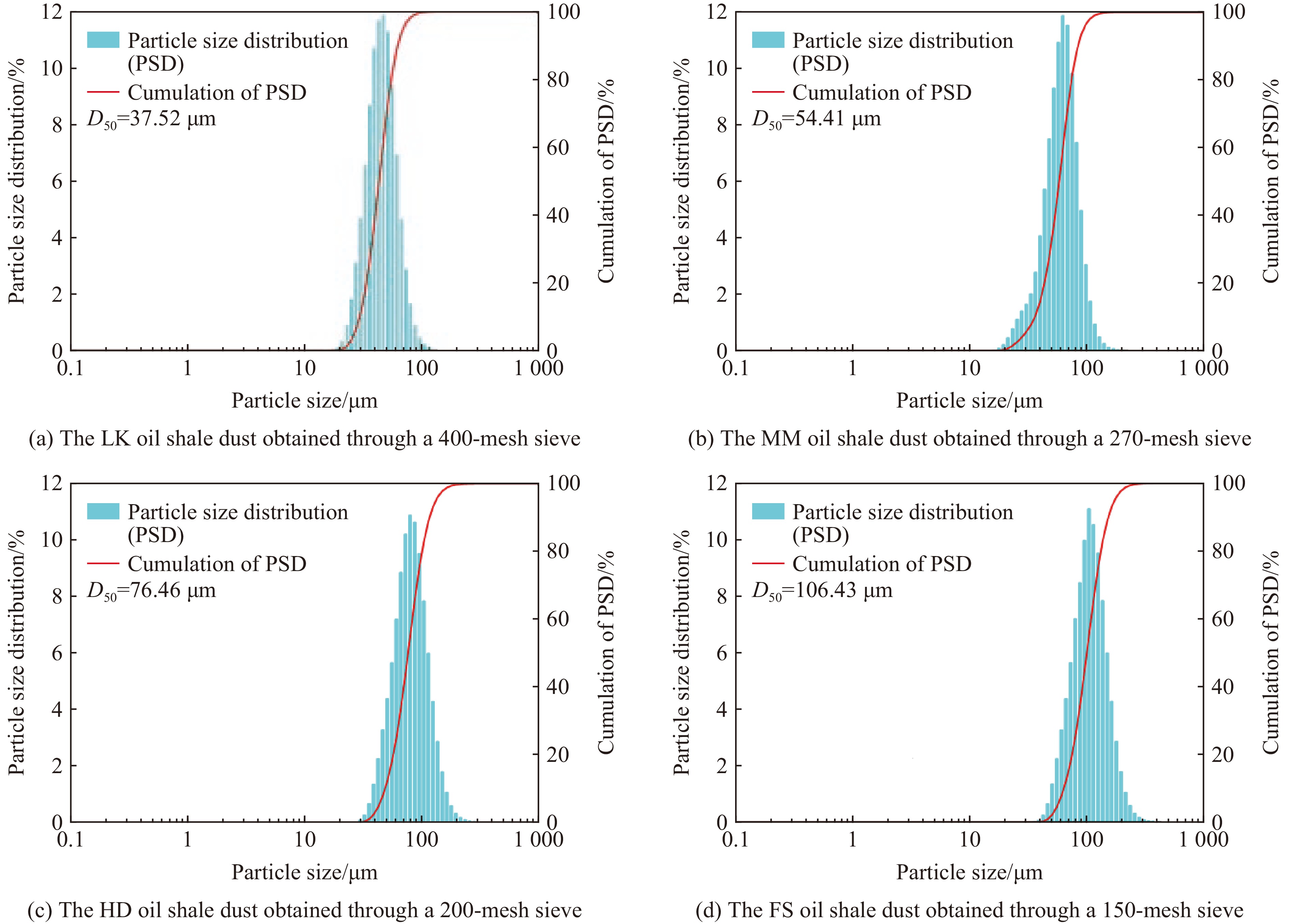

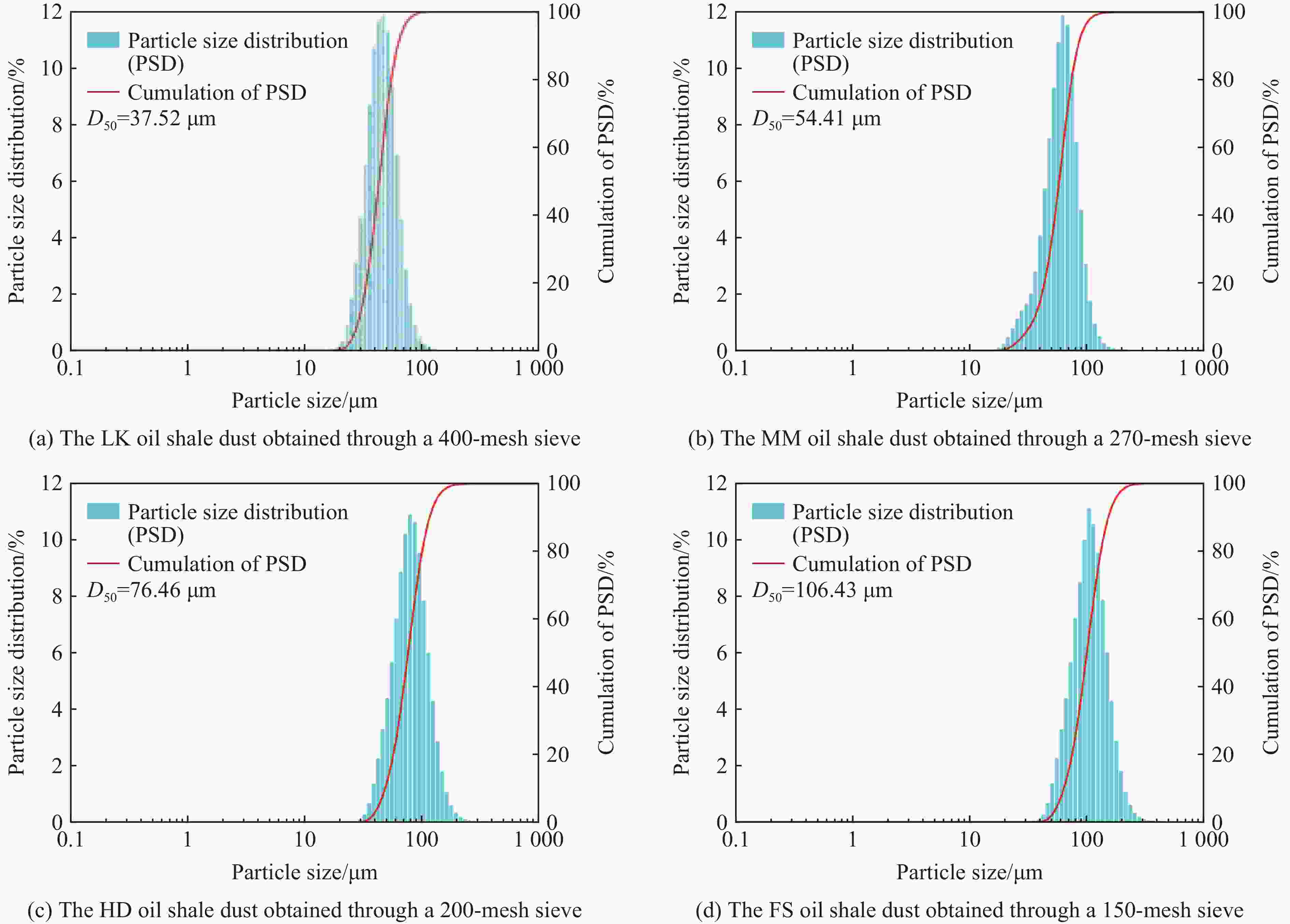

摘要: 为探究油页岩粉尘的爆炸特性,以龙口(Longkou, LK)、茂名(Maoming, MM)、桦甸(Huadian, HD)和抚顺(Fushun, FS)4种油页岩粉尘为研究对象,采用20 L球形爆炸装置,对这4种油页岩粉尘样品开展系统的爆炸实验,探讨油页岩粉尘的粉尘云质量浓度、粒径、挥发分、灰分、氧含量等对其爆炸特性的影响。结果表明:挥发分含量越高,油页岩粉尘的最大爆炸压力pmax、最大压力上升速率(dp/dt)max越高,爆炸下限越低;挥发分和灰分对油页岩粉尘云爆炸分别有显著的促进和抑制作用。在37.52~106.43 μm粒径范围内,这4种油页岩粉尘样品的pmax和(dp/dt)max均随其粉尘粒径的增大而降低,且到达最大爆炸压力的时间逐步缩短,说明小粒径油页岩粉尘较高的脱挥发速率能提高爆炸的反应程度。当粉尘质量浓度在400~2 500 g/m3范围内时,pmax和(dp/dt)max均随粉尘云质量浓度的升高呈现先升高后降低的变化趋势,高于最佳粉尘云质量浓度(1 000 g/m3)时略有下降,但维持在较高水平,表明超过最佳质量浓度的粉尘云引燃后仍有较强的破坏力;LK样品的pmax和(dp/dt)max均最高,分别为0.61 MPa和29.32 MPa/s,与挥发分含量相当的褐煤在同一水平,其爆炸下限为200 g/m3,在4种样品中最低,高于挥发分含量相当的褐煤;在N2惰化条件下,LK样品的pmax和(dp/dt)max均随环境氧含量的降低而降低,当氧含量降至15%时,系统不再发生爆炸,极限氧含量为16%。Abstract: To investigate the explosion characteristics of oil shale dust, four kinds of oil shale dust from main mining areas such as Longkou (LK), Maoming (MM), Huadian (HD) and Fushan (FS) in China were chosen as experimental samples. A 20-litre explosion sphere vessel was used as the experimental device to carry out explosion experiments to systematically explore the influences of the parameters of the samples, including dust mass concentration, particle size, the content of volatile and ash, and oxygen content on the explosion characteristics of oil shale dust. The experimental results show that the higher the volatile content of the oil shale, the higher the maximum explosion pressure, the maximum rise rate of explosion pressure (dp/dt)max, and the lower the minimum explosion mass concentration; the volatile has a significant promoting effect on the explosion of the oil shale dust, while the ash has a significant inhibiting effect on it. In the dust particle size range from 37.52 microns to 106.43 microns, the magnitudes of pmax and (dp/dt)max of the four oil shale samples all decrease with the increase of particle size, and the time to reach pmax decreases gradually as the particle size becomes smaller. The smaller the particles are, the faster the volatiles are released, which can improve the reaction degree of the explosion. In the dust mass concentration range from 400 g/m3 to 2 500 g/m3, the magnitudes of pmax and (dp/dt)max of the four samples all took on a trend of increasing first and then decreasing with the increase of dust mass concentration. After the critical pressure concentration (1000 g/m3) was exceeded, the explosion intensity decreased slightly, but still maintained at a high level, and still had relatively strong destructive power. The magnitudes of pmax (0.61 MPa) and (dp/dt)max (29.32 MPa/s) of the LK sample are the highest in the four samples, which are at the same level as that of lignite with similar volatile content. The minimum explosion concentration (200 g/m3) of the LK sample is the lowest among the four samples, which is higher than that of the lignite with the similar volatile content. By using N2 as the inert gas, the oxidation, the heat released and the magnitudes of pmax and (dp/dt)max of the LK sample all decreased with the decrease of oxygen content. When the oxygen content was reduced to 15%, there were no more explosions in the system, and the limiting oxygen concentration was found to be 16%.

-

表 1 4种油页岩粉尘样品工业分析结果

Table 1. Proximate analyses of four oil shale dust samples

油页岩粉尘 w/% 固定碳 挥发分 灰分 水分 LK 10.07 39.15 49.28 1.50 MM 0.10 29.47 67.76 2.87 HD 0.09 27.11 69.11 3.87 FS 1.08 22.73 74.30 1.98 -

[1] ECKHOFF R K. Understanding dust explosions: the role of powder science and technology [J]. Journal of Loss Prevention in the Process Industries, 2009, 22(1): 105–116. DOI: 10.1016/j.jlp.2008.07.006. [2] JOSEPH G. Combustible dusts: a serious industrial hazard [J]. Journal of Hazardous Materials, 2007, 142(3): 589–591. DOI: 10.1016/j.jhazmat.2006.06.127. [3] JIANG H P, BI M S, LI B, et al. Inhibition evaluation of ABC powder in aluminum dust explosion [J]. Journal of Hazardous Materials, 2019, 361: 273–282. DOI: 10.1016/j.jhazmat.2018.07.045. [4] LIN S, LIU Z T, QIAN J F, et al. Comparison on the explosivity of coal dust and of its explosion solid residues to assess the severity of re-explosion [J]. Fuel, 2019, 251: 438–446. DOI: 10.1016/j.fuel.2019.04.080. [5] ECKHOFF R K. Scaling of dust explosion violence from laboratory scale to full industrial scale: a challenging case history from the past [J]. Journal of Loss Prevention in the Process Industries, 2015, 36: 271–280. DOI: 10.1016/j.jlp.2014.12.020. [6] 李刚, 杨红霞, 于立富. 油页岩利用过程粉尘爆炸研究现状及趋势分析 [J]. 中国安全生产科学技术, 2015, 11(10): 38–42. DOI: 10.11731/j.issn.1673-193x.2015.10.007.LI G, YANG H X, YU L F. Current status and trend analysis of dust explosion research in utilizing process of oil shale [J]. Journal of Safety Science and Technology, 2015, 11(10): 38–42. DOI: 10.11731/j.issn.1673-193x.2015.10.007. [7] 孟祥豹, 王俊峰, 张延松, 等. 惰性粉体对油页岩粉尘爆炸火焰的抑制性能和作用机理研究 [J]. 爆炸与冲击, 2021, 41(10): 105401. DOI: 10.11883/bzycj-2020-0306.MENG X B, WANG J F, ZHANG Y S, et al. Study on the inhibitory property and mechanism of inert powder on dust explosion flame of oil shale [J]. Explosion and Shock Waves, 2021, 41(10): 105401. DOI: 10.11883/bzycj-2020-0306. [8] YU L F, LI G, LIU W C, et al. Experimental investigations on ignition sensitivity of hybrid mixtures of oil shale dust and syngas [J]. Fuel, 2017, 210: 1–7. DOI: 10.1016/j.fuel.2017.06.082. [9] HAMDAN M A, SAKHRIEH A. Dust explosion of oil shale and olive cake solid fuels: a comparison study [J]. International Journal of Energy Research, 2010, 29(10): 871–878. DOI: 10.1002/er.1055. [10] SWEIS F K. The effect of admixed material on the minimum explosible concentration of oil shale [J]. Journal of Loss Prevention in the Process Industries, 2006, 19(6): 701–704. DOI: 10.1016/j.jlp.2006.04.003. [11] WANG J F, ZHANG Y S, SU H F, et al. Explosion characteristics and flame propagation behavior of mixed dust cloud of coal dust and oil shale dust [J]. Energies, 2019, 12(20): 3807–3814. DOI: 10.3390/en12203807. [12] LIU B, ZHANG Y Y, MENG X B, et al. Study on explosion characteristics of the inert substances at Longkou oil shale of China [J]. Process Safety and Environmental Protection, 2020, 136: 324–333. DOI: 10.1016/j.psep.2019.12.033. [13] 韩放, 鲍明福, 高健. 抚顺式油页岩干馏炉安全性分析与评价 [C]//中国职业安全健康协会2009年学术年会论文集. 厦门: 煤炭工业出版社, 2009: 5. [14] 郭文杰. 油页岩干馏炉物料安全生产基础参数研究 [D]. 辽宁阜新: 辽宁工程技术大学, 2011: 35–37. [15] ASTM International. Standard test method for minimum explosible concentration of combustible dust: ASTM E1515−14 [S]. West Conshohocken, PA, USA: ASTM International, 2014: 1–6. DOI: 10.1520/E1515-14. [16] LI Q Z, WANG K, ZHENG Y N, et al. Experimental research of particle size and size dispersity on the explosibility characteristics of coal dust [J]. Powder Technology, 2016, 292: 290–297. DOI: 10.1016/j.powtec.2016.01.035. [17] MITTAL M. Limiting oxygen concentration for coal dusts for explosion hazard analysis and safety [J]. Journal of Loss Prevention in the Process Industries, 2013, 26(6): 1106–1112. DOI: 10.1016/j.jlp.2013.04.012. [18] ASTM International. Standard test method for explosibility of dust clouds: ASTM E1226−19 [S]. West Conshohocken, PA, USA: ASTM International, 2019: 2−4. DOI: 10.1520/E1226-19. [19] 曹卫国. 褐煤粉尘爆炸特性实验及机理研究 [D]. 南京: 南京理工大学, 2016: 73–74.CAO W G. Experimental and mechanism study on explosion characteristic of lignite coal dust [D]. Nanjing: Nanjing University of Science and Technology, 2016: 73-74. [20] 于立富, 李刚, 潘超, 等. 中国油页岩粉尘爆炸特性实验研究 [J]. 东北大学学报 (自然科学版), 2016, 37(8): 1203–1206. DOI: 10.3969/j.issn.1005-3026.2016.08.028.YU L F, LI G, PAN C, et al. Experimental research on China’s oil shale dust explosibility [J]. Journal of Northeastern University (Natural Science), 2016, 37(8): 1203–1206. DOI: 10.3969/j.issn.1005-3026.2016.08.028. [21] 刘雪岭, 张奇. 密闭空间煤粉气动分散湍流对爆炸参数的影响规律 [J]. 煤炭学报, 2018, 43(11): 3137–3144. DOI: 10.13225/j.cnki.jccs.2018.0099.LIU X L, ZHANG Q. Influence of turbulence flow on explosion characteristics of coal dust in 20 L vessel [J]. Journal of China Coal Society, 2018, 43(11): 3137–3144. DOI: 10.13225/j.cnki.jccs.2018.0099. [22] CLONEY C T, RIPLEY R C, PEGG M J, et al. Laminar combustion regimes for hybrid mixtures of coal dust with methane gas below the gas lower flammability limit [J]. Combustion and Flame, 2018, 198: 14–23. DOI: 10.1016/j.combustflame.2018.09.004. [23] 刘天奇, 李雨成, 罗红波. 不同变质程度煤尘爆炸压力特性变化规律实验研究 [J]. 爆炸与冲击, 2019, 39(9): 155–162. DOI: 10.11883/bzycj-2018-0265.LIU T Q, LI Y C, LUO H B. Experimental study on explosion pressure variation law of coal dust with different degrees of metamorphism [J]. Explosion and Shock Waves, 2019, 39(9): 155–162. DOI: 10.11883/bzycj-2018-0265. [24] WANG X, ZHANG Y S, LIU B, et al. Effectiveness and mechanism of carbamide/fly ash cenosphere with bilayer spherical shell structure as explosion suppressant of coal dust [J]. Journal of Hazardous Materials, 2019, 365: 555–564. DOI: 10.1016/j.jhazmat.2018.11.044. [25] 喻健良, 孙会利, 纪文涛, 等. 甲烷/石松子两相混合体系爆炸强度参数 [J]. 爆炸与冲击, 2018, 38(1): 92–97. DOI: 10.11883/bzycj-2016-0276.YU J L, SUN H L, JI W T, et al. Explosion severity parameters of hybrid mixture of methane and lycopodium dust [J]. Explosion and Shock Waves, 2018, 38(1): 92–97. DOI: 10.11883/bzycj-2016-0276. [26] ECKHOFF R K. Dust explosion prevention and mitigation, status and developments in basic knowledge and in practical application [J]. International Journal of Chemical Engineering, 2009, 2009: 569825. DOI: 10.1155/2009/569825. [27] TSAI Y T, HO S C, HUANG A C, et al. Potential explosion hazard of polyester resin dust formed from a granulation process: limiting oxygen concentration with different pressures [J]. Applied Thermal Engineering, 2018, 135: 74–82. DOI: 10.1016/j.applthermaleng.2018.02.047. [28] MIYAMOTO K, HUANG X Y, HASHIMOTO N, et al. Limiting oxygen concentration (LOC) of burning polyethylene insulated wires under external radiation [J]. Fire Safety Journal, 2016, 86: 32–40. DOI: 10.1016/j.firesaf.2016.09.004. [29] GOING J E, CHATRATHI K, CASHDOLLAR K L. Flammability limit measurements for dusts in 20-L and 1-m3 vessels [J]. Journal of Loss Prevention in the Process Industries, 2000, 13(3/4/5): 209–219. DOI: 10.1016/S0950-4230(99)00043-1. [30] 国家煤炭工业局. 煤尘爆炸极限氧含量测定方法: MT/T 837−1999 [S]. 北京: 中国煤炭工业出版社, 2000: 1–2. -

下载:

下载: