In-plane dynamic mechanical properties of partially liquid filled multicell structure

-

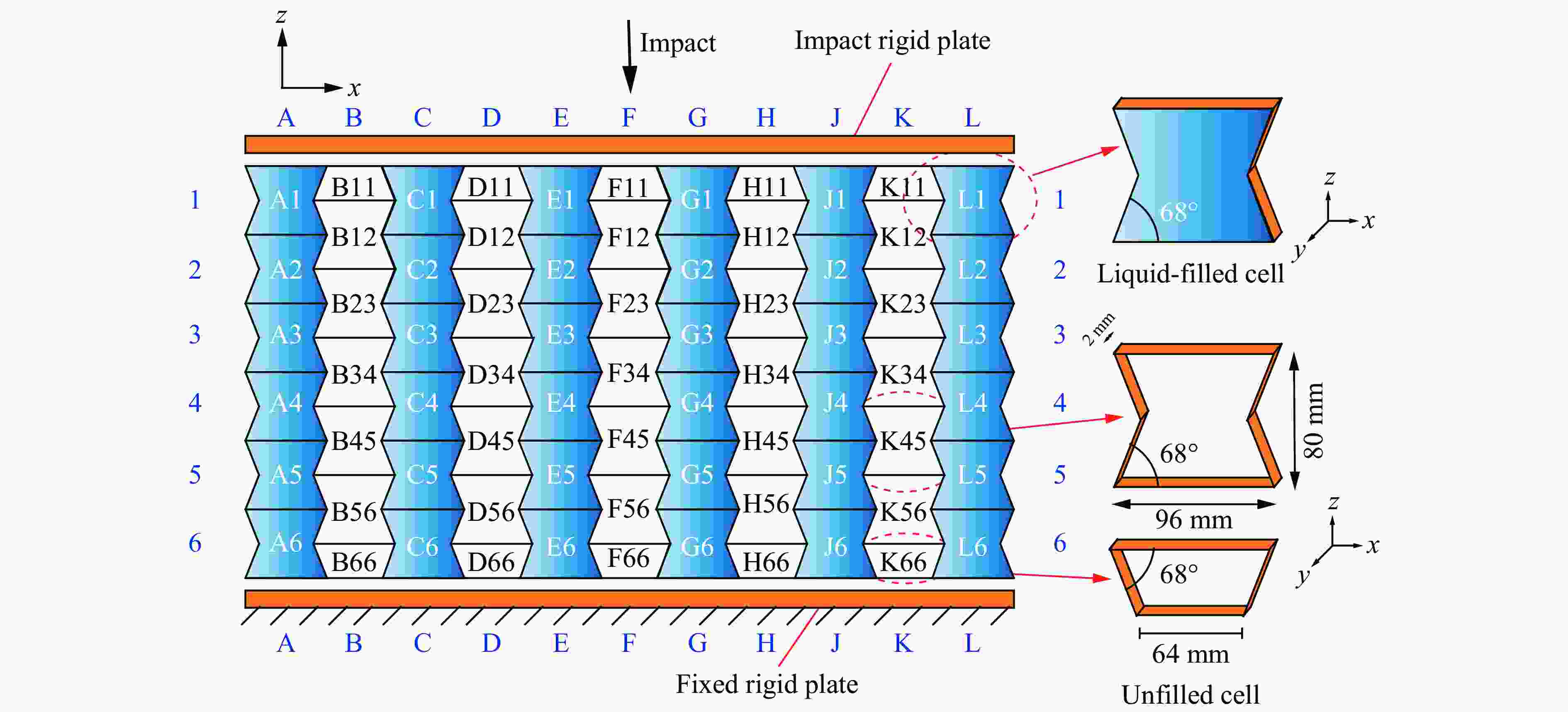

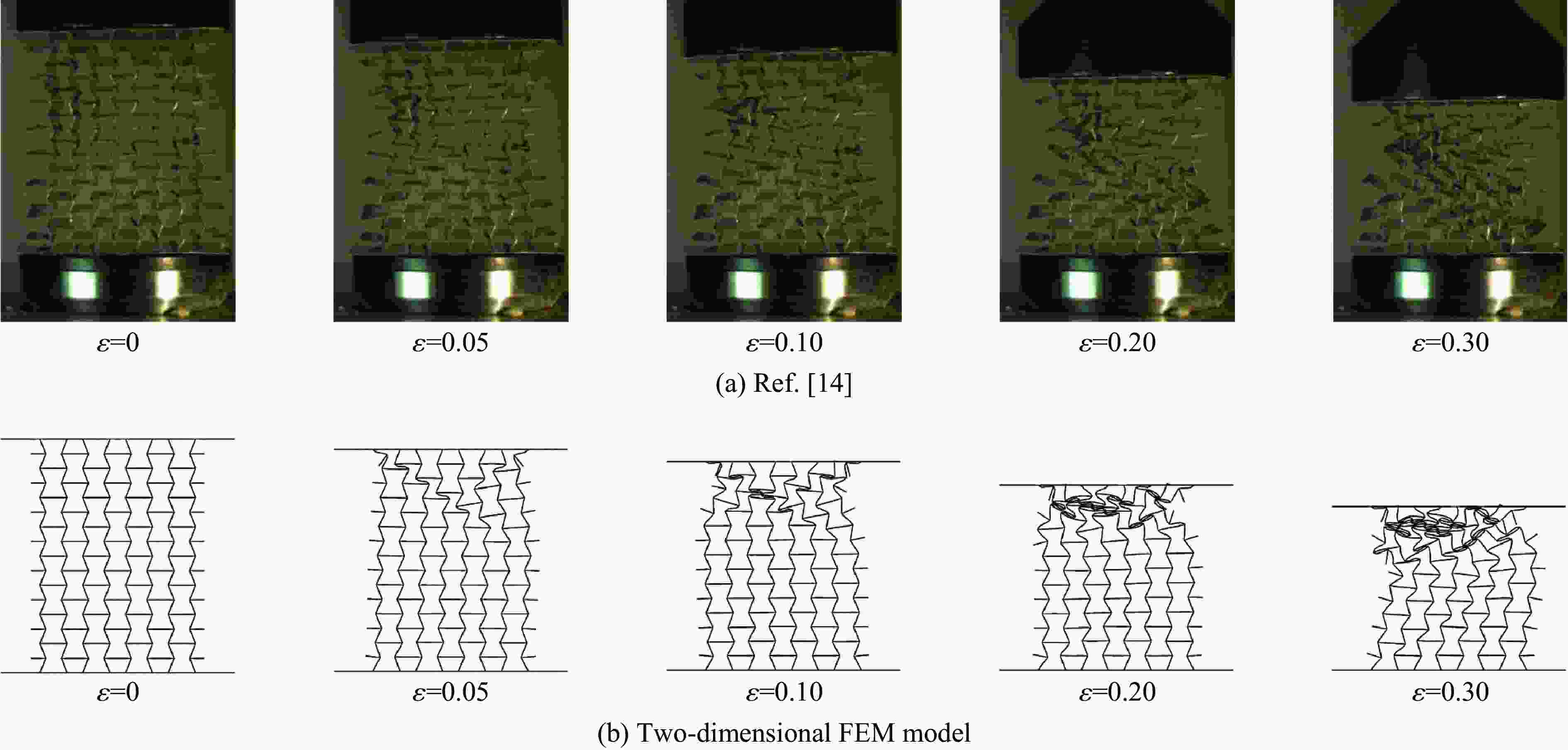

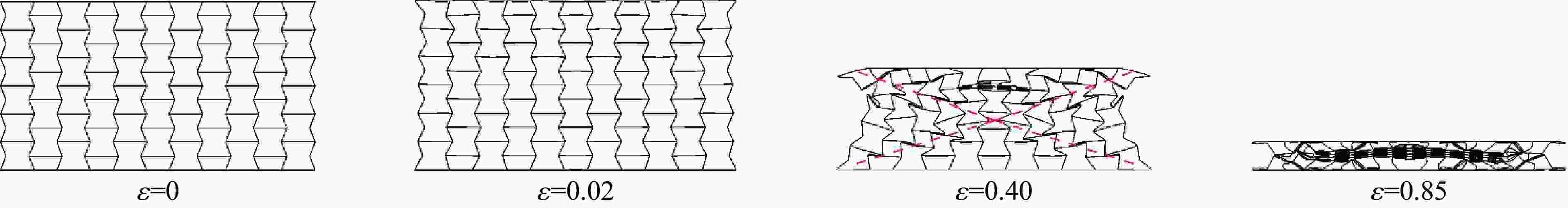

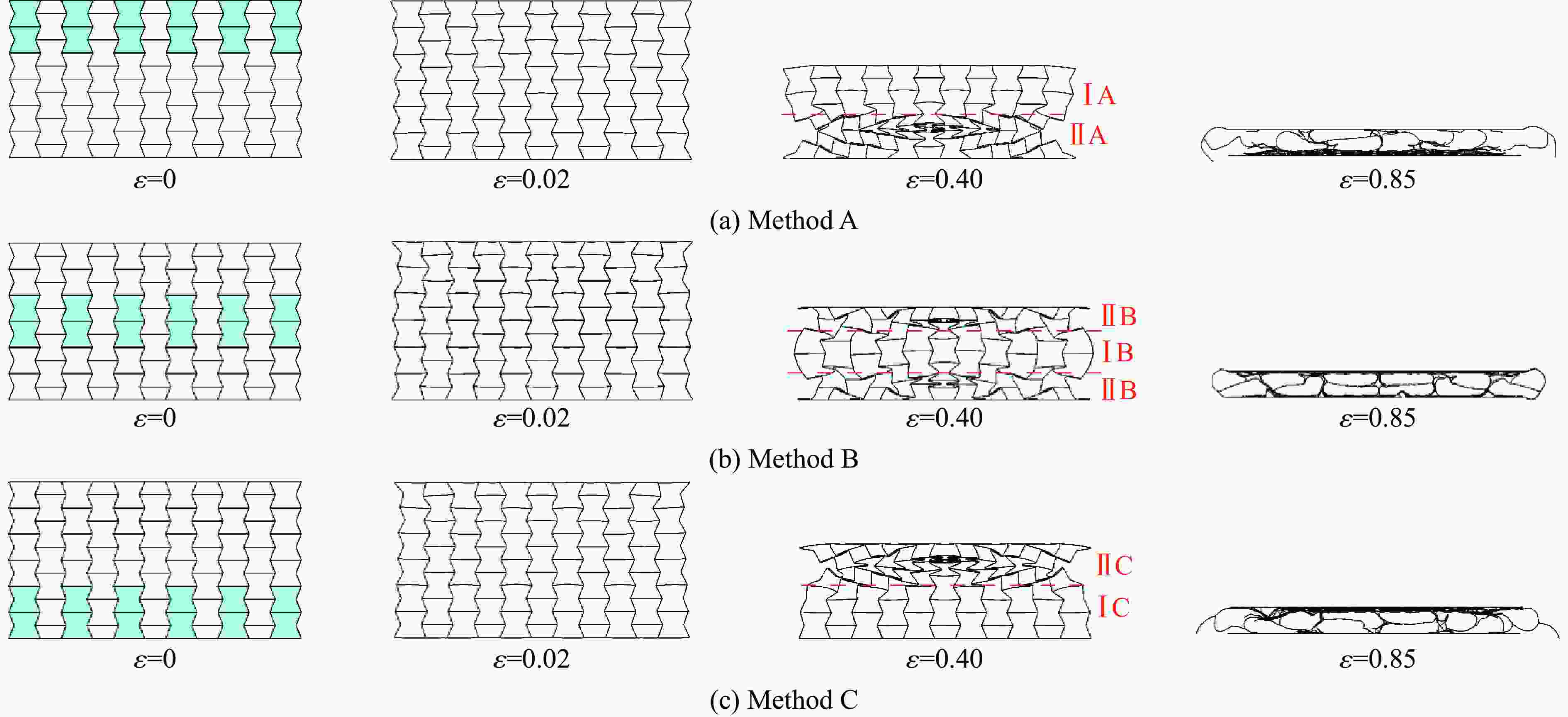

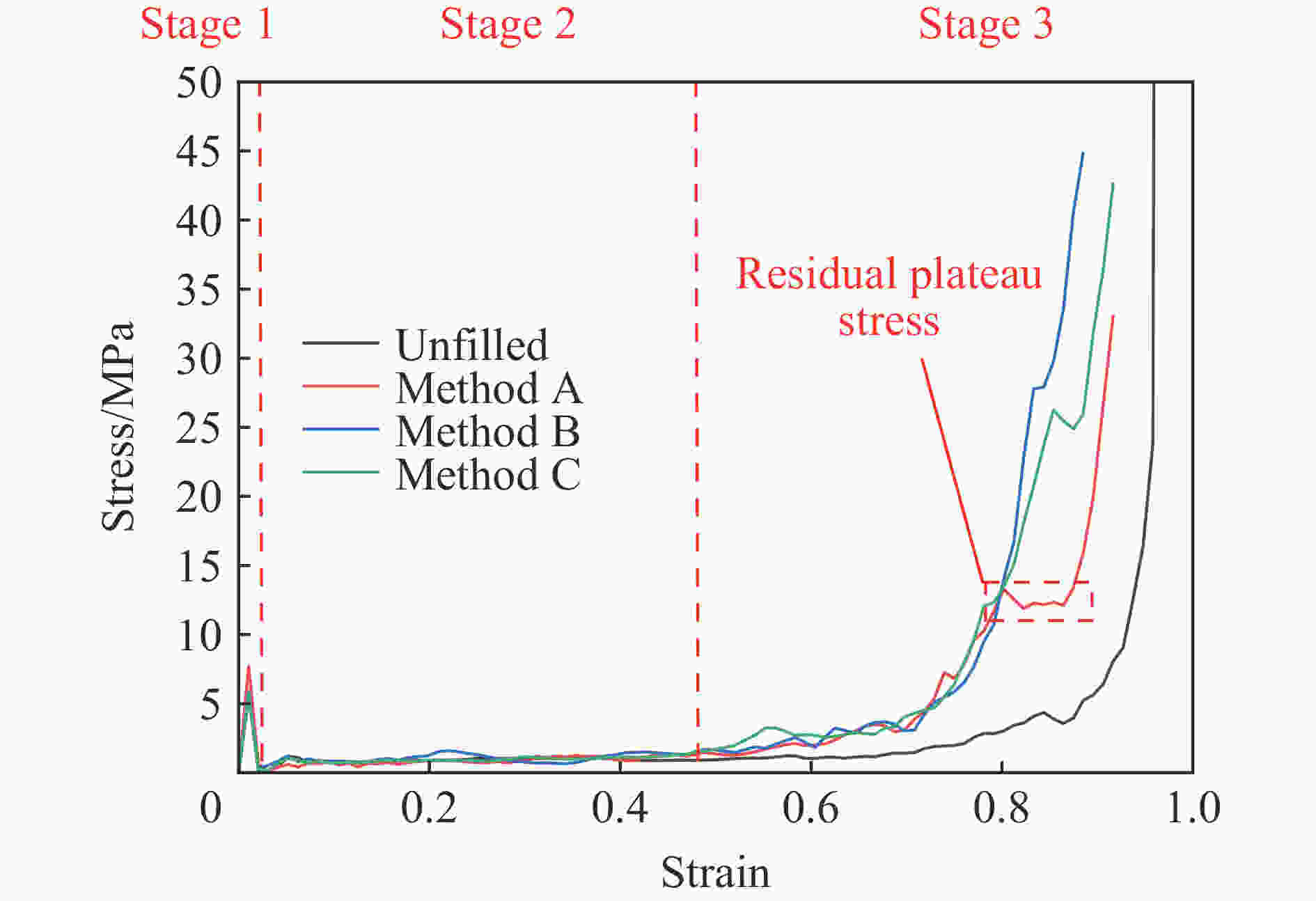

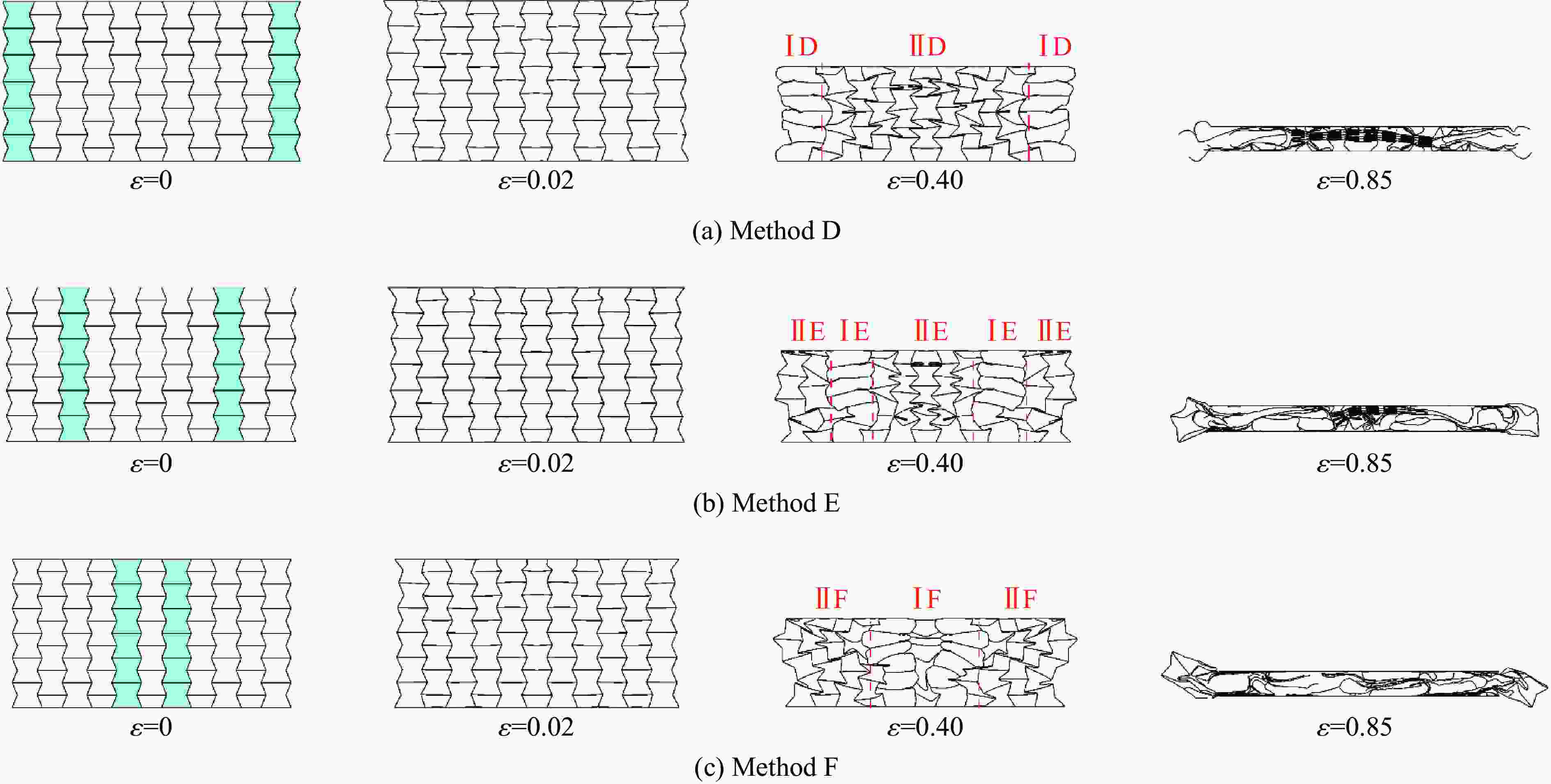

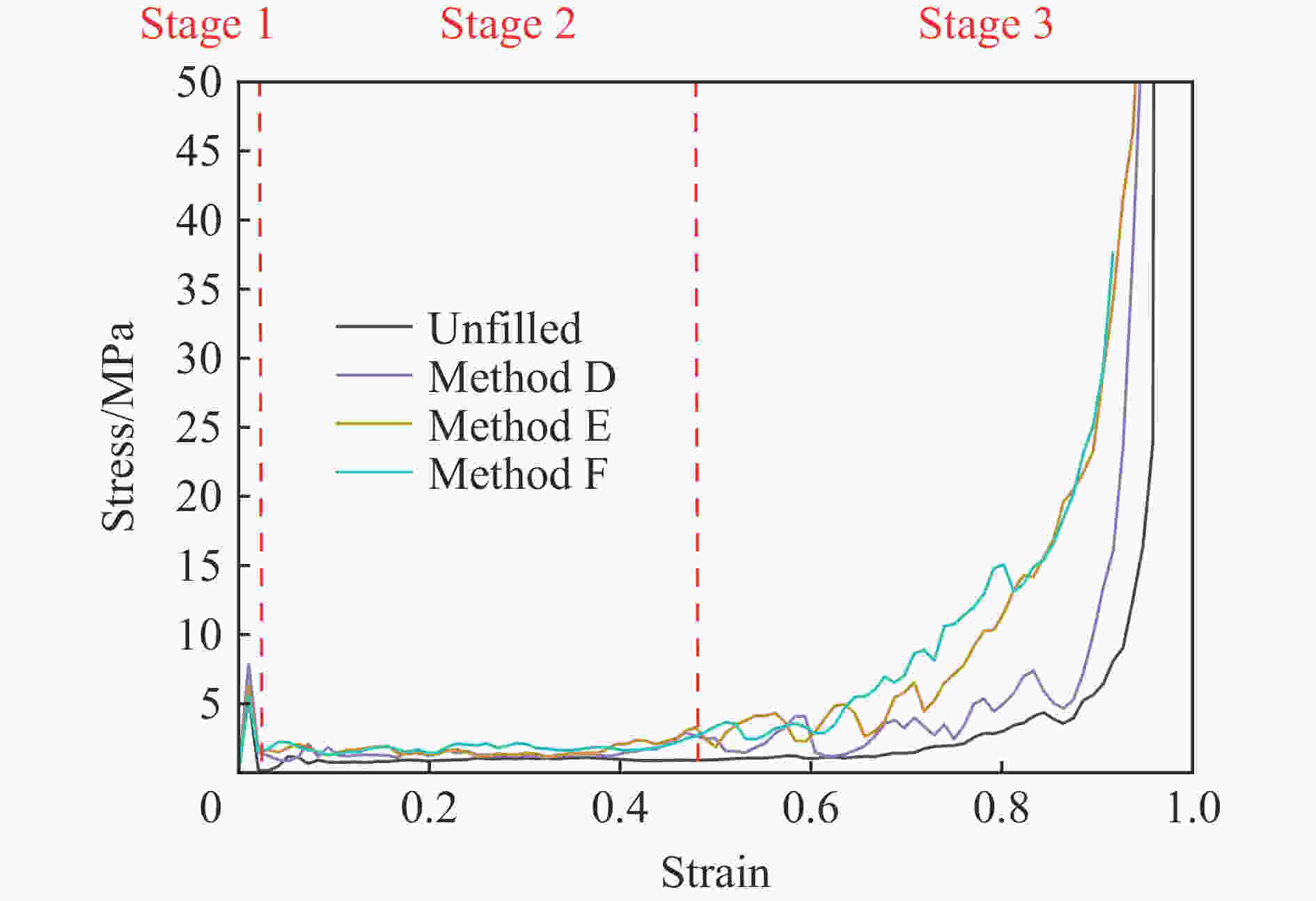

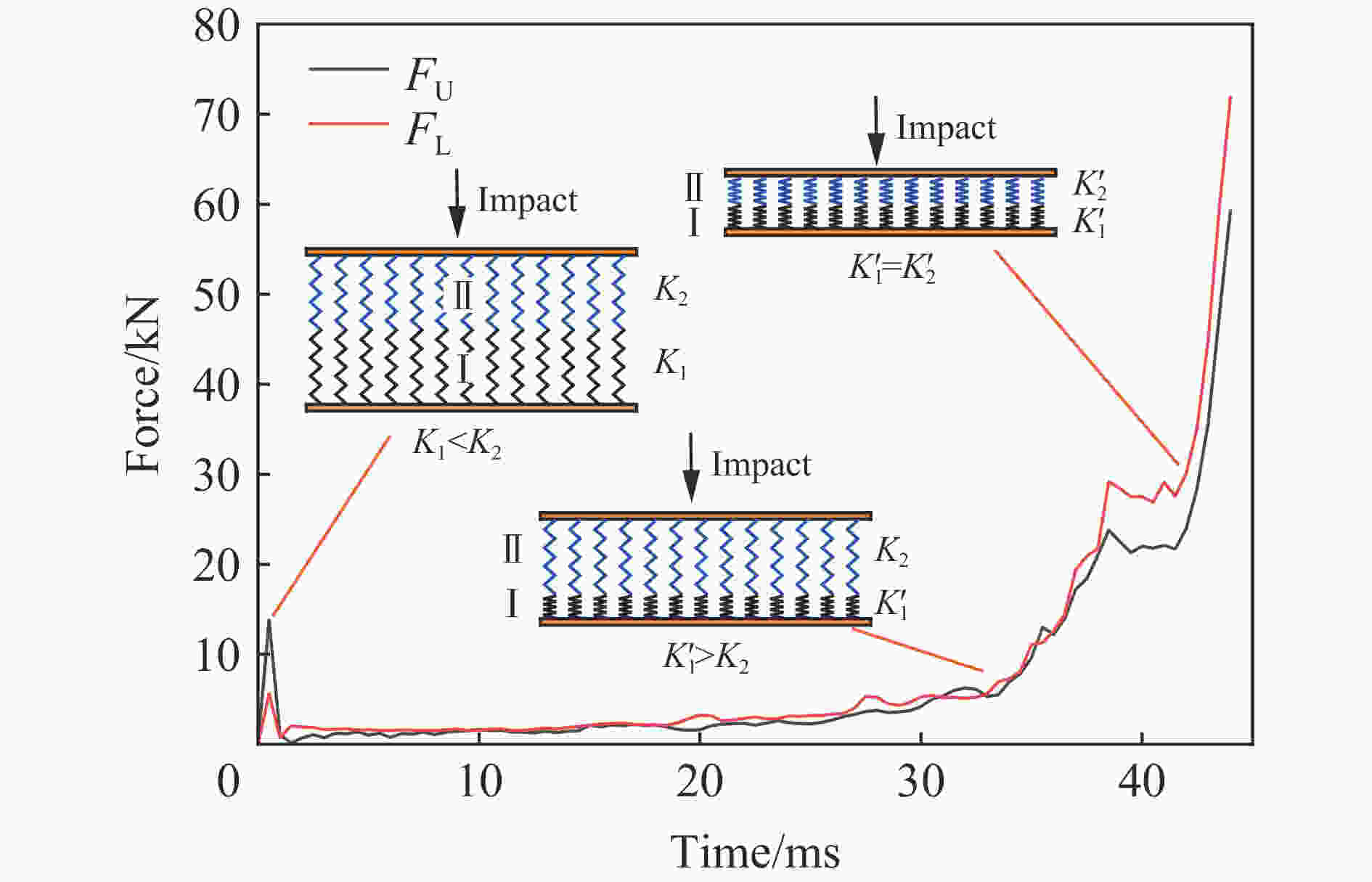

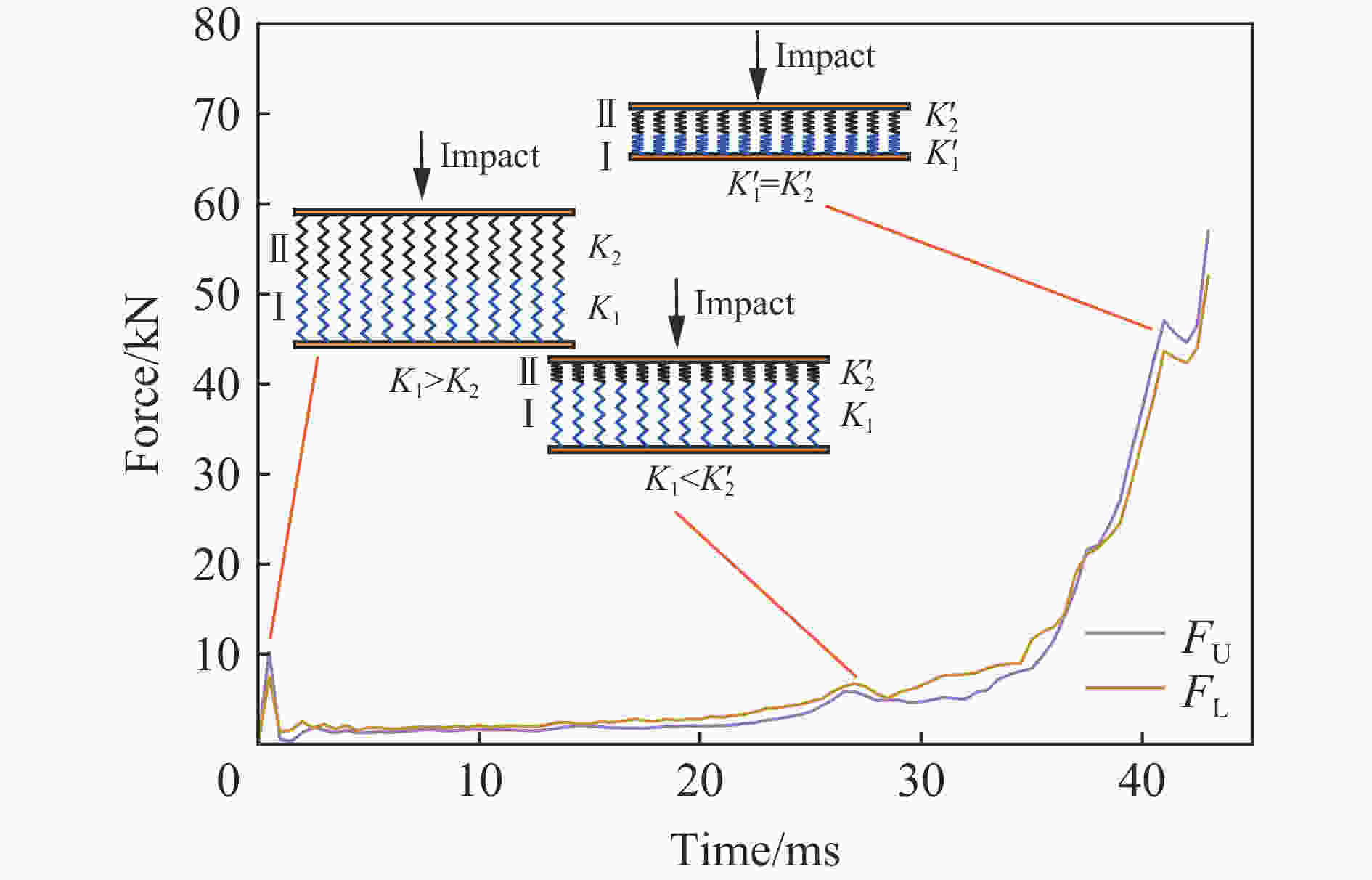

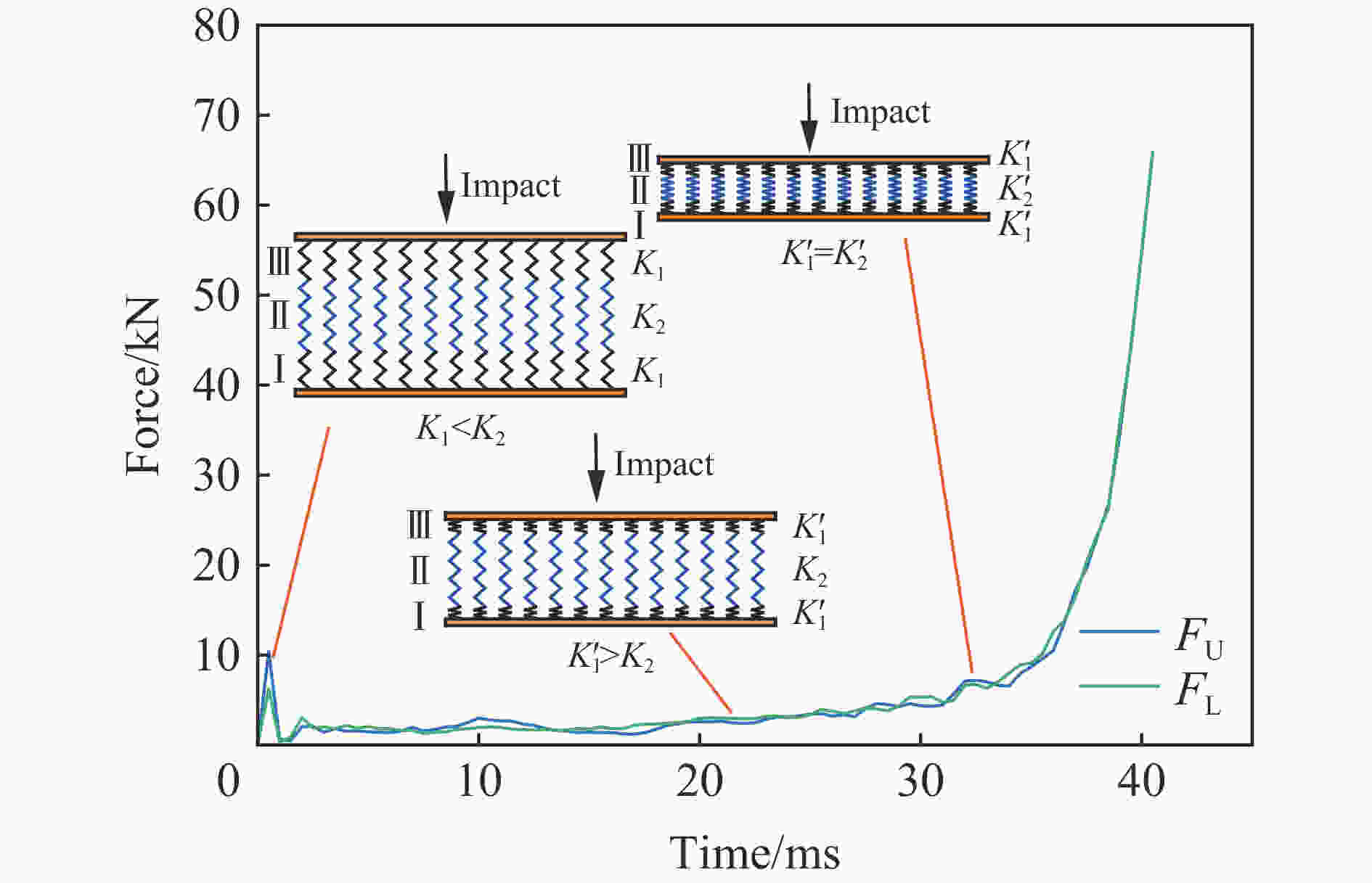

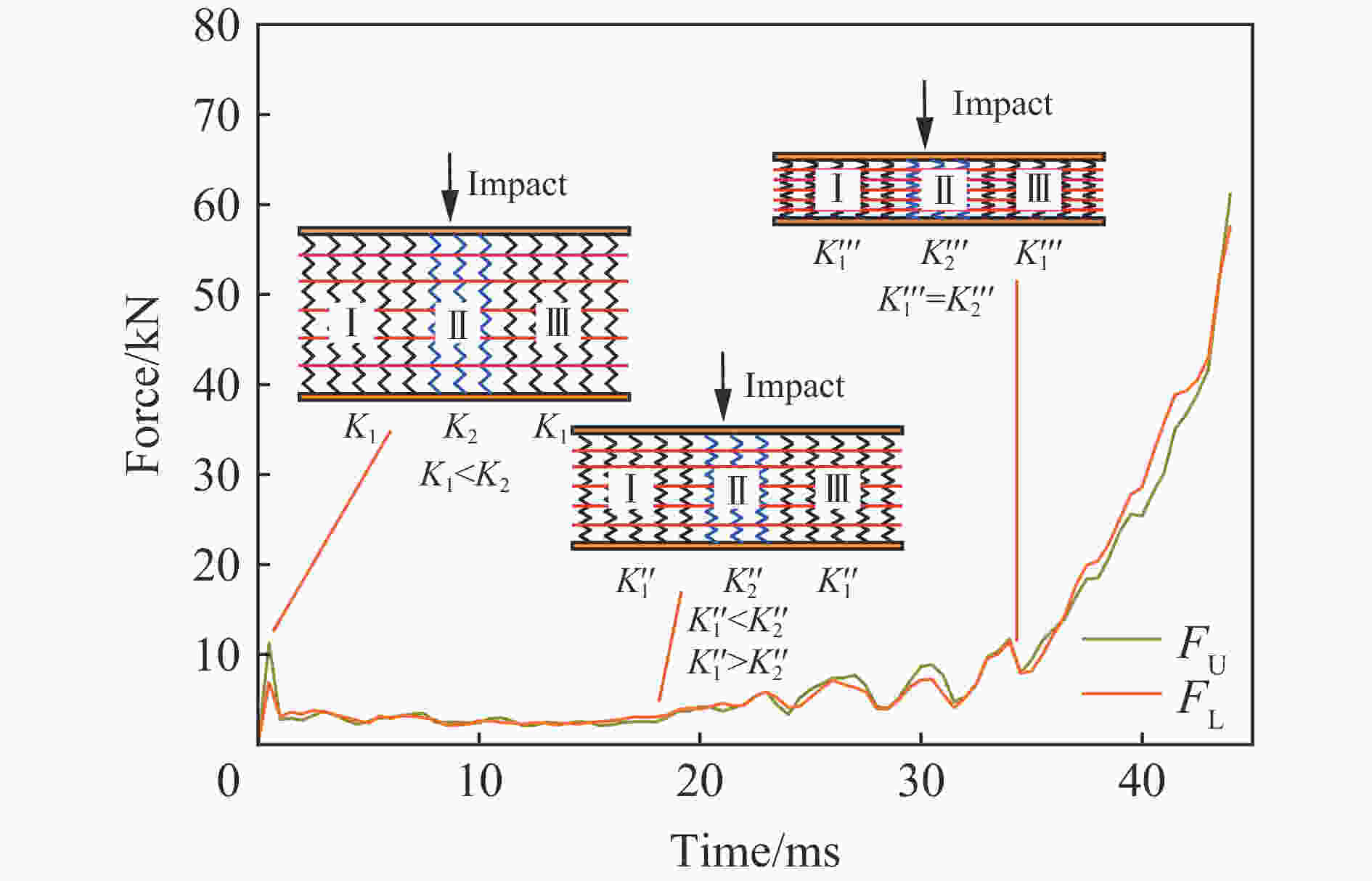

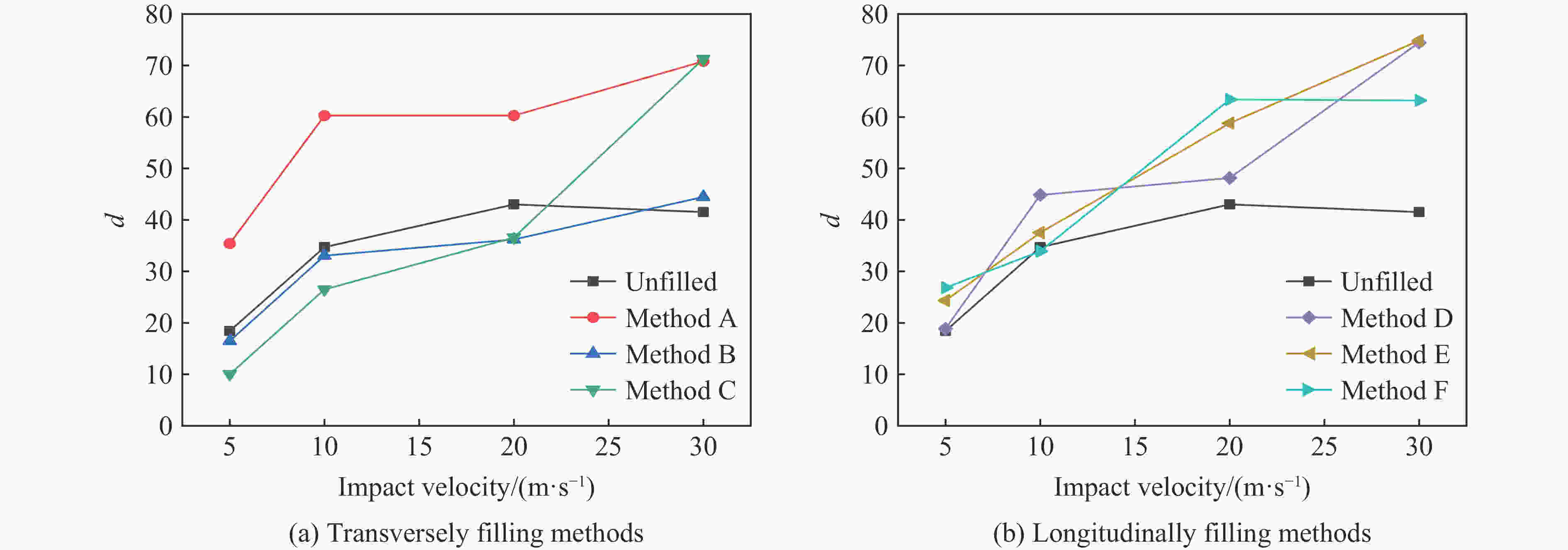

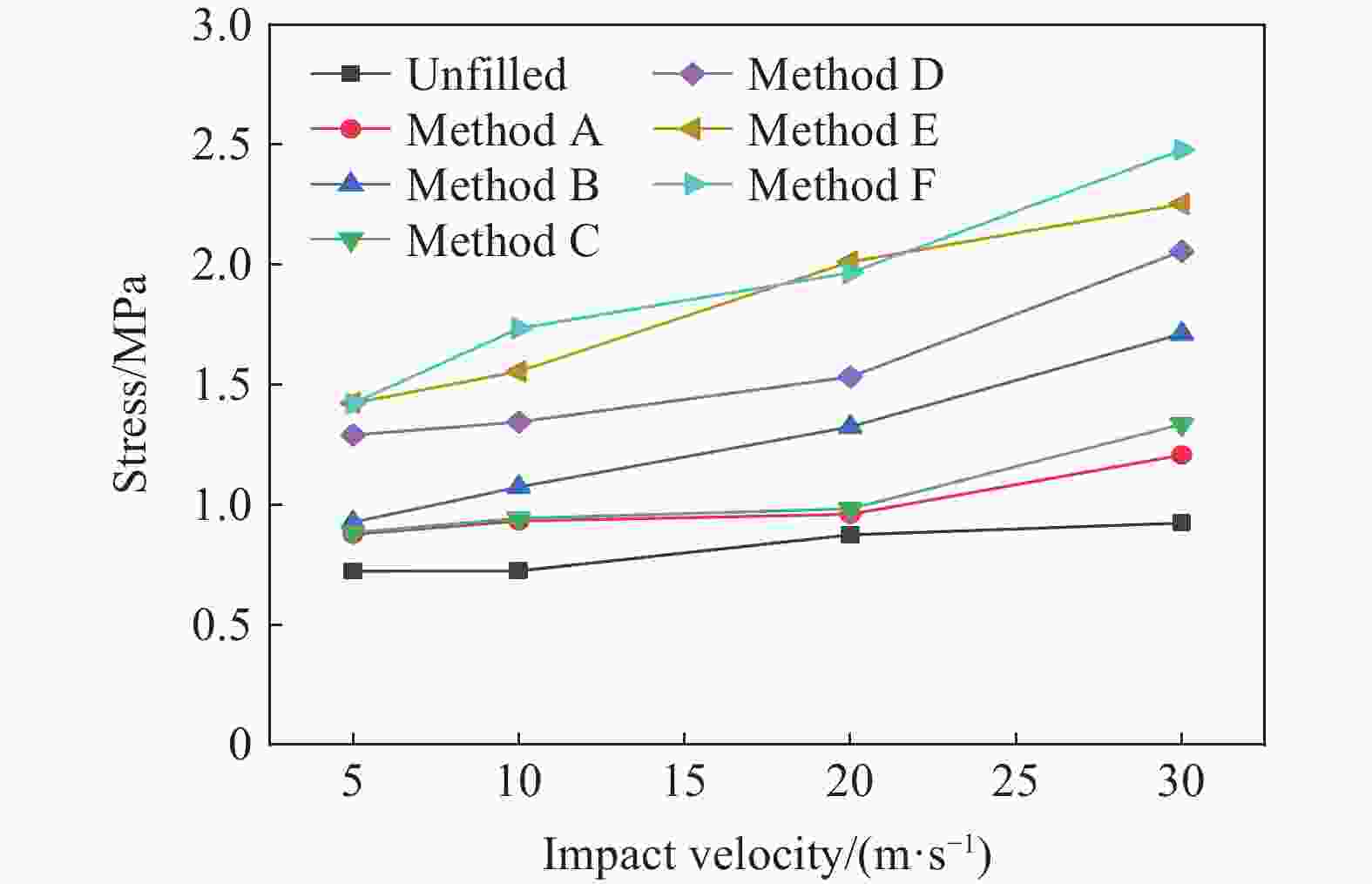

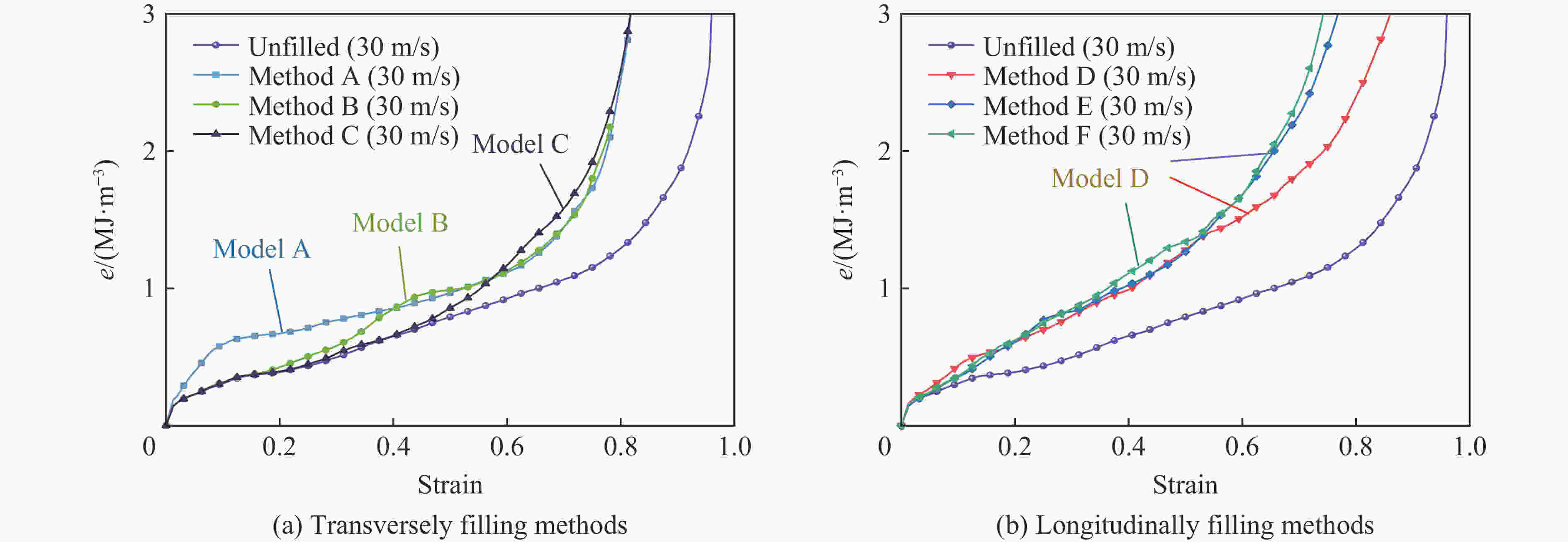

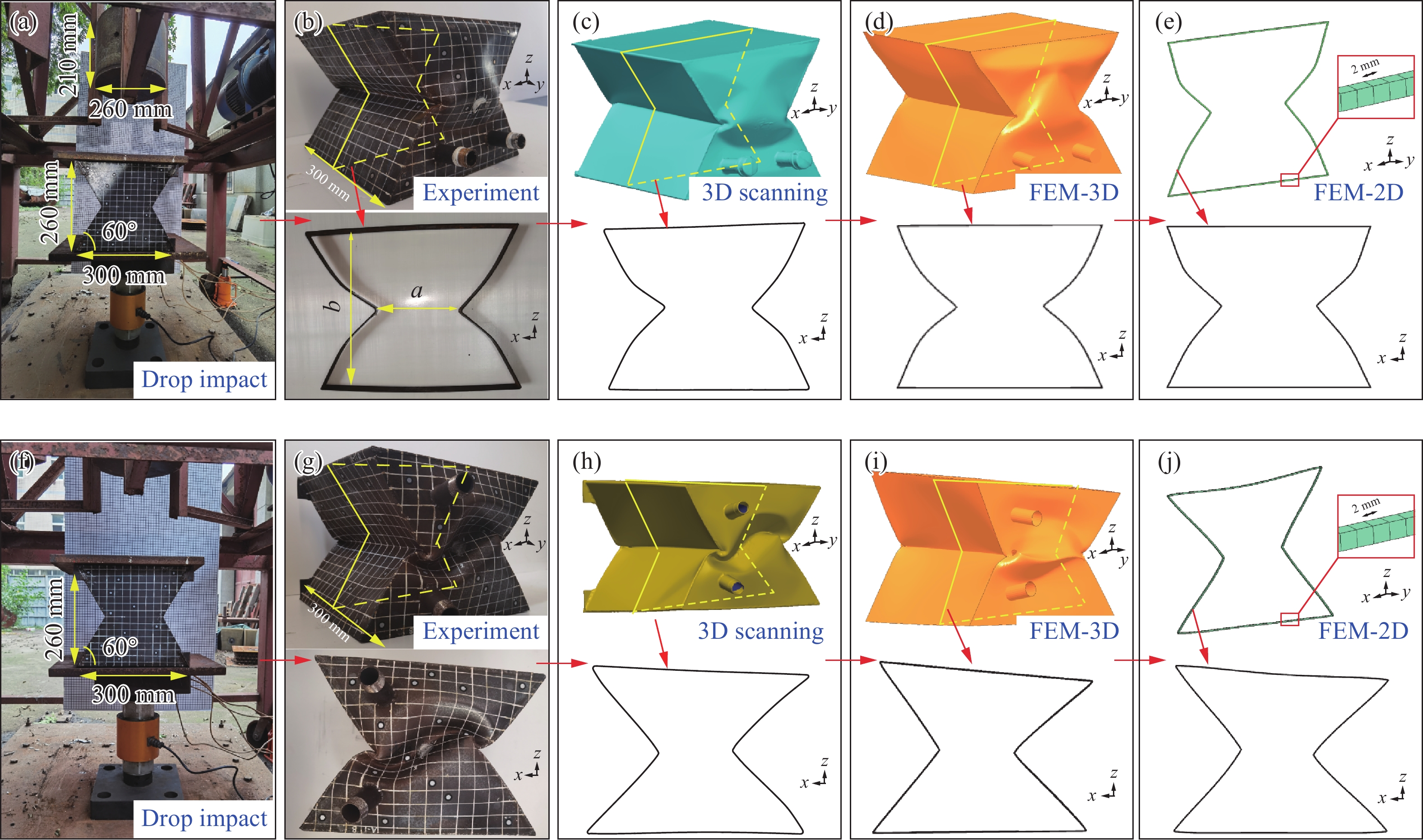

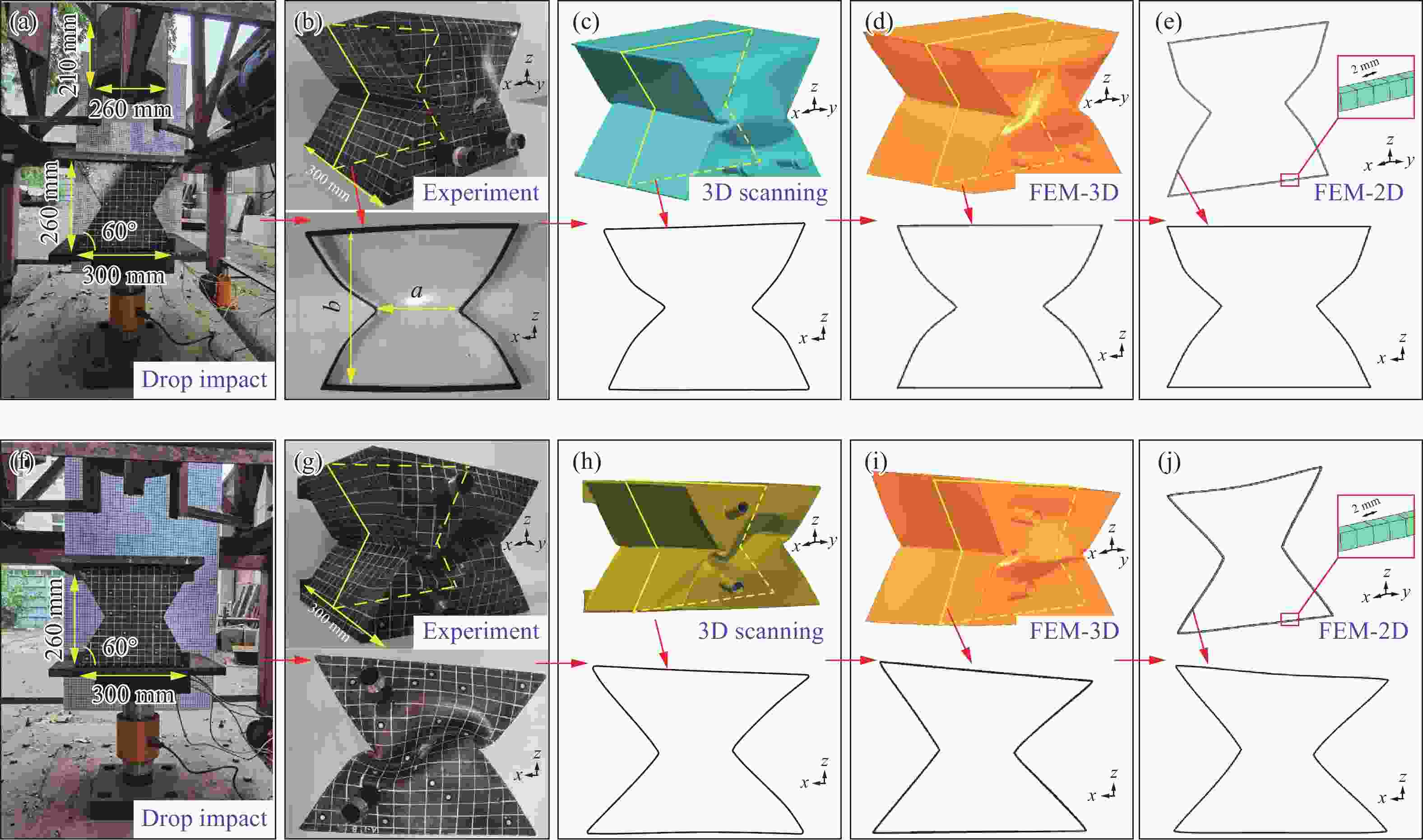

摘要: 为探究部分充液多胞元结构的抗冲击防护性能,结合充液内凹胞元的落锤冲击试验,建立了充液内凹胞元、部分充液内凹多胞元结构的冲击动态特性二维FEM数值分析,计算得到了部分充液内凹多胞元结构的变形破坏模式,讨论了不同冲击速度下部分充液内凹多胞元结构的动力学响应特性。结果表明:在充液胞元破损后,水介质会流入相邻未充液胞元,形成二次鼓胀吸能效应,从而有效提高结构壁面的变形吸能水平;结构中的充液区域和未充液区域的变形破坏模式分别为鼓胀拉伸和屈曲弯折;随着冲击速度的提高,结构的单位体积应变能以及对初始冲击载荷的削弱作用均得到增强。横向充液方式可以等效为变刚度弹簧的串联布置,该方式仅影响结构的局部刚度,纵向充液方式可以等效为多层变刚度弹簧的并联布置,该方式会影响结构的整体刚度;充液区域与未充液区域的等效刚度呈动态变化,结构变形模式由各区域实时的等效刚度决定。当载荷冲击速度较高时,横向和纵向部分充液内凹多胞元结构对初始冲击载荷的削弱能力均优于未充液内凹多胞元结构。Abstract: In order to investigate the impact protection performance of partially liquid filled multicell structure, the two-dimensional FEM numerical analysis of the impact dynamic characteristics of liquid filled inner concave cell structure, unfilled inner concave cell structure, partially liquid filled inner concave multicell structure and unfilled inner concave multicell structure was established by combining the drop hammer impact test of liquid filled and unfilled inner concave cell structure. The deformation/failure mode of partially liquid filled inner concave multicell structure was obtained, and the dynamic response characteristics and energy absorption characteristics of partially liquid filled inner concave multicell structures at different impact velocities were discussed by using the initial load weakening factor and the strain energy per unit volume, respectively. The results show that after the breakage of the liquid filled cell, the water medium will flow into the adjacent unfilled cell, developing a secondary bulging energy absorption effect, thus effectively increasing the deformation energy absorption level of the structure wall; the deformation damage modes of the liquid filled and unfilled regions of the structure are bulging tension and flexural bending, respectively; the strain energy per unit volume of the structure and the weakening effect on the initial impact load are enhanced with the increase of the impact velocity. The transverse filling method can be equated with tandem arrangement of variable stiffness springs, which only affects the local stiffness of the structure. And the longitudinal filling method can be equated with a parallel arrangement of multiple layers of variable stiffness springs, which affects the overall stiffness of the structure; the equivalent stiffness of the filled and unfilled regions changes dynamically, and the deformation mode of the structure is determined by the equivalent stiffness of each region in real time. When the load impact velocity is high, both transverse and longitudinal partially liquid filled inner concave multicell structures are superior to the unfilled inner concave multicell structure in weakening the initial impact load.

-

表 1 水介质模型参数

Table 1. Required parameters for water model

c/(m·s−1) S1 S2 S3 γ0 A EW/(kJ·m−3) V0 1 484 1.979 0 0 0.11 3 0 1 表 2 空气模型参数

Table 2. Required parameters for air model

C0 C1 C2 C3 C4 C5 C6 Ea/(kJ·m−3) 0 0 0 0 0.4 0.4 0 253 表 3 结构模型参数

Table 3. Required parameters for structure model

Rs/(kg·m−3) Es/GPa νs σy/MPa η β C7/s−1 Pc Fs us 7 800 210 0.3 235 0.25 0 0.040 5 5 0.28 0 注:Rs、Es、νs、σ0、η分别为结构的质量密度、杨氏模量、泊松比、屈服应力、切线模量;β为硬化参数,C7和Pc为Cowper-Symonds应变率模型的应变率参数,Fs为侵蚀元素的有效塑性应变,us为速率影响参数。 表 4 充液内凹胞元的侧壁剩余间距及结构剩余高度

Table 4. Rremaining sidewall spacing and remaining structure height of liquid filled concave cell structure

研究方法 侧壁剩余间距/mm 侧壁剩余间距相对误差% 结构剩余高度/mm 结构剩余高度相对误差 落锤试验(3D扫描) 132.5 − 245.7 − 三维FEM模型 142.2 7.32 247.5 0.73% 二维FEM模型 140.6 6.11 244.8 0.37% 表 5 未充液内凹胞元的侧壁剩余间距及结构剩余高度

Table 5. Remaining sidewall spacing and remaining structure height of unfilled concave cell structure

研究方法 侧壁剩余间距/mm 侧壁剩余间距相对误差% 结构剩余高度/mm 结构剩余高度相对误差 落锤试验(3D扫描) 108.9 − 227.2 − 三维FEM模型 106.5 2.20 228.5 0.57% 二维FEM模型 103.2 5.23 220.6 2.90% 表 6 数值分析计算工况

Table 6. Working conditions of numerical simulation

工况 充液方法 充液位置 载荷冲击速度/(m·s−1) 载荷作用时程/ms 工况 充液方法 充液位置 载荷冲击速度/(m·s−1) 载荷作用时程/ms 1 未充液 − 5 96 15 未充液 − 20 24 2 方式A 1和2 5 96 16 方式A 1和2 20 24 3 方式B 3和4 5 96 17 方式B 3和4 20 24 4 方式C 5和6 5 96 18 方式C 5和6 20 24 5 方式D A和L 5 96 19 方式D A和L 20 24 6 方式E C和J 5 96 20 方式E C和J 20 24 7 方式F E和G 5 96 21 方式F E和G 20 24 8 未充液 − 10 48 22 未充液 − 30 16 9 方式A 1和2 10 48 23 方式A 1和2 30 16 10 方式B 3和4 10 48 24 方式B 3和4 30 16 11 方式C 5和6 10 48 25 方式C 5和6 30 16 12 方式D A和L 10 48 26 方式D A和L 30 16 13 方式E C和J 10 48 27 方式E C和J 30 16 14 方式F E和G 10 48 28 方式F E和G 30 16 -

[1] PAN J, FANG H, XU M C, et al. Dynamic performance of a sandwich structure with honeycomb composite core for bridge pier protection from vehicle impact [J]. Thin-Walled Structures, 2020, 157: 107010. DOI: 10.1016/j.tws.2020.107010. [2] ZHOU H Y, ZHANG X J, WANG X J, et al. Response of foam concrete-filled aluminum honeycombs subject to quasi-static and dynamic compression [J]. Composite Structures, 2020, 239: 112025. DOI: 10.1016/j.compstruct.2020.112025. [3] YIN F, CAO W L, XUE S D, et al. Behavior of multicell concrete-filled steel tube columns under eccentric loading [J]. Journal of Constructional Steel Research, 2020, 172: 106218. DOI: 10.1016/j.jcsr.2020.106218. [4] KOCH S, DUVIGNEAU F, ORSZULIK R, et al. Partial filling of a honeycomb structure by granular materials for vibration and noise reduction [J]. Journal of Sound and Vibration, 2017, 393: 30–40. DOI: 10.1016/j.jsv.2016.11.024. [5] XIE S C, YANG S C, YANG C X, et al. Sound absorption performance of a filled honeycomb composite structure [J]. Applied Acoustics, 2020, 162: 107202. DOI: 10.1016/j.apacoust.2019.107202. [6] XIE B, CHENG W L, XU Z M. Studies on the effect of shape-stabilized PCM filled aluminum honeycomb composite material on thermal control [J]. International Journal of Heat and Mass Transfer, 2015, 91: 135–143. DOI: 10.1016/j.ijheatmasstransfer.2015.07.108. [7] KUMAR S J A, KUMAR S J A. Low-velocity impact damage and energy absorption characteristics of stiffened syntactic foam core sandwich composites [J]. Construction and Building Materials, 2020, 246: 118412. DOI: 10.1016/j.conbuildmat.2020.118412. [8] 杨德庆, 马涛, 张梗林. 舰艇新型宏观负泊松比效应蜂窝舷侧防护结构 [J]. 爆炸与冲击, 2015, 35(2): 243–248. DOI: 10.11883/1001-1455(2015)02-0243-06.YANG D Q, MA T, ZHANG G L. A novel auxetic broadside defensive structure for naval ships [J]. Explosion and Shock Waves, 2015, 35(2): 243–248. DOI: 10.11883/1001-1455(2015)02-0243-06. [9] GIBSON L J, ASHBY M F. Cellular solids: structure and properties [M]. Cambridge: Cambridge University Press, 1997. [10] QI D X, LU Q Y, HE C W, et al. Impact energy absorption of functionally graded chiral honeycomb structures [J]. Extreme Mechanics Letters, 2019, 32: 100568. DOI: 10.1016/j.eml.2019.100568. [11] 任毅如, 蒋宏勇, 金其多, 等. 仿生负泊松比拉胀内凹蜂窝结构耐撞性 [J]. 航空学报, 2021, 42(3): 223978. DOI: 10.7527/S1000-6893.2020.23978.REN Y R, JIANG H Y, JIN Q D, et al. Crashworthiness of bio-inspired auxetic reentrant honeycomb with negative Poisson’s ratio [J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(3): 223978. DOI: 10.7527/S1000-6893.2020.23978. [12] ZHONG R C, FU M H, CHEN X, et al. A novel three-dimensional mechanical metamaterial with compression-torsion properties [J]. Composite Structures, 2019, 226: 111232. DOI: 10.1016/j.compstruct.2019.111232. [13] MONTGOMERY S M, KUANG X, ARMSTRONG C D, et al. Recent advances in additive manufacturing of active mechanical metamaterials [J]. Current Opinion in Solid State and Materials Science, 2020, 24(5): 100869. DOI: 10.1016/j.cossms.2020.100869. [14] ZHOU H Y, JIA K C, WANG X J, et al. Experimental and numerical investigation of low velocity impact response of foam concrete filled auxetic honeycombs [J]. Thin-Walled Structures, 2020, 154: 106898. DOI: 10.1016/j.tws.2020.106898. [15] XUE T, MENG J G, JIN Z H. Study on the performance of honeycomb ceramics carrier based on the ordinary paper [J]. Materials Science and Engineering: A, 2011, 528(29/30): 8512–8516. DOI: 10.1016/j.msea.2011.07.051. [16] CHEN X J, YU G C, WANG Z X, et al. Enhancing out-of-plane compressive performance of carbon fiber composite honeycombs [J]. Composite Structures, 2021, 255: 112984. DOI: 10.1016/j.compstruct.2020.112984. [17] WU H H, SUI L, ZHOU T H, et al. Estimation of lateral stiffness for gypsum-filled cold-formed steel shear walls [J]. Structures, 2021, 32: 28–37. DOI: 10.1016/j.istruc.2021.02.067. [18] MOHAMADI Y, AHMADI H, RAZMKHAH O, et al. Axial crushing responses of aluminum honeycomb structures filled with elastomeric polyurethane foam [J]. Thin-Walled Structures, 2021, 164: 107785. DOI: 10.1016/j.tws.2021.107785. [19] LIU Q, FU J, WANG J S, et al. Axial and lateral crushing responses of aluminum honeycombs filled with EPP foam [J]. Composites Part B: Engineering, 2017, 130: 236–247. DOI: 10.1016/j.compositesb.2017.07.041. [20] BAI J W, LIAO X, HUANG E B, et al. Control of the cell structure of microcellular silicone rubber/nanographite foam for enhanced mechanical performance [J]. Materials & Design, 2017, 133: 288–298. DOI: 10.1016/j.matdes.2017.07.064. [21] GAO S Z, LI D, HOU H L, et al. Investigation on dynamic response of liquid-filled concave cell structures subject to the penetration of high-speed projectiles [J]. Thin-Walled Structures, 2020, 157: 107119. DOI: 10.1016/j.tws.2020.107119. [22] 何强, 马大为, 张震东. 含随机填充孔圆形蜂窝结构的面内冲击性能 [J]. 爆炸与冲击, 2015, 35(3): 401–408. DOI: 10.11883/1001-1455-(2015)03-0401-08.HE Q, MA D W, ZHANG Z D. In-plane impact behavior of circular honeycomb structures randomly filled with rigid inclusions [J]. Explosion and Shock Waves, 2015, 35(3): 401–408. DOI: 10.11883/1001-1455-(2015)03-0401-08. [23] CHEN C, LU T J, FLECK N A. Effect of inclusions and holes on the stiffness and strength of honeycombs [J]. International Journal of Mechanical Sciences, 2001, 43(2): 487–504. DOI: 10.1016/S0020-7403(99)00122-8. [24] PRAKASH O, BICHEBOIS P, BRECHET Y, et al. A note on the deformation behaviour of two-dimensional model cellular structures [J]. Philosophical Magazine A, 1996, 73(3): 739–751. DOI: 10.1080/01418619608242994. [25] NAKAMOTO H, ADACHI T, ARAKI W. In-plane impact behavior of honeycomb structures filled with linearly arranged inclusions [J]. International Journal of Impact Engineering, 2009, 36(8): 1019–1026. DOI: 10.1016/j.ijimpeng.2009.01.004. [26] NAKAMOTO H, ADACHI T, ARAKI W. In-plane impact behavior of honeycomb structures randomly filled with rigid inclusions [J]. International Journal of Impact Engineering, 2009, 36(1): 73–80. DOI: 10.1016/j.ijimpeng.2008.04.004. [27] 闫晓刚, 张勇, 林继铭, 等. 新颖圆形多胞复合填充结构的耐撞性 [J]. 复合材料学报, 2018, 35(8): 2166–2176. DOI: 10.13801/j.cnki.fhclxb.20170906.001.YAN X G, ZHANG Y, LIN J M, et al. Crashworthiness for novel circular multi-cell composite filling structures [J]. Acta Materiae Compositae Sinica, 2018, 35(8): 2166–2176. DOI: 10.13801/j.cnki.fhclxb.20170906.001. [28] BAYKASOĞLU A, BAYKASOĞLU C, CETIN E. Multi-objective crashworthiness optimization of lattice structure filled thin-walled tubes [J]. Thin-Walled Structures, 2020, 149: 106630. DOI: 10.1016/j.tws.2020.106630. [29] KIM D H, KIM S W. Evaluation of bird strike-induced damages of helicopter composite fuel tank assembly based on fluid-structure interaction analysis [J]. Composite Structures, 2019, 210: 676–686. DOI: 10.1016/j.compstruct.2018.11.086. [30] 金键, 朱锡, 侯海量, 等. 大型舰船在水下接触爆炸下的毁伤与防护研究综述 [J]. 爆炸与冲击, 2020, 40(11): 111401. DOI: 10.11883/bzycj-2020-0105.JIN J, ZHU X, HOU H L, et al. Review on the damage and protection of large naval warships subjected to underwater contact explosions [J]. Explosion and Shock Waves, 2020, 40(11): 111401. DOI: 10.11883/bzycj-2020-0105. [31] GODOY L A. Buckling of vertical oil storage steel tanks: review of static buckling studies [J]. Thin-Walled Structures, 2016, 103: 1–21. DOI: 10.1016/j.tws.2016.01.026. [32] ZHANG Y H, WU X D, LU G Y, et al. Experimental and numerical studies on dynamic responses of liquid-filled hemispherical shell under axial impact [J]. Thin-Walled Structures, 2018, 131: 606–618. DOI: 10.1016/j.tws.2018.07.003. [33] CHEN Y, HUANG W, CONSTANTINI S. Blast shock wave mitigation using the hydraulic energy redirection and release technology [J]. PLoS One, 2012, 7(6): e39353. DOI: 10.1371/journal.pone.0039353. [34] 金键, 侯海量, 吴梵, 等. 战斗部近炸下防护液舱破坏机理分析 [J]. 国防科技大学学报, 2019, 41(2): 163–169. DOI: 10.11887/j.cn.201902024.JIN J, HOU H L, WU F, et al. Analysis of failure mechanism on protective liquid cabin under warhead close explosion [J]. Journal of National University of Defense Technology, 2019, 41(2): 163–169. DOI: 10.11887/j.cn.201902024. [35] JIN J, HOU H L, CHEN P Y, et al. Experimental study on the combined damage of liquid cabin structure subjected to charge explosion with preset fragments [J]. International Journal of Impact Engineering, 2019, 130: 19–26. DOI: 10.1016/j.ijimpeng.2019.04.001. -

下载:

下载: