Visualization experimental research of oil gas vapor cloud deflagration in large-scale unconfined space

-

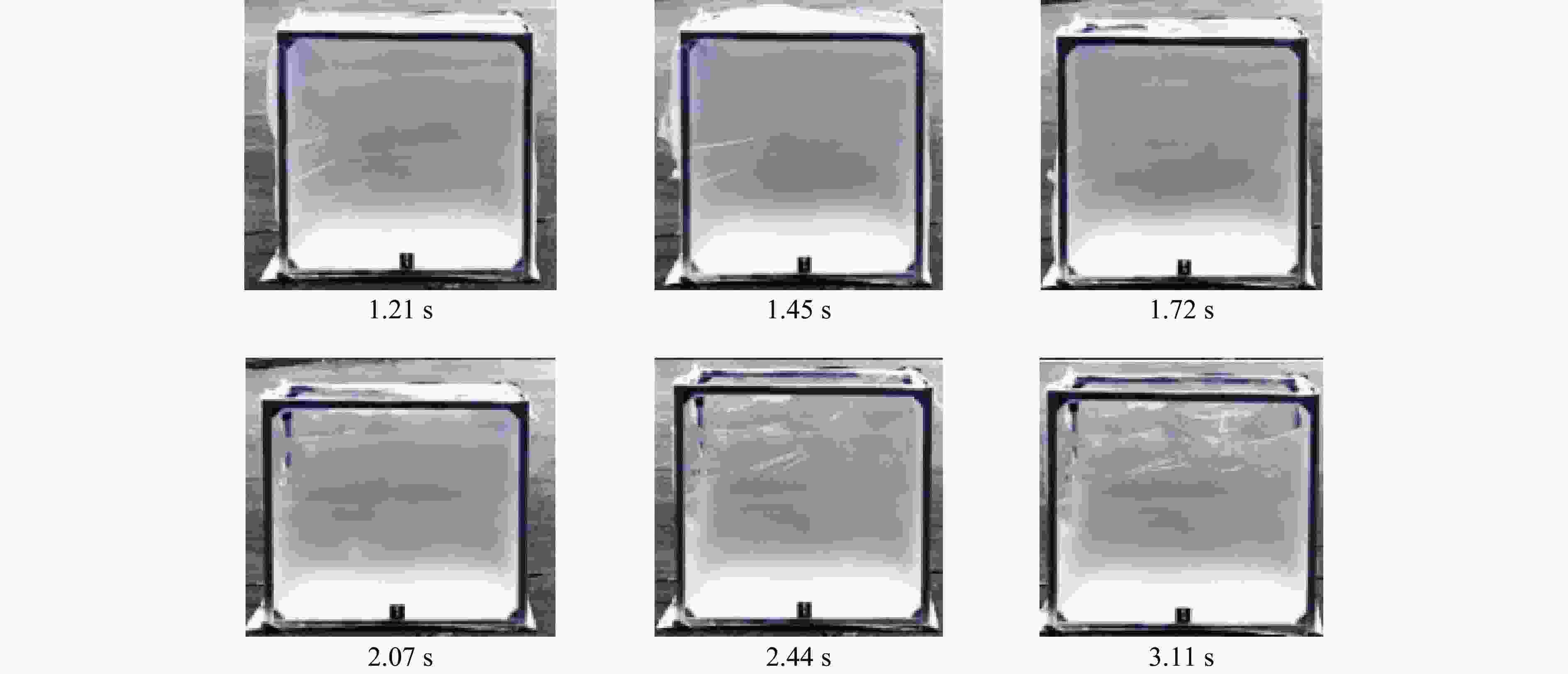

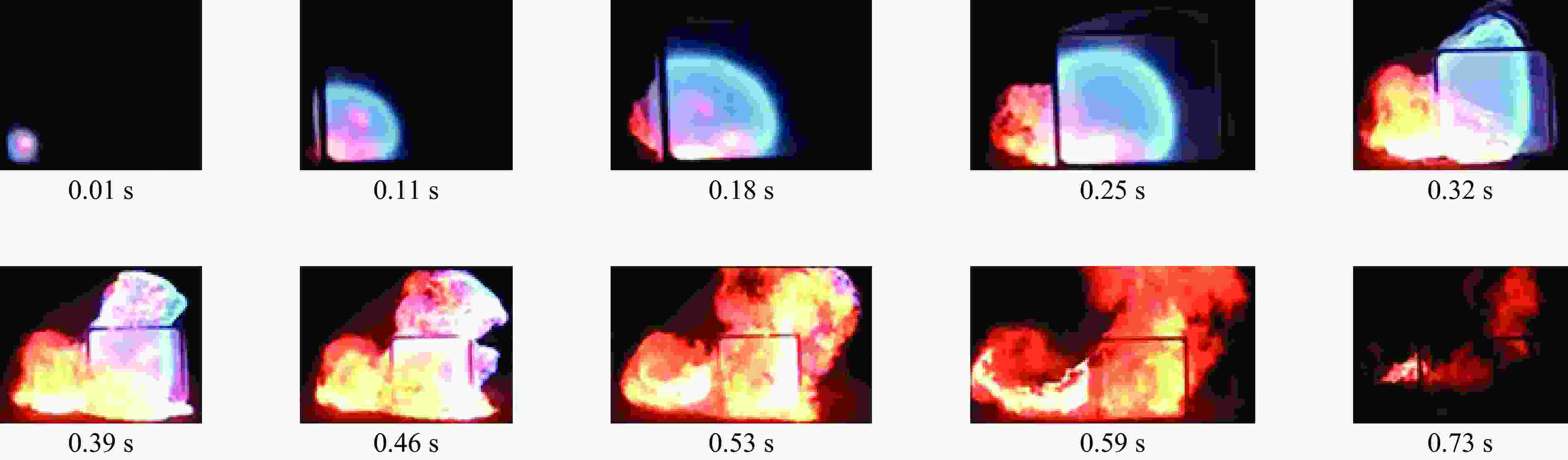

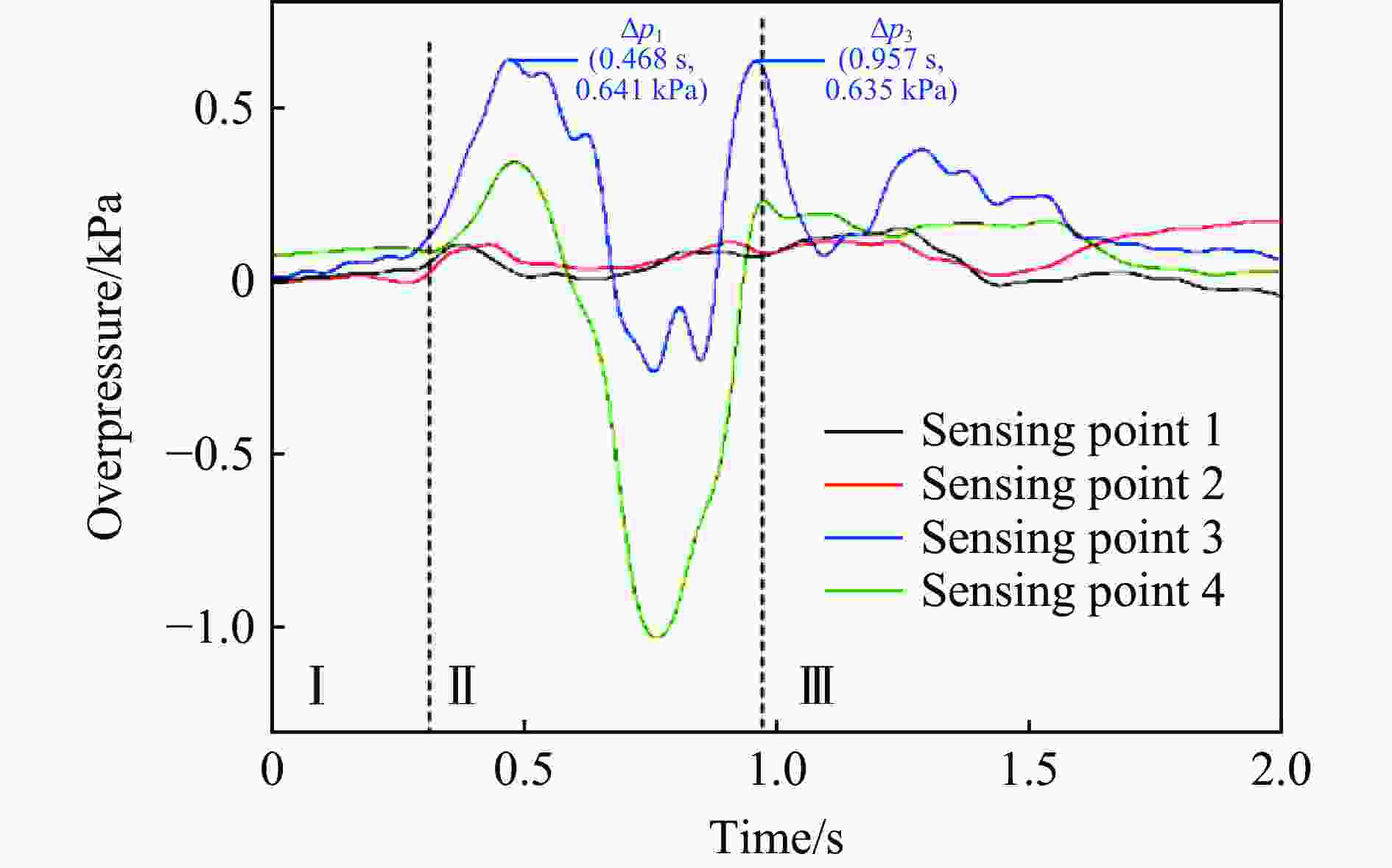

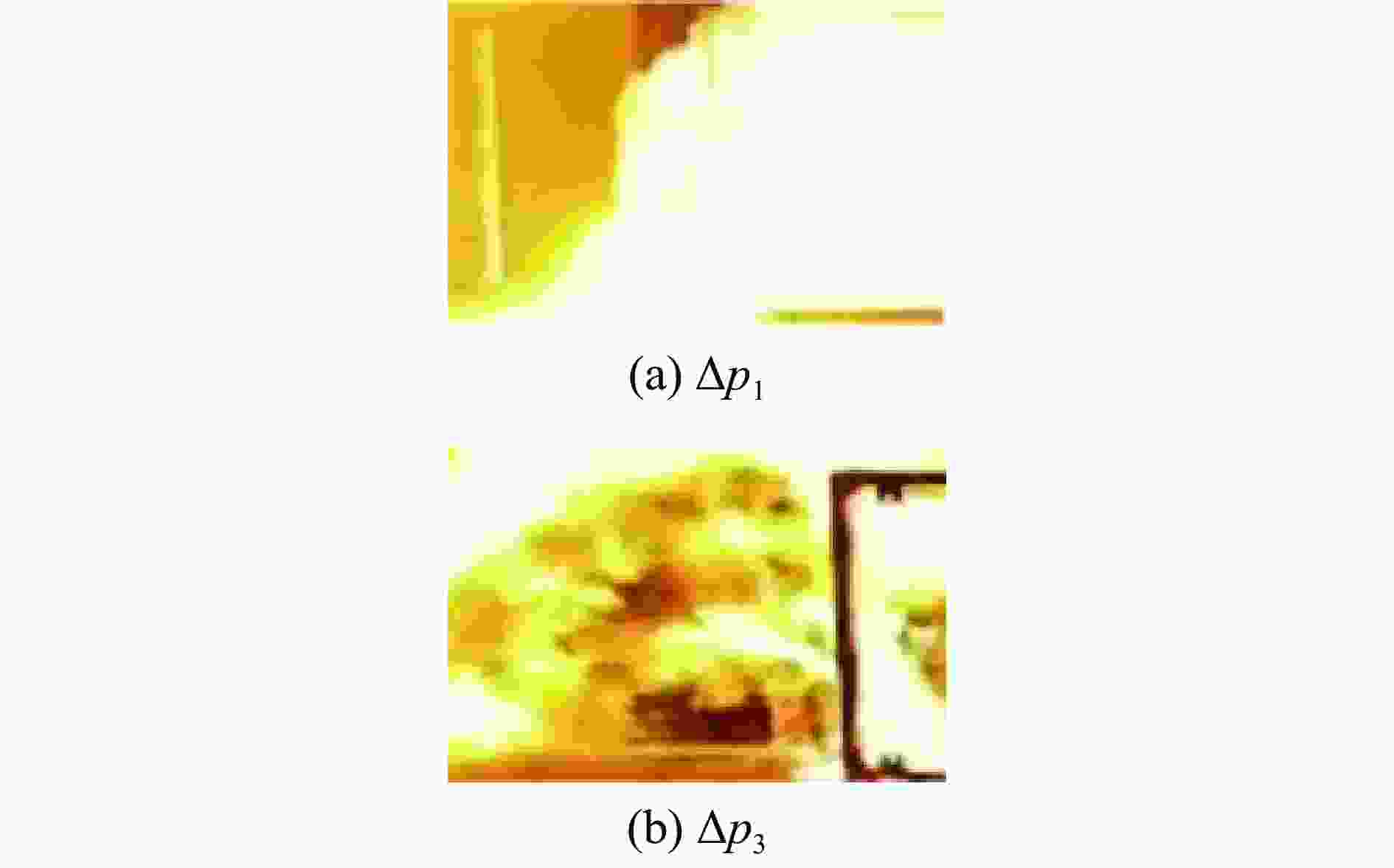

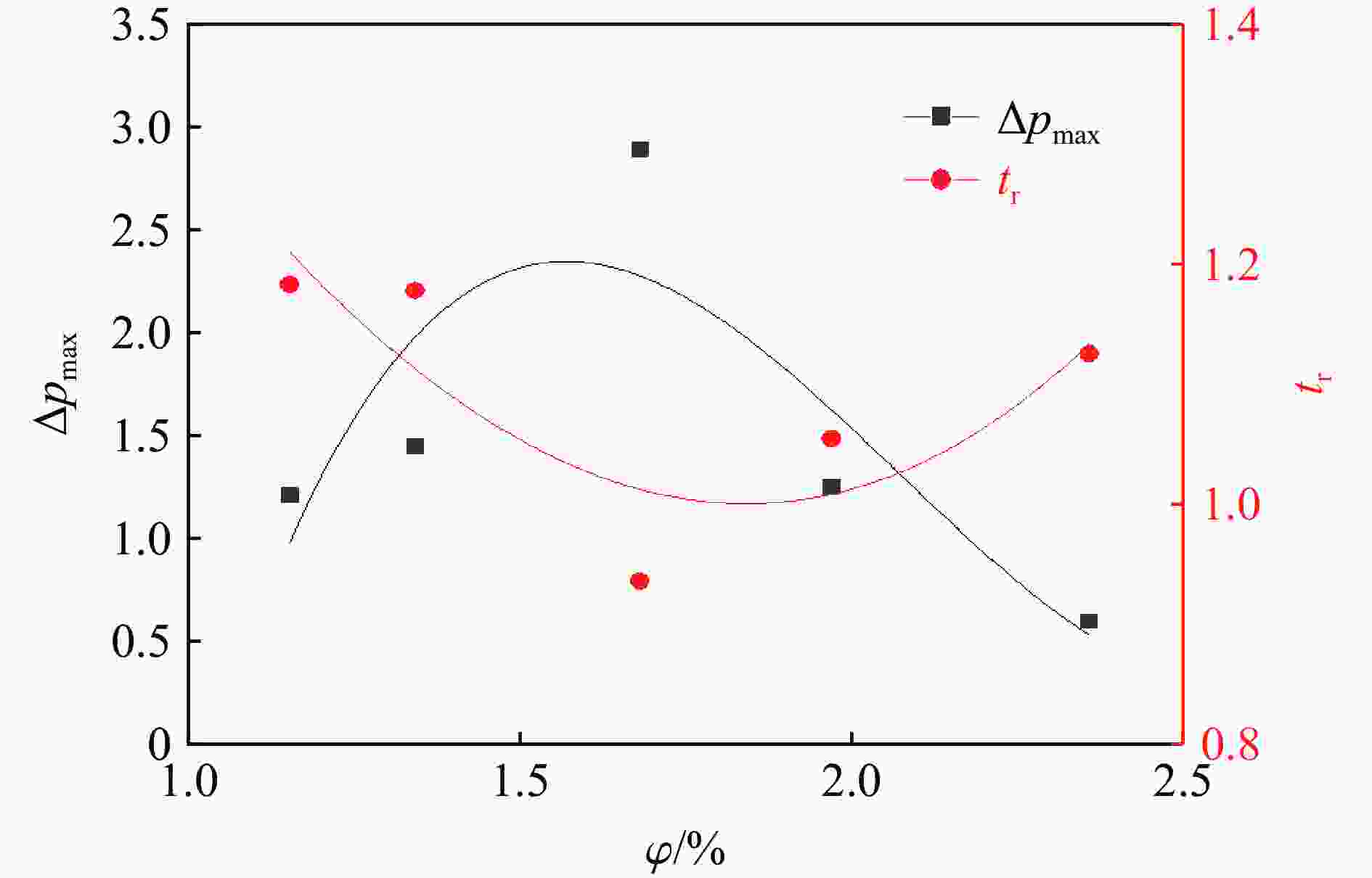

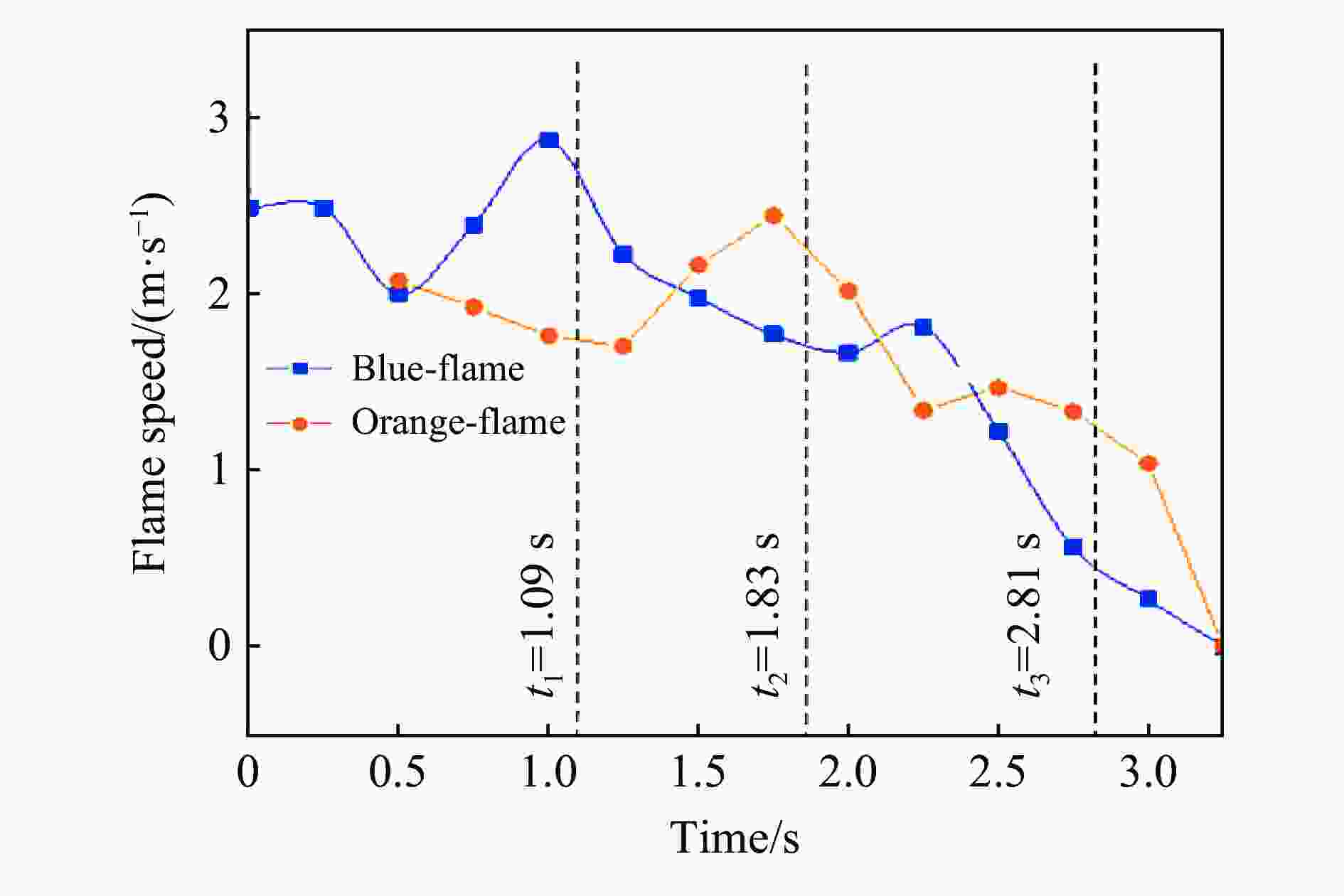

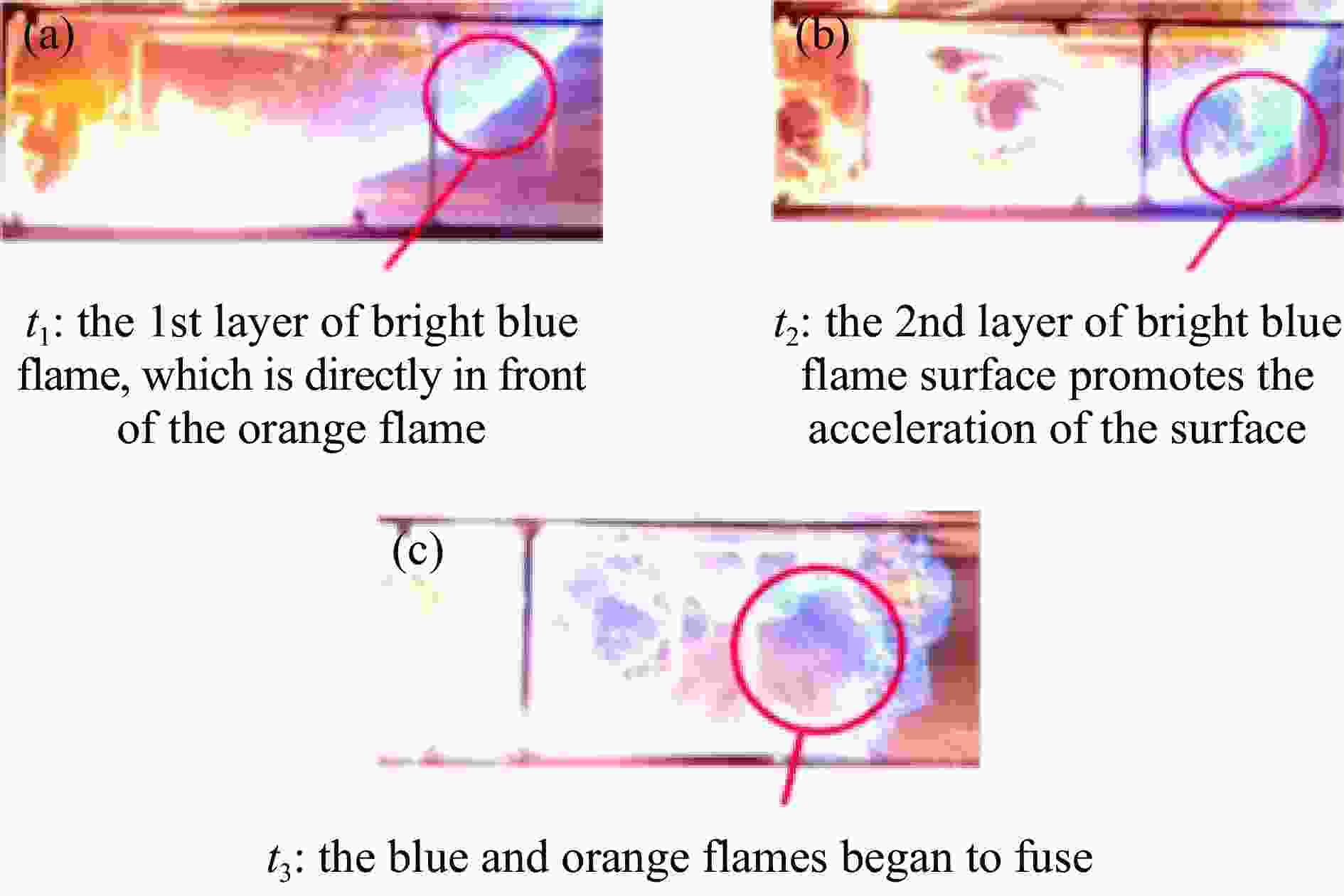

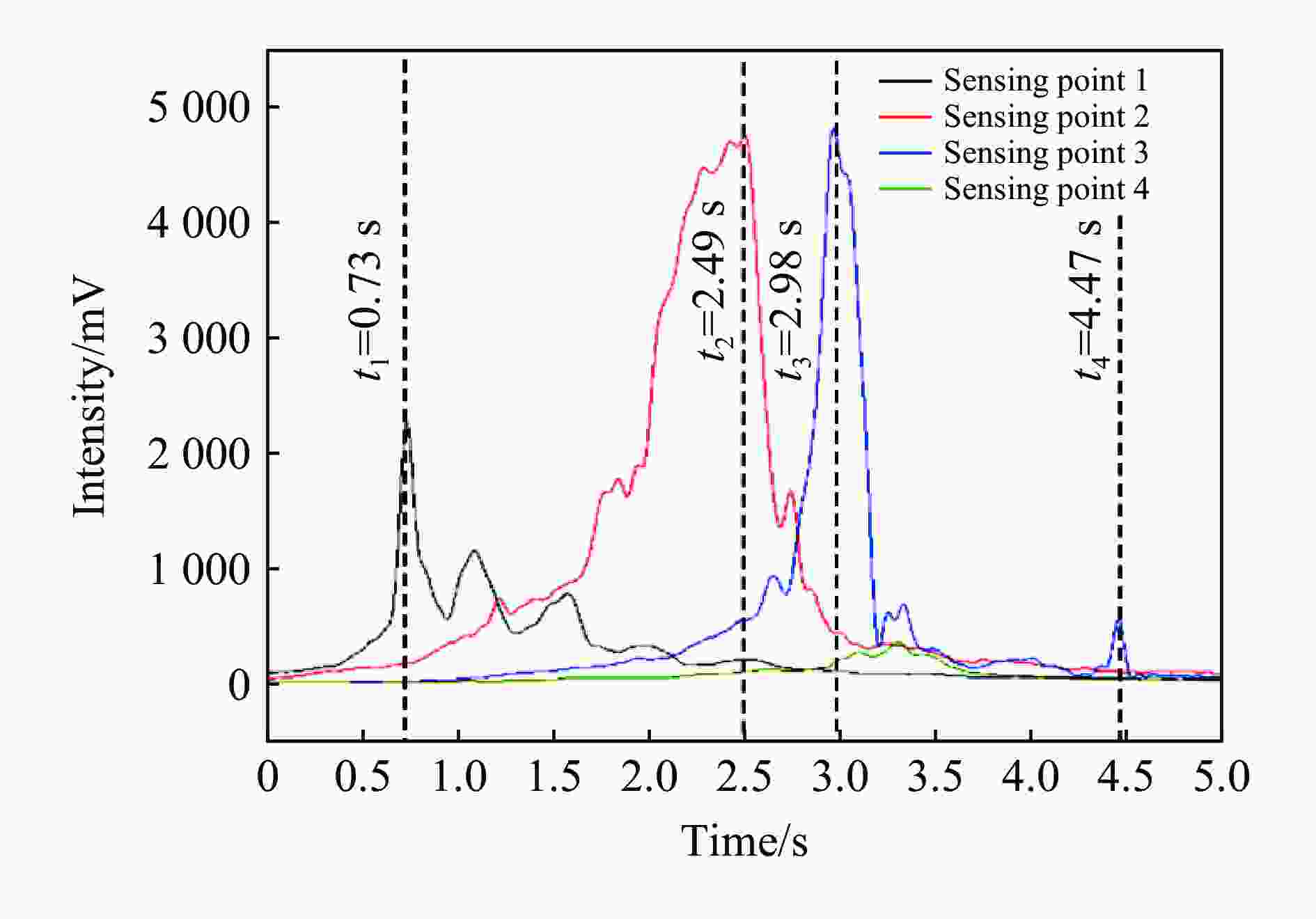

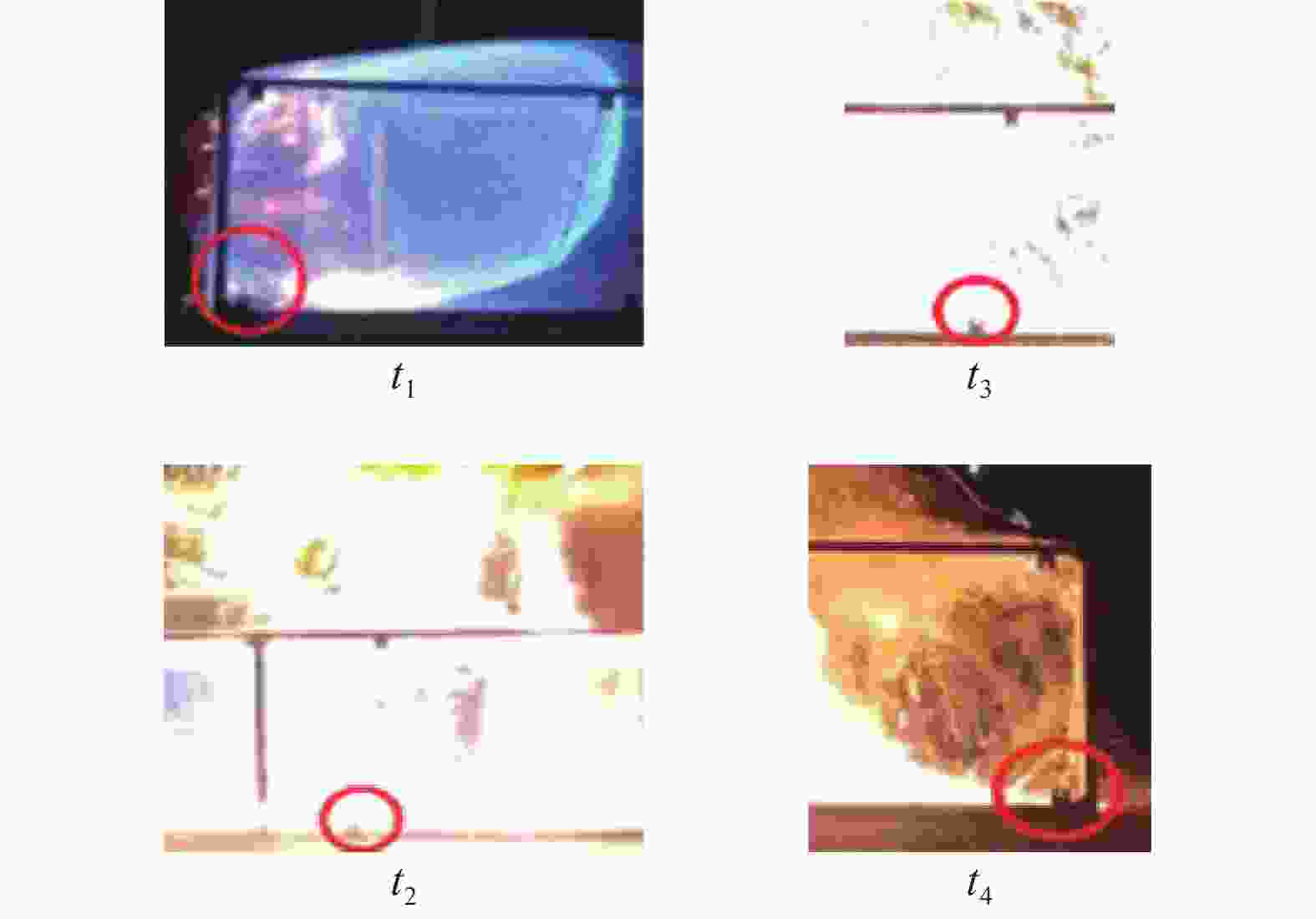

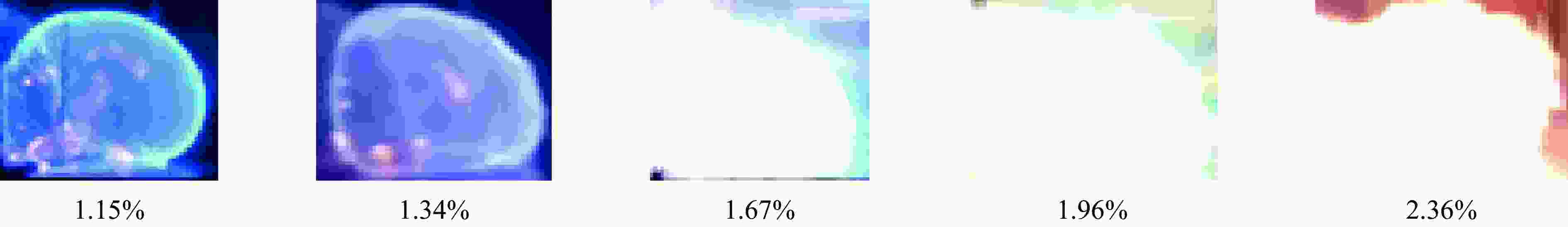

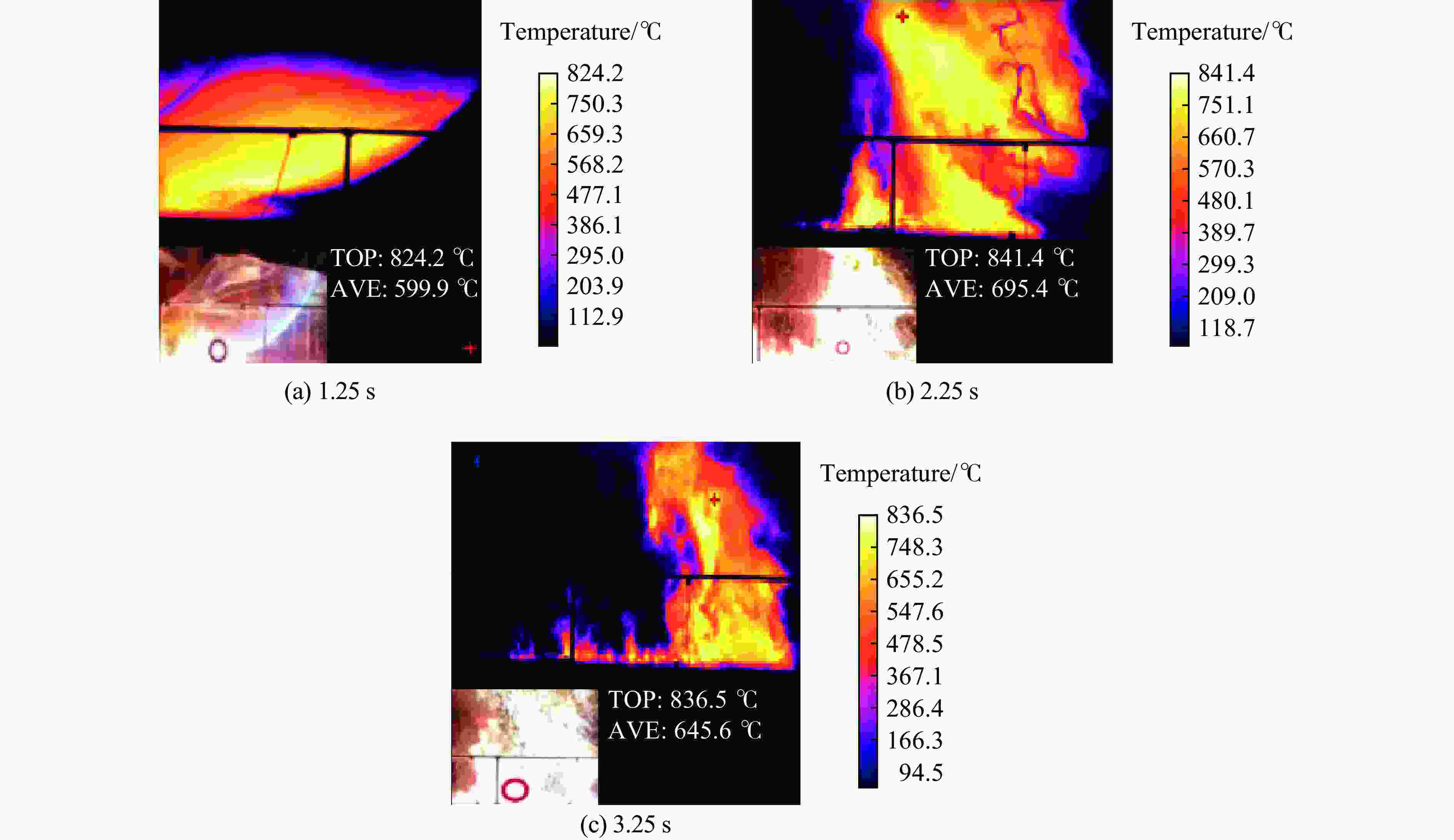

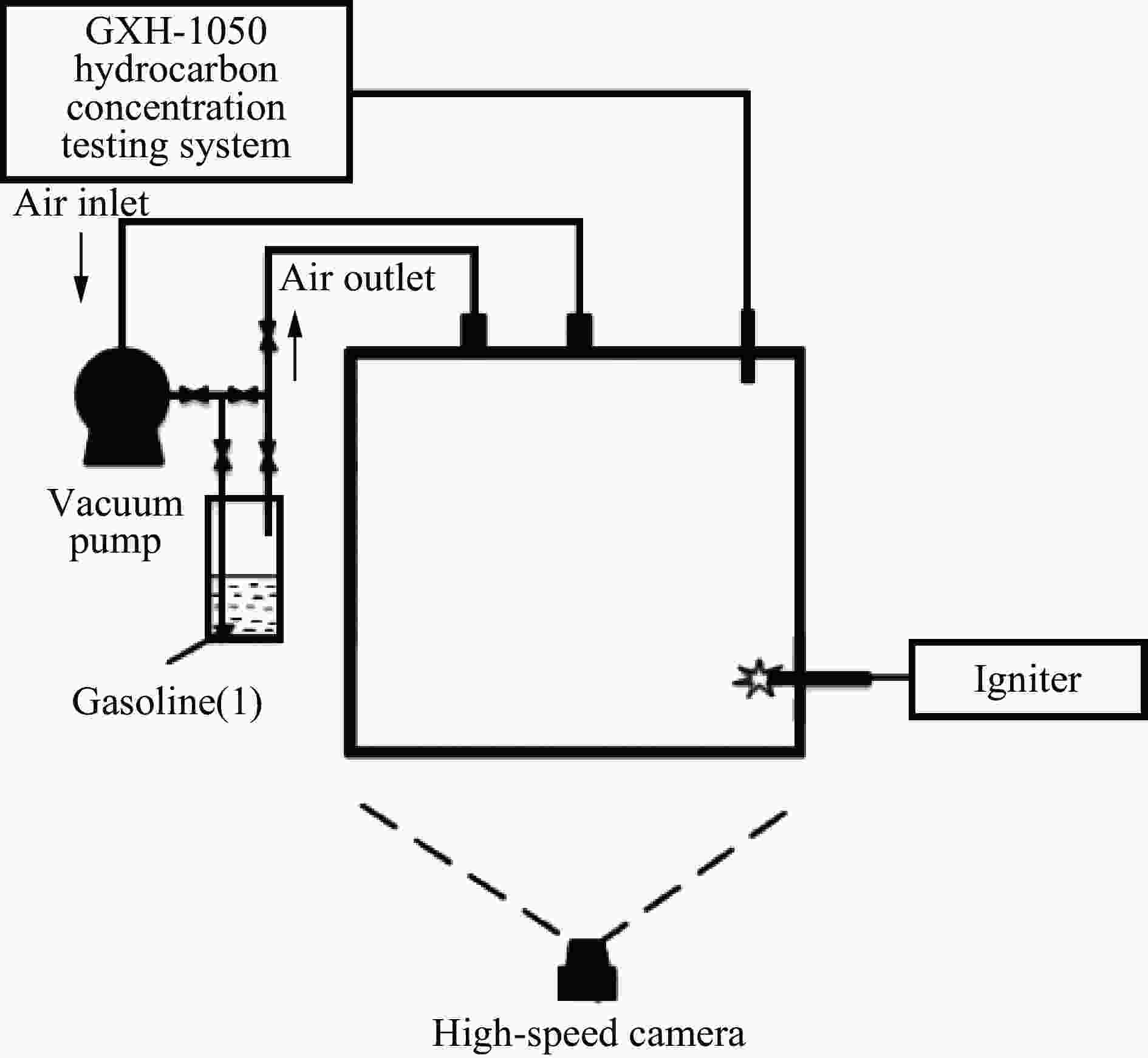

摘要: 为探究大尺度开敞空间油气爆燃动态发展过程,利用自行设计并搭建的大尺度开敞空间油气爆燃模拟实验条件测试系统,通过可视化监测手段及对压力与火焰信号的采集获得了油气爆燃过程中关键参数的变化规律。结果表明:在不同的初始油气浓度下引燃预混油气混合物将形成三类主要的燃烧模式;油气浓度接近爆炸极限范围内时火焰主要分布于台架的内场、点火面后方及正上方,根据动态超压时序发展曲线可将爆燃过程划分为3个子阶段;爆燃火焰传播速度呈波动性下降趋势,并可与超压发展阶段相互耦合;随着初始油气浓度的增加,超压峰值呈现出先减后增的趋势,形成峰值耗时则呈现相反规律;爆燃火焰的温度梯度与火焰行进方向相关,火焰峰面温度梯度通常小于尾端火焰;爆燃辐射峰值形成时间与火焰强度相比具有一定的延时性,爆燃传播末期更易于形成高强度辐射。Abstract: An oil-gas deflagration simulation experimental condition system in the large-scale unconfined space was independently designed and built against the theoretical requirements for safety monitoring and controlling of oil-gas mixture explosions in large-scale unconfined spaces. To begin with, pressure and flame signals, variations in global temperature and radiation indicators in various areas of the system were accurately collected through sensors, thermal imagers and radiometers. Also, high-speed cameras were adopted to capture the dynamic development of flames during deflagration, acquiring specific behavior characteristics of flame shape. The results show that the oil-gas combustion modes in the unconfined space can be divided into fireless gas cloud firing, oil-gas combustion with open flame, and oil-gas deflagration with compression wave, according to the differences in initial oil-gas concentration. To be specific, the flame generated from oil-gas deflagration is in the mirror-image shape of “L”, which can be found in the infield of the bench as well as behind and right above the ignition surface. Moreover, several peaks can be found in the dynamic overpressure sequence development curve. Based on the peak type, the whole deflagration process can be partitioned into stable spread, flame bleeding, and burning collapse. Specifically, the high-intensity area of deflagration flame could be primarily observed at the 1/3 to 2/3 of the bench, with the peak reaching up to 4816.03 mV. It can be observed that the flame is principally presented in blue and orange, and the flame speed is downward in fluctuation along with the deflagration process. It can also be coupled with the overpressure development stage. After that, the overpressure peak is presented in a trend of first decreasing and then increasing along with the increase in the initial oil-gas concentration, whereas time consumed in peak forming is displayed in an opposite law. Note that both can fitted using the cubic polynomial. Besides, temperature gradient of deflagration flames is associated with the flame heading, and the temperature gradient of the flame front surface is typically smaller than that of the tail flame. What’s more, the formation time of radiation peak of deflagration has a certain delay in comparison to the flame intensity, causing that high-intensity radiation can be easily formed at the end of deflagration spreading. To sum up, key parameter supports and theoretical bases are provided for the online monitoring and explosion suppression of oil gas cloud deflagration in the large-scale unconfined space, presenting a significance in guiding the research and development of explosion suppression equipment.

-

表 1 爆燃内场超压参数特征

Table 1. Internal overpressure parameter characteristics during deflagration

采集点 初始油量/L φ/% 点火电压/V Δpmax/kPa tr/s Emax/(kPa2·s−1) 1 2 1.34(16℃) 15 1.275 0.876 23.560 2 1.447 1.178 2.092 3 0.215 1.496 0.221 4 0.083 2.817 0.008 注:Δpmax为最大爆燃超压峰值,tr为到达爆燃峰值的用时. 表 2 爆燃外场超压参数特征

Table 2. External overpressure parameter characteristics during deflagration

采集点 初始油量/L φ/% 点火电压/V Δpmax/kPa tr/s Emax/(kPa2·s−1) 1 2 1.34(16℃) 15 0.155 1.495 0.039 2 0.112 1.151 0.075 3 0.641 0.717 3.699 4 0.313 0.725 0.233 表 3 爆燃高位超压参数特征

Table 3. High ground overpressure parameter characteristics during deflagration

采集点 初始油量/L φ/% 点火电压/V Δpmax/kPa tr/s Emax/(kPa2·s−1) 1 2 1.34(16℃) 15 1.123 1.193 1.057 2 0.996 1.166 4.636 3 0.701 1.138 0.432 4 2.262 1.695 3.896 表 4 不同油气浓度下超压峰值和到达峰值耗时分布

Table 4. Overpressure peaks & time to reach peaks under different concentrations

油料体积/L φ/% 点火电压/V Δpmax/kPa tr/s Emax/(kPa2·s−1) 1.5 1.15% 15 1.202 1.183 1.221 2 1.34% 1.447 1.178 2.092 2.5 1.68% 2.895 0.935 8.964 3 1.97% 1.246 1.054 1.469 3.5 2.36% 0.591 1.125 0.310 表 5 不同初始油气浓度下火焰颜色特征

Table 5. The flame color under different concentrations

油气体积/L φ/% 点火电压/V 火焰传播特征 1.5 1.15 15 蓝色锋面+内部斜上方45°橙色蘑菇状火焰 2.0 1.34 淡蓝色锋面+内部斜上方45°橙色蘑菇状火焰 2.5 1.68 亮蓝色(高亮) 3.0 1.97 蓝绿色(高亮) 3.5 2.36 橙色(高亮) -

[1] LI D, ZHANG Q, MA Q J, et al. Influence of built-in obstacles on unconfined vapor cloud explosion [J]. Journal of Loss Prevention in the Process Industries, 2016, 43: 449–456. DOI: 10.1016/j.jlp.2016.07.007. [2] 郭丹彤, 吕淑然. 受限空间障碍物截面变化对混合气体爆炸特性参数的影响研究 [J]. 中国安全生产科学技术, 2016, 12(2): 83–87. DOI: 10.11731/j.issn.1673-193x.2016.02.015.GUO D T, LYU S R. Research on influence to characteristic parameters of mixed gas explosion by section variation of obstacle in confined space [J]. Journal of Safety Science and Technology, 2016, 12(2): 83–87. DOI: 10.11731/j.issn.1673-193x.2016.02.015. [3] 杜扬, 王世茂, 齐圣, 等. 油气在顶部含弱约束结构受限空间内的爆炸特性 [J]. 爆炸与冲击, 2017, 37(1): 53–60. DOI: 10.11883/1001-1455(2017)01-0053-08.DU Y, WANG S M, QI S, et al. Explosion of gasoline/air mixture in confined space with weakly constrained structure at the top [J]. Explosion and Shock Waves, 2017, 37(1): 53–60. DOI: 10.11883/1001-1455(2017)01-0053-08. [4] CHEEDA V K, KUMAR A, RAMAMURTHI K. Influence of height of confined space on explosion and fire safety [J]. Fire Safety Journal, 2015, 76: 31–38. DOI: 10.1016/j.firesaf.2015.06.002. [5] 谢威, 蒋新生, 徐建楠, 等. 基于高斯多峰法的密闭空间爆炸特性曲线拟合 [J]. 振动与冲击, 2018, 37(24): 201–207. DOI: 10.13465/j.cnki.jvs.2018.24.030.XIE W, JIANG X S, XU J N, et al. Fitting of characteristic curves of explosion in a confined space using a Gaussian multi-peak method [J]. Journal of Vibration and Shock, 2018, 37(24): 201–207. DOI: 10.13465/j.cnki.jvs.2018.24.030. [6] WANG H, WANG L H, DENG J. Improvement and application of three-dimension numerical model for flammable gas explosions in confined space [J]. Journal of Computational and Theoretical Nanoscience, 2015, 12(12): 5179–5183. DOI: 10.1166/jctn.2015.4496. [7] 李祥春, 聂百胜, 杨春丽, 等. 封闭空间内瓦斯浓度对瓦斯爆炸反应动力学特性的影响 [J]. 高压物理学报, 2017, 31(2): 135–147. DOI: 10.11858/gywlxb.2017.02.005.LI X C, NIE B S, YANG C L, et al. Effect of gas concentration on kinetic characteristics of gas explosion in confined space [J]. Chinese Journal of High Pressure Physics, 2017, 31(2): 135–147. DOI: 10.11858/gywlxb.2017.02.005. [8] Center for Chemical Process Safety. Vapor cloud explosions-sample problems [M]// Center for Chemical Process Safety. Guidelines for Evaluating the Characteristics of Vapor Cloud Explosions, Flash Fires, and BLEVEs. New York, USA: American Institute of Chemical Engineers, 1994: 247−275. DOI: 10.1002/9780470938157.ch7. [9] PANG L, ZHANG Q. Influence of vapor cloud shape on temperature field of unconfined vapor cloud explosion [J]. Chinese Journal of Chemical Engineering, 2010, 18(1): 164–169. DOI: 10.1016/S1004-9541(08)60338-9. [10] 李少鹏, 陈国华, 赵杰, 等. 开敞空间可燃气云爆炸冲击波超压及灾害动力响应研究评述 [J]. 中国安全生产科学技术, 2019, 15(11): 11–17. DOI: 10.11731/j.issn.1673-193x.2019.11.002.LI S P, CHEN G H, ZHAO J, et al. Review of research on shock wave overpressure and disaster dynamic response of flammable vapor cloud explosion in unconfined space [J]. Journal of Safety Science and Technology, 2019, 15(11): 11–17. DOI: 10.11731/j.issn.1673-193x.2019.11.002. [11] RAMÍREZ-MARENGO C, DIAZ-OVALLE C, VÁZQUEZ-ROMÁN R, et al. A stochastic approach for risk analysis in vapor cloud explosion [J]. Journal of Loss Prevention in the Process Industries, 2015, 35: 249–256. DOI: 10.1016/j.jlp.2014.09.006. [12] ZHU Y, QIAN X M, LIU Z Y, et al. Analysis and assessment of the Qingdao crude oil vapor explosion accident: lessons learnt [J]. Journal of Loss Prevention in the Process Industries, 2015, 33: 289–303. DOI: 10.1016/j.jlp.2015.01.004. [13] ZHANG S H, ZHANG Q. Influence of geometrical shapes on unconfined vapor cloud explosion [J]. Journal of Loss Prevention in the Process Industries, 2018, 52: 29–39. DOI: 10.1016/j.jlp.2018.01.004. [14] 任新见, 张庆明, 薛一江. 不同点火方式下开敞空间半球形液化气气云爆炸效应试验研究 [J]. 兵工学报, 2014, 35(S2): 139–143.REN X J, ZHANG Q M, XUE Y J. Experimental research on blasting effects of unconfined hemispherical liquid gas cloud by different ignition methods [J]. Acta Armamentarii, 2014, 35(S2): 139–143. [15] NAGURA Y, KASAHARA J, MATSUO A. Multi-frame visualization for detonation wave diffraction [J]. Shock Waves, 2016, 26(5): 645–656. DOI: 10.1007/s00193-016-0663-y. [16] 庞磊, 张奇. 无约束气云爆炸热辐射伤害效应研究 [J]. 北京理工大学学报, 2010, 30(10): 1147–1150. DOI: 10.15918/j.tbit1001-0645.2010.10.008.PANG L, ZHANG Q. Study into injury effect of thermal radiation from unconfined vapor cloud explosion [J]. Transactions of Beijing Institute of Technology, 2010, 30(10): 1147–1150. DOI: 10.15918/j.tbit1001-0645.2010.10.008. [17] JAVIDI M, ABDOLHAMIDZADEH B, RENIERS G, et al. A multivariable model for estimation of vapor cloud explosion occurrence possibility based on a fuzzy logic approach for flammable materials [J]. Journal of Loss Prevention in the Process Industries, 2015, 33: 140–150. DOI: 10.1016/j.jlp.2014.11.003. [18] 党福辉, 董呈杰, 孙旭红. 开敞空间可燃气云爆炸数值模拟研究 [J]. 天津理工大学学报, 2017, 33(6): 51–54. DOI: 10.3969/j.issn.1673-095X.2017.06.011.DANG F H, DONG C J, SUN X H. Numerical simulation study on unconfined flammable vapor cloud explosion [J]. Journal of Tianjin University of Technology, 2017, 33(6): 51–54. DOI: 10.3969/j.issn.1673-095X.2017.06.011. [19] 杨国刚, 岳丹婷, 毕明树. 圆柱形可燃气云爆炸实验研究与数值模拟 [J]. 化工学报, 2008, 59(11): 2954–2959. DOI: 10.3321/j.issn:0438-1157.2008.11.041.YANG G G, YUE D T, BI M S. Experimental and numerical study on cylindrical flammable gas cloud explosion [J]. Journal of Chemical Industry and Engineering (China), 2008, 59(11): 2954–2959. DOI: 10.3321/j.issn:0438-1157.2008.11.041. [20] LI J D, HERNANDEZ F, HAO H, et al. Vented methane-air explosion overpressure calculation—A simplified approach based on CFD [J]. Process Safety and Environmental Protection, 2017, 109: 489–508. DOI: 10.1016/j.psep.2017.04.025. [21] 任少云. 开敞空间液化天然气泄漏低温扩散及爆炸传播规律 [J]. 爆炸与冲击, 2018, 38(4): 891–897. DOI: 10.11883/bzycj-2016-0323.REN S Y. The leakage, low temperature diffusion and explosion of liquefied natural gas in open space [J]. Explosion and Shock Waves, 2018, 38(4): 891–897. DOI: 10.11883/bzycj-2016-0323. [22] LI J D, HAO H. Internal and external pressure prediction of vented gas explosion in large rooms by using analytical and CFD methods [J]. Journal of Loss Prevention in the Process Industries, 2017, 49: 367–381. DOI: 10.1016/j.jlp.2017.08.002. [23] LIND C D, STREHLOW R A. Unconfined vapor cloud explosion study [M]. USA: United States Coast Guard, 1975: 327–331. [24] 丁信伟, 李志义, 李应博. 可燃气体云爆燃实验 [J]. 化工学报, 1999, 50(4): 558–562. DOI: 10.3321/j.issn:0438-1157.1999.04.020.DING X W, LI Z Y, LI Y B. Experimental investigation into deflagrations of combustrial vapor clouds [J]. Journal of Chemical Industry and Engineering, 1999, 50(4): 558–562. DOI: 10.3321/j.issn:0438-1157.1999.04.020. [25] 罗正鸿, 詹晓力, 丁信伟, 等. 小气量开敞空间可燃气云爆燃实验 [J]. 浙江大学学报(工学版), 2002, 36(1): 105–108. DOI: 10.3785/j.issn.1008-973X.2002.01.025.LUO Z H, ZHAN X L, DING X W, et al. Experimental investigation into deflagration of small-volume combustible vapour clouds [J]. Journal of Zhejiang University (Engineering Science), 2002, 36(1): 105–108. DOI: 10.3785/j.issn.1008-973X.2002.01.025. [26] MERCX W P M, VAN DEN BERG A C. The explosion blast prediction model in the revised CPR 14E (yellow book) [J]. Process Safety Progress, 1997, 16(3): 152–159. DOI: 10.1002/prs.680160308. [27] LV D, TAN W, LIU L Y, et al. Research on maximum explosion overpressure in LNG storage tank areas [J]. Journal of Loss Prevention in the Process Industries, 2017, 49: 162–170. DOI: 10.1016/j.jlp.2017.06.010. [28] 王世茂, 杜扬, 李国庆, 等. 含弱约束受限空间油气爆炸外部特性研究 [J]. 振动与冲击, 2017, 36(15): 253–258. DOI: 10.13465/j.cnki.jvs.2017.15.038.WANG S M, DU Y, LI G Q, et al. Tests for external explosion characteristics of fuel-air mixture in a confined space with weak constraint surfaces [J]. Journal of Vibration and Shock, 2017, 36(15): 253–258. DOI: 10.13465/j.cnki.jvs.2017.15.038. [29] TONG M M, WU G Q, HAO J F, et al. Explosion limits for combustible gases [J]. Mining Science and Technology (China), 2009, 19(2): 182–184. DOI: 10.1016/S1674-5264(09)60034-X. [30] FAKANDU B M, MBAM C J, ANDREWS G E, et al. Gas explosion venting: external explosion turbulent flame speeds that control the overpressure [J]. Chemical Engineering Transactions, 2016, 53: 1–6. DOI: 10.3303/CET1653001. [31] 闫伟杰. 基于光谱分析和图像处理的火焰温度及辐射特性检测 [D]. 武汉: 华中科技大学, 2014: 44–57. DOI: 10.7666/d.D608951.YAN W J. Measurement of flame temperature and radiative properties based on spectral analysis and image processing [D]. Wuhan: Huazhong University of Science and Technology, 2014: 44–57. DOI: 10.7666/d.D608951. -

下载:

下载: