Experimental study on the resistance of the ultra high toughness cementitious composites material-fiber concrete composite targets subjected to twice projectiles impact

-

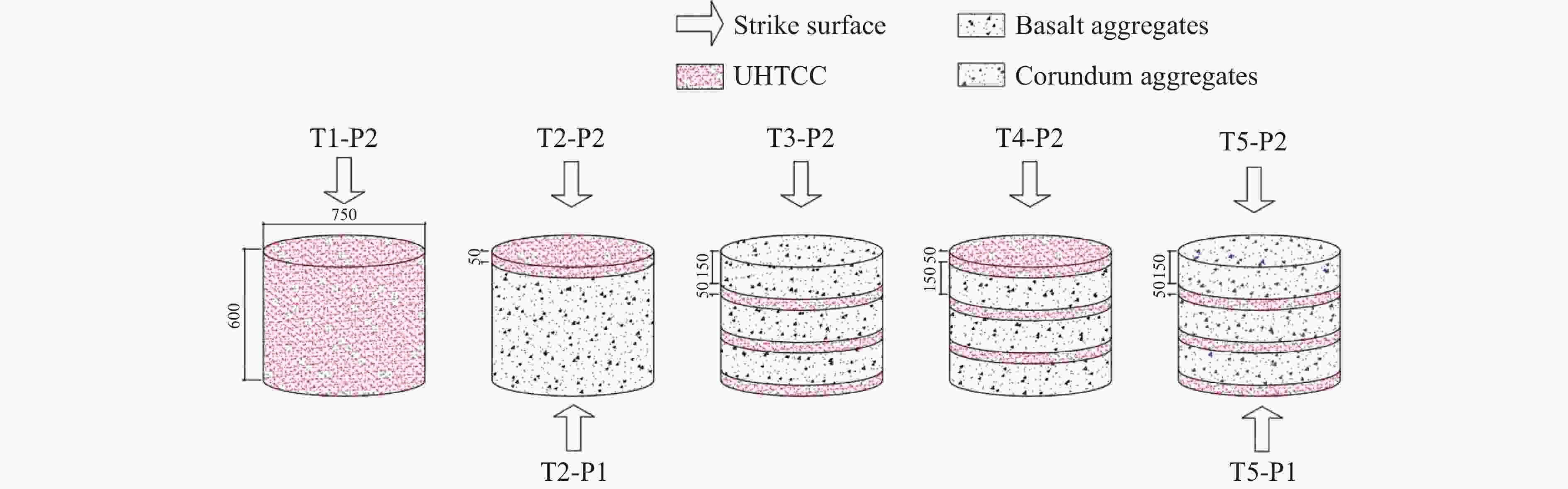

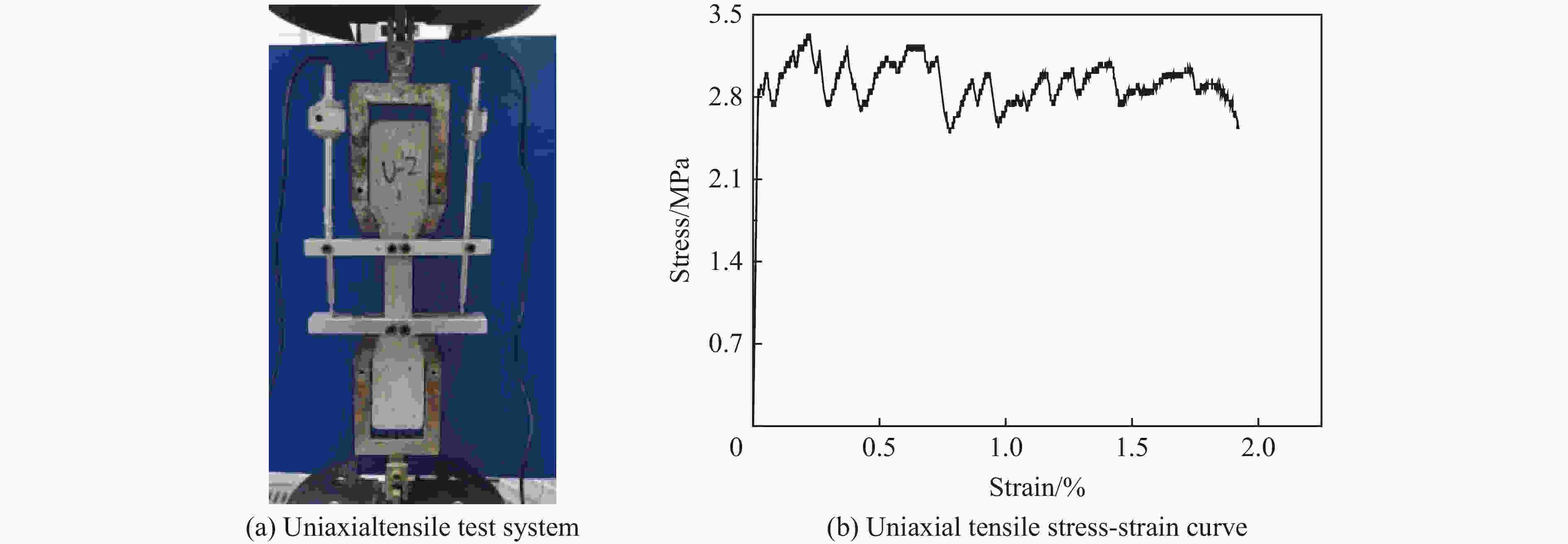

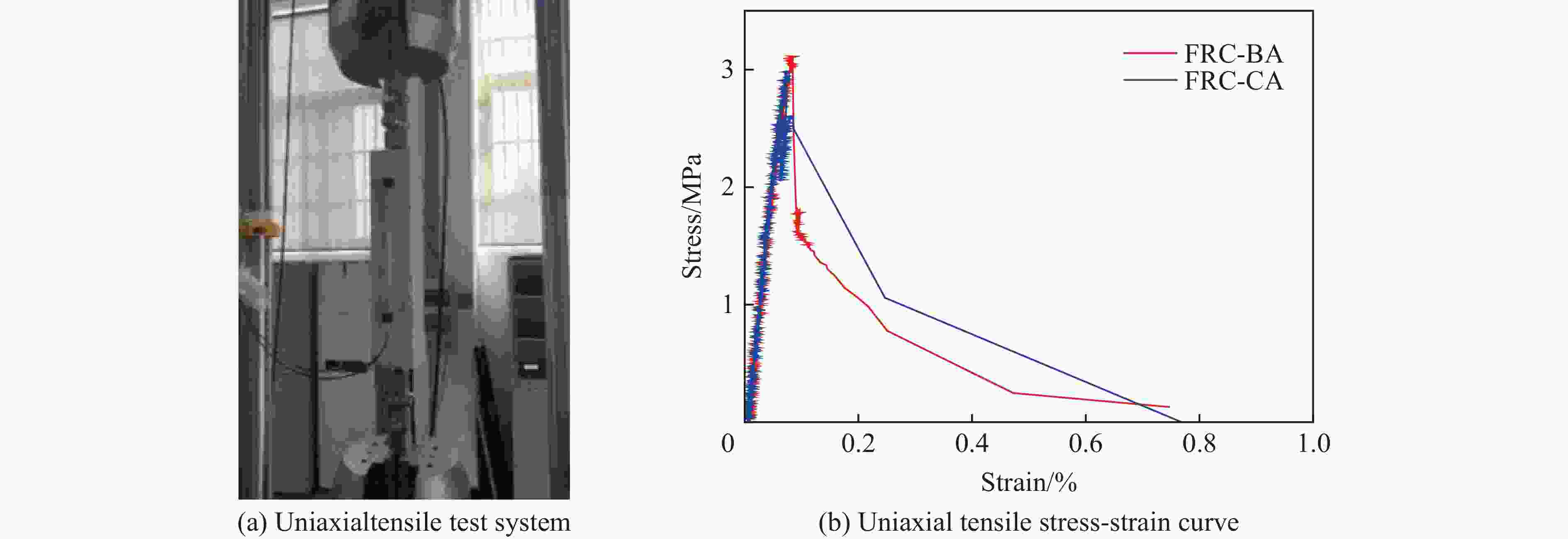

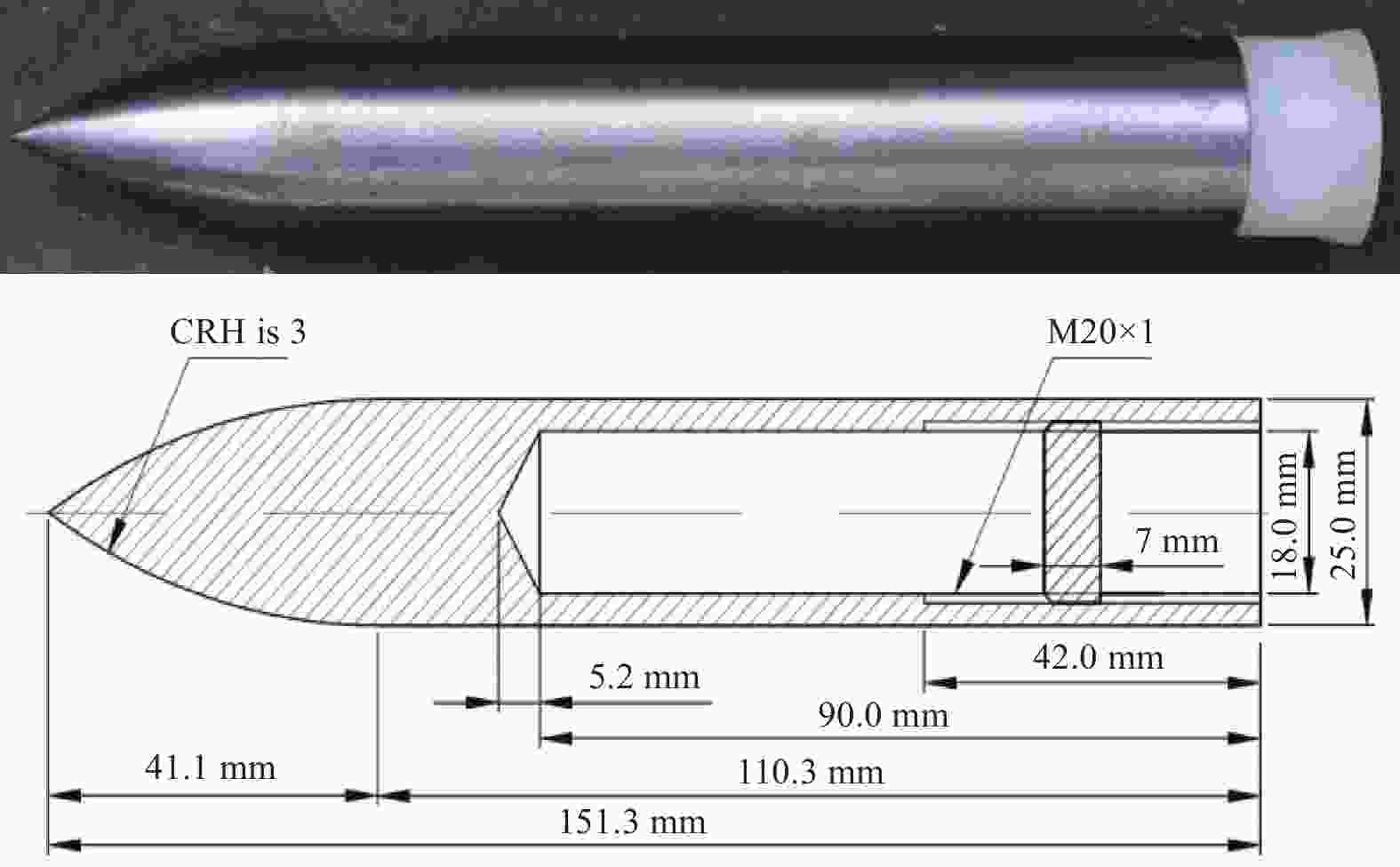

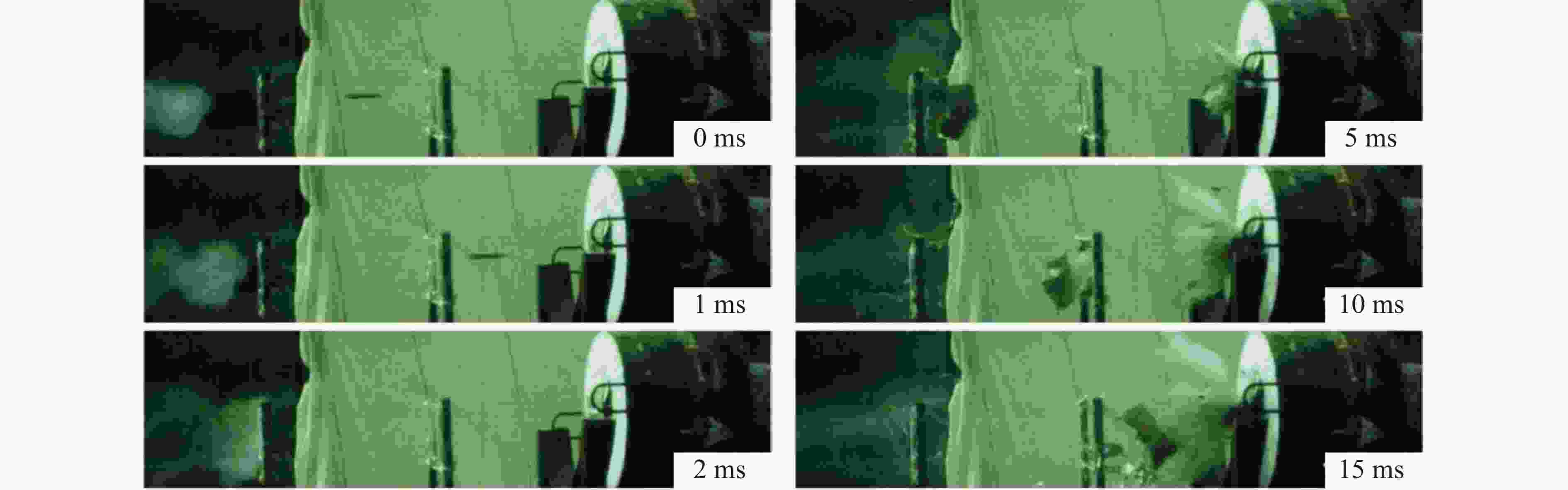

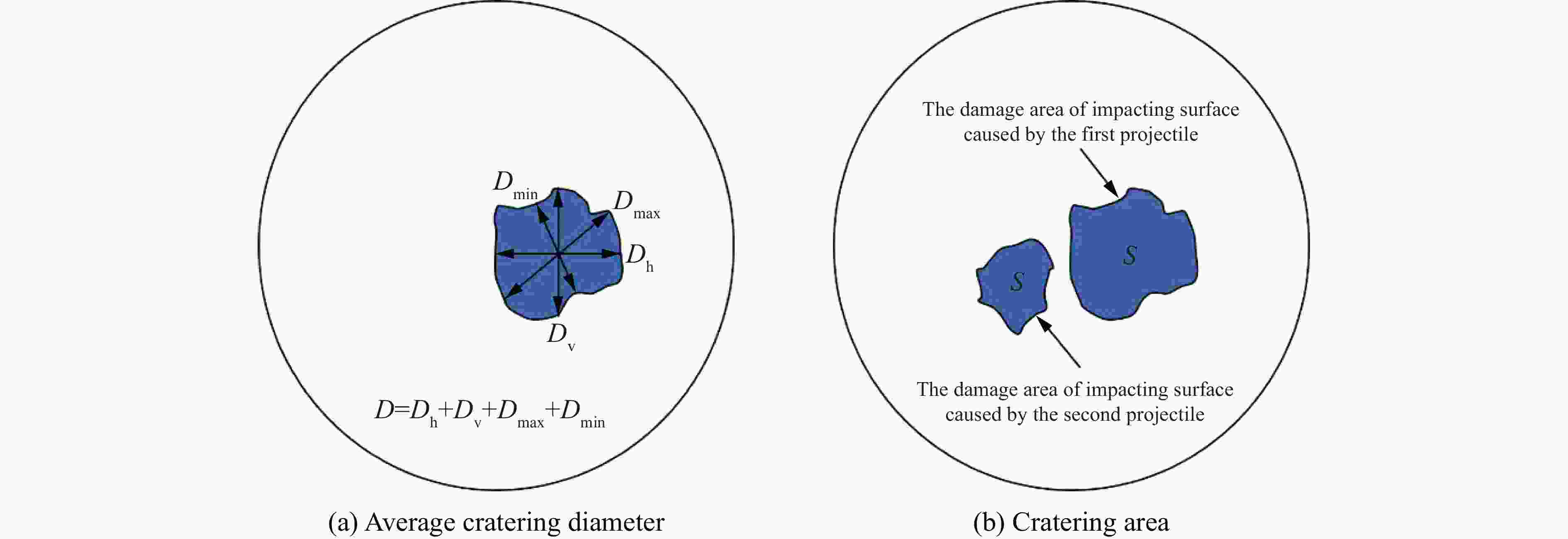

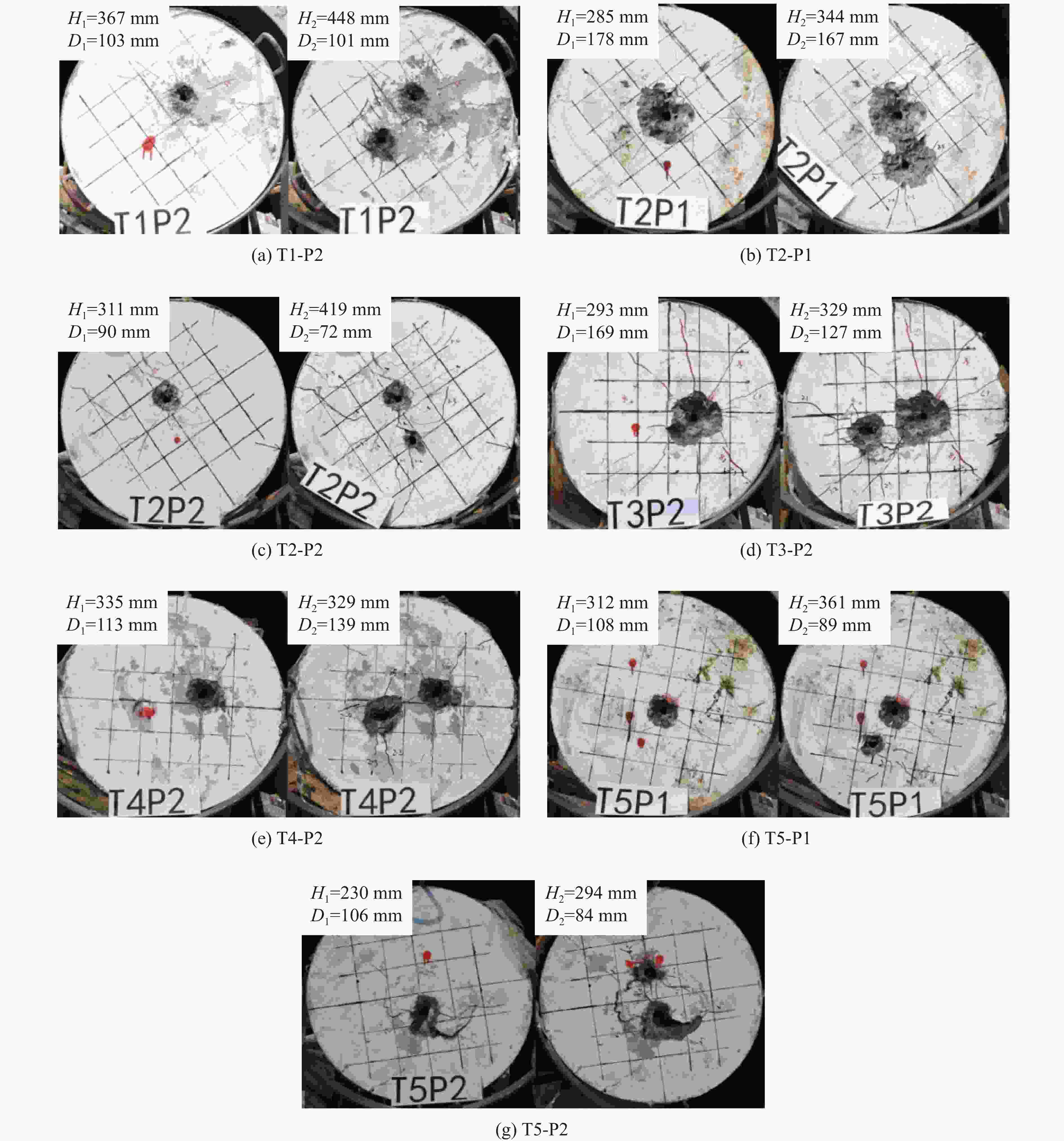

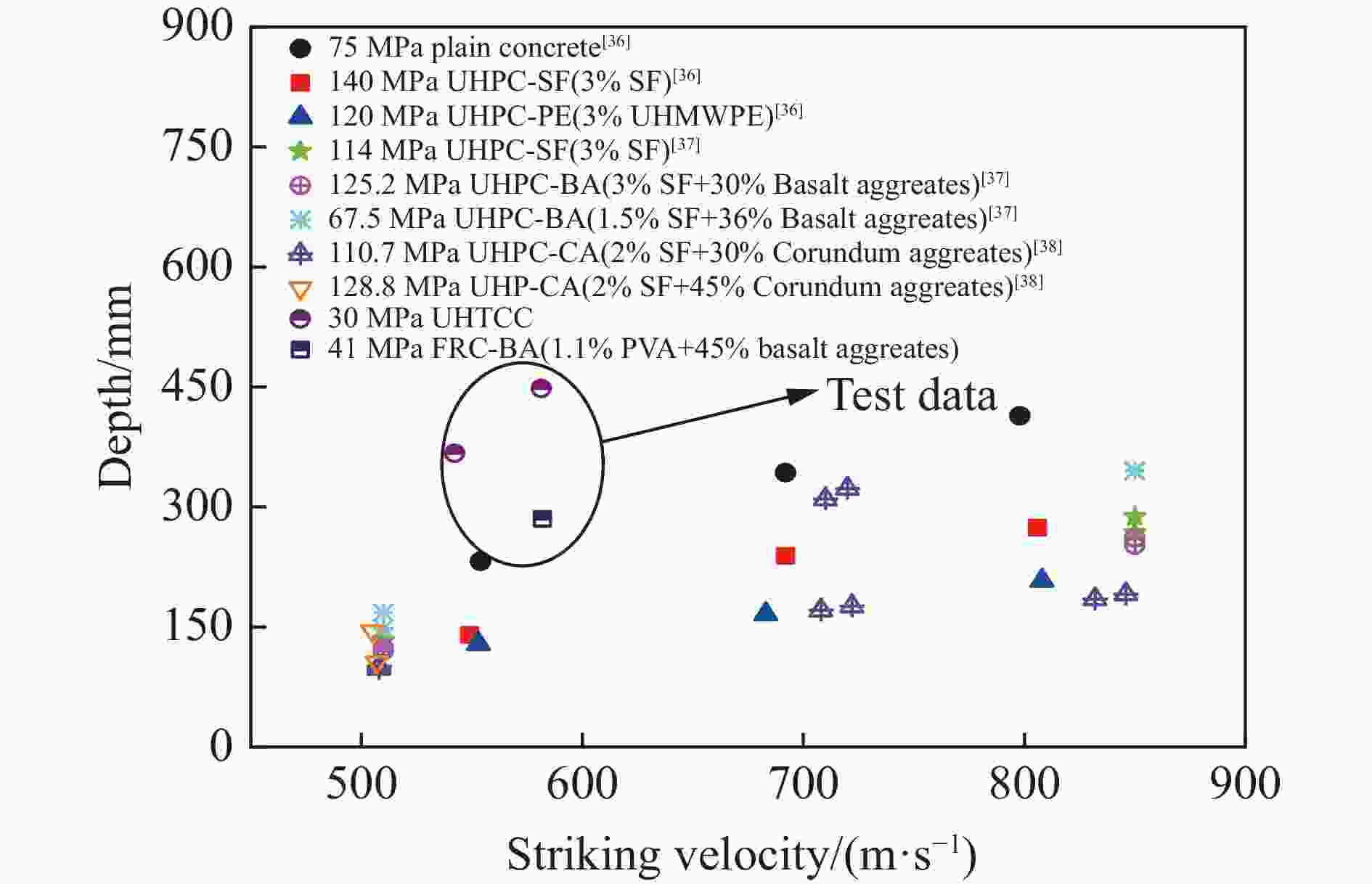

摘要: 超高韧性水泥基复合材料(ultra high toughness cementitious composites, UHTCC)具有超高的韧性、良好的耐久性和优异的耗能效果,这些特性使得UHTCC在防护工程中具有广阔的应用前景。为了更好地研究UHTCC与纤维混凝土组合结构在二次打击条件下的抗侵彻性能,首先测量了UHTCC和聚乙烯醇纤维增强混凝土(polyvinl alcohol fiber reinforced concrete, FRC)的基本力学参数。然后采用25 mm口径的弹道滑膛炮对直径为750 mm、高为600 mm的圆柱形UHTCC靶体、FRC靶体、UHTCC-FRC组合靶体(UHTCC-FRC composite target)进行了弹体速度为550 m/s的二次侵彻试验,得到了弹体和三类靶体的破坏数据,包括弹体的侵彻深度、弹体的磨蚀、靶体迎弹面的开坑直径和面积、弹坑深度、迎弹面的裂纹数量以及裂纹最大宽度。在此基础上分析了骨料、结构形式和两次打击的间距对UHTCC-FRC组合靶体抗侵彻性能的影响。结果表明:相同试验条件下,与普通混凝土和超高性能混凝土相比,UHTCC能够有效的减小迎弹面的开坑直径,但会增加弹体侵彻深度;将50 mm的UHTCC置于组合靶的迎弹面可以有效地减少迎弹面的开坑直径;弹体二次侵彻深度大于弹体一次侵彻深度,靶体在二次冲击下的开坑面积小于靶体初次冲击下的开坑面积。

-

关键词:

- 超高韧性水泥基复合材料 /

- 聚乙烯醇纤维增强混凝土 /

- UHTCC与FRC组合靶体 /

- 二次侵彻试验 /

- 开坑面积

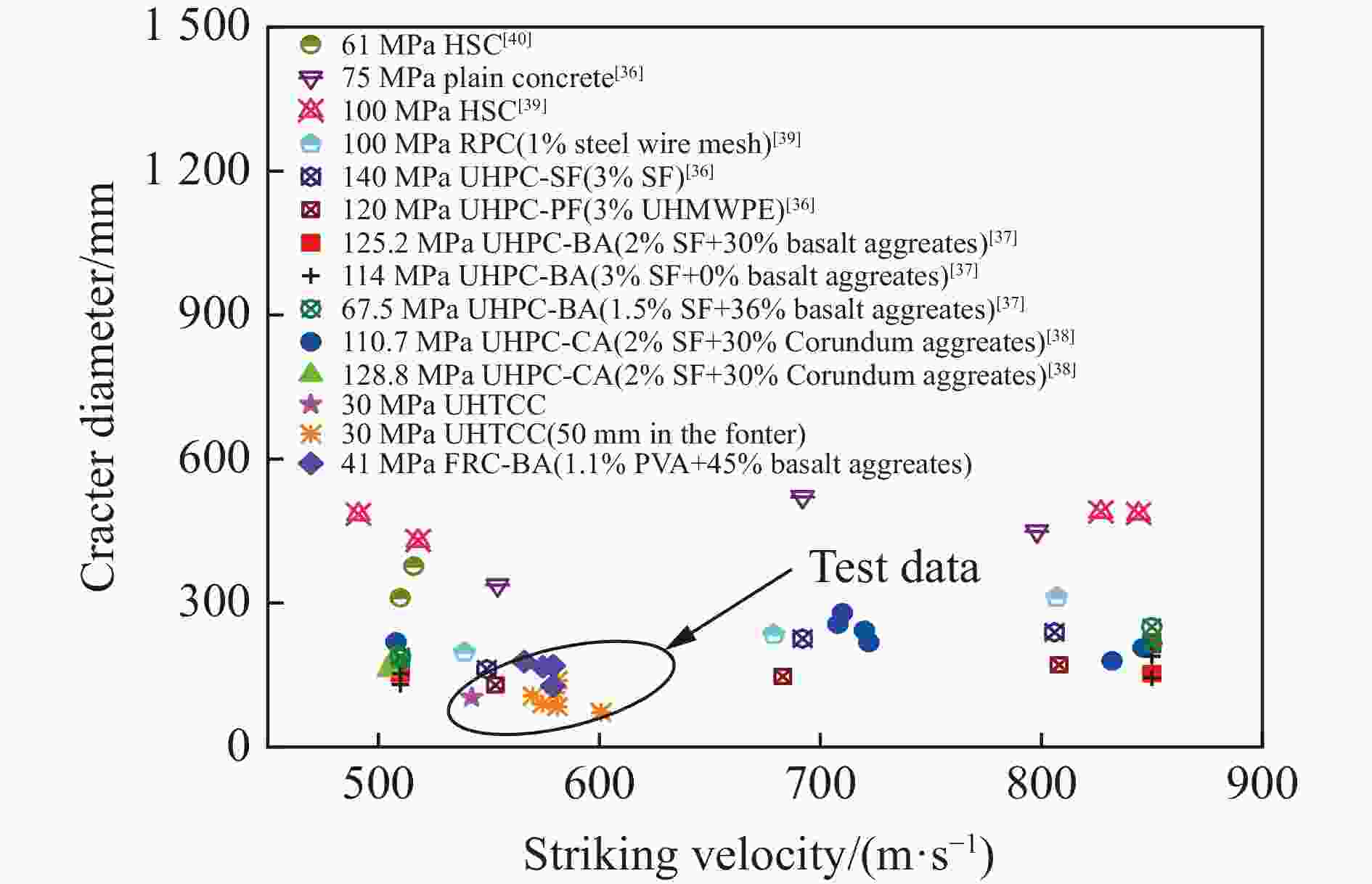

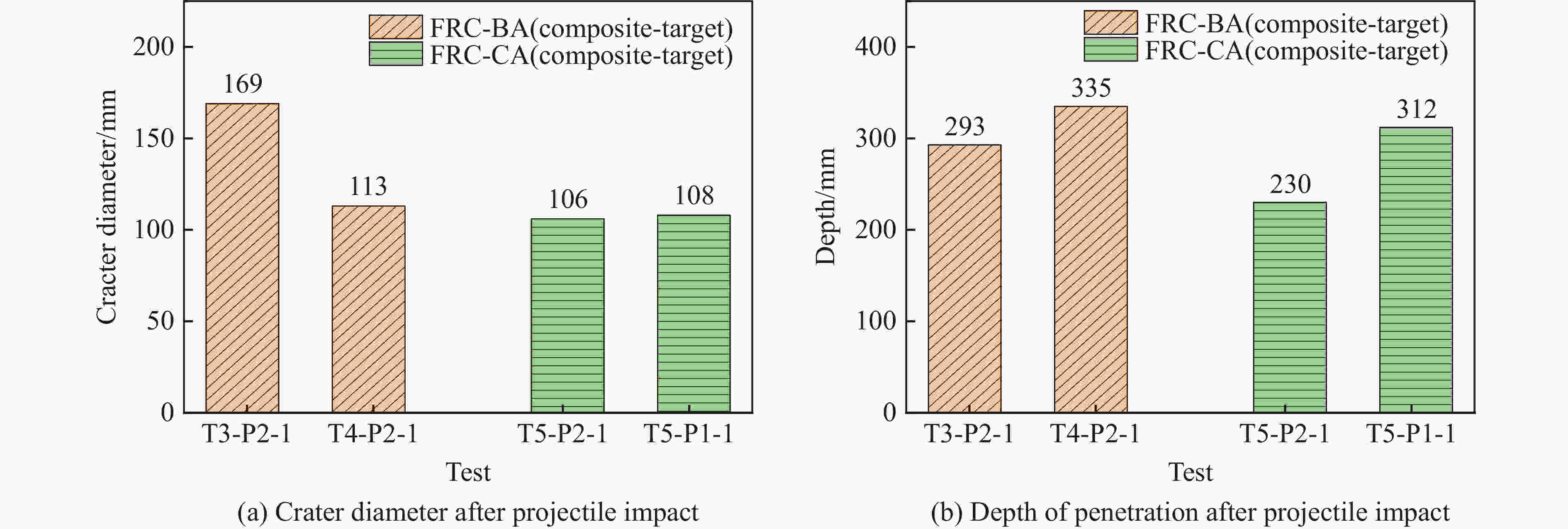

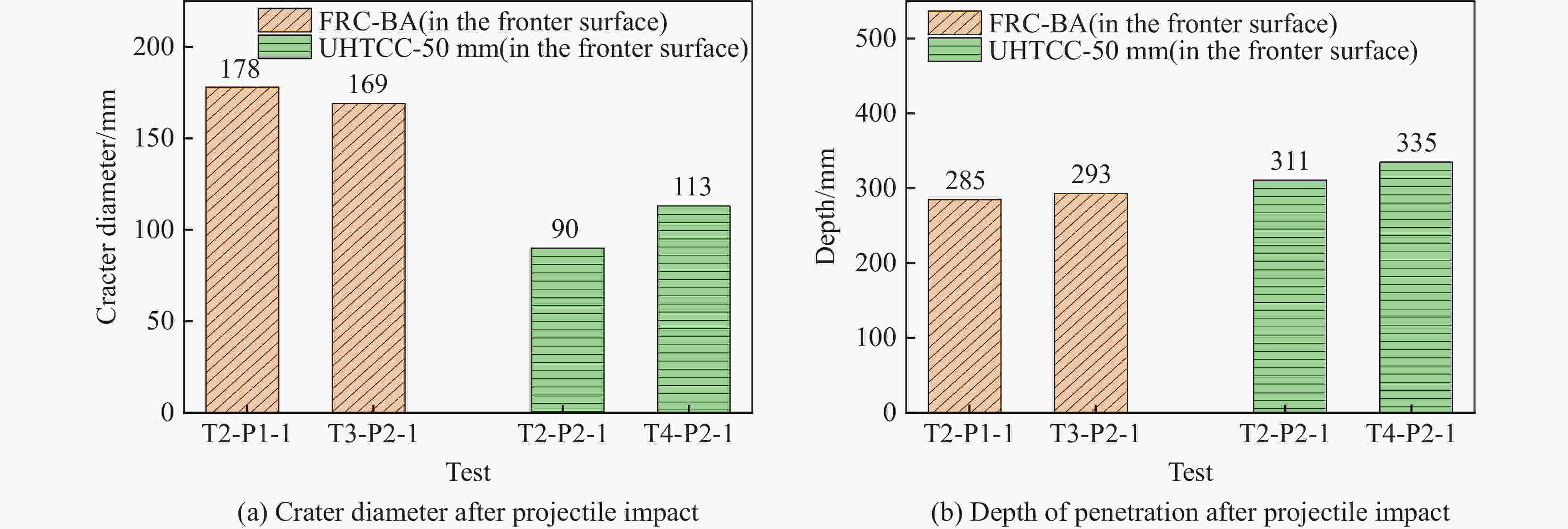

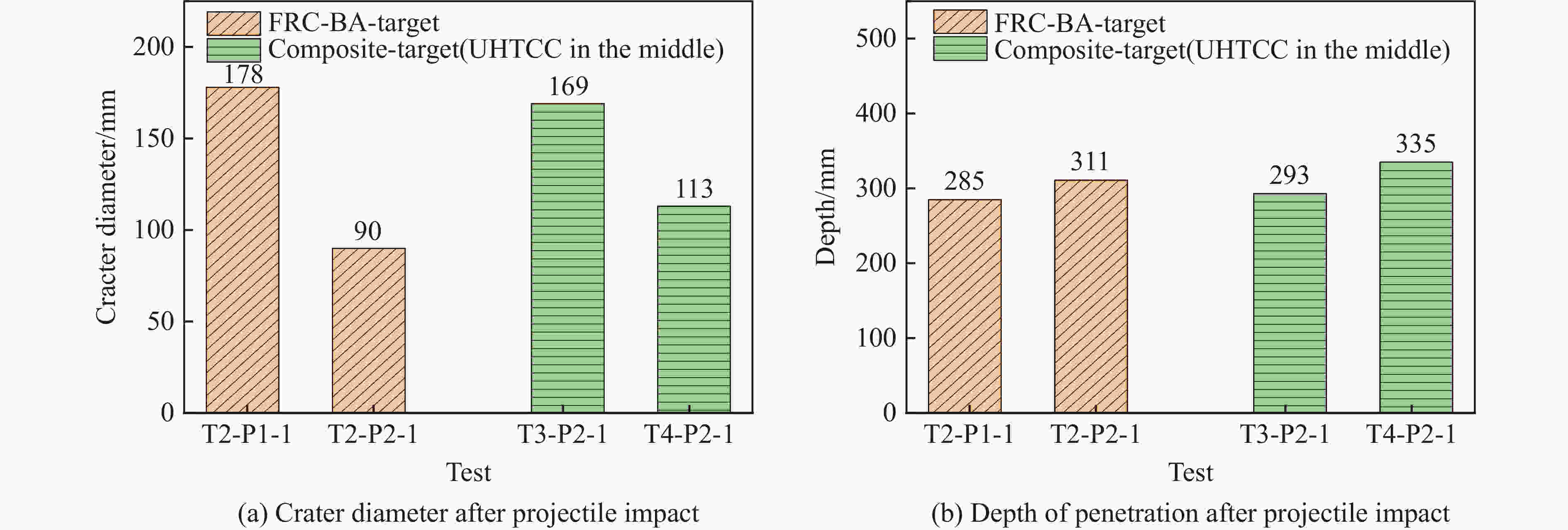

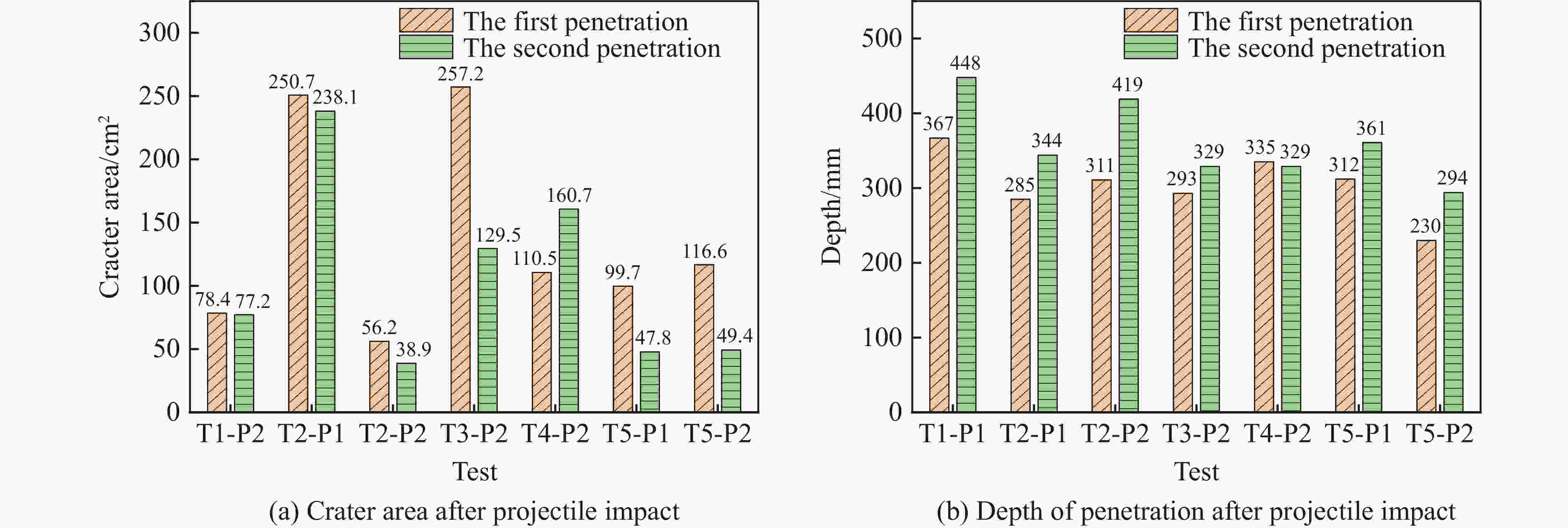

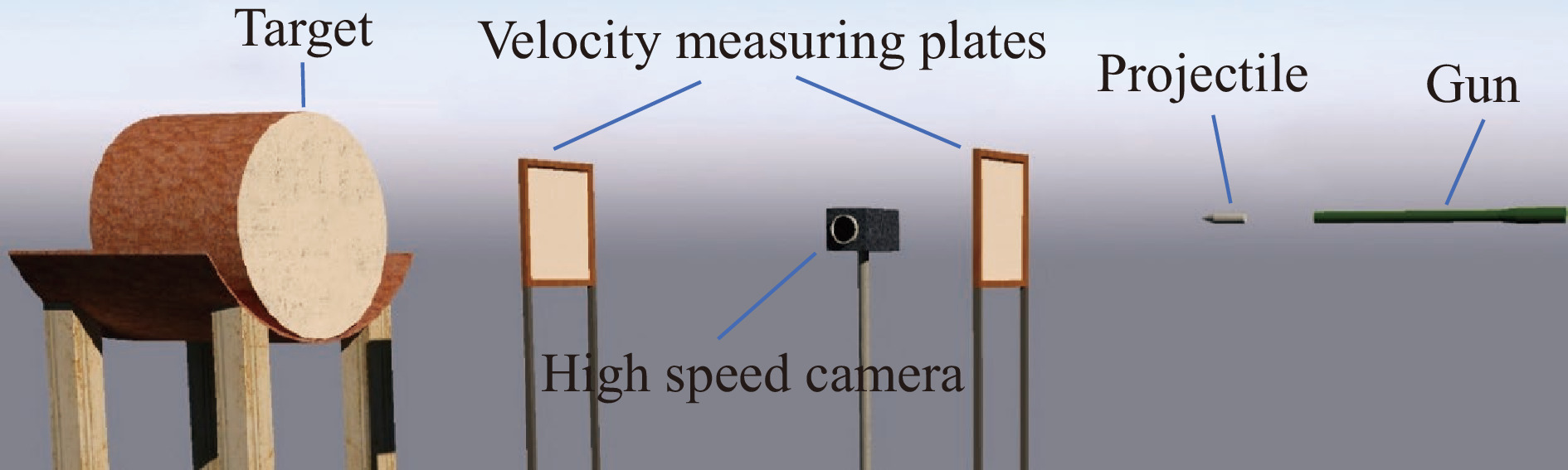

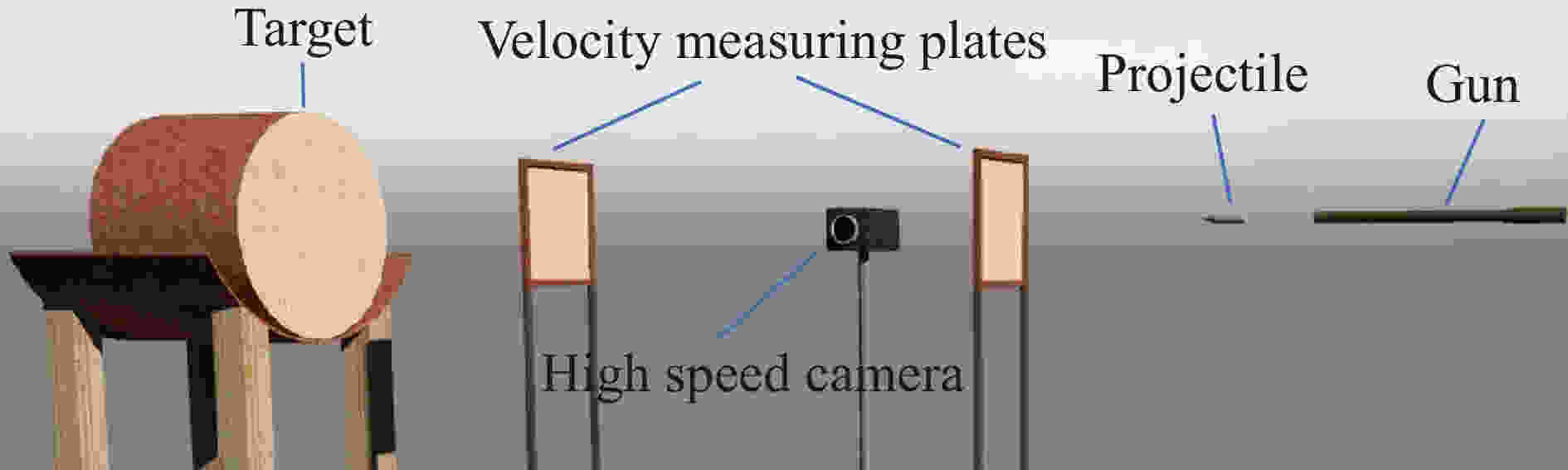

Abstract: Ultra high toughness cementitious composites (UHTCC) have ultra-high toughness, good durability and excellent energy consumption effect. These characteristics make UHTCC have broad applications in protection engineering. To better investigate the penetration resistance of UHTCC composite structure subjected to second strike conditions, the basic mechanical parameters of the UHTCC and polyvinl alcohol fiber reinforced concrete (FRC) were measured first. Then, a 25 mm caliber ballistic smoothbore gun was used against a cylindrical UHTCC, FRC and UHTCC-FRC composite targets with a diameter of 750 mm and a height of 600 mm. The targets were subjected to two-time penetration tests of 550 m/s. The damage data of the projectile and the three types of targets were obtained, including the penetration depth of the projectile, the abrasion of the projectile, the crater diameter and area of the target’s strike surface, the crater depth, the number of cracks and the maximum crack width on the strike surface. On this basis, the influence of aggregate, structure type and distance between two strikes on the penetration resistance of UHTCC composite targets was analyzed. The results show that under the same test conditions, compared with the normal concrete and ultra-high performance concrete, the UHTCC can effectively reduce the crater diameter of the strike surface, but the penetration depth of the projectile increases; the 50mm UHTCC placing on the front surface of the functionally graded target can effectively reduce the cratering diameter of the strike surface; the secondary penetration depth of the projectile is greater than the primary penetration depth of the projectile, and the crater area of the target under the secondary impact is smaller than the crater area of the target under the first impact. -

表 1 UHTCC和FRC各组分的质量浓度(kg/m3)

Table 1. Mass concentrations of components (kg/m3) in UHTCC and FRC

材料 胶凝材料 砂子 减水剂 玄武岩骨料 刚玉骨料 水 PVA UHTCC 1 405 281 2 0 0 390 26 FRC-BA 1 405 281 2 1 056 0 390 14.3 FRC-CA 1 405 281 2 0 1 103 390 14.3 表 2 UHTCC和FRC的力学参数

Table 2. Mechanical parameters of UHTCC and FRC

材料编号 抗压强度/MPa 抗拉强度/MPa UHTCC 30.0 3.5 FRC-BA 41.2 3.1 FRC-CA 42.7 3.0 表 3 错位打击下不同靶体的侵彻试验结果

Table 3. Penetration test results of different targets subjected to dislocation impact

试验编号 m/g v/(m/s) r/mm H/mm Dc/mm D/mm S1/cm2 S/cm2 N wmax/mm T1-P2-1 353.1 542.3 172 367 43 103 83.3 78.4 0 0.1 T1-P2-2 354.2 581.4 448 46 101 80.1 77.2 0 0.1 T2-P1-1 353.2 582.0 147 285 89 178 248.8 250.7 9 1.1 T2-P1-2 353.0 566.0 344 58 167 219.0 238.1 11 2.5 T2-P2-1 353.8 574.4 158 311 51 90 63.6 56.2 4 0.7 T2-P2-2 353.2 600.7 419 30 72 40.7 38.9 7 2.0 T3-P2-1 352.8 579.1 174 293 71 169 224.3 257.2 8 1.2 T3-P2-2 352.4 579.0 329 67 127 126.7 129.5 9 1.2 T4-P2-1 354.0 580.0 192 335 46 113 100.2 110.5 3 1.0 T4-P2-2 353.2 581.0 329 48 139 151.7 160.7 3 1.0 T5-P1-1 352.3 582.5 122 312 48 108 91.6 99.7 2 0.1 T5-P1-2 352.4 587.0 361 39 89 62.2 47.8 3 0.1 T5-P2-1 351.0 570.0 144 230 44 106 116 116.6 0 0.15 T5-P2-2 354.0 581.0 294 30 84 55.4 49.4 0 0.15 -

[1] HANCHAK S J, FORRESTAL M J, YOUNG E R, et al. Perforation of concrete slabs with 48 MPa (7 ksi) and 140 MPa (20 ksi) unconfined compressive strengths [J]. International Journal of Impact Engineering, 1992, 12(1): 1–7. DOI: 10.1016/0734-743X(92)90282-X. [2] WU H, FANG Q, PENG Y, et al. Hard projectile perforation on the monolithic and segmented RC panels with a rear steel liner [J]. International Journal of Impact Engineering, 2015, 76: 232–250. DOI: 10.1016/j.ijimpeng.2014.10.010. [3] 邓勇军, 陈小伟, 钟卫洲, 等. 弹体正侵彻钢筋混凝土靶的试验及数值模拟研究 [J]. 爆炸与冲击, 2020, 40(2): 023101. DOI: 10.11883/bzycj-2019-0001.DENG Y J, CHEN X W, ZHONG W Z, et al. Experimental and numerical study on normal penetration of a projectile into a reinforced concrete target [J]. Explosion and Shock Waves, 2020, 40(2): 023101. DOI: 10.11883/bzycj-2019-0001. [4] ZOLLO R F. Fiber-reinforced concrete: an overview after 30 years of development [J]. Cement and Concrete Composites, 1997, 19(2): 107–122. DOI: 10.1016/S0958-9465(96)00046-7. [5] LI V C, MISHRA D K, WU H C. Matrix design for pseudo-strain-hardening fibre reinforced cementitious composites [J]. Materials and Structures, 1995, 28(10): 586–595. DOI: 10.1007/BF02473191. [6] LI V C, WANG S X, WU C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC) [J]. ACI Materials Journal, 2001, 98(6): 483–492. DOI: 10.1089/apc.2006.20.829. [7] LI V C, HASHIDA T, Engineering ductile fracture in brittle-matrix composites [J]. Journal of Materials Science Letters, 1993, 12(12): 898−901. DOI: 10.1007/BF00455611. [8] NELSON P K, LI V C, KAMADA T. Fracture toughness of microfiber reinforced cement composites [J]. Journal of Materials in Civil Engineering, 2002, 14(5): 384–391. DOI: 10.1061/(ASCE)0899-1561(2002)14:5(384. [9] LI H D, XU S L, LEUNG C K Y. Tensile and flexural properties of ultra high toughness cemontious composite [J]. Journal of Wuhan University of Technology (Materials Science Edition), 2009, 24(4): 677–683. DOI: 10.1007/s11595-009-4677-5. [10] MAALEJ M, QUEK S T, ZHANG J, et al. Behavior of hybrid fiber ECC panels subjected to low and high velocity projectile impact: a review [M]// BRANDT A M, OLEK J, GLINICKI M A, et al. Brittle Matrix Composites 10. Cambridge: Woodhead Publishing, 2012: 335−344. DOI: 10.1533/9780857099891.335. [11] 刘问. 超高韧性水泥基复合材料冲击、断裂、疲劳及疲劳裂纹扩展性能的试验研究 [D]. 大连: 大连理工大学, 2011. [12] MAALEJ M, QUEK S T, ZHANG J. Behavior of hybrid-fiber engineered cementitious composites subjected to dynamic tensile loading and projectile impact [J]. Journal of Materials in Civil Engineering, 2005, 17(2): 143–152. DOI: 10.1061/(ASCE)0899-1561(2005)17:2(143. [13] 赵昕. 超高韧性水泥基复合材料动态力学性能试验与理论研究 [D]. 杭州: 浙江大学, 2018.ZHAO X. Experimental and theoretical study on the dynamic properties of ultra high toughness cementitious composites [D]. Hangzhou: Zhejiang University, 2018. [14] ZHANG J, MAALEJ M, QUEK S T. Performance of hybrid-fiber ECC blast/shelter panels subjected to drop weight impact [J]. Journal of Materials in Civil Engineering, 2007, 19(10): 855–863. DOI: 10.1061/(ASCE)0899-1561(2007)19:10(855. [15] BELL J, ZHANG Y X, SOE K, et al. High velocity impact behaviour of hybrid-fiber engineered cementitious composite panels [J]. Advanced Materials Research, 2012, 450/451: 563–567. DOI: 10.4028/www.scientific.net/AMR.450-451.563. [16] QUEK S T, LIN V W J, MAALEJ M. Development of functionally-graded cementitious panel against high-velocity small projectile impact [J]. International Journal of Impact Engineering, 2010, 37(8): 928–941. DOI: 10.1016/j.ijimpeng.2010.02.002. [17] LAI J Z, YANG H R, WANG H F, et al. Penetration experiments and simulation of three-layer functionally graded cementitious composite subjected to multiple projectile impacts [J]. Construction and Building Materials, 2019, 196: 499–511. DOI: 10.1016/j.conbuildmat.2018.11.154. [18] ANTOUN T H, LOMOV I N, GLENN L A. Simulation of the penetration of a sequence of bombs into granitic rock [J]. International Journal of Impact Engineering, 2003, 29(1): 81–94. DOI: 10.1016/j.ijimpeng.2003.09.006. [19] 邓国强, 杨秀敏. 钻地弹重复打击效应现场试验研究 [J]. 防护工程, 2012, 34(5): 1–5.DENG G Q, YANG X M. Experimental investigation into damage effects of repeated attacks of precision-guided penetration weapons [J]. Protective Engineering, 2012, 34(5): 1–5. [20] 邓国强, 杨秀敏. 工程岩体中多弹重复打击效应的数值模拟分析 [J]. 爆炸与冲击, 2014, 34(3): 361–366. DOI: 10.11883/1001-1455(2014)03-0361-06.DENG G Q, YANG X M. Numerical simulation of the effect of multiply EPW into engineering rock [J]. Explosion and Shock Waves, 2014, 34(3): 361–366. DOI: 10.11883/1001-1455(2014)03-0361-06. [21] 潘景龙, 张宝超, 马晓儒, 等. 武器间接命中条件下FRP约束混凝土抗多次打击能力 [J]. 复合材料报, 2004, 21(5): 128–133. DOI: 10.13801/j.cnki.fhclxb.2004.05.024.PAN J L, ZHANG B C, MA X R. Experimental study of resisting multi-hitting capacity on FRP confined concrete on condition of indirect damage by weapons [J]. Acta Materiae Compositae Sinica, 2004, 21(5): 128–133. DOI: 10.13801/j.cnki.fhclxb.2004.05.024. [22] 左魁, 曾宪明, 王启睿, 等. 钻地模型弹对岩石模拟材料二次侵彻试验 [J]. 解放军理工大学学报(自然科学版), 2007, 8(6): 626–629. DOI: 10.3969/j.issn.1009-3443.2007.06.012.ZUO K, ZENG X M. Second time penetration of earth-penetrating model projectile in rock medium [J]. Journal of PLA University of Science and Technology (Natural Science Edition), 2007, 8(6): 626–629. DOI: 10.3969/j.issn.1009-3443.2007.06.012. [23] PRAKASH A, SRINIVASAN S M, RAO A R M, et al. The assessment of high velocity multi-impact damage in steel fiber reinforced cementitious composite panels [J]. WIT Transactions on the Built Environment, 2014, 141: 243–256. DOI: 10.2495/SUSI140211. [24] 蒋志刚, 万帆, 谭清华, 等. 钢管约束混凝土抗多发打击试验 [J]. 国防科技大学学报, 2016, 38(3): 117–123. DOI: 10.11887/j.cn.201603020.JIANG Z G, WAN F, TAN Q H, et al. Multi-hit experiments of steel-tube-confined concrete targets [J]. Journal of National University of Defense Technology, 2016, 38(3): 117–123. DOI: 10.11887/j.cn.201603020. [25] GOMEZ J T, SHUKLA A. Multiple impact penetration of semi-infinite concrete [J]. International Journal of Impact Engineering, 2001, 25(10): 965–979. DOI: 10.1016/S0734-743X(01)00029-X. [26] FORRESTAL M J, ALTMAN B S, CARGILE J D, et al. An empirical equation for penetration depth of ogive-nose projectiles into concrete targets [J]. International Journal of Impact Engineering, 1994, 15(4): 395–405. DOI: 10.1016/0734-743X(94)80024-4. [27] FORRESTAL M J, FREW D J, HANCHAK S J, et al. Penetration of grout and concrete targets with ogive-nose steel projectiles [J]. International Journal of Impact Engineering, 1996, 18(5): 465–476. DOI: 10.1016/0734-743X(95)00048-F. [28] 赖建中, 朱耀勇, 徐升, 等. 超高性能水泥基复合材料抗多次侵彻性能研究 [J]. 爆炸与冲击, 2013, 33(6): 601–607. DOI: 10.11883/1001-1455(2013)06-0601-07.LAI J Z, ZHU Y Y, XU S, et al. Resistance of ultra-high-performance cementitious composites to multiple impact penetration [J]. Explosion and Shock Waves, 2013, 33(6): 601–607. DOI: 10.11883/1001-1455(2013)06-0601-07. [29] 李金城. 射弹两次打击混凝土介质的累积侵彻效应研究 [D]. 南京: 南京理工大学, 2018. [30] 梁乔恒. UHMWPE纤维混凝土动态材料模型参数与抗多发打击研究 [D]. 长沙: 国防科学技术大学, 2016. [31] LAI J Z, GUO X J, Zhu Y Y. Repeated penetration and different depth explosion of ultra-high performance concrete [J]. International Journal of Impact Engineering, 2015, 84: 1–12. DOI: 10.1016/j.ijimpeng.2015.05.006. [32] FENG J, GAO X D, LI J Z, et al. Penetration resistance of hybrid-fiber-reinforced high-strength concrete under projectile multi-impact [J]. Construction and Building Materials, 2019, 202: 341–352. DOI: 10.1016/j.conbuildmat.2019.01.038. [33] SOE K T, ZHANG Y X, ZHANG L C. Impact resistance of hybrid-fiber engineered cementitious composite panels [J]. Composite Structures, 2013, 104: 320–330. DOI: 10.1016/j.compstruct.2013.01.029. [34] 王会芳. 功能梯度水泥基复合材料制备及抗多次侵彻性能研究 [D]. 南京: 南京理工大学, 2017. [35] Japan Society of Civil Engineers. Recommendations for design and construction of high performance fiber reinforced cement composites with multiple fine cracks (HPFRCC) [R]. Japan Society of Civil Engineers, 2008. [36] LIU J, WU C Q, SU Y, et al. Experimental and numerical studies of ultra-high performance concrete targets against high-velocity projectile impacts [J]. Engineering Structures, 2018, 173: 166–179. DOI: 10.1016/j.engstruct.2018.06.098. [37] WU H, FANG Q, CHEN X W, et al. Projectile penetration of ultra-high performance cement based composites at 510−1 320 m/s [J]. Construction and Building Materials, 2015, 74: 188–200. DOI: 10.1016/j.conbuildmat.2014.10.041. [38] WU H, FANG Q, GONG J, et al. Projectile impact resistance of corundum aggregated UHP-SFRC [J]. International Journal of Impact Engineering, 2015, 84: 38–53. DOI: 10.1016/j.ijimpeng.2015.05.007. [39] LIU J, WU C Q, LI J, et al. Experimental and numerical study of reactive powder concrete reinforced with steel wire mesh against projectile penetration [J]. International Journal of Impact Engineering, 2017, 109: 131–149. DOI: 10.1016/j.ijimpeng.2017.06.006. [40] 张云升, 张文华, 刘建忠. 超高性能水泥基复合材料 [M]. 北京: 科学出版社, 2014. -

下载:

下载: