Numerical study of blast resistance of curved steel-concrete-steel composite slabs

-

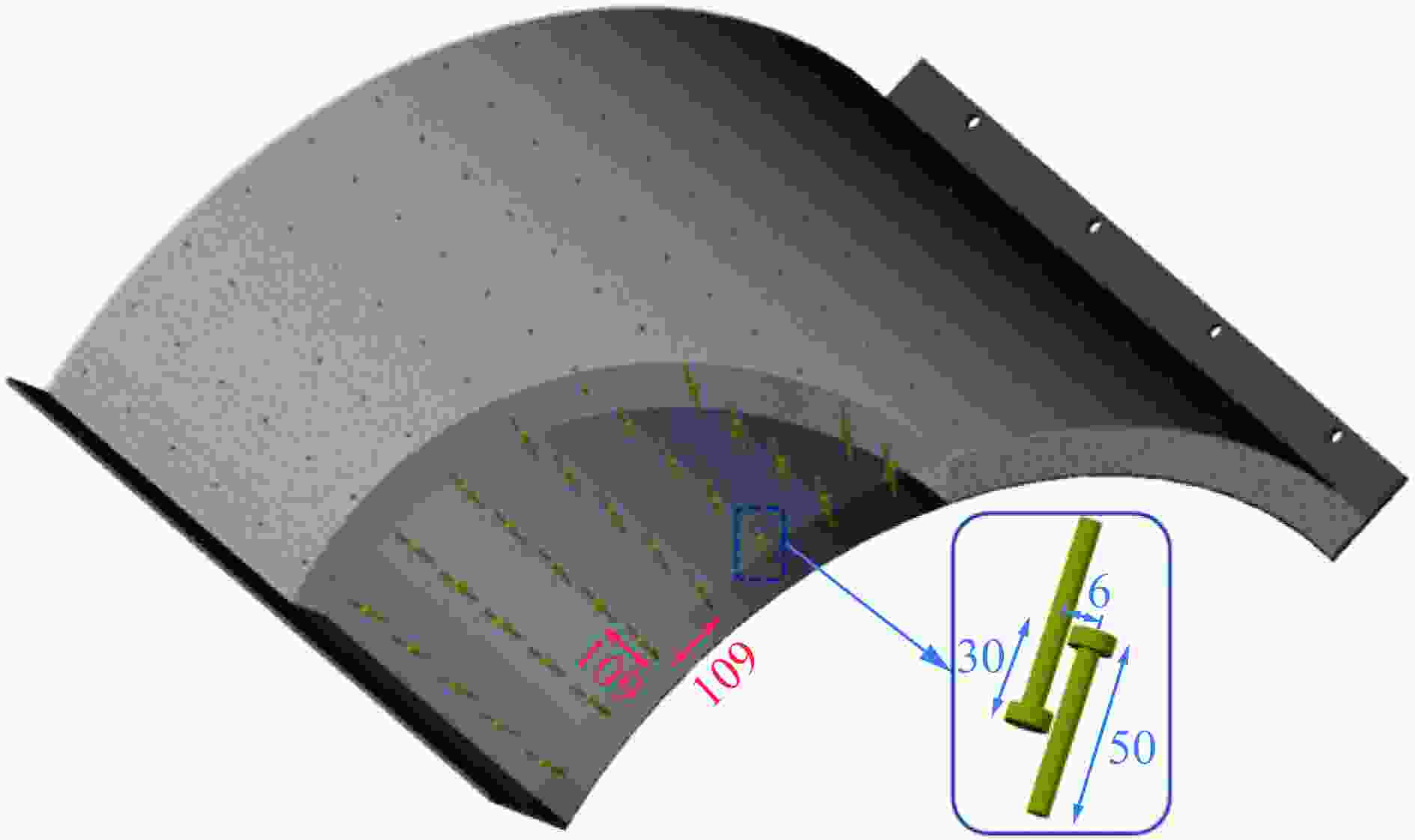

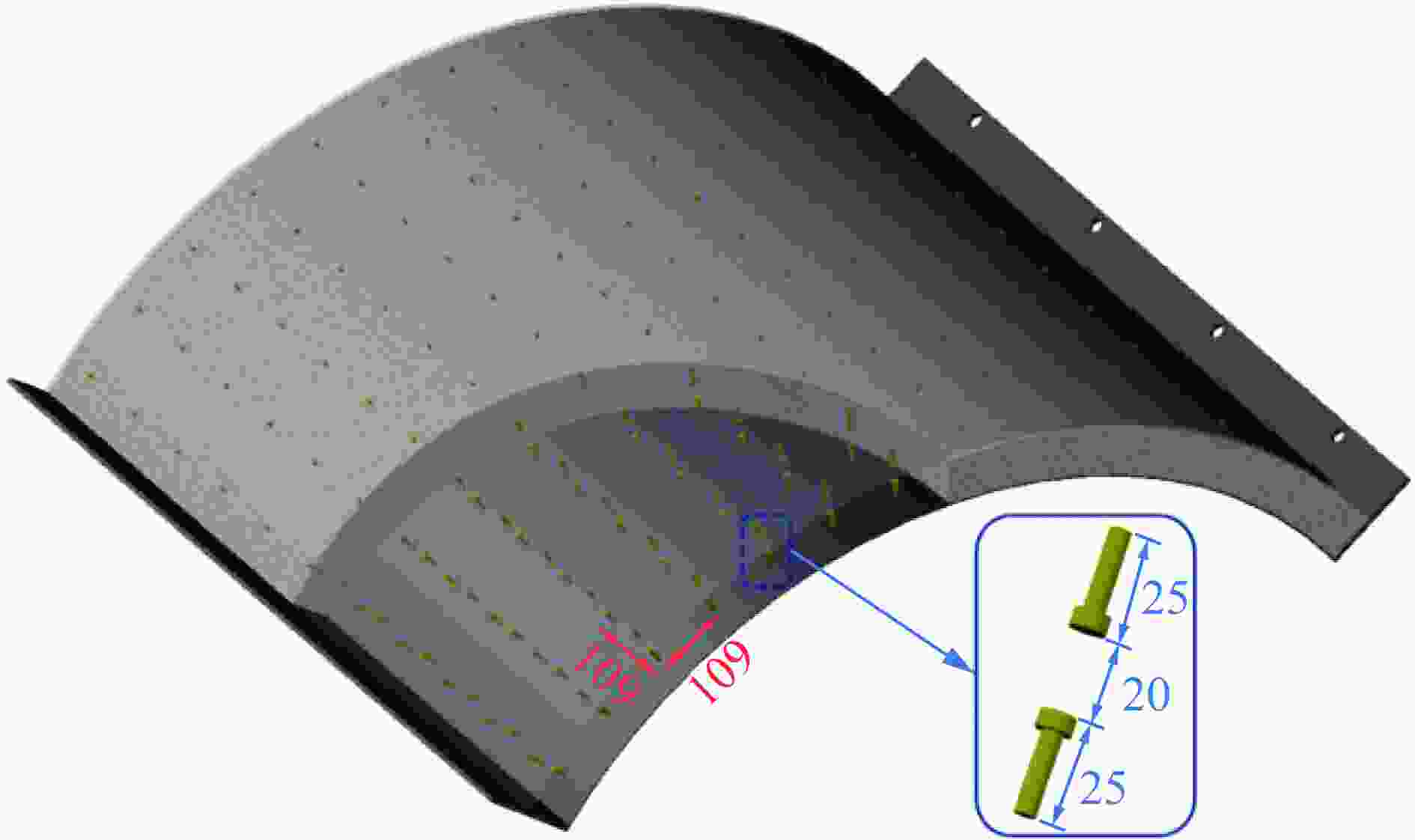

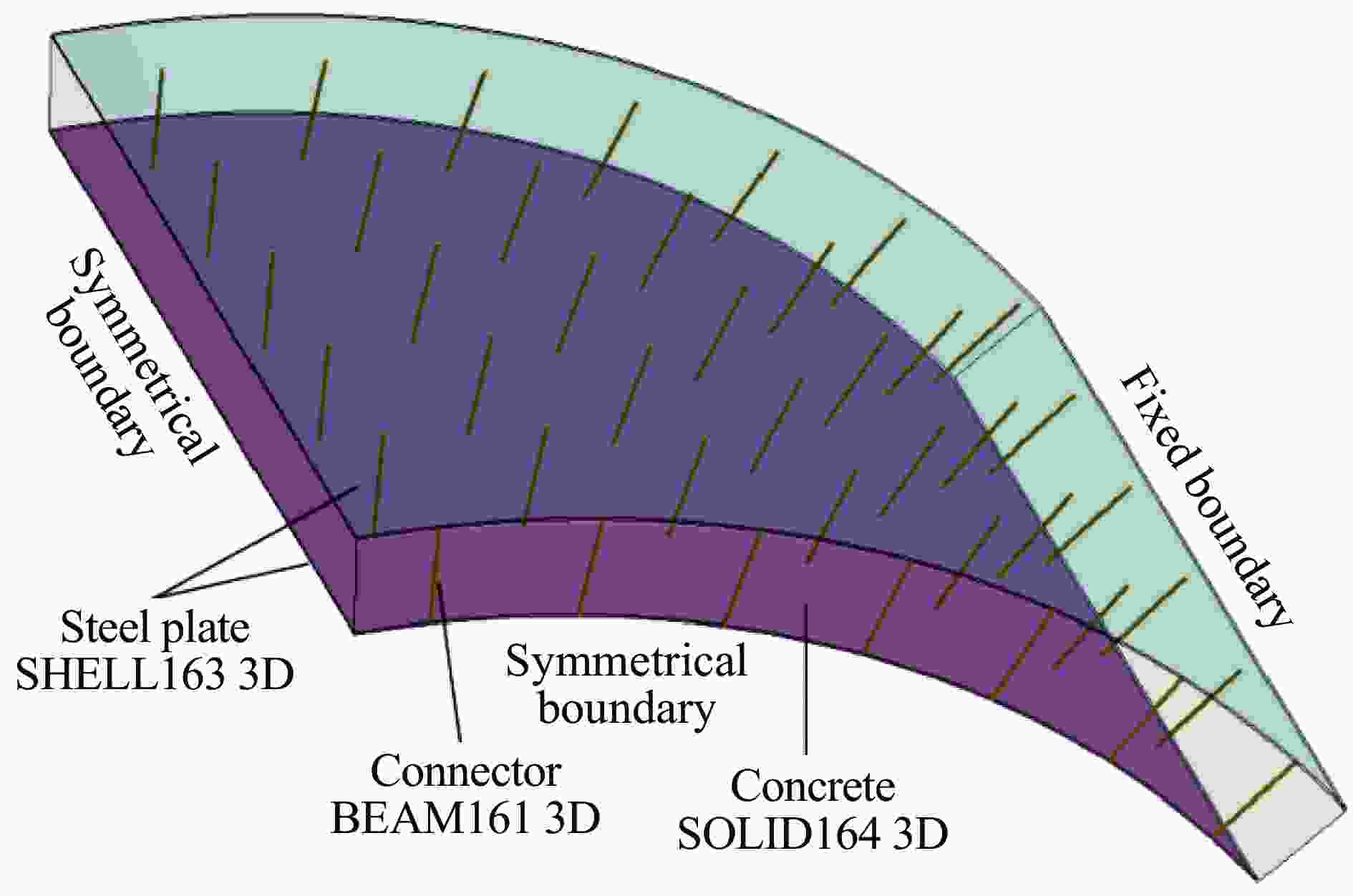

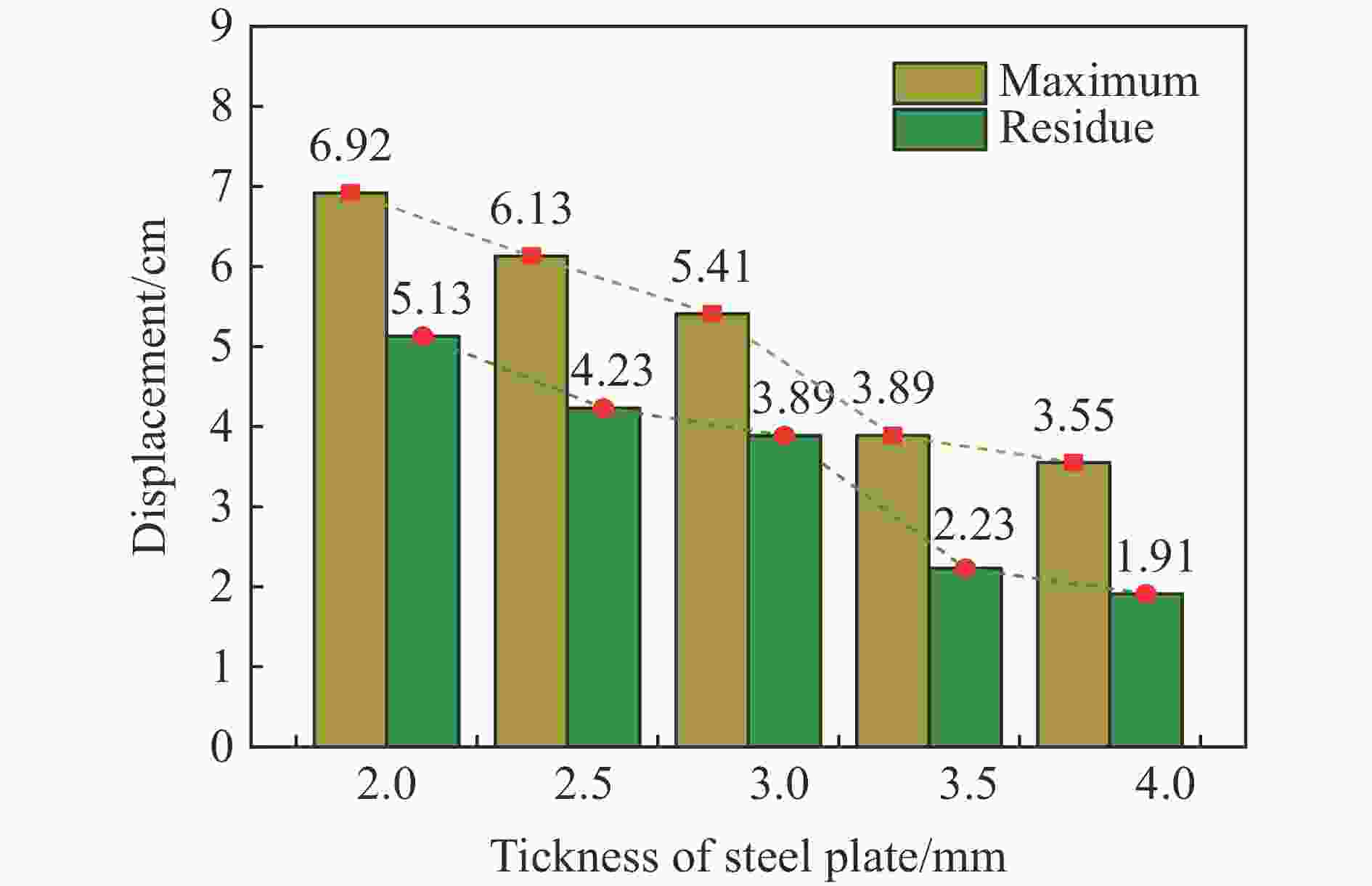

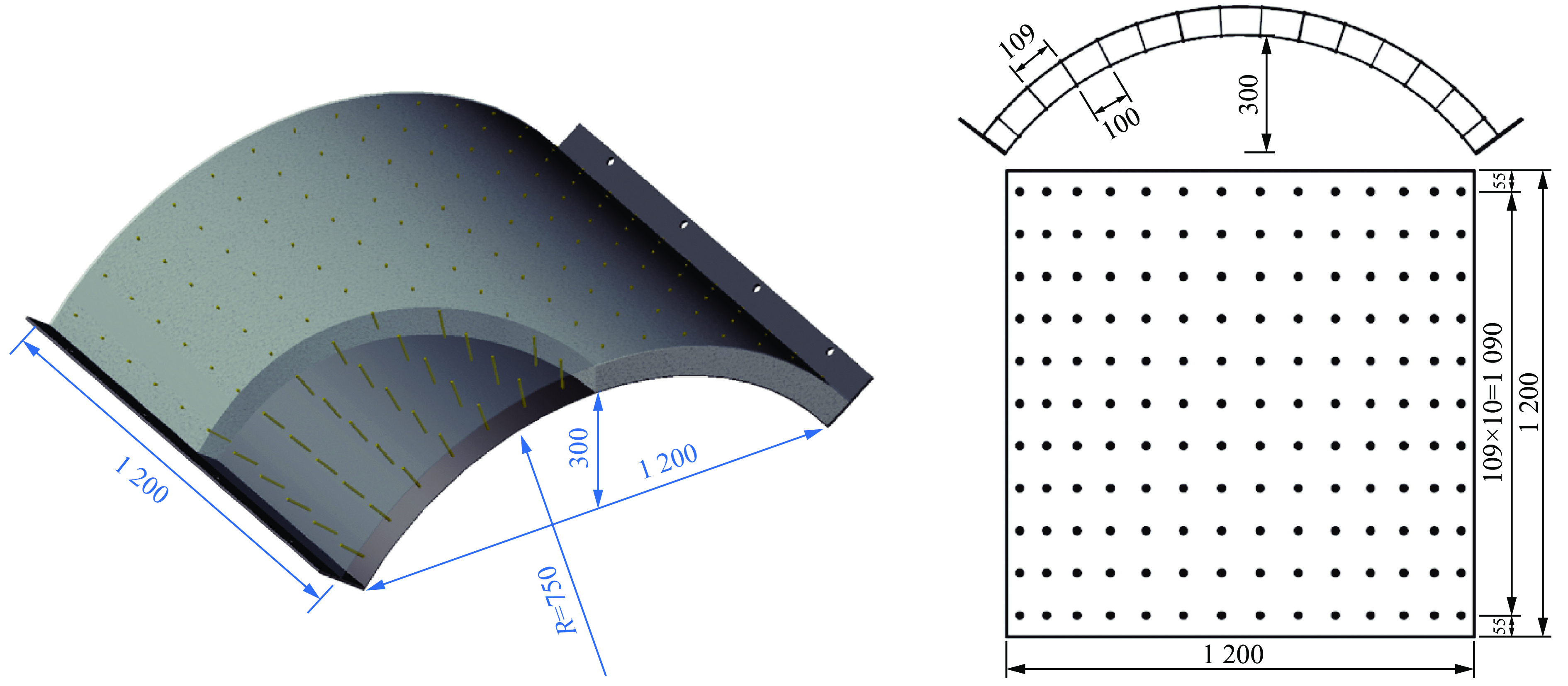

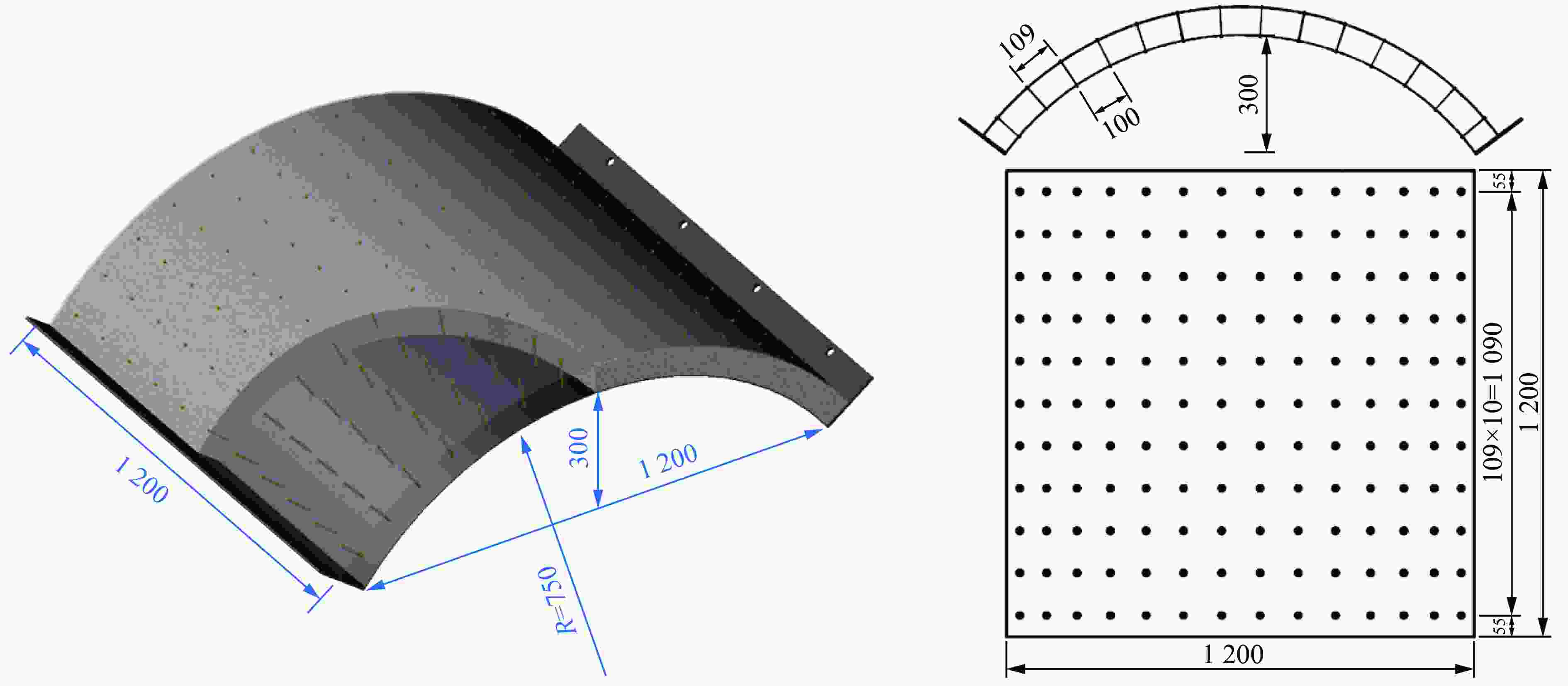

摘要: 依据规范设计了3种不同连接件的弧形双钢板混凝土组合板,基于ANSYS/LS-DYNA非线性有限元程序研究了弧形双钢板混凝土组合板在近场爆炸作用下的损伤模式、跨中位移变化以及能量消耗状况等,对比研究了3种不同板的耗能状况及损伤机理。以背爆面钢板跨中位移为指标,分析了用药量、混凝土强度和钢板厚度等参数对弧形双钢板混凝土板抗爆性能的影响规律。结果表明:在近场爆炸作用下,弧形板均保持良好的整体性,没有出现混凝土飞散现象,仍具有持续承载能力,比传统平面双钢板混凝土组合板具有更加优异的抗爆性能;重叠栓钉的连接性能强于栓钉,稍弱于对拉螺栓;提高混凝土强度不能改善混凝土的损伤状况,但能减小跨中位移;增加钢板厚度能显著减小钢板跨中位移,提高弧形双钢板混凝土组合板的抗爆能力。

-

关键词:

- 爆炸荷载 /

- 弧形双钢板混凝土组合板 /

- 抗爆性能 /

- 动态响应

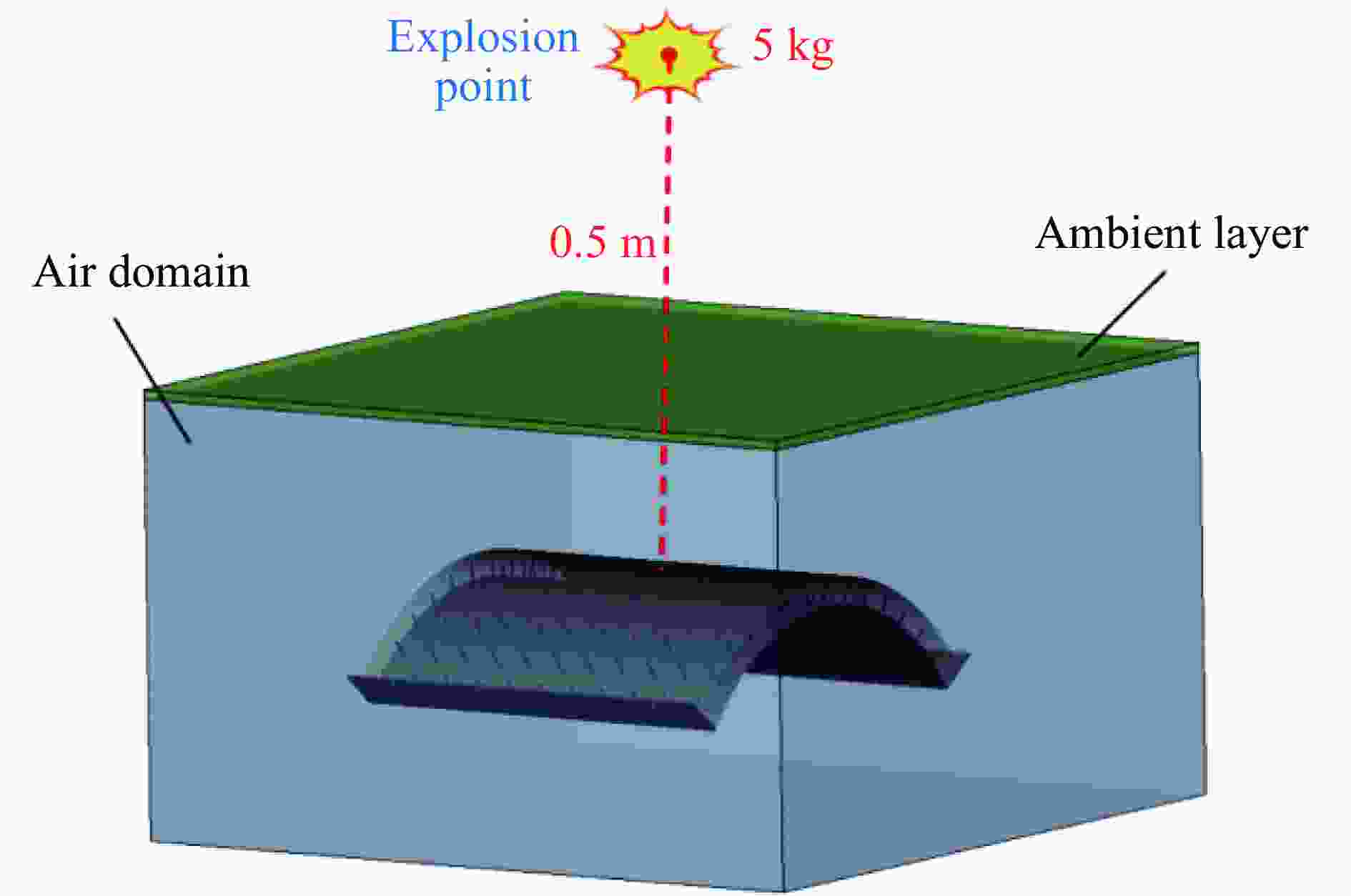

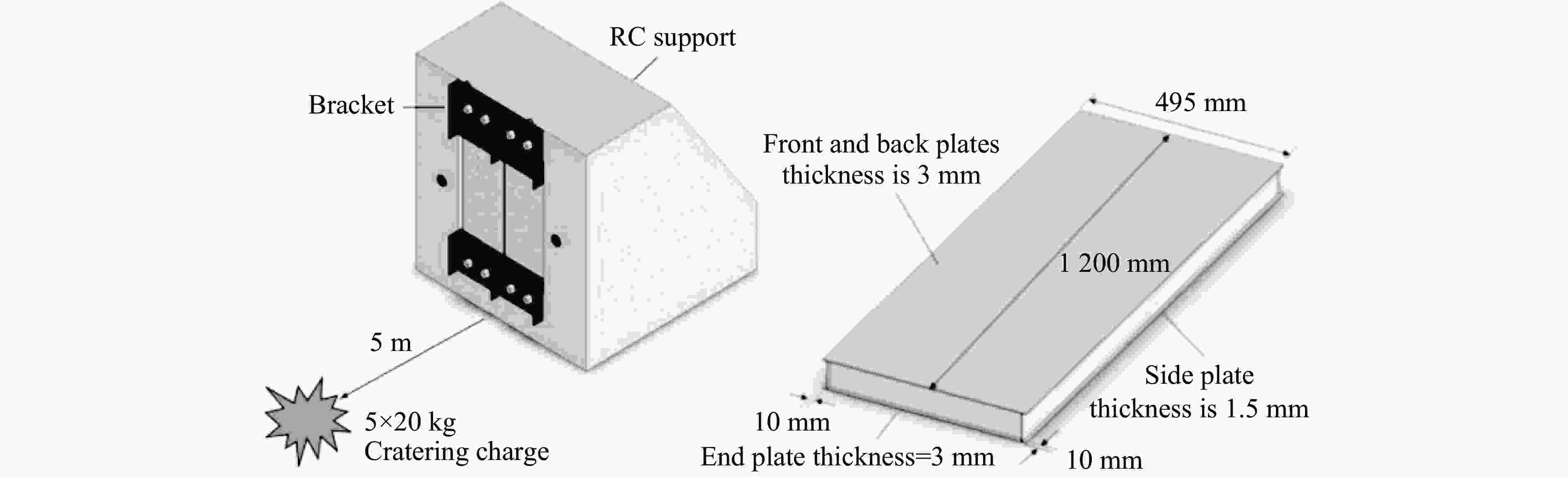

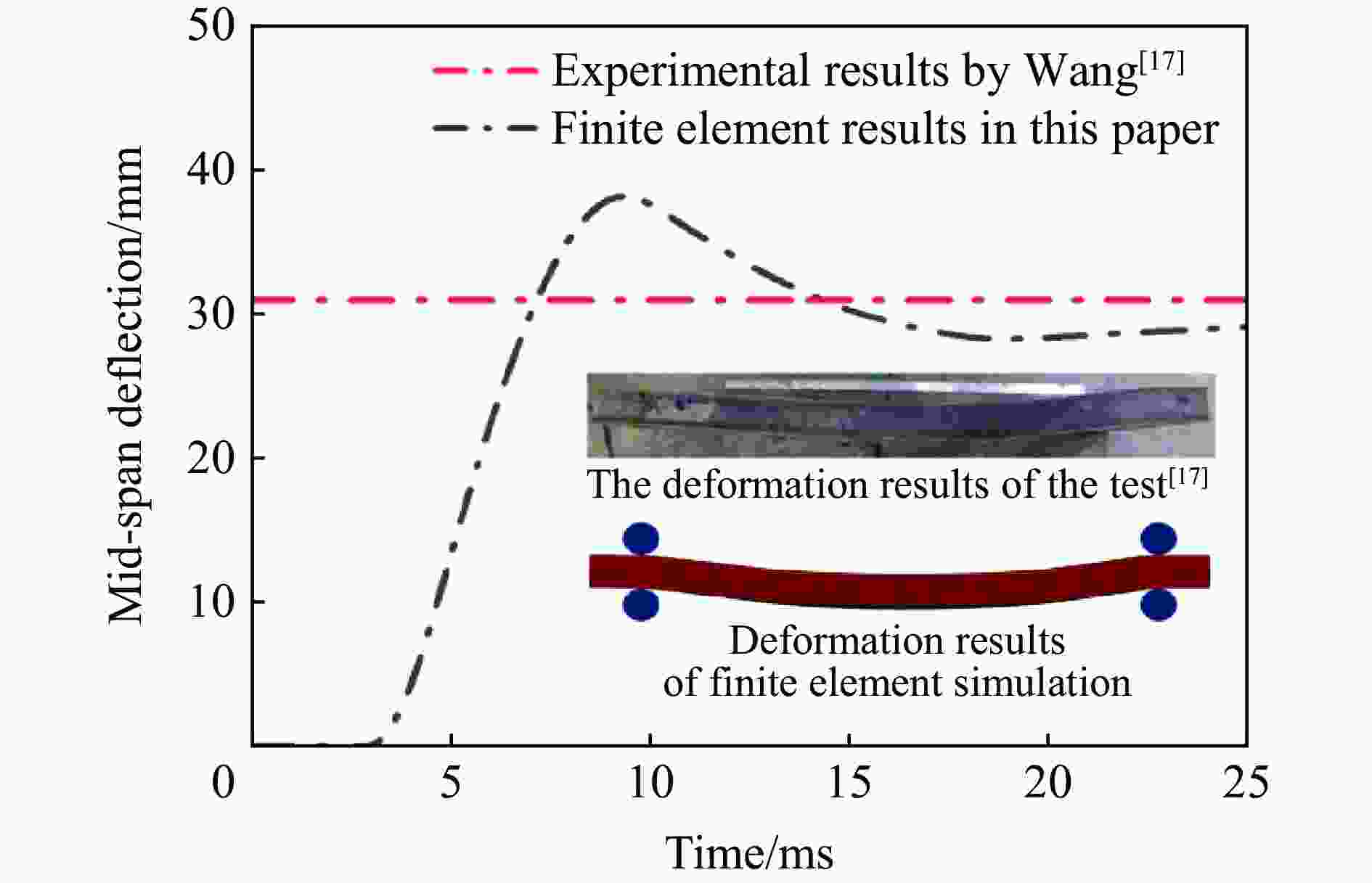

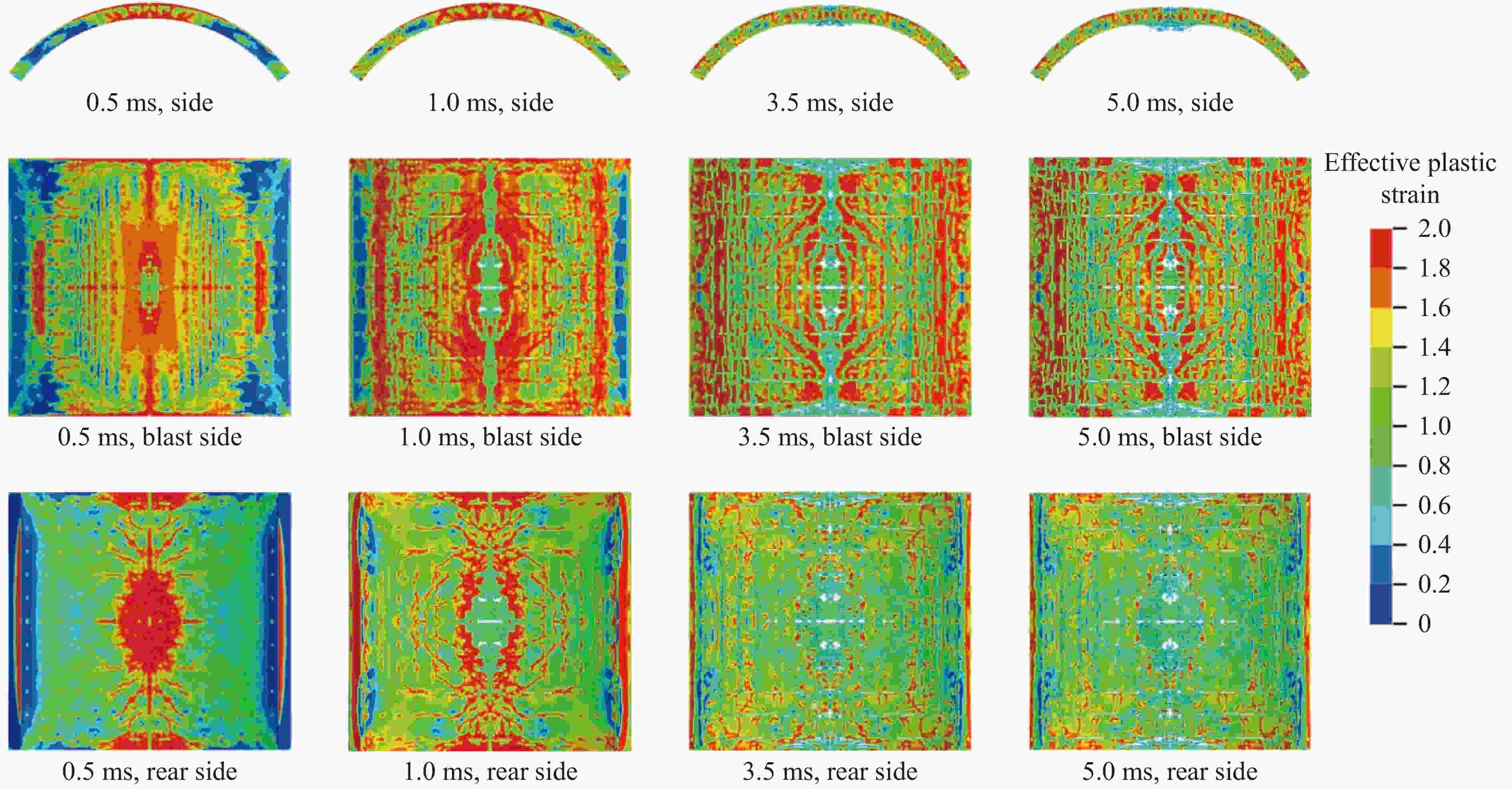

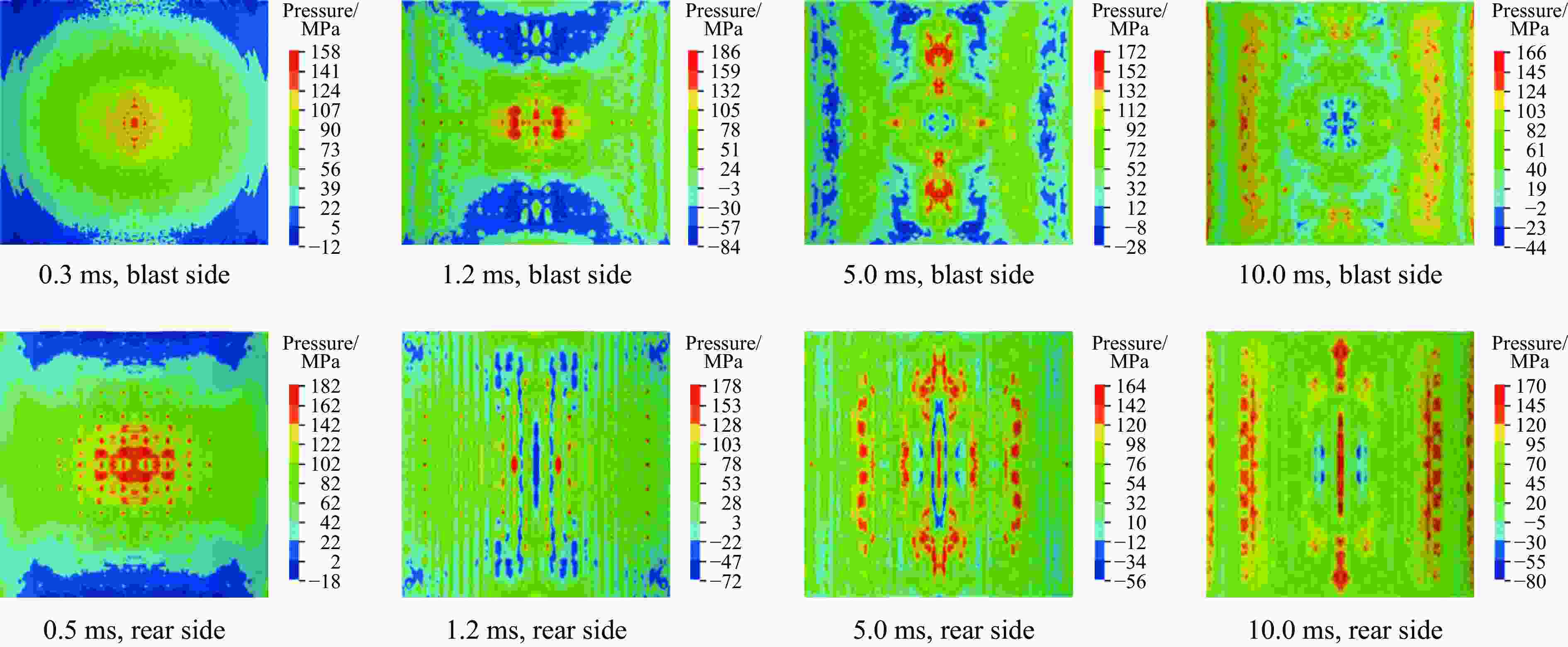

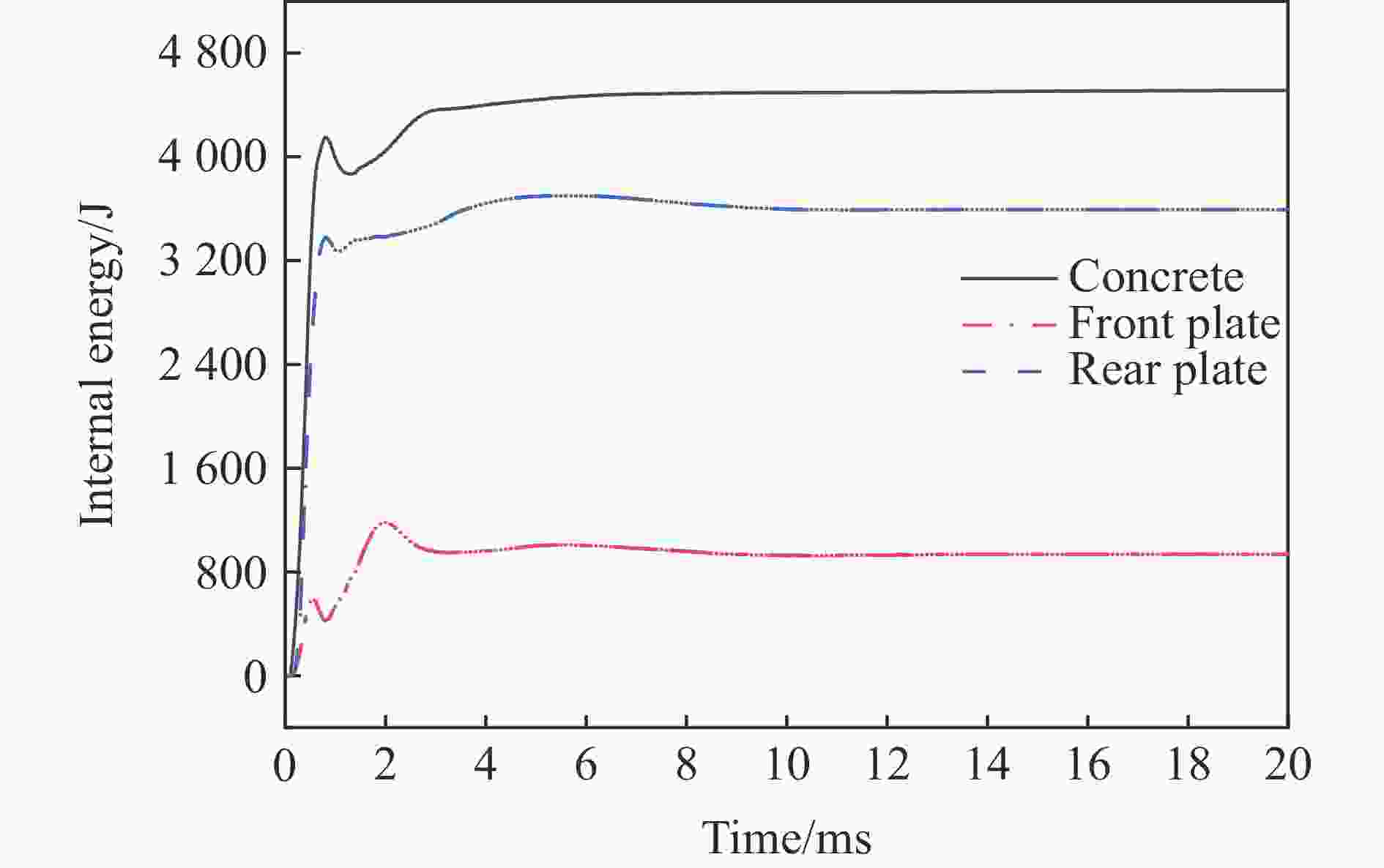

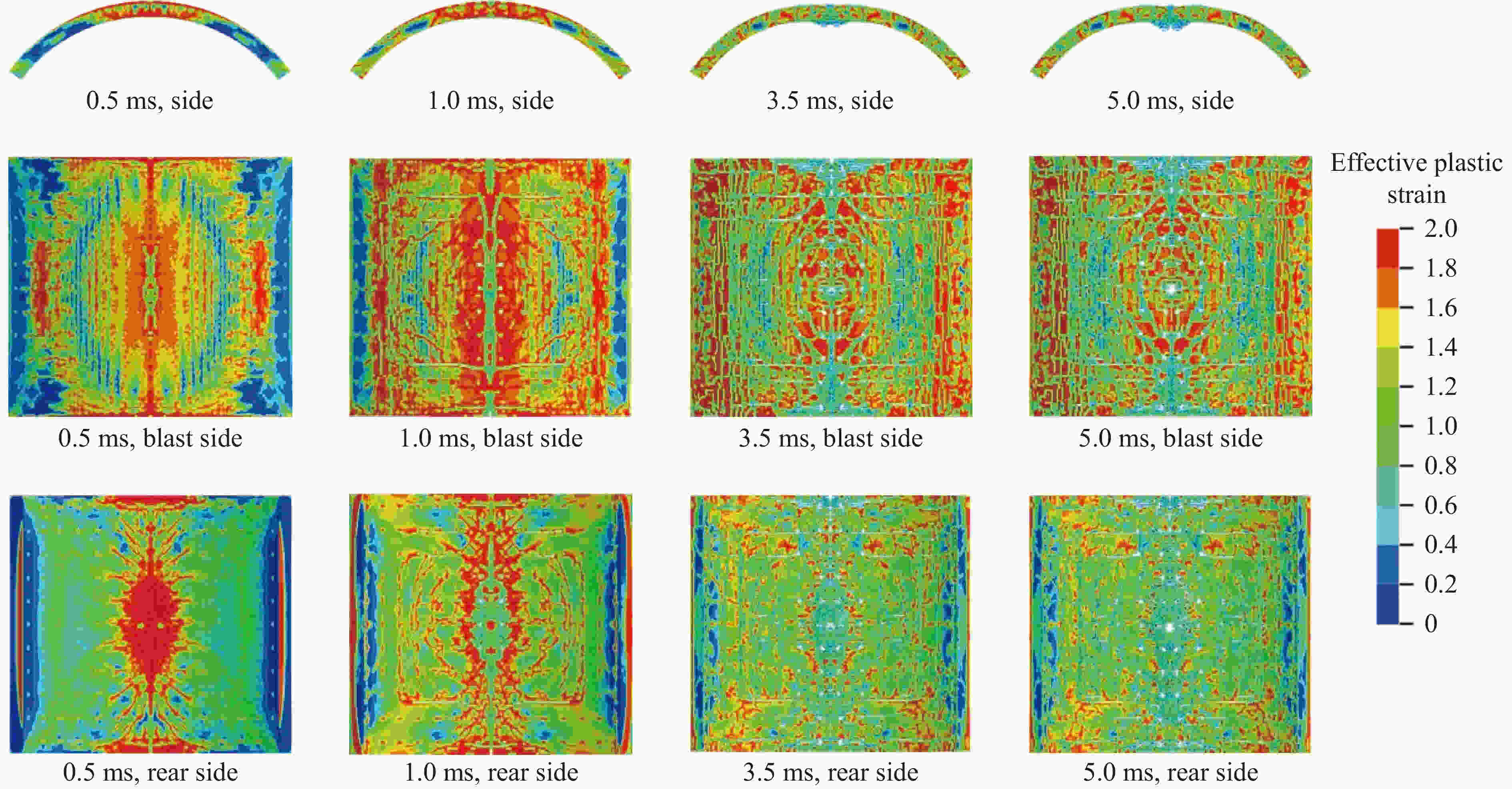

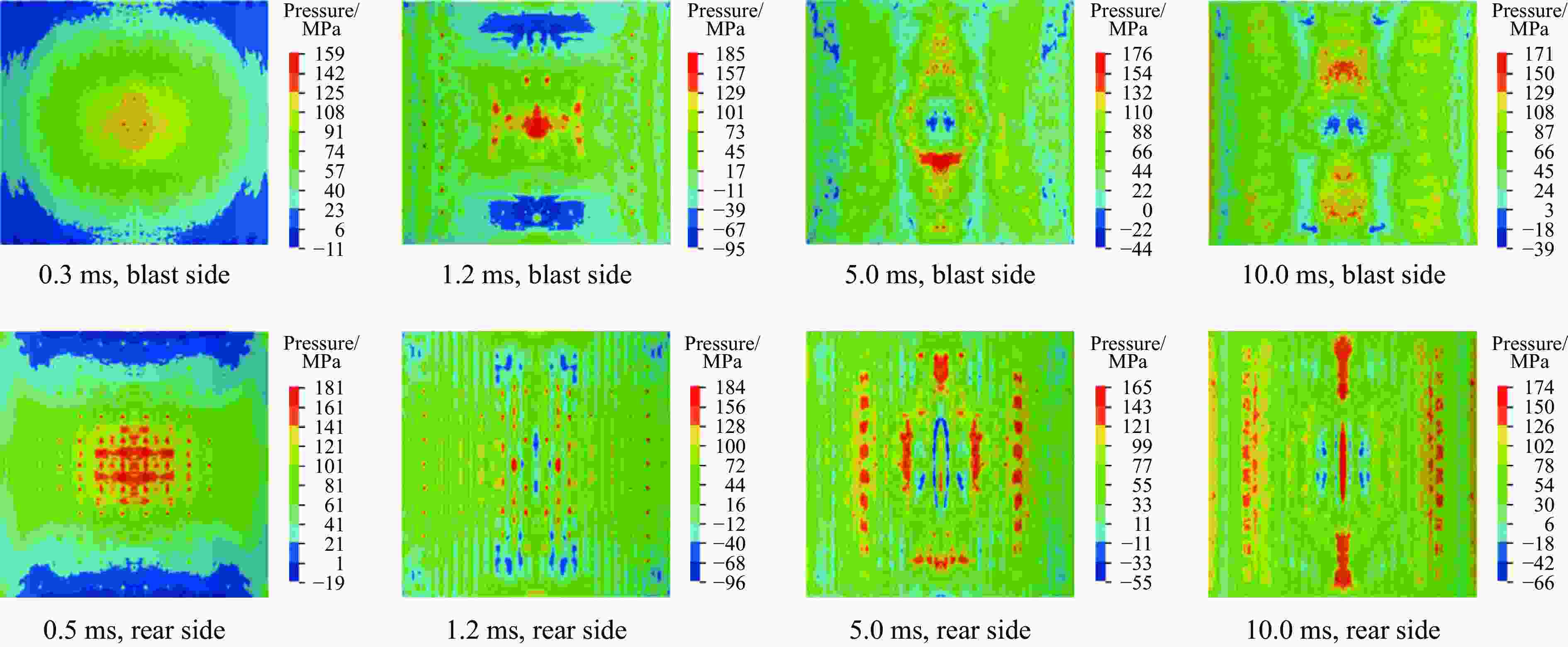

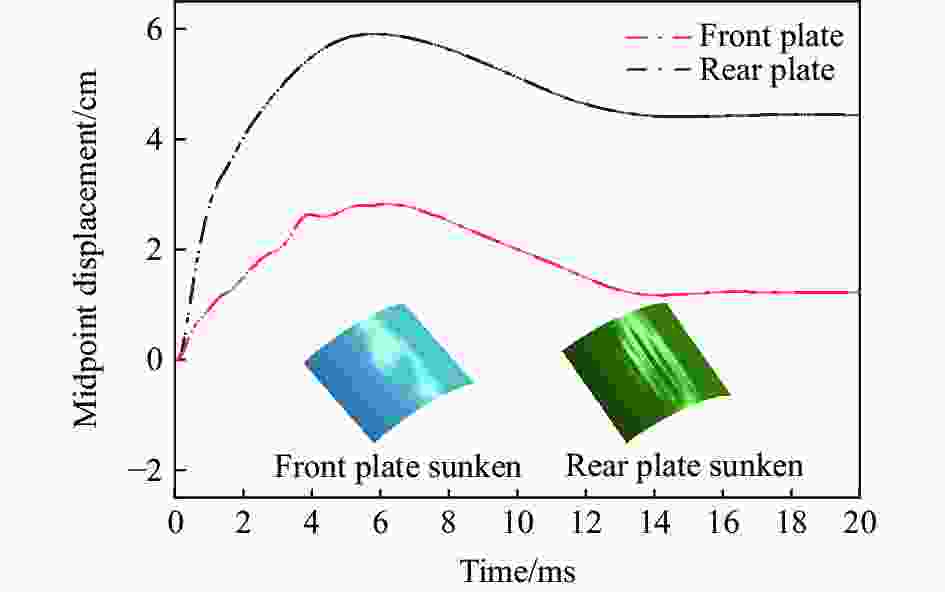

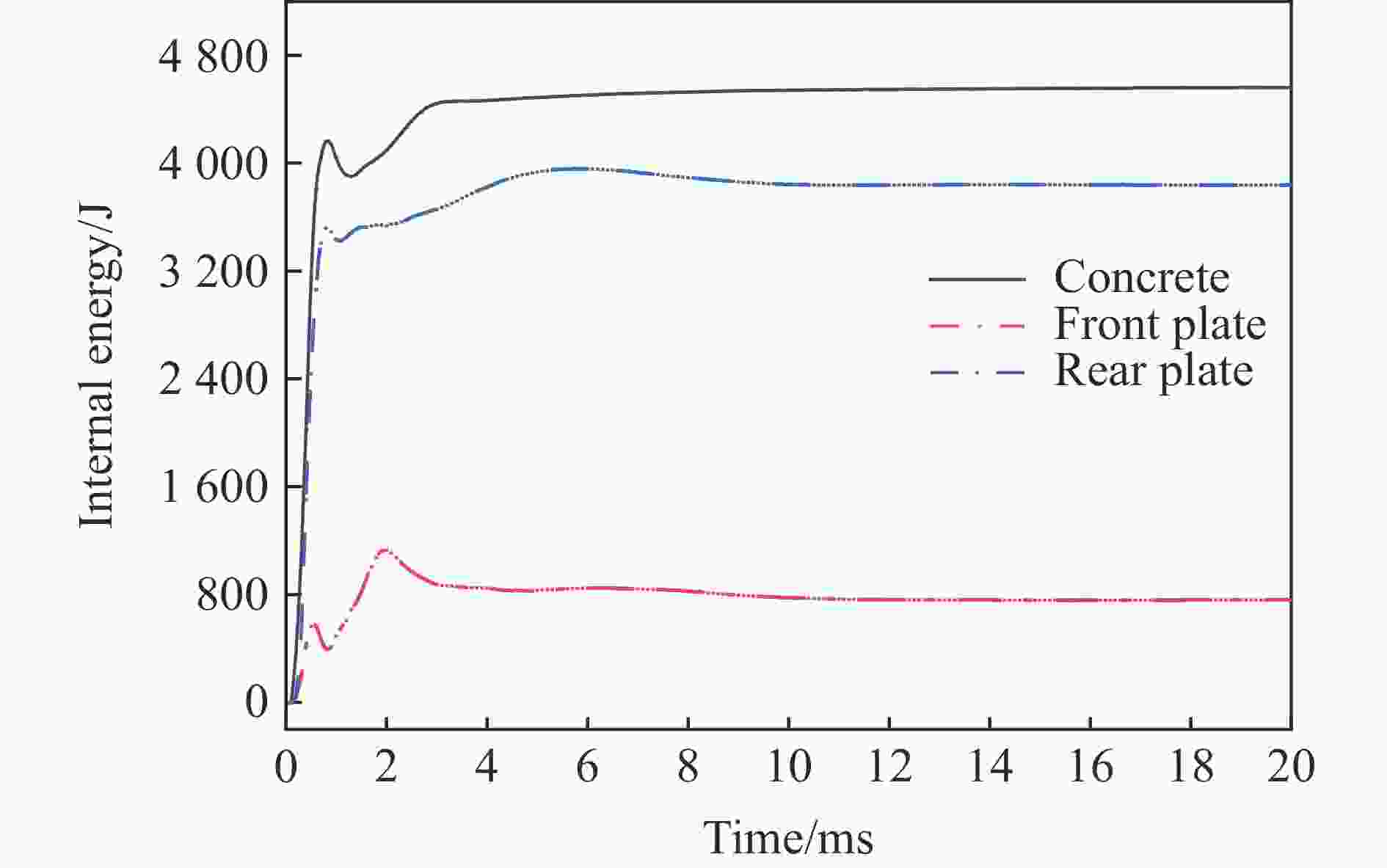

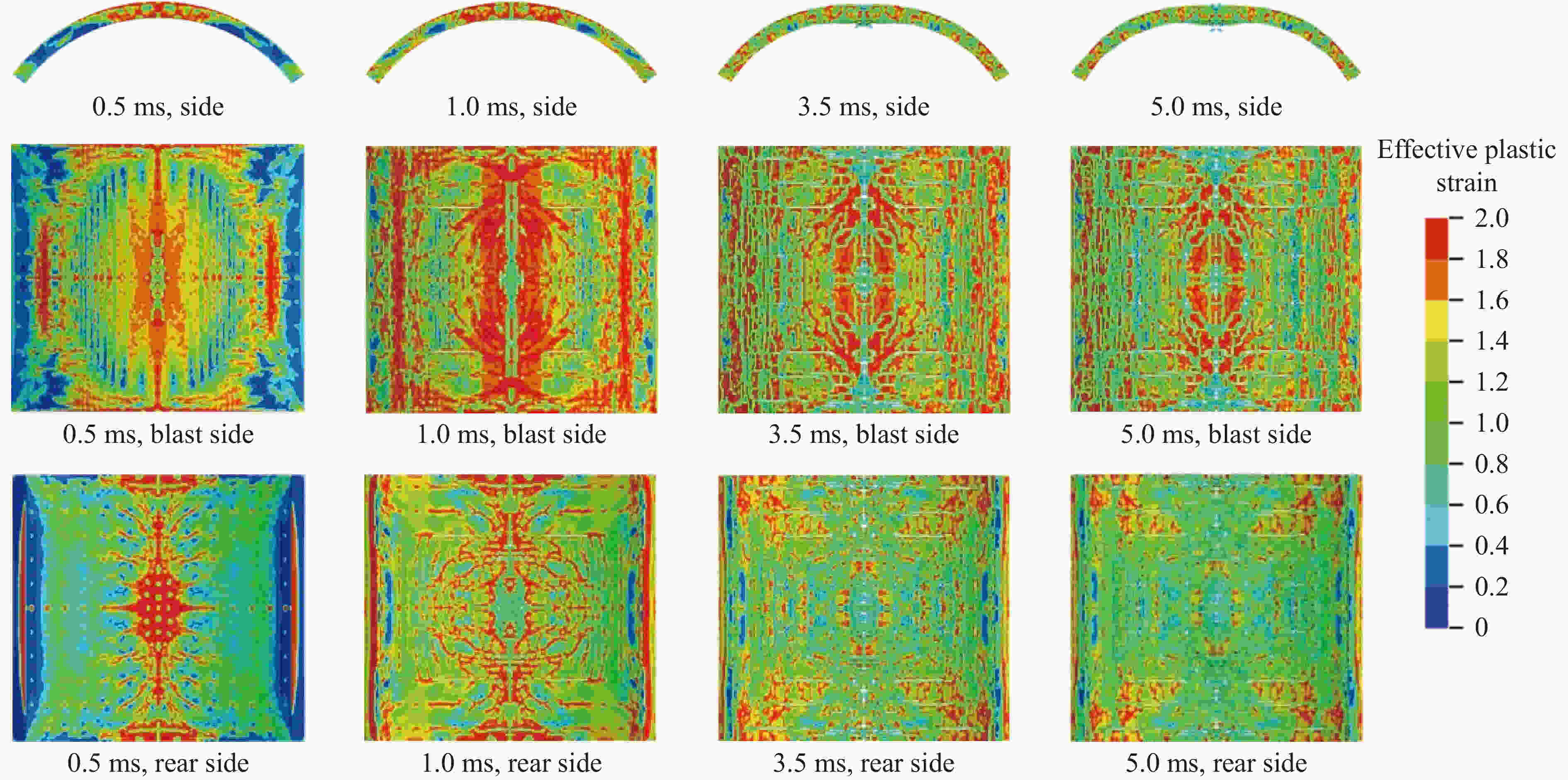

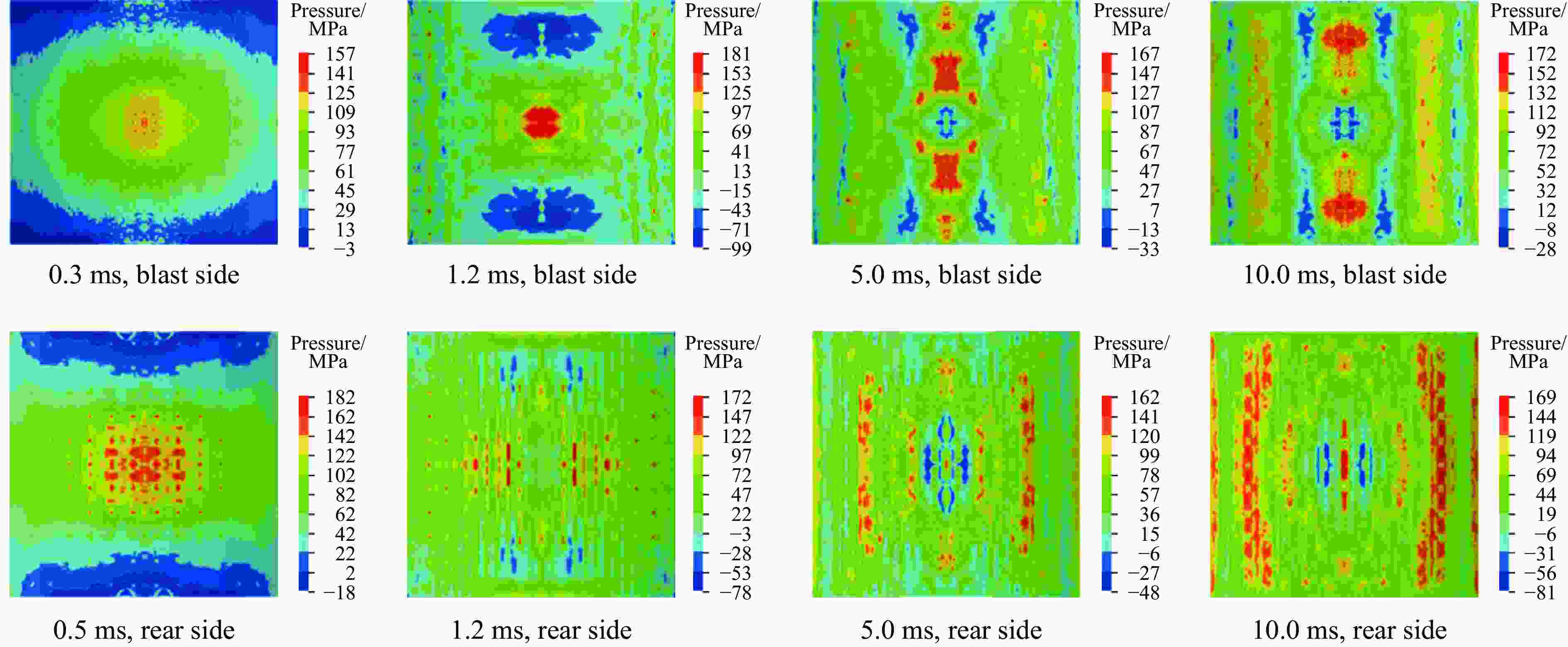

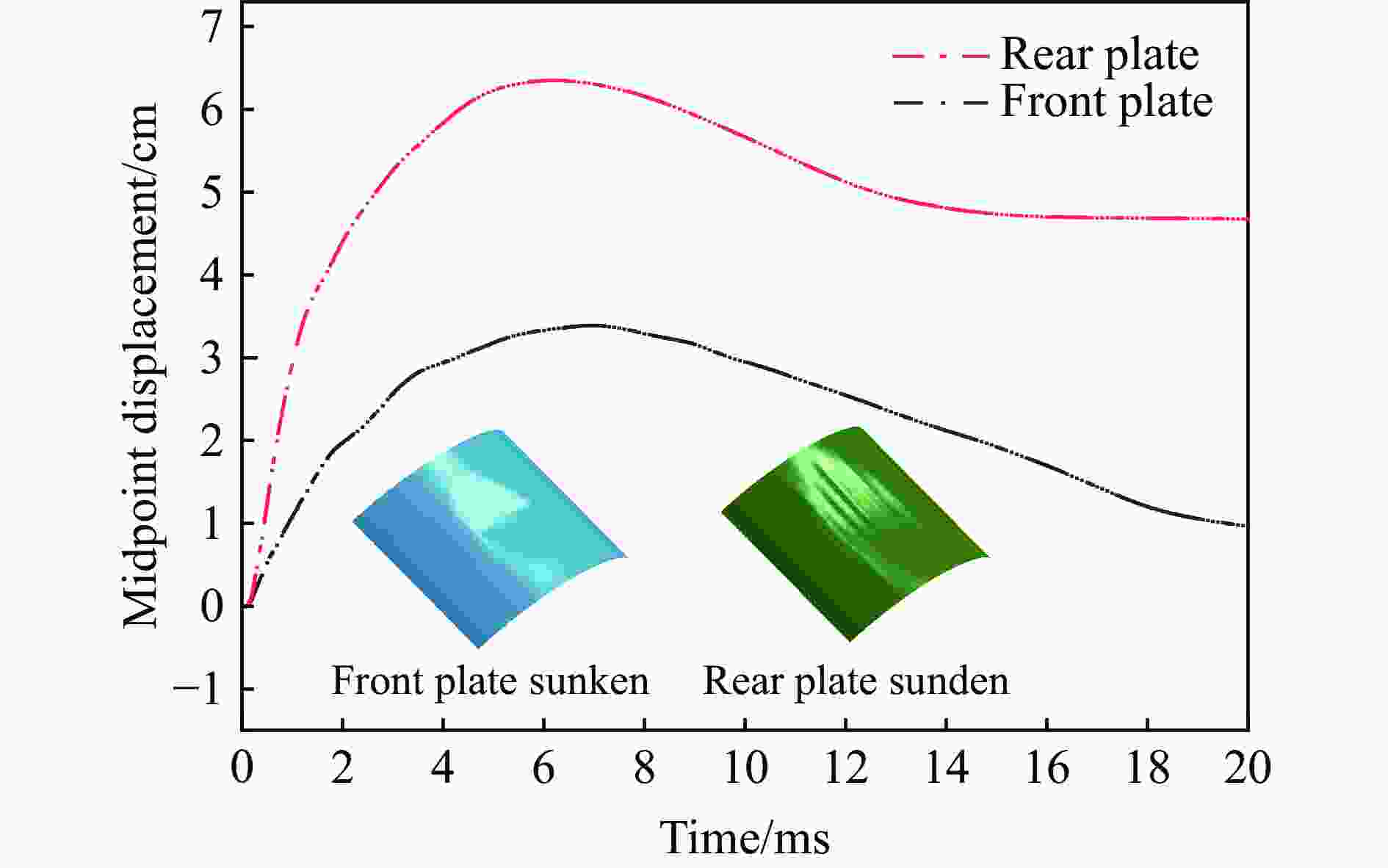

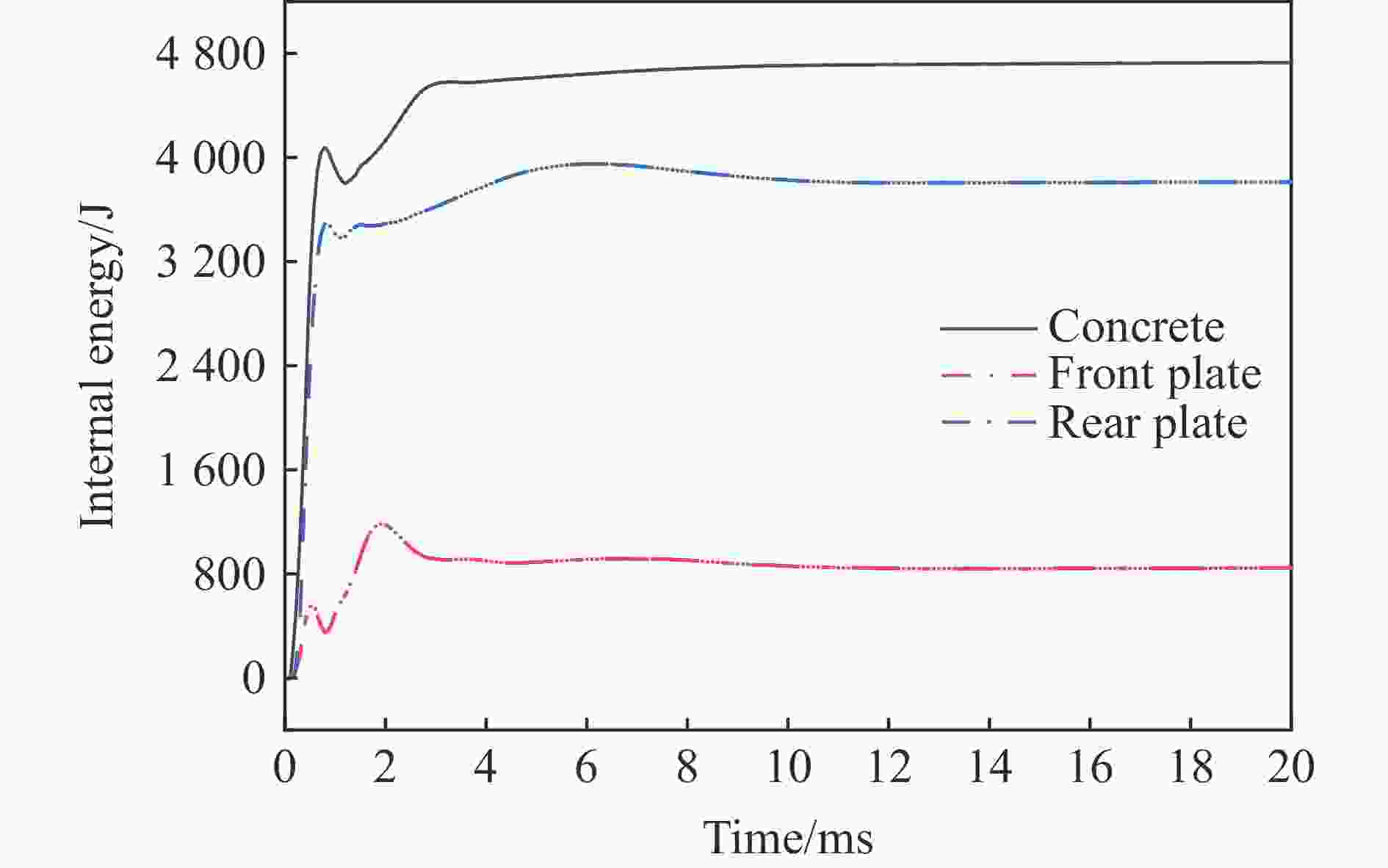

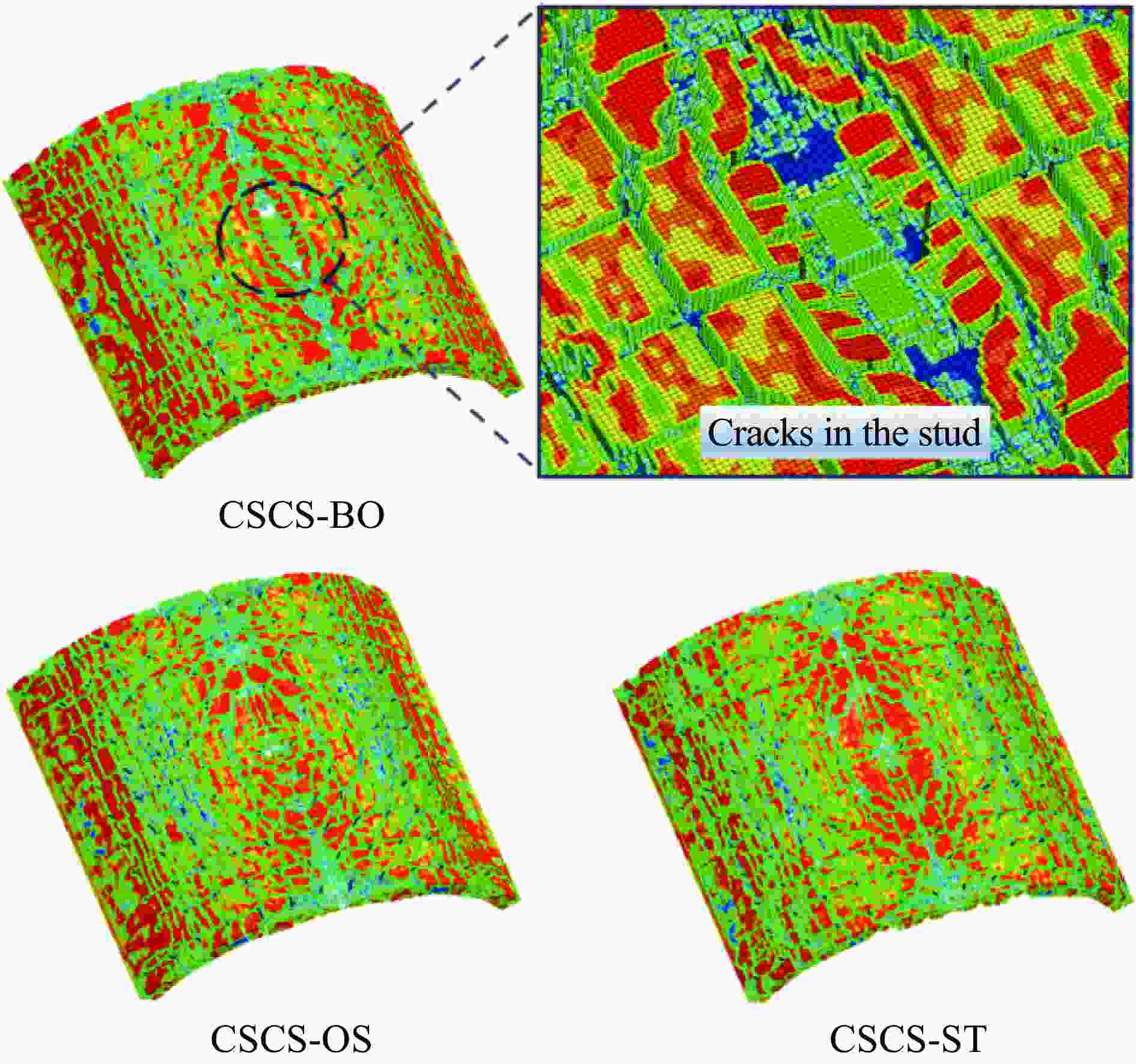

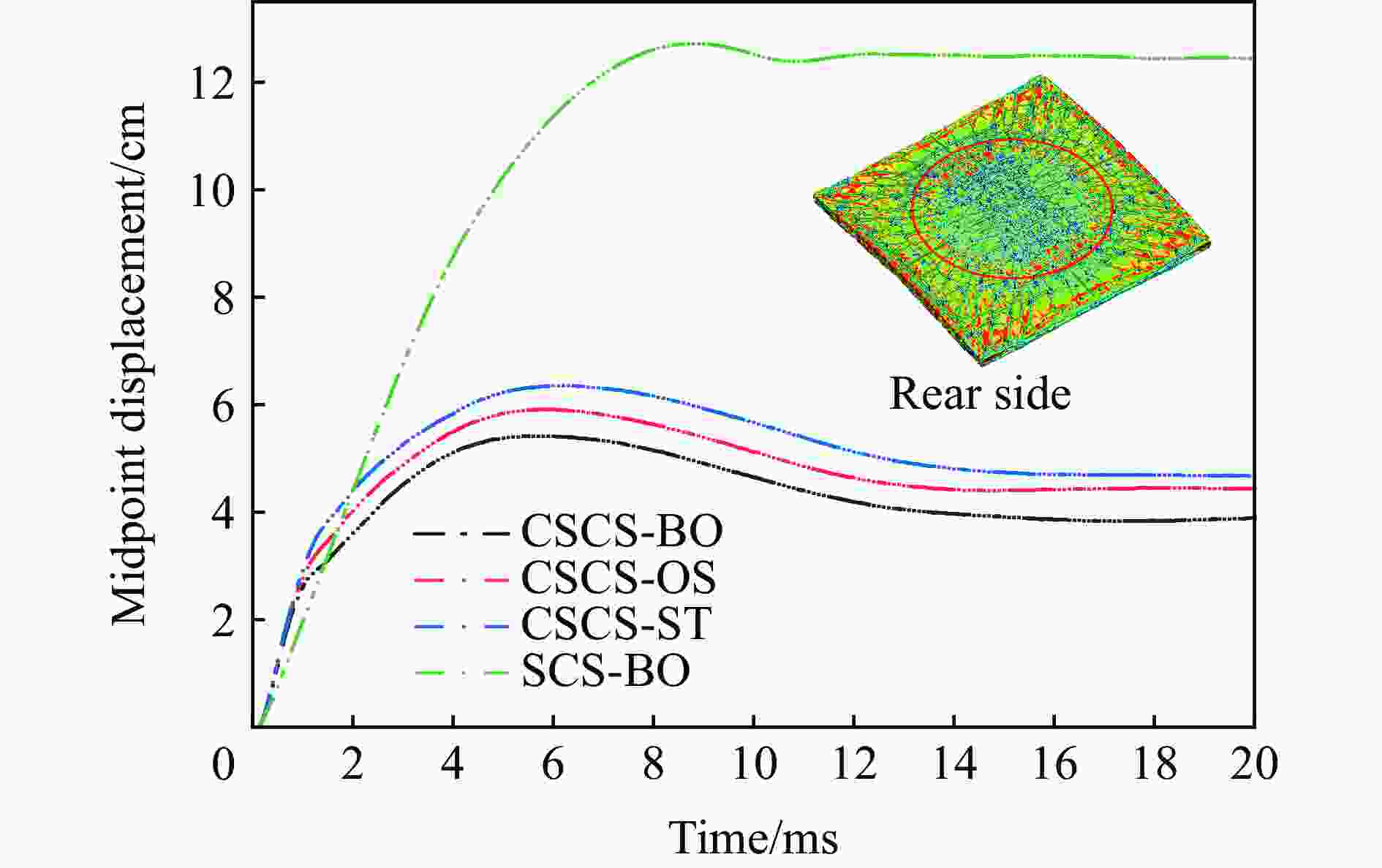

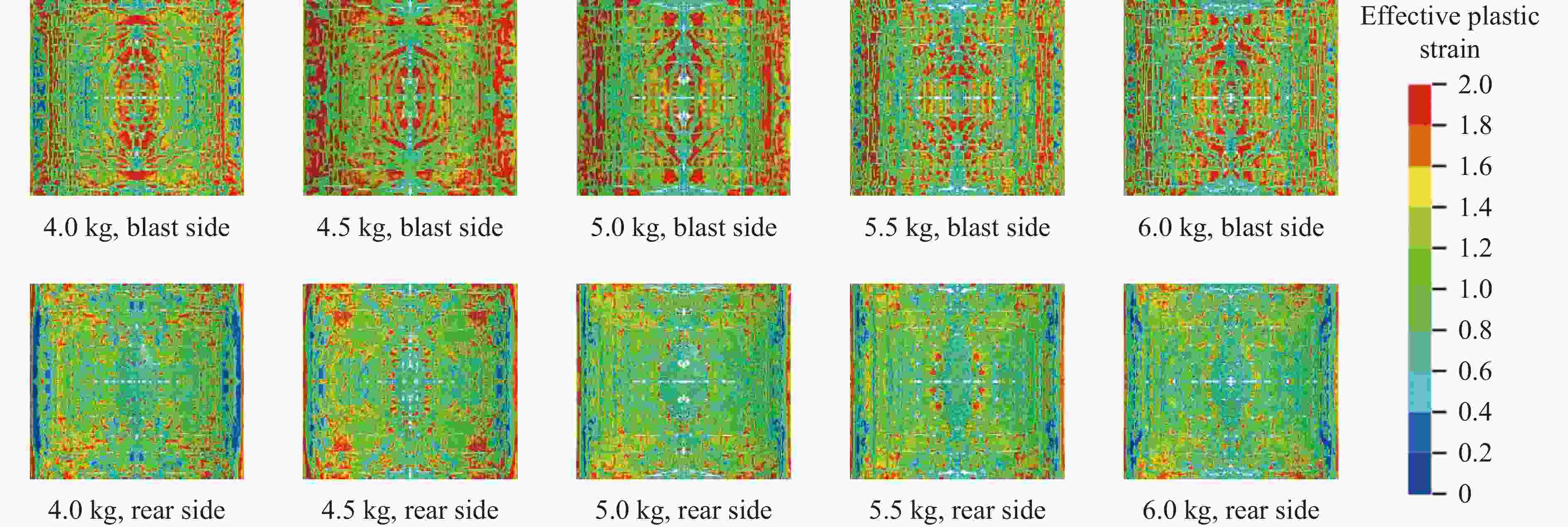

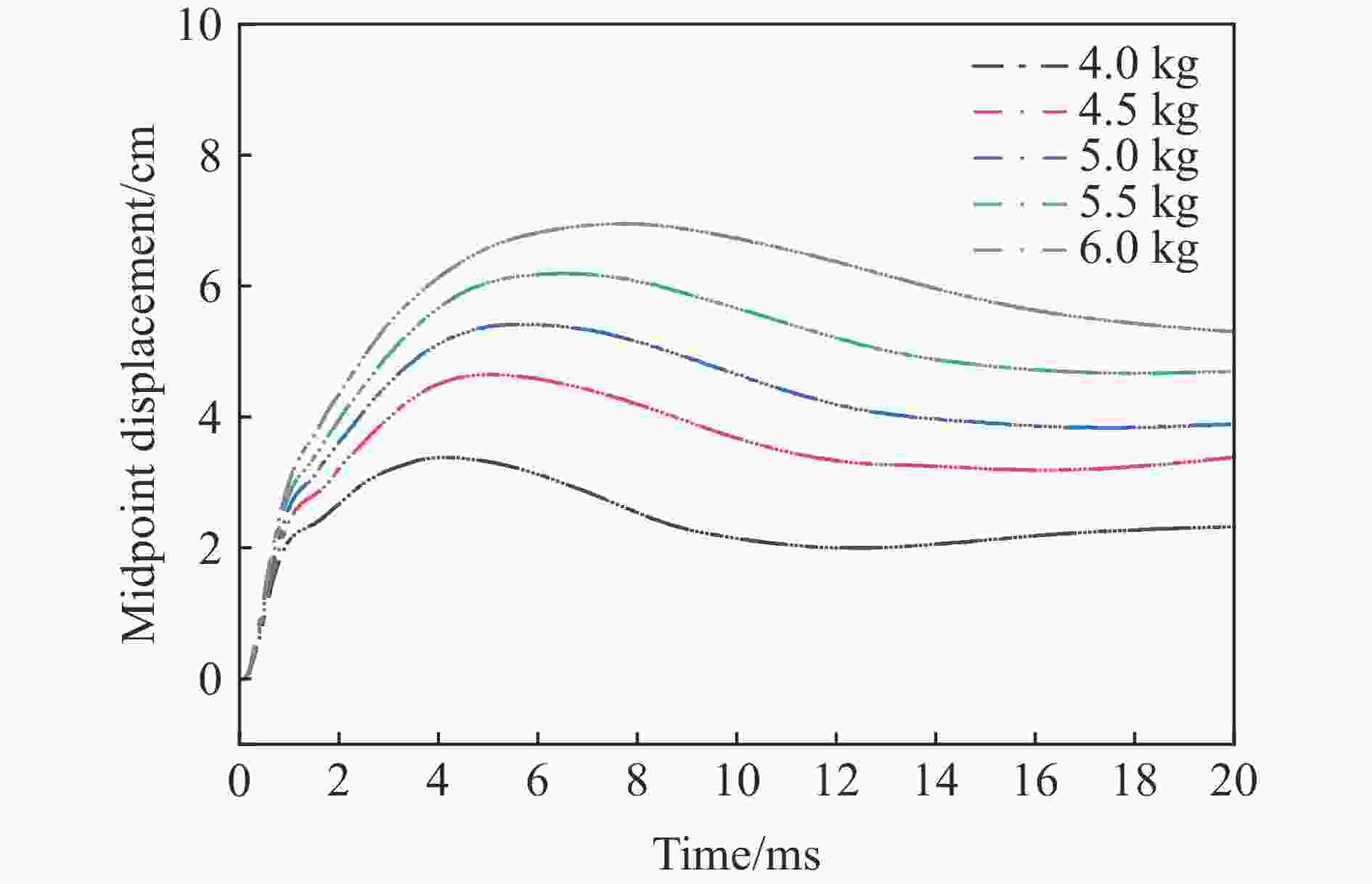

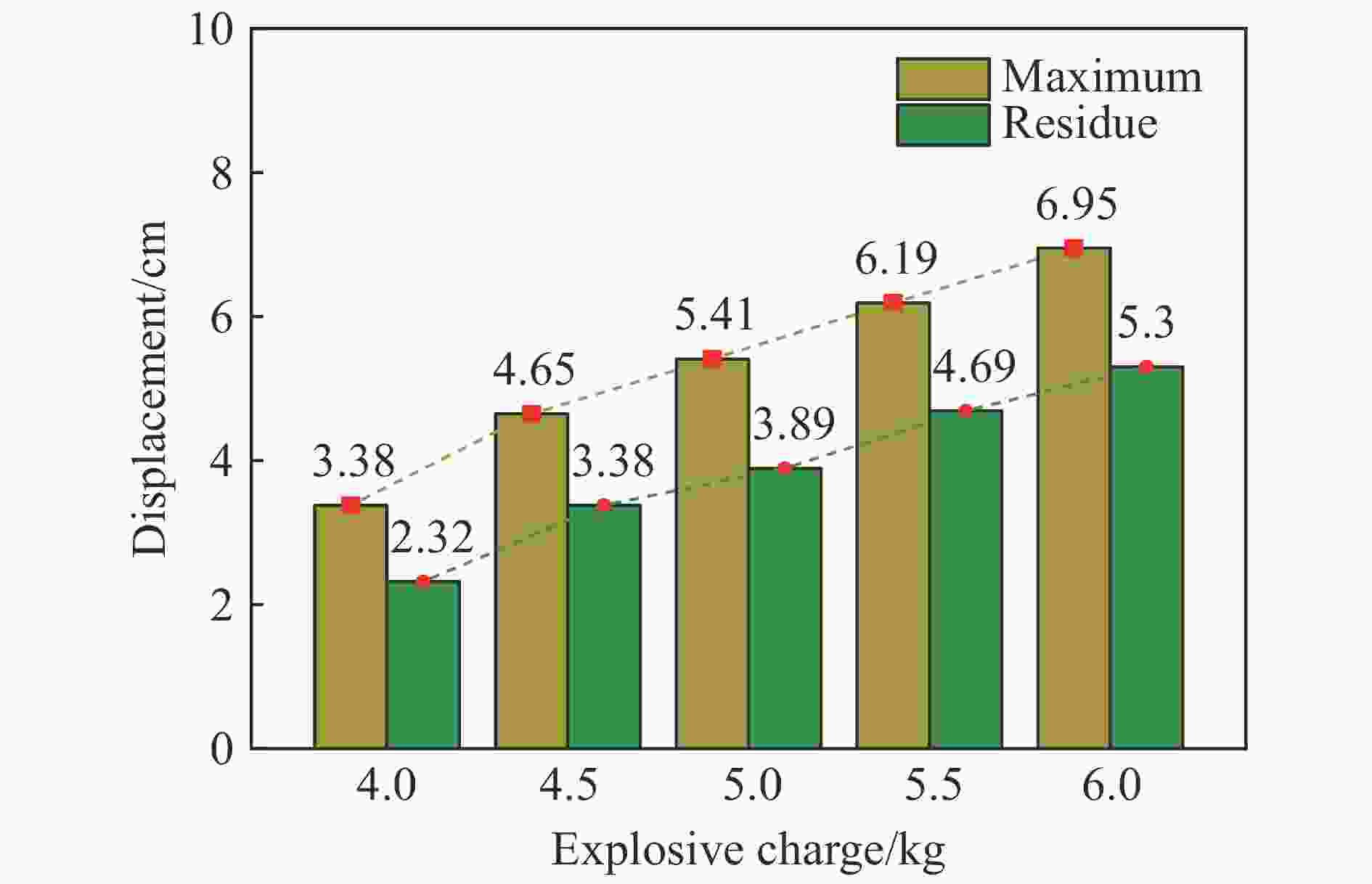

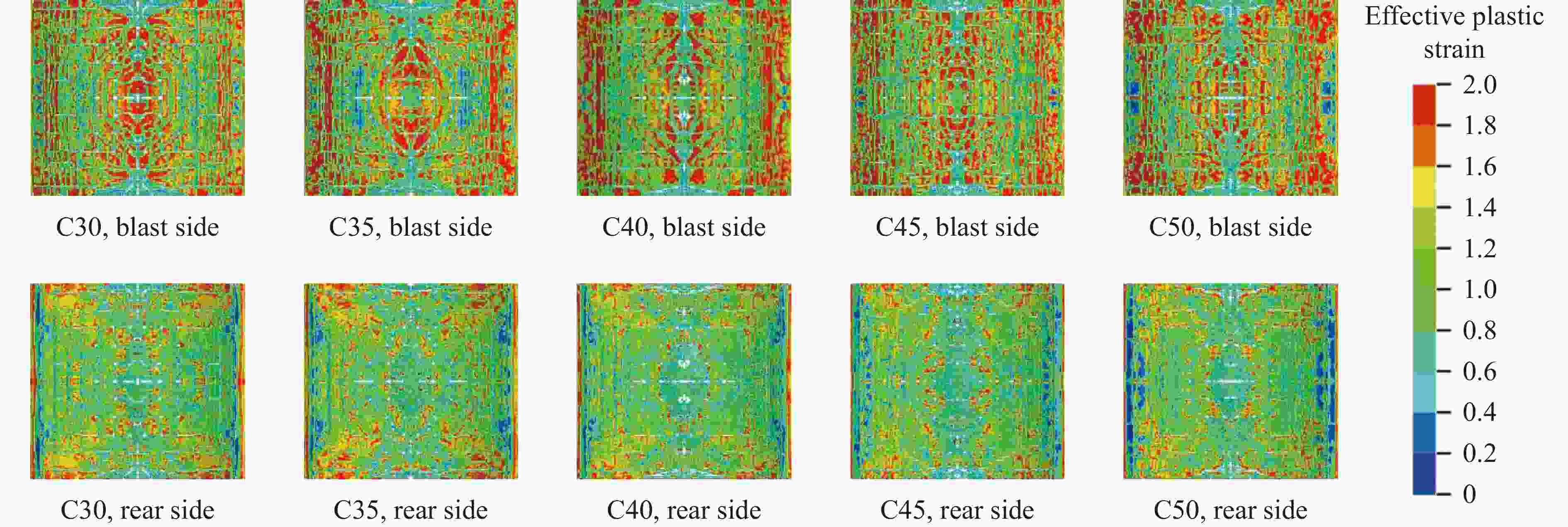

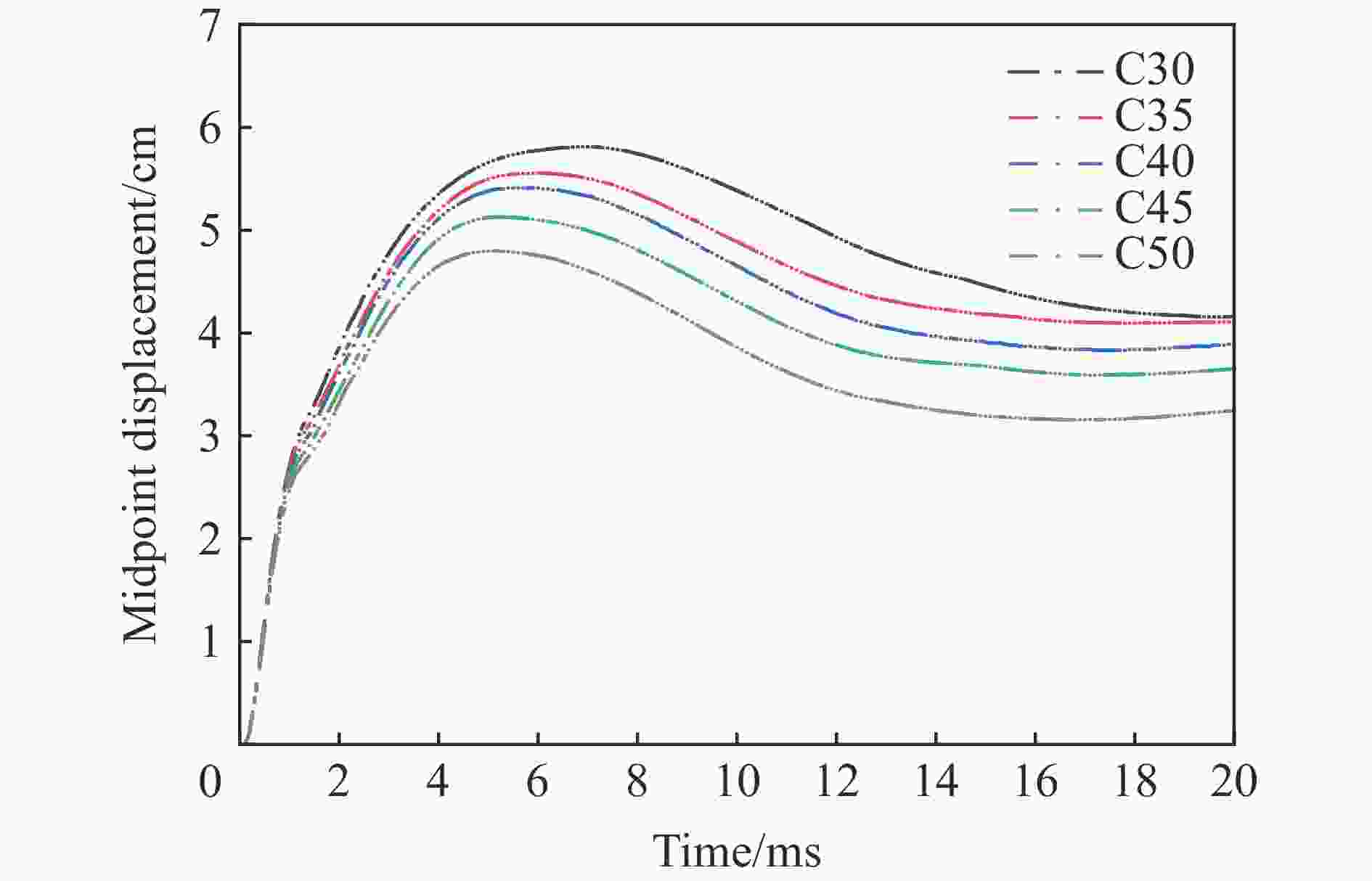

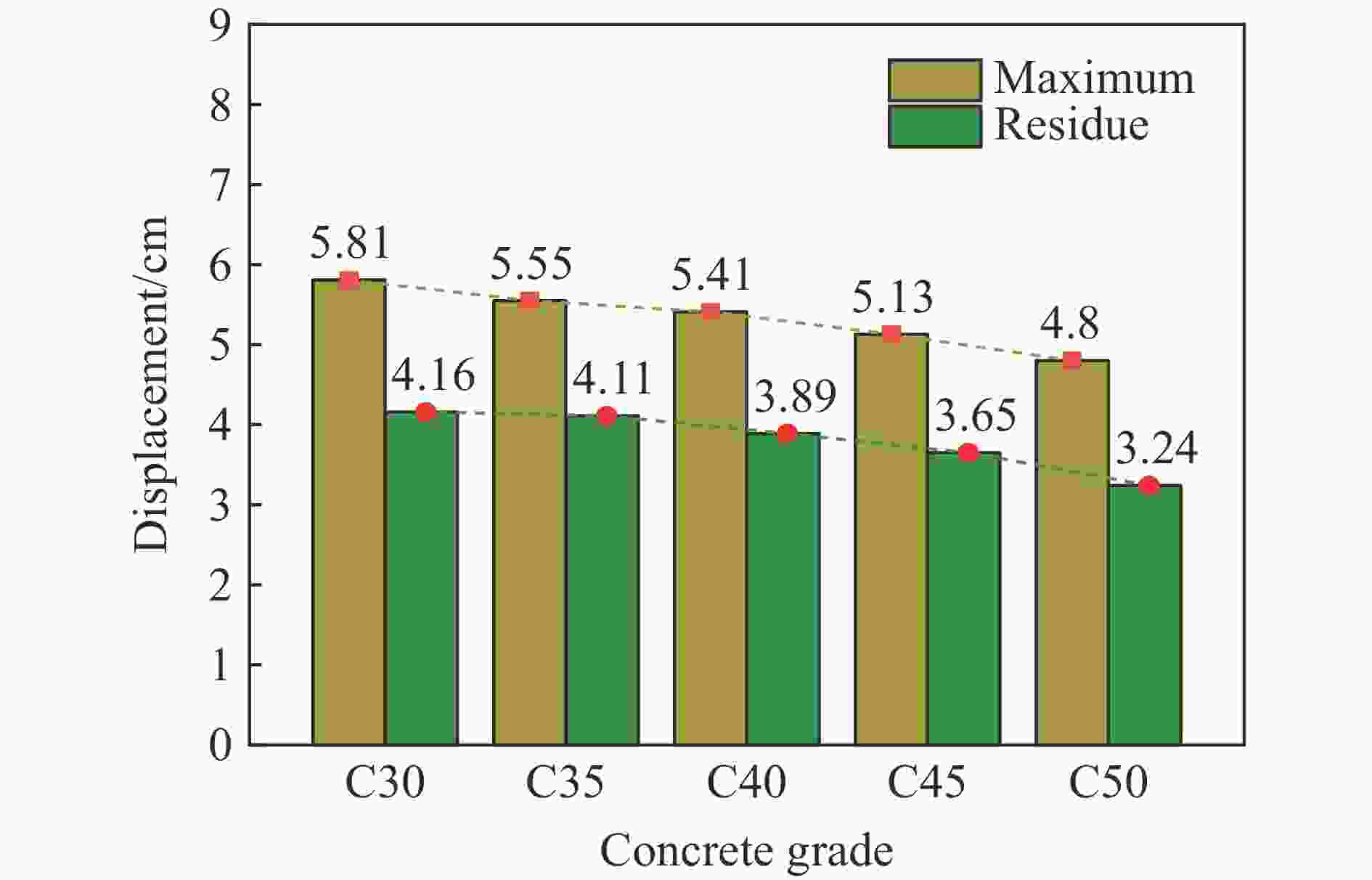

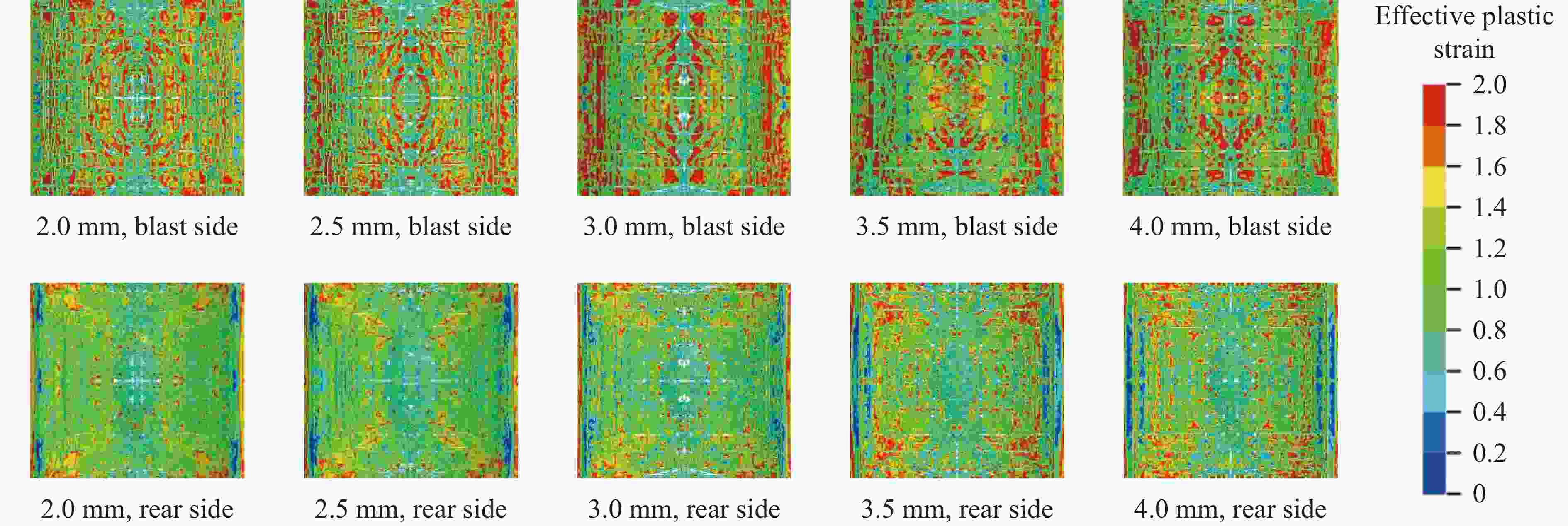

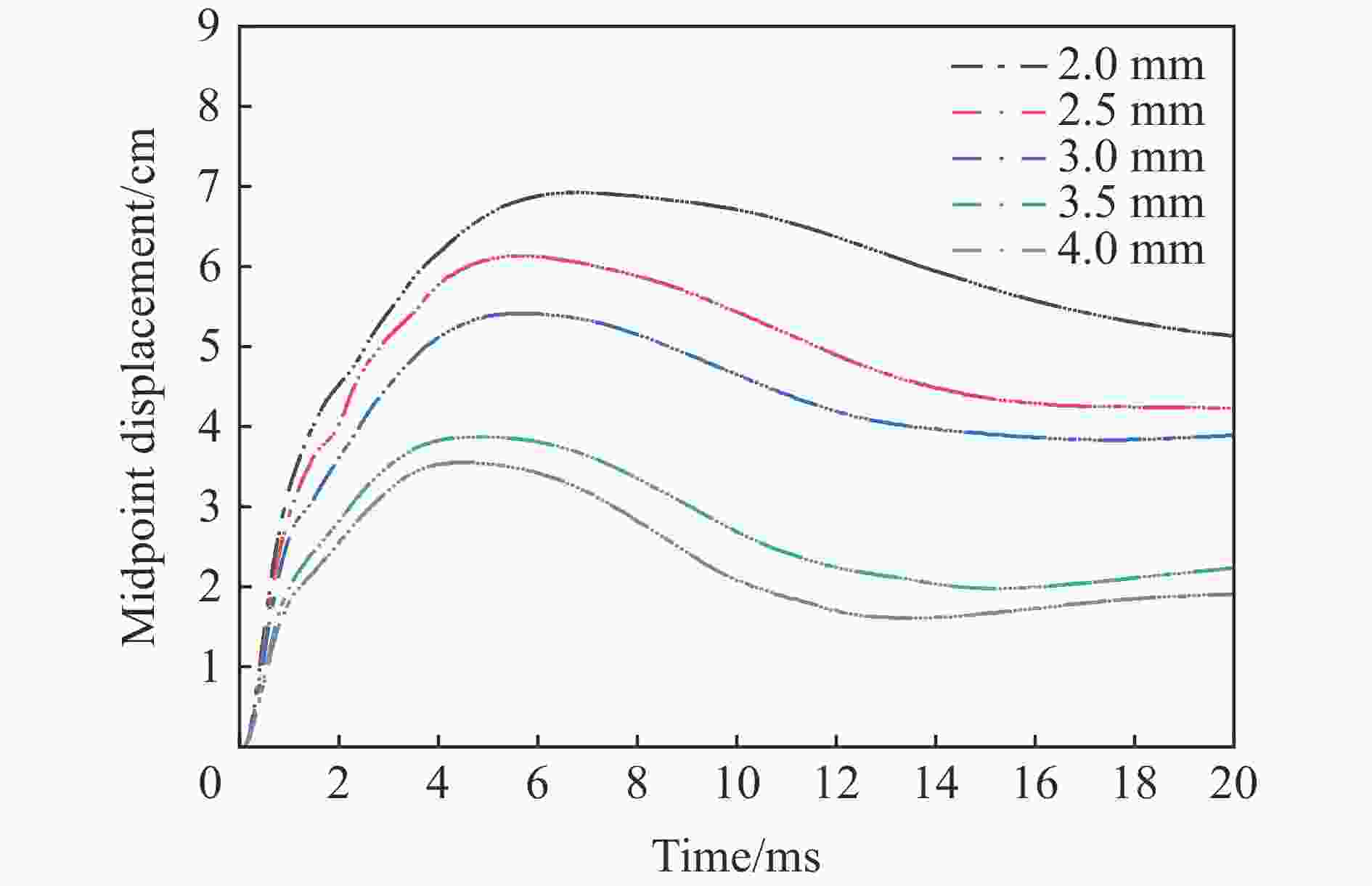

Abstract: Curved steel-concrete-steel (CSCS) composite slabs can increase the compression range of concrete so as to give full play to the compressive strength of the concrete and the tensile strength of the steel plate. It has been used in high-rise buildings, nuclear reactor containment, Arctic caisson and oil storage tanks and other important building structures. According to the specifications, three CSCS composite slabs with different fittings were designed. Based on the nonlinear finite element program ANSYS/LS-DYNA, the damage modes, midpoint displacement, energy consumption, etc. of the composite slabs under the action of near field explosion were studied, and the energy consumption and damage mechanism of the three different slabswere compared. The midpoint displacement and pressure of the CSCS composite slab were extracted from the finite element simulations. The results of the midpoint displacement were compared with the existing field explosion test results, and the results of pressure were compared with the empirical formula, which verified the rationality and effectiveness of the finite element model. Taking the midpoint displacement of the backsteel plate as the index, the effects of the explosive quantity, concrete strength and steel plate thickness on the anti-explosion performance of the CSCScomposite slabswere analyzed. The results show that the curved slabs maintain good integrity under the action of near-field explosion, there is no concrete fragments dispersion phenomenon, and they still have a continuous bearing capacity. Meanwhile, they have a better anti-explosion performance than traditional planar steel-concrete-steel composite slabs. The connection performance of the overlapping studs is stronger than that of the discrete studs, but slightly weaker than that of the pair studs. Increasing the concrete strength can reduce the midpoint displacement but cannot improve the damage condition of the concrete. Increasing the thickness of the steel plate can significantly reduce the midpoint displacement of the steel plate and improve the anti-explosion ability of CSCS composite slabs. -

表 1 连接件参数

Table 1. Material parameters of the connectors

ρ/(g·cm−3) E/GPa 泊松比 屈服强度/MPa 有效塑性应变 7.80 200 0.3 400 0.12 表 2 钢板参数

Table 2. Material parameters of the steel plates

ρ/(g·cm−3) E/GPa μ A/MPa B/MPa n m C 7.83 200 0.28 235 275 0.94 1.03 0.036 表 3 钢板中心迎爆面和背爆面的位移对比

Table 3. Comparison of the midpoint displacement of the steel plates

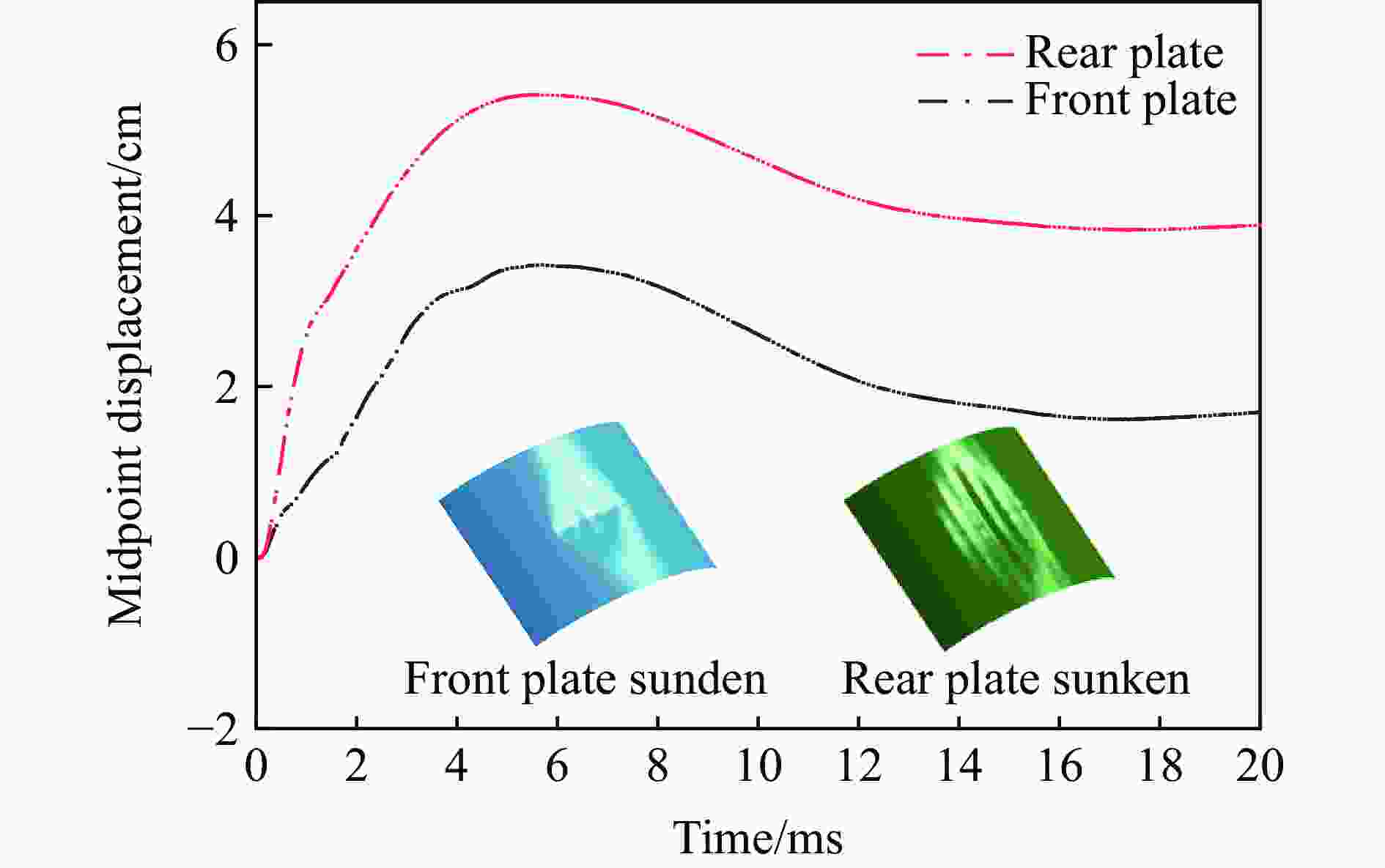

组合板类型 迎爆面钢板最大位移/cm 背爆面钢板最大位移/cm 迎爆面钢板残余位移/cm 背爆面钢板残余位移/cm 背、迎爆面残余位移差/cm CSCS-BO 3.42 5.41 1.70 3.89 2.19 CSCS-OS 2.83 5.91 1.22 4.45 3.23 CSCS-ST 3.39 6.35 0.96 4.68 3.72 SCS-BO — — 8.73 12.44 3.71 -

[1] 赵春风, 卢欣, 何凯城, 等. 单钢板混凝土剪力墙抗爆性能研究 [J]. 爆炸与冲击, 2020, 40(12): 121403. DOI: 10.11883/bzycj-2020-0058.ZHAO C F, LU X, HE K C, et al. Blast resistance property of concrete shear wall with single-side steel plate [J]. Explosion and Shock Waves, 2020, 40(12): 121403. DOI: 10.11883/bzycj-2020-0058. [2] 赵春风, 何凯城, 卢欣, 等. 双钢板混凝土组合板抗爆性能分析 [J]. 爆炸与冲击, 2021, 41(9): 095102. DOI: 10.11883/bzycj-2020-0291.ZHAO C F, HE K C, LU X, et al. Analysis on the blast resistance of steel concrete composite slab [J]. Explosion and Shock Waves, 2021, 41(9): 095102. DOI: 10.11883/bzycj-2020-0291. [3] YAN J B, LIU X M, LIEW J Y R, et al. Steel-concrete-steel sandwich system in Arctic offshore structure: materials, experiments, and design [J]. Materials & Design, 2016, 91: 111–121. DOI: 10.1016/j.matdes.2015.11.084. [4] YAN C, WANG Y H, ZHAI X M, et al. Experimental study on curved steel-concrete-steel sandwich shells under concentrated load by a hemi-spherical head [J]. Thin-Walled Structures, 2019, 137: 117–128. DOI: 10.1016/j.tws.2019.01.007. [5] 彭先泽, 杨军, 李顺波, 等. 爆炸冲击载荷作用下双层钢板混凝土板与钢筋混凝土板动态响应对比研究 [J]. 防灾科技学院学报, 2012, 14(3): 18–23. DOI: 10.3969/j.issn.1673-8047.2012.03.004.PENG X Z, YANG J, LI S B, et al. Comparative study on dynamic response of bi-steel slab and reinforced concrete slab under blast loading [J]. Journal of Institute of Disaster Prevention, 2012, 14(3): 18–23. DOI: 10.3969/j.issn.1673-8047.2012.03.004. [6] 卢欣. 钢-混凝土组合墙板抗接触爆炸性能实验及数值研究 [D]. 合肥: 合肥工业大学, 2020. DOI: 10.27101/d.cnki.ghfgu.2020.001546. [7] HUANG Z Y, LIEW J Y R. Experimental and analytical studies of curved steel-concrete-steel sandwich panels under patch loads [J]. Materials & Design, 2016, 93: 104–117. DOI: 10.1016/j.matdes.2015.12.144. [8] YAN C, WANG Y H, ZHAI X M. Low velocity impact performance of curved steel-concrete-steel sandwich shells with bolt connectors [J]. Thin-Walled Structures, 2020, 150: 106672. DOI: 10.1016/j.tws.2020.106672. [9] YAN J B, XIONG M X, QIAN X D, et al. Numerical and parametric study of curved steel-concrete-steel sandwich composite beams under concentrated loading [J]. Materials and Structures, 2016, 49(10): 3981–4001. DOI: 10.1617/s11527-015-0768-2. [10] MENG L Z, WANG Y H, ZHAI X M. Modeling anddynamic response ofcurved steel-concrete-steel sandwich shells under blast loading [J]. International Journal of Steel Structures, 2020, 20(5): 1663–1681. DOI: 10.1007/s13296-020-00403-8. [11] HUANG Z Y, LIEW J Y R. Nonlinear finite element modelling and parametric study of curved steel-concrete-steel double skin composite panels infilled with ultra-lightweight cement composite [J]. Construction and Building Materials, 2015, 95: 922–938. DOI: 10.1016/j.conbuildmat.2015.07.134. [12] 中华人民共和国住房和城乡建设部. 钢板剪力墙技术规程: JGJ/T 380—2015 [S]. 北京: 中国建筑工业出版社, 2016. [13] 周云波, 郭启涛, 佘磊, 等. 基于LBE方法的驾驶室防护模拟 [J]. 北京理工大学学报, 2016, 36(3): 237–241. DOI: 10.15918/j.tbit1001-0645.2016.03.004.ZHOU Y B, GUO Q T, SHE L, et al. Simulation of vehicle cabin protection based on load blast enhanced method [J]. Transactions of Beijing Institute of Technology, 2016, 36(3): 237–241. DOI: 10.15918/j.tbit1001-0645.2016.03.004. [14] HAN Y Z, LIU H B. Finite element simulation of medium-range blast loading using LS-DYNA [J]. Shock and Vibration, 2015(2): 1–9. DOI: 10.1155/2015/631493. [15] BAKER W E. Explosions in air[M]. Texas, USA: University of Texas press, 1973. [16] HALLQUIST J O. LS-DYNA keyword user’s manuaL [Z]. California, USA: Livermore Software Technology Corporation, 2007. [17] BISCHOFF P H, PERRY S H. Compressive behaviour of concrete at high strain rates [J]. Materials and Structures, 1991, 24(6): 425–450. DOI: 10.1007/BF02472016. [18] WANG Y H, LIEW J Y R, LEE S C. Theoretical models for axially restrained steel-concrete-steel sandwich panels under blast loading [J]. International Journal of Impact Engineering, 2015, 76: 221–231. DOI: 10.1016/j.ijimpeng.2014.10.005. -

下载:

下载: