Experimental and analytical study on blast resistance performance of brick infill walls strengthened with polyuria

-

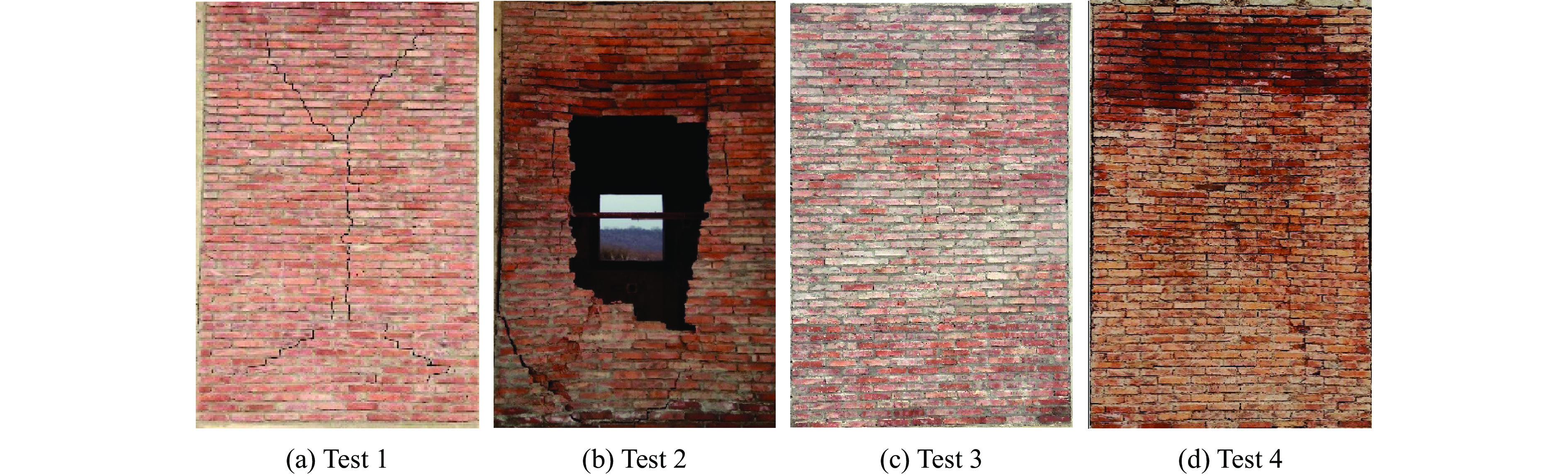

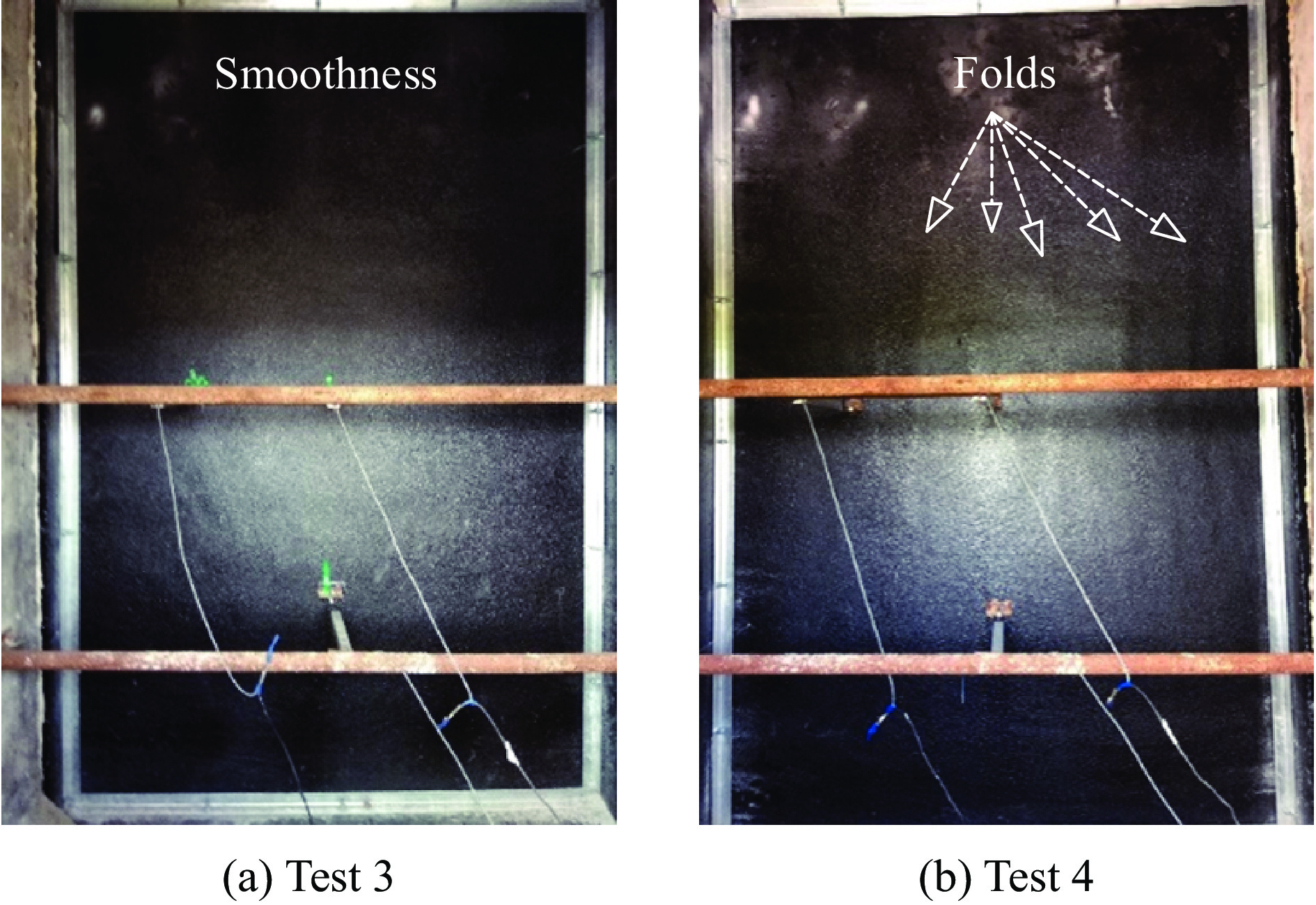

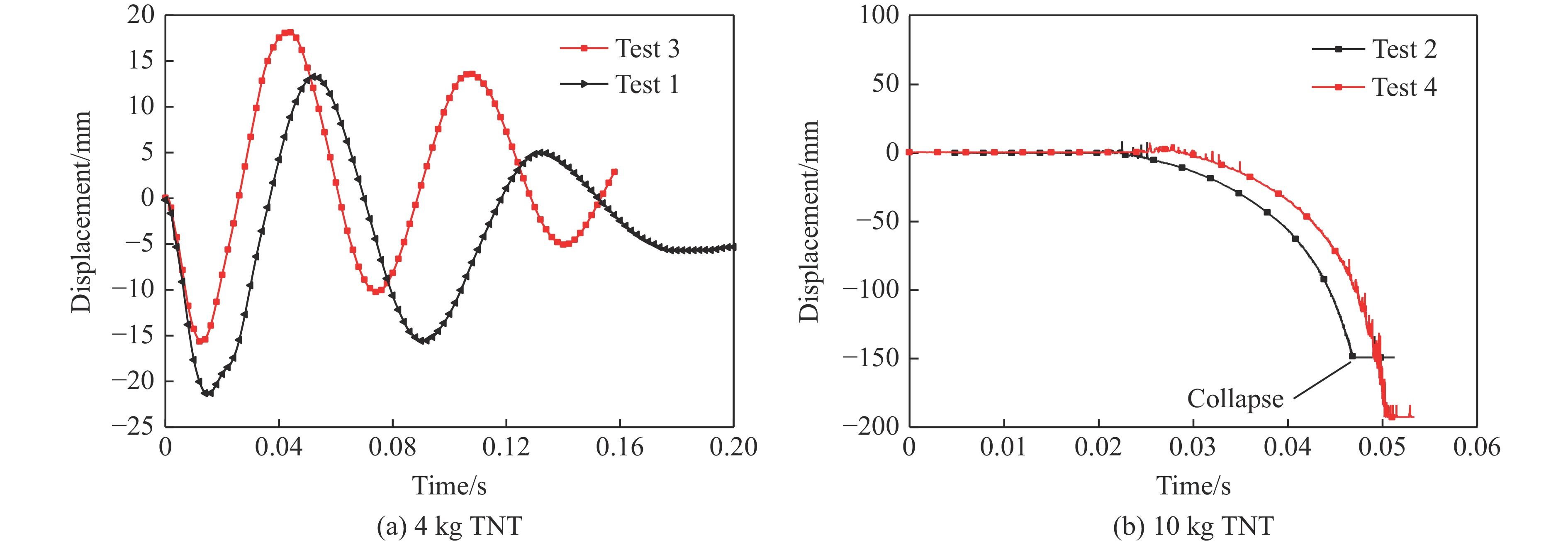

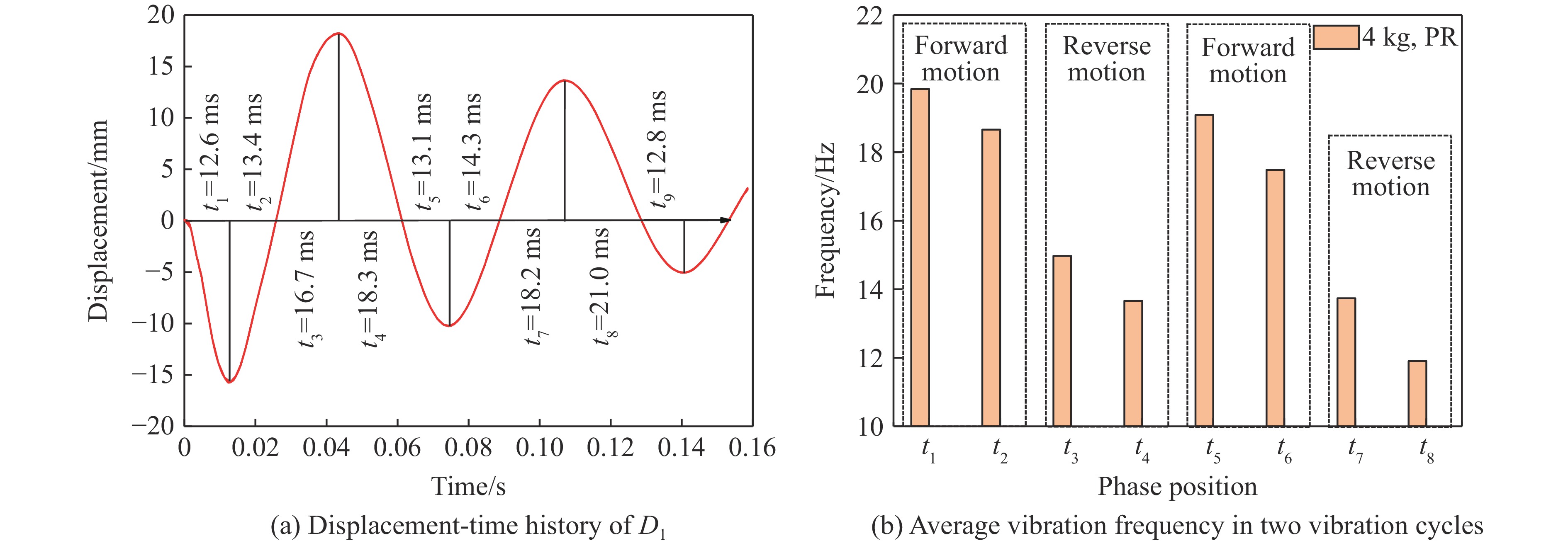

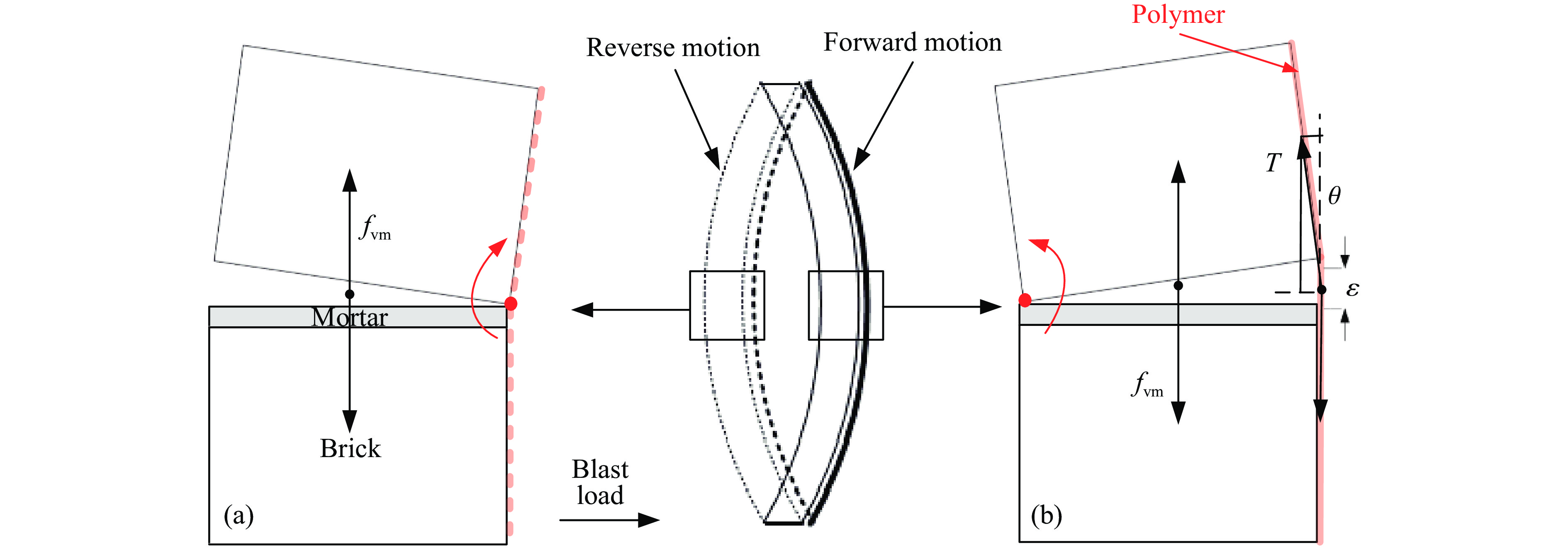

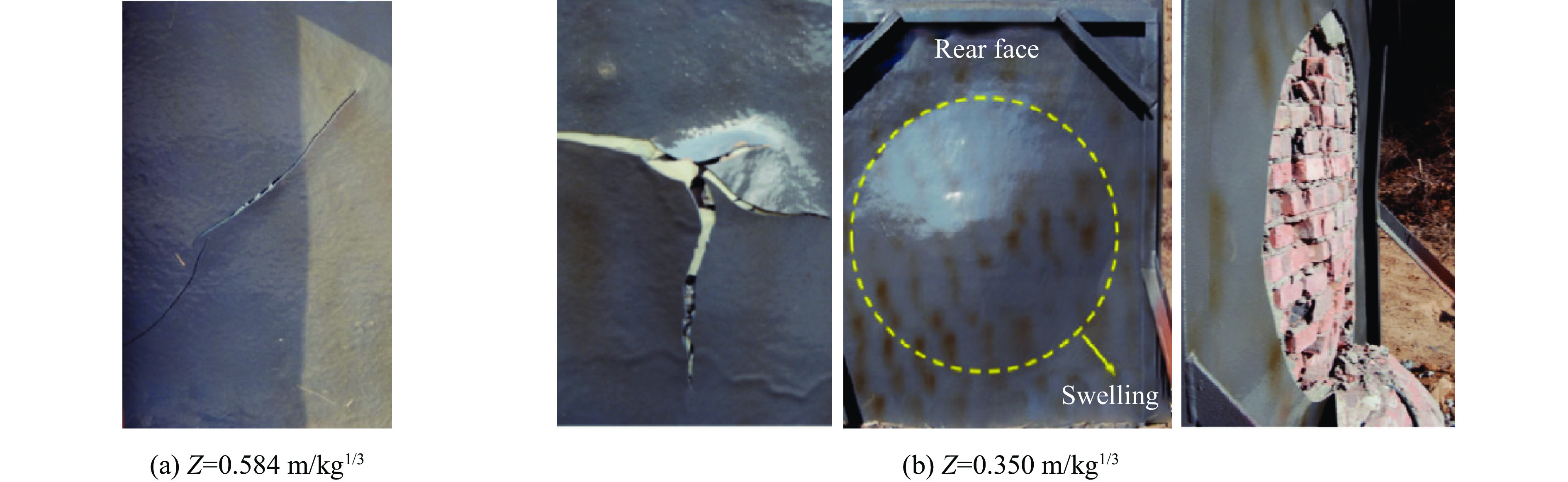

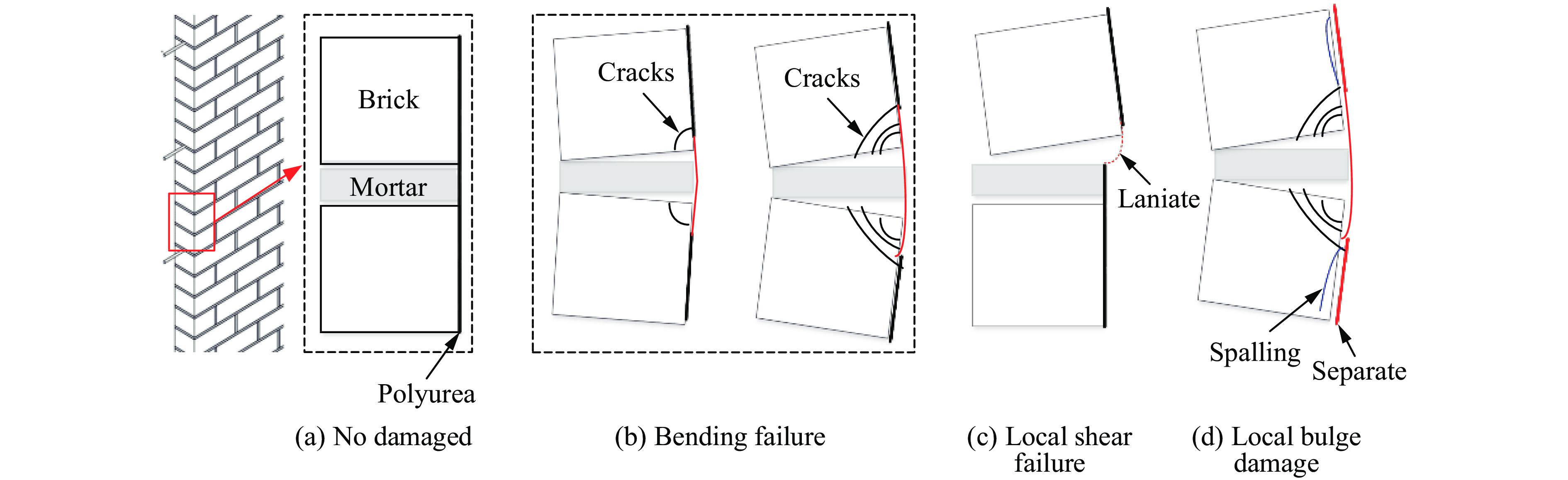

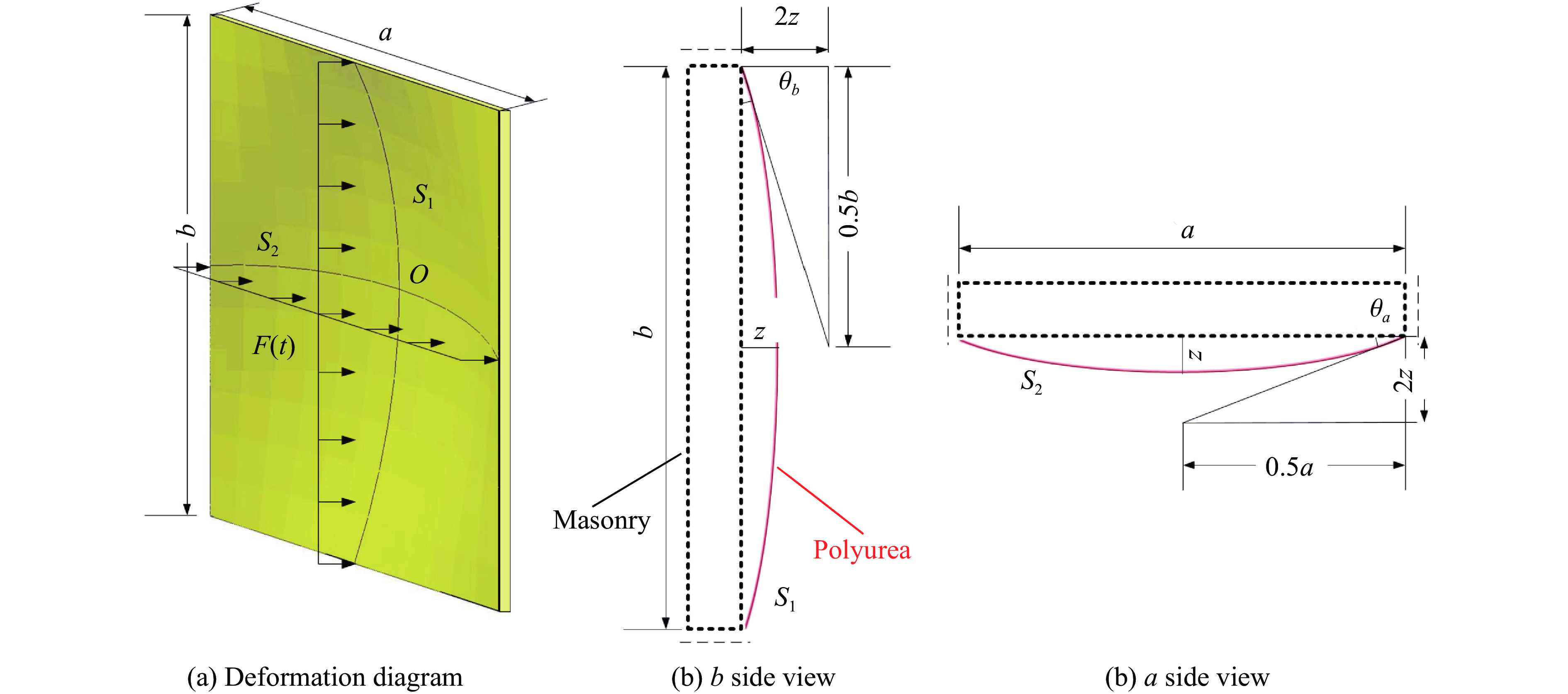

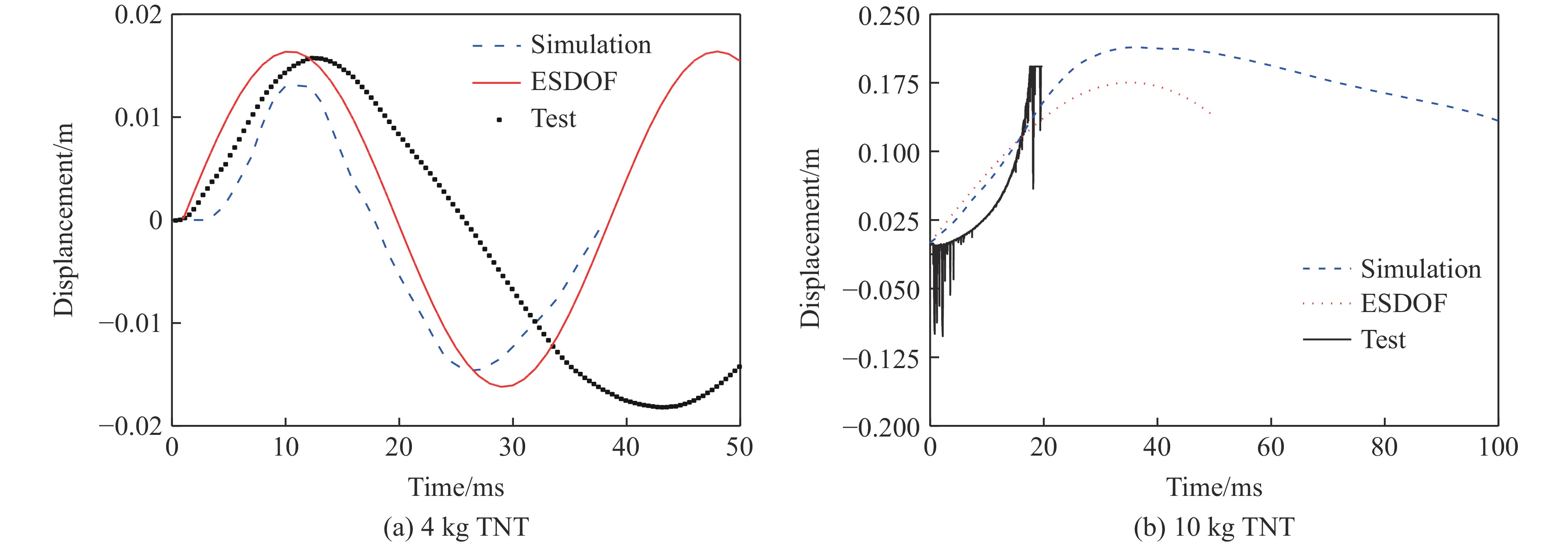

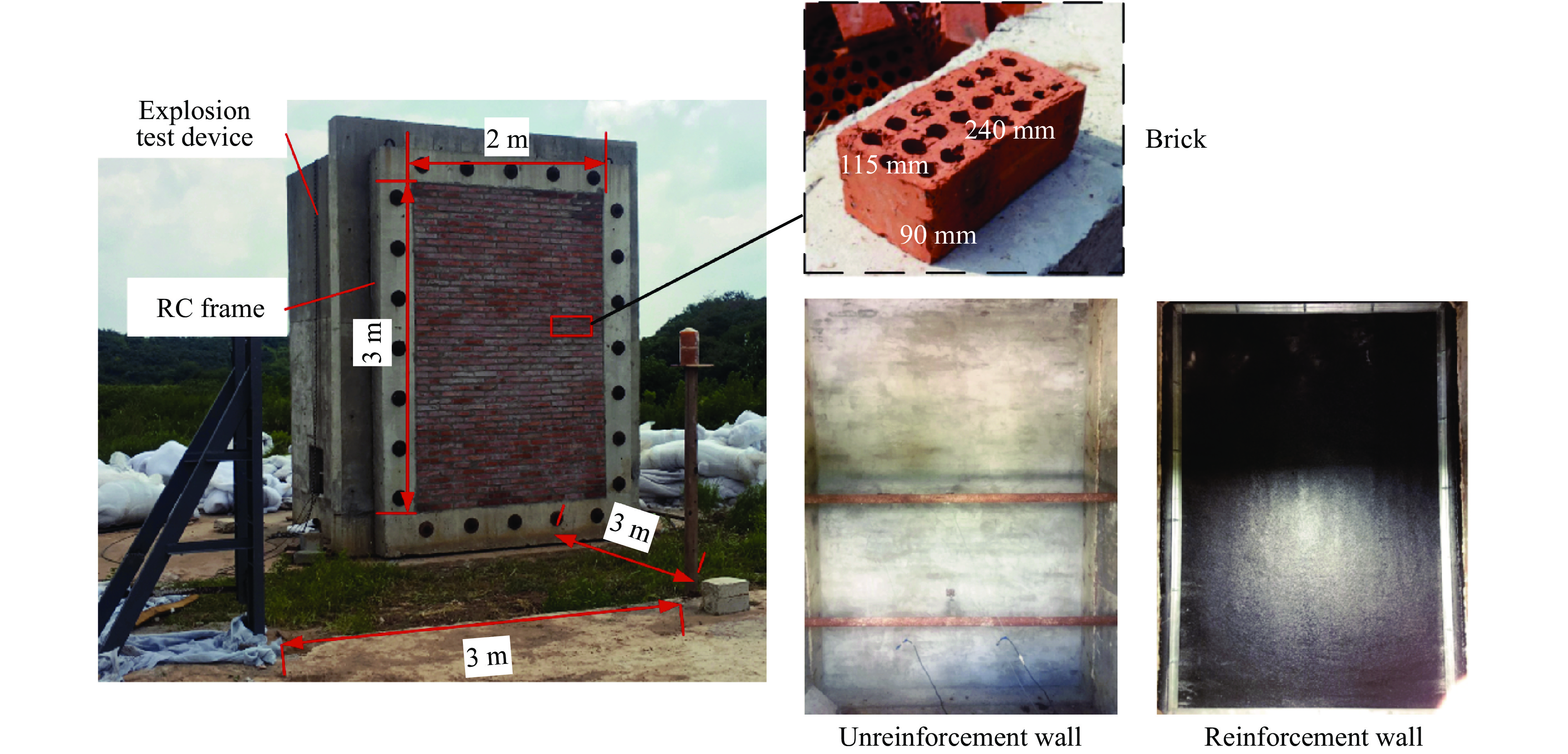

摘要: 为了掌握聚脲喷涂加固砖填充墙的抗爆特性,基于一种改进的大型爆炸试验装置,开展了聚脲加固框架砖填充墙的原型爆炸试验,分析了爆炸荷载作用下加固砖墙的动力响应特征和破坏过程及模式,揭示了其失效破坏机理。研究结果表明,聚脲加固可大幅提升填充墙构件的抗爆性能,显著增加填充墙构件的变形延性;加固砖墙受爆炸荷载作用发生振动的过程其体系刚度不断变化,最高相差133%;随着比例距离降低,加固砖墙的破坏模式逐渐由弯曲破坏转为剪切破坏,聚脲厚度超过6 mm可以有效限制局部剪切破坏现象;基于砖墙和聚脲涂层的抗力函数建立的理论计算模型,可以较为准确地预测爆炸作用下背爆面加固双向砖墙的正向位移响应过程。Abstract: In order to study the blast-resistance characteristics of polyurea sprayed reinforced brick infill walls, a prototype explosion test of polyurea sprayed reinforced frame infill walls was carried out based on an improved large-scale explosion test device. This test device eliminates the influence of the sparse wave formed by the air shock wave at the edge of the wall and the diffraction behind the wall on the real blast resistance test dynamic response of the wall, and significantly improves the accuracy of the blast resistance test of brick infill walls strengthened with polyuria. The dynamic response characteristics, failure process and mode of reinforced brick walls under explosion load were analyzed, and the failure mechanism was revealed. The results show that under small deformation conditions, polyurea reinforcement can improve the blast-resistance of infilled wall members. Under large deformation conditions, polyurea reinforcement can increase the ductility of filled wall members. The system stiffness of reinforced brick wall changes continuously during forced vibration, and the maximum difference is 133%. With the decrease of the proportional distance, the failure mode of the reinforced brick wall gradually changes from bending failure to shear failure. The polyurea thickness of more than 6 mm can effectively limit the local shear failure phenomenon. The theoretical calculation model based on the resistance function of brick wall and polyurea coating can accurately predict the forward displacement response process of two-way brick wall reinforced by back blasting surface under explosion.

-

Key words:

- polyuria /

- brick wall /

- blast-resistance test /

- system stiffness /

- resistance function

-

岩石动力学主要研究岩石(体)在动载荷(如爆炸、冲击、地震、振动等)作用下,其动态力学性质与本构关系,破岩效应与机理、岩石(体)中应力波传播与衰减规律,岩石工程的安全与防护,岩石(体)动态特性的数值计算与数字仿真,有很强的工程应用背景。

从广义的角度,岩石力学可分为岩石静力学与岩石动力学,它们虽然都是以固体力学为基础,严格地说是以弹塑性、黏弹塑性力学为其理论基础,但它们有荷载形式不同这个主要差别。就本质而言,所有力学问题都是动力学问题,只有当材料的惯性效应可忽略时,才能作为静力学问题处理。应变率在10−2~104 s−1的荷载,属于岩石动力学的研究范畴。

在我国,岩石动力学研究最早可以追溯到20世纪60年代初大冶铁矿边坡稳定性研究中的“爆破动力效应试验”。较全面的岩石动力学研究,应该始于国家“防护工程问题的研究”。1977年始历时10年的“地下炸药库安全问题的研究”,以及国家经济快速发展带来的深路基、长隧道(洞)、高边坡爆破开挖等工程技术难题,促进了岩石动力学研究的进步。

在国际上,在20世纪50~60年代,美国进行了多次核试验,开展了大量与岩石动力学相关的研究,成果主要以AD报告的形式发表。Josef Henrych撰写的《The dynamics of explosion and its use》(1979年)、George B Clark撰写的《Principles of rock fragmentation》(1987年)等著作,对岩石动力学研究发展有重大影响。

在岩石动力学研究中,现场借助于压力、位移、速度和加速度等测量系统,室内借助于岩石动载机、霍布金森压杆、球面波与平面波爆炸实验装置、动光弹与高速摄影等一系列实验设备。开展了岩石(体)在爆炸冲击作用下不同时空尺寸的动态本构模型研究;获得了基于粒子速度测量和拉格朗日分析方法的岩石动力特性与本构关系;提出了考虑岩石强度依赖应变率的莫尔库仑准则,确定了岩体的破坏尺寸与应变率的关系。获得了不同爆炸、不同当量、不同比例距离下的岩体自由场应力波传播和衰减规律;研究了冲击载荷作用下岩石变形破坏的宏、细观结构特性;对条状装药在岩石介质中爆破破坏过程的应力场、爆破漏斗形成有了充分认识;利用有限元方法等对岩石构筑物的安全、稳定性分析,并取得了重要成果。

由于岩石材料的特殊性和复杂性,岩石材料动态本构关系的建立十分困难,用一种本构关系表现岩石材料的共性是不现实的。针对某种具特定地理位置、特定生成年代、特定埋深的岩石材料,研究其本构特性,将是今后研究的主要方向。进一步完善岩石变形与破坏的时间构造性、岩石动力强度理论和破坏准则以及破坏过程,仍是深入研究的课题。大尺度、多尺度、多因素问题及耦合效应,也是主攻方向之一。应力波通过层状介质结构面(如裂隙、节理、断层等)的相互作用,波与结构物、构造物的相互作用,高阻抗失配材料中波的传播和衰减规律,波传播反问题的不适定性根源的研究,都有着十分重要的战略意义。研究岩体损伤、断裂随时间增长发展最终破坏失稳的机制、模式和判据,确定岩体时效损伤断裂的统一机制十分必要;应变速率效应和软化、围岩加固和应力转移技术等的研究,尤被关注。数值模拟不单纯是一种分析手段,也是一种实验具。应大力发展岩石动力断裂过程的数值模拟与虚拟仿真技术,并求得岩石动力学问题的精确解。

高地应力条件下硬脆性岩体突发岩爆、矿井深部冲击地压的监测、预警与防治技术,高烈度地震区洞、基、坡的抗震与减振,隧道及地下构筑物的耐久性与安全防护关键技术,也是工程上亟需解决的难题。

岩石动力学专业委员会副主任委员兼秘书长 黄理兴 原中国科学院武汉岩土力学研究所副总工程师 -

表 1 砖和砂浆的力学参数

Table 1. Material parameters of brick and mortar

材料 密度/(kg·m−3) 杨氏模量/MPa 泊松比 抗拉强度/MPa 剪切强度/MPa 屈服强度/MPa 砖 1200 897 0.15 5.5 5.5 14.1 砂浆 2100 913 0.25 3.5 3.5 7.03 表 2 聚脲的力学参数

Table 2. Polyurea material parameters

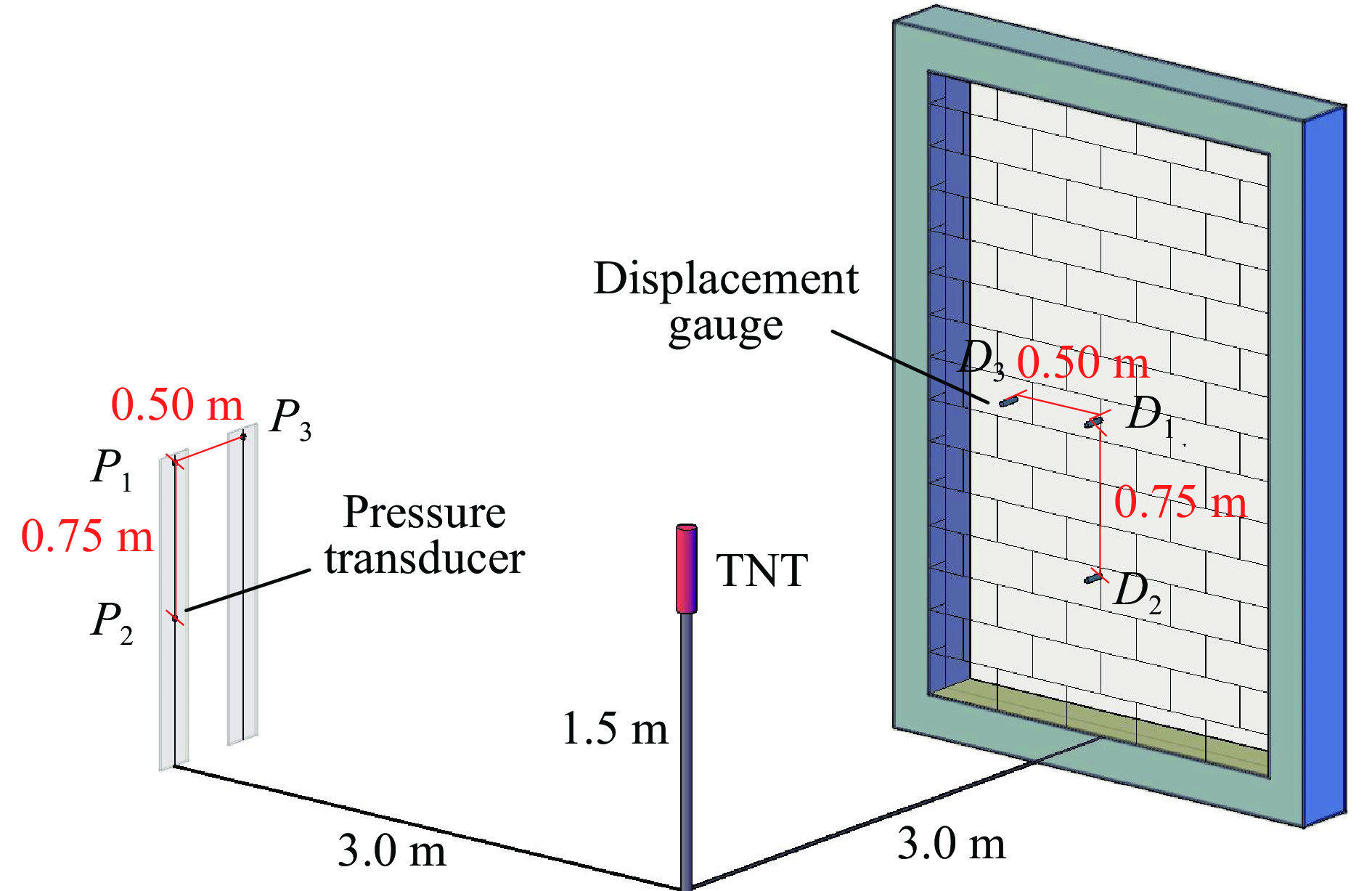

密度/(kg·m−3) 杨氏模量/MPa 泊松比 抗拉强度/MPa 屈服强度/MPa 切线模量/MPa 真实失效应变 1150 80 0.17 15 5.5 14.1 1.2 表 3 试验工况

Table 3. Test conditions

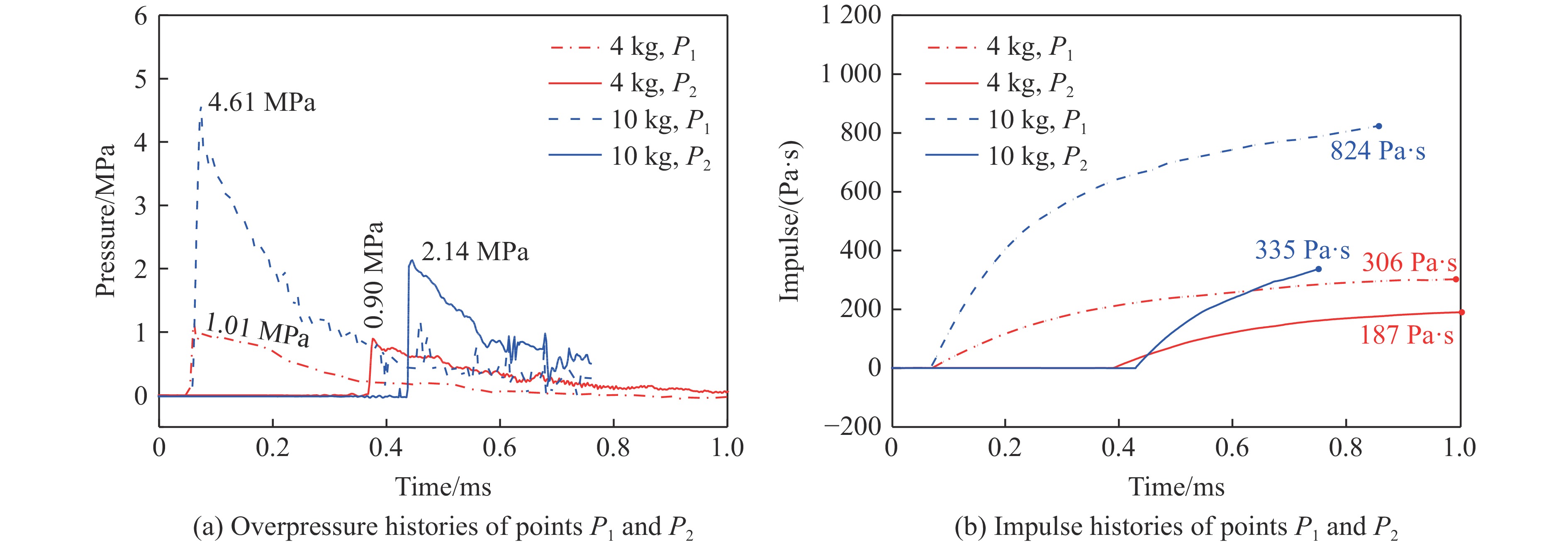

试验 聚脲厚度/mm 比例爆距/(m·kg−1/3) 装药当量/kg 1 0 1.89 4 2 0 1.39 10 3 6 1.89 4 4 6 1.39 10 表 4 爆炸荷载验证

Table 4. Explosion load verification

装药/kg 冲量/(Pa·s) 误差/% 测点P1 文献[17]方法 4 306 400 23.5 10 824 790 4.3 破坏等级 边界条件 支座转角/(°) 跨中允许挠度/mm 可修复 单向 0.5 8.72 双向 0.5 8.72 不可修复 单向 1 17.45 双向 2 34.90 -

[1] 范俊余, 方秦, 陈力, 等. 砌体填充墙的抗爆性能 [J]. 爆炸与冲击, 2014, 34(1): 59–66. DOI: 10.11883/1001-1455(2014)01-0059-08.FAN J Y, FANG Q, CHEN L, et al. Anti-blast properties of masonry infill walls [J]. Explosion and Shock Waves, 2014, 34(1): 59–66. DOI: 10.11883/1001-1455(2014)01-0059-08. [2] SHI Y C, XIONG W, LI Z X, et al. Experimental studies on the local damage and fragments of unreinforced masonry walls under close-in explosions [J]. International Journal of Impact Engineering, 2016, 90: 122–131. DOI: 10.1016/j.ijimpeng.2015.12.002. [3] SARVA S S, DESCHANEL S, BOYCE M C, et al. Stress-strain behavior of a polyurea and a polyurethane from low to high strain rates [J]. Polymer, 2007, 48(8): 2208–2213. DOI: 10.1016/j.polymer.2007.02.058. [4] RAMAN S N, NGO T, LU J, et al. Experimental investigation on the tensile behavior of polyurea at high strain rates [J]. Materials & Design, 2013, 50: 124–129. DOI: 10.1016/j.matdes.2013.02.063. [5] CHEN Y S, WANG B, ZHANG B, et al. Polyurea coating for foamed concrete panel: an efficient way to resist explosion [J]. Defence Technology, 2020, 16(1): 136–149. DOI: 10.1016/j.dt.2019.06.010. [6] DAVIDSON J S, FISHER J W, HAMMONS M I, et al. Failure mechanisms of polymer-reinforced concrete masonry walls subjected to blast [J]. Journal of Structural Engineering, 2005, 131(8): 1194–1205. DOI: 10.1061/(ASCE)0733-9445(2005)131:8(1194). [7] 蔡桂杰. 弹性体涂覆钢筋混凝土板抗爆作用设计方法研究 [D]. 太原: 中北大学, 2015.CAI G J. The design method of the reinforced concrete plate coated polyurea under the action of explosion [D]. Taiyuan: North University of China, 2015. [8] IQBAL N, SHARMA P K, KUMAR D, et al. Protective polyurea coatings for enhanced blast survivability of concrete [J]. Construction and Building Materials, 2018, 175: 682–690. DOI: 10.1016/j.conbuildmat.2018.04.204. [9] 王军国. 喷涂聚脲加固粘土砖砌体抗动载性能试验研究及数值分析 [D]. 合肥: 中国科学技术大学, 2017.WAMG J G. Experimental and numerical investigation of clay brick masonry walls strengthened with spary polyurea elastomer under blast loads [D]. Hefei: University of Science and Technology of China, 2017. [10] BIGGS J M. Introduction to structural dynamics [M]. New York: McGraw-Hill Companies, 1964. [11] US Department of Defence. Structures to resist the effects of accidental explosions: UFC 3-340-02 [S]. Washington DC: US Department of Defence, 2008. [12] URGESSA G S, MAJI A K. Dynamic response of retrofitted masonry walls for blast loading [J]. Journal of Engineering Mechanics, 2010, 136(7): 858–864. DOI: 10.1061/(ASCE)EM.1943-7889.0000128. [13] ABOU-ZEID B M, EL-DAKHAKHNI W W, RAZAQPUR A G, et al. Response of arching unreinforced concrete masonry walls to blast loading [J]. Journal of Structural Engineering, 2011, 137(10): 1205–1214. DOI: 10.1061/(ASCE)ST.1943-541X.0000344. [14] ABOU-ZEID B M, EL-DAKHAKHNI W W, RAZAQPUR A G, et al. Time-response analysis of arching unreinforced concrete block walls subjected to blast loads [J]. Journal of Structural Engineering, 2014, 140(4): 04013099. DOI: 10.1061/(ASCE)ST.1943-541X.0000893. [15] MORISON C M. Dynamic response of walls and slabs by single-degree-of-freedom analysis: a critical review and revision [J]. International Journal of Impact Engineering, 2006, 32(8): 1214–1247. DOI: 10.1016/j.ijimpeng.2004.11.008. [16] IRSHIDAT M, AL-OSTAZ A, CHENG A H D, et al. Nanoparticle reinforced polymer for blast protection of unreinforced masonry wall: laboratory blast load simulation and design models [J]. Journal of Structural Engineering, 2011, 137(10): 1193–1204. DOI: 10.1061/(ASCE)ST.1943-541X.0000361. [17] US Department of the Army. Fundamentals of protective design for conventional weapons: TM 5-855-1 [S]. Washington DC: Department of the Army, 1986. [18] 方秦. 地下防护结构 [M]. 北京: 中国水利水电出版社, 2010. [19] WU G, JI C, WANG X, et al. Blast response of clay brick masonry unit walls unreinforced and reinforced with polyurea elastomer [J]. Defence Technology, 2022, 18(4): 20. DOI: 10.1016/j.dt.2021.03.004. [20] DENG Z, WANG X J. Analysis of sheet metal stress-strain relations in uniaxial and biaxial tension [J]. Journal of University of Science and Technology Beijing (English Edition), 1994, 1(1/2): 70–75. [21] 汪维. 钢筋混凝土构件在爆炸载荷作用下的毁伤效应及评估方法研究 [D]. 长沙: 国防科学技术大学, 2012.WANG W. Study on damage effects and assessments method of reinforced concrete structural members under blast loading [D]. Changsha: National University of Defense Technology, 2012. [22] 陈力, 方秦, 还毅, 等. 爆炸荷载作用下钢筋混凝土梁板结构的面力效应 [J]. 工程力学, 2010, 27(8): 156–163.CHEN L, FANG Q, HUAN Y, et al. Membrane action on reinforced concrete beam-slab structures subjected to blast loads [J]. Engineering Mechanics, 2010, 27(8): 156–163. [23] 彭培, 李展, 张亚栋, 等. 燃气爆炸作用下蒸压加气混凝土砌体墙的加固性能 [J]. 爆炸与冲击, 2020, 40(3): 035101. DOI: 10.11883/bzycj-2018-0252.PENG P, LI Z, ZHANG Y D, et al. Performance of retrofitted autoclaved aerated concrete masonry walls subjected to gas explosions [J]. Explosion and Shock Waves, 2020, 40(3): 035101. DOI: 10.11883/bzycj-2018-0252. [24] LI Z, CHEN L, FANG Q, et al. Experimental and numerical study of basalt fiber reinforced polymer strip strengthened autoclaved aerated concrete masonry walls under vented gas explosions [J]. Engineering Structures, 2017, 152: 901–919. DOI: 10.1016/j.engstruct.2017.09.055. [25] LI Z, CHEN L, FANG Q, et al. Study of autoclaved aerated concrete masonry walls under vented gas explosions [J]. Engineering Structures, 2017, 141: 444–460. DOI: 10.1016/j.engstruct.2017.03.033. -

下载:

下载: