Simulation on penetration of a 12.7-mm projectile into steel targets with different strengths

-

摘要: 针对12.7 mm弹侵彻不同强度钢靶时可能出现子弹保持完整或发生破碎的情况,过去的数值模拟仅限于模拟单一模式的子弹侵彻行为。为了克服这种数值模拟的局限性,开展了模型算法、网格尺寸对模拟结果影响的研究,并将模拟结果与实验结果进行了对比,提出了一种能够用于模拟子弹保持完整或破碎的弹靶模型。研究结果表明,为模拟子弹保持完整状态,子弹和靶板应分别采用基于Lagrange算法的有限元法和光滑粒子算法,而且子弹网格尺寸和靶板粒子间距之比应至少保持在5.3左右,否则弹头会产生与实验结果不符合的异常变形。但是,在模拟子弹发生破碎侵蚀时,该比例的网格/粒子尺寸比会引起计算中止。为了克服该问题,进一步建立了一种弹体表面采用大尺寸网格、内部采用细化小尺寸网格的有限元/光滑粒子法耦合弹靶模型。计算结果表明,改进的弹靶模型可模拟子弹保持完整或者发生破碎的情况。

-

关键词:

- 有限元/光滑粒子法耦合弹靶模型 /

- 弹体破碎 /

- 钢靶 /

- 侵彻

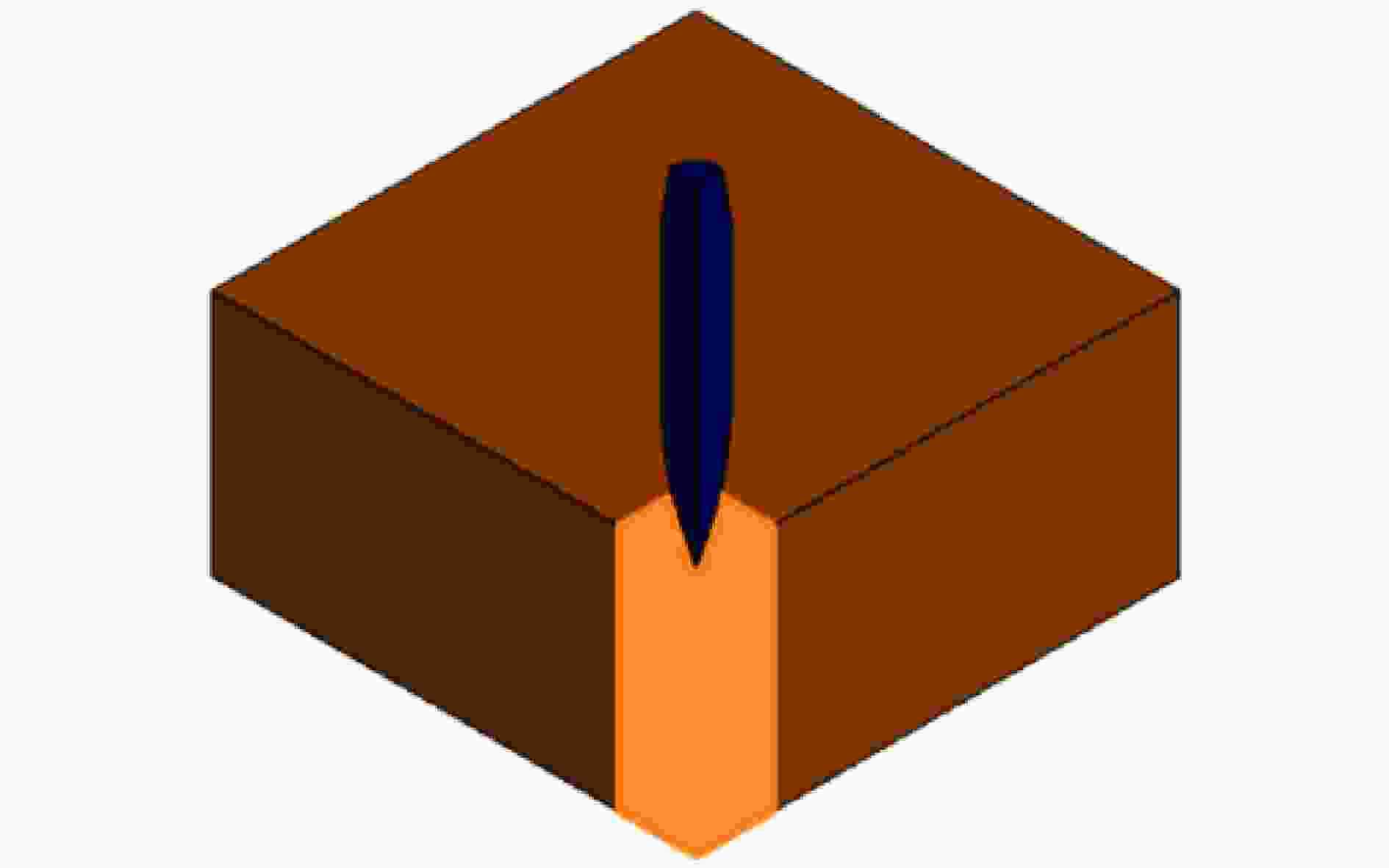

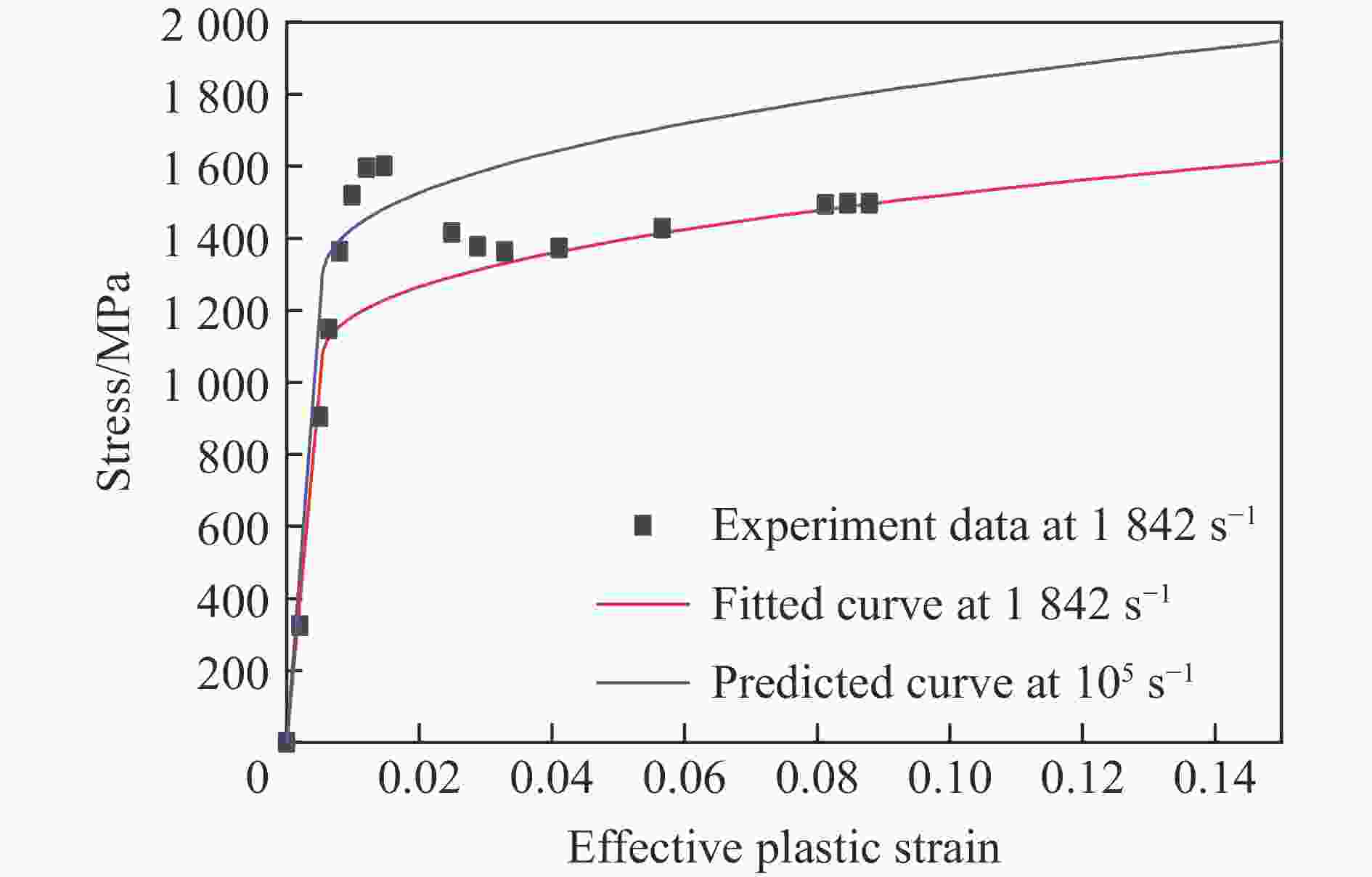

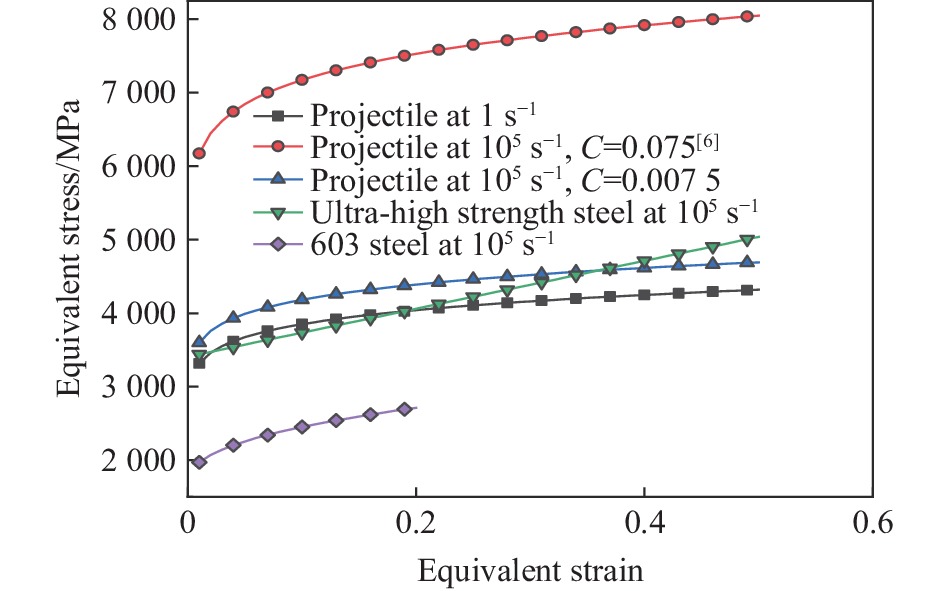

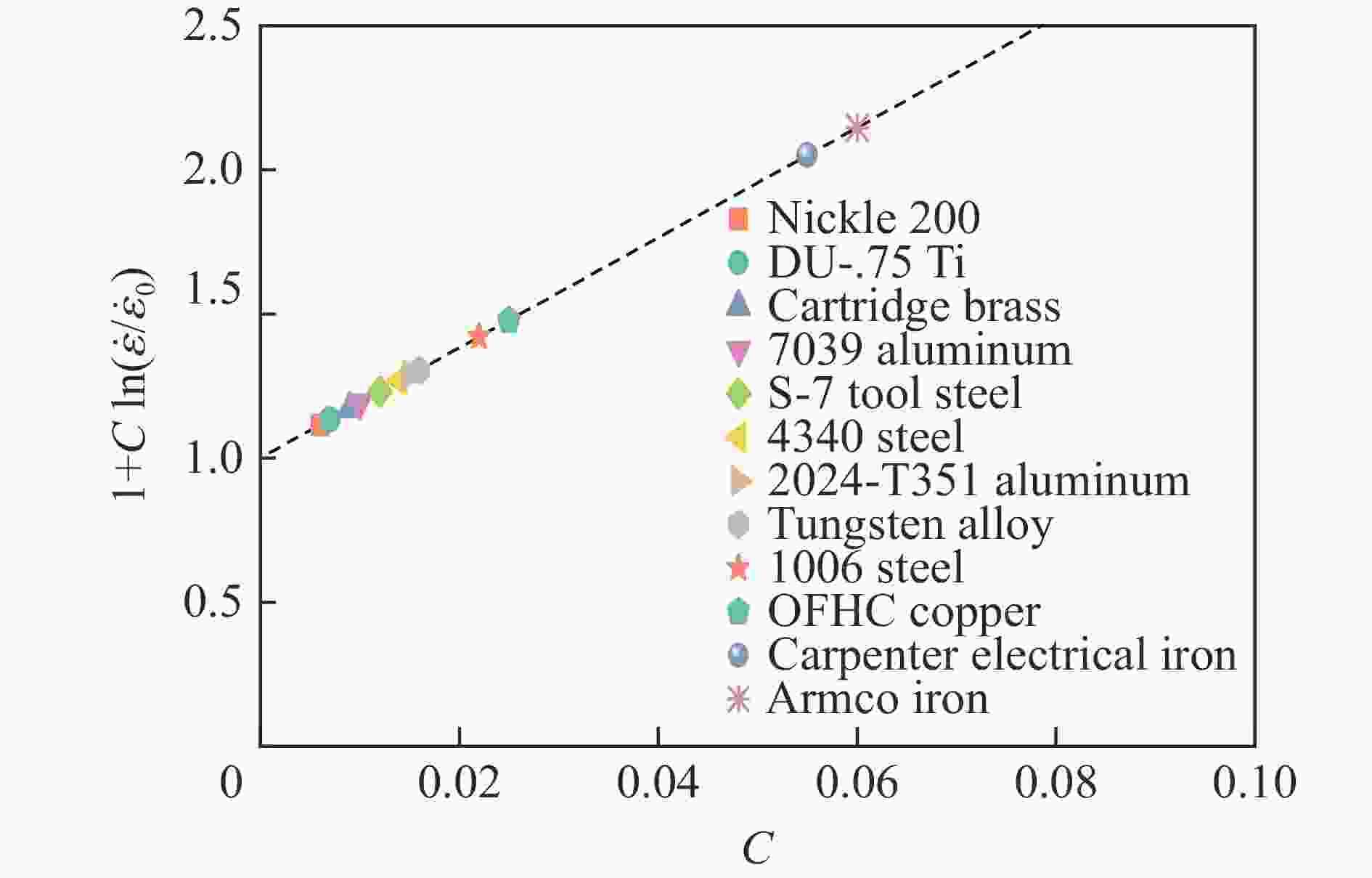

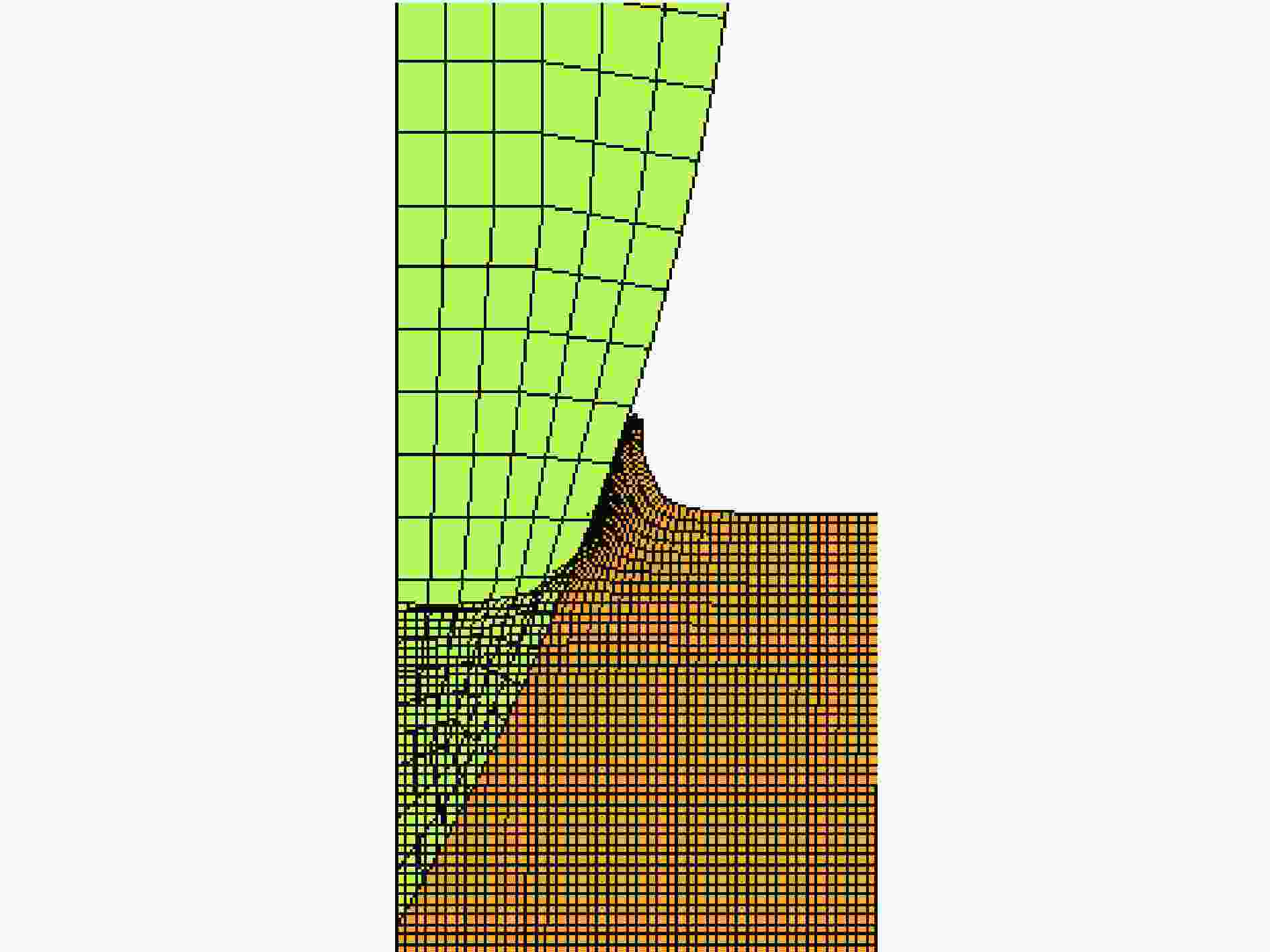

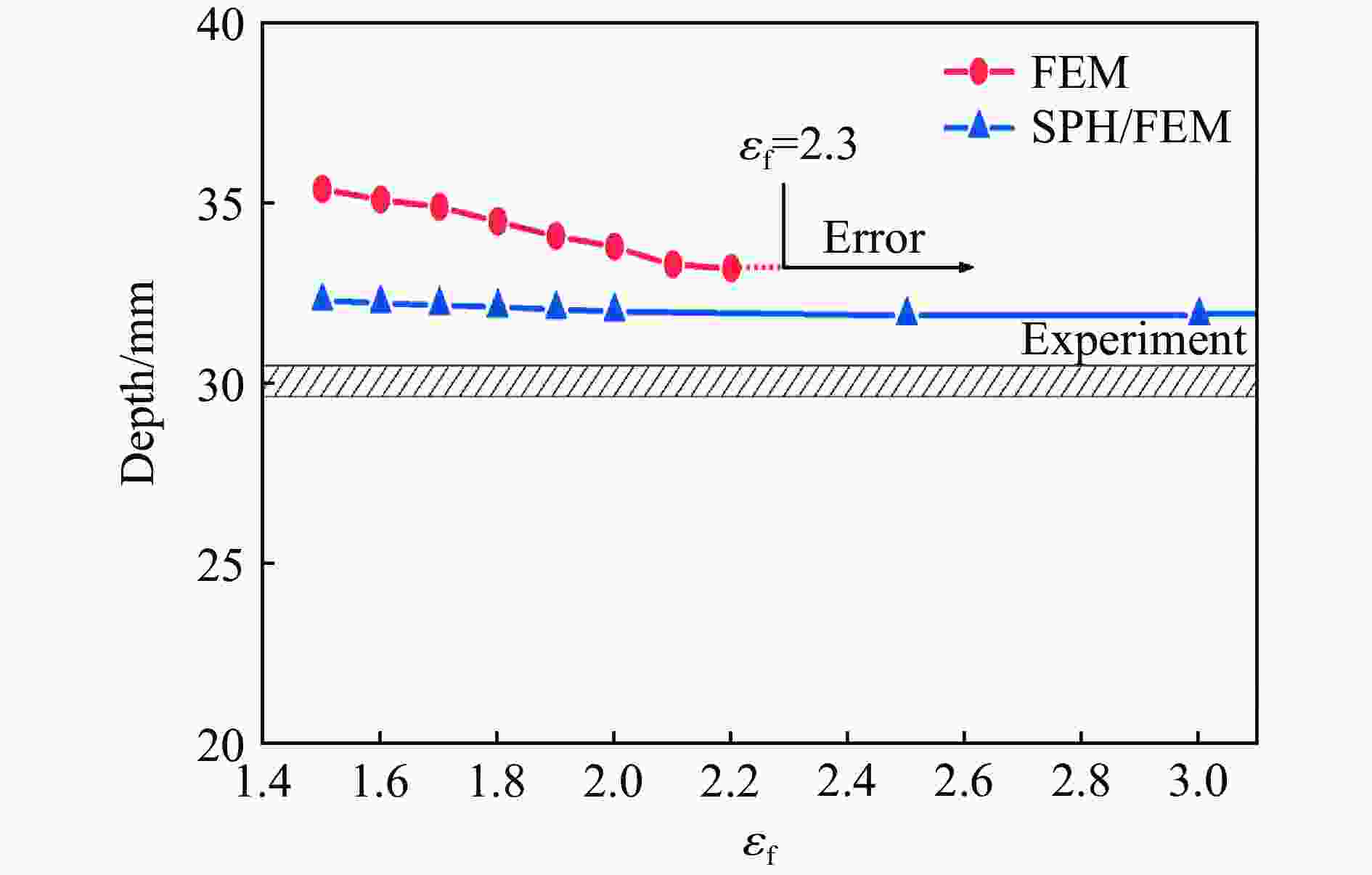

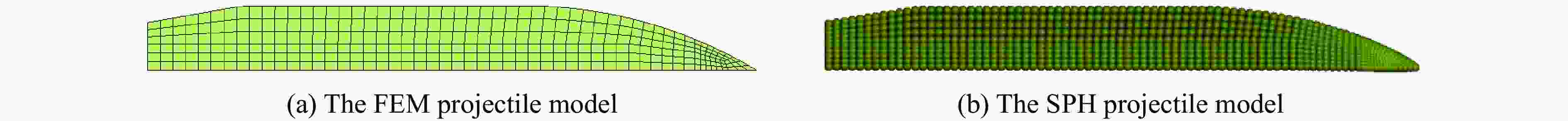

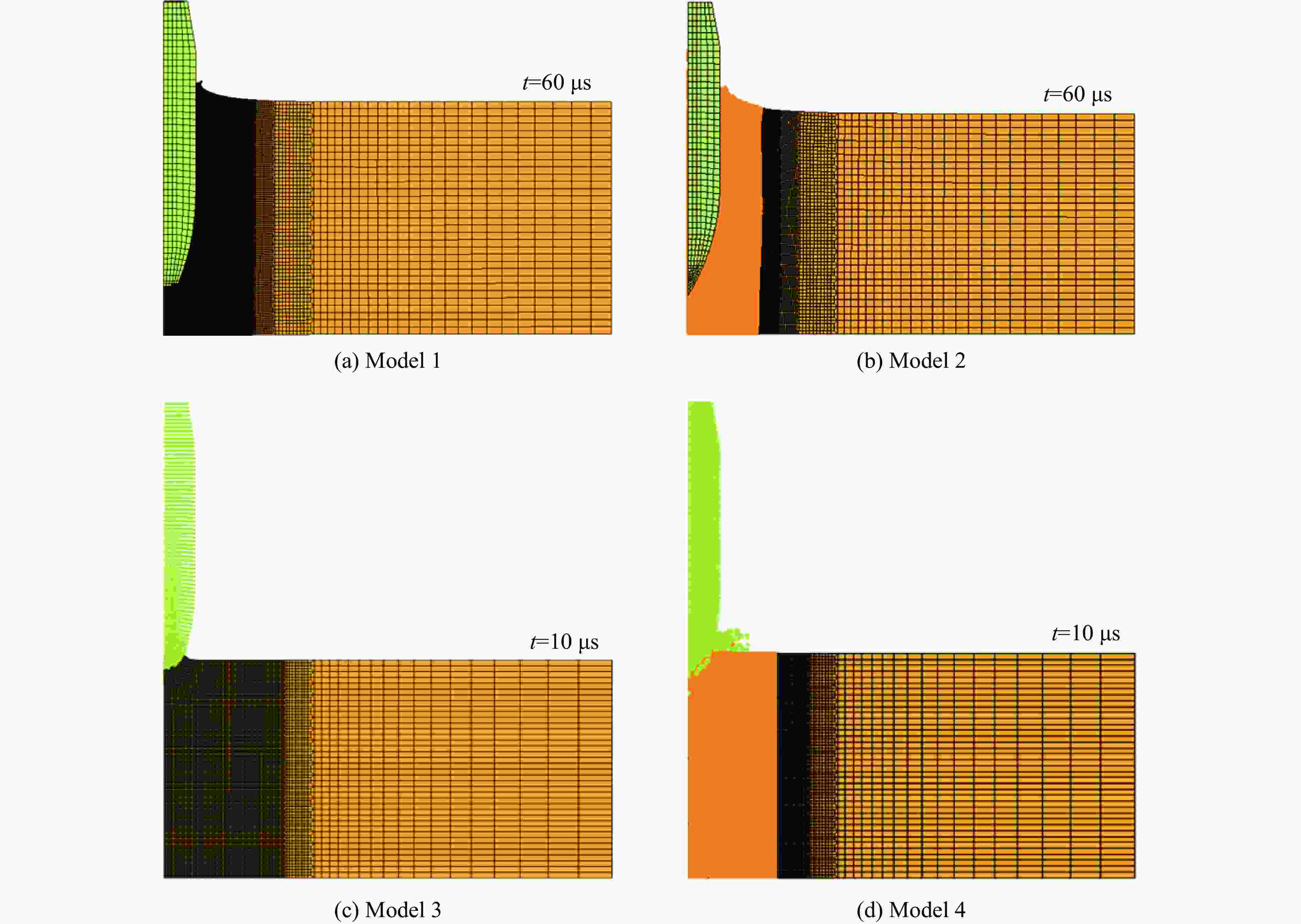

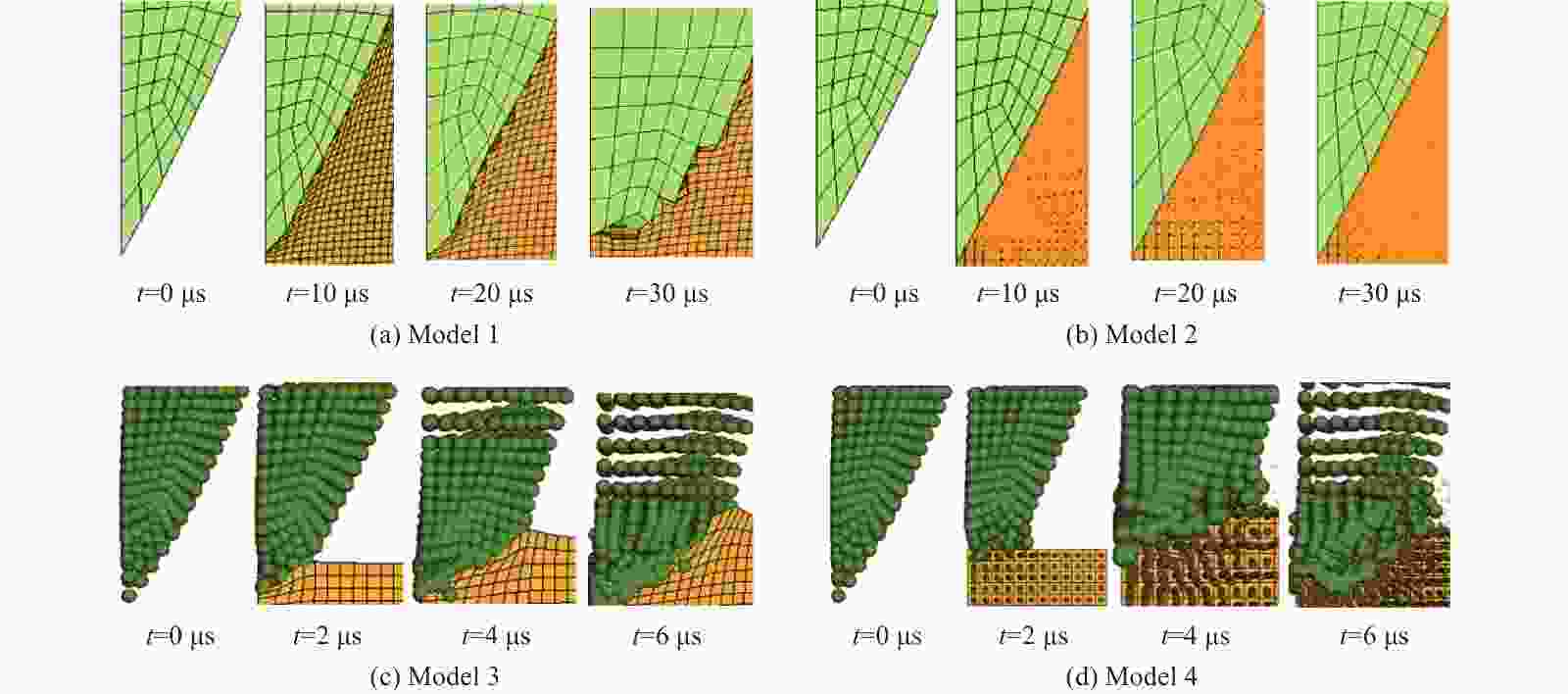

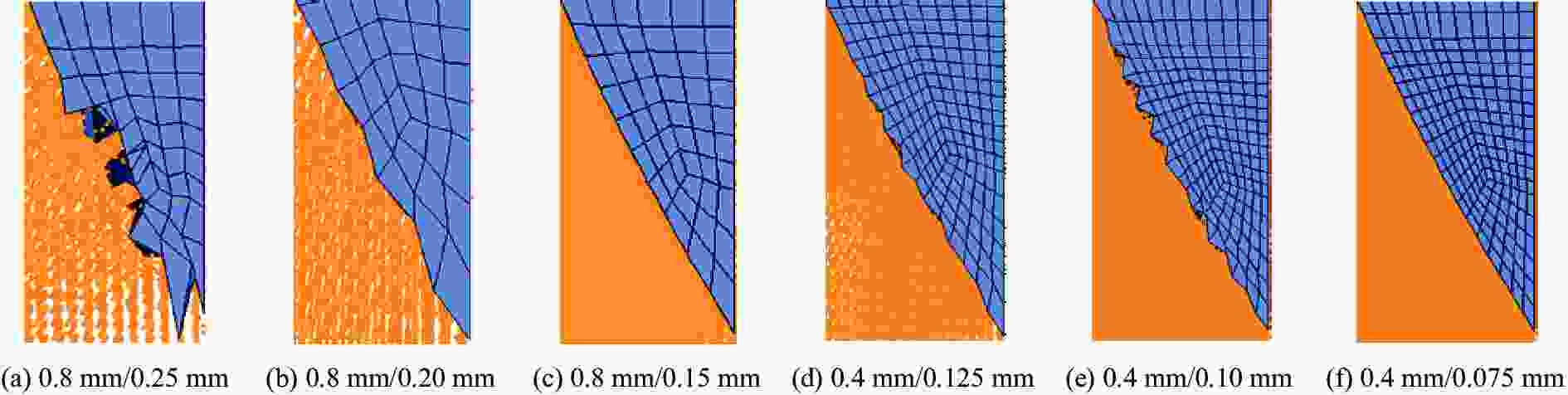

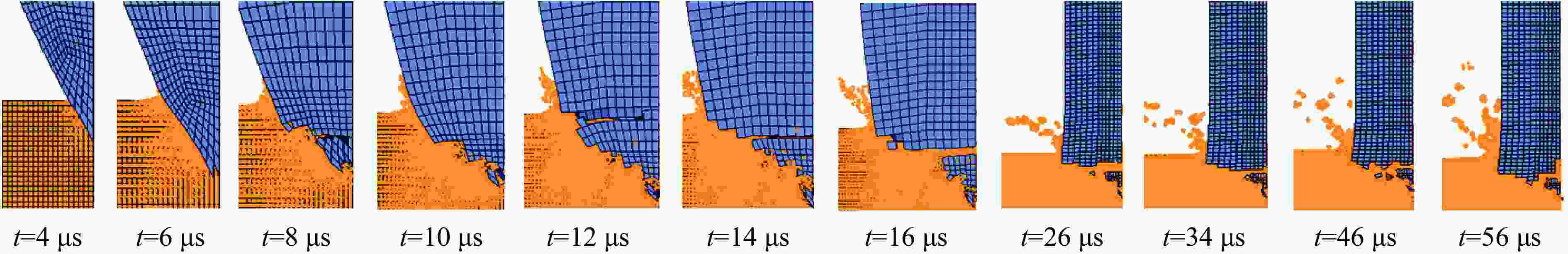

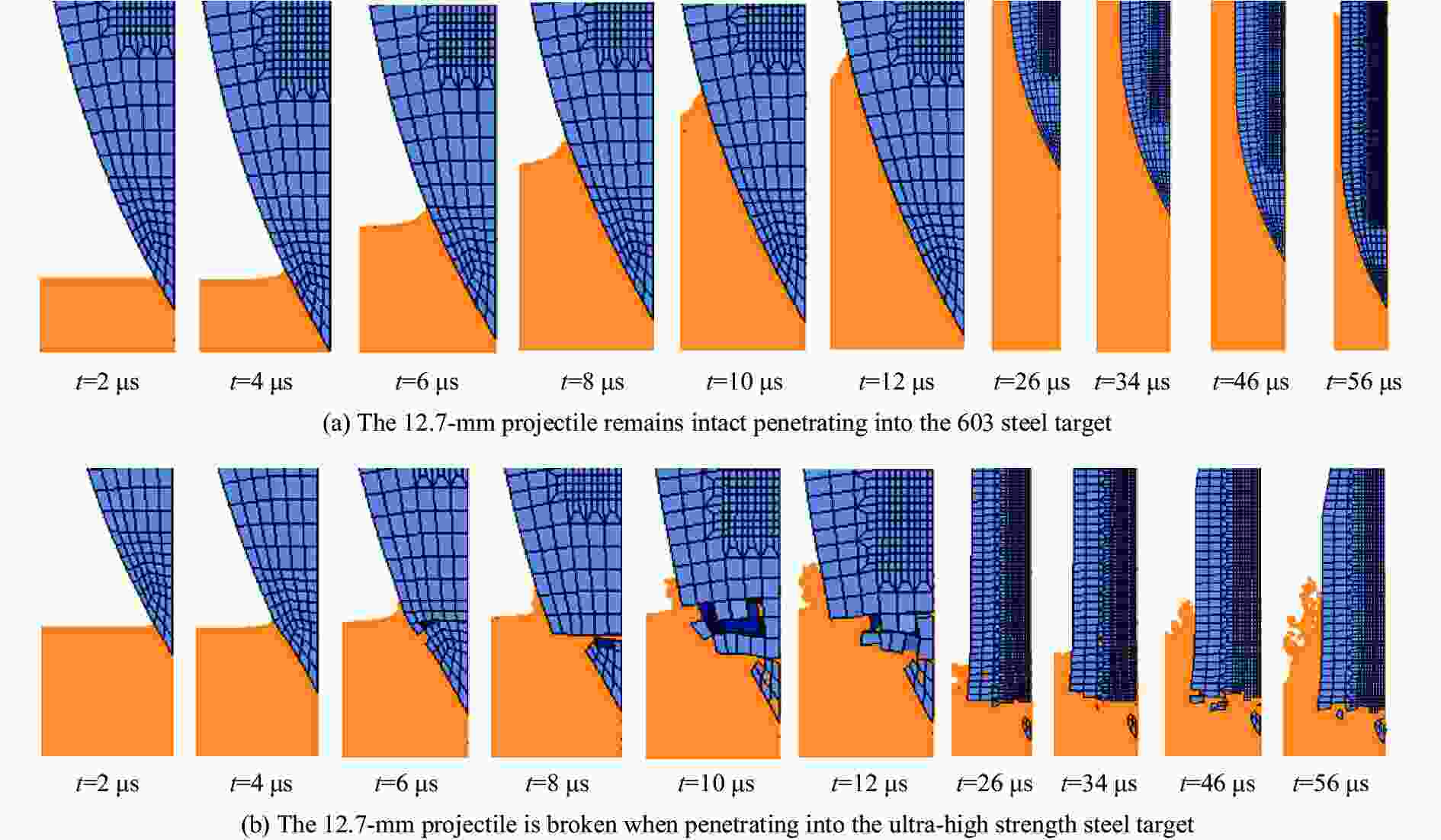

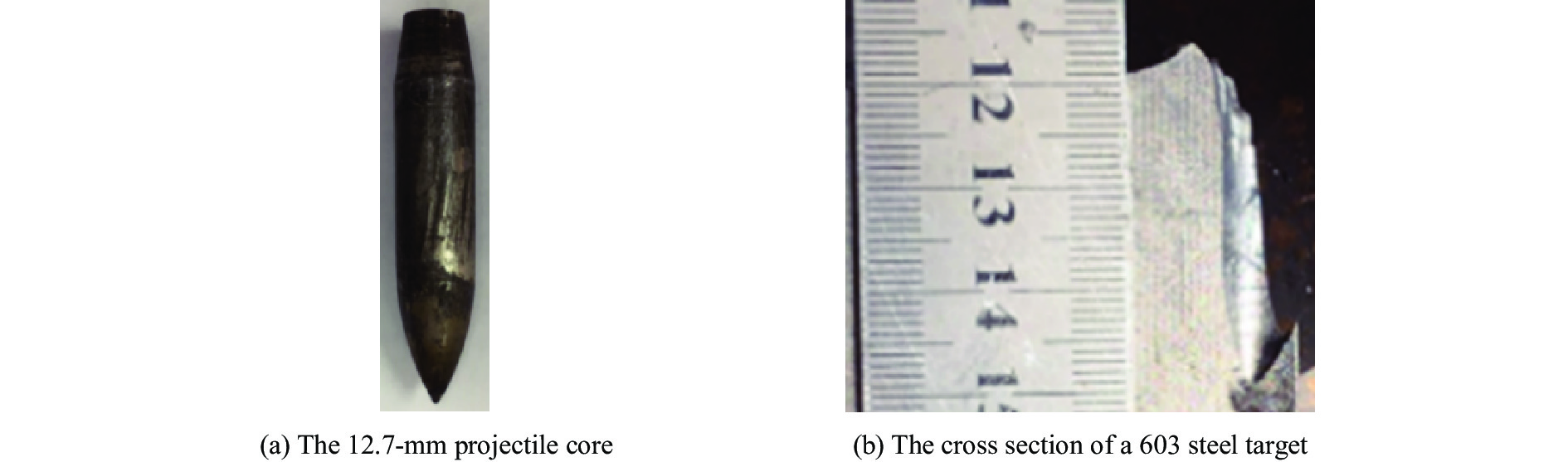

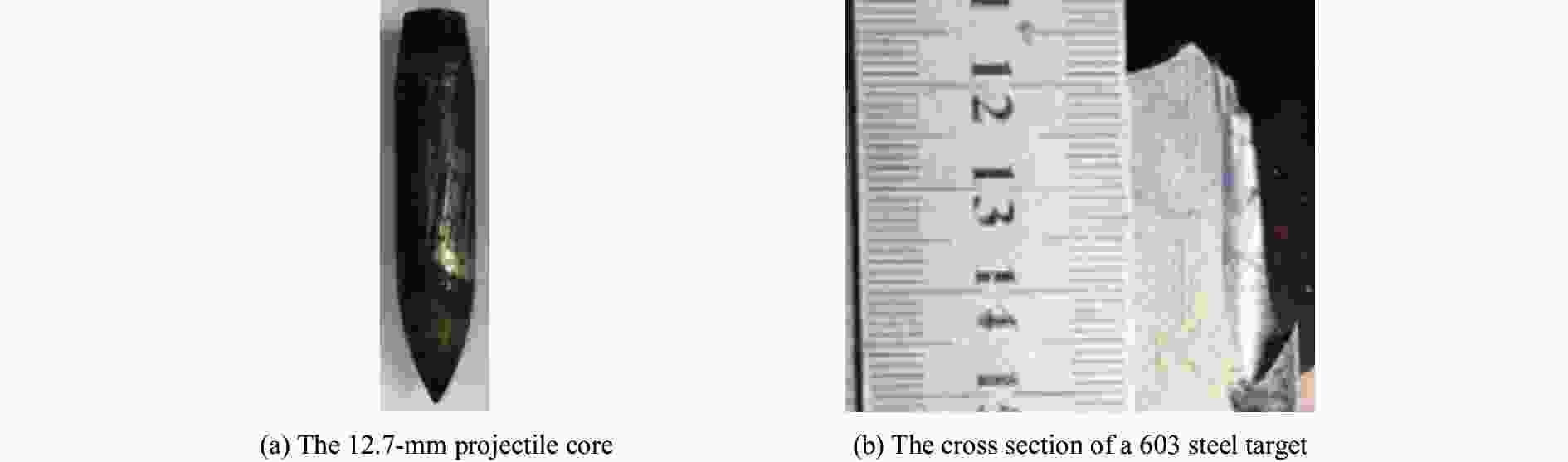

Abstract: A 12.7-mm projectile may remain intact or be broken during penetrating into steel targets with different strengths. However, previous simulations were limited to simulating a single situation. To break this limitation, the numerical simulation methods of the 12.7-mm projectile penetration into steel targets were studied, leading to a projectile-target model which was capable of simulating both the intact and broken cases. In the intact projectile case, the ballistic tests were implemented to study the dynamic behavior of the 12.7-mm projectile penetrating into the 603 steel targets. Two different modeling algorithms based on the finite element method (FEM) and the smooth particle hydrodynamics particles (SPH) method, respectively, were compared with the experimental results. Then the influences of finite element and particle sizes on the numerical results were studied to establish the numerical model to simulate the intact projectile case. Furthermore, the established model was applied to simulate the broken projectile case by changing the target material and the element sizes. The numerical results were then compared with the experimental results. The numerical study shows that the projectile and target should be discretized using the FEM and SPH, respectively, for simulating the intact case. Meanwhile, a large ratio between the finite element mesh size and the SPH particle spacing should be used, such as 5.3. Otherwise, an abnormal numerical deformation may occur around the projectile head, which is inconsistent with the experimental result. This model can also be used to simulate the broken projectile case, as verified with the experimental results. However, the large ratio between the finite element mesh size and the SPH particle spacing leads to numerical problems and abort of simulations. To overcome this difficulty, an FEM/SPH coupled projectile-target model is proposed, in which the projectile was discretized using coarse meshes close to the surface and fine meshes in the core region. Numerical results show that the proposed projectile-target model can be used to simulate the penetration process no matter the projectile remains intact or broken.-

Key words:

- FEM/SPHcoupled projectile-targetmodel /

- broken projectile /

- steel target /

- penetration

-

表 1 12.7 mm穿甲弹弹芯和靶板的材料参数

Table 1. The material parameters for the 12.7-mm-diameter armor-piercing projectiles and targets

-

[1] DEY S, BØRVIK T, TENG X, et al. On the ballistic resistance of double-layered steel plates: an experimental and numerical investigation [J]. International Journal of Solids and Structures, 2007, 44(20): 6701–6723. DOI: 10.1016/j.ijsolstr.2007.03.005. [2] FLORES-JOHNSON E A, SALEH M, EDWARDS L. Ballistic performance of multi-layered metallic plates impacted by a 7.62-mm APM2 projectile [J]. International Journal of Impact Engineering, 2011, 38(12): 1022–1032. DOI: 10.1016/j.ijimpeng.2011.08.005. [3] GAO G H, ZHANG H, GUI X L, et al. Enhanced ductility and toughness in an ultrahigh-strength Mn–Si–Cr–C steel: the great potential of ultrafine filmy retained austenite [J]. Acta Materialia, 2014, 76: 425–433. DOI: 10.1016/j.actamat.2014.05.055. [4] CHANG Z Y, LI Y J, WU D. Enhanced ductility and toughness in 2000 MPa grade press hardening steels by auto-tempering [J]. Materials Science and Engineering: A, 2020, 784: 139342. DOI: 10.1016/j.msea.2020.139342. [5] SOURMAIL T, CABALLERO F G, GARCIA-MATEO C, et al. Evaluation of potential of high Si high C steel nanostructured bainite for wear and fatigue applications [J]. Materials Science and Technology, 2013, 29(10): 1166–1173. DOI: 10.1179/1743284713Y.0000000242. [6] FRAS T, MURZYN A, PAWLOWSKI P. Defeat mechanisms provided by slotted add-on bainitic plates against small-calibre 7.62mm×51 AP projectiles [J]. International Journal of Impact Engineering, 2017, 103: 241–253. DOI: 10.1016/j.ijimpeng.2017.01.015. [7] KILIC N, BEDIR S, ERDIK A, et al. Ballistic behavior of high hardness perforated armor plates against 7.62-mm armor piercing projectile [J]. Materials and Design, 2014, 63: 427–438. DOI: 10.1016/j.matdes.2014.06.030. [8] 魏刚. 金属动能弹变形与断裂特性及其机理研究 [D]. 哈尔滨: 哈尔滨工业大学, 2014: 142–146. DOI: 10.7666/d.D593970.WEI Gang. Investigation of deformation and fracture behavior associated mechanisms of the metal kinetic energy projeciles [D]. Harbin, Heilongjiang, China: Harbin Institute of Technology, 2014: 142–146. DOI: 10.7666/d.D593970. [9] 赵太勇, 王维占, 赵军强, 等. 12.7 mm动能弹侵彻装甲钢板的结构响应特性研究 [J]. 兵器装备工程学报, 2020, 41(10): 146–149. DOI: 10.11809/bqzbgcxb2020.10.026.ZHAO T Y, WANG W Z, ZHAO J Q, et al. Study on structural response characteristics of 12.7 mm kinetic energy projectile penetrating armor plate [J]. Journal of Ordnance Equipment Engineering, 2020, 41(10): 146–149. DOI: 10.11809/bqzbgcxb2020.10.026. [10] CHEN X W, CHEN G, ZHANG F J. Deformation and failure modes of soft steel projectiles impacting harder steel targets at increasing velocity [J]. Experimental Mechanics, 2008, 48(3): 335–354. DOI: 10.1007/s11340-007-9110-4. [11] 陈刚, 陈小伟, 陈忠富, 等. A3钢钝头弹撞击45钢板破坏模式的数值分析 [J]. 爆炸与冲击, 2007, 27(5): 390–397. DOI: 10.11883/1001-1455(2007)05-0390-08.CHEN G, CHEN X W, CHEN Z F, et al. Simulations of A3 steel blunt projectiles impacting onto 45 steel plates [J]. Explosion and Shock Waves, 2007, 27(5): 390–397. DOI: 10.11883/1001-1455(2007)05-0390-08. [12] CHEN X W, ZHANG F J, LIANG B, et al. Three modes of penetration mechanisms of A3 steel cylindrical projectiles impact onto 45 steel plates [J]. Key Engineering Materials, 2007, 340/341: 295–300. DOI: 10.4028/www.scientific.net/KEM.340-341.295. [13] PARIS V, WEISS A, VIZEL A, et al. Fragmentation of armor piercing steel projectiles upon oblique perforation of steel plates [C]//EPJ Web of Conferences, 2012, 26: 04032. DOI: 10.1051/epjconf/20122604032. [14] 石益建, 杜忠华, 高光发, 等. 异形B4C/Al复合靶板抗侵彻数值模拟分析 [J]. 弹箭与制导学报, 2020, 40(2): 67–71. DOI: 10.15892/j.cnki.djzdxb.2020.02.017.SHI Y J, DU Z H, GAO G F, et al. Numerical simulation and analysis of abnormal B4C/Al composite target [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2020, 40(2): 67–71. DOI: 10.15892/j.cnki.djzdxb.2020.02.017. [15] WOODWARD R L, O'DONNELL R G, FLOCKHART C J. Failure mechanisms in impacting penetrators [J]. Journal of Materials Science, 1992, 27(23): 6411–6416. DOI: 10.1007/BF00576292. [16] 谢恒, 吕振华. 钢芯弹冲击高强度钢过程的数值模拟分析 [J]. 高压物理学报, 2012, 26(3): 259–265. DOI: 10.11858/gywlxb.2012.03.003.XIE H, LÜ Z H. Perforation simulations of high-strength steel by steel core bullets [J]. Chinese Journal of High Pressure Physics, 2012, 26(3): 259–265. DOI: 10.11858/gywlxb.2012.03.003. [17] BØRVIK T, DEY S, CLAUSEN A H. Perforation resistance of five different high-strength steel plates subjected to small-arms projectiles [J]. International Journal of Impact Engineering, 2009, 36(7): 948–964. DOI: 10.1016/j.ijimpeng.2008.12.003. [18] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures [J]. Engineering Fracture Mechanics, 1983, 21: 541–548. [19] IQBAL M A, SENTHIL K, MADHU V, et al. Oblique impact on single, layered and spaced mild steel targets by 7.62 AP projectiles [J]. International Journal of Impact Engineering, 2017, 110: 26–38. DOI: 10.1016/j.ijimpeng.2017.04.011. [20] JOHNSON G R, COOK W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures [J]. Engineering Fracture Mechanics, 1985, 21(1): 31–48. DOI: 10.1016/0013-7944(85)90052-9. [21] XIAO X K, ZHANG W, WEI G, et al. Experimental and numerical investigation on the deformation and failure behavior in the Taylor test [J]. Materials and Design, 2011, 32(5): 2663–2674. DOI: 10.1016/j.matdes.2011.01.016. -

下载:

下载: