Experimental research on low-velocity impact and compression after impact of braided composites based on infrared thermal imaging

-

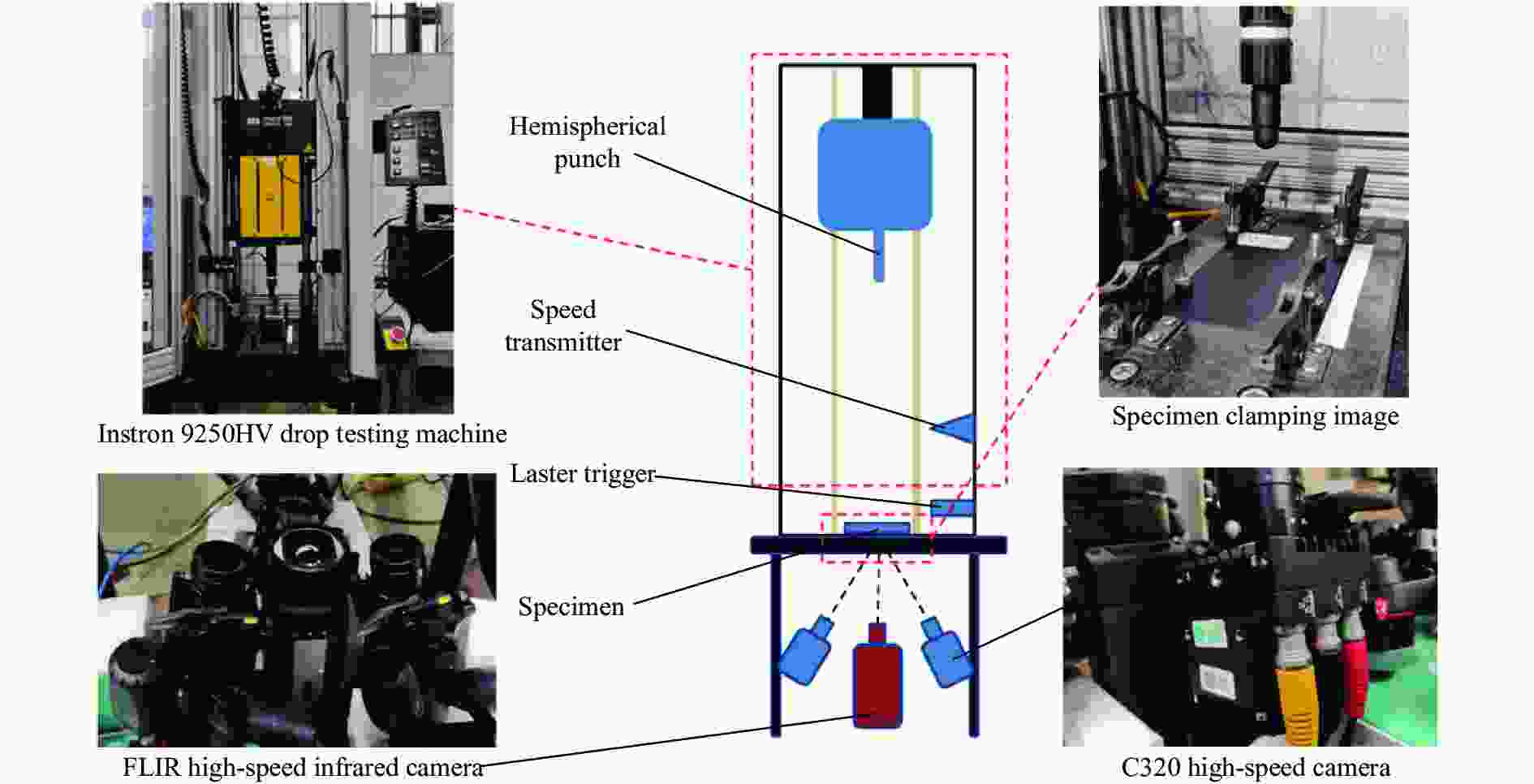

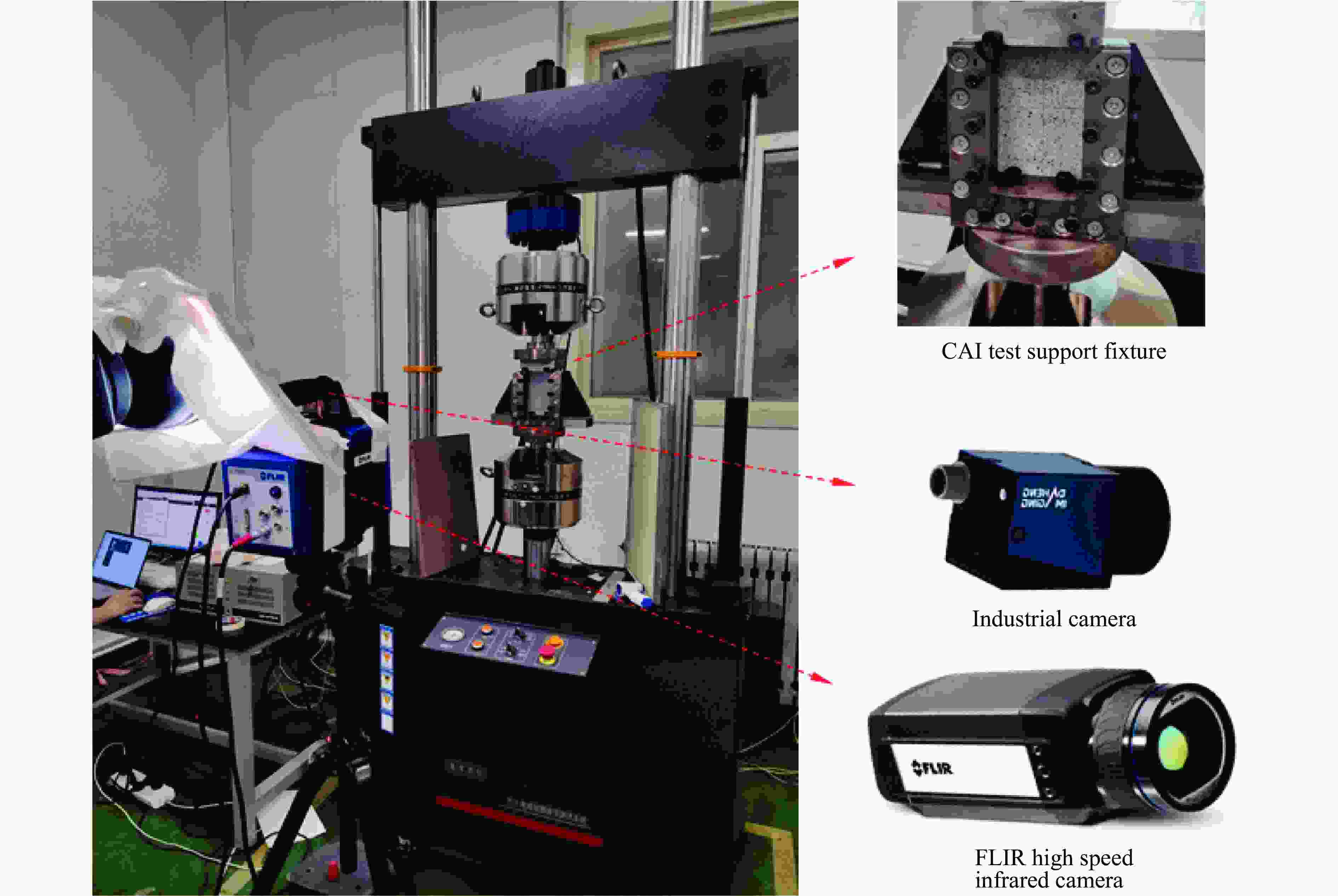

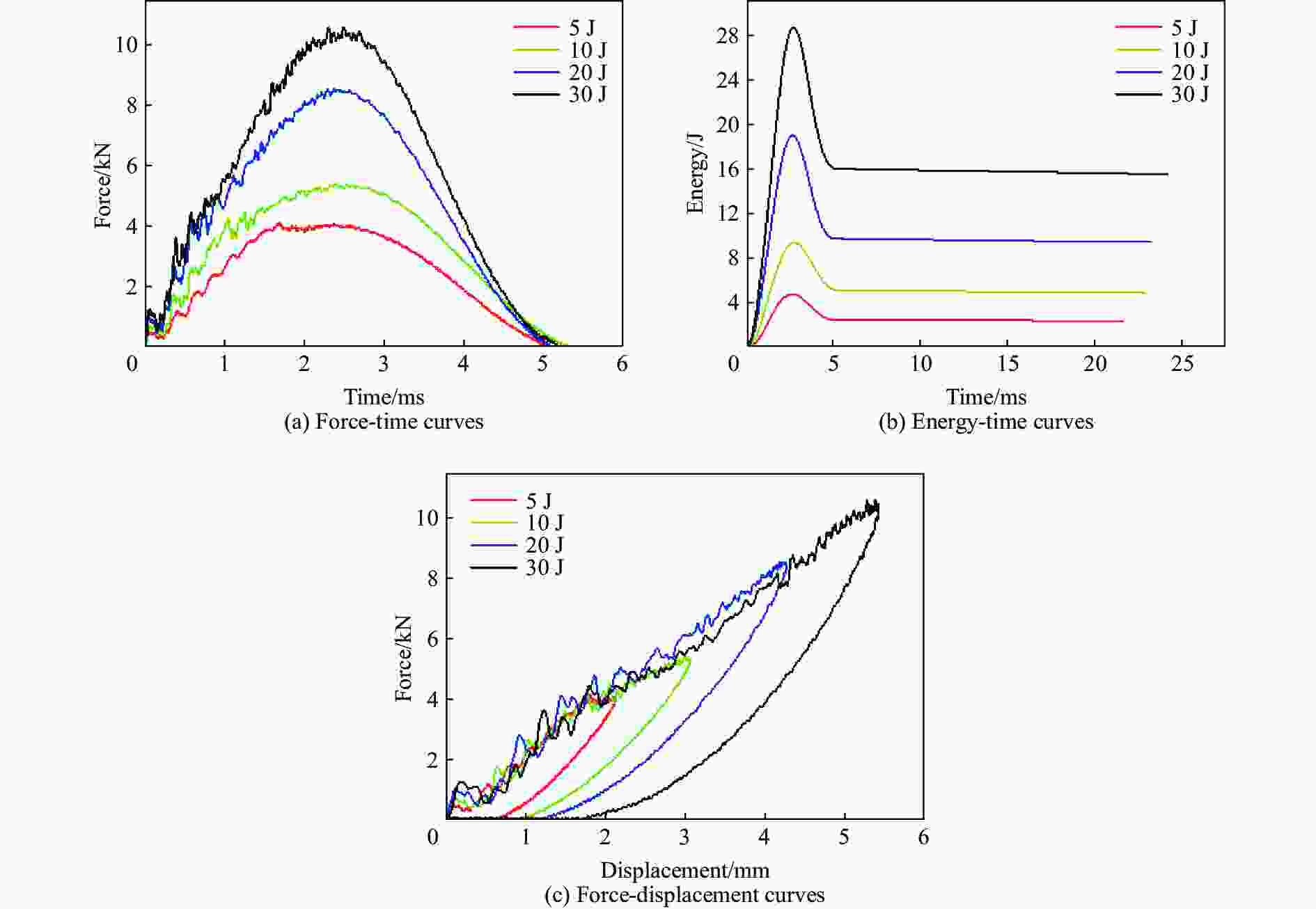

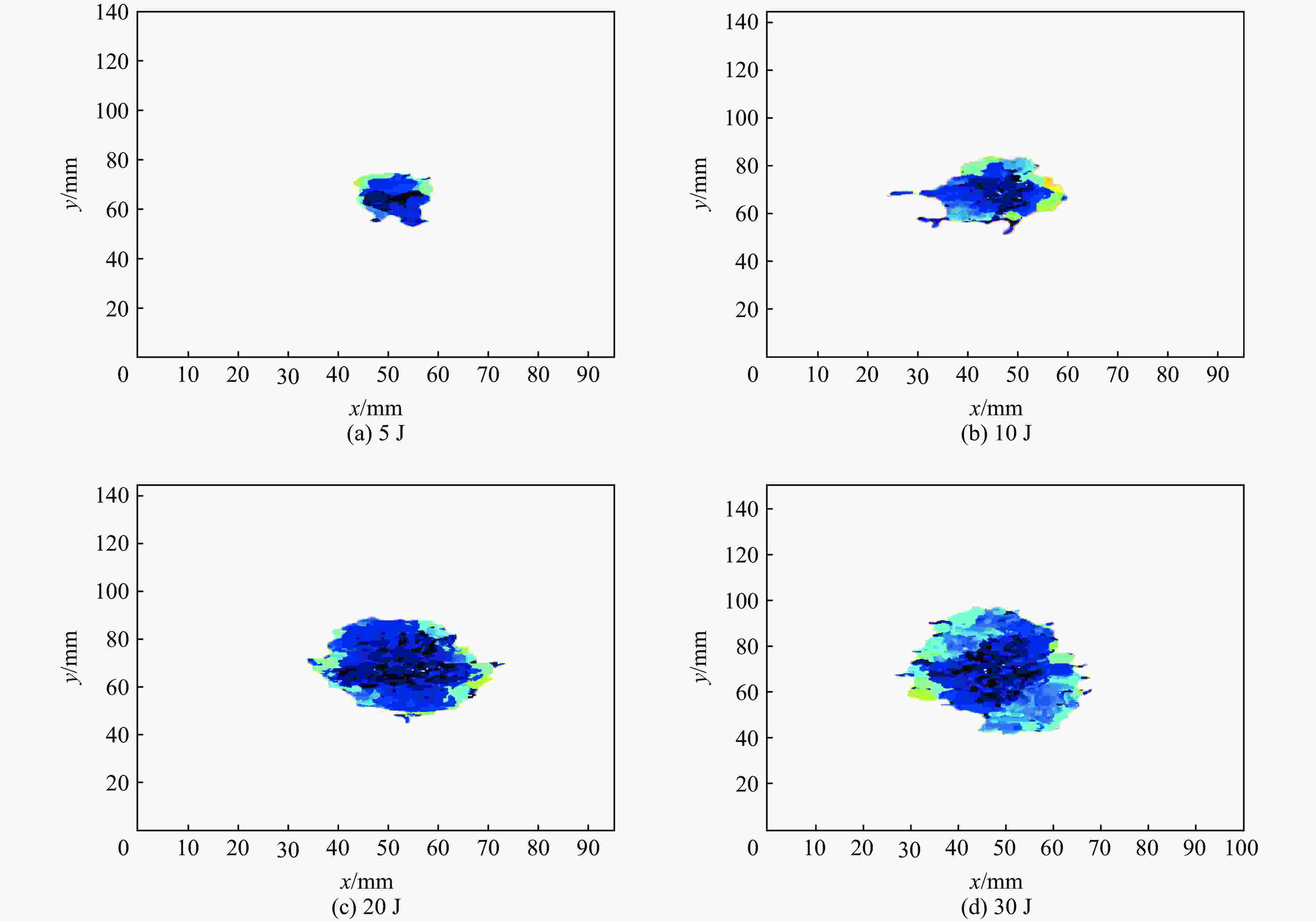

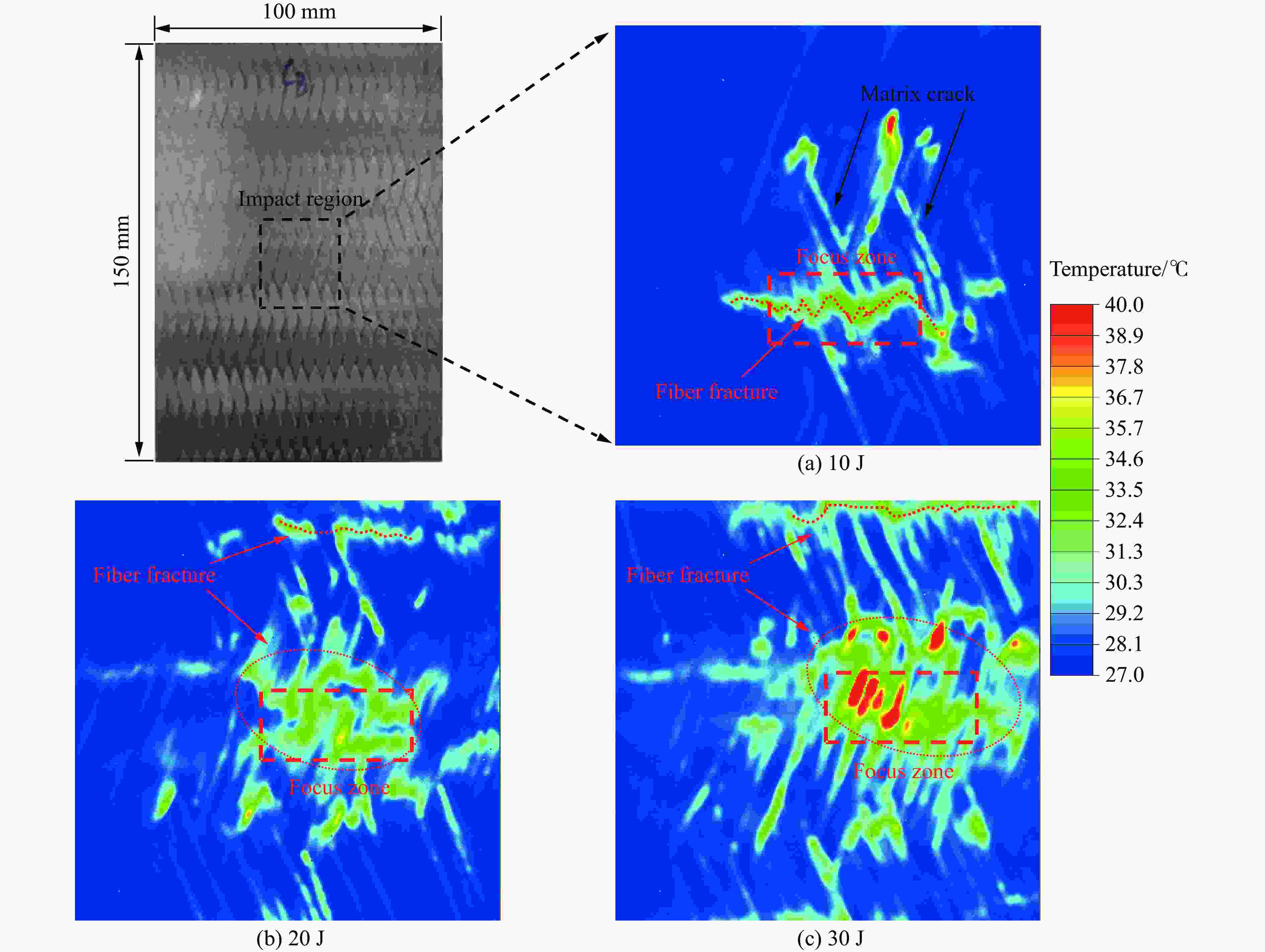

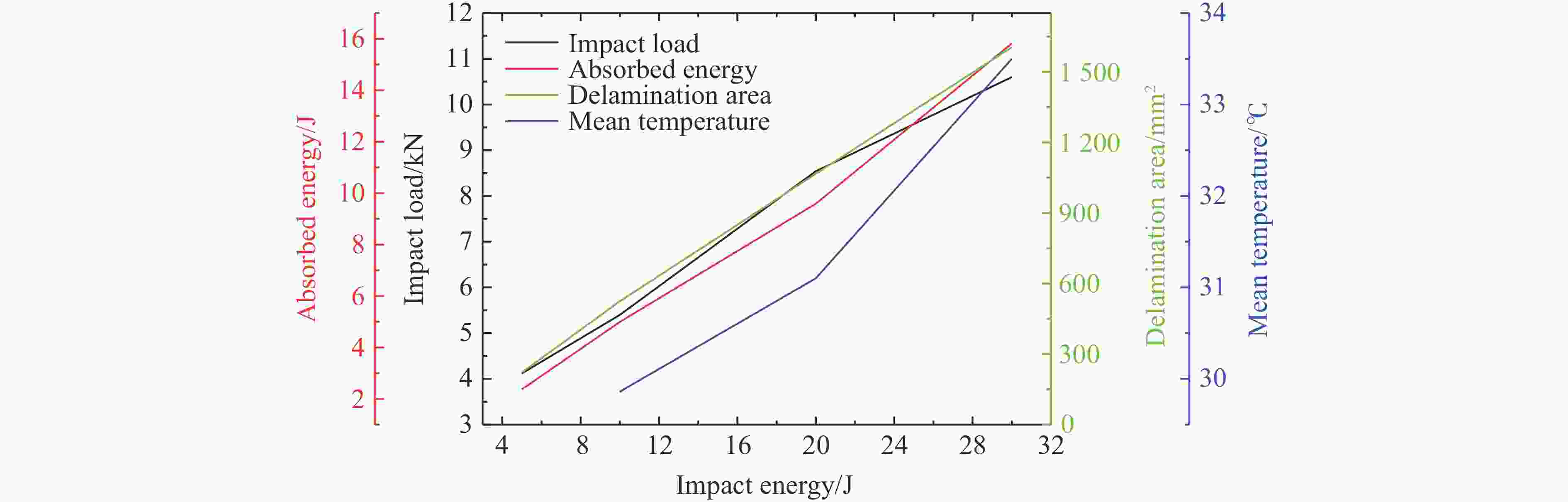

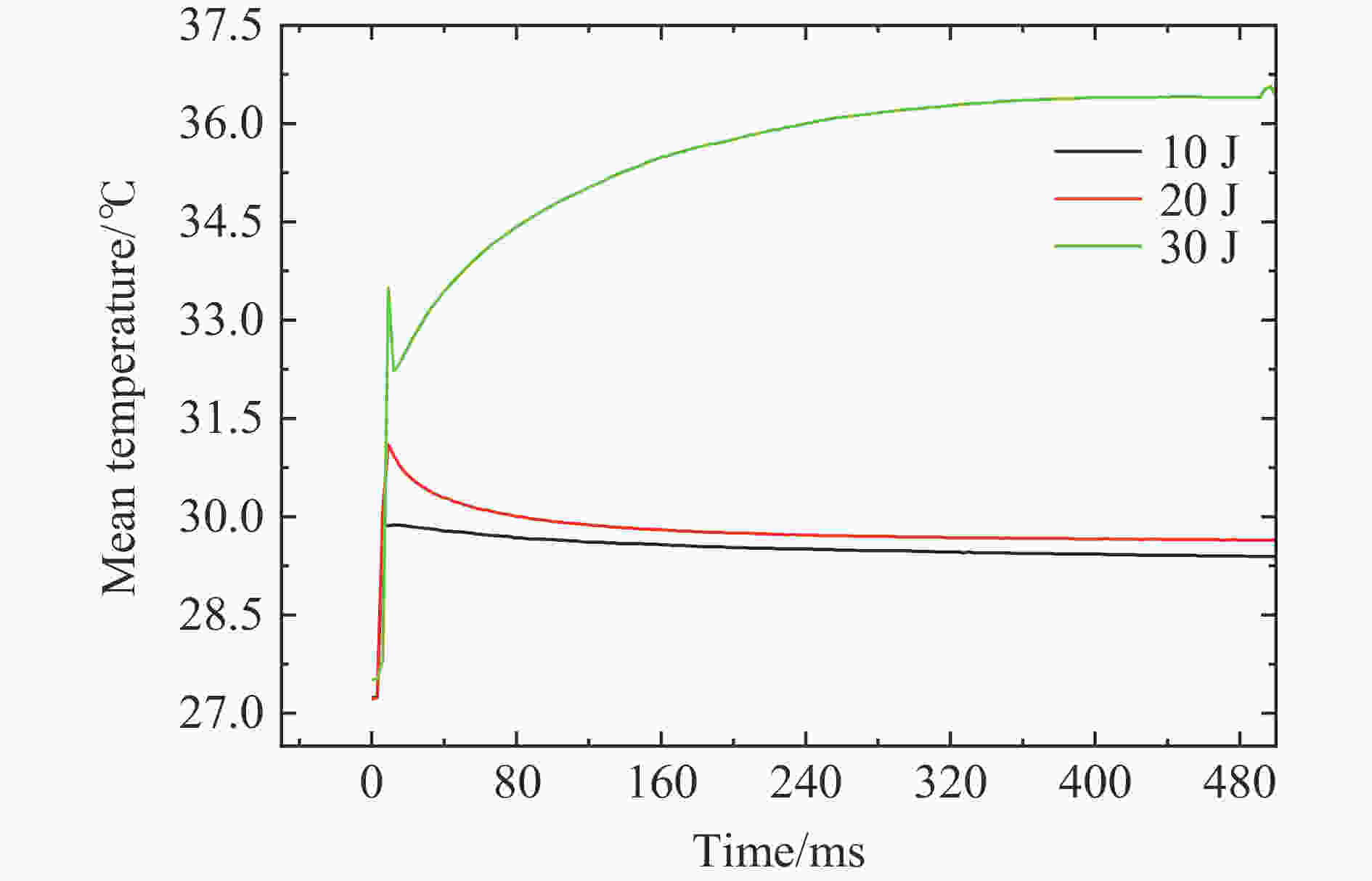

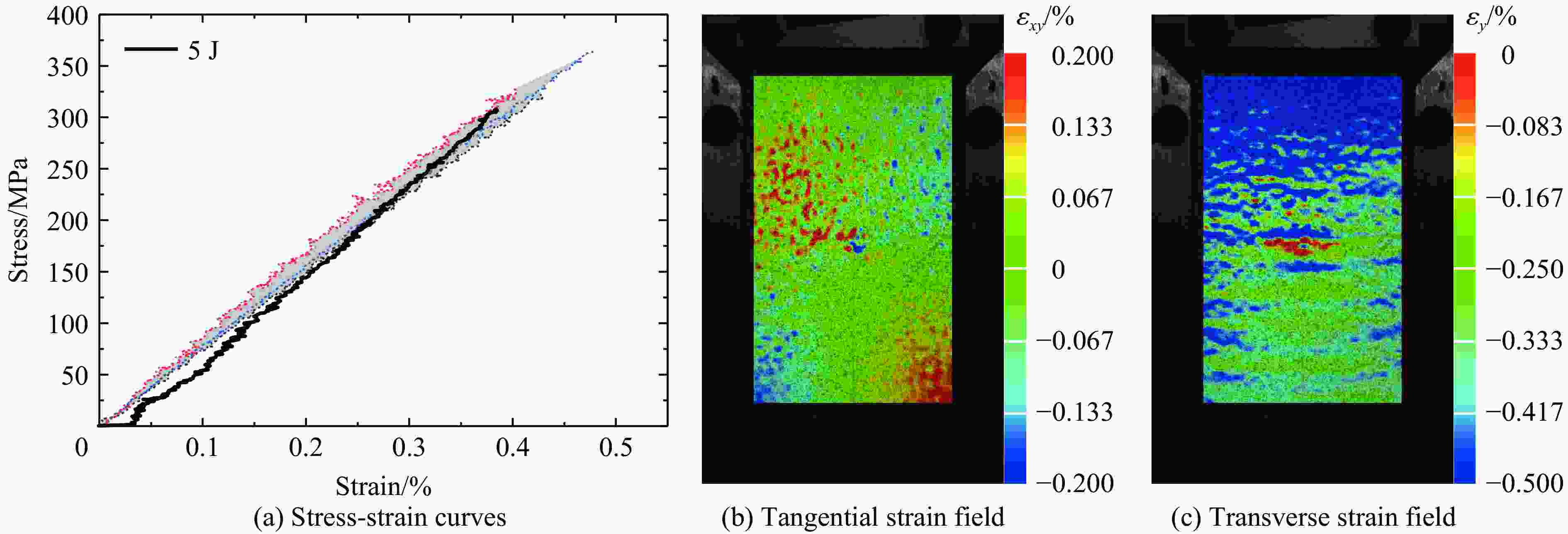

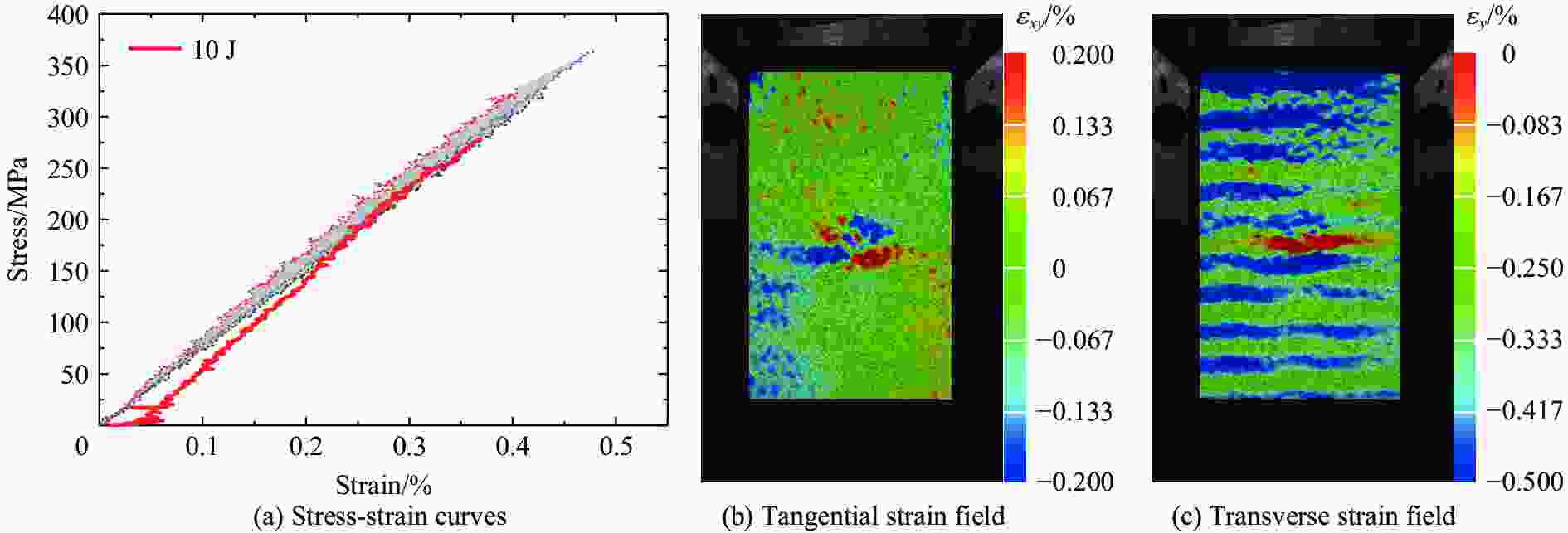

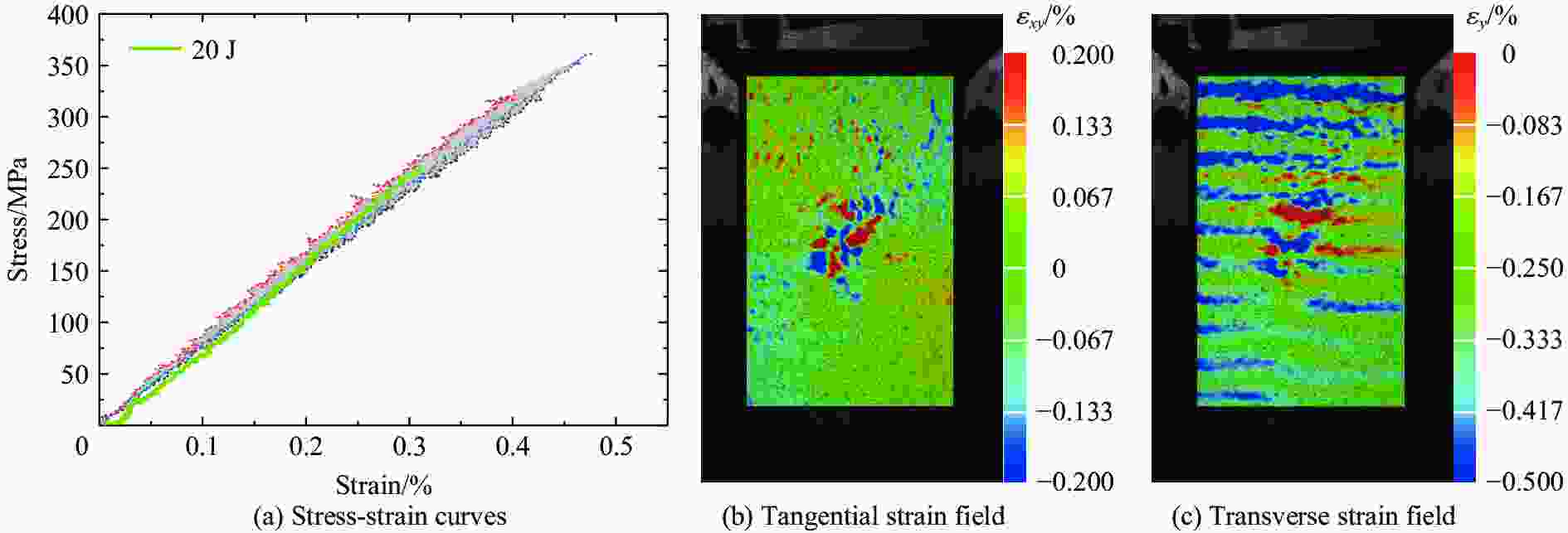

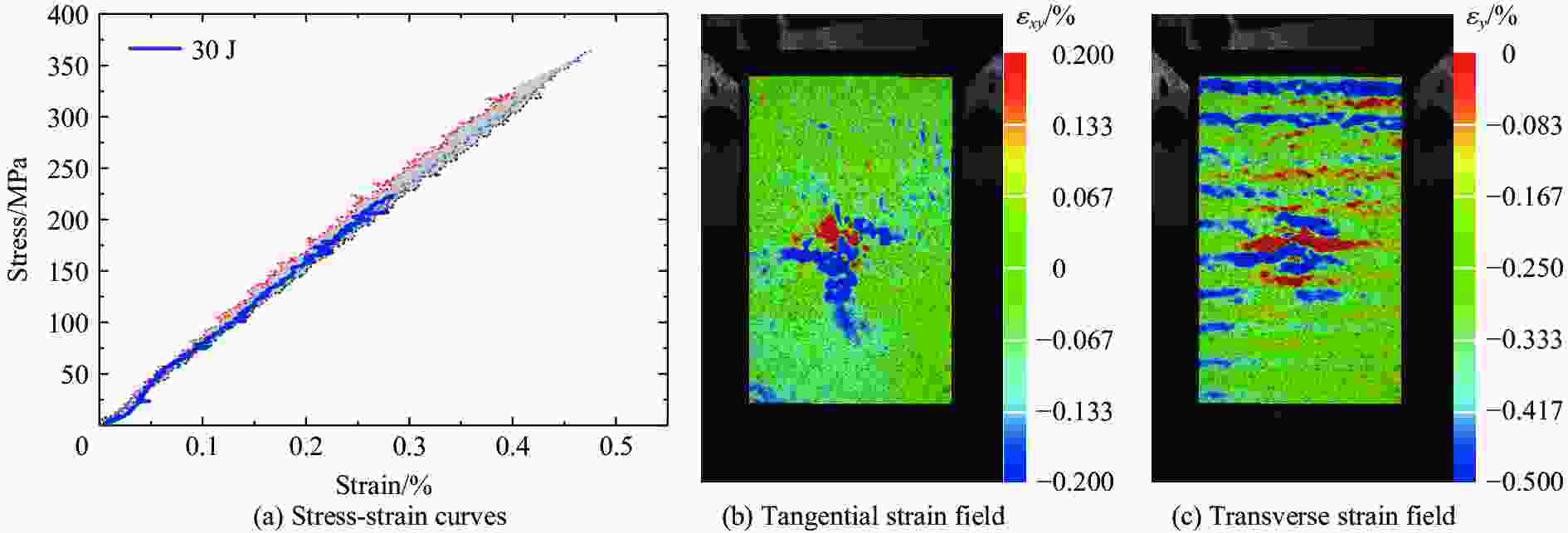

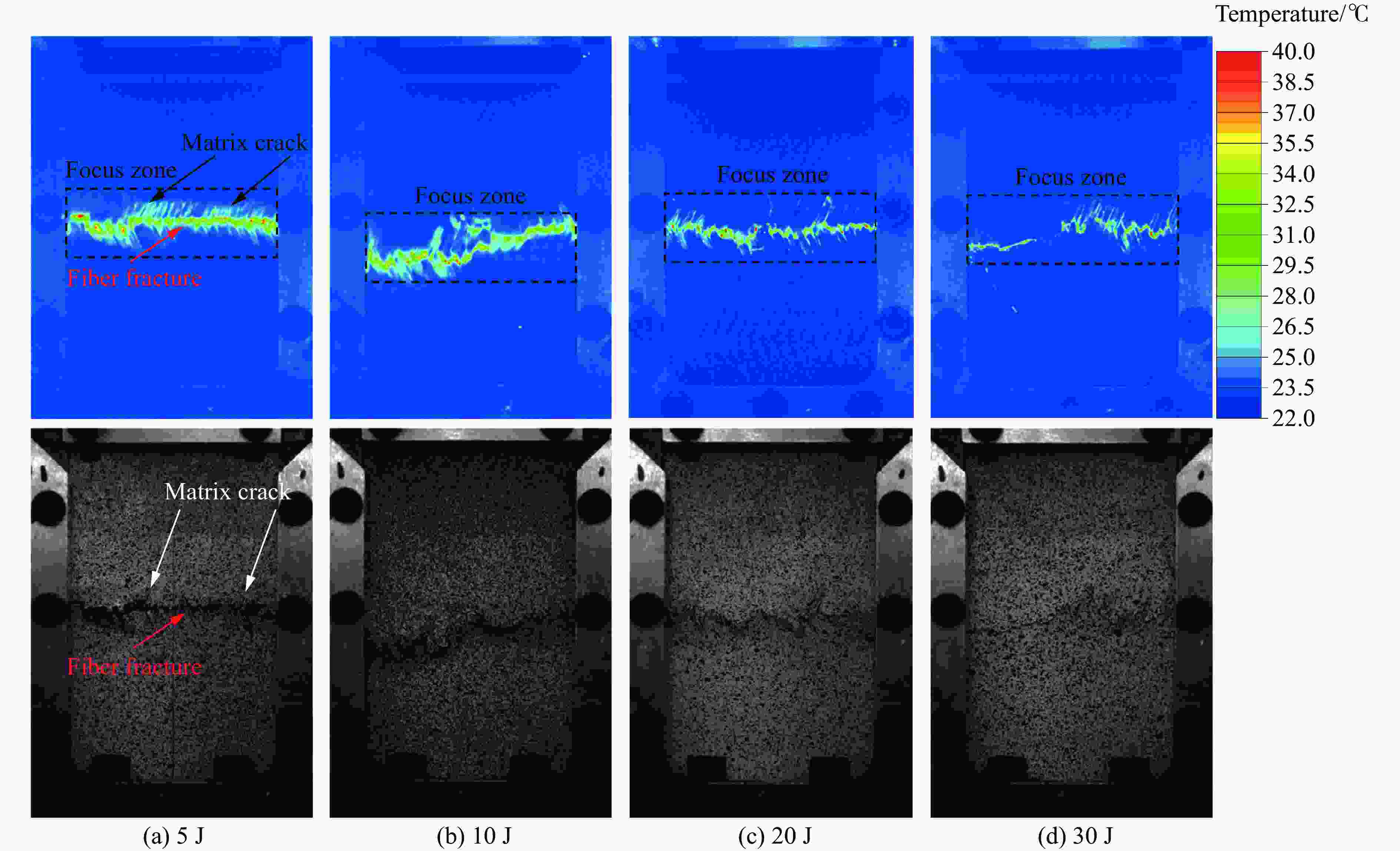

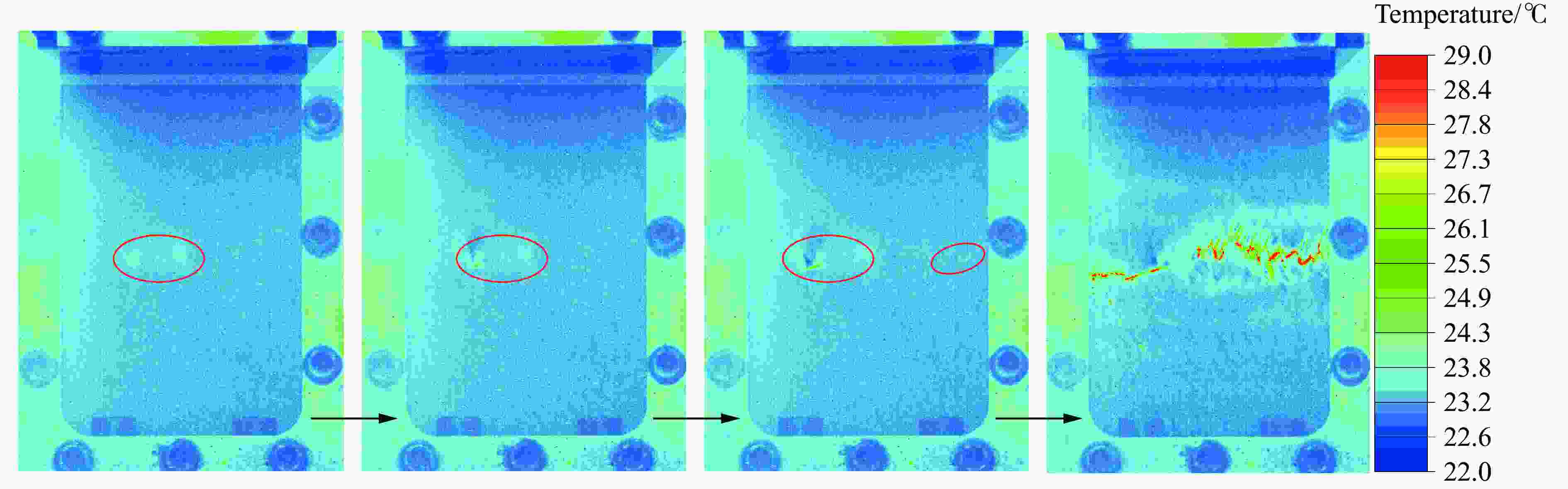

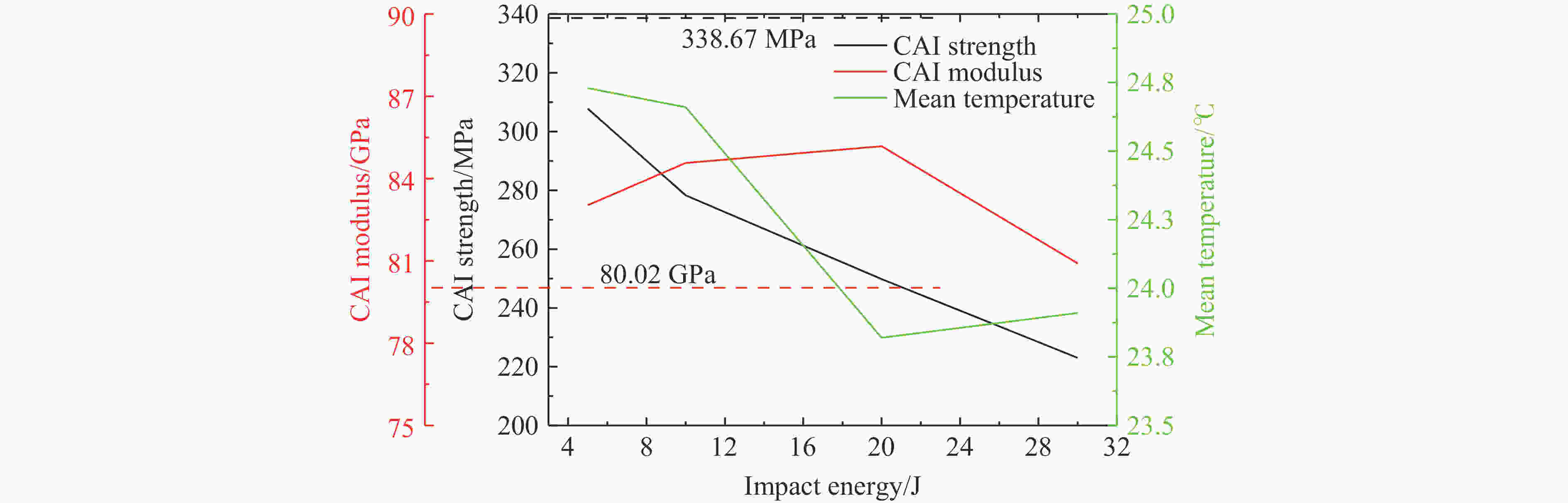

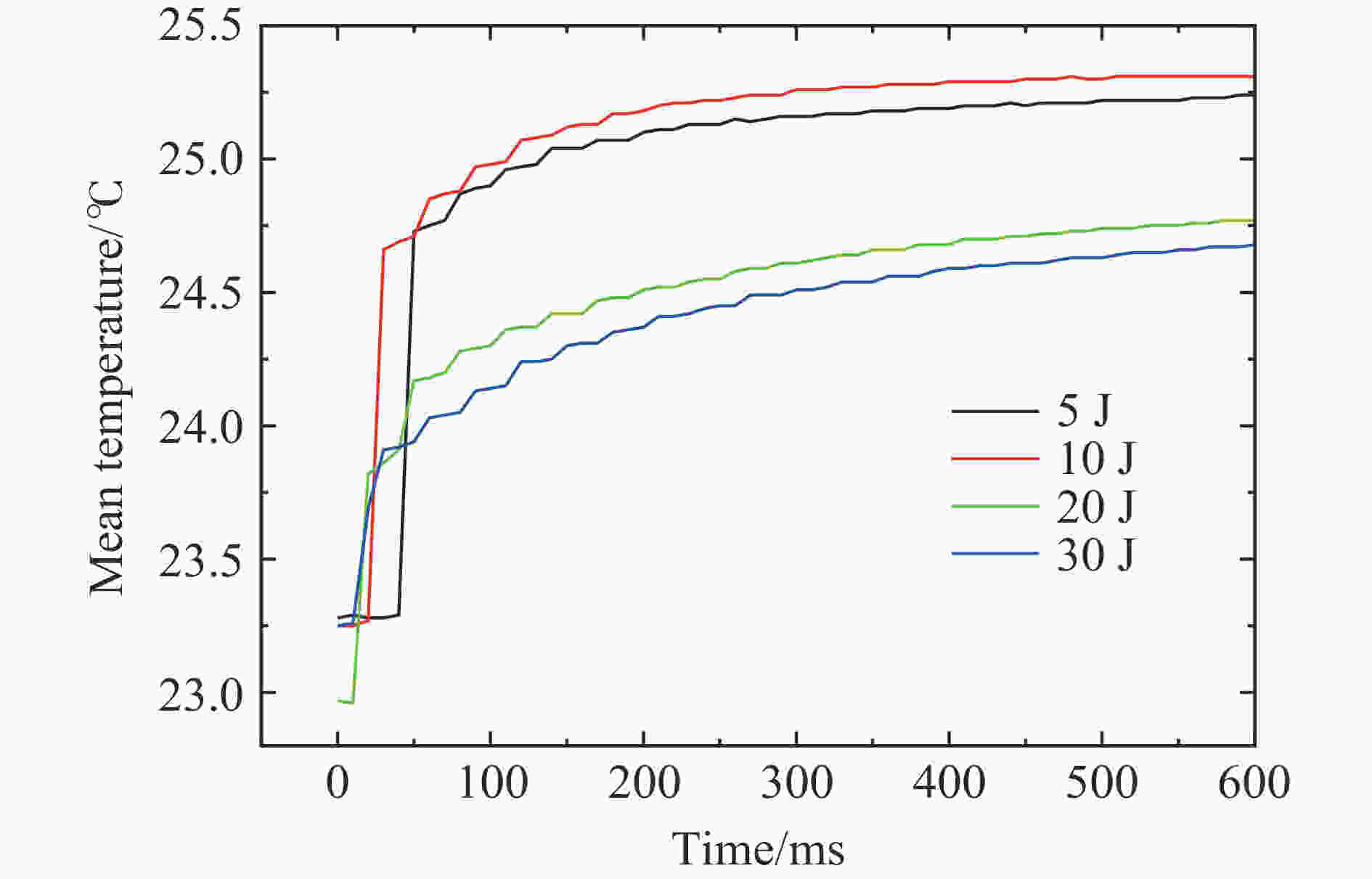

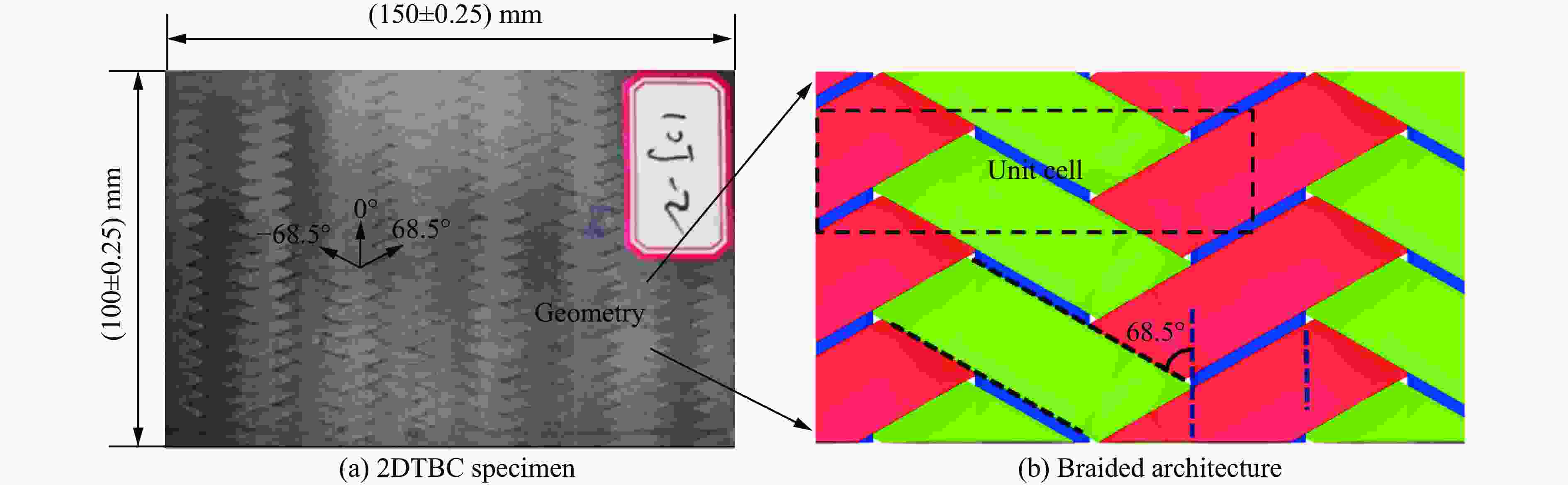

摘要: 针对二维三轴编织复合材料(two-dimensional triaxially braided composite, 2DTBC)在低速冲击和冲击后压缩(compression after impact, CAI)载荷下的损伤失效机理,开展了2DTBC试样的不同能量低速冲击试验以及相应的CAI试验,并采用红外热像仪监测在低速冲击和CAI试验过程中的温升现象。通过C扫描表征了不同能量低速冲击后试样的分层损伤情况,讨论了试样背面温度场分布特性及其随冲击能量的演化规律;对比分析了2DTBC冲击后剩余压缩强度与冲击能量的对应关系,基于数字图像相关(digital image correlation, DIC)技术监测了CAI试验中的全局应变场,结合热成像、变形场和光学图像数据,阐明了不同能量冲击后2DTBC的压缩失效特性,讨论了基于红外热成像技术表征编织复合材料损伤失效行为的有效性。试验结果显示:编织复合材料低速冲击和CAI试验中的温度场分布图与编织几何构型有明显关联度;低速冲击试验的温升幅值随冲击能量的增加而快速上升,CAI试验的温升现象随着冲击能量的增加而减弱;分层面积随冲击能量的增大而增大,冲击后剩余压缩强度随冲击能量的增大而降低。研究结果表明:红外热成像技术能够很好地捕捉试样破坏瞬间释放断裂能所产生的温升现象,温度场图像相较于全局应变场能更好地捕捉破坏的起始位置和失效特征。Abstract: The damage and failure mechanism of two-dimensional triaxially braided composite (2DTBC) under low-velocity impact and compression after impact (CAI) was experimentally investigated through tests with various impact energies (5, 10, 20 and 30 J). The low-velocity impact specimens were prepared according to the ASTM D7136 standard and tested using the Instron drop tower 9250HV with a hemispherical punch, and CAI tests were carried out on an Aowei PLD-250 fatigue machine following the ASTM D7137 standard. An infrared thermal imaging camera was employed to monitor the temperature distribution of the specimens during the low-velocity impact and CAI tests. Delamination damage of impacted specimens was characterized by an ICS-Ⅱ ultrasonic C-scanner. The relationship between impact energy and residual compression strength of 2DTBC after impact load was compared and analyzed. The evolution of the temperature field and its sensitivity against impact energy were discussed based on the infrared image data. Regarding the CAI tests, the global strain field was measured using the digital image correlation (DIC). Combining the thermal and deformation fields, and the optical failure images, the compression failure behavior of 2DTBC after impact of different energies were systematically investigated, validating the feasibility of infrared thermal imaging technology on characterizing the damage and failure behavior of braided composites. The experimental results show that the temperature field contours in low-velocity impact and CAI tests of braided composites are significantly correlated with braided architecture. The magnitude of temperature rise during the low-velocity impact test increases rapidly with the increase of impact energy, while the magnitude of temperature rise during the CAI test decreases with the increase of impact energy. Moreover, the maximum temperature rise is about 56.2 ºC in the 30 J low-velocity impact test. The delamination area is found to increase with the increase of impact energy, and the residual compression strength after impact decreases with the increase of impact energy. The residual compression strengths ratios are 90.9%, 82.2%, 73.8% and 65.8% for specimens after 5, 10, 20 and 30 J impacts, respectively. Through this study, we demonstrate that infrared thermal imaging camera can clearly capture the temperature rise phenomenon of composite specimens, which is caused by the releasing of fracture energy at the failure instant. More notably, the temperature contour can better reflect the damage location and failure characteristics than the global strain field.

-

表 1 试样信息和冲击能量

Table 1. Sample information and impact energy

序号 冲击能量/J 试件尺寸/(mm×mm×mm) 试件质量/g 1 5 150.14×100.20×4.64 104.4 2 10 149.62×98.10×4.48 101.7 3 20 149.60×100.00×4.60 105.3 4 30 149.66×98.32×4.56 102.3 -

[1] 范玉青, 张丽华. 超大型复合材料机体部件应用技术的新进展: 飞机制造技术的新跨越 [J]. 航空学报, 2009, 30(3): 534–543. DOI: 10.3321/j.issn:1000-6893.2009.03.022.FAN Y Q, ZHANG L H. New development of extra large composite aircraft components application technology-advance of aircraft manufacture technology [J]. Acta Aeronautica et Astronautica Sinica, 2009, 30(3): 534–543. DOI: 10.3321/j.issn:1000-6893.2009.03.022. [2] ASTM Committee D30 on Composite Materials. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136M—15 [S]. West Conshohocken, PA, United States: ASTM International, 2015. [3] ASTM Committee D30 on Composite Materials. Standard test method for compressive residual strength properties of damaged polymer matrix composite plates: ASTM D7137/D7137M—17 [S]. West Conshohocken, PA, United States: ASTM International, 2017. [4] Technical Committee PRI/42. Carbon-fibre-reinforced plastics: determination of compression-after-impact properties at a specified impact-energy level: BS ISO 18352: 2009 [S]. Switzerland: International Organization for Standardization, 2009. [5] 中华人民共和国国家质量监督检验检疫总局、中国国家标准化管理委员会. 纤维增强塑料层合板冲击后压缩性能试验方法: GB/T 21239—2007 [S]. 北京: 质检出版社, 2007. [6] TUO H L, LU Z X, MA X P, et al. Damage and failure mechanism of thin composite laminates under low-velocity impact and compression-after-impact loading conditions [J]. Composites Part B: Engineering, 2019, 163: 642–654. DOI: 10.1016/j.compositesb.2019.01.006. [7] JOHNSTON J P, PEREIRA J M, RUGGERI C R, et al. High-speed infrared thermal imaging during ballistic impact of triaxially braided composites [J]. Journal of Composite Materials, 2018, 52(25): 3549–3562. DOI: 10.1177/0021998318765290. [8] ZHANG W, GU B H, SUN B Z. Thermal-mechanical coupling modeling of 3D braided composite under impact compression loading and high temperature field [J]. Composites Science and Technology, 2017, 140: 73–88. DOI: 10.1016/j.compscitech.2016.12.019. [9] PAN Z X, WU Z Y, XIONG J. High-speed infrared imaging and mesostructural analysis of localized temperature rise in damage and failure behavior of 3-D braided carbon/epoxy composite subjected to high strain-rate compression [J]. Polymer Testing, 2019, 80: 106151. DOI: 10.1016/j.polymertesting.2019.106151. [10] SORINI C, CHATTOPADHYAY A, GOLDBERG R K. Micromechanical modeling of the effects of adiabatic heating on the high strain rate deformation of polymer matrix composites [J]. Composite Structures, 2019, 215: 377–384. DOI: 10.1016/j.compstruct.2019.02.016. [11] LI Z Y, GHOSH S. Micromechanics modeling and validation of thermal-mechanical damage in DER353 epoxy/borosilicate glass composite subject to high strain rate deformation [J]. International Journal of Impact Engineering, 2020, 136: 103414. DOI: 10.1016/j.ijimpeng.2019.103414. [12] 刘永贵, 唐志平, 崔世堂. 冲击载荷下瞬态温度的实时测量方法 [J]. 爆炸与冲击, 2014, 34(4): 471–475. DOI: 10.11883/1001-1455(2014)04-0471-05.LIU Y G, TANG Z P, CUI S T. Real-time measuring methods for transient temperature under shock loading [J]. Explosion and Shock Waves, 2014, 34(4): 471–475. DOI: 10.11883/1001-1455(2014)04-0471-05. [13] 刘永贵, 唐志平, 崔世堂. TiNi合金冲击相变过程中温度变化规律的实验研究 [J]. 爆炸与冲击, 2014, 34(6): 679–684. DOI: 10.11883/1001-1455(2014)06-0679-06.LIU Y G, TANG Z P, CUI S T. Experimental study on temperature evolution of TiNi alloy during shock-induced phase transformation [J]. Explosion and Shock Waves, 2014, 34(6): 679–684. DOI: 10.11883/1001-1455(2014)06-0679-06. [14] 李涛, 傅华, 李克武, 等. 单轴压缩下2种PBX炸药的动态变形损伤及其温升效应 [J]. 爆炸与冲击, 2017, 37(1): 120–125. DOI: 10.11883/1001-1455(2017)01-0120-06.LI T, FU H, LI K W, et al. Deformation with damage and temperature-rise of two types of plastic-bonded explosives under uniaxial compression [J]. Explosion and Shock Waves, 2017, 37(1): 120–125. DOI: 10.11883/1001-1455(2017)01-0120-06. [15] 李茜. 冲击载荷下复合材料的损伤模型适用性研究 [D]. 西安: 西北工业大学, 2018.LI X. Comparison of different damage models for laminated composites under impact loading [D]. Xi’an, Shaanxi, China: Northwestern Polytechnical University, 2018. [16] 朱炜垚, 许希武. 含低速冲击损伤复合材料层合板剩余压缩强度及疲劳性能试验研究 [J]. 复合材料学报, 2012, 29(5): 171–178. DOI: 10.13801/j.cnki.fhclxb.2012.05.025.ZHU W Y, XU X W. Experiment research on residual compressive strength and fatigue performance of composite laminates with low velocity impact damage [J]. Acta Materiae Compositae Sinica, 2012, 29(5): 171–178. DOI: 10.13801/j.cnki.fhclxb.2012.05.025. [17] 严实, 郭留雨, 赵金阳, 等. 三维五向编织复合材料低速冲击及冲击后压缩性能实验研究 [J]. 材料工程, 2017, 45(12): 65–70. DOI: 10.11868/j.issn.1001-4381.2015.000861.YAN S, GUO L Y, ZHAO J Y, et al. Experimental investigation on low-velocity impact and compression after impact properties of three-dimensional five-directional braided composites [J]. Journal of Materials Engineering, 2017, 45(12): 65–70. DOI: 10.11868/j.issn.1001-4381.2015.000861. [18] 刘丽敏, 孙颖, 李涛涛, 等. 芳纶/炭混编三维编织复合材料冲击后压缩性能实验研究 [J]. 固体火箭技术, 2016, 39(6): 803–808. DOI: 10.7673/j.issn.1006-2793.2016.06.012.LIU L M, SUN Y, LI T T, et al. Experimental investigation on the compression properties of Kevlar/carbon hybrid 3D braided composites after impact [J]. Journal of Solid Rocket Technology, 2016, 39(6): 803–808. DOI: 10.7673/j.issn.1006-2793.2016.06.012. [19] MARSH G. Aero engines lose weight thanks to composites [J]. Reinforced Plastics, 2012, 56(6): 32–35. DOI: 10.1016/S0034-3617(12)70146-7. [20] MCGREGOR C, VAZIRI R, XIAO X R. Finite element modelling of the progressive crushing of braided composite tubes under axial impact [J]. International Journal of Impact Engineering, 2010, 37(6): 662–672. DOI: 10.1016/j.ijimpeng.2009.09.005. [21] ROBERTS G D, PEREIRA J M, REVILOCK D M, et al. Ballistic impact of braided composites with a soft projectile [J]. Journal of Aerospace Engineering, 2005, 18(1): 3–7. DOI: 10.1061/(ASCE)0893-1321(2005)18:1(3). [22] PEREIRA J M, ROBERTS G D, RUGGERI C R, et al. Experimental techniques for evaluating the effects of aging on impact and high strain rate properties of triaxial braided composite materials: NASA/TM-2010-216763 [R]. Austin: NASA, 2010. [23] LIU L L, XUAN H J, CHEN G T, et al. Ballistic impact testing and analysis of triaxial braided composite fan case material [J]. Advanced Materials Research, 2012, 535/356/537: 121–132. DOI: 10.4028/www.scientific.net/AMR.535-537.121. [24] CHENG J Y. Material modeling of strain rate dependent polymer and 2D triaxially braided composites [D]. Akron, Ohio, USA: University of Akron, 2006. [25] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 三维编织物及其树脂基复合材料压缩性能试验方法: GB/T 33614—2017 [S]. 北京: 质检出版社, 2017. -

下载:

下载: