A study of the response characteristics of Al/PTFE reactive materials under shock loading

-

摘要: 为了研究铝(Al)/聚四氟乙烯(polytetrafluoroethylene, PTFE)活性材料冲击载荷作用下响应特性,制备了具有反应活性的Al/PTFE块体材料,设计了拉氏实验,采用不同厚度的铝隔板控制入射冲击波幅值,利用锰铜压阻计测量了冲击波在材料中传播过程压力演化过程。同时,基于AUTODYN有限元软件,采用Lee-Tarver三项式点火模型对Al/PTFE活性材料拉氏实验进行数值模拟,并探讨了冲击波在500 mm长的Al/PTFE活性材料中长距离传播行为。研究结果表明,冲击波压力在Al/PTFE活性材料内短距离传播过程中存在明显的衰减,但是,当冲击波传播到远距离时,冲击波压力幅值和冲击波速度趋于稳定,分别为1.3 GPa和2 180 m/s;同时,距离铝隔板越远的材料,其反应度越低并最终趋于0.17。正是由于材料化学反应释能,导致了冲击波压力传播过程最终趋于稳定状态。

-

关键词:

- Al/PTFE活性材料 /

- 拉氏实验 /

- 冲击反应 /

- Lee-Tarver三项式点火模型

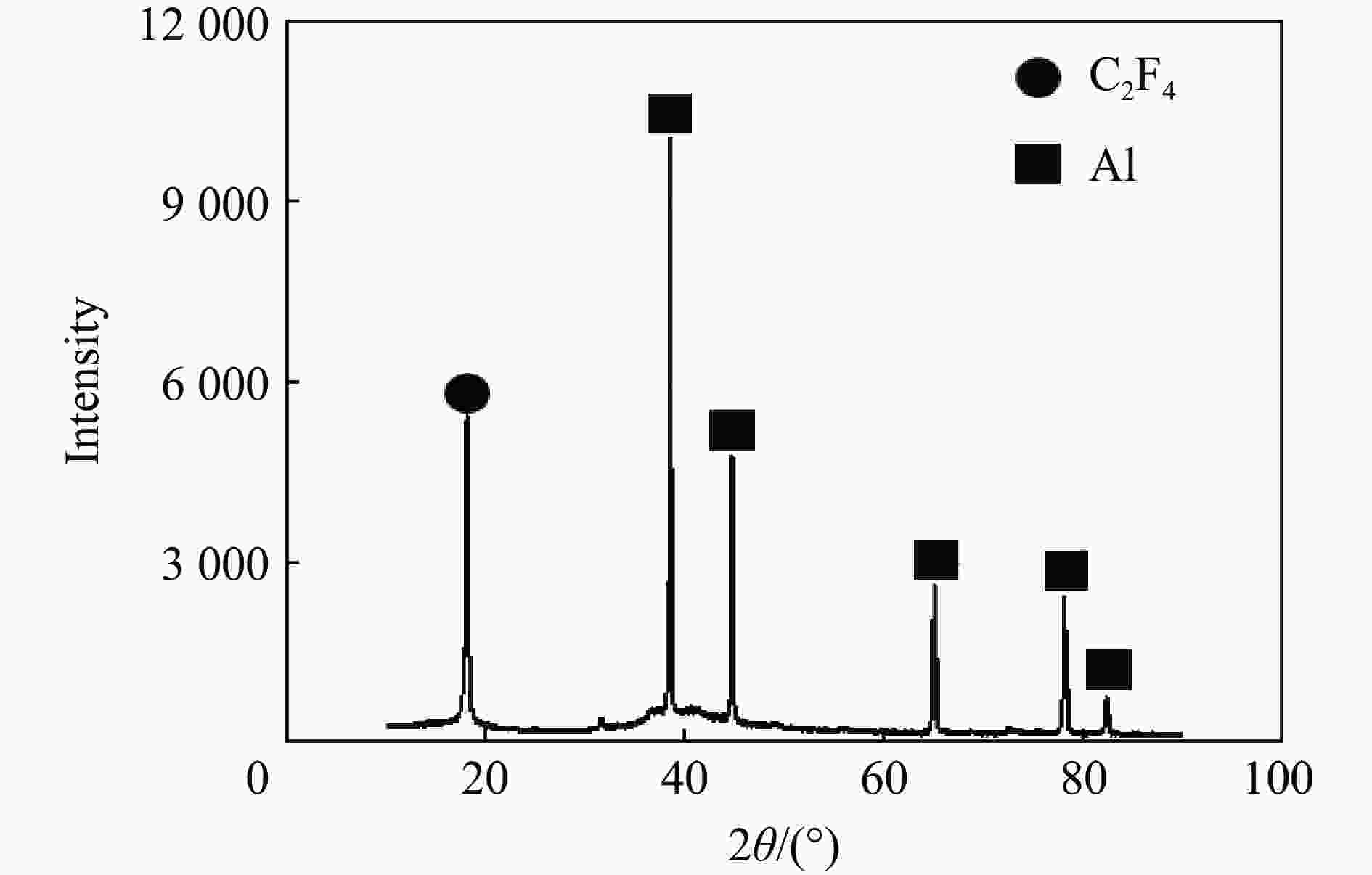

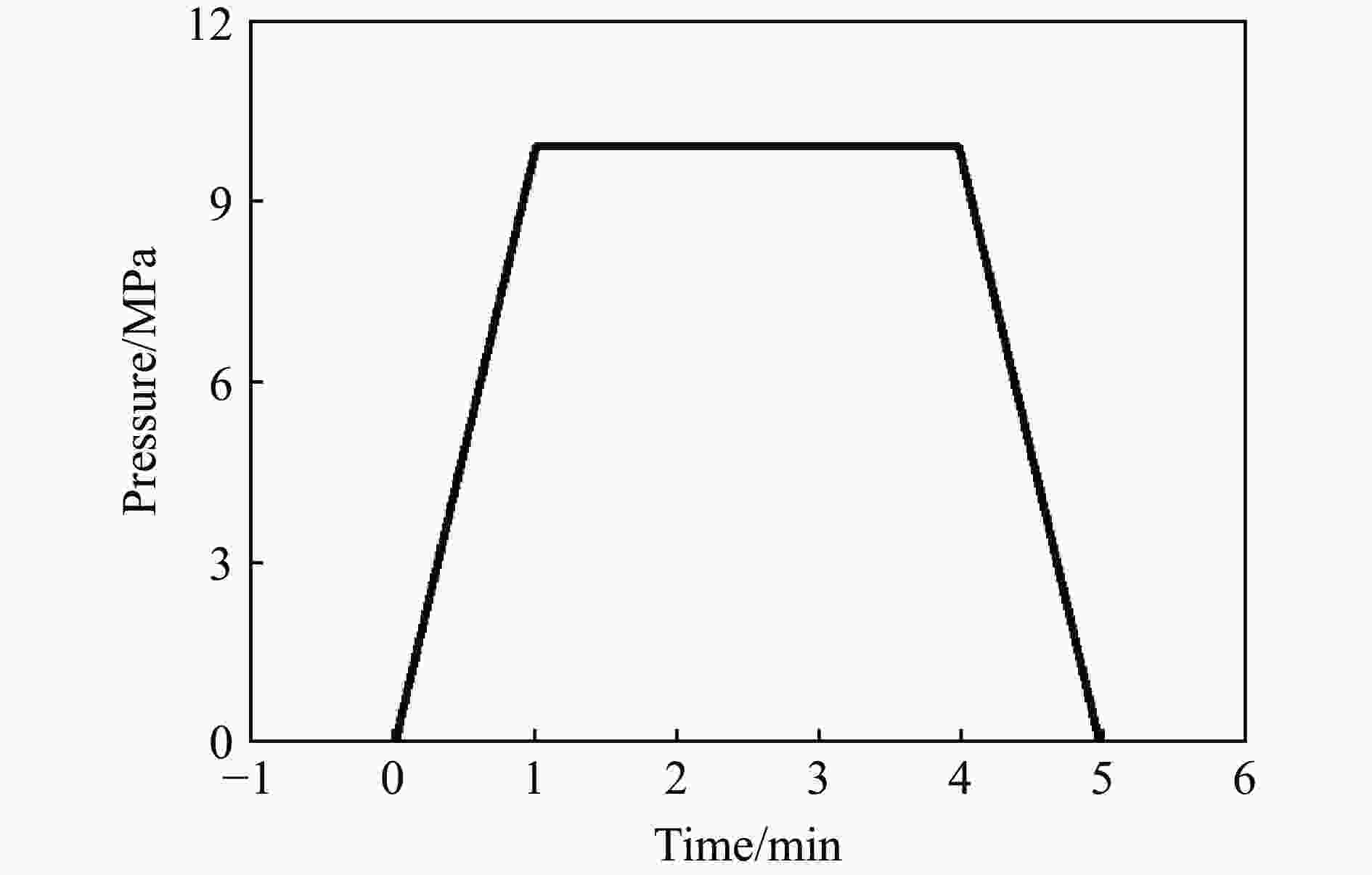

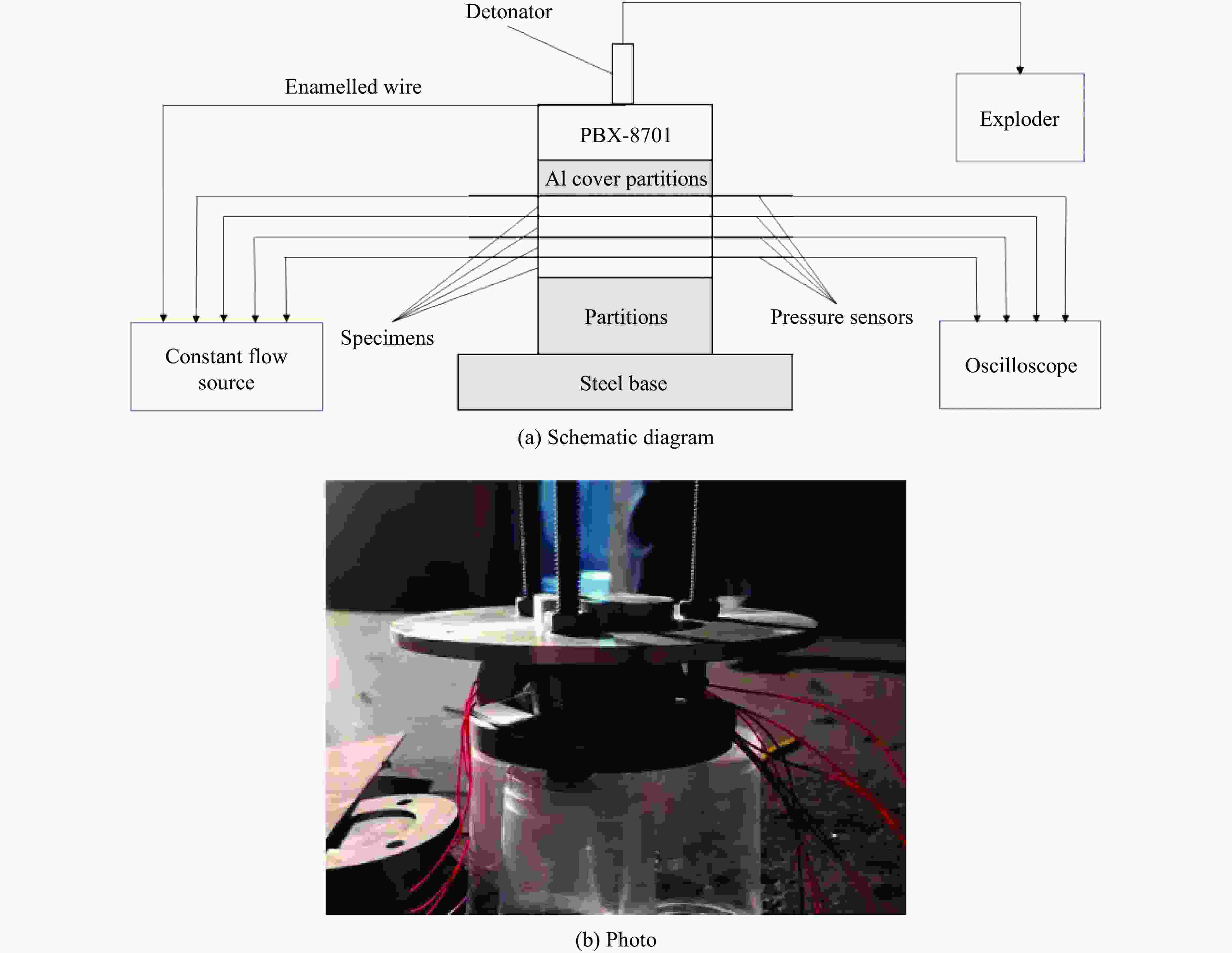

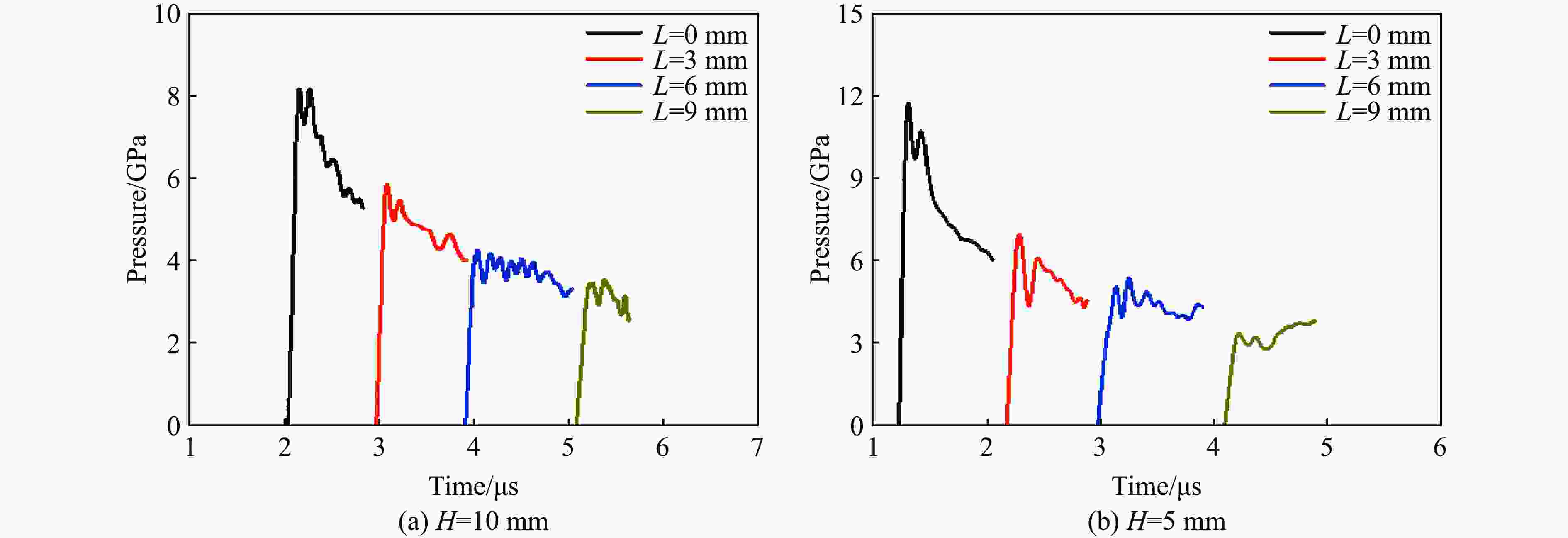

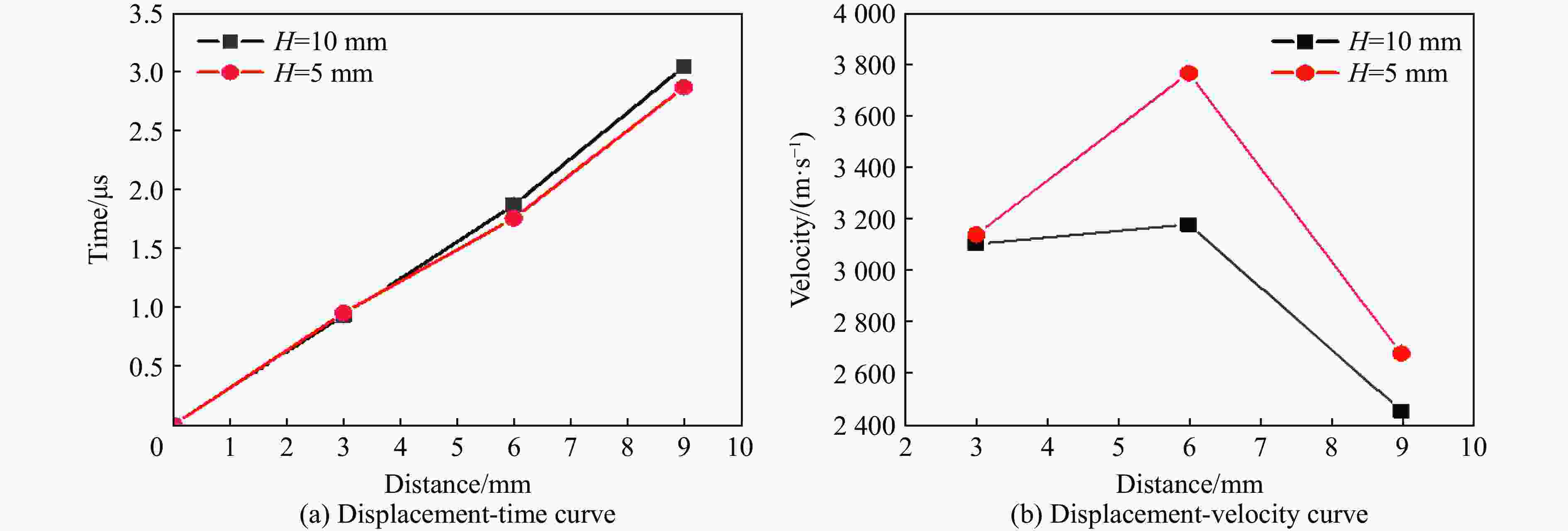

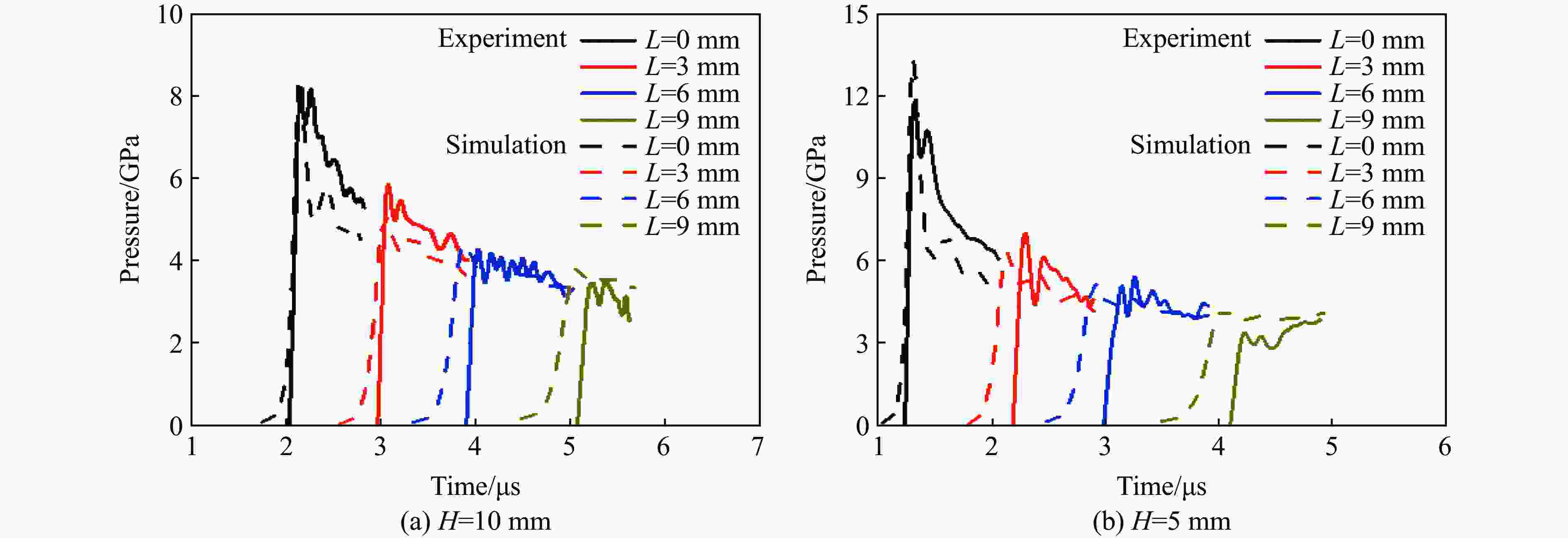

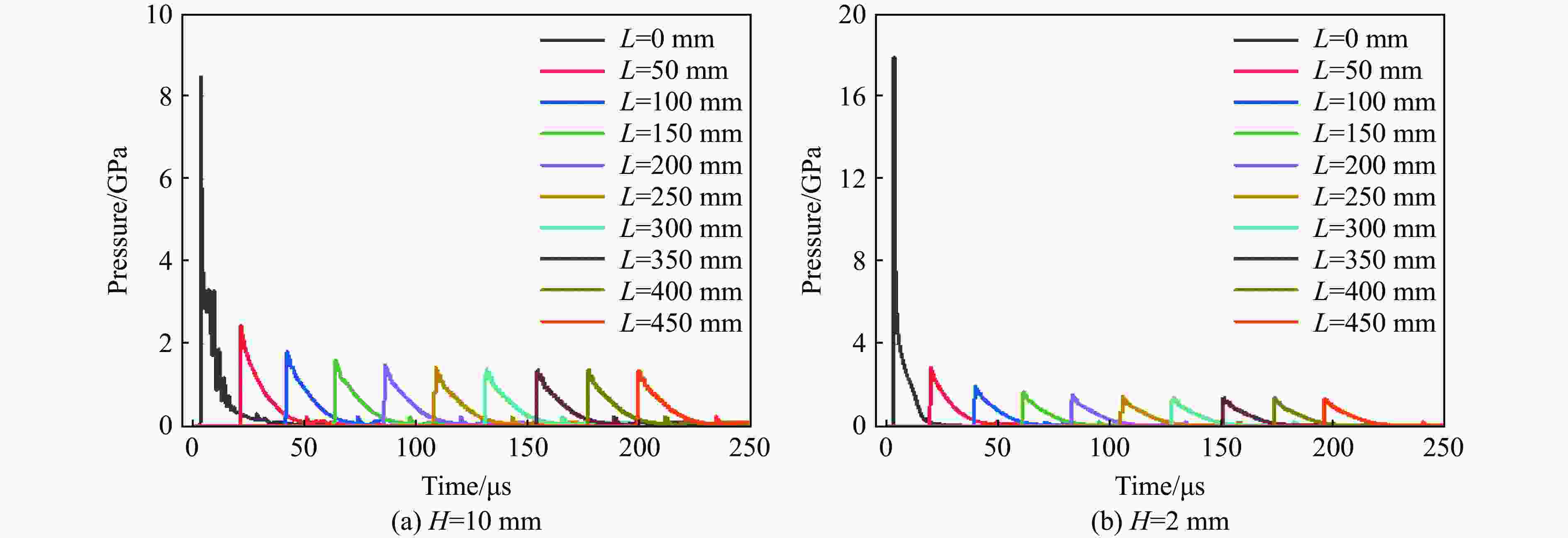

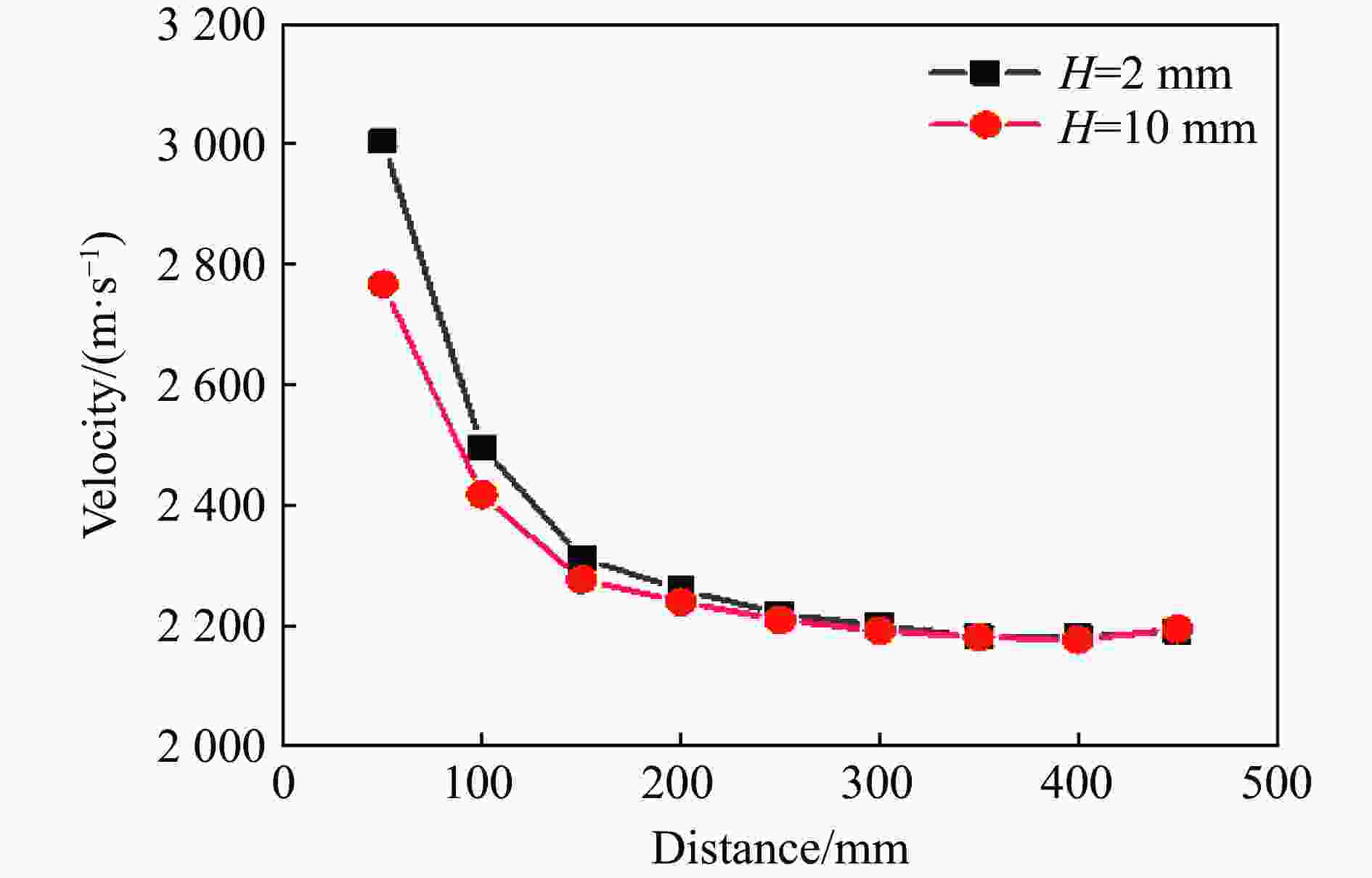

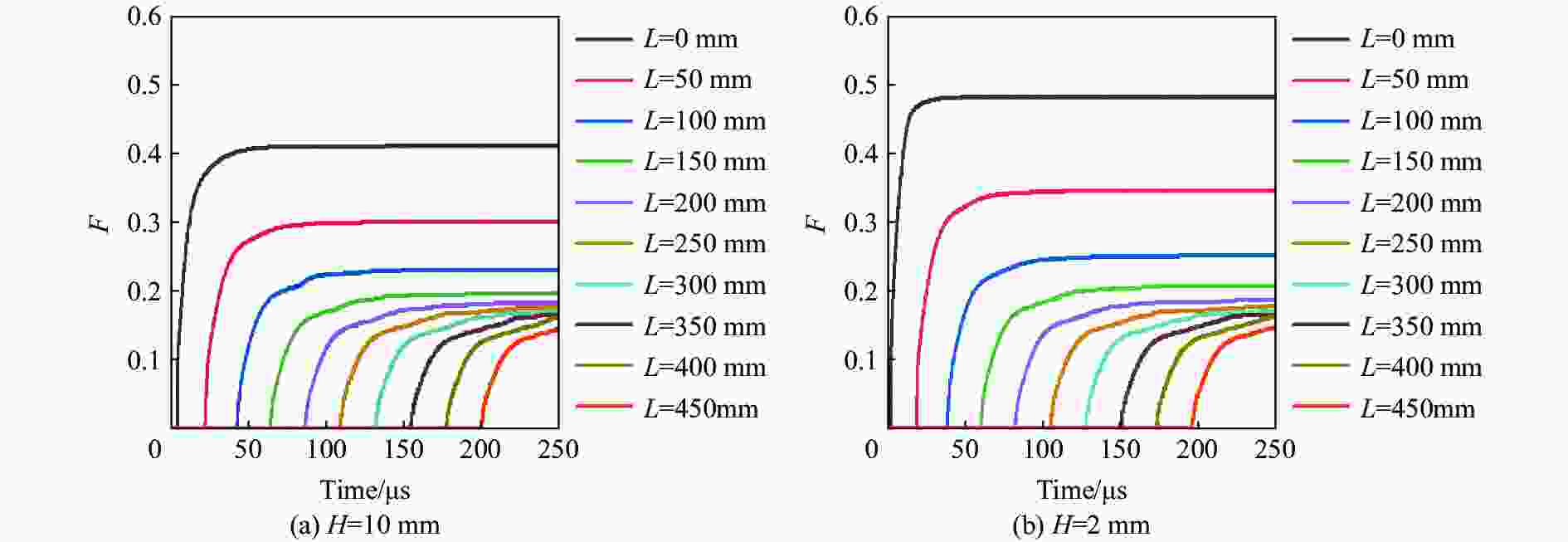

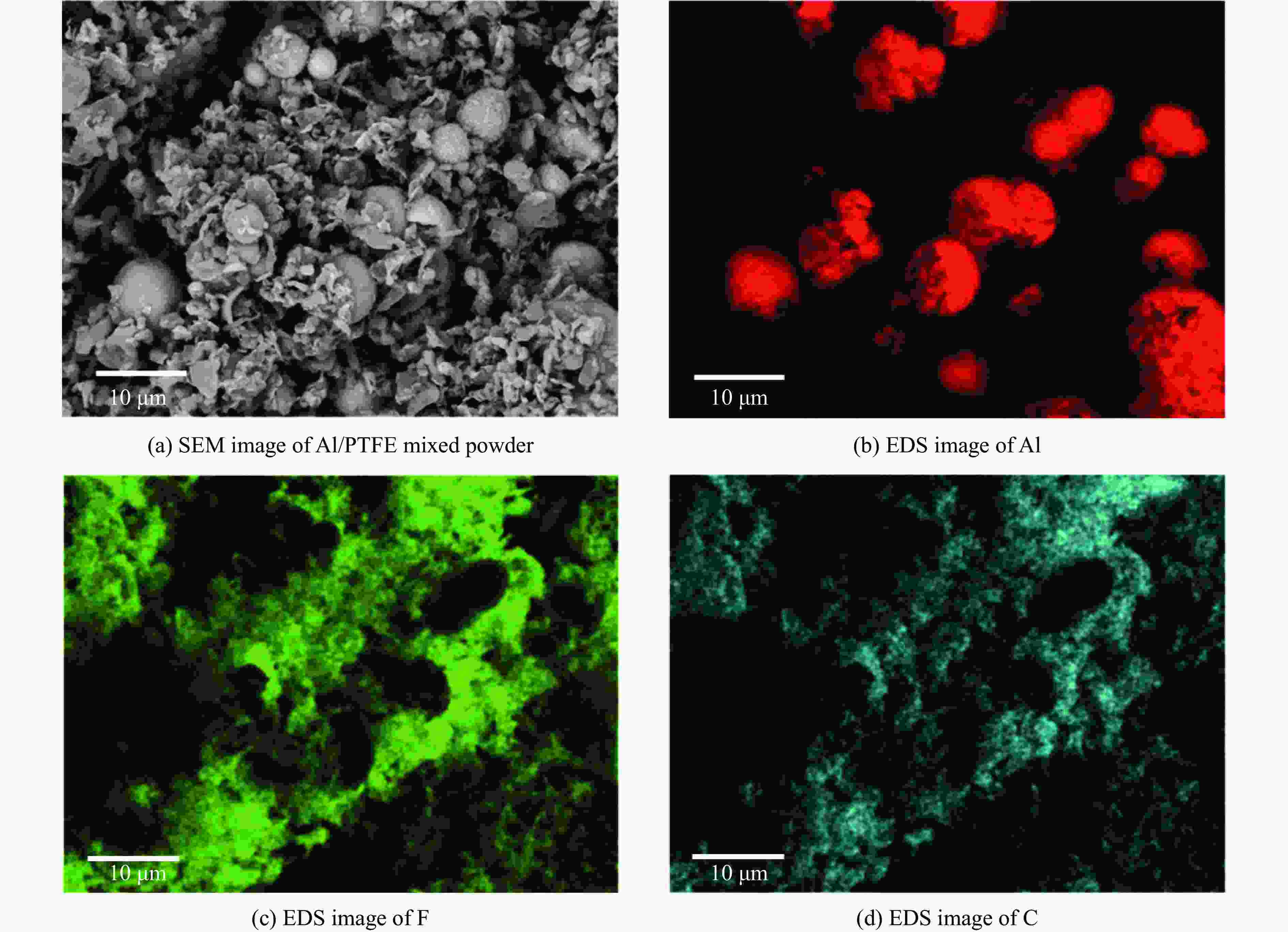

Abstract: To investigate the response characteristics of aluminum/polytetrafluoroethylene (Al/PTFE) reactive materials under shock loading, the Al powder with the diameter of 10 μm and the PTFE powder with the diameter of 15 μm were mixed. Scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS) and X-ray diffraction (XRD) analysis were performed to ensure the uniformity and reactivity of the Al/PTFE mixed powders. The Al/PTFE specimen was prepared by using a cold pressing technique. The density of the Al/PTFE materials was 1.92 g/cm3. The Lagrangian experiment was designed to understand the response characteristics of the Al/PTFE specimen under shock loading. PBX8701 was used to produce high pressure. The shock loading was attenuated after passing an aluminum partition and acted on the specimen. Four block specimens with the sizes of$\varnothing$ 50 mm×3 mm were used, and manganin piezo-resistance gauges were mounted at the top surface and the end surface of the specimens to measure the pressure. It should be emphasized that the thickness of the aluminum partition was set to be 5 and 10 mm to control the input pressure acting on the specimens. In these two cases, the pressure and the shock velocity were analyzed. The measurement shows that both the pressure and the shock velocity are attenuated. The Lee-Tarver ignition and growth model was used to simulate the Lagrangian experiment by AUTODYN. The parameters in the model were validated by comparing the simulation and the experiment. Further, the Lagrangian experiment for the 500-mm-long Al/PTFE specimen was simulated. The results show that when the shock wave propagates through a long distance, although at the beginning the pressure and the velocity reduce quickly, up to some distance, the pressure and the velocity are close to a constant value around 1.3 GPa and 2180 m/s, respectively. The reaction was also analyzed. At the beginning, the value can be up to around 0.48 due to the high pressure. As the distance increases to 450 mm, the value reduces to 0.17. These results demonstrate that under the shock, the energy release of the Al/PTFE specimens prevents the energy dissipation during the shock wave propagation. -

表 2 Al隔板材料 Johnson-Cook模型参数

Table 2. The Johnson-Cook-model parameters of the aluminum partition

A/GPa B/GPa n C m Tm/K 27.6 0.426 0.34 0.015 1 775 -

[1] 张先锋, 赵晓宁. 多功能含能结构材料研究进展 [J]. 含能材料, 2009, 17(6): 731–739. DOI: 10.3969/j.issn.1006-9941.2009.06.021.ZHANG X F, ZHAO X N. Review on multifunctional energetic structural materials [J]. Chinese Journal of Energetic Materials, 2009, 17(6): 731–739. DOI: 10.3969/j.issn.1006-9941.2009.06.021. [2] 王海福, 刘宗伟, 俞为民, 等. 活性破片能量输出特性实验研究 [J]. 北京理工大学学报, 2009, 29(8): 663–666.WANG H F, LIU Z W, YU W M, et al. Experimental investigation of energy release characteristics of reactive fragments [J]. Transactions of Beijing Institute of Technology, 2009, 29(8): 663–666. [3] 帅俊峰, 蒋建伟, 王树有, 等. 复合反应破片对钢靶侵彻的实验研究 [J]. 含能材料, 2009, 17(6): 722–725. DOI: 10.3969/j.issn.1006-9941.2009.06.019.SHUAI J F, JIANG J W, WANG S Y, et al. Compound reactive fragment penetrating steel target [J]. Chinese Journal of Energetic Materials, 2009, 17(6): 722–725. DOI: 10.3969/j.issn.1006-9941.2009.06.019. [4] 辛春亮, 史文卿, 张雷雷, 等. 活性药型罩聚能装药子弹对钢锭的毁伤效应研究 [C]//2014’(第六届)含能材料与钝感弹药技术学术研讨会论文集. 四川绵阳: 《含能材料》编辑部, 2014. [5] 汪德武, 任柯融, 江增荣, 等. 活性材料冲击释能行为研究进展 [J]. 爆炸与冲击, 2021, 41(3): 031408. DOI: 10.11883/bzycj-2020-0337.WANG D W, REN K R, JIANG Z R, et al. Shock-induced energy release behaviors of reactive materials [J]. Explosion and Shock Waves, 2021, 41(3): 031408. DOI: 10.11883/bzycj-2020-0337. [6] 叶文君, 汪涛, 鱼银虎. 氟聚物基含能反应材料研究进展 [J]. 宇航材料工艺, 2022, 42(6): 19–23. DOI: 10.3969/j.issn.1007-2330.2012.06.003.YE W J, WANG T, YU Y H. Research progress of fluoropolymer-matrix energetic reactive materials [J]. Aerospace Materials & Technology, 2022, 42(6): 19–23. DOI: 10.3969/j.issn.1007-2330.2012.06.003. [7] KOCH E C. Metal-fluorocarbon based energetic materials [M]. Weinheim: Wiley-VCH, 2012. [8] JOSHI V S. Process for making polytetrafluoroethylene-aluminum composite and product made: US 6547993B1 [P]. 2003-04-15. [9] 阳世清, 徐松林, 张彤. PTFE/Al反应材料制备工艺及性能 [J]. 国防科技大学学报, 2008, 30(6): 39–42; 62. DOI: 10.3969/j.issn.1001-2486.2008.06.009.YANG S Q, XU S L, ZHANG T. Preparation and performance of PTEF/Al reactive materials [J]. Journal of National University of Defense Technology, 2008, 30(6): 39–42; 62. DOI: 10.3969/j.issn.1001-2486.2008.06.009. [10] NIELSON D B, TANNER R L, LUND G K. High strength reactive materials: US20030096897A1 [P]. 2003-05-22. [11] 于钟深, 方向, 高振儒, 等. TiH2含量对Al/PTFE准静态压缩力学性能和反应特性的影响 [J]. 含能材料, 2018, 26(8): 720–724. DOI: 10.11943/CJEM2017387.YU Z S, FANG X, GAO Z R, et al. Effect of TiH2 content on mechanical properties and reaction characteristics of Al/PTFE under quasi-static compression [J]. Chinese Journal of Energetic Materials, 2018, 26(8): 720–724. DOI: 10.11943/CJEM2017387. [12] FENG B, FANG X, WANG H F, et al. The effect of crystallinity on compressive properties of Al-PTFE [J]. Polymers, 2016, 8(10): 356. DOI: 10.3390/polym8100356. [13] WANG L, LIU J X, LI S K, et al. Investigation on reaction energy, mechanical behavior and impact insensitivity of W-PTFE-Al composites with different W percentage [J]. Materials and Design, 2016, 92: 397–404. DOI: 10.1016/j.matdes.2015.12.045. [14] GE C, YU Q B, ZHANG H, et al. On dynamic response and fracture-induced initiation characteristics of aluminum particle filled PTFE reactive material using hat-shaped specimens [J]. Materials and Design, 2020, 188: 108472. DOI: 10.1016/j.matdes.2020.108472. [15] REN H L, LI W, NING J G, et al. The influence of initial defects on impact ignition of aluminum/polytetrafluoroethylene reactive material [J]. Advanced Engineering Materials, 2020, 22(3): 1900821. DOI: 10.1002/adem.201900821. [16] WANG H F, ZHENG Y F, YU Q B, et al. Impact-induced initiation and energy release behavior of reactive materials [J]. Journal of Applied Physics, 2011, 110(7): 074904. DOI: 10.1063/1.3644974. [17] ZHANG X F, SHI A S, QIAO L, et al. Experimental study on impact-initiated characters of multifunctional energetic structural materials [J]. Journal of Applied Physics, 2013, 113(8): 083508. DOI: 10.1063/1.4793281. [18] XIONG W, ZHANG X F, WU Y, et al. Influence of additives on microstructures, mechanical properties and shock-induced reaction characteristics of Al/Ni composites [J]. Journal of Alloys and Compounds, 2015, 648: 540–549. DOI: 10.1016/j.jallcom.2015.07.004. [19] WANG Y, JIANG W, ZHANG X F, et al. Energy release characteristics of impact-initiated energetic aluminum–magnesium mechanical alloy particles with nanometer-scale structure [J]. Thermochimica Acta, 2011, 512(1/2): 233–239. DOI: 10.1016/j.tca.2010.10.013. [20] LI Y, JIANG C L, WANG Z C, et al. Experimental study on reaction characteristics of PTFE/Ti/W energetic materials under explosive loading [J]. Materials, 2016, 9(11): 936. DOI: 10.3390/ma9110936. [21] LEE J H S, GOROSHIN S, YOSHINAKA A, et al. Attempts to initiate detonations in metal-sulphur mixtures [J]. AIP Conference Proceedings, 2000, 505(1): 775–778. DOI: 10.1063/1.1303587. [22] GUR’EV D L, GORDOPOLOV Y A, BATSANOV S S, et al. Solid-state detonation in the zinc-sulfur system [J]. Applied Physics Letters, 2006, 88(2): 024102. DOI: 10.1063/1.2164411. [23] DOLGOBORODOV A Y, MAKHOV M N, KOLBANEV I V, et al. Detonation in an aluminum-Teflon mixture [J]. Journal of Experimental and Theoretical Physics Letters, 2005, 81(7): 311–314. DOI: 10.1134/1.1944069. [24] ZHANG X F, SHI A S, ZHANG J, et al. Thermochemical modeling of temperature controlled shock-induced chemical reactions in multifunctional energetic structural materials under shock compression [J]. Journal of Applied Physics, 2012, 111(12): 123501. DOI: 10.1063/1.4729048. [25] 赵锋, 孙承纬, 卫玉章, 等. 梯恩梯/黑索今(35/65)炸药的反应速率函数 [J]. 爆炸与冲击, 1989, 9(4): 338–347.ZHAO F, SUN C W, WEI Y Z, et al. Reaction rates of TNT/RDX(35/65) explosive [J]. Explosion and Shock Waves, 1989, 9(4): 338–347. [26] LEE E L, TARVER C M. Phenomenological model of shock initiation in heterogeneous explosives [J]. The Physics of Fluids, 1980, 23(12): 2362–2372. DOI: 10.1063/1.862940. [27] 李军宝, 李伟兵, 汪衡, 等. 爆炸载荷下铝粉与橡胶复合材料中的冲击波传播特性 [J]. 兵工学报, 2020, 41(10): 2001–2007. DOI: 10.3969/j.issn.1000-1093.2020.10.009.LI J B, LI W B, WANG H, et al. Propagation properties of shock wave in aluminum powder/rubber composites under explosion loading [J]. Acta Armamentarii, 2020, 41(10): 2001–2007. DOI: 10.3969/j.issn.1000-1093.2020.10.009. [28] 李维新. 一维不定常流与冲击波 [M]. 北京: 国防工业出版社, 2003. [29] 许世昌. 双层含能药型罩射流成型机理及侵彻性能研究 [D]. 南京: 南京理工大学, 2015: 29.XU S C. Study on jet forming mechanism and penetration performance of double layer liners comprised of reactive material [D]. Nanjing, Jiangsu, China: Nanjing University of Science and Technology, 2015: 29 [30] 郭俊. 活性分段动能杆对混凝土靶的毁伤效应研究 [D]. 北京: 北京理工大学, 2016: 94.GUO J. Damage of concrete target induced by reactive segmented kinetic rods [D]. Beijing, China: Beijing Institute of Technology, 2016: 94 [31] JIANG J W, WANG S Y, ZHANG M, et al. Modeling and simulation of JWL equation of state for reactive Al/PTFE mixture [J]. Journal of Beijing Institute of Technology, 2012, 21(2): 150–156. DOI: 10.15918/j.jbit1004-0579.2012.02.003. [32] RAFTENBERG M N, MOCK W JR, KIRBY G C. Modeling the impact deformation of rods of a pressed PTFE/Al composite mixture [J]. International Journal of Impact Engineering, 2008, 35(12): 1735–1744. DOI: 10.1016/j.ijimpeng.2008.07.041. -

下载:

下载: