Advances in the research of metallic thermo-viscoplastic constitutive relationships

-

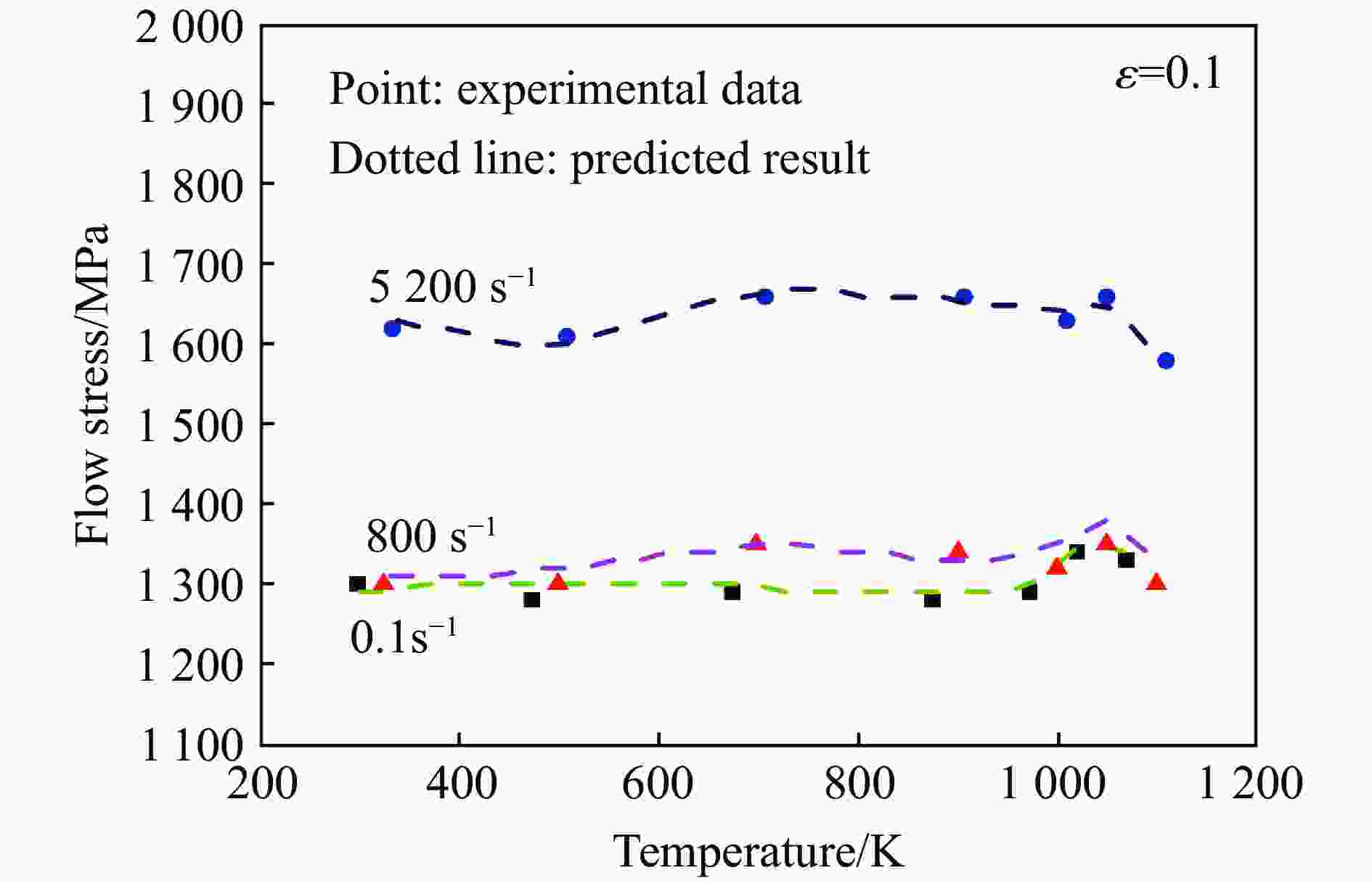

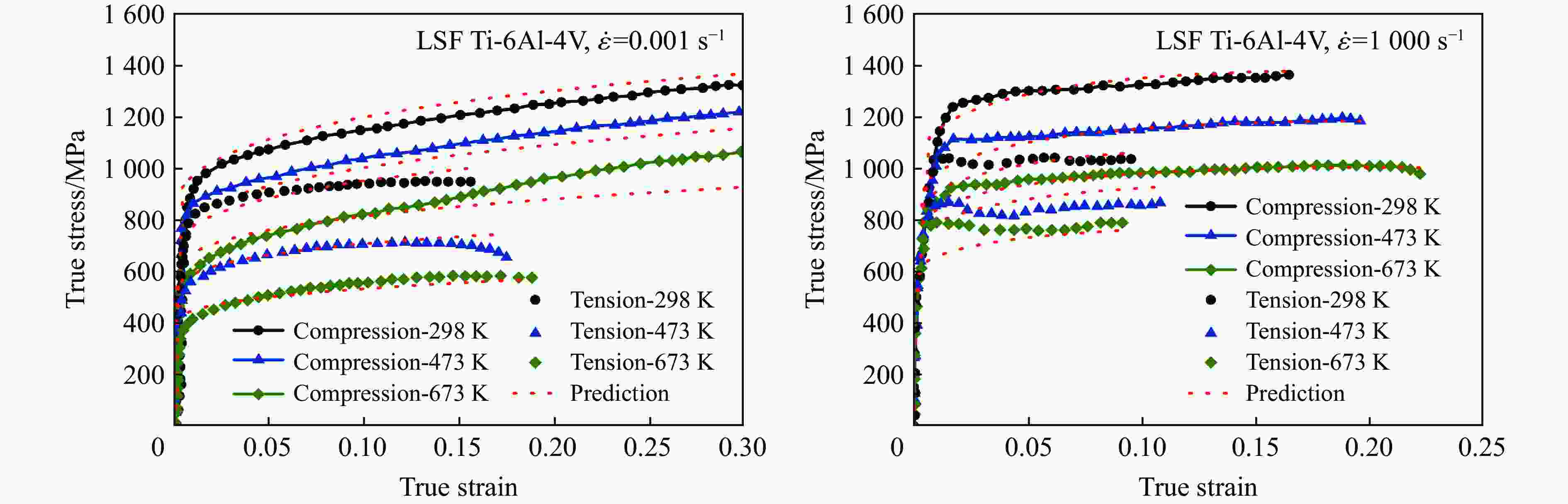

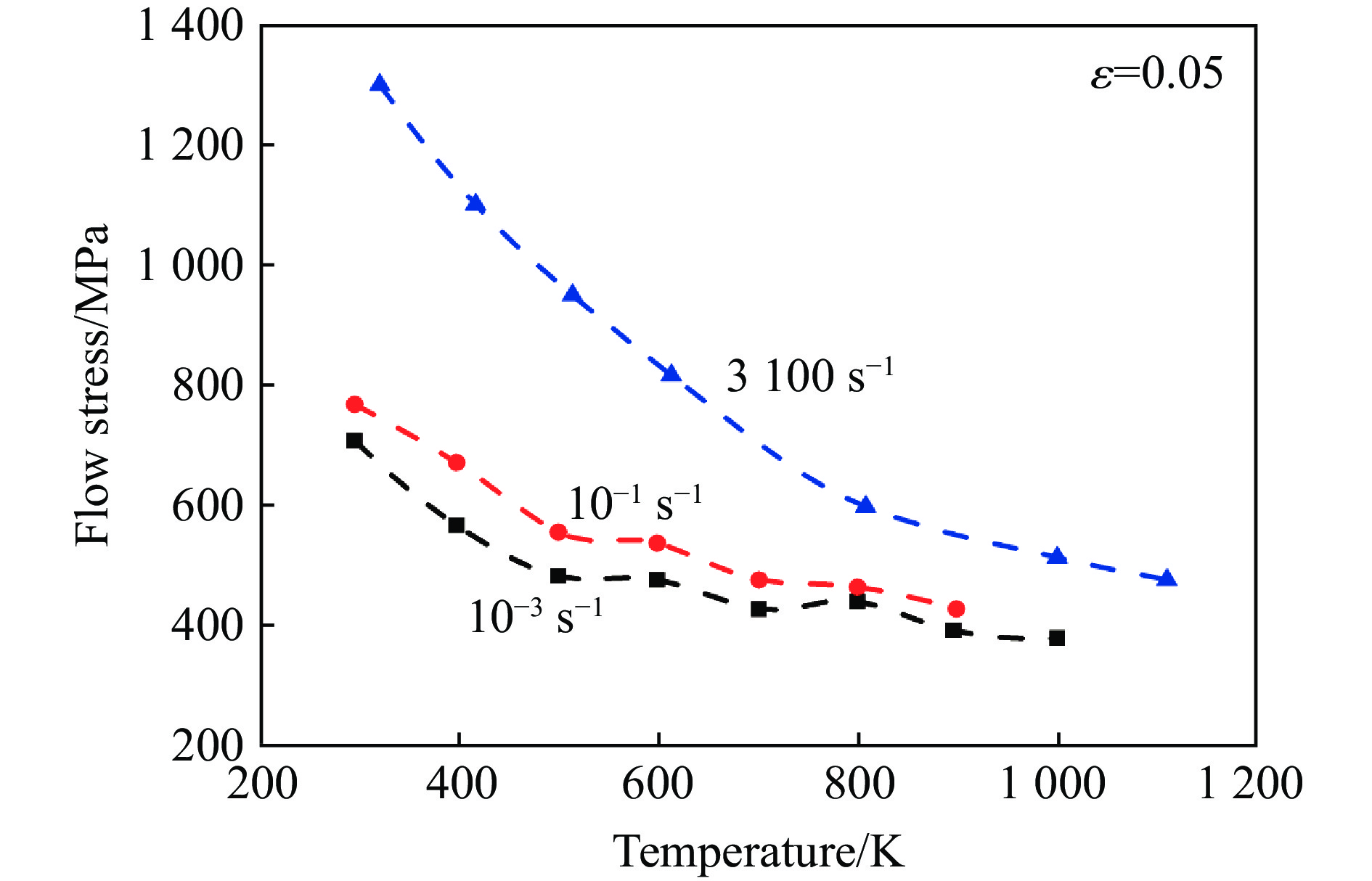

摘要: 金属材料的塑性流动行为依赖于温度和应变率,温度和应变率敏感性是金属材料塑性流动的最重要的本质特性之一,建立合适的热黏塑性本构关系来准确描述金属塑性流动行为的温度和应变率依赖性,是金属材料能被广泛应用的必要前提。为此,对金属热黏塑性本构关系的最新研究进展进行了综述,介绍了常见的几种金属热黏塑性本构关系并进行了详细讨论,给出了各本构关系的优势与不足,最后系统介绍了包含金属塑性流动行为中出现的第三型应变时效、或K-W锁位错结构引起的流动应力随温度变化出现的反常应力峰以及拉压不对称等行为的金属热黏塑性本构关系的研究进展。Abstract: The studies of the plastic flow behaviour of metallic materials show that the plastic deformation process of metallic materials is dependent on temperature and strain rate, so the temperature and strain rate sensitivities are the most important essential properties of plastic deformation of metallic materials. It is therefore necessary to establish appropriate thermo-viscoplastic constitutive relations to accurately describe the temperature and strain rate dependences of the plastic flow behaviour of metals over a wide range of temperatures and strain rates. Advantages and disadvantages of these constitutive relationships are first reviewed in the present paper. With the increasing applications of metallic materials and the emergence of new materials, the 3rd type strain aging, K-W lock induced anomalous stress peak, and tensile-compression asymmetry are often observed in the plastic flow behaviour of metals. Due to the occurrence of those phenomena, the traditional metal thermo-viscoplastic constitutive relations may no longer be applicable. In view of the significant roles played by the 3rd type strain aging, K-W lock dislocation structure-induced anomalous stress peaks, and tensile-compression asymmetry in the plastic flow behaviour of metals, especially in high temperature loading, it is necessary to take those particular phenomena into account in the framework of the thermo-viscoplastic constitutive relationship of metals. Thus, a large variety of constitutive relation, which considers the interaction of strain, temperature and strain rate, has been established to predict the deformation behaviors of metals. In this context, this paper presents a systematic review of the thermo-viscoplastic constitutive relationships of metals, which includes the anomalous stress peaks in the flow stresses with temperature due to the 3rd type strain aging or K-W-locked dislocation structures, and the tensile-compression asymmetry. In addition, the forms of these thermo-viscoplastic constitutive relationship considering the 3rd type strain aging, K-W lock dislocation structure-induced anomalous stress peaks and tensile-compression asymmetry in the flow stress of metals, are discussed and analysed.

-

表 1 唯象型本构关系的模型对比

Table 1. Comparison of phenomenological constitutive relations

本构关系 年份 模型 应变率范围/s−1 主要特征 J-C 1983 Johnson-Cook[20] >104 (1)形式简单,材料常数容易获得

(2)考虑了应变率效应

(3)考虑了温度效应

(4)不能准确描述流动应力随对数应变率呈非线性关系的金属材料的塑性流动行为的应变率敏感性

(5)不能描述对于金属塑性流动行为中的应变、应变率和温度对流动应力的影响为非独立的现象1991 Holmquist[24] 10−3~500 (1)应变率项修正为幂函数

(2)不能描述对于金属塑性流动行为中的应变、应变率和温度对流动应力的影响为非独立的现象

(3)对高应变率范围内的应变率敏感性的加强描述依旧有限1998 Rule-Jones[25] >103 (1)高速率情况下,可以更好地描述应变率敏感性的作用

(2)不能描述对于金属塑性流动行为中的应变、应变率和温度对流动应力的影响为非独立的现象1999 Kang-Cho[26] 10−3~5000 (1)应变率项中引入了对数应变率的二次型项

(2)不能描述对于金属塑性流动行为中的应变、应变率和温度对流动应力的影响为非独立的现象

(3)对高应变率范围内的应变率敏感性的加强描述依旧有限2009 Vural-Cairo[27] 10−2~104 (1)在应变和应变率项中加入了温度效应

(2)可以描述对于金属塑性流动行为中的应变、应变率和温度对流动应力的影响为非独立的现象2010 Lin-Xia[28] 10−2~10 (1)考虑温度和应变率耦合效应

(2)应变项为抛物线形式K-H 1992 Khan-Huang[16] 10−5~104 (1)考虑了应变率效应

(2)假定依赖于J2不变量

(3)没有考虑温度效应2009 Yu-Guo[35] 10−4~1.6×103 没有考虑温度效应 1999 Khan-Liang[36] 10−6~104 (1)考虑了应变率对应变硬化的影响。

(2)应变率项为幂函数形式2000 Khan-Zhang[37] 10−4~103 (1)考虑了晶粒尺寸对金属流动应力的影响

(2)考虑了应变率对应变硬化的影响

(3)应变率项为幂函数形式2004 Farrokh-Khan[38] 10−4~103 (1)可以描述晶粒细化引起的不同多晶金属的塑性流动行为

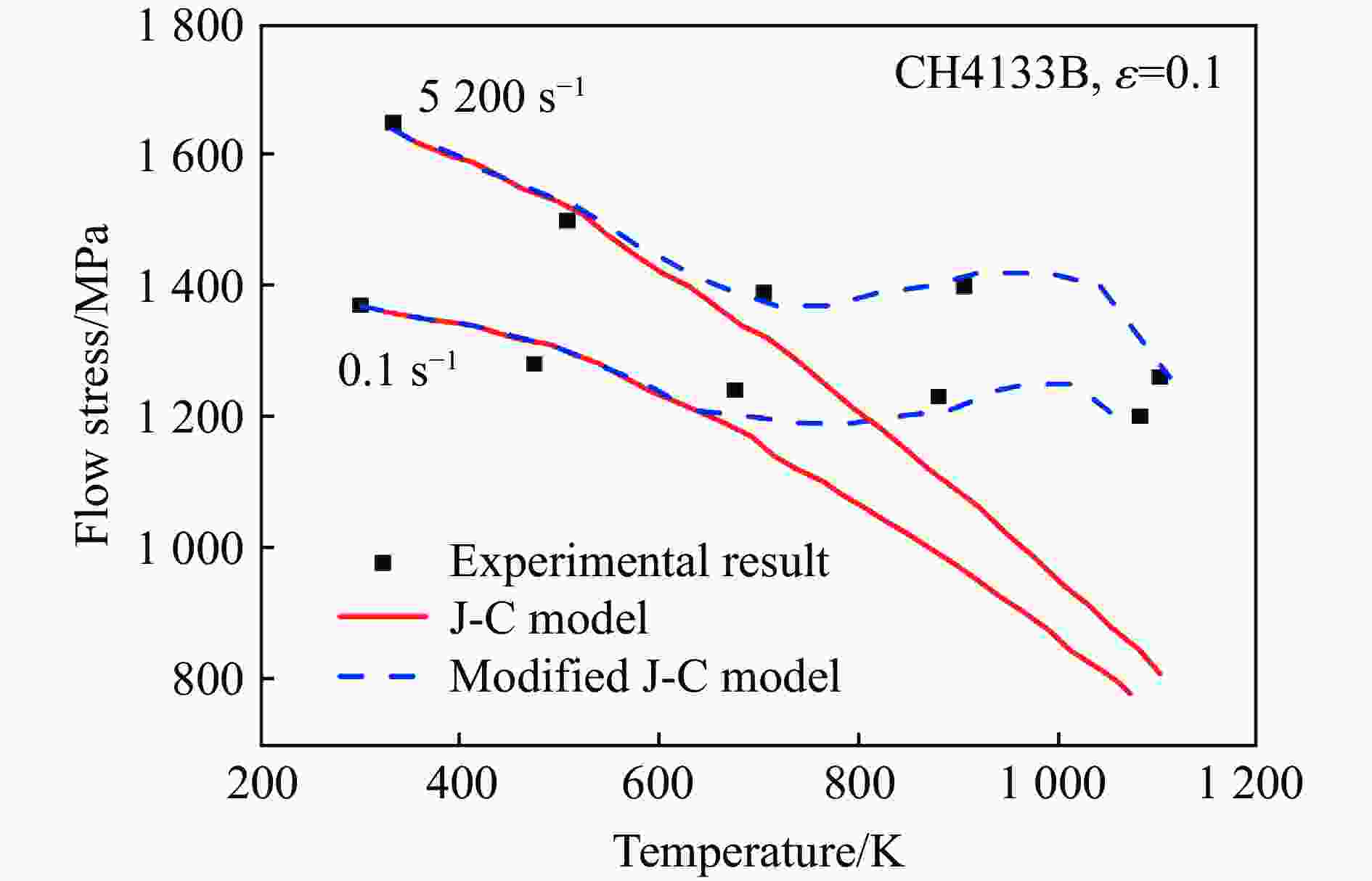

(2)考虑了应变率对应变硬化的影响

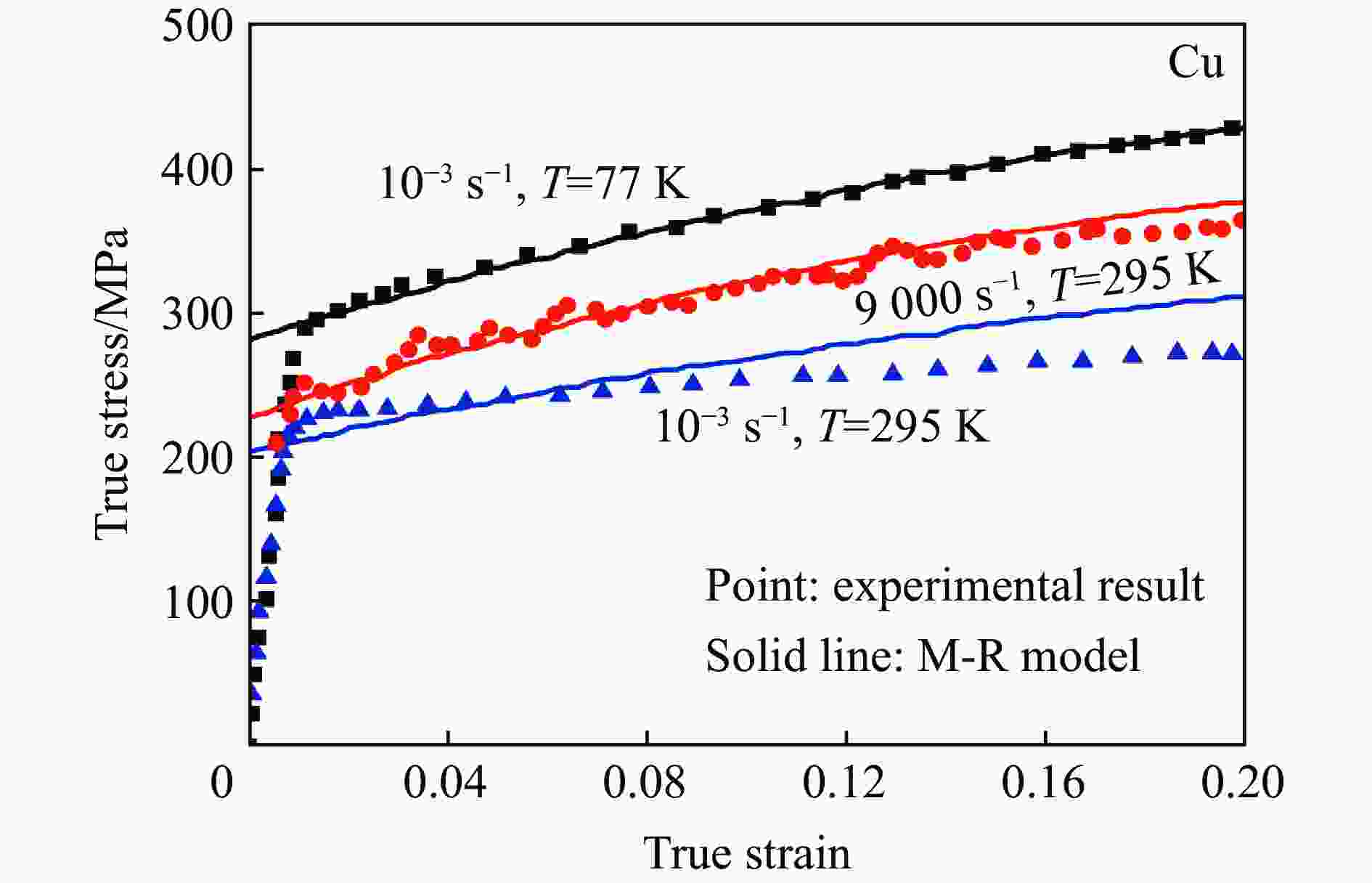

(3)应变率项为幂函数形式其他 1976 Voce-Kocks[39-40] 10 考虑温度和应变率对饱和应力${\sigma _{\rm{s}}}$的影响 2005 Molinari-Ravichandran[41] 10−3~8.5×104 考虑了微观结构的演化 表 2 唯象型本构关系的方程形式

Table 2. Equations of phenomenological constitutive relationships relations

模型 方程形式 Johnson-Cook[20] $\sigma = \left( {A + B{\varepsilon ^n}} \right)\left( {1 + C\ln {{\dot \varepsilon }^ * }} \right)\left( {1 - {T^{ * m}}} \right)$ Holmquist[24] $\sigma = \left( {A + B{\varepsilon ^n}} \right)\left( {{{\dot \varepsilon }^{ * C}}} \right)\left( {1 - {T^{ * m}}} \right)$ Rule-Jones[25] $\sigma = \left( {A + B{\varepsilon ^n}} \right)\left[ {1 + C\ln {{\dot \varepsilon }^ * } + {C_4}\left( {\dfrac{1}{{{C_5} - \ln {{\dot \varepsilon }^ * }}} - \dfrac{1}{{{C_5}}}} \right)} \right]\left( {1 - {T^{ * m}}} \right)$ Kang-Cho[26] $\sigma = \left( {A + B{\varepsilon ^n}} \right)\left[ {1 + {C_1}\ln {{\dot \varepsilon }^ * } + {C_2}{{\left( {\ln {{\dot \varepsilon }^ * }} \right)}^2}} \right]\left( {1 - {T^{ * m}}} \right)$ Vural-Cairo[27] $\sigma = \left\{ {A + {B_0}\left[ {1 - {{\left( {\dfrac{{T - {T_0}}}{{{T_{\text{m}}} - {T_0}}}} \right)}^p}} \right]{\varepsilon ^n}} \right\}\left[ {1 + \left( {{c_1}T_{\text{r}}^{ * p} + {c_2}H} \right)\ln \left( {\dfrac{{\dot \varepsilon }}{{{{\dot \varepsilon }_0}}}} \right)} \right]\left[ {1 - {{\left( {\dfrac{{T - {T_0}}}{{{T_{\text{r}}} - {T_0}}}} \right)}^p}} \right]$ Lin-Xia[28] $\sigma = \left( {A + {B_1}\varepsilon + {B_2}{\varepsilon ^2}} \right)\left( {1 + C\ln {{\dot \varepsilon }^ * }} \right)\exp \left[ {\left( {{\lambda _1} + {\lambda _2}\ln {{\dot \varepsilon }^ * }} \right)\left( {T - {T_{\text{r}}}} \right)} \right]$ Khan-Huang[16] ${J_2} = {f_1}\left( \varepsilon \right){f_2}\left( {D_2^{\text{p}}} \right)$ Yu-Guo[35] $\sigma = f\left( {\varepsilon ,\dot \varepsilon } \right) = {\sigma _0}{\hat f_2}\left( {\dot \varepsilon } \right) + {E_\infty }\varepsilon - a{{\text{e}}^{ - \alpha \varepsilon }}$ Khan-Liang[36] $\sigma = \left[ {A + B{ {\left( {1 - \dfrac{ {\ln {\dot \varepsilon } } }{ {\ln {D_0^{\text{p} } } } } } \right)}^{ {n_1} } }{\varepsilon ^{ {n_0} } } } \right]\left( {1 - {T^{*m} } } \right){\dot \varepsilon ^C}$ Khan-Zhang[37] $\sigma = \left[ { \left({a{}_1 + \dfrac{ { {k_1} } }{ {\sqrt d } } }\right) + B{ {\left( {1 - \dfrac{ {\ln {\dot \varepsilon } } }{ {\ln {D_0^{\text{p} } } } } } \right)}^{ {n_1} } }{\varepsilon ^{ {n_0} } } } \right]\left( {1 - {T^{ * m} } } \right){\dot \varepsilon ^C}$ Farrokh-Khan[38] $\sigma {\text{ = } }\left\{ {\left( { {a_1} + \dfrac{ { {k_1} } }{ {\sqrt d } } } \right) + B{ {\left( {\dfrac{d}{ { {d_0} } } } \right)}^{ {n_2} } }{ {\left[ {\left( {1 - \dfrac{ {\ln {\dot \varepsilon } } }{ {\ln {D_0^{\text{p} } } } } } \right) {\dfrac{ { {T_{\text{m} } } } }{T} } } \right]}^{ {n_1} } }{ {\left( \varepsilon \right)}^{ {n_0} } } } \right\}{\left( {\dfrac{ { {T_{\text{m} } } - T} }{ { {T_{\text{m} } } - {T_{\text{r} } } } } } \right)^m}{\left( {\dfrac{ {\dot \varepsilon } }{ { { {\dot \varepsilon }^ * } } } } \right)^C}$ Voce-Kocks[39-40] $\sigma = {\sigma _{\text{s}}} + \left[ {\left( {{\sigma _0} - {\sigma _{\text{s}}}} \right)\exp \left( { - \dfrac{\varepsilon }{{{\varepsilon _{\text{r}}}}}} \right)} \right]$ Molinari-Ravichandran[41] $\dfrac{ { {\delta _{\text{r} } } } }{ { {\delta _{ {\text{r0} } } } } } = {\left[ {1 - { {\left( { {k_{\text{r} } } {\dfrac{T}{ { {T_{ {\text{r0} } } } } } } \lg {\dfrac{ { { {\dot \varepsilon }_{ {\text{r0} } } } } }{ {\dot \varepsilon } } } } \right)}^{ {p_{\text{r} } } } } } \right]^{ {q_{\text{r} } } } }\text{,}\dfrac{ { {\delta _{\text{s} } } } }{ { {\delta _{ {\text{s0} } } } } } = \dfrac{1}{ { { {\left[ {1 - { {\left( { {k_{\text{s} } } {\dfrac{T}{ { {T_{ {\text{s0} } } } } } } \lg {\dfrac{ { { {\dot \varepsilon }_{ {\text{r0} } } } } }{ {\dot \varepsilon } } } } \right)}^{ {p_{\text{s} } } } } } \right] }^{ {q_{\text{s} } } } } } }$ 表 3 物理概念本构关系的模型对比

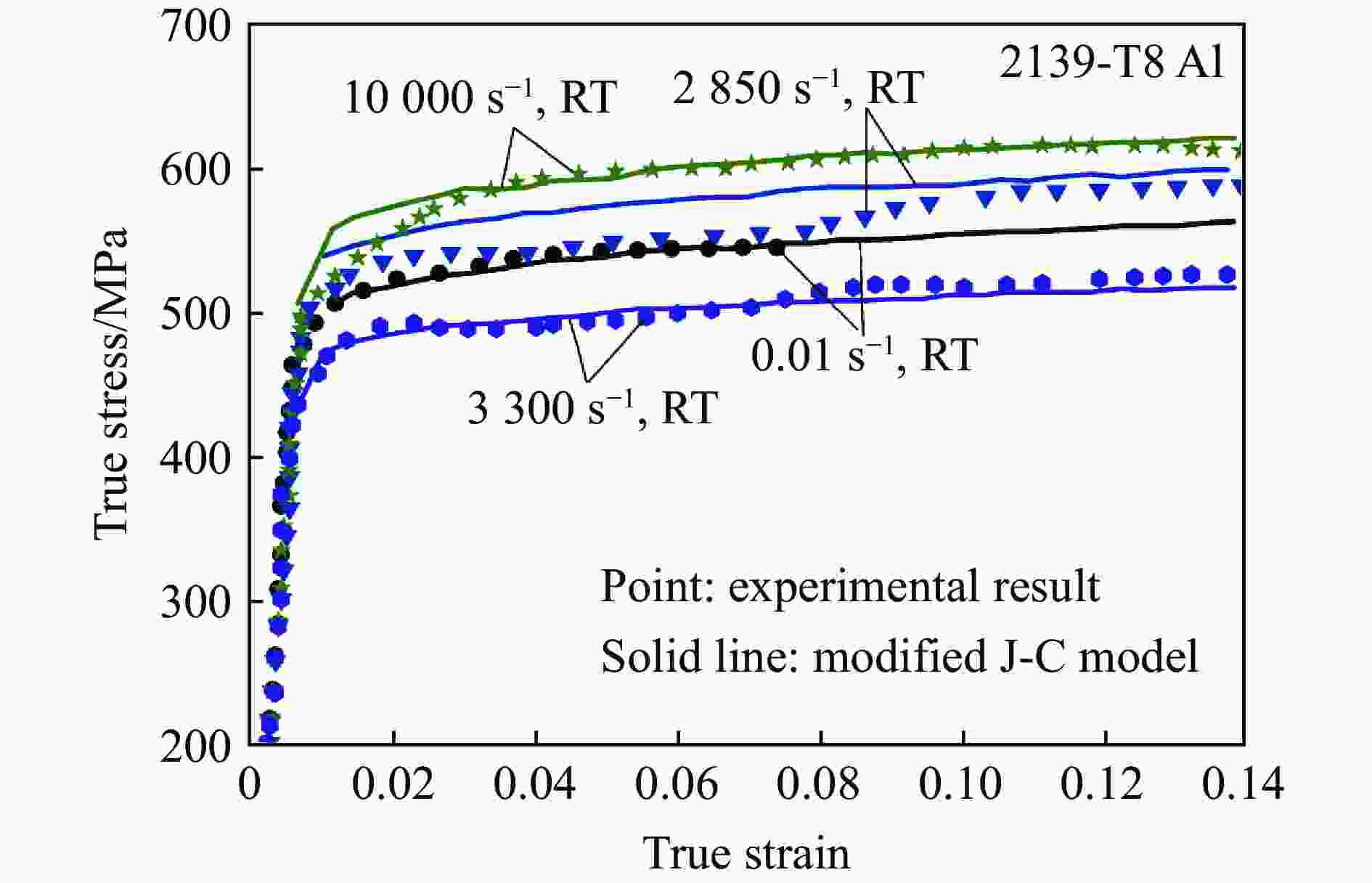

Table 3. Comparison of physically based constitutive relations

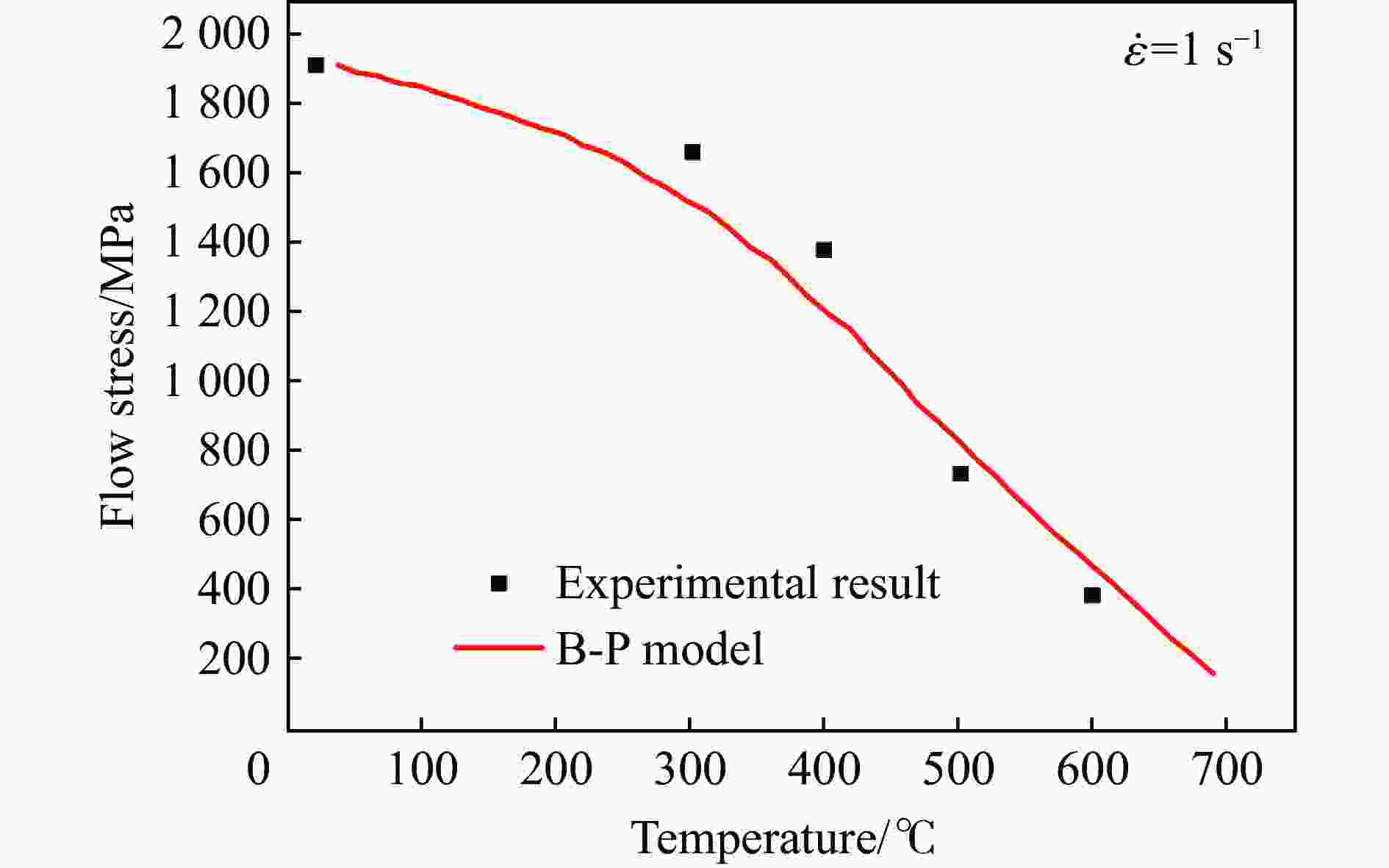

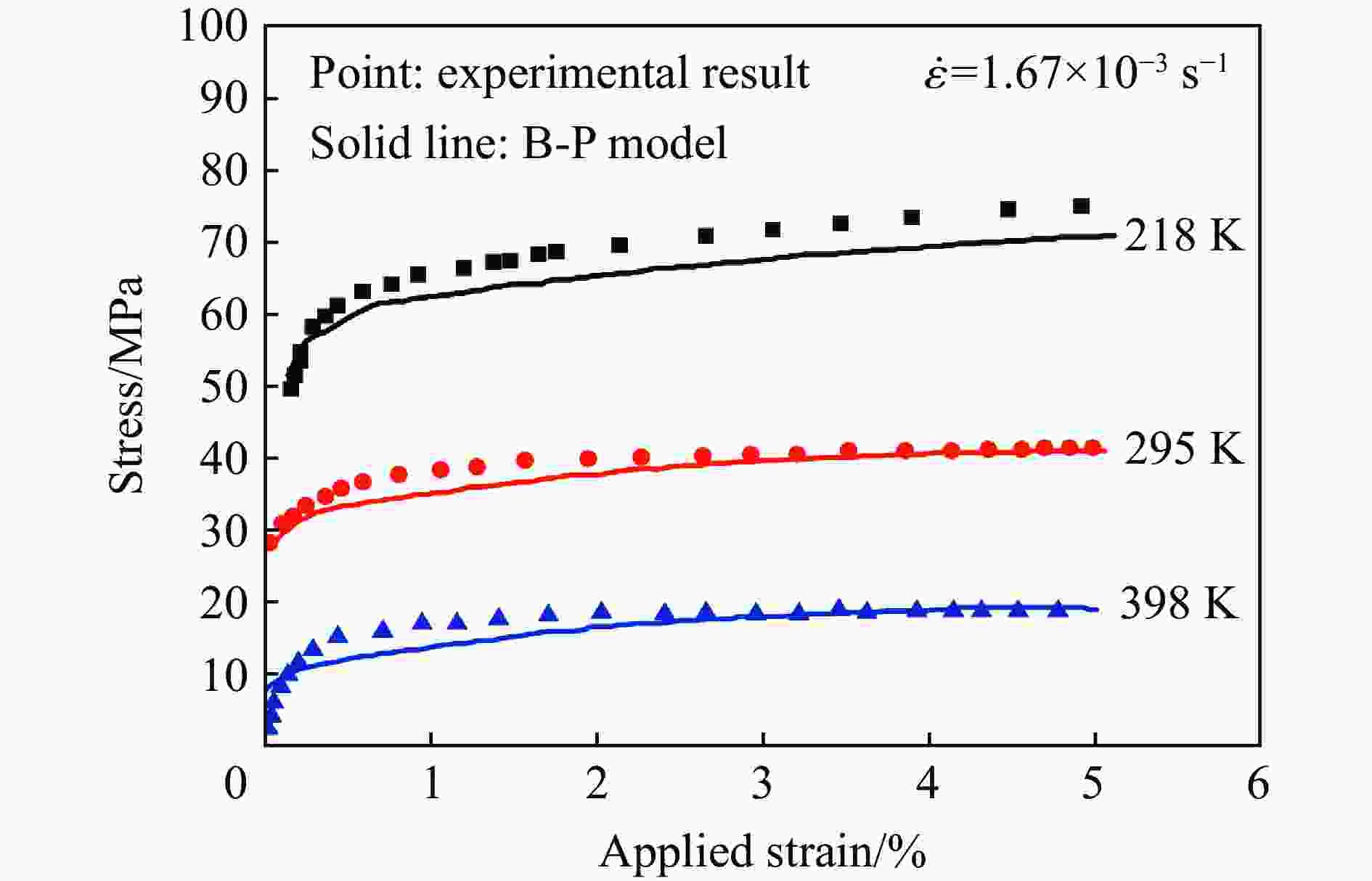

本构关系 年份 模型 应变率范围/s−1 本构关系的主要特征 B-P 1975 Bodner-Partom[18] 10−3~1 (1)将材料的总变形率分为弹性和塑性两部分

(2)通过塑性功项合并应变硬化效应

(3)没有考虑温度效应Z-A 1987 Zerilli-Armstrong[17] 4×103 (1)考虑了晶粒尺寸的影响

(2)基于热激活理论2009 Zhang-Wen[48] 10−5~10−2 考虑了温度、应变率和变形过程对Z-A模型中参数的影响 2009 Samantaray-Mandal[49] 10−3~1 考虑了温度与应变、温度与应变率的耦合效应对流动应力的影响 2005 Abed-Voyiadjis[50] 10−4~104 (1)可用于预测等温和绝热塑性变形的应力应变曲线

(2)将模型参数准确的与微观结构物理参数联系起来M-T-S 1988 Follansbee[10,51] 10−4~104 (1)认为应变率敏感性的上升应归因于结构演化的速率敏感性

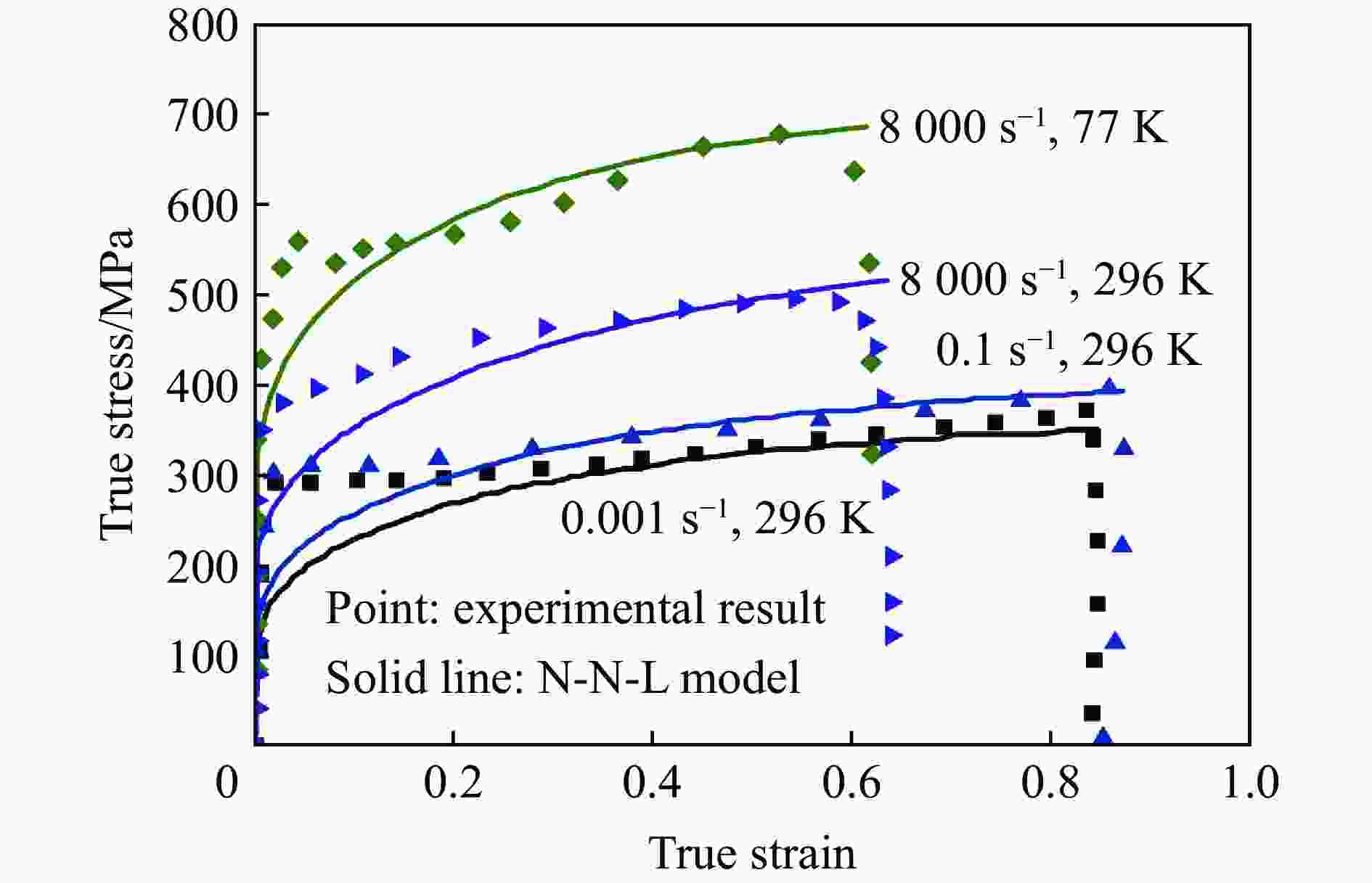

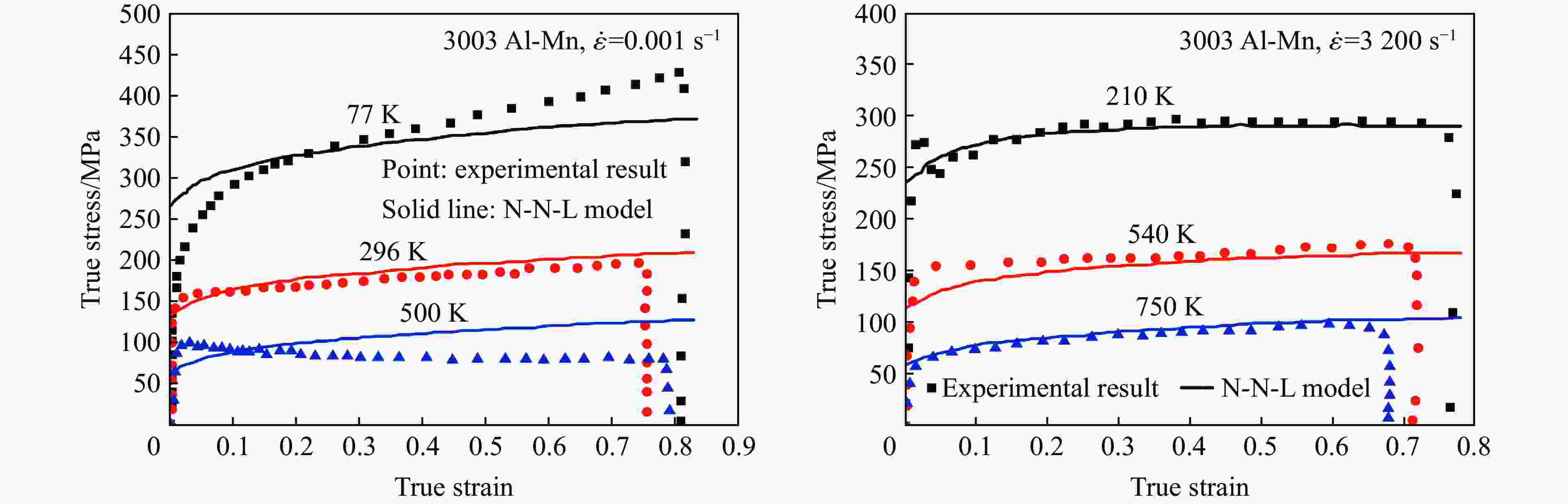

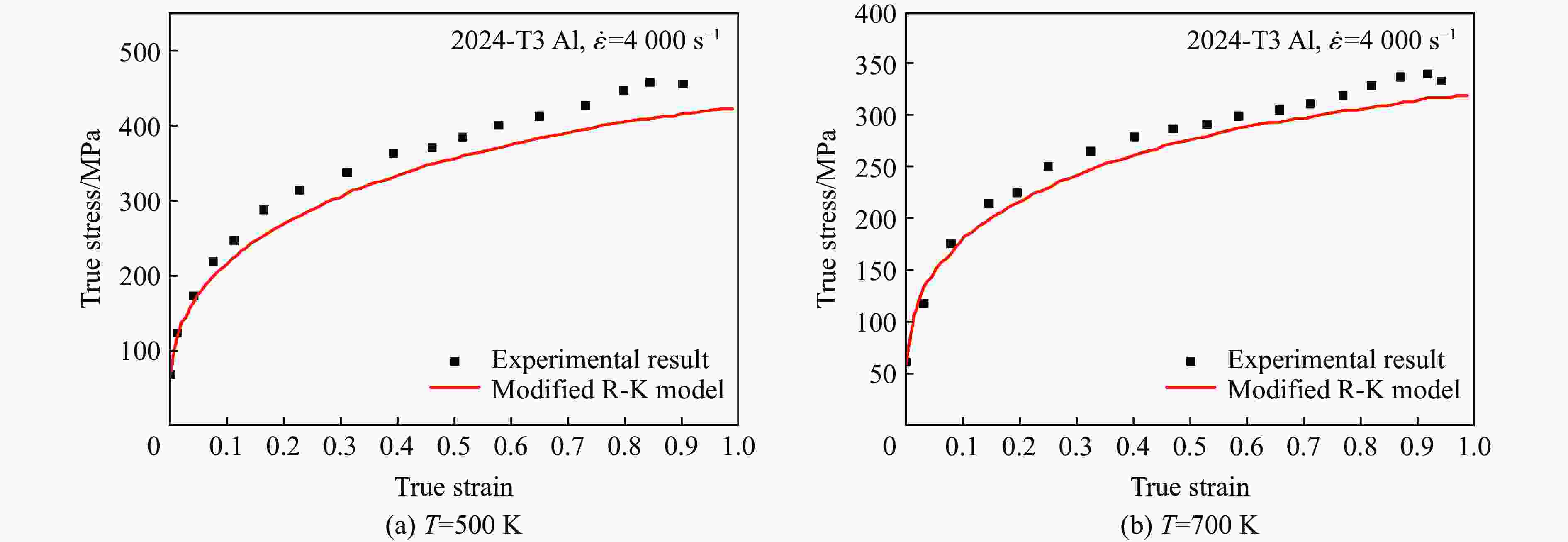

(2)考虑了阈值应力N-N-L 1998 Nemat-Nasser-Li[57] 10−3~104 考虑了位错密度随应变和温度的变化 其他 2001 Rusinek-Klepaczko[61,62] 10−4~103 考虑了应变率历史效应对金属材料塑性流动行为的影响 2009 Rusinek-Rodrguez-Martnez[63] 10−4~104 (1)添加一个第三项来扩展该本构关系的应用范围

(2)考虑负应变率敏感性和粘性阻力2010 Sung[66] 10−3~10 通过Hollomon和Voce应变硬化方程的线性组合来揭示应变硬化率的温度敏感 2010 Gao-Zhang[67] 10−3~104 考虑FCC金属变形过程中微观结构的演变建立阈值应力与应变、温度和应变率的关系 表 4 物理概念本构关系的方程形式

Table 4. Equations of physically based constitutive relations

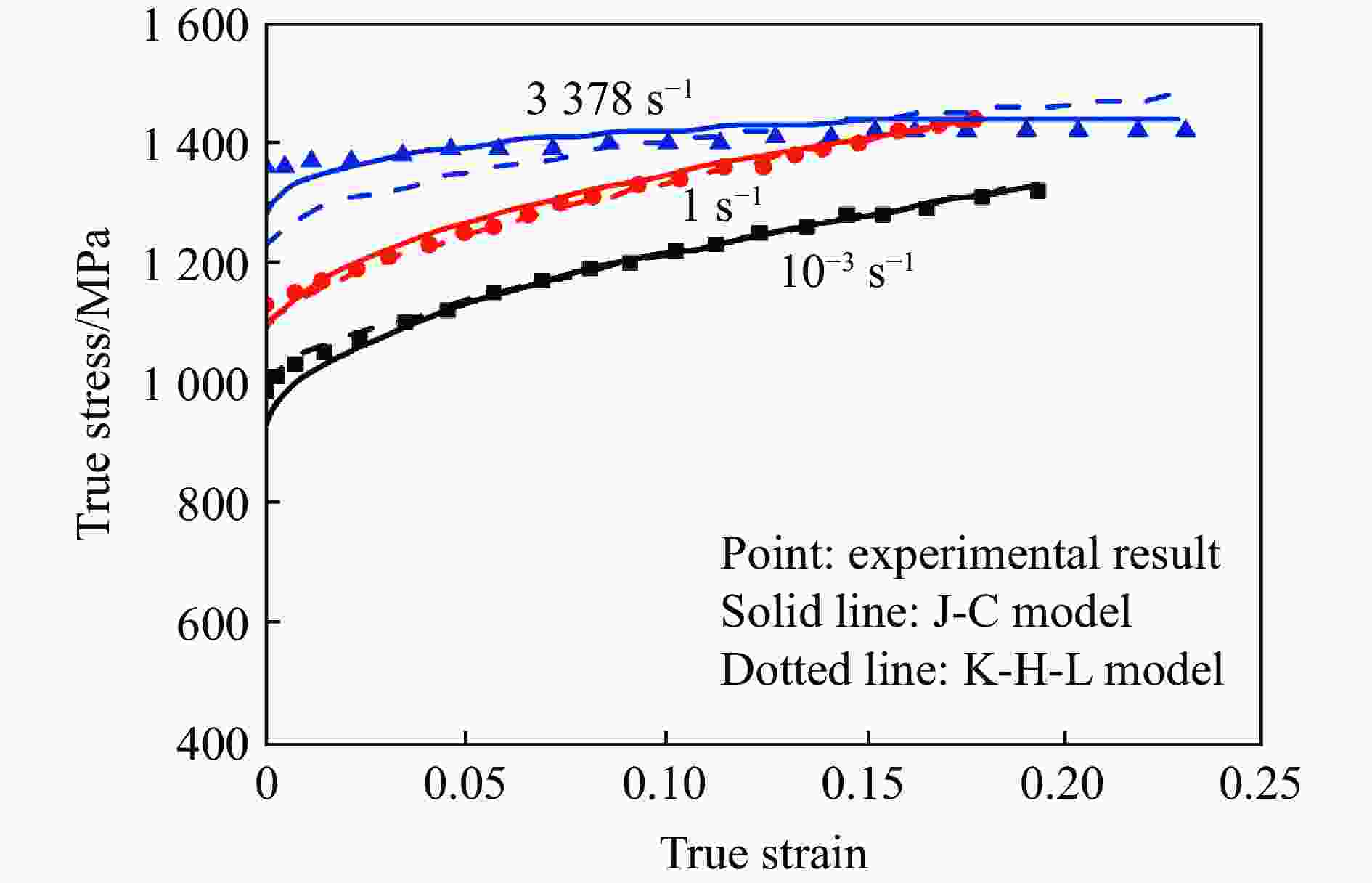

模型 方程形式 Bodner-Partom[18] $D_2^{\text{p}} = D_0^2\exp \left[ { - \left( {\dfrac{{n + 1}}{n}} \right){{\left( {\dfrac{{{Z^2}}}{{3{J_2}}}} \right)}^n}} \right]$ Zerilli-Armstrong[17] 对于FCC: $\sigma = {\sigma _{\text{a}}} + B{\varepsilon ^{1/2}}\exp \left( { - \alpha T} \right)$和$\alpha {\text{ = }}{\alpha _0} - {\alpha _1}\ln \dot \varepsilon $

对于BCC:$\sigma = {\sigma _{\text{a}}} + B\exp \left( { - \beta T} \right) + {B_0}{\varepsilon ^n}$和$\beta {\text{ = }}{\beta _0} - {\beta _1}\ln \dot \varepsilon $

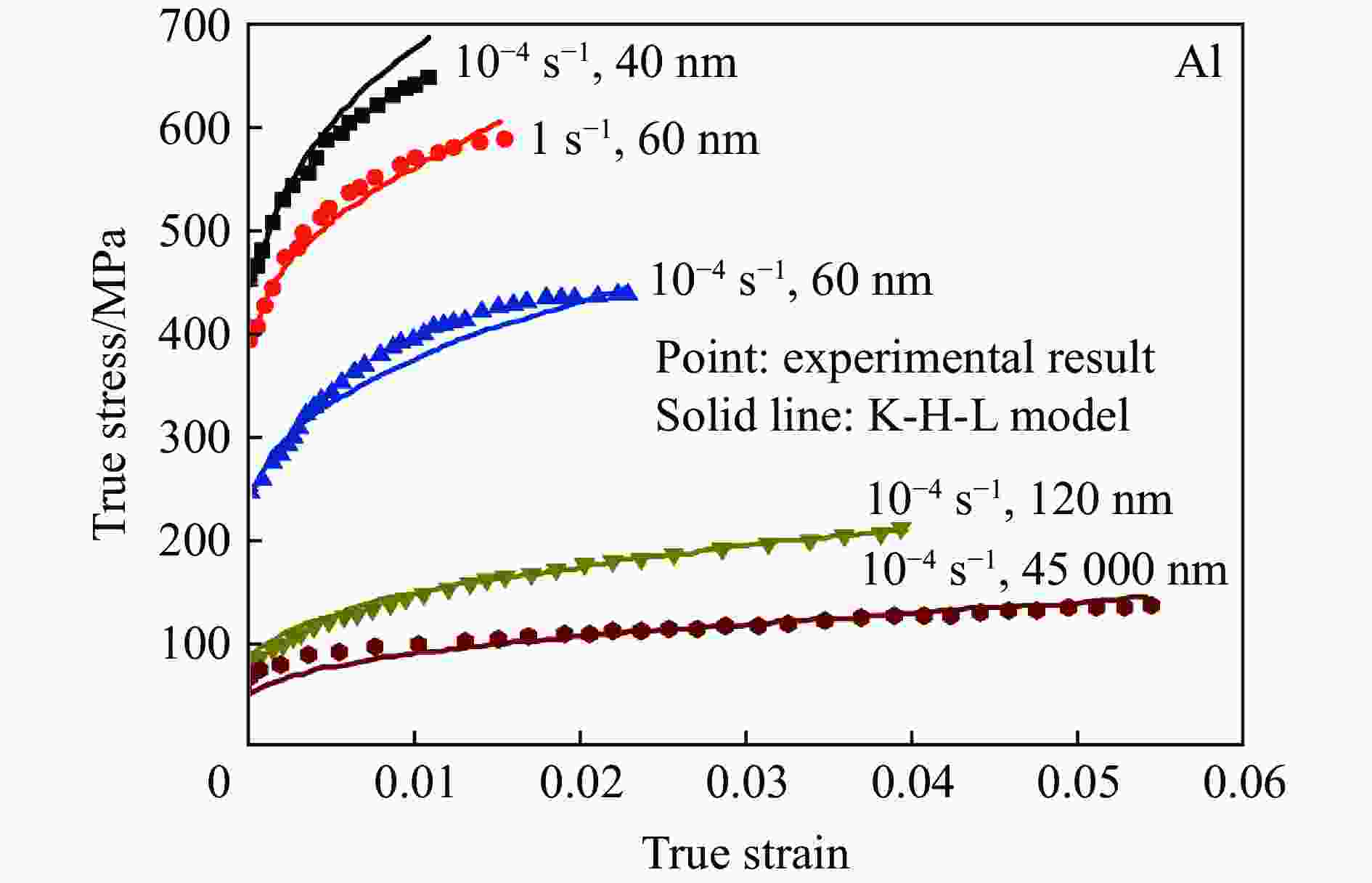

对于HCP:$\sigma = {\sigma _{\text{a}}} + B\exp \left( { - \beta T} \right) + {B_0}{\varepsilon ^{^{1/2}}}\exp \left( { - \alpha T} \right)$Zhang-Wen[48] 对于FCC:$\sigma = {\sigma _{\text{a}}} + {C_1}{\varepsilon ^{1/2}}\exp \left\{ {\left[ { - {C''_3}T + {C'_4}T\ln \left( {\dfrac{{\dot \varepsilon }}{{r\left( \varepsilon \right)r\left( {\dot \varepsilon } \right)}}} \right)} \right]H\left( T \right)} \right\}$

对于BCC:$\sigma = {\sigma _{\text{a}}} + {C_2}\exp \left\{ {\left[ { - {C''_3}T + {C'_4}T\ln \left( {\dfrac{{\dot \varepsilon }}{{r\left( \varepsilon \right)r\left( {\dot \varepsilon } \right)}}} \right)} \right]H\left( T \right)} \right\} + {C_5}{\varepsilon ^n}$Samantaray-Mandal[49] $\sigma = \left( {{C_1} + {C_2}{\varepsilon ^n}} \right)\exp \left[ { - \left( {{C_3} + {C_4}\varepsilon } \right){T^ * } + \left( {{C_5} + {C_6}{T^ * }} \right)\ln {{\dot \varepsilon }^ * }} \right]$ Abed-Voyiadjis[50] 对于FCC:$\sigma = {C_2}{\varepsilon ^{0.5}}\left( {1 - {X^{1/2}} - X + {X^{3/2}}} \right) + {C_6}$和$X = {C_4}T\ln \left( {1/{{\dot \varepsilon }^ * }} \right)$

对于BCC:$\sigma = {C_1}\left( {1 - {X^{1/2}} - X + {X^{3/2}}} \right) + {C_5}{\varepsilon ^n} + {C_6}$Follansbee[10,51] $\sigma = {\sigma _{\text{a}}} + \left( {\hat \sigma - {\sigma _{\text{a}}}} \right){\left[ {1 - {{\left( {\dfrac{{kT}}{{{g_0}\mu {b^3}}}\ln \dfrac{{{{\dot \varepsilon }_0}}}{{\dot \varepsilon }}} \right)}^{1/q}}} \right]^{1/p}}$ Nemat-Nasser-Li[57] $\sigma \left( {\dot \varepsilon ,\varepsilon ,T} \right) = {\sigma ^0}{\left\{ {1 - {{\left[ { - \dfrac{{kT}}{{{G'_0}}}\left( {\ln \dfrac{{\dot \varepsilon }}{{{{\dot \varepsilon }_0}}} + \ln \left( {1 + a\left( T \right){\varepsilon ^{1/2}}} \right)} \right)} \right]}^{\tfrac{1}{2}}}} \right\}^{\tfrac{3}{2}}}\left[ {1 + a\left( T \right){\varepsilon ^{\tfrac{1}{2}}}} \right] + \sigma _{\text{a}}^0{\varepsilon ^{{n_1}}}$ Rusinek-Klepaczko[61,62] $\sigma = \dfrac{{E\left( T \right)}}{{{E_0}}}\left[ {{B_0}\theta _{\text{m}}^{ - v}{{\left( {{\varepsilon _0} + {\varepsilon _{\text{p}}}} \right)}^{n\left( {1 - {D_2}{\theta _n}} \right)}} + \sigma _0^*{{\left( {1 - {D_1}{\theta _{\text{m}}}} \right)}^m}} \right]$ Rusinek-Rodrguez-Martnez[63] ${\sigma _{{\text{ns}}}}\left( {\dot \varepsilon ,T} \right) = \sigma _0^{{\text{ns}}} \left[ {\lg \left( {\dfrac{{{{\dot \varepsilon }_{{\text{trans}}}}}}{{\dot \varepsilon }}} \right)} \right] \left[ {1 - {D_3}\left( {\dfrac{{{T_{\text{m}}}}}{T}} \right)\lg \left( {\dfrac{{\dot \varepsilon }}{{{{\dot \varepsilon }_{\max }}}}} \right)} \right]$ Sung[66] $\sigma = \sigma \left( {\varepsilon ,\dot \varepsilon ,T} \right) = f\left( {\varepsilon ,T} \right)g\left( {\dot \varepsilon } \right)h\left( T \right)$ Gao-Zhang[67] $\sigma {\text{ = }}{\sigma _{\text{a}}} + \hat Y{\varepsilon ^n}\exp \left[ {{c_3}T\ln \left( {\dfrac{{\dot \varepsilon }}{{{{\dot \varepsilon }_{{\text{s0}}}}}}} \right)} \right]{\left\{ {1 - {{\left[ { - {c_4}T\ln \left( {\dfrac{{\dot \varepsilon }}{{{{\dot \varepsilon }_0}}}} \right)} \right]}^{1/q}}} \right\}^{1/p}}$ -

[1] 李永池, 谭福利, 姚磊, 等. 含损伤材料的热粘塑性本构关系及其应用 [J]. 爆炸与冲击, 2004, 24(4): 289–298.LI Y C, TAN F L, YAO L, et al. Thermo-viscoplastic constitutive relation of damaged materials with application [J]. Explosion and Shock Waves, 2004, 24(4): 289–298. [2] REMINGTON B A, BAZAN G, BELAK J, et al. Materials science under extreme conditions of pressure and strain rate [J]. Metallurgical and Materials Transactions A, 2004, 35(9): 2587–2607. DOI: 10.1007/s11661-004-0205-6. [3] 王建军. 典型金属塑性流动中反常应力峰及其本构关系 [D]. 西安: 西北工业大学, 2017: 47–100. DOI: 10.7666/d.D01601051.WANG J J. Anomalous stress peak in the plastic flow of typical metals and its constitutive model [D]. Xi’an: Northwestern Polytechnical University, 2017: 47–100. DOI: 10.7666/d.D01601051. [4] CHENG J Y, NEMAT-NASSER S, GUO W G. A unified constitutive model for strain-rate and temperature dependent behavior of molybdenum [J]. Mechanics of Materials, 2001, 33(11): 603–616. DOI: 10.1016/S0167-6636(01)00076-X. [5] SEIDT J D, GILAT A. Plastic deformation of 2024-T351 aluminum plate over a wide range of loading conditions [J]. International Journal of Solids and Structures, 2013, 50(10): 1781–1790. DOI: 10.1016/j.ijsolstr.2013.02.006. [6] WIERZBICKI T, BAO Y B, LEE Y W, et al. Calibration and evaluation of seven fracture models [J]. International Journal of Mechanical Sciences, 2005, 47(4/5): 719–743. DOI: 10.1016/j.ijmecsci.2005.03.003. [7] WILKINS M L, STREIT R D, REAUGH J E. Cumulative-strain-damage model of ductile fracture: simulation and prediction of engineering fracture tests [R]. San Leandro: Lawrence Livermore National Laboratory, 1980. DOI: 10.2172/6628920. [8] GILIOLI A, MANES A, GIGLIO M, et al. Predicting ballistic impact failure of aluminium 6061-T6 with the rate-independent Bao-Wierzbicki fracture model [J]. International Journal of Impact Engineering, 2015, 76: 207–220. DOI: 10.1016/j.ijimpeng.2014.10.004. [9] BAIG M, KHAN A S, CHOI S H, et al. Shear and multiaxial responses of oxygen free high conductivity (OFHC) copper over wide range of strain-rates and temperatures and constitutive modeling [J]. International Journal of Plasticity, 2013, 40: 65–80. DOI: 10.1016/j.ijplas.2012.07.004. [10] FOLLANSBEE P S, KOCKS U F. A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an internal state variable [J]. Acta Metallurgica, 1988, 36(1): 81–93. DOI: 10.1016/0001-6160(88)90030-2. [11] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures [C]//Proceedings of the 7th International Symposium on Ballistics. The Hague, Netherlands, 1983: 541–547. [12] JOHNSON G R, COOK W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures [J]. Engineering Fracture Mechanics, 1985, 21(1): 31–48. DOI: 10.1016/0013-7944(85)90052-9. [13] KHAN A S, SUH Y S, KAZMI R. Quasi-static and dynamic loading responses and constitutive modeling of titanium alloys [J]. International Journal of Plasticity, 2004, 20(12): 2233–2248. DOI: 10.1016/j.ijplas.2003.06.005. [14] NEMAT-NASSER S, GUO W G, NESTERENKO V F, et al. Dynamic response of conventional and hot isostatically pressed Ti-6Al-4V alloys: experiments and modeling [J]. Mechanics of Materials, 2001, 33(8): 425–439. DOI: 10.1016/S0167-6636(01)00063-1. [15] LIANG R Q, KHAN A S. A critical review of experimental results and constitutive models for BCC and FCC metals over a wide range of strain rates and temperatures [J]. International Journal of Plasticity, 1999, 15(9): 963–980. DOI: 10.1016/S0749-6419(99)00021-2. [16] KHAN A S, HUANG S J. Experimental and theoretical study of mechanical behavior of 1100 aluminum in the strain rate range 10−5−104 s−1 [J]. International Journal of Plasticity, 1992, 8(4): 397–424. DOI: 10.1016/0749-6419(92)90057-J. [17] ZERILLI F J, ARMSTRONG R W. Dislocation-mechanics-based constitutive relations for material dynamics calculations [J]. Journal of Applied Physics, 1987, 61(5): 1816–1825. DOI: 10.1063/1.338024. [18] BODNER S R, PARTOM Y. Constitutive equations for elastic-viscoplastic strain-hardening materials [J]. Journal of Applied Mechanics, 1975, 42(2): 385–389. DOI: 10.1115/1.3423586. [19] 王礼立. 冲击动力学进展 [M]. 合肥: 中国科学技术大学出版社, 1992: 58–87. [20] LEMAITRE J, CHABOCHE J L, MAJI A K. Mechanics of Solid Materials [J]. Journal of Engineering Mechanics, 1993, 119(3): 642–643. DOI: 10.1061/(ASCE)0733-9399(1993)119:3(642.2). [21] SALVADO F C, TEIXEIRA-DIAS F, WALLEY S M, et al. A review on the strain rate dependency of the dynamic viscoplastic response of FCC metals [J]. Progress in Materials Science, 2017, 88: 186–231. DOI: 10.1016/j.pmatsci.2017.04.004. [22] GAMBIRASIO L, RIZZI E. An enhanced Johnson-Cook strength model for splitting strain rate and temperature effects on lower yield stress and plastic flow [J]. Computational Materials Science, 2016, 113: 231–265. DOI: 10.1016/j.commatsci.2015.11.034. [23] WANG J J, GUO W G, LI P H, et al. Modified Johnson-Cook description of wide temperature and strain rate measurements made on a nickel-base superalloy [J]. Materials at High Temperatures, 2017, 34(3): 157–165. DOI: 10.1080/09603409.2016.1252164. [24] HOLMQUIST T J, JOHNSON G R. Determination of constants and comparison of results for various constitutive models [J]. Journal de Physique Ⅳ, 1991, 1(C3): 853–860. DOI: 10.1051/jp4:19913119. [25] RULE W K, JONES S E. A revised form for the Johnson-Cook strength model [J]. International Journal of Impact Engineering, 1998, 21(8): 609–624. DOI: 10.1016/S0734-743X(97)00081-X. [26] KANG W J, CHO S S, HUH H, et al. Modified Johnson-Cook model for vehicle body crashworthiness simulation [J]. International Journal of Vehicle Design, 1999, 21(4/5): 424–435. DOI: 10.1504/ijvd.1999.005594. [27] VURAL M, CARO J. Experimental analysis and constitutive modeling for the newly developed 2139-T8 alloy [J]. Materials Science and Engineering:A, 2009, 520(1/2): 56–65. DOI: 10.1016/j.msea.2009.05.026. [28] LIN Y C, XIA Y C, CHEN X M, et al. Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain rate [J]. Computational Materials Science, 2010, 50(1): 227–233. DOI: 10.1016/j.commatsci.2010.08.003. [29] LIN Y C, CHEN X M, LIU G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel [J]. Materials Science and Engineering: A, 2010, 527(26): 6980–6986. DOI: 10.1016/j.msea.2010.07.061. [30] SHIN H, KIM J B. A phenomenological constitutive equation to describe various flow stress behaviors of materials in wide strain rate and temperature regimes [J]. Journal of Engineering Materials and Technology, 2010, 132(2): 021009. DOI: 10.1115/1.4000225. [31] WANG Y, ZHOU Y X, XIA Y M. A constitutive description of tensile behavior for brass over a wide range of strain rates [J]. Materials Science and Engineering: A, 2004, 372(1/2): 186–190. DOI: 10.1016/j.msea.2003.12.009. [32] HOU Q Y, WANG J T. A modified Johnson-Cook constitutive model for Mg-Gd-Y alloy extended to a wide range of temperatures [J]. Computational Materials Science, 2010, 50(1): 147–152. DOI: 10.1016/j.commatsci.2010.07.018. [33] DOU W, XU Z J, HU H Z, et al. A generalized plasticity model incorporating stress state, strain rate and temperature effects [J]. International Journal of Impact Engineering, 2021, 155: 103897. DOI: 10.1016/j.ijimpeng.2021.103897. [34] 刘旭红, 黄西成, 陈裕泽, 等. 强动载荷下金属材料塑性变形本构模型评述 [J]. 力学进展, 2007, 37(3): 361–374. DOI: 10.3321/j.issn:1000-0992.2007.03.004.LIU X H, HUANG X C, CHEN Y Z, et al. A review on constitutive models for plastic deformation of metal materials under dynamic loading [J]. Advances in Mechanics, 2007, 37(3): 361–374. DOI: 10.3321/j.issn:1000-0992.2007.03.004. [35] YU H D, GUO Y J, ZHANG K Z, et al. Constitutive model on the description of plastic behavior of DP600 steel at strain rate from 10−4 to 103 s−1 [J]. Computational Materials Science, 2009, 46(1): 36–41. DOI: 10.1016/j.commatsci.2009.01.025. [36] KHAN A S, LIANG R Q. Behaviors of three BCC metal over a wide range of strain rates and temperatures: experiments and modeling [J]. International Journal of Plasticity, 1999, 15(10): 1089–1109. DOI: 10.1016/S0749-6419(99)00030-3. [37] KHAN A S, ZHANG H Y, TAKACS L. Mechanical response and modeling of fully compacted nanocrystalline iron and copper [J]. International Journal of Plasticity, 2000, 16(12): 1459–1476. DOI: 10.1016/S0749-6419(00)00023-1. [38] FARROKH B, KHAN A S. Grain size, strain rate, and temperature dependence of flow stress in ultra-fine grained and nanocrystalline Cu and Al: synthesis, experiment, and constitutive modeling [J]. International Journal of Plasticity, 2009, 25(5): 715–732. DOI: 10.1016/j.ijplas.2008.08.001. [39] VOCE E. The relationship between stress and strain for homogeneous deformation [J]. Journal of the Institute of Metals, 1948, 74: 537–562. [40] KOCKS U F. Laws for work-hardening and low-temperature creep [J]. Journal of Engineering Materials and Technology, 1976, 98(1): 76–85. DOI: 10.1115/1.3443340. [41] MOLINARI A, RAVICHANDRAN G. Constitutive modeling of high-strain-rate deformation in metals based on the evolution of an effective microstructural length [J]. Mechanics of Materials, 2005, 37(7): 737–752. DOI: 10.1016/j.mechmat.2004.07.005. [42] NADERI M, DURRENBERGER L, MOLINARI A, et al. Constitutive relationships for 22MnB5 boron steel deformed isothermally at high temperatures [J]. Materials Science and Engineering: A, 2008, 478(1/2): 130–139. DOI: 10.1016/j.msea.2007.05.094. [43] HUANG S, KHAN A S. Modeling the mechanical behaviour of 1100-0 aluminum at different strain rates by the bodner-partom model [J]. International Journal of Plasticity, 1992, 8(5): 501–517. DOI: 10.1016/0749-6419(92)90028-B. [44] CHEN S Y, HUANG C G, WANG C K, et al. Mechanical properties and constitutive relationships of 30CrMnSiA steel heated at high rate [J]. Materials Science and Engineering: A, 2008, 483/484: 105–108. DOI: 10.1016/j.msea.2006.09.132. [45] 马鑫, 王莉, 方洪渊, 等. Sn-Pb共晶钎料合金的Bodner-Partom本构方程 [J]. 应用力学学报, 1998, 15(2): 89–92; 148.MA X, WANG L, FANG H Y, et al. Viscoplastic constitutive equations for Tin-Lead eutectic solder alloy [J]. Chinese Journal of Applied Mechanics, 1998, 15(2): 89–92; 148. [46] HOLT W H, MOCK JR W, ZERILLI F J, et al. Experimental and computational study of the impact deformation of titanium Taylor cylinder specimens [J]. Mechanics of Materials, 1994, 17(2/3): 195–201. DOI: 10.1016/0167-6636(94)90059-0. [47] ZERILLI F J, ARMSTRONG R W. Constitutive equation for HCP metals and high strength alloy steels [C]//ASME International Mechanical Engineering Congress and Exposition. San Francisco, CA: ASME, 1995. [48] ZHANG H J, WEN W D, CUI H T, et al. A modified Zerilli-Armstrong model for alloy IC10 over a wide range of temperatures and strain rates [J]. Materials Science and Engineering: A, 2009, 527(1/2): 328–333. DOI: 10.1016/j.msea.2009.08.008. [49] SAMANTARAY D, MANDAL S, BORAH U, et al. A thermo-viscoplastic constitutive model to predict elevated-temperature flow behaviour in a titanium-modified austenitic stainless steel [J]. Materials Science and Engineering: A, 2009, 526(1/2): 1–6. DOI: 10.1016/j.msea.2009.08.009. [50] ABED F H, VOYIADJIS G Z. A consistent modified Zerilli-Armstrong flow stress model for BCC and FCC metals for elevated temperatures [J]. Acta Mechanica, 2005, 175(1): 1–18. DOI: 10.1007/s00707-004-0203-1. [51] CHAWLA K K. Metallurgical applications of shock-wave and high-strain-rate phenomena: L. E. Murr, K. P. Staudhammer, and M. A. Meyers (eds. ), (Marcel Dekker, New York, 1986), 1120 pages, $145.00 [J]. Metallography, 1987, 20(2): 249–250. DOI: 10.1016/0026-0800(87)90034-6. [52] FOLLANSBEE P S. Recent results and continued development of the MTS (mechanical threshold stress) model [R]. Los Alamos: Los Alamos National Laboratory, 1988. [53] DARIDON L, OUSSOUADDI O, AHZI S. Influence of the material constitutive models on the adiabatic shear band spacing: MTS, power law and Johnson-Cook models [J]. International Journal of Solids and Structures, 2004, 41(11/12): 3109–3124. DOI: 10.1016/j.ijsolstr.2004.01.008. [54] BANERJEE B. The mechanical threshold stress model for various tempers of AISI 4340 steel [J]. International Journal of Solids and Structures, 2007, 44(3/4): 834–859. DOI: 10.1016/j.ijsolstr.2006.05.022. [55] MAUDLIN P J, DAVIDSON R F, HENNINGER R J. Implementation and assessment of the mechanical-threshold-stress model using the EPIC2 and PINON computer codes [R]. Los Alamos: Los Alamos National Laboratory, 1990. DOI: 10.2172/6537785. [56] NEMAT-NASSER S, ISAACS J B. Direct measurement of isothermal flow stress of metals at elevated temperatures and high strain rates with application to Ta and Ta-W alloys [J]. Acta Materialia, 1997, 45(3): 907–919. DOI: 10.1016/S1359-6454(96)00243-1. [57] NEMAT-NASSER S, LI Y L. Flow stress of f. c. c. polycrystals with application to OFHC Cu [J]. Acta Materialia, 1998, 46(2): 565–577. DOI: 10.1016/S1359-6454(97)00230-9. [58] GUO W G, ZHANG X Q, SU J, et al. The characteristics of plastic flow and a physically-based model for 3003 Al-Mn alloy upon a wide range of strain rates and temperatures [J]. European Journal of Mechanics—A/Solids, 2011, 30(1): 54–62. DOI: 10.1016/j.euromechsol.2010.09.001. [59] NEMAT-NASSER S, GUO W G, LIU M Q. Experimentally-based micromechanical modeling of dynamic response of molybdenum [J]. Scripta Materialia, 1999, 40(7): 859–872. DOI: 10.1016/S1359-6462(99)00041-X. [60] NEMAT-NASSER S, GUO W G, CHENG J Y. Mechanical properties and deformation mechanisms of a commercially pure titanium [J]. Acta Materialia, 1999, 47(13): 3705–3720. DOI: 10.1016/S1359-6454(99)00203-7. [61] RUSINEK A, KLEPACZKO J R. Shear testing of a sheet steel at wide range of strain rates and a constitutive relation with strain-rate and temperature dependence of the flow stress [J]. International Journal of Plasticity, 2001, 17(1): 87–115. DOI: 10.1016/S0749-6419(00)00020-6. [62] KLEPACZKO J. Thermally activated flow and strain rate history effects for some polycrystalline f. c. c. metals [J]. Materials Science and Engineering, 1975, 18(1): 121–135. DOI: 10.1016/0025-5416(75)90078-6. [63] RUSINEK A, RODRÍGUEZ-MARTÍNEZ J A. Thermo-viscoplastic constitutive relation for aluminium alloys, modeling of negative strain rate sensitivity and viscous drag effects [J]. Materials & Design, 2009, 30(10): 4377–4390. DOI: 10.1016/j.matdes.2009.04.011. [64] RUSINEK A, RODRÍGUEZ-MARTÍNEZ J A, ARIAS A. A thermo-viscoplastic constitutive model for FCC metals with application to OFHC copper [J]. International Journal of Mechanical Sciences, 2010, 52(2): 120–135. DOI: 10.1016/j.ijmecsci.2009.07.001. [65] VOYIADJIS G Z, ABED F H. Microstructural based models for BCC and FCC metals with temperature and strain rate dependency [J]. Mechanics of Materials, 2005, 37(2/3): 355–378. DOI: 10.1016/j.mechmat.2004.02.003. [66] SUNG J H, KIM J H, WAGONER R H. A plastic constitutive equation incorporating strain, strain-rate, and temperature [J]. International Journal of Plasticity, 2010, 26(12): 1746–1771. DOI: 10.1016/j.ijplas.2010.02.005. [67] GAO C Y, ZHANG L C. A constitutive model for dynamic plasticity of FCC metals [J]. Materials Science and Engineering: A, 2010, 527(13/14): 3138–3143. DOI: 10.1016/j.msea.2010.01.083. [68] XU Z J, HUANG F L. Comparison of physically based constitutive models characterizing armor steel over wide temperature and strain rate ranges [J]. Modelling and Simulation in Materials Science and Engineering, 2012, 20(1): 015005. DOI: 10.1088/0965-0393/20/1/015005. [69] XU Z J, HUANG F L. Comparison of constitutive models for FCC metals over wide temperature and strain rate ranges with application to pure copper [J]. International Journal of Impact Engineering, 2015, 79: 65–74. DOI: 10.1016/j.ijimpeng.2014.10.003. [70] XU Z J, HUANG F L. Thermomechanical behavior and constitutive modeling of tungsten-based composite over wide temperature and strain rate ranges [J]. International Journal of Plasticity, 2013, 40: 163–184. DOI: 10.1016/j.ijplas.2012.08.004. [71] NEMAT-NASSER S, GUO W G. Thermomechanical response of DH-36 structural steel over a wide range of strain rates and temperatures [J]. Mechanics of Materials, 2003, 35(11): 1023–1047. DOI: 10.1016/S0167-6636(02)00323-X. [72] NEMAT-NASSER S, GUO W G. Thermomechanical response of HSLA-65 steel plates: experiments and modeling [J]. Mechanics of Materials, 2005, 37(2/3): 379–405. DOI: 10.1016/j.mechmat.2003.08.017. [73] 郭伟国, 左红星, 孟卫华, 等. 第三种应变时效与机械波谱关联性探讨 [J]. 材料科学与工艺, 2012, 20(1): 128–134. DOI: 10.11951/j.issn.1005-0299.20120126.GUO W G, ZUO H X, MENG W H, et al. Discussion of the relevancy of the third-type strain aging and mechanical spectroscopy [J]. Materials Science and Technology, 2012, 20(1): 128–134. DOI: 10.11951/j.issn.1005-0299.20120126. [74] WANG J J, GUO W G, GAO X S, et al. The third-type of strain aging and the constitutive modeling of a Q235B steel over a wide range of temperatures and strain rates [J]. International Journal of Plasticity, 2015, 65: 85–107. DOI: 10.1016/j.ijplas.2014.08.017. [75] 王建军, 袁康博, 张晓琼, 等. 第三型应变时效的提出与研究进展 [J]. 爆炸与冲击, 2021, 41(5): 051101. DOI: 10.11883/bzycj-2020-0422.WANG J J, YUAN K B, ZHANG X Q, et al. Proposition and research progress of the third-type strain aging [J]. Explosion and Shock Waves, 2021, 41(5): 051101. DOI: 10.11883/bzycj-2020-0422. [76] XIAO J Y, WANG J J, GUO W G, et al. The influence of heat treatment and strain rate on the third type strain ageing phenomenon [J]. Materials at High Temperatures, 2019, 36(2): 104–110. DOI: 10.1080/09603409.2018.1467108. [77] WEAVER M L, NOEBE R D, KAUFMAN M J. The influence of C and Si on the flow behavior of NiAl single crystals [J]. Scripta Materialia, 1996, 34(6): 941–948. DOI: 10.1016/1359-6462(95)00590-0. [78] VARADHAN S, BEAUDOIN A J, FRESSENGEAS C. Lattice incompatibility and strain-aging in single crystals [J]. Journal of the Mechanics and Physics of Solids, 2009, 57(10): 1733–1748. DOI: 10.1016/j.jmps.2009.06.007. [79] WEAVER M L, NOEBE R D, LEWANDOWSKI J J, et al. Observations of static strain-aging in polycrystalline NiAl [J]. Intermetallics, 1996, 4(7): 533–542. DOI: 10.1016/0966-9795(96)00040-4. [80] HONG S I. Influence of dynamic strain aging on the apparent activation volume for deformation [J]. Materials Science and Engineering, 1985, 76: 77–81. DOI: 10.1016/0025-5416(85)90082-5. [81] GILAT A, WU X R. Plastic deformation of 1020 steel over a wide range of strain rates and temperatures [J]. International Journal of Plasticity, 1997, 13(6/7): 611–632. DOI: 10.1016/S0749-6419(97)00028-4. [82] CHENG J Y, NEMAT-NASSER S. A model for experimentally-observed high-strain-rate dynamic strain aging in titanium [J]. Acta Materialia, 2000, 48(12): 3131–3144. DOI: 10.1016/S1359-6454(00)00124-5. [83] LEE K W, KIM S K, KIM K T, et al. Ductility and strain rate sensitivity of Zircaloy-4 nuclear fuel claddings [J]. Journal of Nuclear Materials, 2001, 295(1): 21–26. DOI: 10.1016/S0022-3115(01)00509-8. [84] LEE K O, LEE S B. Modeling of materials behavior at various temperatures of hot isostatically pressed superalloys [J]. Materials Science and Engineering: A, 2012, 541: 81–87. DOI: 10.1016/j.msea.2012.02.005. [85] GUO W G, GAO X S. On the constitutive modeling of a structural steel over a range of strain rates and temperatures [J]. Materials Science and Engineering: A, 2013, 561: 468–476. DOI: 10.1016/j.msea.2012.10.065. [86] SONG Y, VOYIADJIS G Z. Constitutive modeling of dynamic strain aging for HCP metals [J]. European Journal of Mechanics—A/Solids, 2020, 83: 104034. DOI: 10.1016/j.euromechsol.2020.104034. [87] 郭扬波, 唐志平, 程经毅. 一种基于位错机制的动态应变时效模型 [J]. 固体力学学报, 2002, 23(3): 249–256. DOI: 10.3969/j.issn.0254-7805.2002.03.001.GUO Y B, TANG Z P, CHENG J Y. A dislocation-mechanics-based constitutive model for dynamic strain aging [J]. Acta Mechanica Solida Sinica, 2002, 23(3): 249–256. DOI: 10.3969/j.issn.0254-7805.2002.03.001. [88] 孟卫华, 郭伟国, 苏静, 等. DH-36钢的塑性流动统一本构关系研究 [J]. 力学学报, 2011, 43(5): 958–962. DOI: 10.6052/0459-1879-2011-5-lxxb2010-676.MENG W H, GUO W G, SU J, et al. Study of plastic flow unified constitutive relation for steel DH-36 [J]. Chinese Journal of Theoretical and Applied Mechanics, 2011, 43(5): 958–962. DOI: 10.6052/0459-1879-2011-5-lxxb2010-676. [89] 孟卫华, 郭伟国, 王建军, 等. DH36钢拉伸塑性流动特性及本构关系 [J]. 爆炸与冲击, 2013, 33(4): 438–443. DOI: 10.11883/1001-1455(2013)04-0438-06.MENG W H, GUO W G, WANG J J, et al. Tensile plasticity flow characteristics of DH36 steel and its constitutive relation [J]. Explosion and Shock Waves, 2013, 33(4): 438–443. DOI: 10.11883/1001-1455(2013)04-0438-06. [90] SU J, GUO W, MENG W, et al. Plastic behavior and constitutive relations of DH-36 steel over a wide spectrum of strain rates and temperatures under tension [J]. Mechanics of Materials, 2013, 65: 76–87. DOI: 10.1016/j.mechmat.2013.06.002. [91] VOYIADJIS G Z, SONG Y. A physically based constitutive model for dynamic strain aging in Inconel 718 alloy at a wide range of temperatures and strain rates [J]. Acta Mechanica, 2020, 231(1): 19–34. DOI: 10.1007/s00707-019-02508-6. [92] SUN Y Q, HAZZLEDINE P M. A TEM weak-beam study of dislocations in γ' in a deformed Ni-based superalloy [J]. Philosophical Magazine A, 1988, 58(4): 603–617. DOI: 10.1080/01418618808209940. [93] HIRSCH P B. A new theory of the anomalous yield stress in L12 alloys [J]. Philosophical Magazine A, 1992, 65(3): 569–612. DOI: 10.1080/01418619208201539. [94] HIRSCH P B. A model of the anomalous yield stress for (111) slip in L12 alloys [J]. Progress in Materials Science, 1992, 36: 63–88. DOI: 10.1016/0079-6425(92)90005-R. [95] LOUCHET F. Stress anomaly in L12 alloys: the ‘extended-locking /unzipping’ model [J]. Materials Science and Engineering: A, 1997, 234: 275–278. DOI: 10.1016/S0921-5093(97)00197-4. [96] CAILLARD D, PAIDAR V. A model for the anomalous mechanical properties of nickel-base L12 ordered alloys—Ⅰ. Dislocations dynamics [J]. Acta Materialia, 1996, 44(7): 2759–2771. DOI: 10.1016/1359-6454(95)00388-6. [97] LUO Z P, WU Z T, MILLER D J. The dislocation microstructure of a nickel-base single-crystal superalloy after tensile fracture [J]. Materials Science and Engineering: A, 2003, 354(1/2): 358–368. DOI: 10.1016/S0921-5093(03)00039-X. [98] MACLACHLAN D W, KNOWLES D M. Modelling and prediction of the stress rupture behaviour of single crystal superalloys [J]. Materials Science and Engineering: A, 2001, 302(2): 275–285. DOI: 10.1016/S0921-5093(00)01829-3. [99] WANG J J, GUO W G, SU Y, et al. Anomalous behaviors of a single-crystal Nickel-base superalloy over a wide range of temperatures and strain rates [J]. Mechanics of Materials, 2016, 94: 79–90. DOI: 10.1016/j.mechmat.2015.11.015. [100] LI W G, MA J Z, KOU H B, et al. Modeling the effect of temperature on the yield strength of precipitation strengthening Ni-base superalloys [J]. International Journal of Plasticity, 2019, 116: 143–158. DOI: 10.1016/j.ijplas.2019.01.002. [101] KOPPENAAL T J, KUHLMANN-WILSDORF D. The effect of prestressing on the strength of neutron-irradiated copper single crystals [J]. Applied Physics Letters, 1964, 4(3): 59–61. DOI: 10.1063/1.1753962. [102] NEMBACH E, CHOW C K. Experimental investigation into the relation between γ′ particle dispersion and the yield stress of PE 16 [J]. Materials Science and Engineering, 1978, 36(2): 271–279. DOI: 10.1016/0025-5416(78)90080-0. [103] REPPICH B, SCHEPP P, WEHNER G. Some new aspects concerning particle hardening mechanisms in γ' precipitating nickel-base alloys—Ⅱ. Experiments [J]. Acta Metallurgica, 1982, 30(1): 95–104. DOI: 10.1016/0001-6160(82)90049-9. [104] FOREMAN A J E, MAKIN M J. Dislocation movement through random arrays of obstacles [J]. Canadian Journal of Physics, 1967, 45(2): 511–517. DOI: 10.1139/p67-044. [105] POLLOCK T M, ARGON A S. Creep resistance of CMSX-3 nickel base superalloy single crystals [J]. Acta Metallurgica et Materialia, 1992, 40(1): 1–30. DOI: 10.1016/0956-7151(92)90195-K. [106] REED R C. The superalloys: fundamentals and applications [M]. Cambridge: Cambridge University Press, 2006. DOI: 10.1017/CBO9780511541285. [107] WANG J J, WANG R F, MENG W H, et al. Double-humped temperature dependence of plastic behaviour of K403 superalloy and its constitutive model [J]. Materials at High Temperatures, 2022, 39(1): 55–67. DOI: 10.1080/09603409.2021.2007009. [108] GILLES G, HAMMAMI W, LIBERTIAUX V, et al. Experimental characterization and elasto-plastic modeling of the quasi-static mechanical response of TA-6 V at room temperature [J]. International Journal of Solids and Structures, 2011, 48(9): 1277–1289. DOI: 10.1016/j.ijsolstr.2011.01.011. [109] KHAN A S, YU S J. Deformation induced anisotropic responses of Ti-6Al-4V alloy. Part Ⅰ: experiments [J]. International Journal of Plasticity, 2012, 38: 1–13. DOI: 10.1016/j.ijplas.2012.03.015. [110] LI P H, GUO W G, YUAN K B, et al. Effects of processing defects on the dynamic tensile mechanical behavior of laser-solid-formed Ti-6Al-4 V [J]. Materials Characterization, 2018, 140: 15–29. DOI: 10.1016/j.matchar.2018.03.032. [111] DRUCKER D C, PRAGER W. Soil mechanics and plastic analysis or limit design [J]. Quarterly of Applied Mathematics, 1952, 10(2): 157–165. DOI: 10.1090/qam/48291. [112] BARDET J P. Lode dependences for isotropic pressure-sensitive elastoplastic materials [J]. Journal of Applied Mechanics, 1990, 57(3): 498–506. DOI: 10.1115/1.2897051. [113] RICHMOND O, SPITZIG W A. Pressure dependence and dilatancy of plastic flow [J]. Theoretical and Applied Mechanics, 1980(1): 377–386. [114] GAO X S, ZHANG T T, HAYDEN M, et al. Effects of the stress state on plasticity and ductile failure of an aluminum 5083 alloy [J]. International Journal of Plasticity, 2009, 25(12): 2366–2382. DOI: 10.1016/j.ijplas.2009.03.006. [115] KHAN A S, YU S J, LIU H W. Deformation induced anisotropic responses of Ti-6Al-4V alloy. Part Ⅱ: a strain rate and temperature dependent anisotropic yield criterion [J]. International Journal of Plasticity, 2012, 38: 14–26. DOI: 10.1016/j.ijplas.2012.03.013. [116] TUNINETTI V, GILLES G, MILIS O, et al. Anisotropy and tension-compression asymmetry modeling of the room temperature plastic response of Ti-6Al-4V [J]. International Journal of Plasticity, 2015, 67: 53–68. DOI: 10.1016/j.ijplas.2014.10.003. [117] LOWDEN M A W, HUTCHINSON W B. Texture strengthening and strength differential in titanium-6Al-4V [J]. Metallurgical Transactions A, 1975, 6(3): 441–448. DOI: 10.1007/BF02658401. [118] JONES I P, HUTCHINSON W B. Stress-state dependence of slip in titanium-6Al-4V and other H. C. P. metals [J]. Acta Metallurgica, 1981, 29(6): 951–968. DOI: 10.1016/0001-6160(81)90049-3. [119] PRAKASH D G L, DING R, MOAT R J, et al. Deformation twinning in Ti-6Al-4 V during low strain rate deformation to moderate strains at room temperature [J]. Materials Science and Engineering: A, 2010, 527(21/22): 5734–5744. DOI: 10.1016/j.msea.2010.05.039. [120] AIFANTIS E C. The physics of plastic deformation [J]. International Journal of Plasticity, 1987, 3(3): 211–247. DOI: 10.1016/0749-6419(87)90021-0. [121] BAMMANN D J, AIFANTIS E C. A model for finite-deformation plasticity [J]. Acta Mechanica, 1987, 69(1): 97–117. DOI: 10.1007/BF01175716. [122] KUBIN L P, ESTRIN Y. Evolution of dislocation densities and the critical conditions for the Portevin-Le Chtelier effect [J]. Acta Metallurgica et Materialia, 1990, 38(5): 697–708. DOI: 10.1016/0956-7151(90)90021-8. [123] KOCKS U F, ARGONr A S, ASHBY M F. Thermodynamics and kinetics of slip [J]. Progress in Materials Science, 1975, 19: 141–145. [124] HOGE K G, MUKHERJEE A K. The temperature and strain rate dependence of the flow stress of tantalum [J]. Journal of Materials Science, 1977, 12(8): 1666–1672. DOI: 10.1007/BF00542818. [125] YAN S L, YANG H, LI H W, et al. A unified model for coupling constitutive behavior and micro-defects evolution of aluminum alloys under high-strain-rate deformation [J]. International Journal of Plasticity, 2016, 85: 203–229. DOI: 10.1016/j.ijplas.2016.07.011. [126] GAO C Y, ZHANG L C. Constitutive modelling of plasticity of FCC metals under extremely high strain rates [J]. International Journal of Plasticity, 2012, 32/33: 121–133. DOI: 10.1016/j.ijplas.2011.12.001. [127] GAO C Y, ZHANG L C, YAN H X. A new constitutive model for HCP metals [J]. Materials Science and Engineering: A, 2011, 528(13/14): 4445–4452. DOI: 10.1016/j.msea.2011.02.053. [128] MEYERS M A, VÖHRINGER O, LUBARDA V A. The onset of twinning in metals: a constitutive description [J]. Acta Materialia, 2001, 49(19): 4025–4039. DOI: 10.1016/S1359-6454(01)00300-7. [129] LU L, DAO M, ZHU T, et al. Size dependence of rate-controlling deformation mechanisms in nanotwinned copper [J]. Scripta Materialia, 2009, 60(12): 1062–1066. DOI: 10.1016/j.scriptamat.2008.12.039. -

下载:

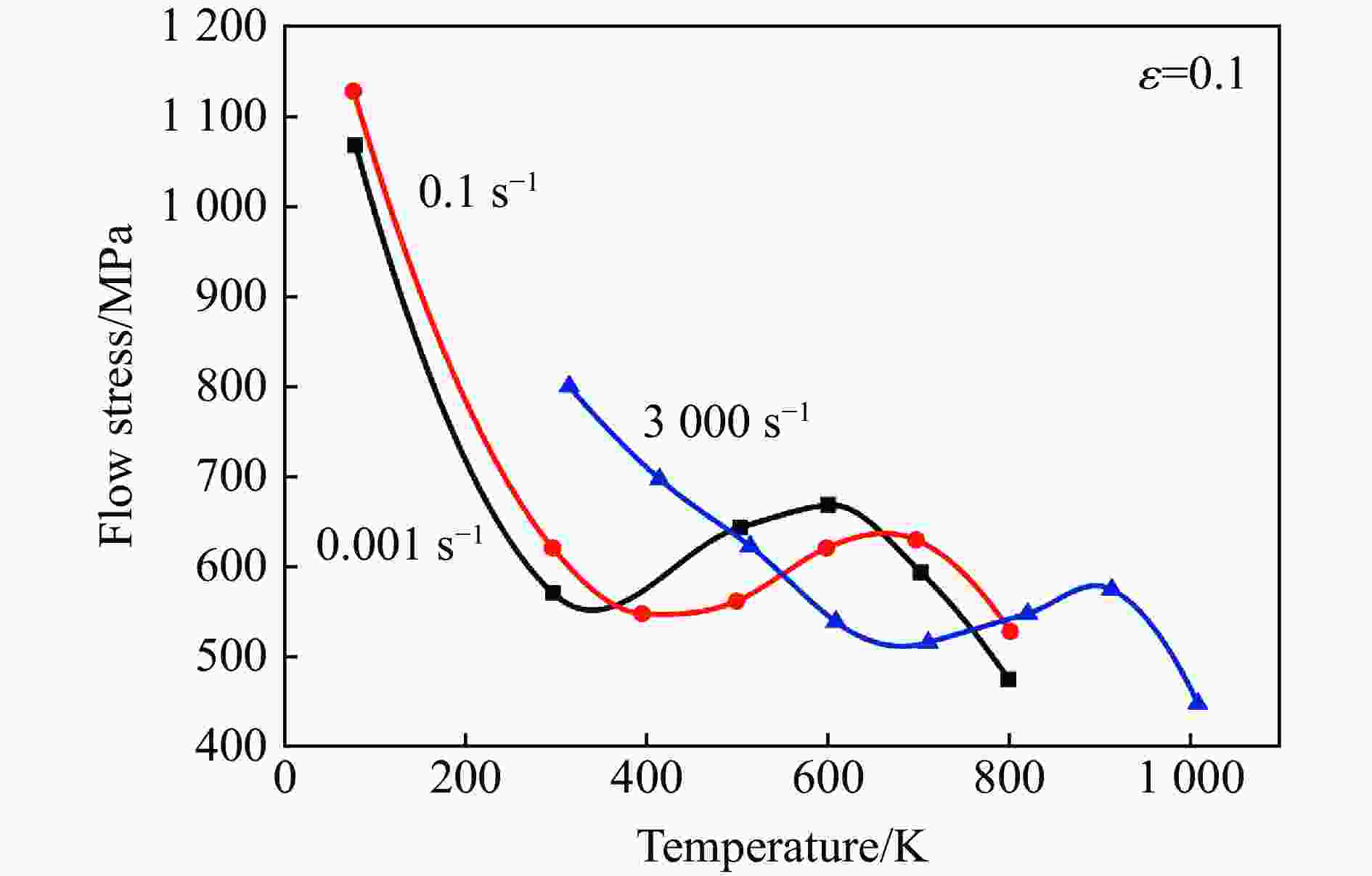

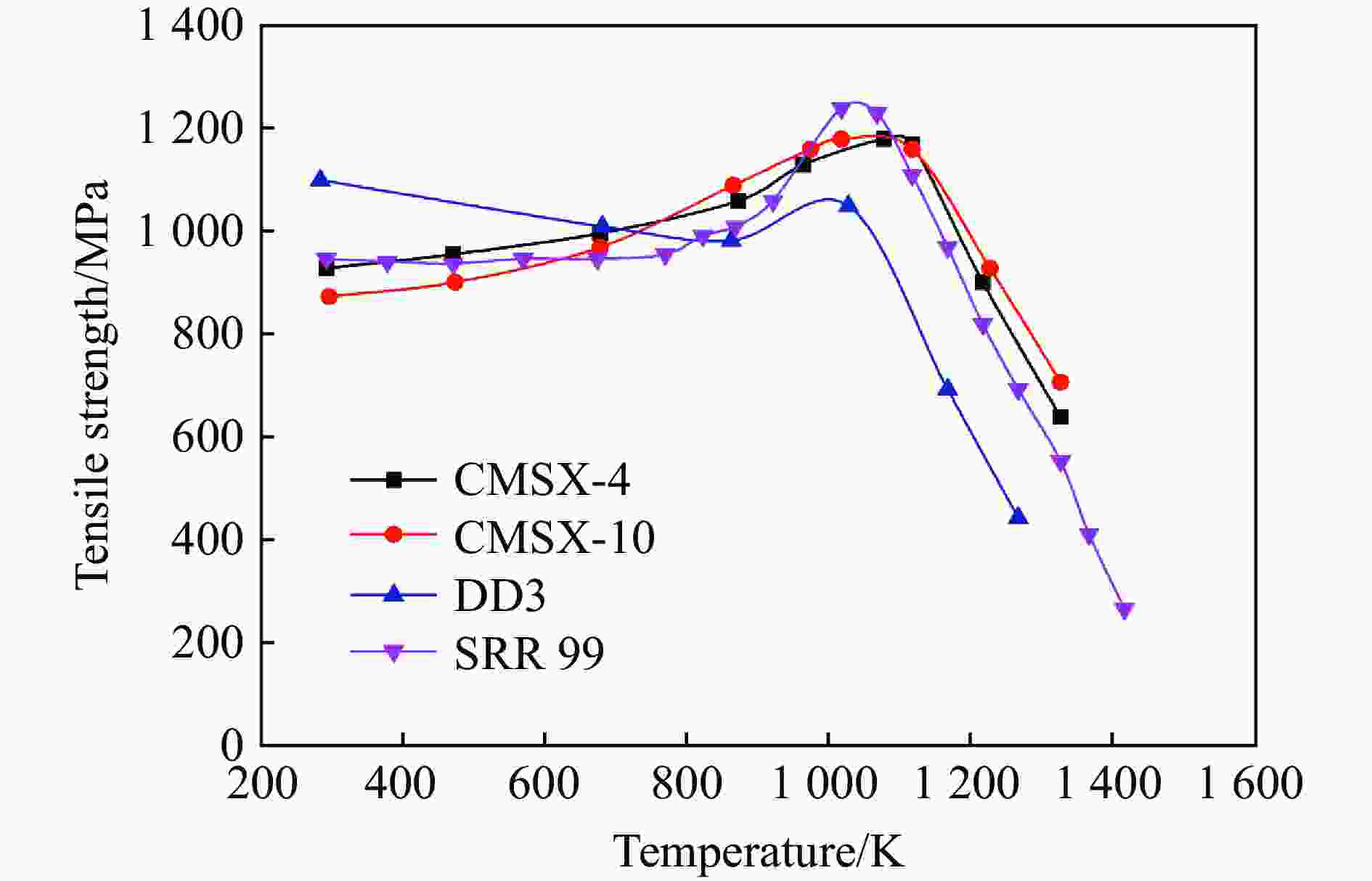

下载: