| [1] |

BIL C, MASSEY K, ABDULLAH E J. Wing morphing control with shape memory alloy actuators [J]. Journal of Intelligent Material Systems and Structures, 2013, 24(7): 879–898. DOI: 10.1177/1045389X12471866.

|

| [2] |

HARTL D J, LAGOUDAS D C. Aerospace applications of shape memory alloys [J]. Proceedings of the Institution of Mechanical Engineers: Journal of Aerospace Engineering, 2007, 221(4): 535–552. DOI: 10.1243/09544100JAERO211.

|

| [3] |

KAHN H, HUFF M A, HEUER A H. The TiNi shape-memory alloy and its applications for MEMS [J]. Journal of Micromechanics and Microengineering, 1998, 8(3): 213–221. DOI: 10.1088/0960-1317/8/3/007.

|

| [4] |

PETRINI L, MIGLIAVACCA F. Biomedical applications of shape memory alloys [J]. Journal of Metallurgy, 2011, 2011: 501483. DOI: 10.1155/2011/501483.

|

| [5] |

MACHADO L G, SAVI M A. Medical applications of shape memory alloys [J]. Brazilian Journal of Medical and Biological Research, 2003, 36(6): 683–691. DOI: 10.1590/s0100-879x2003000600001.

|

| [6] |

STOECKEL D, YU W. Superelastic Ni-Ti wire [J]. Wire Journal International, 1991, 24(3): 45–50.

|

| [7] |

CHEN W W, WU Q P, KANG J H, et al. Compressive superelastic behavior of a NiTi shape memory alloy at strain rates of 0.001–750 s−1 [J]. International Journal of Solids and Structures, 2001, 38(50/51): 8989–8998. DOI: 10.1016/S0020-7683(01)00165-2.

|

| [8] |

DAYANANDA G N, RAO M S. Effect of strain rate on properties of superelastic NiTi thin wires [J]. Materials Science and Engineering: A, 2008, 486(1/2): 96–103. DOI: 10.1016/j.msea.2007.09.006.

|

| [9] |

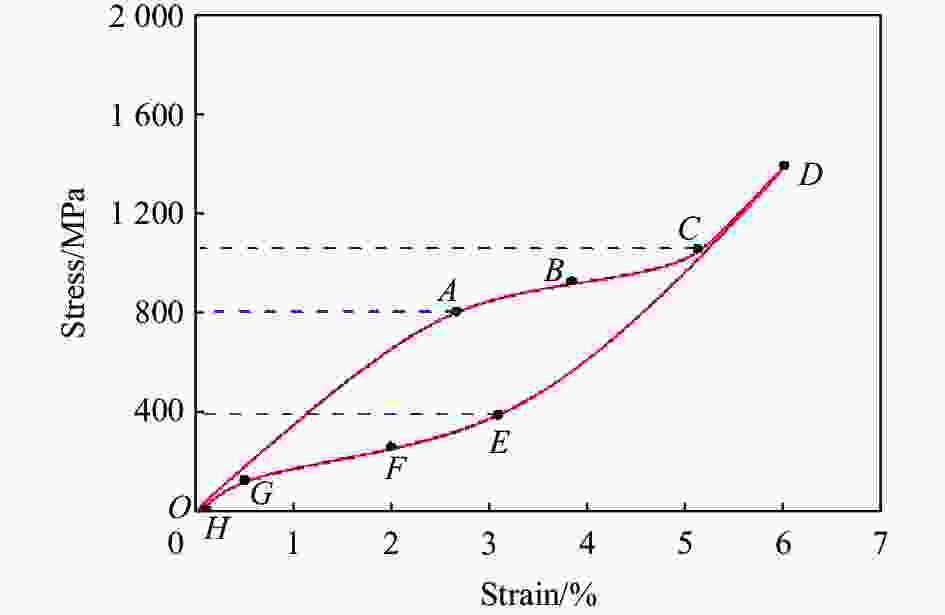

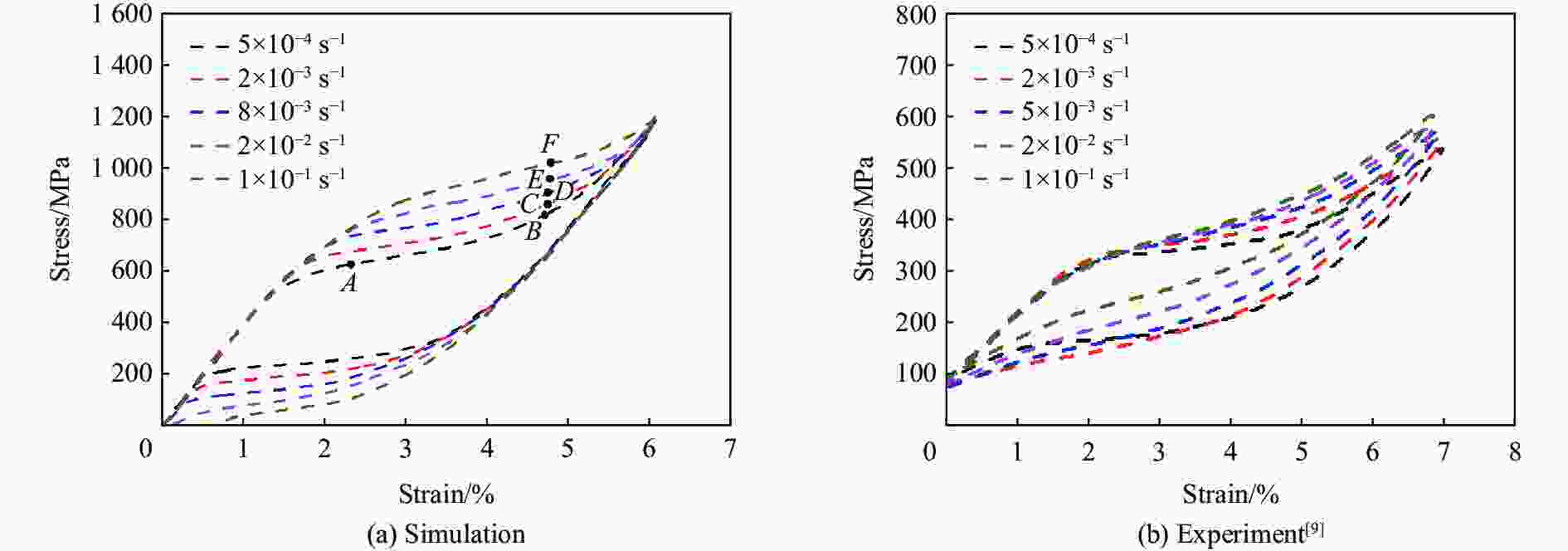

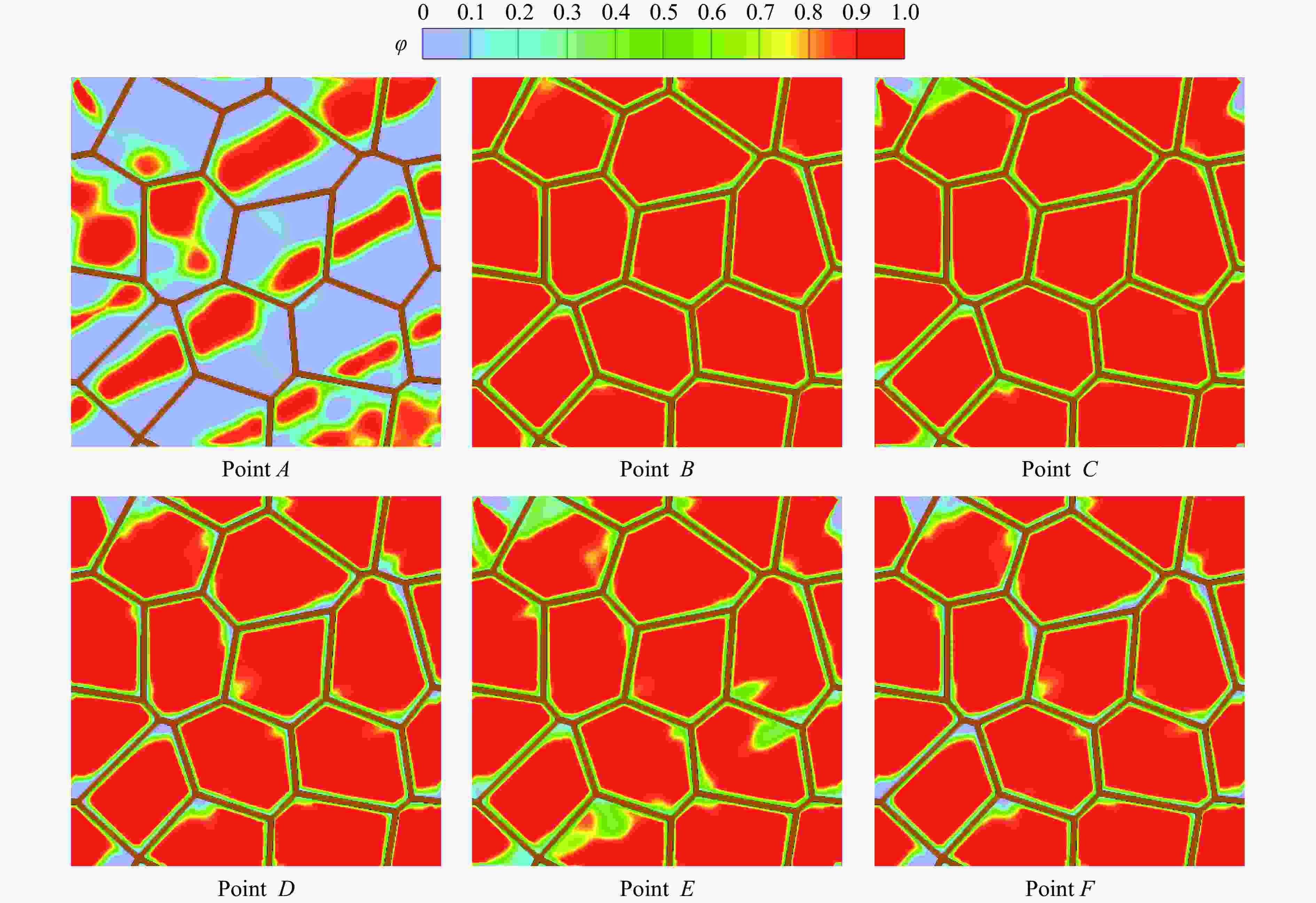

AHADI A, SUN Q P. Effects of grain size on the rate-dependent thermomechanical responses of nanostructured superelastic NiTi [J]. Acta Materialia, 2014, 76: 186–197. DOI: 10.1016/j.actamat.2014.05.007.

|

| [10] |

KIM S, CHO M. A strain rate effect of Ni-Ti shape memory alloy wire [J]. Japanese Journal of Applied Physics, 2010, 49(11R): 115801. DOI: 10.1143/JJAP.49.115801.

|

| [11] |

王礼立. 高应变率下材料动态力学性能 [J]. 力学与实践, 1982, 4(1): 9–19, 26. DOI: 10.6052/1000-0879-1982-002.WANG L L. Dynamic mechanical properties of materials at high strain rates [J]. Mechanics in Engineering, 1982, 4(1): 9–19, 26. DOI: 10.6052/1000-0879-1982-002.

|

| [12] |

YANG Z L, WANG H, HUANG Y L, et al. Strain rate dependent mechanical response for monoclinic NiTi shape memory alloy: micromechanical decomposition and model validation via neutron diffraction [J]. Materials & Design, 2020, 191: 108656. DOI: 10.1016/j.matdes.2020.108656.

|

| [13] |

LIU S, LIN Y, HAN L Y, et al. Atomistic simulation of microstructure evolution of NiTi single crystals in bending deformation [J]. Computational Materials Science, 2021, 199: 110733. DOI: 10.1016/j.commatsci.2021.110733.

|

| [14] |

SUN Y Z, LUO J, ZHU J M. Phase field study of the microstructure evolution and thermomechanical properties of polycrystalline shape memory alloys: grain size effect and rate effect [J]. Computational Materials Science, 2018, 145: 252–262. DOI: 10.1016/j.commatsci.2018.01.014.

|

| [15] |

NEMAT-NASSER S, CHOI J Y, GUO W G, et al. High strain-rate, small strain response of a NiTi shape-memory alloy [J]. Journal of Engineering Materials and Technology, 2005, 127(1): 83–89. DOI: 10.1115/1.1839215.

|

| [16] |

JIANG D J, XIAO Y. Modelling on grain size dependent thermomechanical response of superelastic NiTi shape memory alloy [J]. International Journal of Solids and Structures, 2021, 210/211: 170–182. DOI: 10.1016/j.ijsolstr.2020.11.036.

|

| [17] |

AHLUWALIA R, QUEK S S, WU D T. Simulation of grain size effects in nanocrystalline shape memory alloys [J]. Journal of Applied Physics, 2015, 117(24): 244305. DOI: 10.1063/1.4923044.

|

| [18] |

XU B, KANG G Z, KAN Q H, et al. Phase field simulation on the cyclic degeneration of one-way shape memory effect of NiTi shape memory alloy single crystal [J]. International Journal of Mechanical Sciences, 2020, 168: 105303. DOI: 10.1016/j.ijmecsci.2019.105303.

|

| [19] |

CISSÉ C, ZAEEM M A. A phase-field model for non-isothermal phase transformation and plasticity in polycrystalline yttria-stabilized tetragonal zirconia [J]. Acta Materialia, 2020, 191: 111–123. DOI: 10.1016/j.actamat.2020.03.025.

|

| [20] |

ARTEMEV A, JIN Y, KHACHATURYAN A G. Three-dimensional phase field model of proper martensitic transformation [J]. Acta Materialia, 2001, 49(7): 1165–1177. DOI: 10.1016/S1359-6454(01)00021-0.

|

| [21] |

WANG Y U, JIN Y M, KHACHATURYAN A G. The effects of free surfaces on martensite microstructures: 3D phase field microelasticity simulation study [J]. Acta Materialia, 2004, 52(4): 1039–1050. DOI: 10.1016/j.actamat.2003.10.037.

|

| [22] |

ZHONG Y, ZHU T. Phase-field modeling of martensitic microstructure in NiTi shape memory alloys [J]. Acta Materialia, 2014, 75: 337–347. DOI: 10.1016/j.actamat.2014.04.013.

|

| [23] |

YEDDU H K, MALIK A, ÅGREN J, et al. Three-dimensional phase-field modeling of martensitic microstructure evolution in steels [J]. Acta Materialia, 2012, 60(4): 1538–1547. DOI: 10.1016/j.actamat.2011.11.039.

|

| [24] |

CUI S S, WAN J F, RONG Y H, et al. Phase-field simulations of thermomechanical behavior of MnNi shape memory alloys using finite element method [J]. Computational Materials Science, 2017, 139: 285–294. DOI: 10.1016/j.commatsci.2017.08.010.

|

| [25] |

CUI S S, WAN J F, ZUO X W, et al. Three-dimensional, non-isothermal phase-field modeling of thermally and stress-induced martensitic transformations in shape memory alloys [J]. International Journal of Solids and Structures, 2017, 109: 1–11. DOI: 10.1016/j.ijsolstr.2017.01.001.

|

| [26] |

MALIK A, YEDDU H K, AMBERG G, et al. Three dimensional elasto-plastic phase field simulation of martensitic transformation in polycrystal [J]. Materials Science and Engineering: A, 2012, 556: 221–232. DOI: 10.1016/j.msea.2012.06.080.

|

| [27] |

MIKULA J, QUEK S S, JOSHI S P, et al. The role of bimodal grain size distribution in nanocrystalline shape memory alloys [J]. Smart Materials and Structures, 2018, 27(10): 105004. DOI: 10.1088/1361-665X/aada30.

|

| [28] |

ZHANG W, JIN Y M, KHACHATURYAN A G. Phase field microelasticity modeling of heterogeneous nucleation and growth in martensitic alloys [J]. Acta Materialia, 2007, 55(2): 565–574. DOI: 10.1016/j.actamat.2006.08.050.

|

| [29] |

ZHU J M, LUO J, SUN Y Z. Phase field study of the grain size and temperature dependent mechanical responses of tetragonal zirconia polycrystals: a discussion of tension-compression asymmetry [J]. Computational Materials Science, 2020, 172: 109326. DOI: 10.1016/j.commatsci.2019.109326.

|

| [30] |

HEO T W, CHEN L Q. Phase-field modeling of displacive phase transformations in elastically anisotropic and inhomogeneous polycrystals [J]. Acta Materialia, 2014, 76: 68–81. DOI: 10.1016/j.actamat.2014.05.014.

|

| [31] |

CHEN L Q, WANG Y Z. The continuum field approach to modeling microstructural evolution [J]. JOM, 1996, 48(12): 13–18. DOI: 10.1007/BF03223259.

|

| [32] |

JIN Y M, ARTEMEV A, KHACHATURYAN A G. Three-dimensional phase field model of low-symmetry martensitic transformation in polycrystal: simulation of ζ′2 martensite in AuCd alloys [J]. Acta Materialia, 2001, 49(12): 2309–2320. DOI: 10.1016/S1359-6454(01)00108-2.

|

| [33] |

YAMANAKA A, TAKAKI T, TOMITA Y. Elastoplastic phase-field simulation of martensitic transformation with plastic deformation in polycrystal [J]. International Journal of Mechanical Sciences, 2010, 52(2): 245–250. DOI: 10.1016/j.ijmecsci.2009.09.020.

|

| [34] |

MAMIVAND M, ZAEEM M A, EL KADIRI H. Shape memory effect and pseudoelasticity behavior in tetragonal zirconia polycrystals: a phase field study [J]. International Journal of Plasticity, 2014, 60: 71–86. DOI: 10.1016/j.ijplas.2014.03.018.

|

| [35] |

THAMBURAJA P, ANAND L. Polycrystalline shape-memory materials: effect of crystallographic texture [J]. Journal of the Mechanics and Physics of Solids, 2001, 49(4): 709–737. DOI: 10.1016/S0022-5096(00)00061-2.

|

| [36] |

HATCHER N, KONTSEVOI O Y, FREEMAN A J. Role of elastic and shear stabilities in the martensitic transformation path of NiTi [J]. Physical Review B, 2009, 80(14): 144203. DOI: 10.1103/PhysRevB.80.144203.

|

| [37] |

XIE X, KANG G Z, KAN Q H, et al. Phase field modeling for cyclic phase transition of NiTi shape memory alloy single crystal with super-elasticity [J]. Computational Materials Science, 2018, 143: 212–224. DOI: 10.1016/j.commatsci.2017.11.017.

|

| [38] |

XI S B, SU Y. Phase field study of the microstructural dynamic evolution and mechanical response of NiTi shape memory alloy under mechanical loading [J]. Materials, 2021, 14(1): 183. DOI: 10.3390/MA14010183.

|

| [39] |

LIU Y, LI Y L, RAMESH K T, et al. High strain rate deformation of martensitic NiTi shape memory alloy [J]. Scripta Materialia, 1999, 41(1): 89–95. DOI: 10.1016/S1359-6462(99)00058-5.

|

| [40] |

ELIBOL C, WAGNER M F X. Strain rate effects on the localization of the stress-induced martensitic transformation in pseudoelastic NiTi under uniaxial tension, compression and compression-shear [J]. Materials Science and Engineering: A, 2015, 643: 194–202. DOI: 10.1016/j.msea.2015.07.039.

|

| [41] |

XIAO Y, ZENG P, LEI L P, et al. Experimental investigation on rate dependence of thermomechanical response in superelastic NiTi shape memory alloy [J]. Journal of Materials Engineering and Performance, 2015, 24(10): 3755–3760. DOI: 10.1007/s11665-015-1688-6.

|

下载:

下载: