| [1] |

田勇, 李敬明. 弹药安全的新发展:安全弹药刍议 [J]. 含能材料, 2017, 25(2): 91–93. DOI: 10.11943/j.issn.1006-9941.2017.02.00X.TIAN Y, LI J M. New development of ammunition safety: Robust munition [J]. Chinese Journal of Energetic Materials, 2017, 25(2): 91–93. DOI: 10.11943/j.issn.1006-9941.2017.02.00X.

|

| [2] |

董海山. 钝感弹药的由来及重要意义 [J]. 含能材材, 2006, 14(5): 321–322. DOI: 10.3969/j.issn.1006-9941.2006.05.001.DONG H S. The importance of the insensitive munitions [J]. Chinese Journal of Energetic Materials, 2006, 14(5): 321–322. DOI: 10.3969/j.issn.1006-9941.2006.05.001.

|

| [3] |

李军, 焦清介, 庞爱民, 等. 固体发动机低易损性评估研究进展 [J]. 固体火箭技术, 2019, 42(1): 1–6. DOI: 10.7673/j.issn.1006-2793.2019.01.001.LI J, JIAO Q J, PANG A M, et al. Recent progress on evaluation of low-vulnerability properties for solid rocket motor [J]. Journal of Solid Rocket Technology, 2019, 42(1): 1–6. DOI: 10.7673/j.issn.1006-2793.2019.01.001.

|

| [4] |

YE Q, YU Y G. Numerical simulation of cook-off characteristics for AP/HTPB [J]. Defence Technology, 2018, 14: 451–456. DOI: 10.3969/j.issn.2214-9147.2018.05.017.

|

| [5] |

YE Q, YU Y G. Study on cook-off behavior of HTPE propellant in solid rocket motor [J]. Applied Thermal Engineering, 2019, 167(8): 114798. DOI: 10.1016/j.applthermaleng.2019.114798.

|

| [6] |

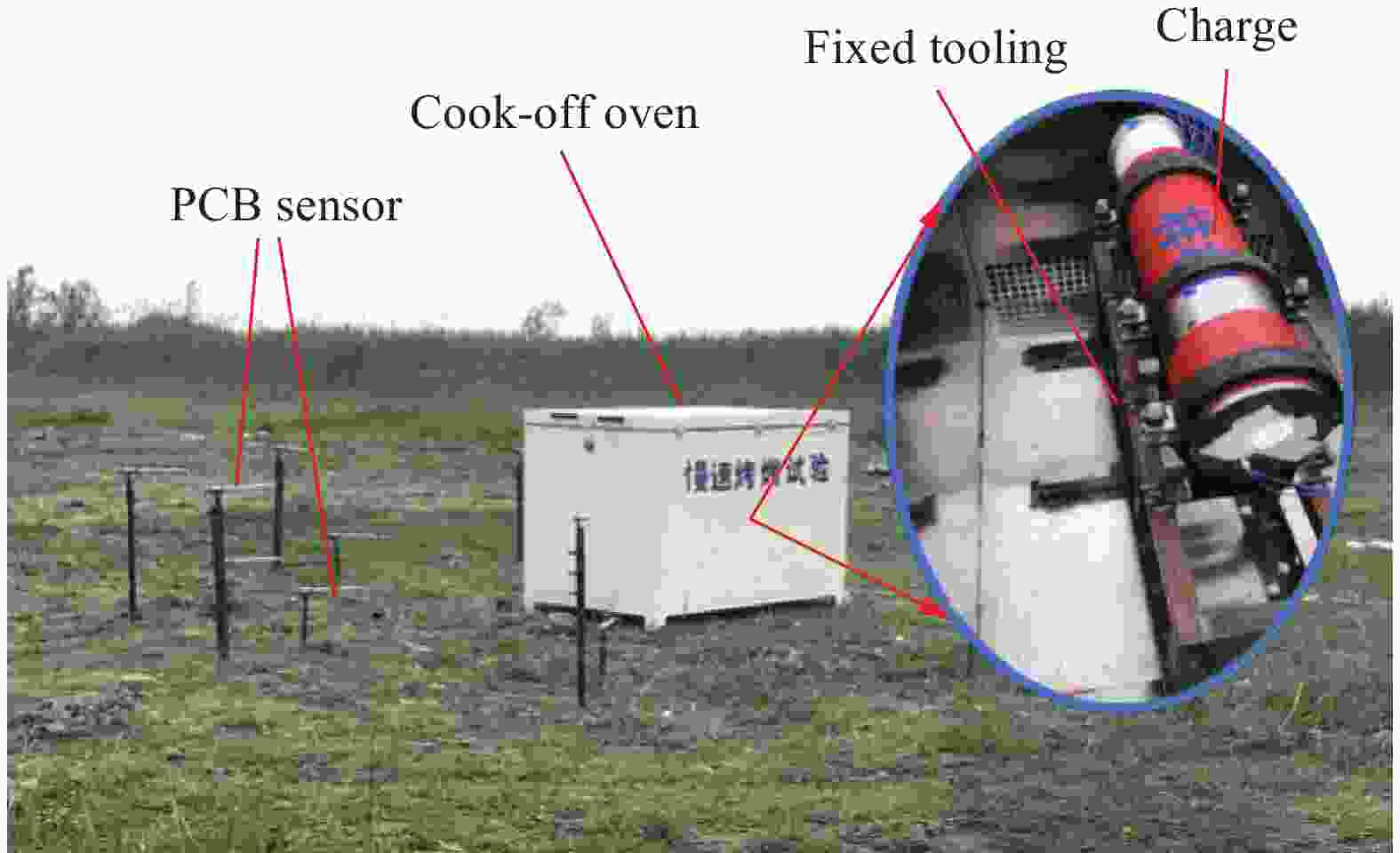

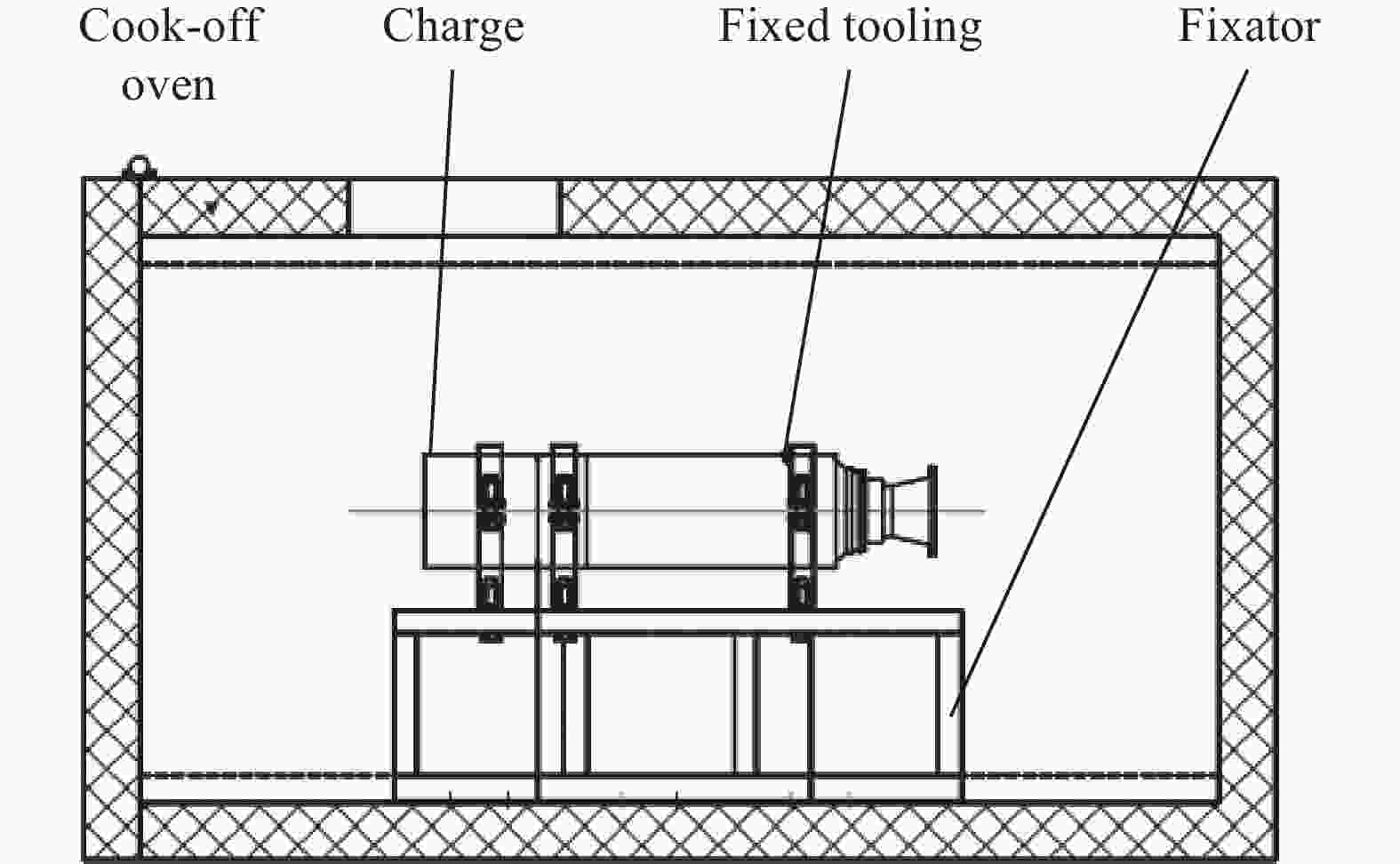

戴湘晖, 段建, 沈子楷, 等. 侵彻弹体慢速烤燃响应特性实验研究 [J]. 兵工学报, 2020, 41(2): 291–297. DOI: 10.3969/j.issn.1000-1093.2020.02.010.DAI X H, DUAN J, SHEN Z K, et al. Experiment of slow cook-off response characteristics of penetrator. [J]. Acta Armamentarii, 2020, 41(2): 291–297. DOI: 10.3969/j.issn.1000-1093.2020.02.010.

|

| [7] |

DENG H, SHEN F, LIANG Z F, et al. Numerical simulation and experimental study on slow cook-off response characteristics of composite B [J]. Journal of Physics Conference Series, 2020, 1507: 022014. DOI: 10.1016/j.dt.2020.08.001.

|

| [8] |

陈中娥, 唐承志, 赵孝彬. HTPB/AP推进剂的慢速烤燃特征 [J]. 含能材料, 2006, 14(2): 155–157. DOI: 10.3969/j.issn.1006-9941.2006.02.024.CHEN Z E, TANG C Z, ZHAO X B. Characteristics of HTPB/AP propellants in slow cook-off [J]. Chinese Journal of Energetic Materials, 2006, 14(2): 155–157. DOI: 10.3969/j.issn.1006-9941.2006.02.024.

|

| [9] |

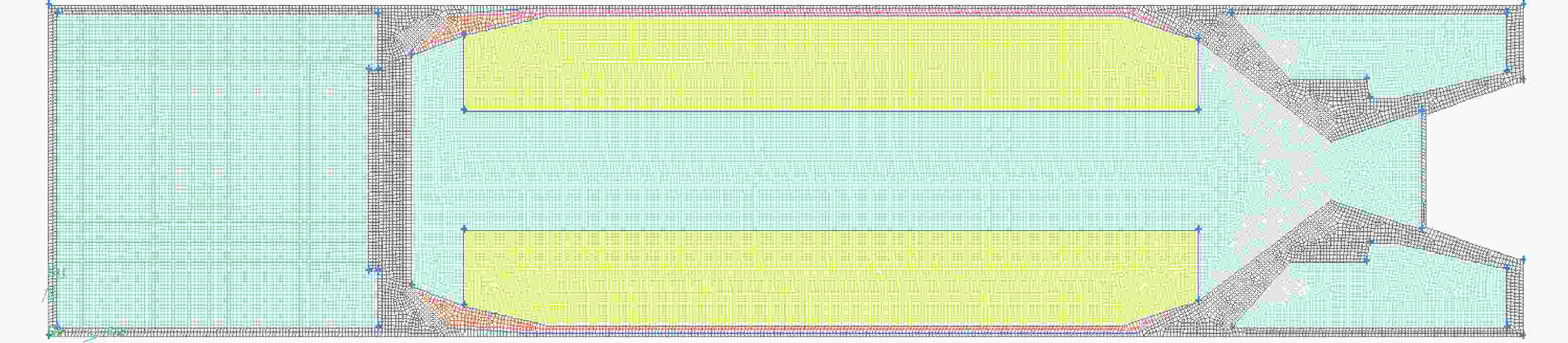

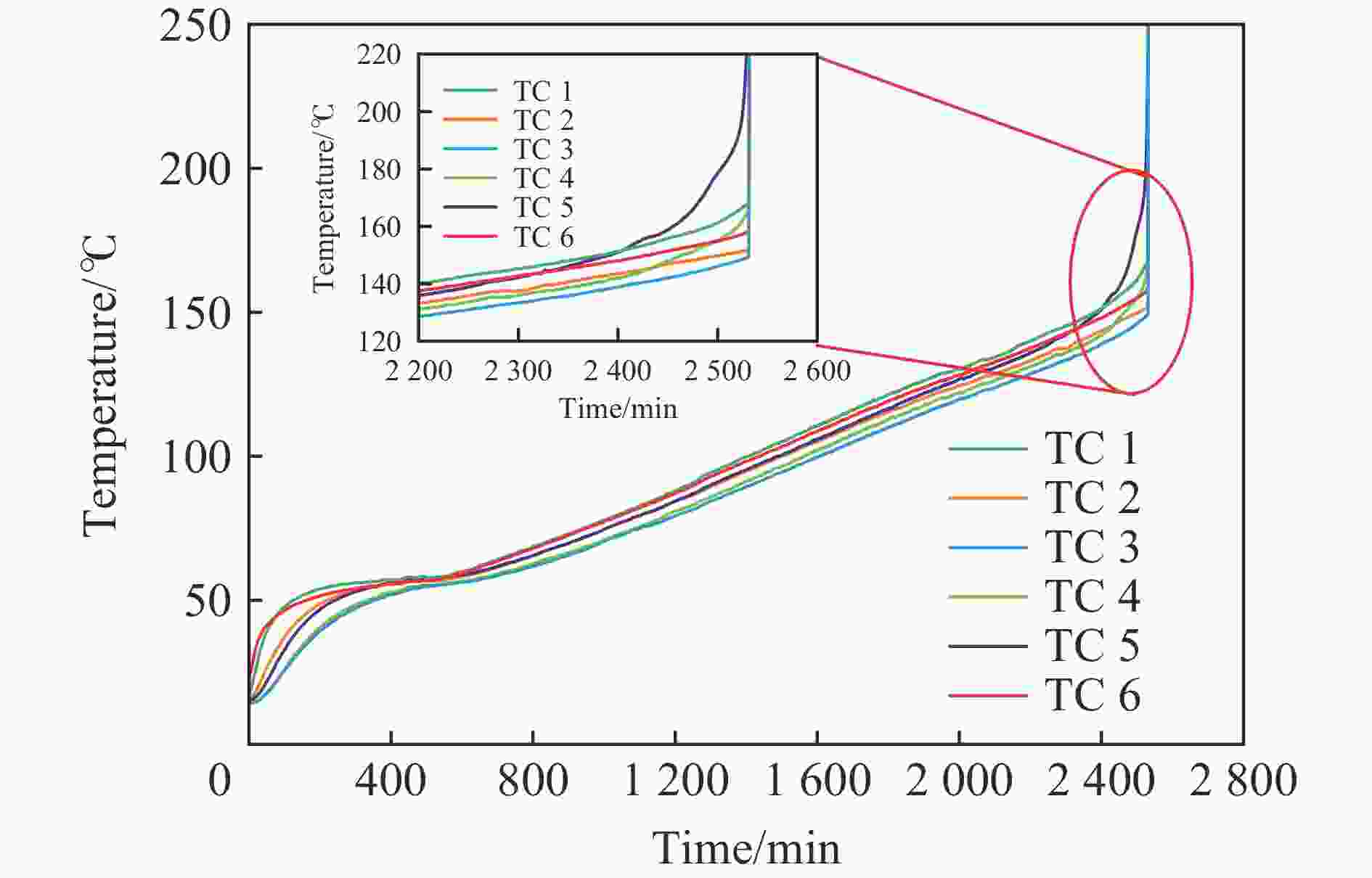

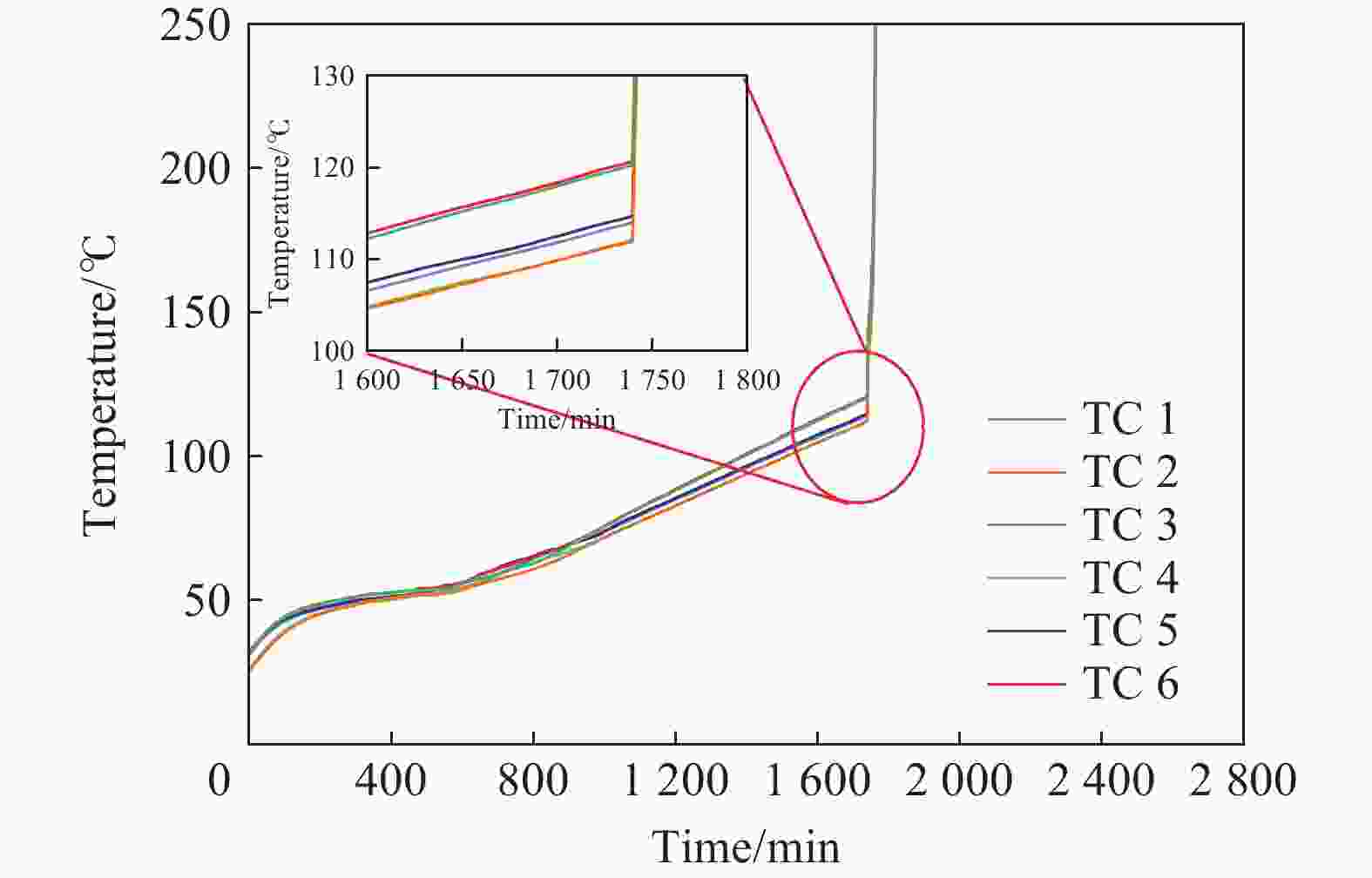

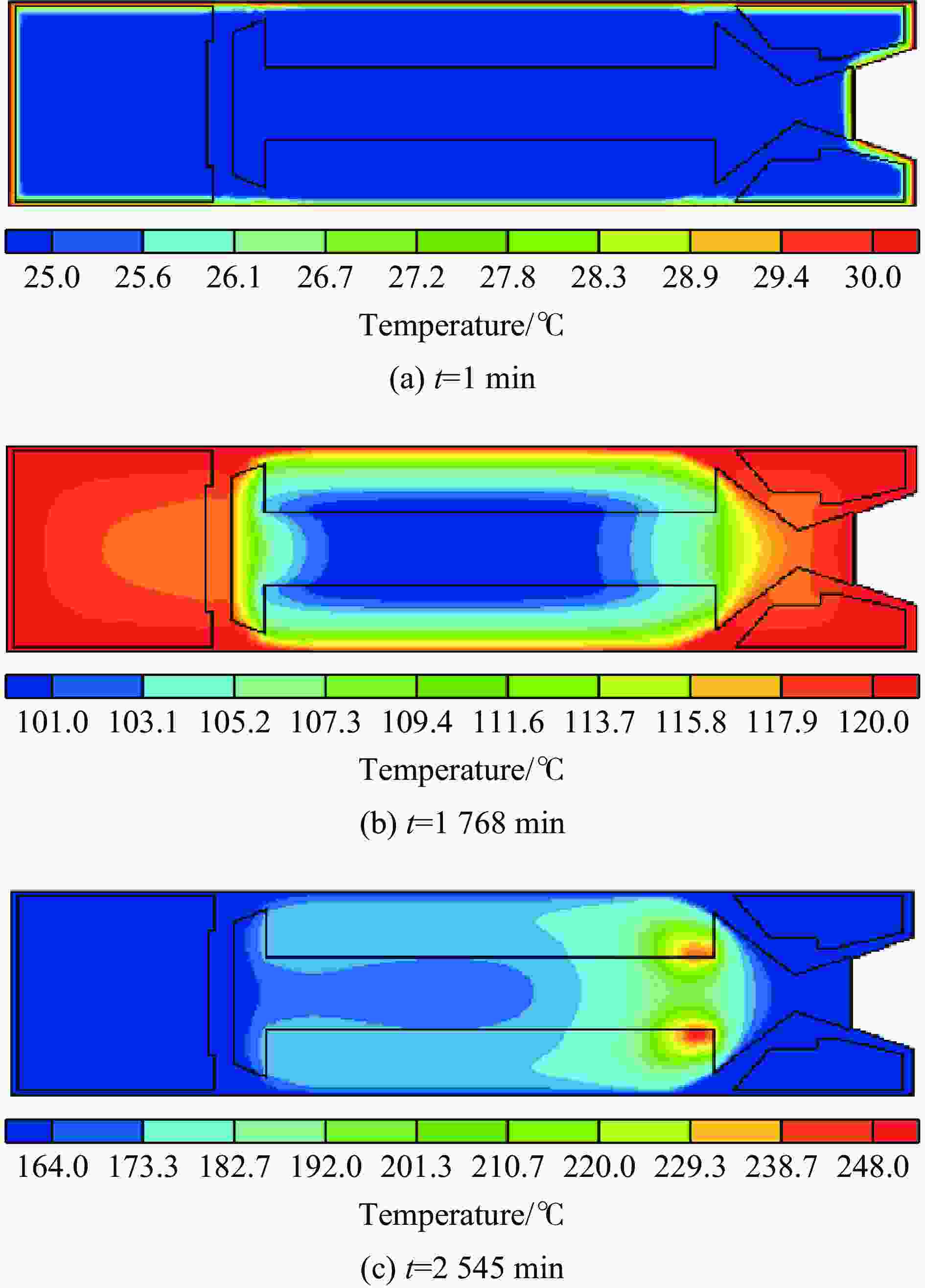

KOU Y, CHEN L, LU J, et al. Assessing the thermal safety of solid propellant charges based on slow cook-off tests and numerical simulations [J]. Combustion and Flame, 2021, 228: 154–162. DOI: 10.1016/j.combustflame.2021.01.043.

|

| [10] |

KLAUS M, SIEGFRIED E, MANFRED B. Fast burning minmum smoke propellant based on AP/CL20/GAP[C]// Bordeaux: Insensitive Munitions & Energetic Materials Technology Symposium, 2001.

|

| [11] |

冯晓军, 王晓峰, 韩助龙. 炸药装药尺寸对慢速烤燃响应的研究 [J]. 爆炸与冲击, 2005, 25(3): 285–288.FENG X J, WANG X F, HAN Z L. The study of charging size influence on the response of explosives in slow cook-off test [J]. Explosion and Shock Waves, 2005, 25(3): 285–288.

|

| [12] |

陈朗, 马欣, 黄毅民, 等. 炸药多点测温烤燃实验和数值模拟 [J]. 兵工学报, 2011, 32(10): 1230–1236.CHEN L, MA X, HUANG Y M, et al. Multipoint temperature measuring cook-off test and numerical simulation of explosive [J]. Acta Armamentarii, 2011, 32(10): 1230–1236.

|

| [13] |

周捷, 智小琦, 王帅, 等. B炸药慢速烤燃过程的流变特性 [J]. 爆炸与冲击, 2020, 40(5): 052301. DOI: 10.11883/bzycj-2019-0321.ZHOU J, ZHI X Q, WANG S, et al. Rheological properties of composition B in slow cook-off process [J]. Explosion and Shock Waves, 2020, 40(5): 052301. DOI: 10.11883/bzycj-2019-0321.

|

| [14] |

朱道理, 周霖, 张向荣, 等. DNAN及TNT基熔铸炸药综合性能比较 [J]. 含能材料, 2019, 27(11): 923–930. DOI: 10.11943/CJEM2019170.ZHU D L, ZHOU L, ZHOU X R, et al. Comparison of comprehensive properties for DNAN and TNT-based melt-cast explosives [J]. Chinese Journal of Energetic Materials, 2019, 27(11): 923–930. DOI: 10.11943/CJEM2019170.

|

| [15] |

HO S Y, FERSCHL T, FOUREUR J. Ccorrelation of cook-off behaviour of rocket propellants with thermal mechanical and thermochemical properties: A274983[R]. MRL Technical Report.

|

| [16] |

李文凤. AP/HTPB底排药烤燃特性的实验研究和数值模拟[D]. 南京: 南京理工大学, 2018.

|

| [17] |

宋柳芳, 李尚文, 王拯, 等. HTPE推进剂烤燃试验尺寸效应及数值模拟 [J]. 含能材料, 2019, 27(9): 735–742. DOI: 10.11943/CJEM2019003.SONG L F, LI S W, WANG Z, et al. Size effect and numerical simulation of cook-off tests for HTPE propellant [J]. Chinese Journal of Energetic Materials, 2019, 27(9): 735–742. DOI: 10.11943/CJEM2019003.

|

| [18] |

Hazard assessment tests for nonnuclear munitions: MIL-STD-2105D [S]. USA: Department of Defense Test Method Standard, 2011.

|

| [19] |

谭惠民. 固体推进剂化学与技术[M]. 北京: 北京理工大学出版社, 2015: 73–75.

|

| [20] |

张海军, 聂建新, 王领等. 端羟基聚醚推进剂慢速烤燃尺寸效应 [J]. 兵工学报, 2021, 42(9): 1858–1866. DOI: 10.3969/j.issn.1000-1093.2021.09.006.ZHANG H J, NIE J X, WANG L, et al. Numerical dimulation on dize effect of hydroxyl terminated polyether propellant engine during slow cook-off [J]. Acta Armamentarii, 2021, 42(9): 1858–1866. DOI: 10.3969/j.issn.1000-1093.2021.09.006.

|

下载:

下载: