Crashworthiness analysis and optimization on bio-inspired multi-cell thin-walled tubes

-

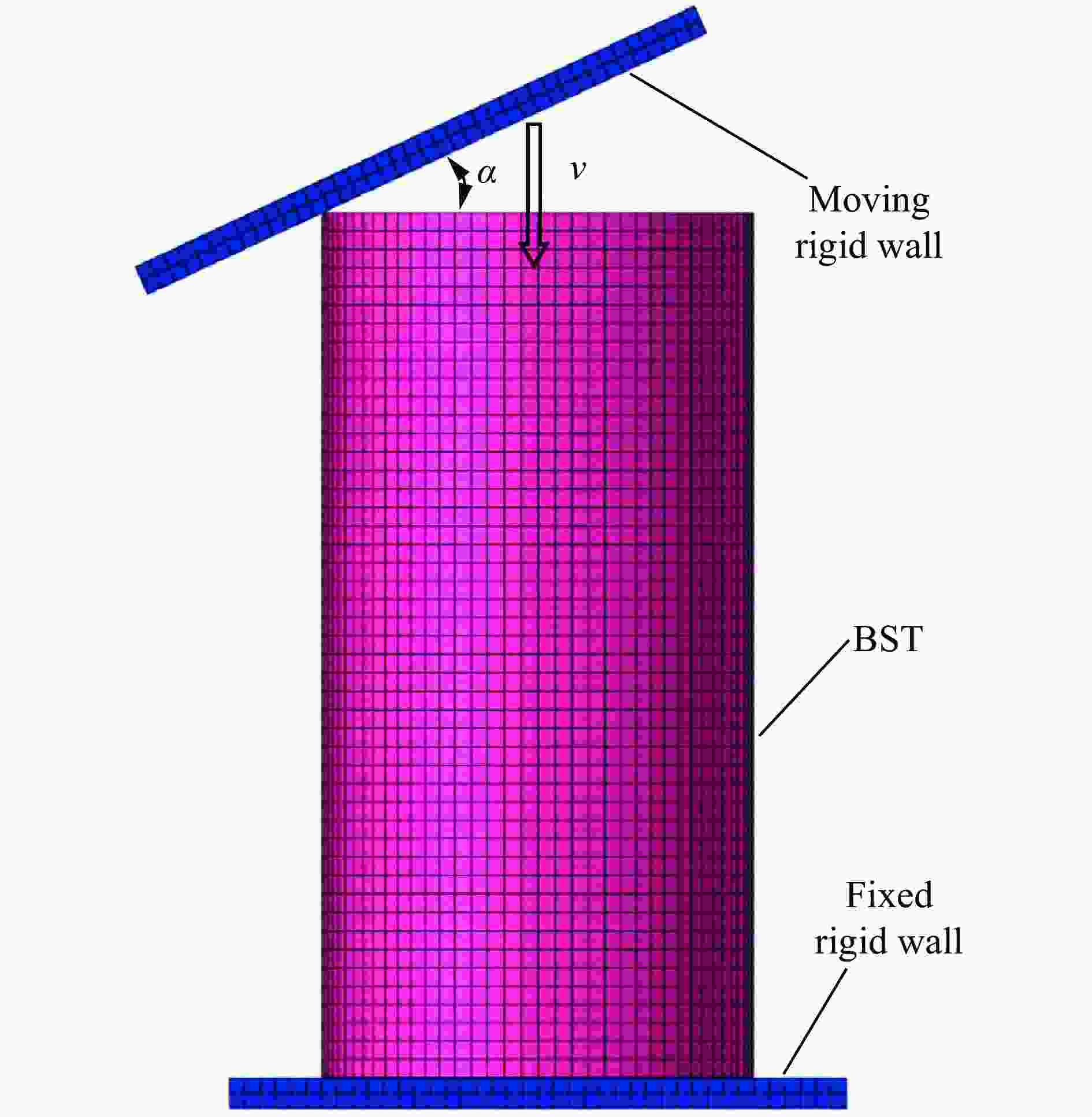

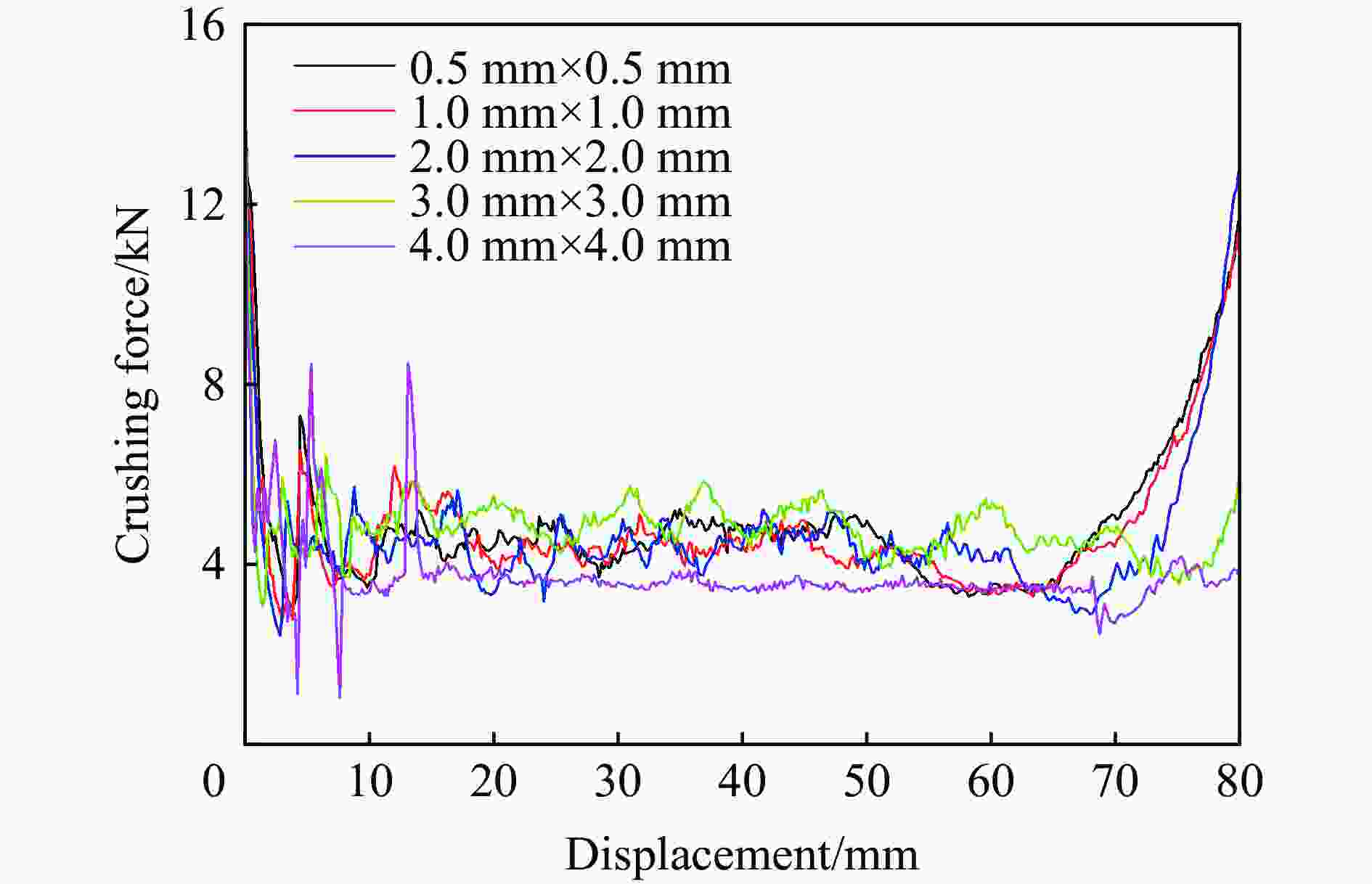

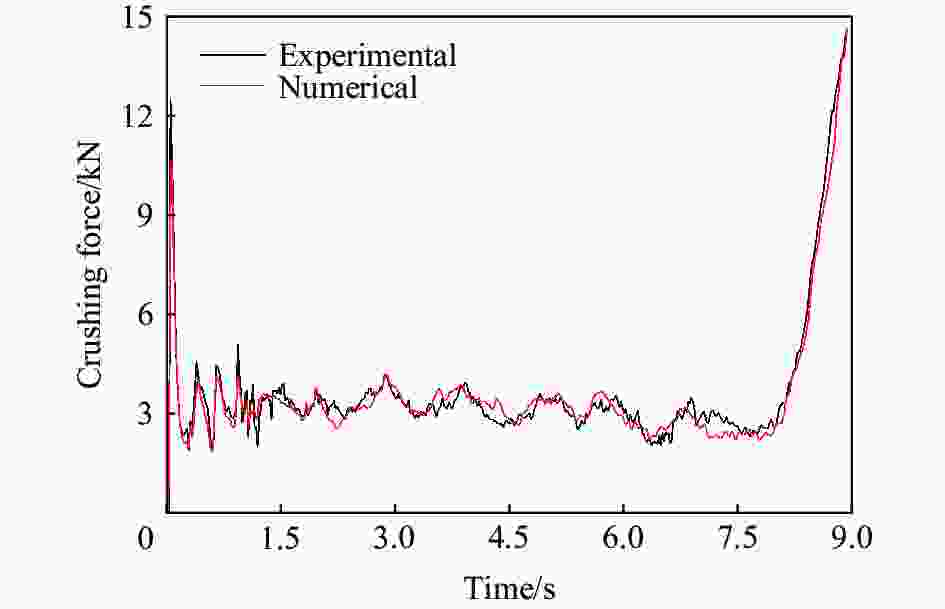

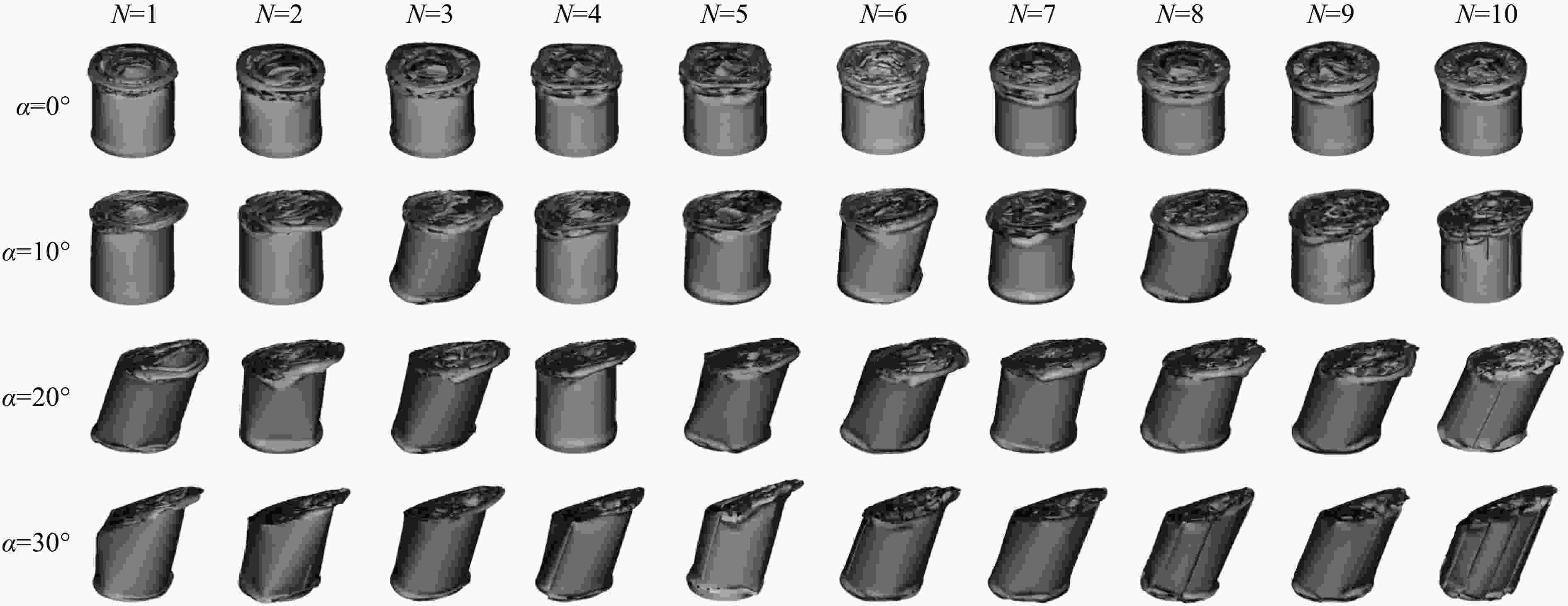

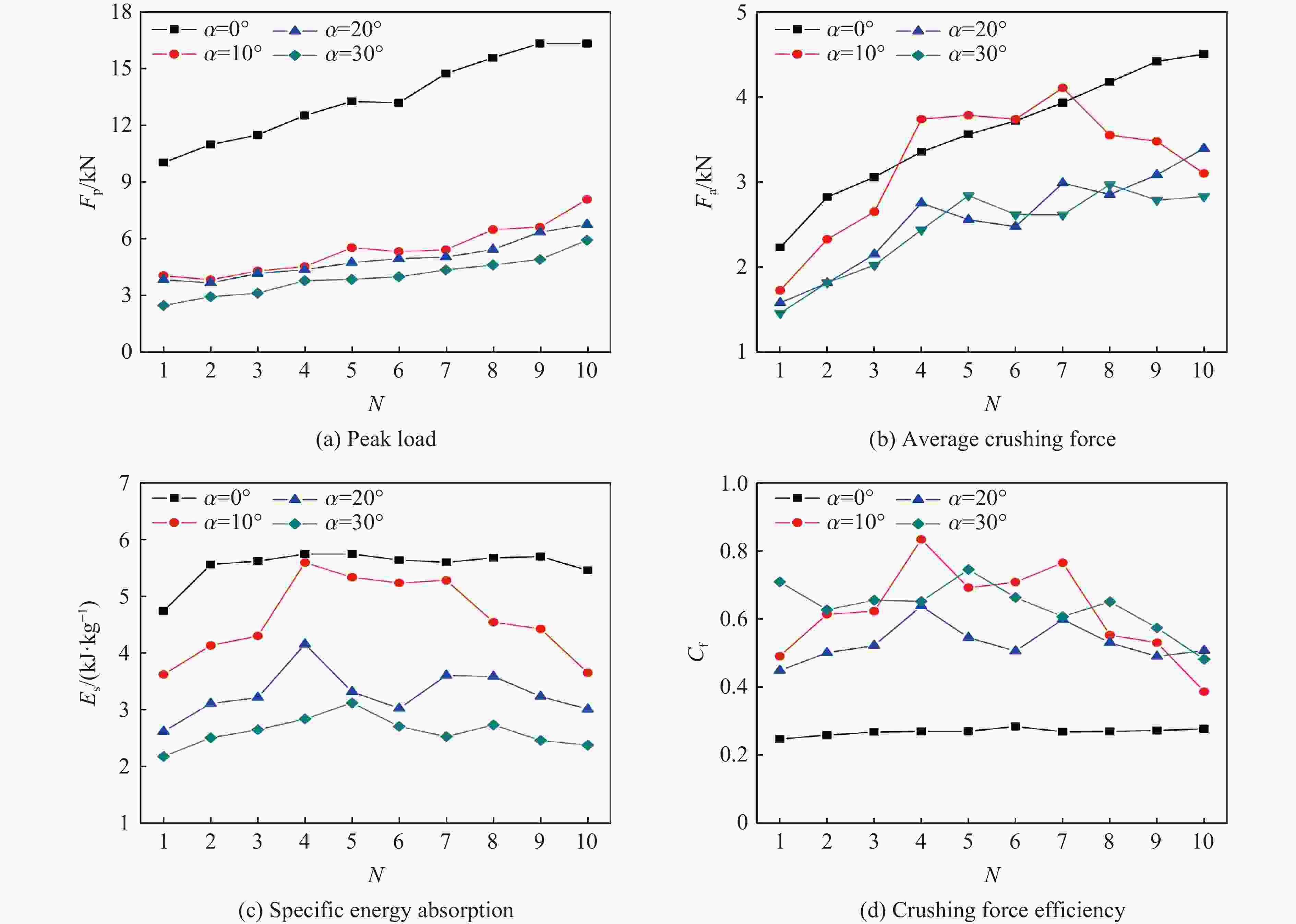

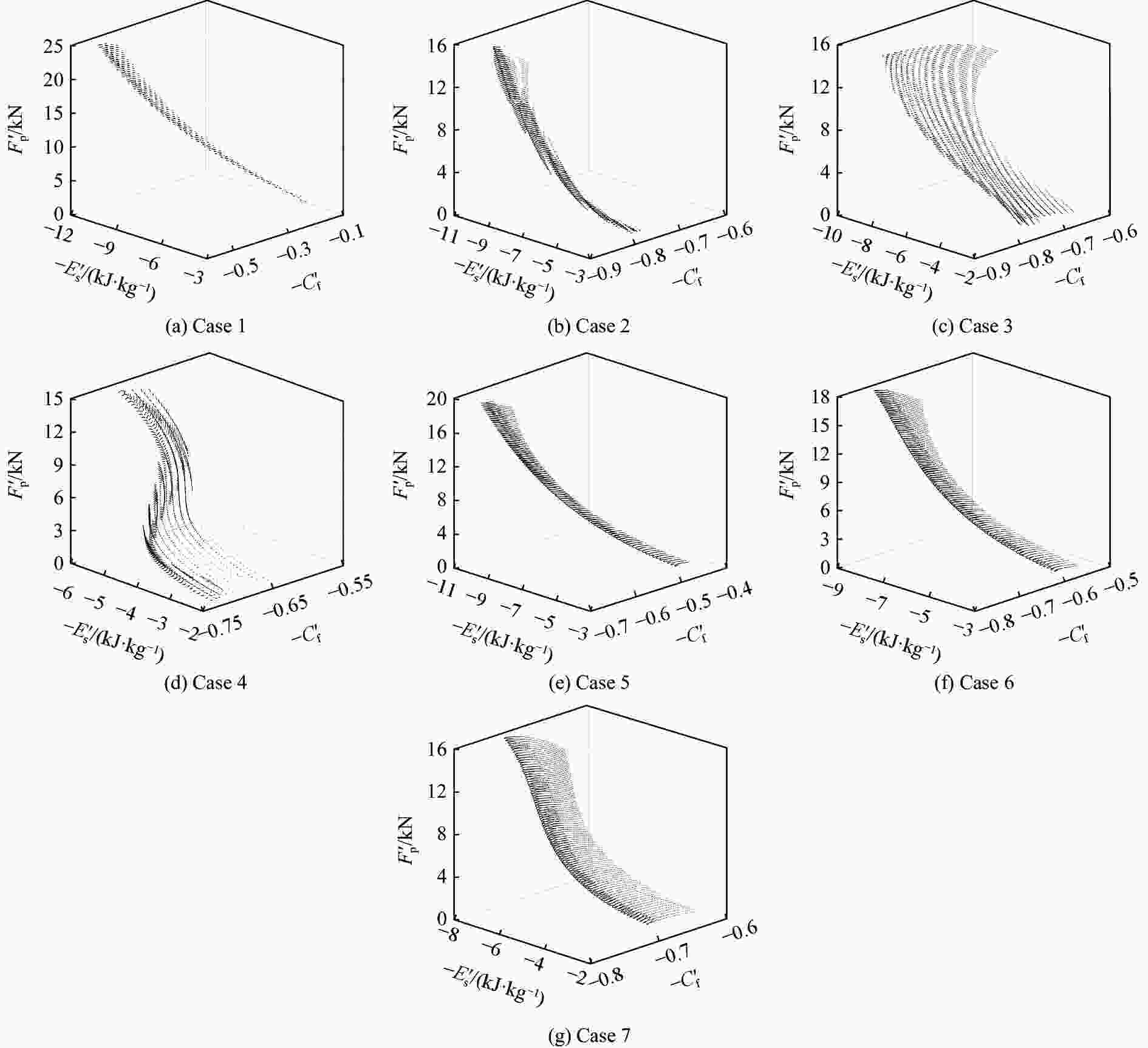

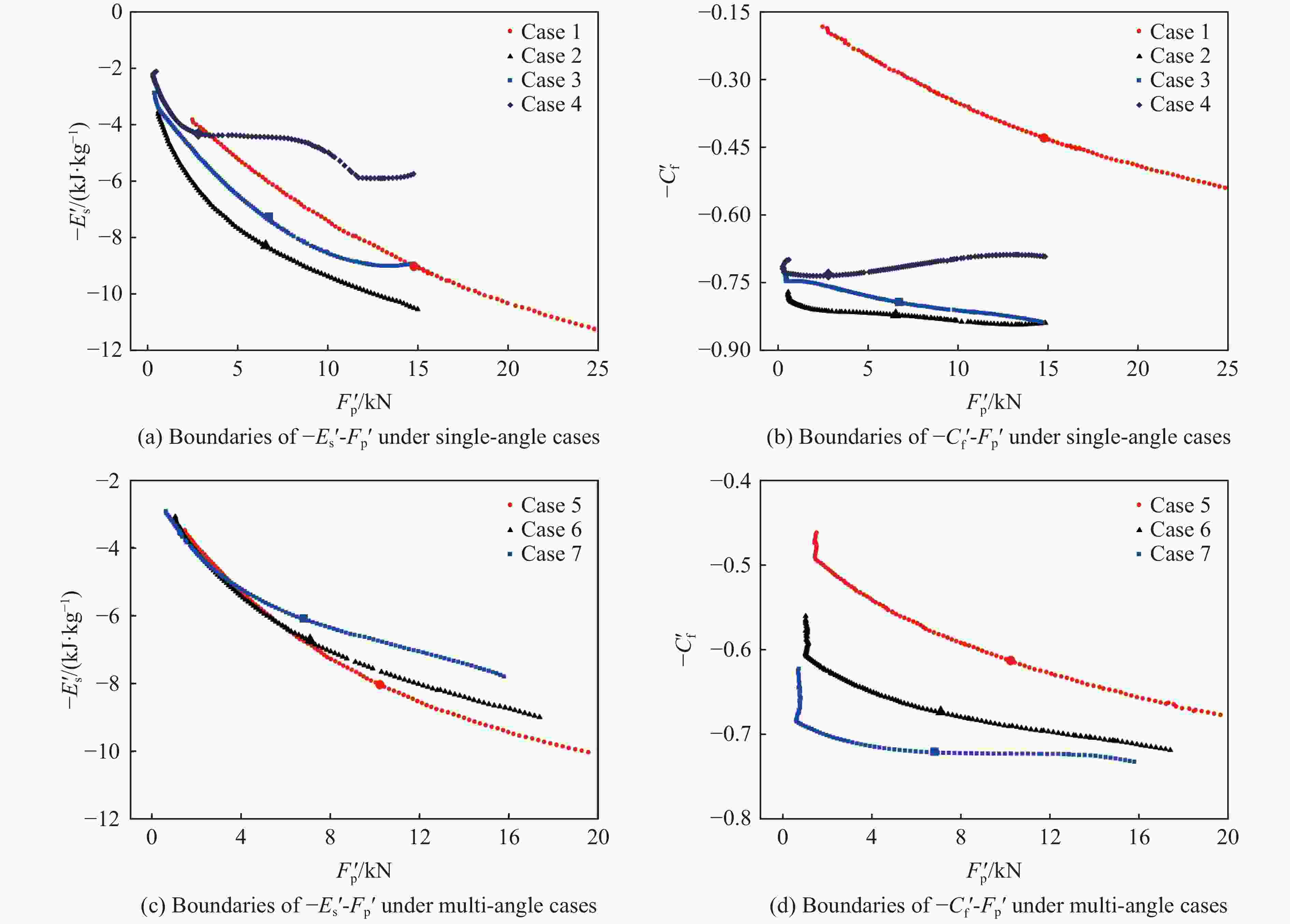

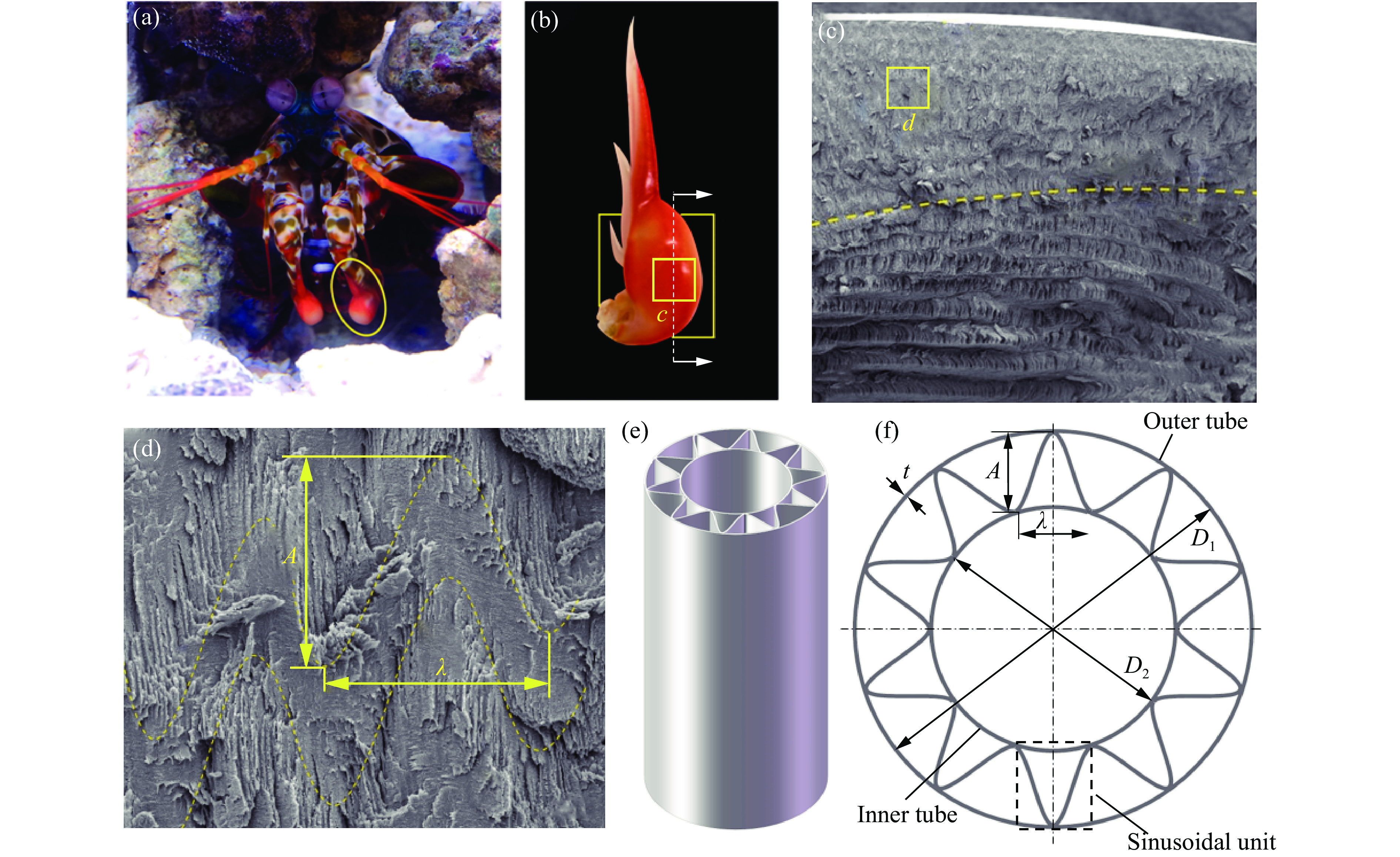

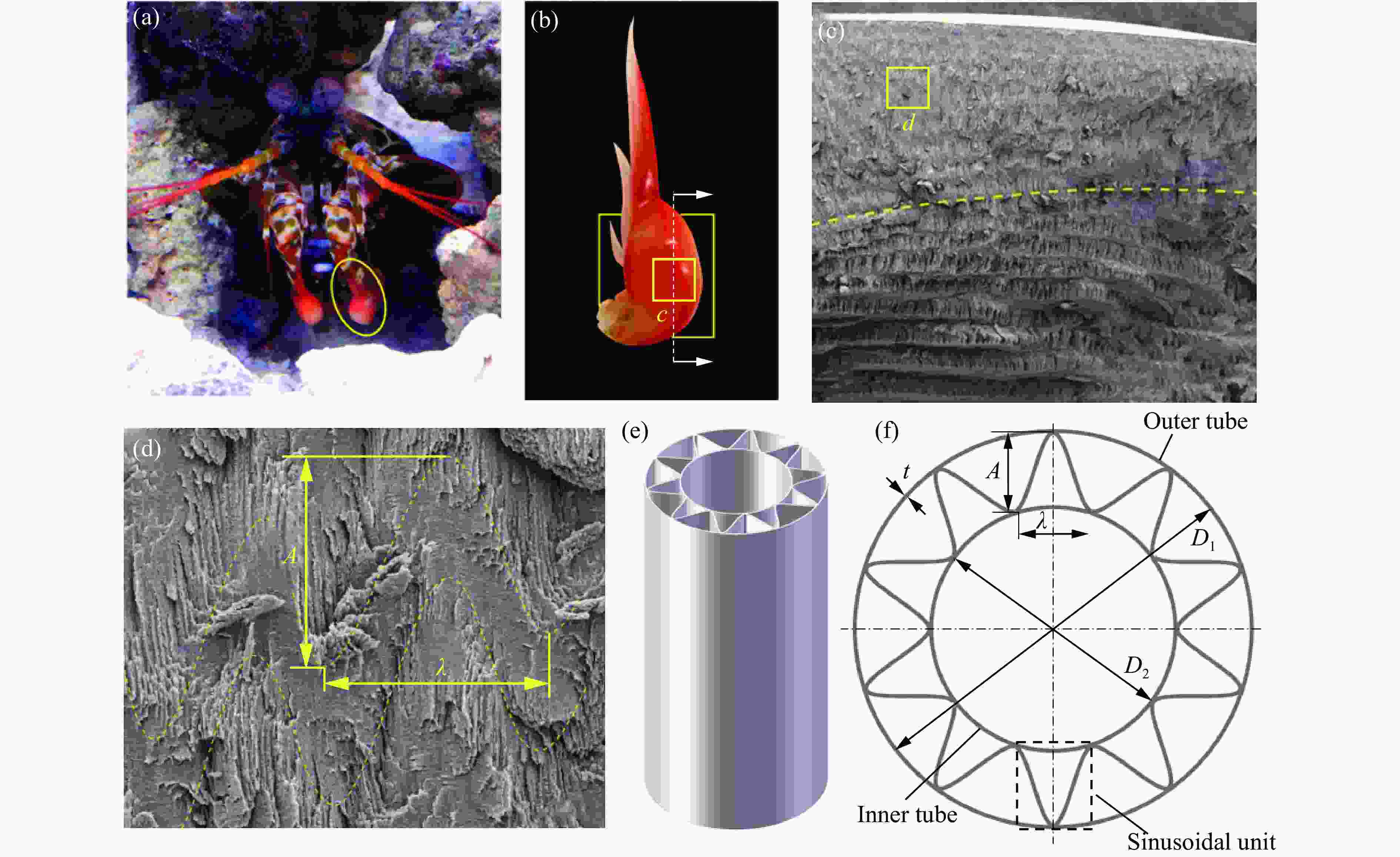

摘要: 为提高薄壁管结构耐撞性,以雀尾螳螂虾螯为仿生原型,结合仿生学设计方法,设计一种含正弦胞元的多胞薄壁管结构。以初始峰值载荷、比吸能和碰撞力效率为耐撞性指标,通过有限元数值模拟分析了不同碰撞角度(0º、10º、20º和30º)条件下,仿生胞元数对薄壁管耐撞性的影响,通过多目标的复杂比例评估法获取仿生薄壁管的最优胞元数。基于不同碰撞角度权重因子组合,设置了4种单一角度工况和3种多角度工况,采用多目标粒子群优化方法获取了不同工况下薄壁管结构最优胞元高宽比和壁厚。复杂比例评估结果表明,胞元数为4的薄壁管为最优晶胞数仿生薄壁管。优化结果表明,单一角度工况下,最优结构参数高宽比的范围为0.88~1.50,壁厚的范围为0.36~0.60 mm,碰撞角度为0º和10º的最优高宽比明显小于碰撞角度为20º和30º的;多角度工况下,最优高宽比范围为1.01~1.10,壁厚范围为0.49~0.57 mm。Abstract: To improve the crashworthiness of thin-walled tube structures, a series of bio-inspired multi-cell thin-walled tubes with sinusoidal cells (abbreviated BSTs) were designed based on the dactyl club microstructure of Odontodactylus scyllarus (O. scyllarus) using bionic design methods. By taking initial peak load, specific energy absorption and crushing force efficiency as crashworthiness indexes, the influences of cell numbers on the crashworthiness of the BSTs under different impact angles (0º, 10º, 20º and 30º) conditions were analyzed under low-velocity impact condition using the nonlinear finite element (FE) method through LS-DYNA. The optimal number of bionic cells was obtained using complex proportion assessment. A complex proportional assessment (COPRAS) method was used to select the optimal number configuration under multiple loading angles. Base on the combination of weight factor values of different impact angles, four single-angle cases (1–4) and three multi-angle cases (5–7) were set. A metamodel-based multi-objective optimization method based on polynomial regression (PR) metamodels and a multi-objective particle optimization (MOPSO) algorithm were employed to optimize the dimensions of the optimal cell number configuration, where the initial peak load, specific energy absorption and crushing force efficiency were taken as objectives and the height-width ratio and thickness were regarded as the design variables. According to the results of the COPRAS method, the BST with four sinusoidal cells was determined to be the best design based on the multi-criteria process. The optimization results of single-angel cases show that, the optimal height-width ratio ranges from 0.88 to 1.50, and the optimal thickness ranges from 0.36 mm to 0.60 mm. The optimal height-width ratios of cases 1–2 are significantly smaller than those of cases 3–4 . The BST with four sinusoidal cells has the maximum optimal thickness of 0.6 mm when the impact angles is 0º. For multi-angel cases, the optimal height-width ratio ranges from 1.01 to 1.10, and the optimal thickness ranges from 0.49 mm to 0.57 mm. The results above are helpful for exploring the lightweight design of new thin-walled tube structures and providing new ideas for their application in energy absorption and crashing field.

-

Key words:

- multi-cell thin-walled tube /

- crashworthiness /

- multi-objective optimization /

- bionic design /

- impact

-

表 1 复杂比例评价法计算结果

Table 1. Results calculated by the complex proportional assessment method

N S+i S−i Qi 排序 1 0.0146 0.0061 0.0255 5 2 0.0165 0.0064 0.0269 2 3 0.0164 0.0069 0.0260 3 4 0.0190 0.0075 0.0278 1 5 0.0177 0.0082 0.0259 4 6 0.0171 0.0082 0.0252 6 7 0.0177 0.0088 0.0252 7 8 0.0167 0.0096 0.0237 8 9 0.0161 0.0102 0.0227 9 10 0.0151 0.0111 0.0211 10 表 2 不同工况的角度权重因子值

Table 2. The values of angle weight for different design cases

工况 wα1 wα2 wα3 wα4 1 (α=0º) 1.0000 0.0000 0.0000 0.0000 2 (α=10º) 0.0000 1.0000 0.0000 0.0000 3 (α=20º) 0.0000 0.0000 1.0000 0.0000 4 (α=30º) 0.0000 0.0000 0.0000 1.0000 5 0.4668 0.2776 0.1603 0.0953 6 0.2500 0.2500 0.2500 0.2500 7 0.0953 0.1603 0.2776 0.4668 表 3 模型误差分析

Table 3. Error analysis of model

α/(º) Fp Es Cf $ \delta $/% Rm/kN $ \delta $/% Rm/(kJ·kg−1) $ \delta $/% Rm 0 0.14 0.016 0.77 0.068 0.78 0.003 10 5.56 0.379 1.35 0.11 4.83 0.07 20 5.85 0.178 5.75 0.431 3.36 0.034 30 9.98 0.339 4.96 0.276 8.15 0.067 表 4 单一角度工况下的最优结果

Table 4. The optimal results for single-angle cases

工况 α/(º) η t /mm Fp /kN Es /(kJ·kg−1) Cf 1 0 0.88 0.60 14.78 9.03 0.43 2 10 0.71 0.56 6.55 8.30 0.82 3 20 1.23 0.55 6.74 7.28 0.79 4 30 1.50 0.36 2.81 4.35 0.72 表 5 多角度工况下的最优结果

Table 5. The optimal results for multi-angle cases

工况 α/(º) η t /mm Fp /kN Es /(kJ·kg−1) Cf $ {F'_{\text{p}}} $/kN $ {E'_{\text{s}}} $/(kJ·kg−1) $ {C'_{\text{f}}} $ 5 0 1.01 0.57 14.04 8.78 0.42 10.24 8.04 0.61 10 7.05 8.41 0.81 20 6.89 7.48 0.77 30 6.49 4.27 0.72 6 0 1.09 0.54 13.32 8.53 0.41 8.03 7.02 0.68 10 6.57 8.08 0.81 20 6.39 7.23 0.78 30 5.84 4.24 0.72 7 0 1.10 0.49 12.09 8.14 0.39 5.96 5.88 0.72 10 5.71 7.72 0.81 20 5.55 6.80 0.77 30 5.04 4.23 0.72 -

[1] 黄晗, 许述财, 陈姮. 仿生波纹夹层结构耐撞性分析及优化 [J]. 爆炸与冲击, 2021, 41(8): 083102. DOI: 10.11883/bzycj-2020-0275.HUANG H, XU S C, CHEN H. Crashworthiness analysis and optimization of bionic corrugated sandwich structures [J]. Explosion and Shock Waves, 2021, 41(8): 083102. DOI: 10.11883/bzycj-2020-0275. [2] YIN H F, XIAO Y Y, WEN G L, et al. Crushing analysis and multi-objective optimization design for bionic thin-walled structure [J]. Materials and Design, 2015, 87: 825–834. DOI: 10.1016/j.matdes.2015.08.095. [3] 于鹏山, 刘志芳, 李世强. 新型仿竹薄壁圆管的设计与吸能特性分析 [J]. 高压物理学报, 2021, 35(5): 054205. DOI: 10.11858/gywlxb.20210710.YU P S, LIU Z F, LI S Q. Design and energy absorption characteristic analysis of a new bio-bamboo thin-walled circular tube [J]. Chinese Journal of High Pressure Physics, 2021, 35(5): 054205. DOI: 10.11858/gywlxb.20210710. [4] SONG J F, XU S C, WANG H X, et al. Bionic design and multi-objective optimization for variable wall thickness tube inspired bamboo structures [J]. Thin-Walled Structures, 2018, 125: 76–88. DOI: 10.1016/j.tws.2018.01.010. [5] 许述财, 邹猛, 魏灿刚, 等. 仿竹结构薄壁管的轴向耐撞性分析及优化 [J]. 清华大学学报(自然科学版), 2014, 54(3): 299–304. DOI: 10.16511/j.cnki.qhdxxb.2014.03.007.XU S C, ZOU M, WEI C G, et al. Axial crashworthiness analysis and optimization of a bionic thin-walled tube based on bamboo structure [J]. Journal of Tsinghua University (Science and Technology), 2014, 54(3): 299–304. DOI: 10.16511/j.cnki.qhdxxb.2014.03.007. [6] XU T, LIU N, YU Z L, et al. Crashworthiness design for bionic bumper structures inspired by cattail and bamboo [J]. Applied Bionics and Biomechanics, 2017, 2017: 5894938. DOI: 10.1155/2017/5894938. [7] LIU S T, TONG Z Q, TANG Z L, et al. Bionic design modification of non-convex multi-corner thin-walled columns for improving energy absorption through adding bulkheads [J]. Thin-Walled Structures, 2015, 88: 70–81. DOI: 10.1016/j.tws.2014.11.006. [8] 陈晓薇, 马彬, 陈勇. 仿方竹电池箱体薄壁管结构优化及耐撞性分析 [J]. 机械设计, 2021, 38(1): 78–84. DOI: 10.13841/j.cnki.jxsj.2021.01.012.CHEN X W, MA B, CHEN Y. Crashworthiness analysis and structural optimization of the bionic square-bamboo battery box’s thin-walled tube [J]. Journal of Machine Design, 2021, 38(1): 78–84. DOI: 10.13841/j.cnki.jxsj.2021.01.012. [9] 邹猛, 于用军, 张荣荣, 等. 仿牛角结构薄壁管吸能特性仿真分析 [J]. 吉林大学学报(工学版), 2015, 45(6): 1863–1868. DOI: 10.13229/j.cnki.jdxbgxb201506020.ZOU M, YU Y J, ZHANG R R, et al. Simulation analysis of energy-absorption properties of thin-wall tube based on horn structure [J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(6): 1863–1868. DOI: 10.13229/j.cnki.jdxbgxb201506020. [10] LIU S F, XU S C, SONG J F, et al. Mechanical properties and failure deformation mechanisms of yak horn under quasi-static compression and dynamic impact [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2020, 107: 103753. DOI: 10.1016/j.jmbbm.2020.103753. [11] 霍鹏, 许述财, 范晓文, 等. 鹿角骨单位仿生薄壁管斜向冲击耐撞性研究 [J]. 爆炸与冲击, 2020, 40(11): 113102. DOI: 10.11883/bzycj-2020-0035.HUO P, XU S C, FAN X W, et al. Oblique impact resistance of a bionic thin-walled tube based on antles osteon [J]. Explosion and Shock Waves, 2020, 40(11): 113102. DOI: 10.11883/bzycj-2020-0035. [12] PALOMBINI F L, MARIATH J E D A, OLIVEIRA B F D. Bionic design of thin-walled structure based on the geometry of the vascular bundles of bamboo [J]. Thin-Walled Structures, 2020, 155: 106936. DOI: 10.1016/j.tws.2020.106936. [13] 杨欣, 范晓文, 许述财, 等. 仿虾螯结构薄壁管设计及耐撞性分析 [J]. 爆炸与冲击, 2020, 40(4): 043301. DOI: 10.11883/bzycj-2019-0280.YANG X, FAN X W, XU S C, et al. Design and crashworthiness analysis of thin-walled tubes based on a shrimp chela structure [J]. Explosion and Shock Waves, 2020, 40(4): 043301. DOI: 10.11883/bzycj-2019-0280. [14] HUANG H, XU S C. Crashworthiness analysis and bionic design of multi-cell tubes under axial and oblique impact loads [J]. Thin-Walled Structures, 2019, 144: 106333. DOI: 10.1016/j.tws.2019.106333. [15] PATEK S N, KORFF W L, CALDWELL R L. Deadly strike mechanism of a mantis shrimp [J]. Nature, 2004, 428(6985): 819–820. DOI: 10.1038/428819a. [16] PATEK S N, CALDWELL R L. Extreme impact and cavitation forces of a biological hammer: strike forces of the peacock mantis shrimp Odontodactylus scyllarus [J]. Journal of Experimental Biology, 2005, 208(19): 3655–3664. DOI: 10.1242/jeb.01831. [17] WEAVER J C, MILLIRON G W, MISEREZ A, et al. The stomatopod dactyl club: a formidable damage-tolerant biological hammer [J]. Science, 2012, 336(6086): 1275–1280. DOI: 10.1126/science.1218764. [18] CLAVERIE T, CHAN E, PATEK S N. Modularity and scaling in fast movements: power amplification in mantis shrimp [J]. Evolution:International Journal of Organic Evolution, 2011, 65(2): 443–461. DOI: 10.1111/j.1558-5646.2010.01133.x. [19] YARAGHI N A, GUARÍN-ZAPATA N, GRUNENFELDER L K, et al. A sinusoidally architected helicoidal biocomposite [J]. Advanced Materials, 2016, 28(32): 6835–6844. DOI: 10.1002/adma.201600786. [20] 黄晗, 闫庆昊, 向枳昕, 等. 基于虾螯的仿生多胞薄壁管耐撞性分析及优化 [J]. 吉林大学学报(工学版), 2022, 52(3): 716–724. DOI: 10.13229/j.cnki.jdxbgxb20200838.HUANG H, YAN Q H, XIANG Z X, et al. Crashworthiness investigation and optimization of bionic multi-cell tube based on shrimp chela [J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(3): 716–724. DOI: 10.13229/j.cnki.jdxbgxb20200838. [21] YANG X F, MA J X, SHI Y L, et al. Crashworthiness investigation of the bio-inspired bi-directionally corrugated core sandwich panel under quasi-static crushing load [J]. Materials and Design, 2017, 135: 275–290. DOI: 10.1016/j.matdes.2017.09.040. [22] QIU N, GAO Y K, FANG J G, et al. Crashworthiness analysis and design of multi-cell hexagonal columns under multiple loading cases [J]. Finite Elements in Analysis and Design, 2015, 104: 89–101. DOI: 10.1016/j.finel.2015.06.004. -

下载:

下载: