Experimental study of gasoline-air mixture explosion in imitated vertical dome oil tank

-

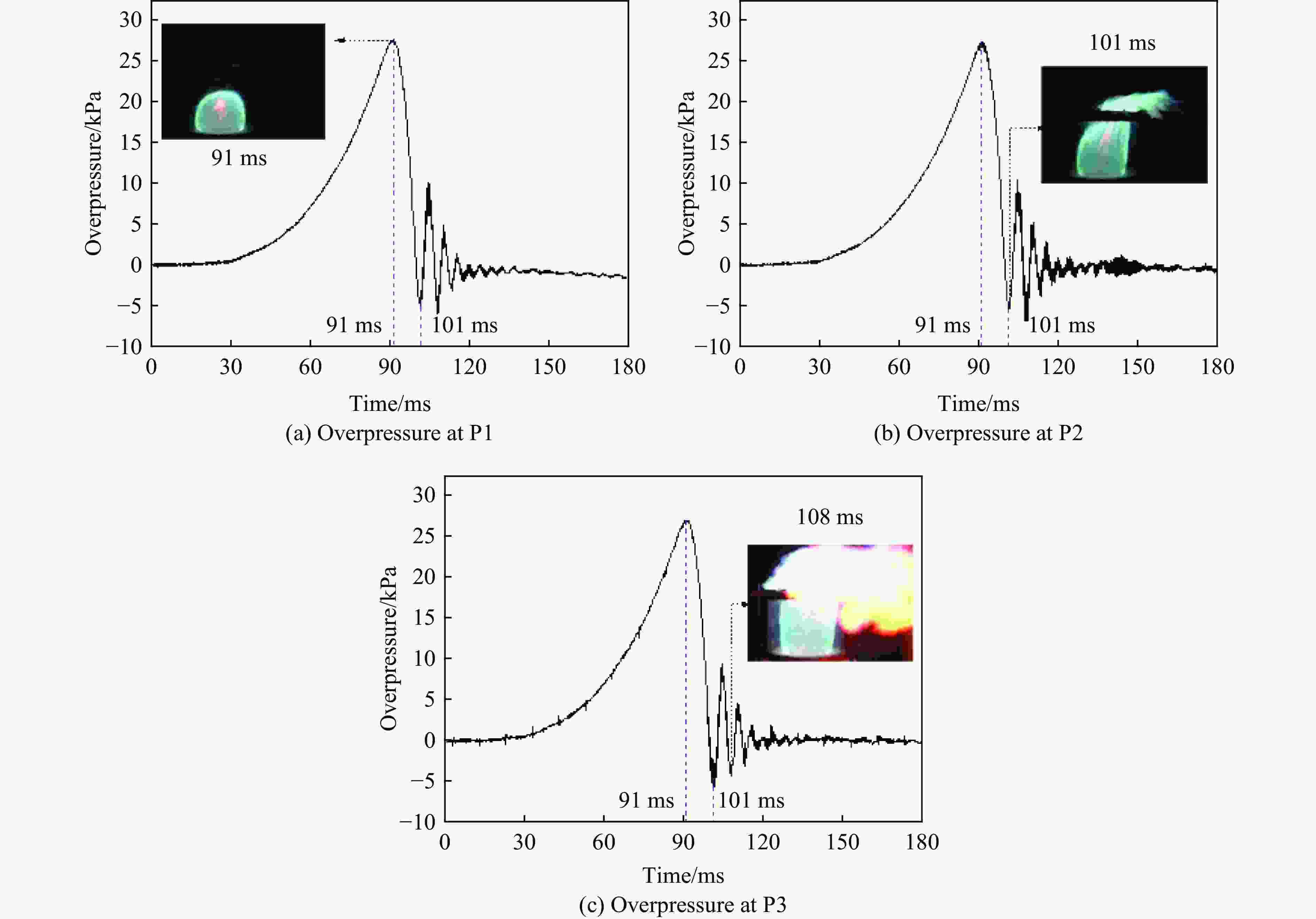

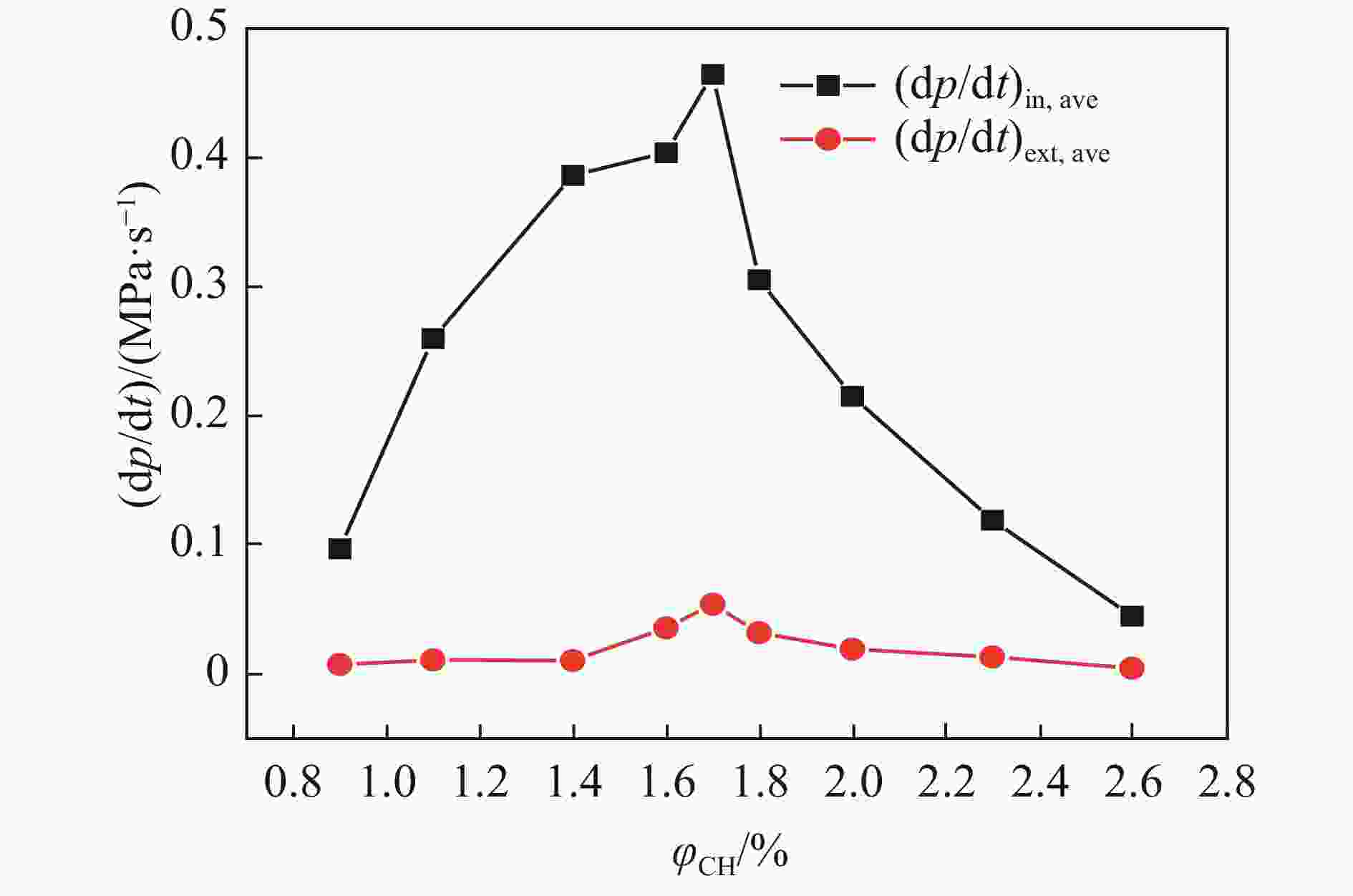

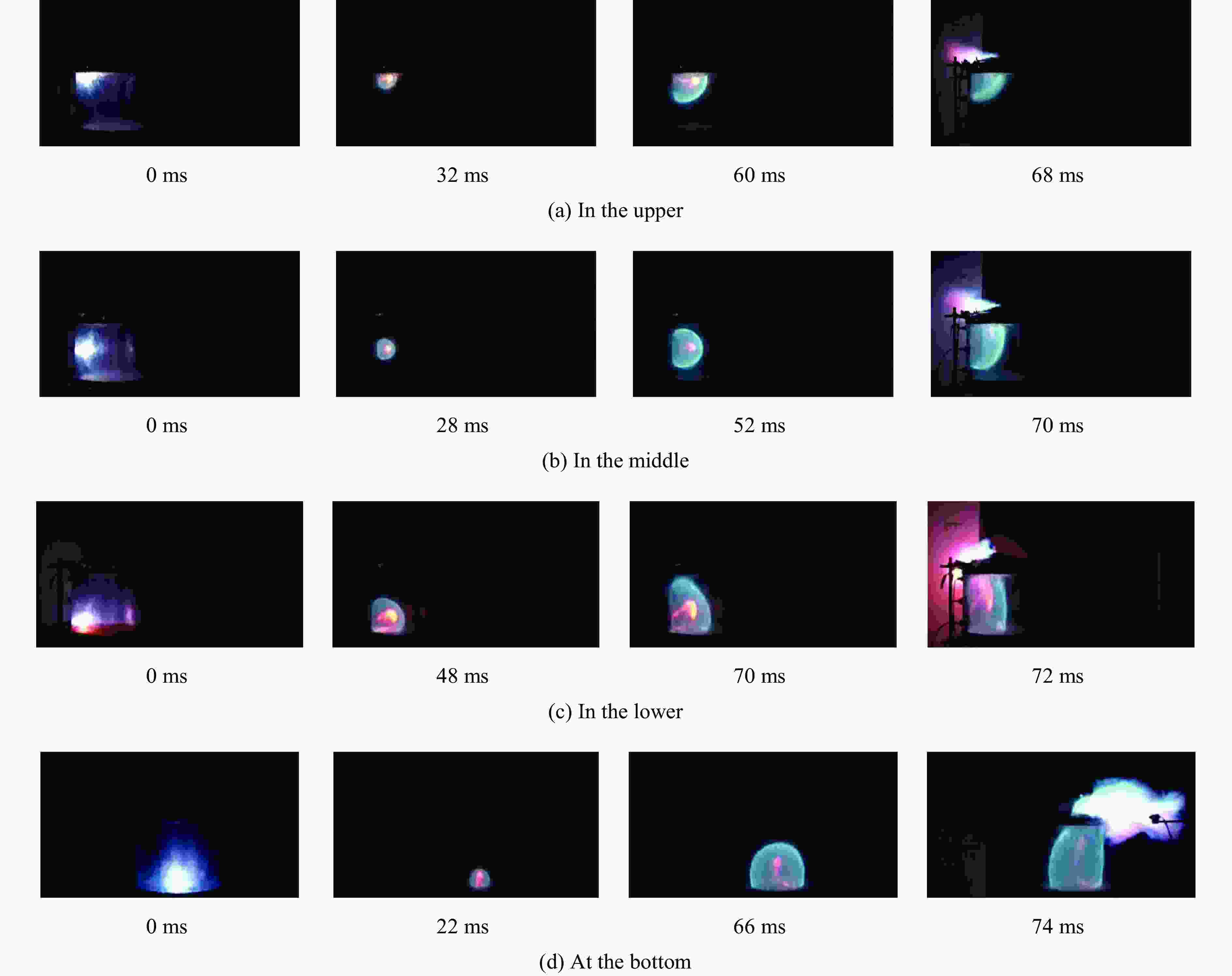

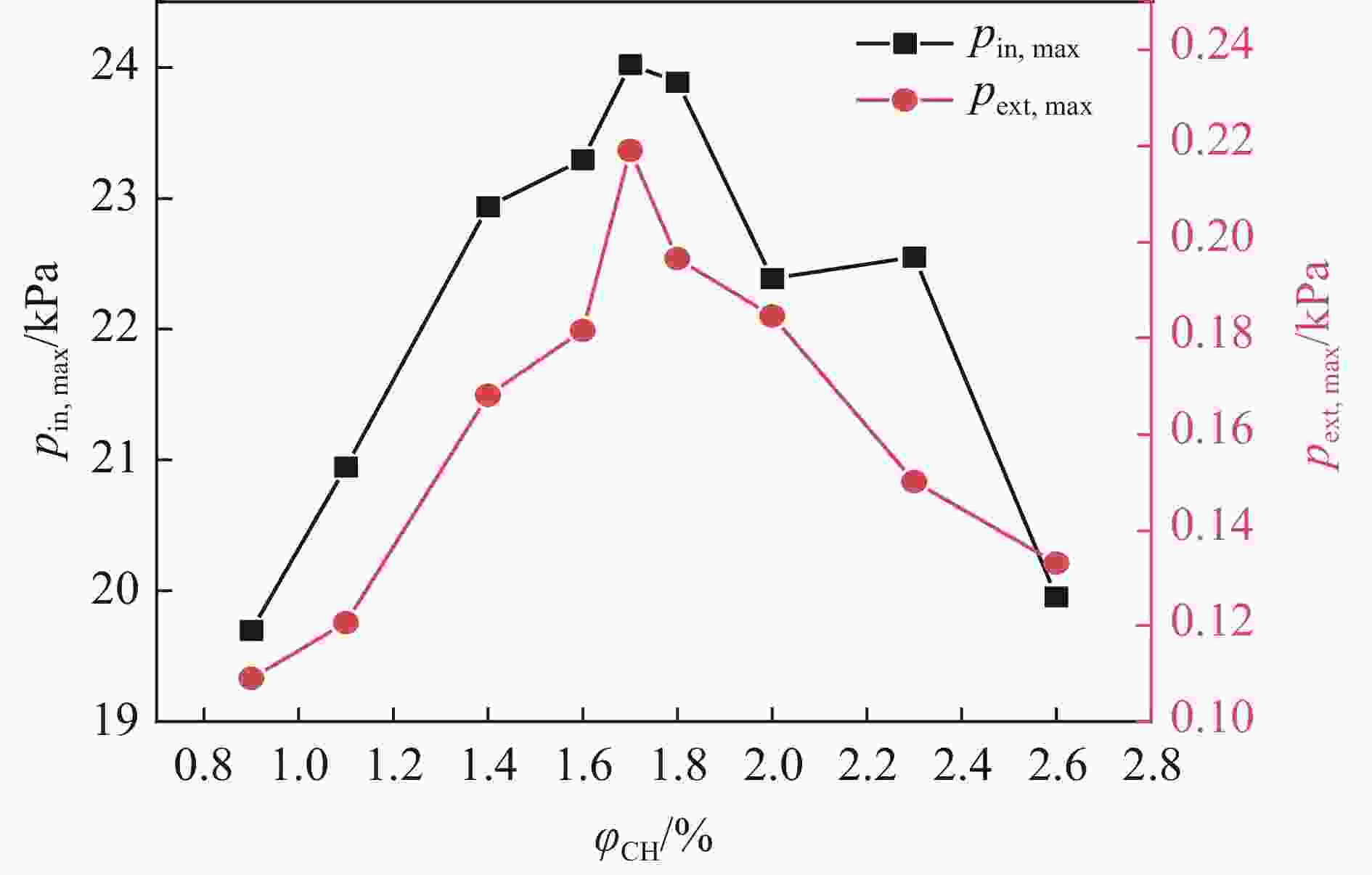

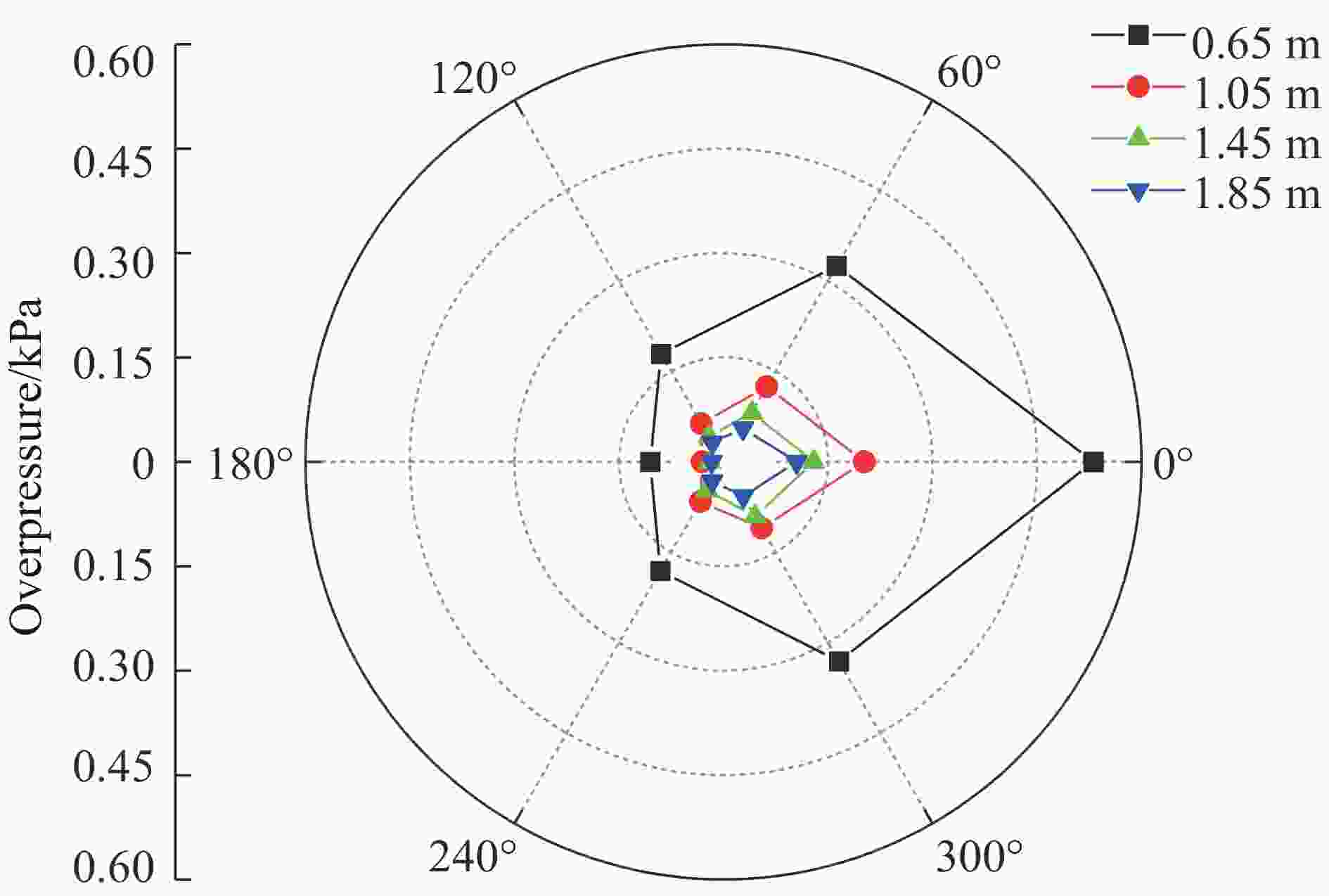

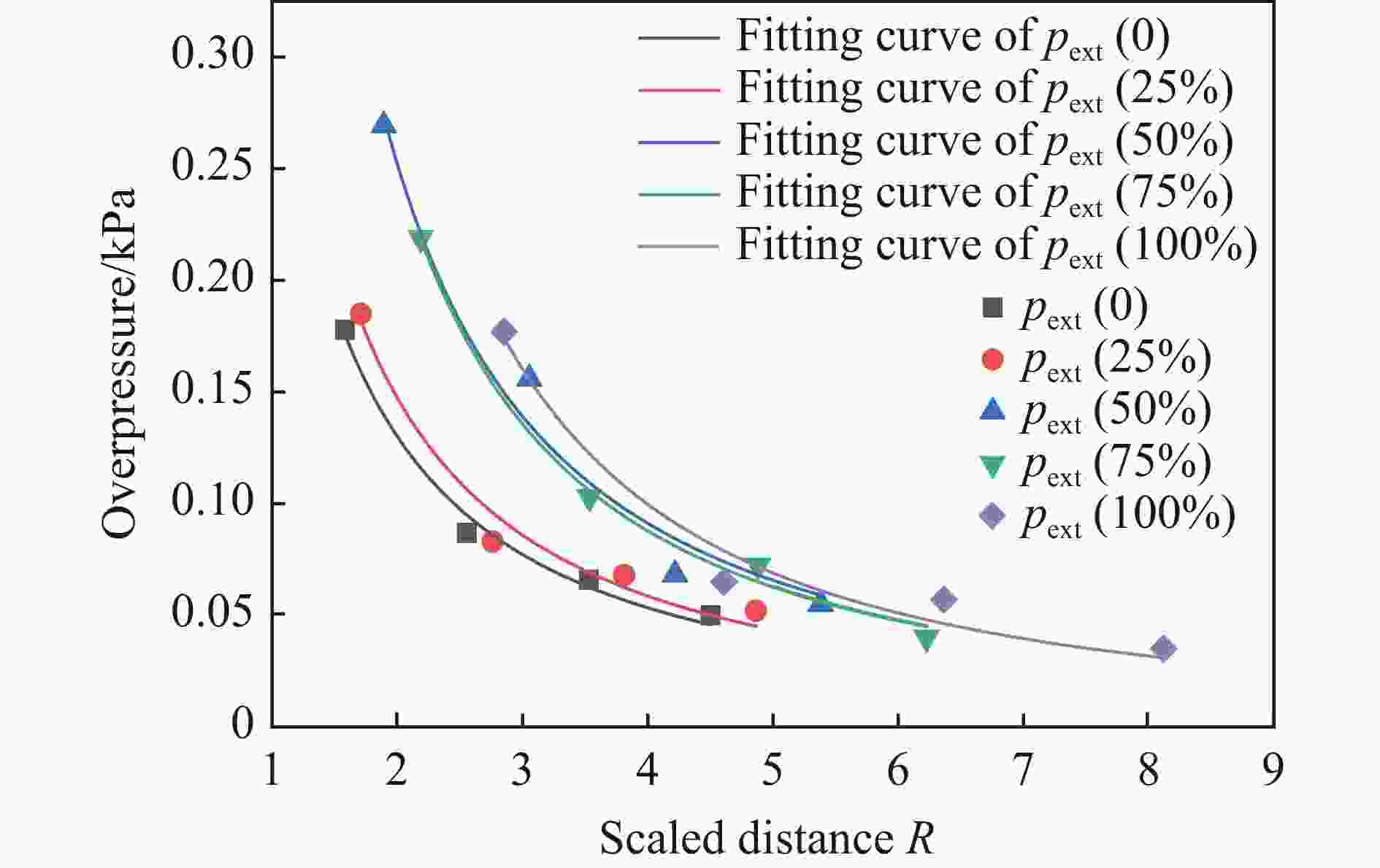

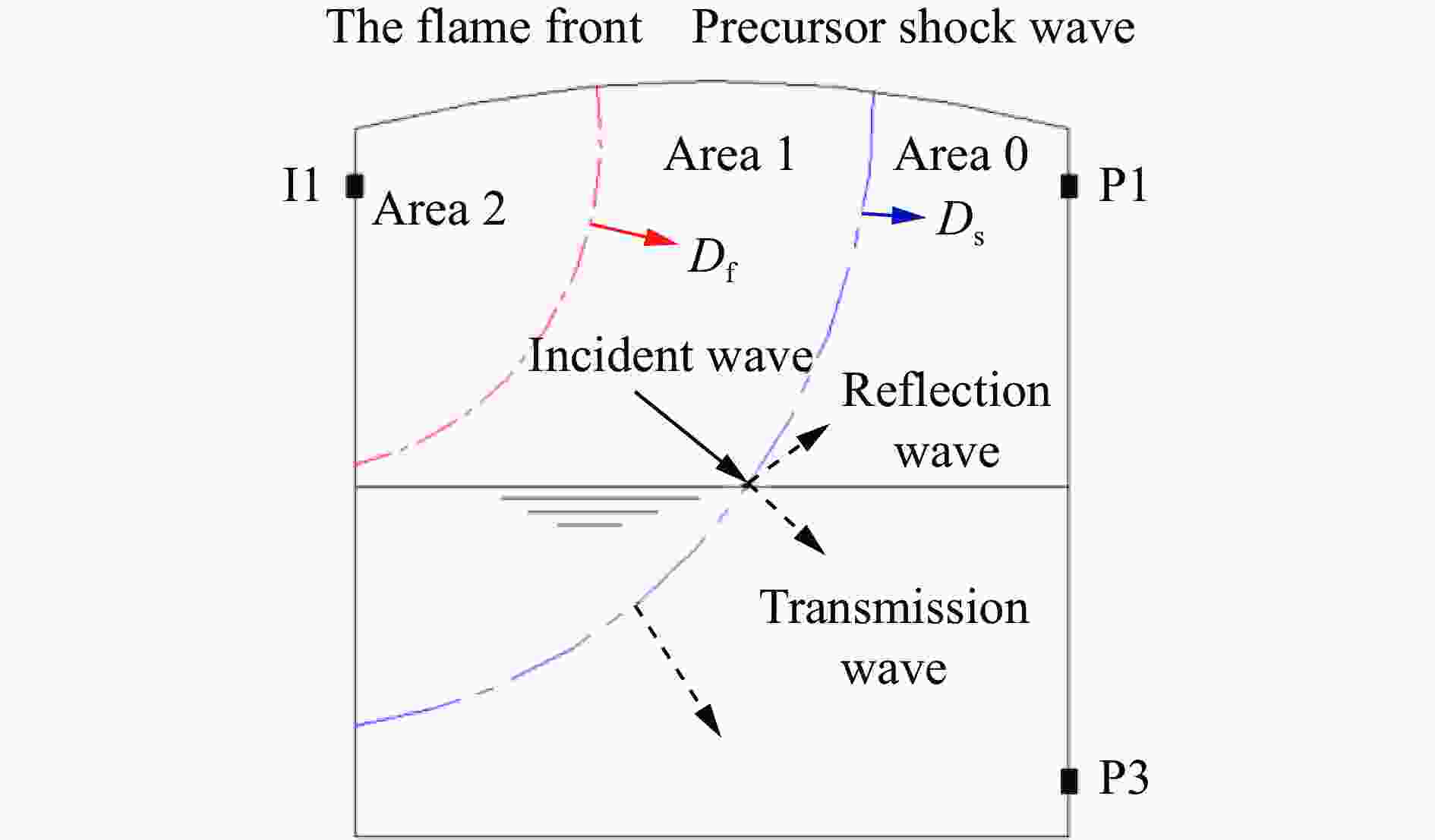

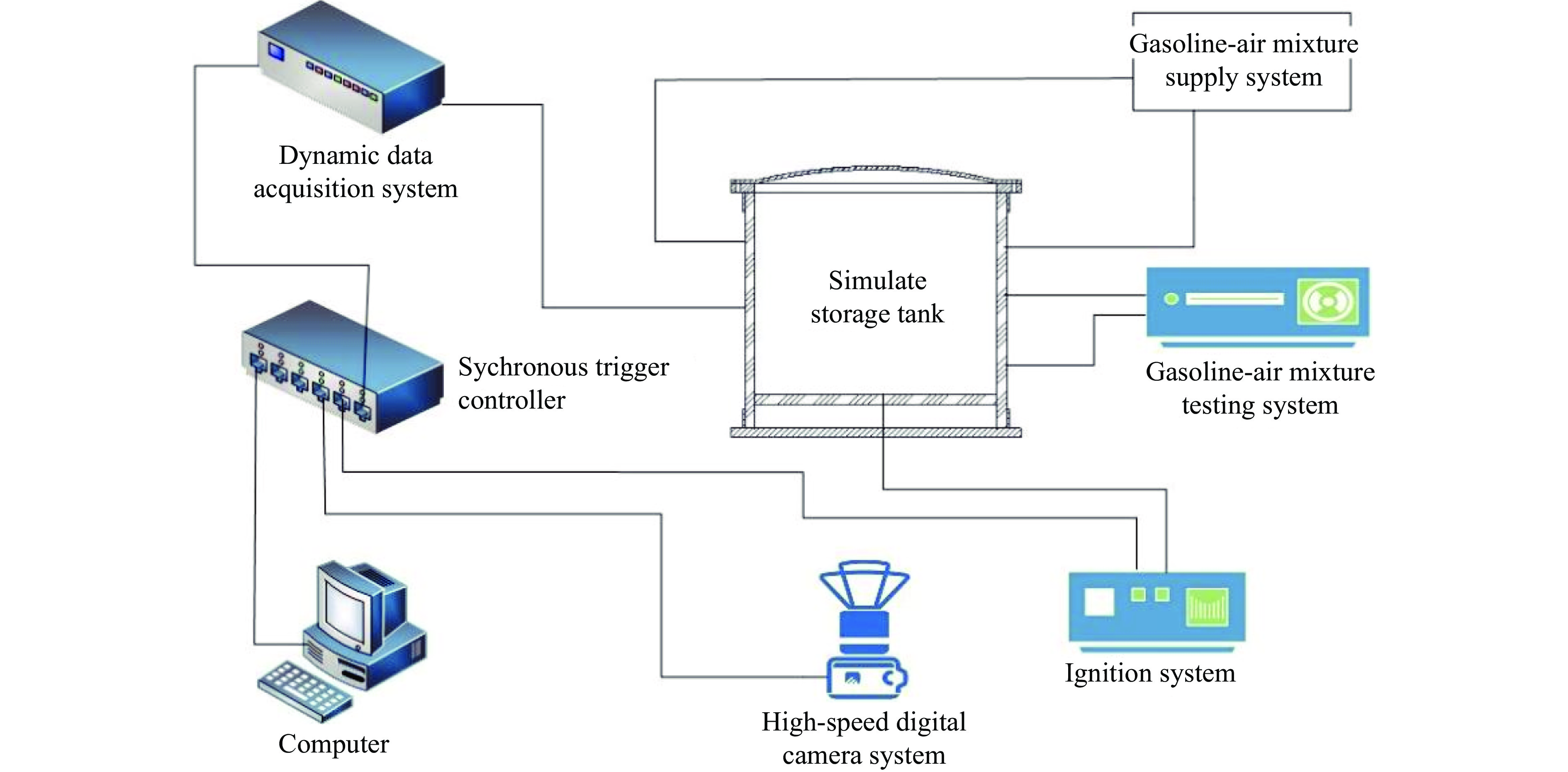

摘要: 为探究立式拱顶油罐内油气体积分数、点火位置和液位对爆炸超压特性参数与火焰发展的影响规律,开展了一系列的实验研究,得到以下结果:(1)1.7%是任一工况下的最危险油气体积分数,内场超压发展都可以分为超压上升、超压泄放和振荡衰减3个阶段。爆炸过程中CH、C2、OH等自由基的生成和空间分布,使得不同初始油气体积分数下或不同爆炸阶段的火焰呈现不同的颜色变化。(2)点火位置对油气爆炸超压特性参数的影响较大,位置越靠下,爆炸威力越大。罐底中心点火时,内外场平均升压速率取得最大值,分别为0.46和0.05 MPa/s。(3)液位变化对油气爆炸内外场超压的影响较大,油罐侧壁上部位置点火时,50%液位是最危险的液位。任意液位下外场超压随比例距离的增大都呈现幂指数衰减规律,不同液位下油气爆炸外场冲击波超压峰值与距离和油气混合物体积的关系可以用一个公式统一表示。相比于气相空间,液相空间的超压变化具有延后性、负压增强和振荡衰减更快的特点。Abstract: To investigate the influence of gasoline-air mixture volume fraction, ignition position and liquid level on explosion overpressure parameters and flame development in vertical dome oil tank, a series of experiments with nine initial hydrocarbon volume fractions, four ignition positions and five liquid levels were carried out in a transparent imitated oil tank. Dynamic data acquisition system and high-speed camera were employed to detect the changes of internal and external field pressure, and to record the transformation of flame shape. The following results were found. (1) 1.7% is the most dangerous gasoline-air mixture volume fraction under any working condition. The development of overpressure in the inner field can be divided into three stages: overpressure rise, overpressure release and oscillation attenuation. The formation and spatial distribution of free radicals such as CH, C2 and OH during the explosion process make the flame show different color changes under different initial volume fractions or at different explosion stages. (2) Ignition position has a great influence on explosion overpressure parameters. The lower the ignition position is, the greater the explosion power is. When the ignition position is in the center of the bottom of the tank, the average pressure boost rate of the internal and external fields reaches the maximum value, being 0.464 MPa/s and 0.053 MPa/s, respectively. (3) The change of liquid level has a great influence on the overpressure of the internal and external field of oil and gas explosion. When the position ignition is located at the top of the side wall of the oil tank, the 50% liquid level is the most dangerous level. At any liquid level, the outfield overpressure decreases exponentially with the increase of scaled distance. The relationship among the maximum overpressure peak of the outfield shock wave of gasoline-air mixture explosion at different liquid levels, the distance and the volume of gasoline-air mixture can be expressed by a unified expression. Compared with gas space, the overpressure in liquid space has the characteristics of delay, enhancement of negative overpressure and faster oscillation attenuation frequency.

-

Key words:

- vertical dome oil tank /

- gasoline-air mixture explosion /

- chemical reaction /

- overpressure /

- flame

-

表 1 不同初始体积分数下的油气爆炸内场超压参数

Table 1. Internal field overpressure parameters of gasoline-air mixture explosion at different initial volume fractions

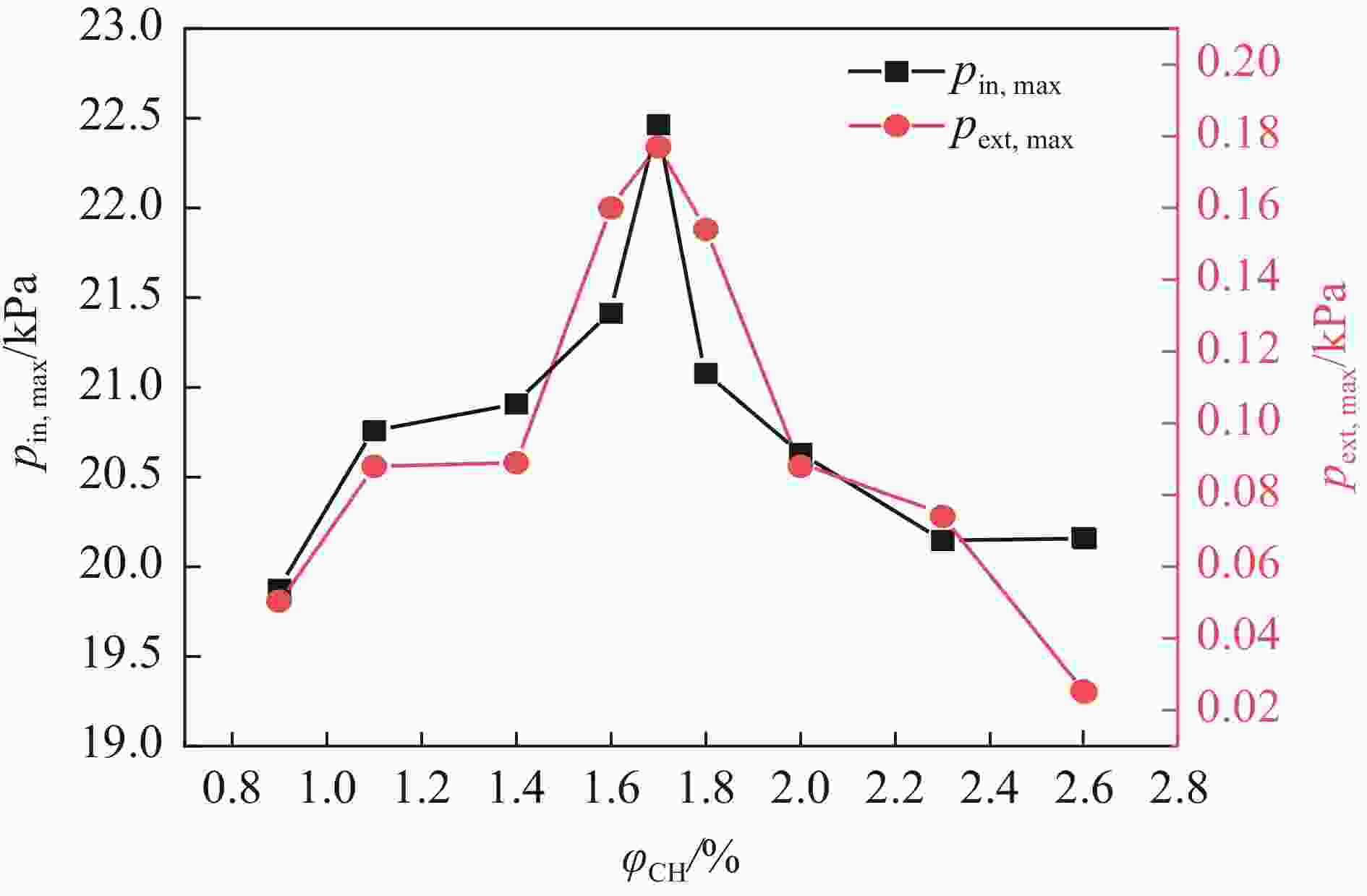

φCH/% pin,max/kPa tin,max/ms (dp/dt)in,ave/(MPa·s−1) 0.9 20.37 212 0.10 1.1 26.71 103 0.26 1.4 27.02 70 0.39 1.6 27.86 69 0.40 1.7 31.59 68 0.46 1.8 27.44 90 0.31 2.0 24.67 115 0.22 2.3 22.98 194 0.12 2.6 20.26 462 0.04 表 2 不同初始体积分数下油气爆炸罐内火焰强度最大峰值和形成时间

Table 2. Maximum peak flame intensity and time of formation in the tank at different initial volume fractions

φCH/% Imax/mV tmax/ms 0.9 14 483 1.1 69 238 1.4 190 175 1.6 137 184 1.7 107 188 1.8 70 238 2.0 97 313 2.3 162 485 2.6 161 798 表 3 不同点火位置的油气爆炸超压参数

Table 3. Overpressure parameters of gasoline-air mixture explosion at different ignition locations

点火位置 pin,max/kPa tin,max/ms (dp/dt)in,ave/(MPa·s−1) pext,max /kPa text,max/ms (dp/dt)ext,ave/(MPa·s−1) 上部点火 21.91 64 0.34 0.18 5 0.04 中部点火 22.60 64 0.35 0.27 9 0.03 下部点火 26.22 65 0.40 0.37 12 0.03 底部点火 31.59 68 0.47 0.53 10 0.05 表 4 不同液位下不同初始体积分数油气爆炸内外场最大超压峰值

Table 4. The maximum overpressure peak in the internal and external field of gasoline-air mixture explosion with different initial volume fraction at different liquid levels

φCH/% 75%液位 100%液位 pin, max/kPa pext, max /kPa pin, max/kPa pext, max /kPa 0.9 19.70 0.11 19.88 0.05 1.1 20.95 0.12 20.76 0.09 1.4 22.94 0.17 20.91 0.09 1.6 23.29 0.18 21.41 0.16 1.7 24.02 0.22 22.47 0.18 1.8 23.89 0.20 21.08 0.15 2.0 22.39 0.19 20.63 0.09 2.3 22.55 0.15 20.15 0.07 2.6 19.95 0.13 20.16 0.03 表 5 不同液位油气爆炸内场超压参数

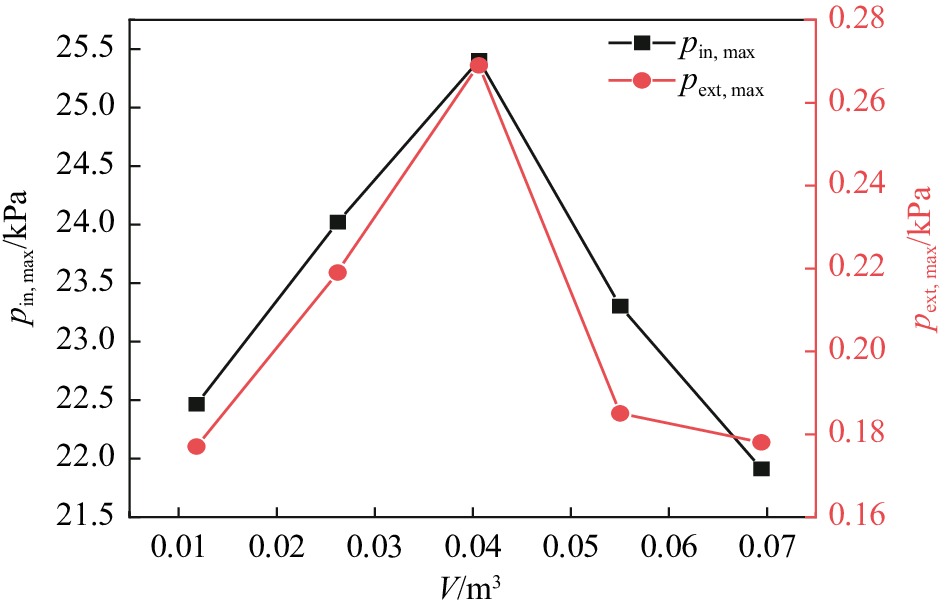

Table 5. Overpressure parameters inside tank of gasoline-air mixture explosion at different liquid levels

液位/% pin,max/kPa tin,max/ms (dp/dt)in,ave/(MPa·s−1) 0 21.91 64 0.34 25 23.30 63 0.37 50 25.40 59 0.43 75 24.02 56 0.43 100 22.47 53 0.42 -

[1] COZZANI V, ANTONIONI G, SPADONI G. Quantitative assessment of domino scenarios by a GIS-based software tool [J]. Journal of Loss Prevention in the Process Industries, 2006, 19(5): 463–477. DOI: 10.1016/j.jlp.2005.11.007. [2] LANDUCCI G, GUBINELLI G, ANTONIONI G, et al. The assessment of the damage probability of storage tanks in domino events triggered by fire [J]. Accident Analysis & Prevention, 2009, 41(6): 1206–1215. DOI: 10.1016/j.aap.2008.05.006. [3] ATKINSON G, COLDRICK S, GANT S, et al. Flammable vapor cloud generation from overfilling tanks: learning the lessons from Buncefield [J]. Journal of Loss Prevention in the Process Industries, 2015, 35(5): 329–338. DOI: 10.1016/j.jlp.2014.11.011. [4] HERBERT I. The UK Buncefield incident–The view from a UK risk assessment engineer [J]. Journal of Loss Prevention in the Process Industries, 2010, 23(6): 913–920. DOI: 10.1016/j.jlp.2010.09.001. [5] RUI S, WANG C, LUO X, et al. Experimental study on the effects of ignition location and vent burst pressure on vented hydrogen-air deflagrations in a cubic vessel [J]. Fuel, 2020, 278(10): 118342. DOI: 10.1016/j.fuel.2020.118342. [6] LI P, HUANG P, LIU Z, et al. Experimental study on vented explosion overpressure of methane/air mixtures in manhole [J]. Journal of Hazardous Materials, 2019, 374(7): 349–355. DOI: 10.1016/j.jhazmat.2019.04.046. [7] 苏航, 蒋利桥, 曹海亮, 等. 微小空间内丙烷/空气火焰传播特性与加氢爆燃实验 [J]. 爆炸与冲击, 2018, 38(2): 381–389. DOI: 10.11883/bzycj-2016-0198.SU H, JIANG L Q, CAO H L, et al. Characteristics of propane/air flame propagation and propane/hydrogen/air detonation in a micro chamber [J]. Explosion and Shock Waves, 2018, 38(2): 381–389. DOI: 10.11883/bzycj-2016-0198. [8] 吴松林, 杜扬, 张培理, 等. 点火方式对受限空间油气爆燃规律的影响 [J]. 化工学报, 2016, 67(4): 1626–1632. DOI: 10.11949/j.issn.0438-1157.20150958.WU S L. DU Y, ZHANG P L, et al. Effect of ignition node on gasoline-air deflagration behavior in confined space [J]. Journal of Chemical Industry and Engineering, 2016, 67(4): 1626–1632. DOI: 10.11949/j.issn.0438-1157.20150958. [9] LI G Q, WU J, WANG S M, et al. Effects of gas concentration and obstacle location on overpressure and flame propagation characteristics of hydrocarbon fuel-air explosion in a semi-confined pipe [J]. Fuel, 2021, 285(9): 119268. DOI: 10.1016/j.fuel.2020.119268. [10] 李国庆, 杜扬, 齐圣, 等. 障碍物位置和油气浓度对油气泄压爆炸特性影响 [J]. 化工学报, 2018, 69(5): 2327–2336. DOI: 10.11949/j.issn.0438-1157.20171184.LI G Q, DU Y, QI S, et al. Effects of obstacle position and gas concentration on gasoline-air explosion venting [J]. CIESC Journal, 2018, 69(5): 2327–2336. DOI: 10.11949/j.issn.0438-1157.20171184. [11] WANG S M, YAN Z H, LI X D, et al. The venting explosion process of premixed fuel vapour and air in a half-open vessel: An analysis of the overpressure dynamic process and flame evolution behaviour [J]. Fuel, 2020, 268(5): 117508. [12] 李蒙, 杜扬, 李国庆, 等. 含90°直角弯管结构受限空间油气泄压爆炸实验与大涡模拟研究 [J]. 化工学报, 2018, 69(12): 5370–5378. DOI: 10.11949/j.issn.0438-1157.20180519.LI M, DU Y, LI G Q, et al. Experimental and large eddy simulation study on gasoline-air mixture explosions in semi-confined pipe with 90° right-angle bend [J]. CIESC Journal, 2018, 69(12): 5370–5378. DOI: 10.11949/j.issn.0438-1157.20180519. [13] 杜扬, 李蒙, 李国庆, 等. 含双侧分支结构受限空间油气泄压爆炸超压特性与火焰行为 [J]. 化工进展, 2018, 37(7): 2557–2564. DOI: 10.16085/j.issn.1000-6613.2017-2522.DU Y, LI M, LI G Q, et al. Effects of bilateral branches structure on characteristics of gasoline-air mixtures explosion overpressure and flame behavior in a semi-confined space [J]. Chemical Industry and Engineering Progress, 2018, 37(7): 2557–2564. DOI: 10.16085/j.issn.1000-6613.2017-2522. [14] 杜扬, 王世茂, 袁广强, 等. 含弱约束端面短管道油气爆炸特性实验研究 [J]. 爆炸与冲击, 2018, 38(2): 465–472. DOI: 10.11883/bzycj-2015-0242.DU Y, WANG S M, YUAN G Q, et al. Experimental study of fuel-air mixture explosion characteristics in the short pipe containing weakly confined face at the end [J]. Explosion and Shock Waves, 2018, 38(2): 465–472. DOI: 10.11883/bzycj-2015-0242. [15] WANG S M, WU D J, GUO H, et al. Effects of concentration, temperature, ignition energy and relative humidity on the overpressure transients of fuel-air explosion in a medium-scale fuel tank [J]. Fuel, 2020, 259(1): 116265.1–116265.8. DOI: 10.1016/j.fuel.2019.116265. [16] CAI Y X, JIANG X S, WANG S M, et al. Experimental study on explosion overpressure and flame propagation characteristics of simulated vertical dome oil tank [J]. Journal of Loss Prevention in the Process Industries, 2022, 76: 104752. DOI: 10.1016/j.jlp.2022.104752. [17] 刘洪涛, 陈志莉, 胡潭高, 等. 油料池火焰红外光谱特性分析研究 [J]. 光谱学与光谱分析, 2016, 36(10): 3442–3448. DOI: 10.3964/j.issn.1000-0593(2016)10-3442-07.LIU H T, CHEN Z L, HU T G, et al. Analytic study on the characteristics of infrared spectrum of oil pool flame [J]. Spectroscopy and Spectral Analysis, 2016, 36(10): 3442–3448. DOI: 10.3964/j.issn.1000-0593(2016)10-3442-07. [18] 蒋新生, 徐建楠, 冯军, 等. 汽油着火初期光谱特征及燃烧动力学分析 [J]. 发光学报, 2018, 39(11): 1639–1645. DOI: 10.3788/fgxb20183911.1639.JIANG X S, XU J N, FENG J, et al. Flame spectral characteristics and analysis of combustion kinetics at initial stage of gasoline fire [J]. Chinese Journal of Luminescence, 2018, 39(11): 1639–1645. DOI: 10.3788/fgxb20183911.1639. [19] ZHANG P L, WANG J, LIANG J J, et al. Explosions of gasoline vapor/air mixture in closed vessels with different shapes and sizes [J]. Journal of Loss Prevention in the Process Industries, 2018, 57: 327–334. DOI: 10.1016/j.jlp.2018.12.010. [20] 段晓瑜, 崔庆忠, 郭学永, 等. 炸药在空气中爆炸冲击波的地面反射超压实验研究 [J]. 兵工学报, 2016, 37(12): 2277–2283. DOI: 10.3969/j.issn.1000-1093.2016.12.013.DUAN X Y, CUI Q Z, GUO X Y, et al. Experimental investigation of ground reflected overpressure of shock wave in air blast [J]. Acta Armamentarii, 2016, 37(12): 2277–2283. DOI: 10.3969/j.issn.1000-1093.2016.12.013. [21] ZHOU Z Q, NIE J X, OU Z C, et al. Effects of the aluminum content on the shock wave pressure and the acceleration ability of RDX-based aluminized explosives [J]. Journal of Applied Physics, 2014, 116(14): 113–33305. DOI: 10.1063/1.4897658. [22] DISIMILE P J, DAVIS J, TOY N. Mitigation of shock waves within a liquid filled tank [J]. International Journal of Impact Engineering, 2011, 38: 61–72. DOI: 10.1016/j.ijimpeng.2010.10.006. [23] 徐海斌, 张德志, 秦学军, 等. 炸药周围水层对空气冲击波反射超压影响的实验研究 [J]. 兵工学报, 2014, 35(7): 1027–1031. DOI: 10.3969/j.issn.1000-1093.2014.07.014.XU H B, ZHANG D Z, QIN X J, et al. An investigation on mitigation effect of water surrounding an explosive on reflected overpressure of shock wave [J]. Acta Armamentarii, 2014, 35(7): 1027–1031. DOI: 10.3969/j.issn.1000-1093.2014.07.014. [24] 杨亚东, 李向东, 王晓鸣. 长方体密闭结构内爆炸冲击波传播与叠加分析模型 [J]. 兵工学报, 2016, 37(8): 1449–1455. DOI: 10.3969/j.issn.1000-1093.2016.08.016.YANG Y D, LI X D, WANG X M. An analytical model for propagation and superposition of internal explosion shockwaves in closed cuboid structure [J]. Acta Armamentarii, 2016, 37(8): 1449–1455. DOI: 10.3969/j.issn.1000-1093.2016.08.016. [25] 刘小龙, 黄建国, 雷开卓. 水下等离子体声源的冲击波负压特性 [J]. 物理学报, 2013, 62(20): 1–7. DOI: 10.7498/aps.62.204301.LIU X L, HUANG J G, LEI K Z. Shock wave negative pressure characteristics of underwater plasma sound source [J]. Acta Physica Sinica, 2013, 62(20): 1–7. DOI: 10.7498/aps.62.204301. [26] 陈先锋. 丙烷—空气预混火焰微观结构及加速传播过程中的动力学研究[D]. 合肥: 中国科学技术大学, 2007.CHEN X F. Study on fine flame structure behavior and flame accelerating mechanism of premixed propane-air[D]. Hefei: University of Science and Technology China, 2007. [27] WU F, JOMAAS G, LAW C K. An experimental investigation on self-acceleration of cellular spherical flames [J]. Proceedings of the Combustion Institute, 2013, 34(1): 937–945. DOI: 10.1016/j.proci.2012.05.068. [28] WEI S, YU M, PEI B, et al. Suppression of CO2 and H2O on the cellular instability of premixed methane/air flame [J]. Fuel, 2020, 264(9): 116862. DOI: 10.1016/j.fuel.2019.116862. [29] XIAO H H, MAKAROV D, SUN J, et al. Experimental and numerical investigation of premixed flame propagation with distorted tulip shape in a closed duct [J]. Combustion and Flame, 2012, 159(4): 1523–38. DOI: 10.1016/j.combustflame.2011.12.003. [30] LI Y C, BI M, GAO W. Theoretical pressure prediction of confined hydrogen explosion considering flame instabilities [J]. Journal of Loss Prevention in the Process Industries, 2019, 57(1): 320–326. DOI: 10.1016/j.jlp.2019.01.001. -

下载:

下载: