Application of high-speed 3D-DIC measurement technology in perforation test of armor steel

-

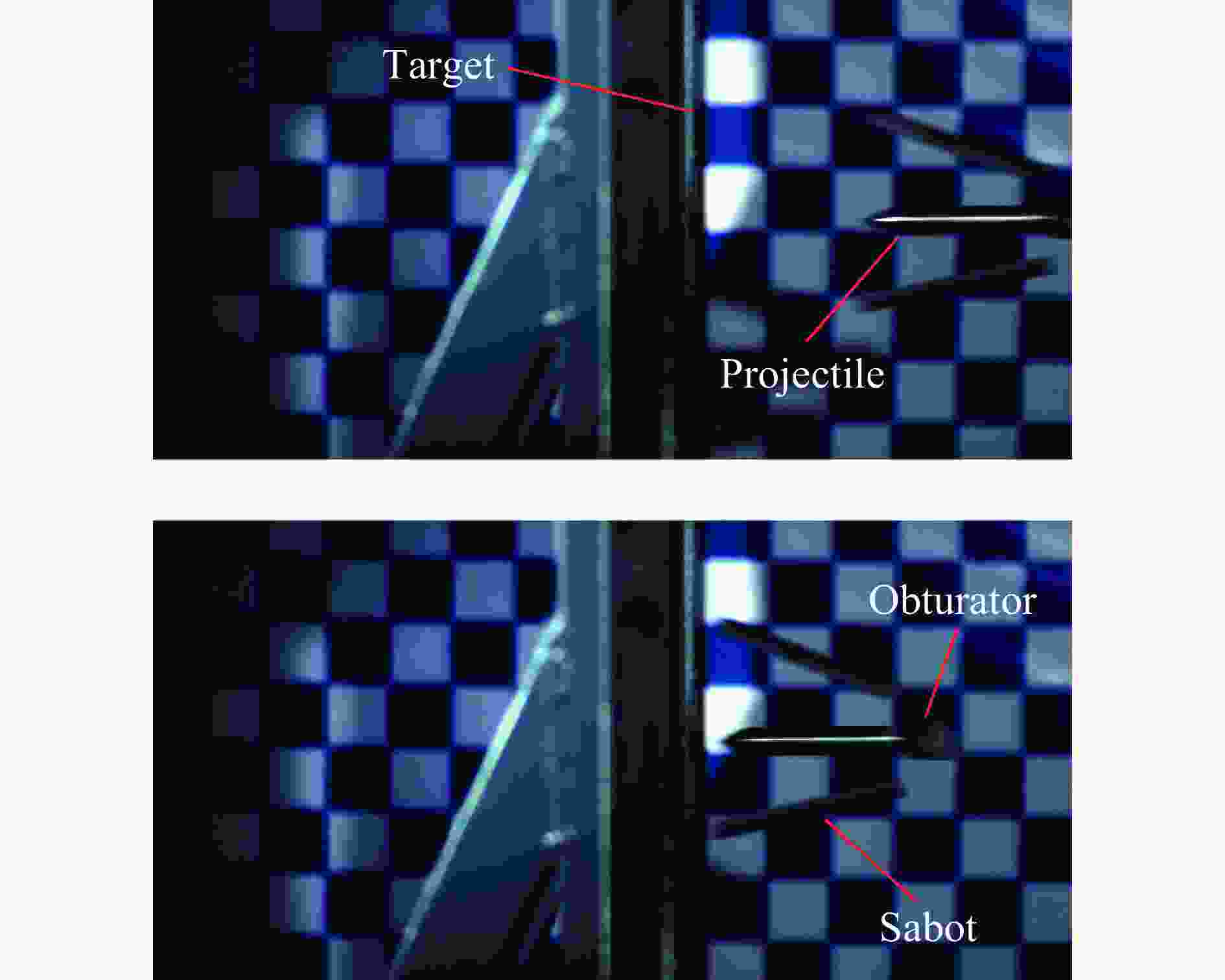

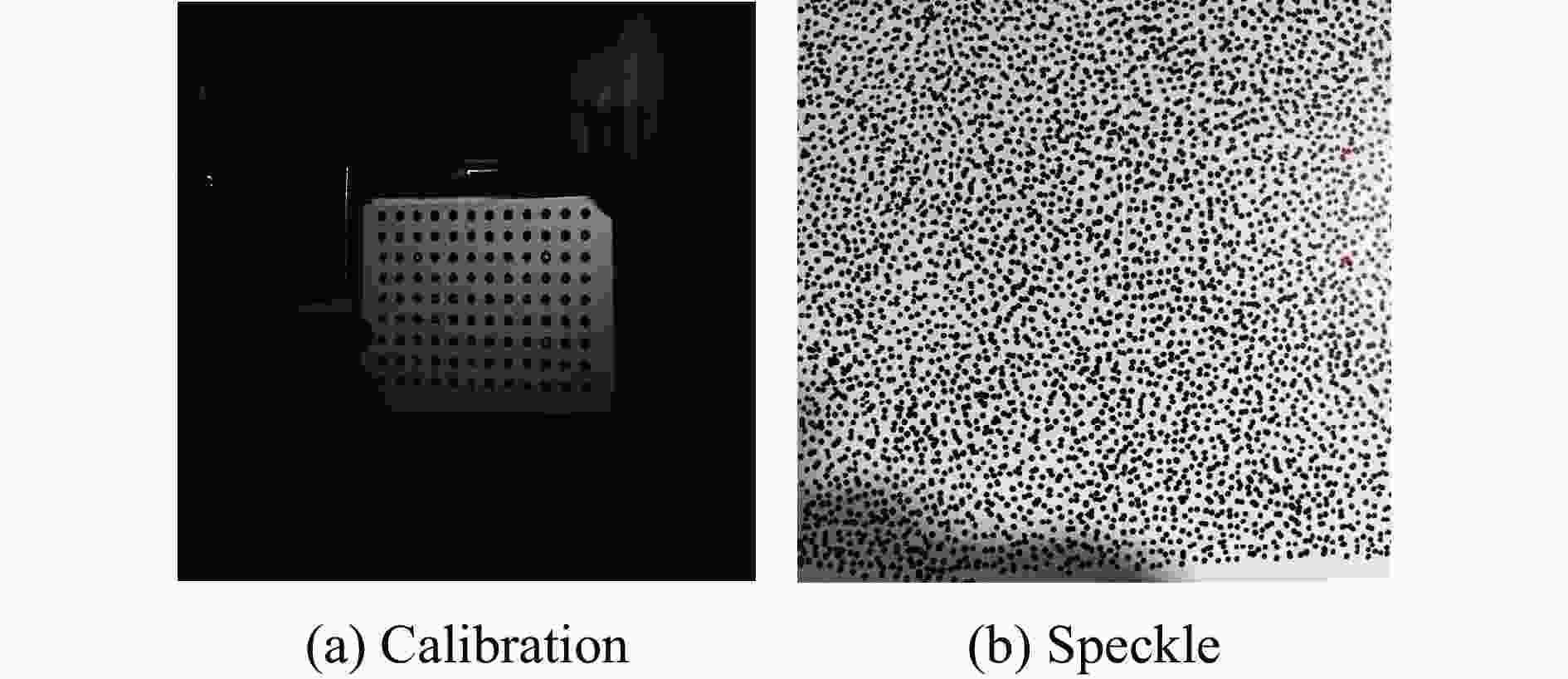

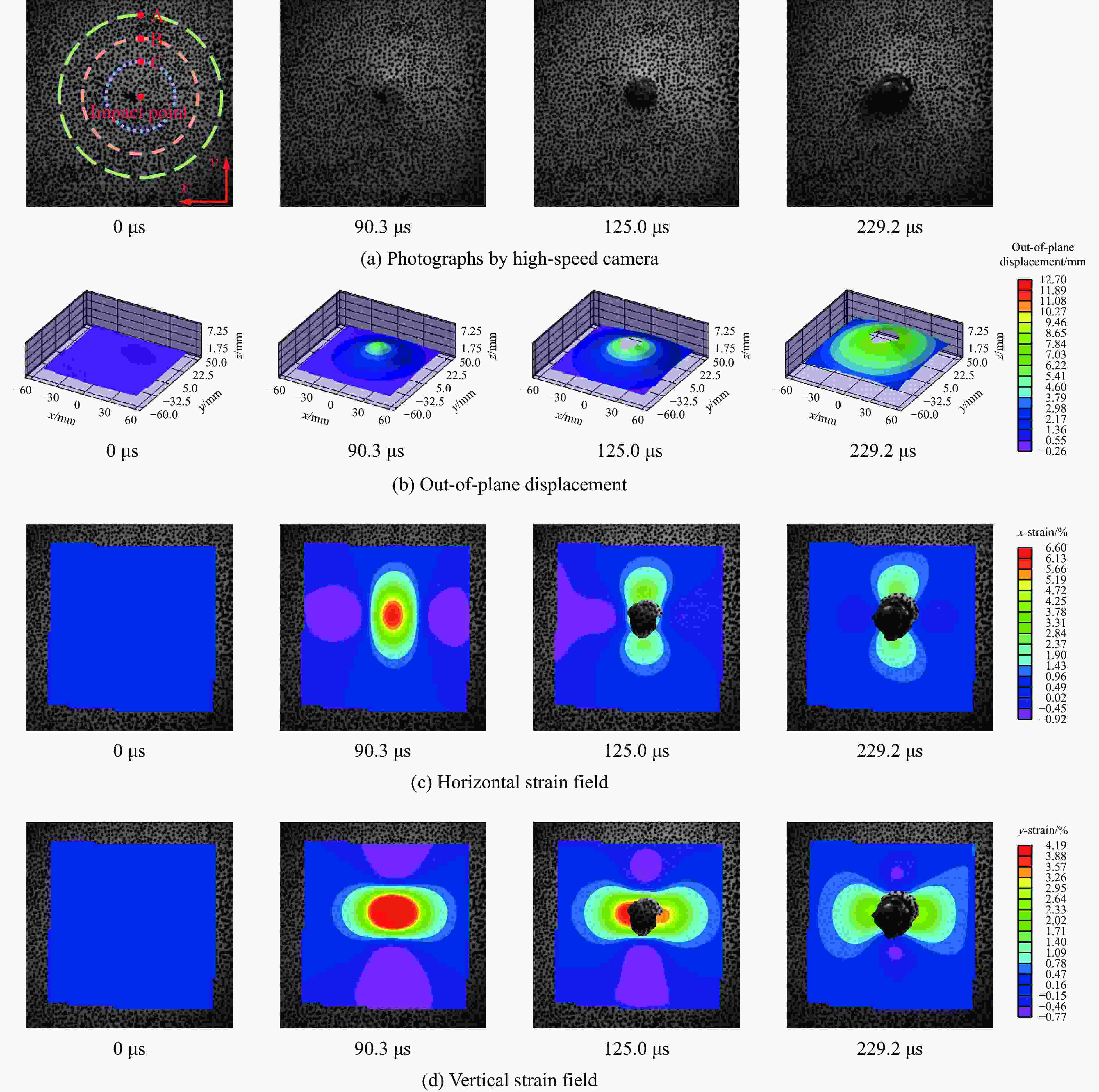

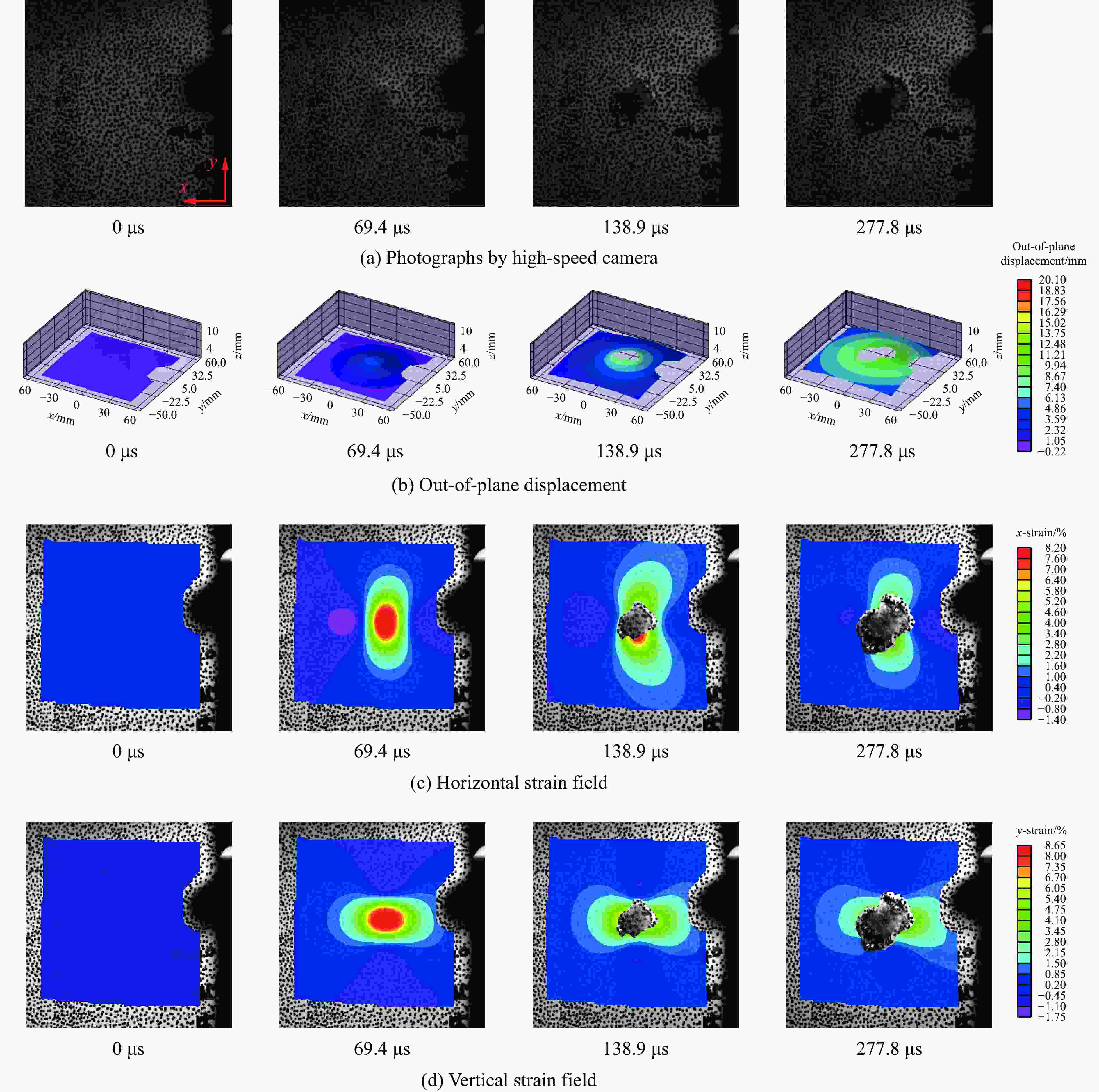

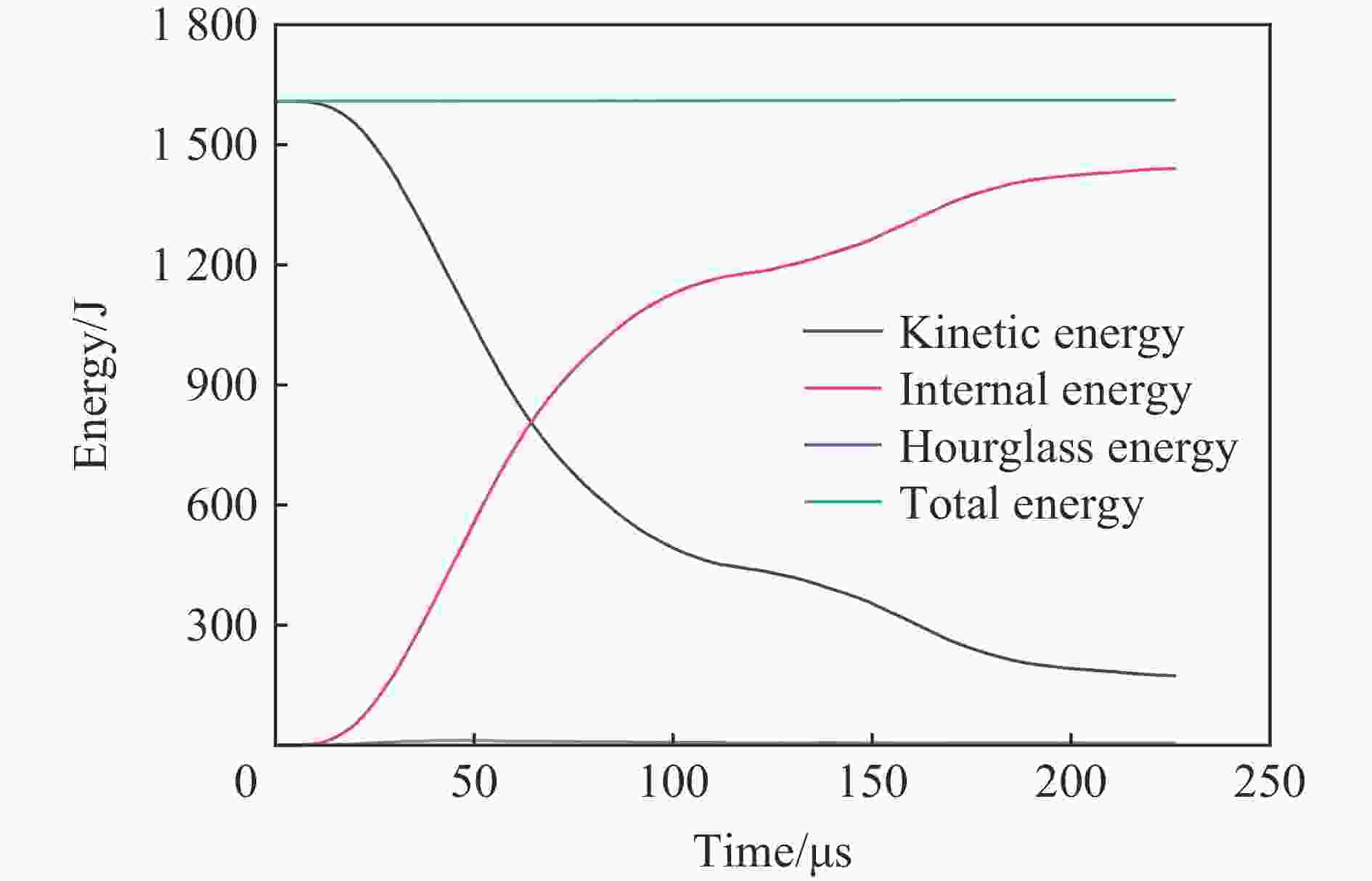

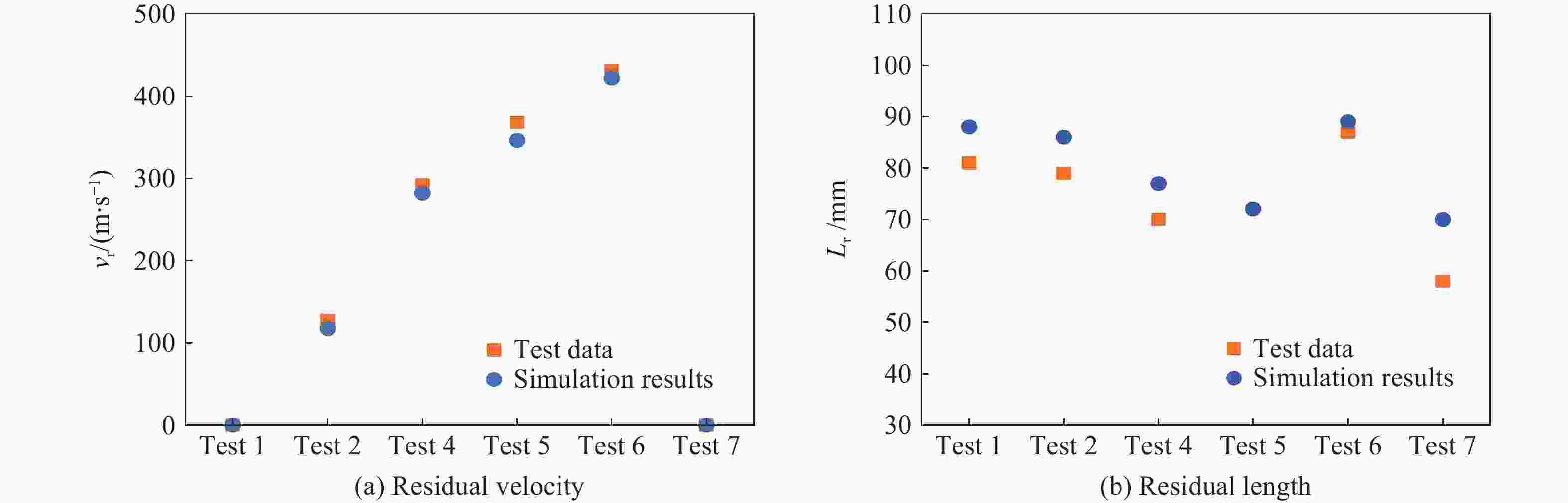

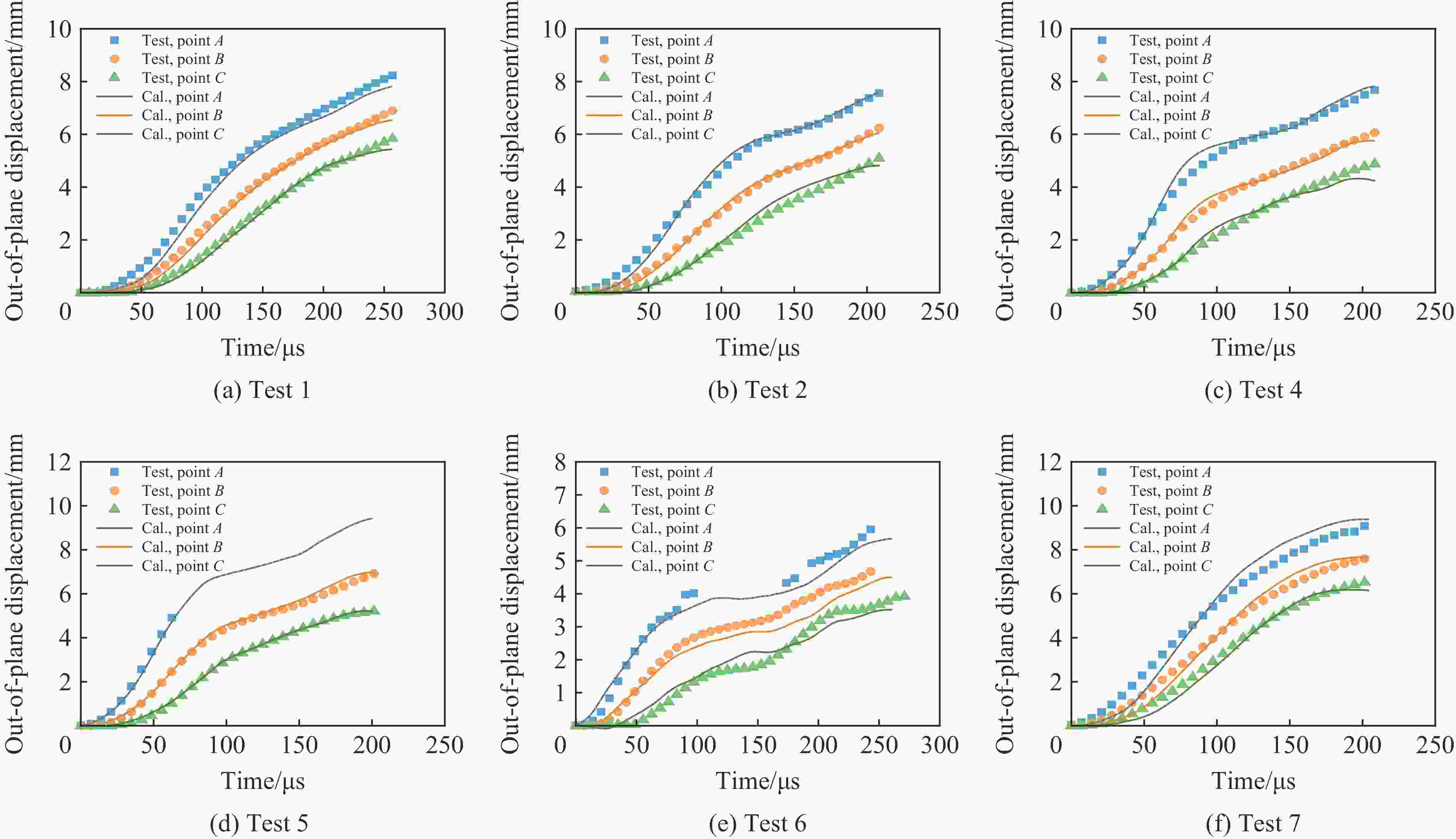

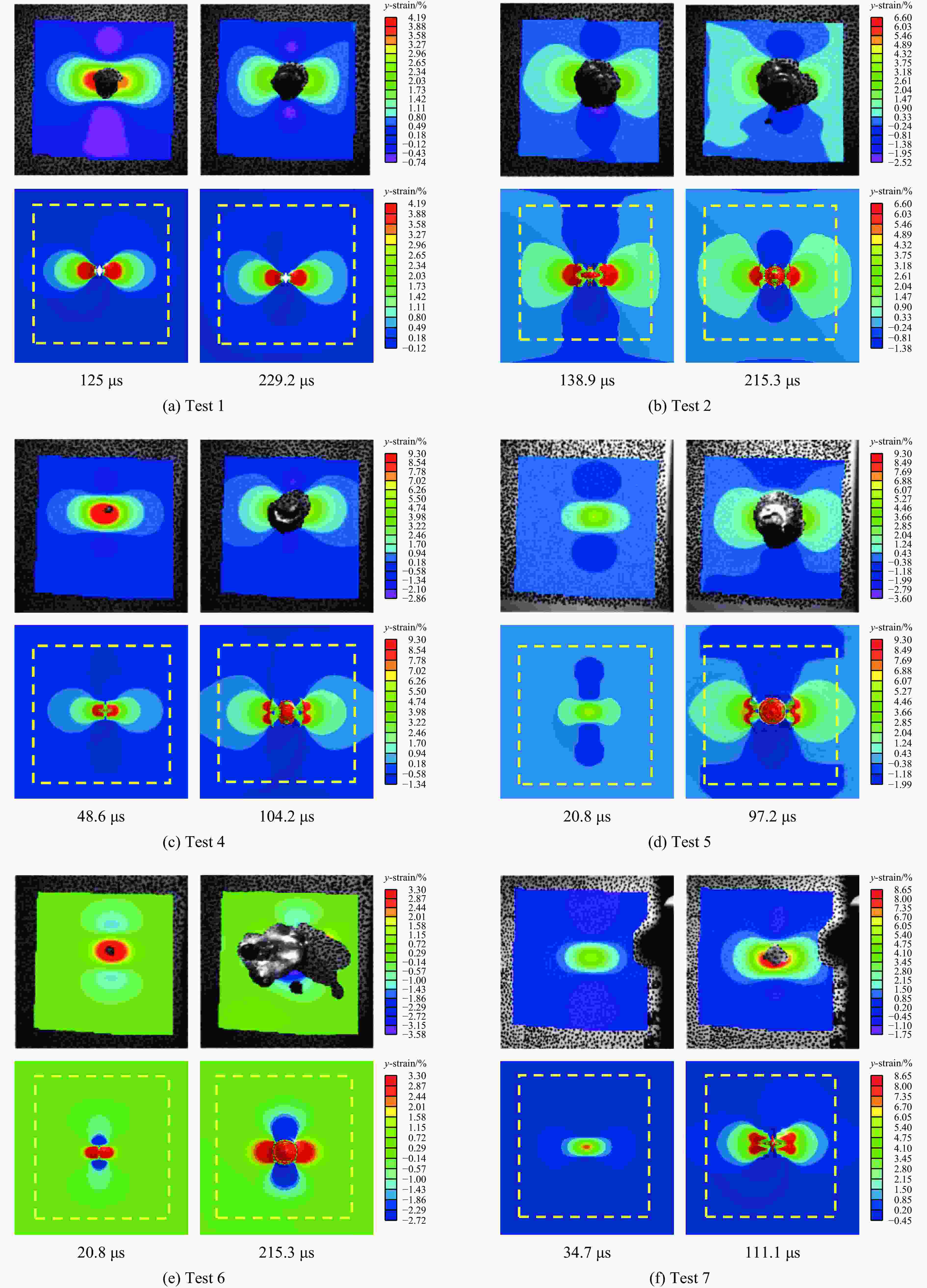

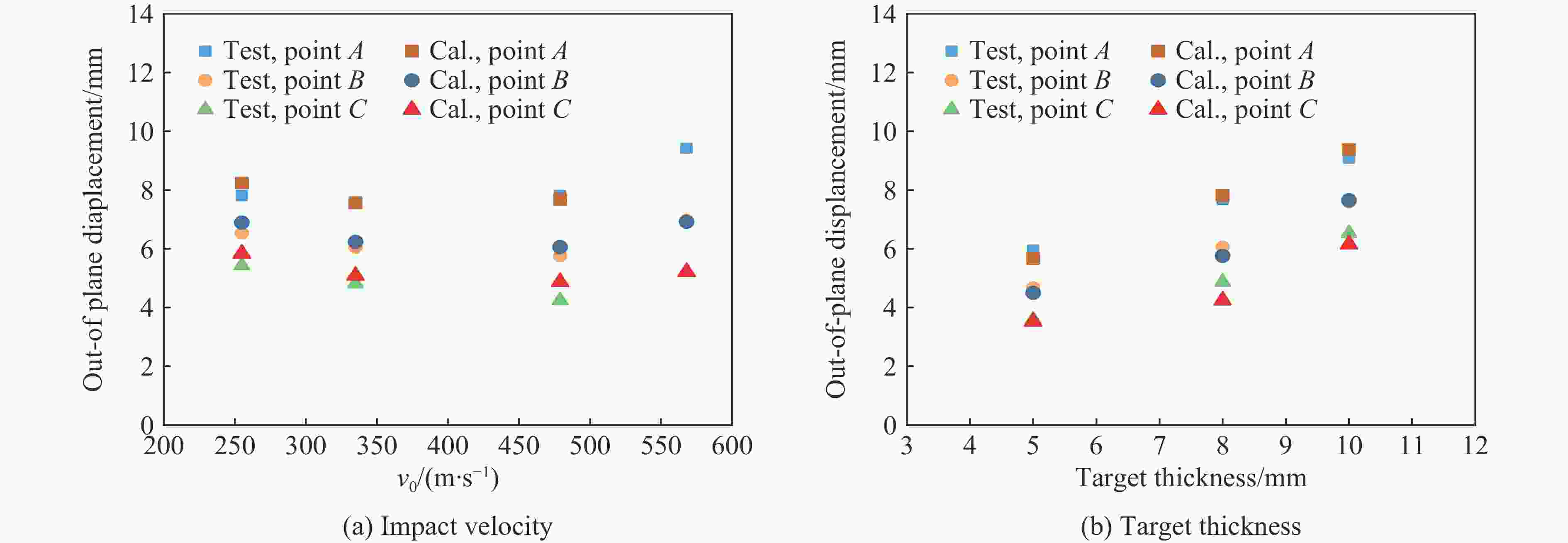

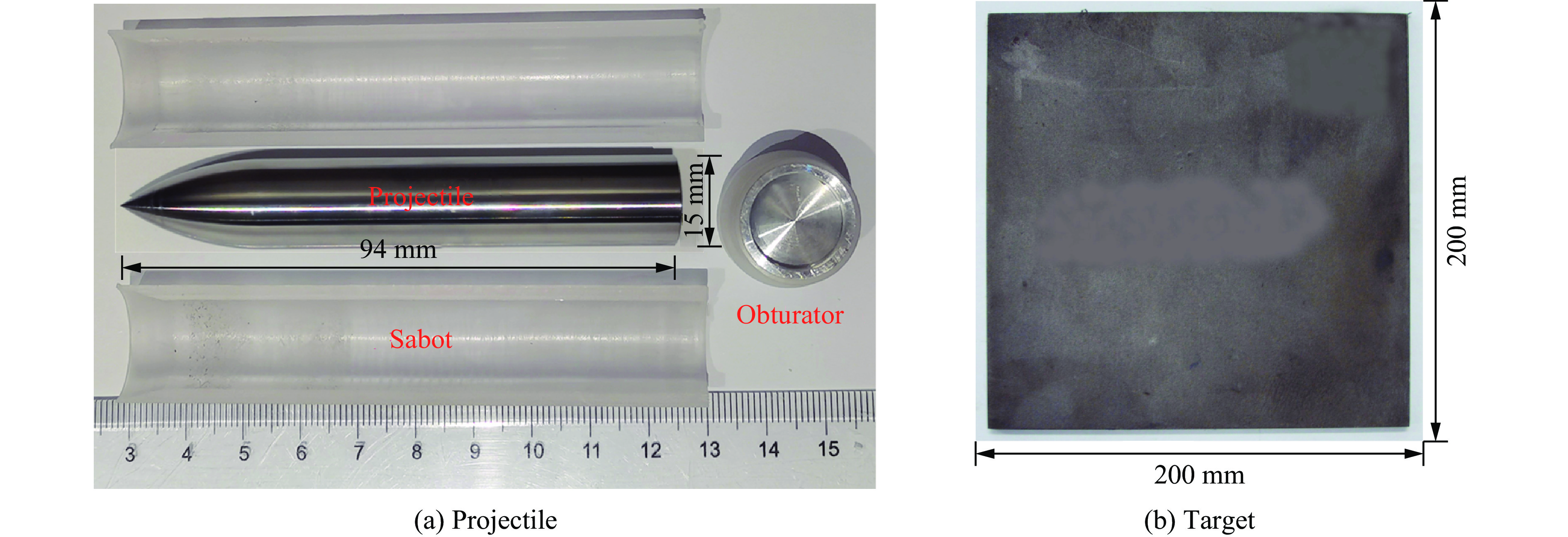

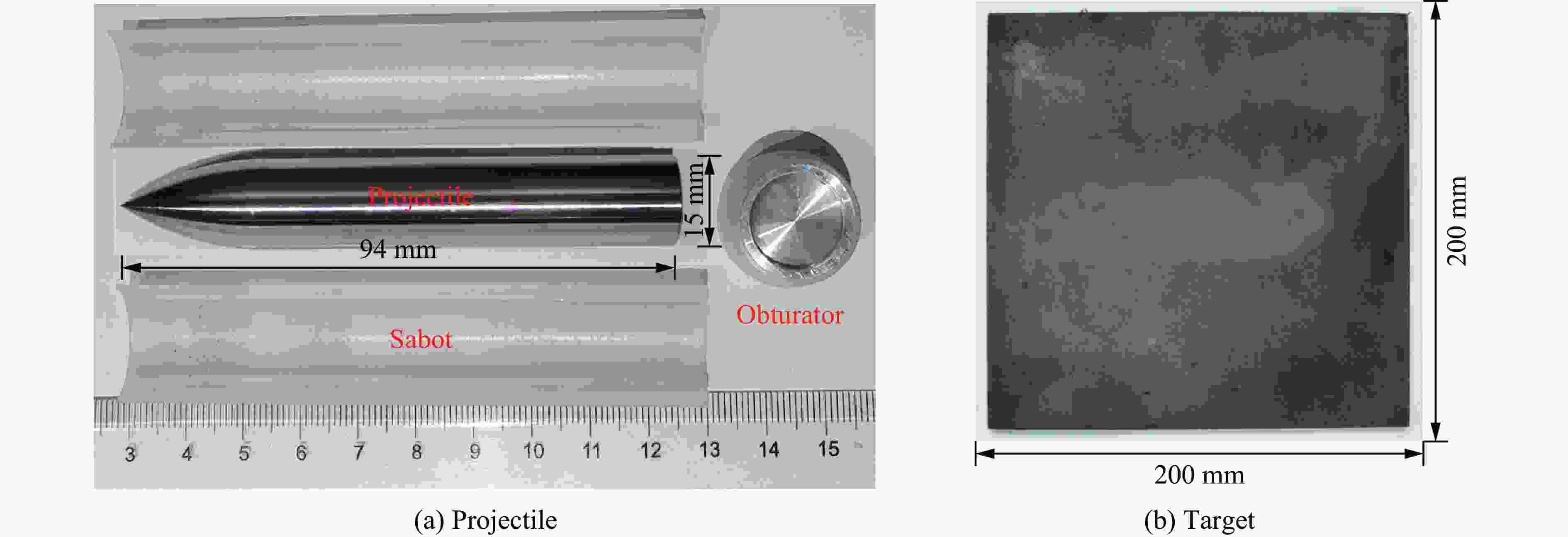

摘要: 数字图像相关(digital image correlation, DIC)技术作为一种非接触、非干涉的全场无损光学量测技术,可获取材料表面的动态变形信息和破坏过程。为了评估装甲钢的抗弹性能并探索高速三维数字图像相关(3D-DIC)技术在钢板贯穿试验测试中的应用,基于氢氧爆轰驱动弹道枪开展了7发15 mm口径可变形弹体以不同速度(255~568 m/s)冲击不同厚度(5、8和10 mm)高强高硬装甲钢板的试验,并结合帧率为144 000 s−1的高速3D-DIC测试技术获取了靶板的离面位移和应变时程。随后,基于前期标定并验证的装甲钢本构模型参数,对上述试验进行了数值模拟。通过对比弹体残余速度和长度验证了有限元分析方法的可靠性。进一步通过对比试验与数值模拟得到的靶背离面位移时程曲线和不同时刻靶背的应变云图,验证了高速3D-DIC测试结果的准确性。最后,对比分析了靶板最大离面位移与弹体冲击速度和装甲钢板厚度的关系。高速3D-DIC测试技术的应用可为相关试验测试提供参考,靶板最大离面位移分析结果可为屏障类防护结构的分析验证和优化设计提供试验依据。Abstract: As a non-contact, non-interference full-field non-destructive optical measurement technology, digital image correlation (DIC) technology can obtain the dynamic deformation information on the surface of materials and failure process. Aiming to evaluate the ballistic performance of armor steel and explore the application of high-speed three-dimensional digital image correlation (3D-DIC) technology in perforation test of armor steel plates, impact tests by seven shots on high strength and hardness armor steel plates with different thicknesses were conducted, in which 15-mm-caliber deformable projectile at various velocities were fired by using hydrogen-oxygen detonation ballistic gun, whilst the high-speed 3D-DIC measurement technology with frame rate of 144000 s−1 was adopted to extract the out-of-plane displacement and strain field-time histories of the target. Then, based on the calibrated and validated constitutive model parameters of armor steel obtained in previous work, the current impact test is numerically simulated and the corresponding finite element model is validated by comparing with the simulated residual projectile velocities and lengths with test data. Furthermore, by comparing the out-of-plane displacement-time histories and strain contours at the rear of target obtained by numerical simulation and test, the accuracy of results obtained by high-speed 3D-DIC is validated. Finally, the relationship between maximum out-of-plane displacement with projectile impact velocity and armor steel plate thickness is analyzed. The results show that the relatively smaller out-of-plane displacements were obtained due to the shear plugging failure for 8 mm-thick targets. Under the identical impact energy, the unperforated targets with the thickness of 10 mm absorb the most of energy and exhibit larger out-of-plane displacements compared with those in targets with the thicknesses of 5 mm and 8 mm. The application of high-speed 3D-DIC technology in this study can provide a reference for related tests, and the analysis result of maximum out-of-plane displacement of target can be used as the experimental basis for the analysis, verification and optimal design in protective barrier structures.

-

Key words:

- high-speed 3D-DIC /

- armor steel /

- perforation test /

- residual velocity /

- out-of-plane displacement

-

表 1 试验数据

Table 1. Test data

试验 板厚/mm v0/(m·s−1) vr/(m·s−1) Mr/g Lr/mm 1 8 255 0 109.4 81 2 8 335 127 109.6 79 3 8 406 111 91.0 67 4 8 479 292 95.3 70 5 8 568 368 − − 6 5 491 431 112.4 87 7 10 489 − 73.5 58 表 2 三个位置点处不同时刻的离面位移

Table 2. The out-of-plane displacement of three points at various times

试验 Out-of-plane displacement/mm 62.5 μs 125 μs 173.6 μs 点 A 点 B 点 C 点 A 点 B 点 C 点 A 点 B 点 C 1 1.536 0.829 0.365 4.848 3.376 2.301 6.302 4.961 3.932 2 2.555 1.359 0.560 5.677 4.076 2.699 6.593 5.213 4.070 4 3.237 1.665 0.702 5.856 4.186 2.947 6.813 5.306 4.202 5 4.906 2.461 1.014 − 5.043 3.704 − 6.156 4.887 6 2.981 1.659 0.352 − 2.979 1.674 4.330 3.519 2.319 7 3.237 2.077 1.290 6.791 5.395 4.313 8.503 7.070 6.008 注:“−”表示由于散斑脱落导致无法读取位移值。 表 3 弹靶J-C本构模型参数

Table 3. J-C constitutive model parameters of projectile and target

强度参数 损伤参数 状态方程参数 A/MPa B/MPa n C m D1 D2 D3 D4 D5 c/(m∙s−1) s1 s2,s3 γ0 a 1230 1647 0.4985 0.013 1.0 0.696 1.827 −2.184 −0.05 0 4578 1.33 0 1.67 0.43 -

[1] FRAS T, ROTH C C, MOHR D. Fracture of high-strength armor steel under impact loading [J]. International Journal of Impact Engineering, 2018, 111: 147–164. DOI: 10.1016/j.ijimpeng.2017.09.009. [2] FRAS T, ROTH C C, MOHR D. Dynamic perforation of ultra-hard high-strength armor steel: impact experiments and modeling [J]. International Journal of Impact Engineering, 2019, 131: 256–271. DOI: 10.1016/j.ijimpeng.2019.05.008. [3] CHOUDHARY S, SINGH P K, KHARE S, et al. Ballistic impact behaviour of newly developed armour grade steel: an experimental and numerical study [J]. International Journal of Impact Engineering, 2020, 140: 103557. DOI: 10.1016/j.ijimpeng.2020.103557. [4] CHEVALIER L, CALLOCH S, HILD F, et al. Digital image correlation used to analyze the multiaxial behavior of rubber-like materials [J]. European Journal of Mechanics - A/Solids, 2001, 20(2): 169–187. DOI: 10.1016/S0997-7538(00)01135-9. [5] MENG S Q, LI J M, LIU Z H, et al. Study of flexural and crack propagation behavior of layered fiber-reinforced cementitious mortar using the digital image correlation (DIC) technique [J]. Materials, 2021, 14(6): 4700. DOI: 10.3390/ma14164700. [6] 杨洋, 孙炜, 王亮, 等. 基于DIC方法的TC4钛合金高温拉伸试验 [J]. 材料热处理学报, 2021, 42(2): 44–51. DOI: 10.13289/j.issn.1009-6264.2020-0378.YANG Y, SUN W, WANG L, et al. High temperature tensile test of TC4 titanium alloy based on digital image correlation method [J]. Transactions of Materials and Heat Treatment, 2021, 42(2): 44–51. DOI: 10.13289/j.issn.1009-6264.2020-0378. [7] 陈学文, 白荣忍, 刘佳琪, 等. 基于数字图像相关技术的X12合金钢高温损伤模型试验验证方法 [J]. 材料热处理学报, 2021, 42(8): 163–169. DOI: 10.13289/j.issn.1009-6264.2021-0073.CHEN X W, BAI R R, LIU J Q, et al. High temperature damage model test verification method of X12 alloy steel based on digital image correlation technology [J]. Transactions of Materials and Heat Treatment, 2021, 42(8): 163–169. DOI: 10.13289/j.issn.1009-6264.2021-0073. [8] 徐纪鹏, 董新龙, 付应乾, 等. 不同加载边界下混凝土巴西劈裂过程及强度的DIC实验分析 [J]. 力学学报, 2020, 52(3): 864–876. DOI: 10.6052/0459-1879-19-303.XU J P, DONG X L, FU Y Q, et al. Experimental analysis of process and tensile strength for concrete Brazilian splitting test with different loading boundaries by DIC method [J]. Chinese Journal of Theoretical and Applied Mechanics, 2020, 52(3): 864–876. DOI: 10.6052/0459-1879-19-303. [9] 杨国梁, 毕京九, 郭伟民, 等. 加载角度对层理页岩裂纹扩展影响的实验研究 [J]. 爆炸与冲击, 2021, 41(9): 093101. DOI: 10.11883/bzycj-2021-0097.YANG G L, BI J J, GUO W M, et al. Experimental study on the effect of loading angle on crack propagation in bedding shale [J]. Explosion and Shock Waves, 2021, 41(9): 093101. DOI: 10.11883/bzycj-2021-0097. [10] 宋海鹏, 刘长春. 基于数字图像相关的预腐蚀2024-T4铝合金疲劳开裂实验 [J]. 航空材料学报, 2020, 40(2): 43–52. DOI: 10.11868/j.issn.1005-5053.2019.000164.SONG H P, LIU C C. Experimental study on fatigue cracking in pre-corroded aluminum alloy 2024-T4 via digital image correlation [J]. Journal of Aeronautical Materials, 2020, 40(2): 43–52. DOI: 10.11868/j.issn.1005-5053.2019.000164. [11] PAN B, YU L P, YANG Y Q, et al. Full-field transient 3D deformation measurement of 3D braided composite panels during ballistic impact using single-camera high-speed stereo-digital image correlation [J]. Composite Structures, 2016, 157: 25–32. DOI: 10.1016/j.compstruct.2016.08.017. [12] 徐振洋, 杨军, 郭连军. 爆炸聚能作用下混凝土试件劈裂的高速3D DIC实验 [J]. 爆炸与冲击, 2016, 36(3): 400–406. DOI: 10.11883/1001-1455(2016)03-0400-07.XU Z Y, YANG J, GUO L J. Study of the splitting crack propagation morphology using high-speed 3D DIC [J]. Explosion and Shock Waves, 2016, 36(3): 400–406. DOI: 10.11883/1001-1455(2016)03-0400-07. [13] ROLFE E, KABOGLU C, QUINN R, et al. High velocity impact and blast loading of composite sandwich panels with novel carbon and glass construction [J]. Journal of Dynamic Behavior of Materials, 2018, 4(3): 359–372. DOI: 10.1007/s40870-018-0163-5. [14] XING H Z, ZHAO J, WU G, et al. Perforation model of thin rock slab subjected to rigid projectile impact at an intermediate velocity [J]. International Journal of Impact Engineering, 2020, 139: 103536. DOI: 10.1016/j.ijimpeng.2020.103536. [15] 魏宏健, 姜雄文, 赵庚, 等. 爆炸冲击波载荷下预制孔铝板的动态响应 [J]. 兵工学报, 2021, 42(S1): 96–104. DOI: 10.3969/j.issn.1000-1093.2021.S1.013.WEI H J, JIANG X W, ZHAO G, et al. Dynamic response of aluminum plates with pre-formed holes under airblast loading [J]. Acta Armamentarii, 2021, 42(S1): 96–104. DOI: 10.3969/j.issn.1000-1093.2021.S1.013. [16] LIU X, YANG J, XU Z Y, et al. Experimental investigations on crack propagation characteristics of granite rectangle plate with a crack (GRPC) under different blast loading rates [J]. Shock and Vibration, 2020, 2020: 8885582. DOI: 10.1155/2020/8885582. [17] 范亚夫, 魏延鹏, 薛跃军, 等. 数字图像相关测试技术在霍普金森杆加载实验中的应用 [J]. 实验力学, 2015, 30(5): 590–598. DOI: 10.7520/1001-4888-14-273.FAN Y F, WEI Y P, XUE Y J, et al. On the application of digital image correlation testing technology in Hopkinson bar loading [J]. Journal of Experimental Mechanics, 2015, 30(5): 590–598. DOI: 10.7520/1001-4888-14-273. [18] 邢灏喆, 王明洋, 范鹏贤, 等. 基于高速3D-DIC技术的砂岩动力特性粒径效应研究 [J]. 爆炸与冲击, 2021, 41(11): 113101. DOI: 10.11883/bzycj-2021-0088.XING H Z, WANG M Y, FAN P X, et al. Grain-size effect on dynamic behavior of sandstone based on high-speed 3D-DIC technique [J]. Explosion and Shock Waves, 2021, 41(11): 113101. DOI: 10.11883/bzycj-2021-0088. [19] ATAPEK S H, KARAGOZ S. Ballistic impact behaviour of a tempered bainitic steel against 7.62 mm armour piercing projectile [J]. Defence Science Journal, 2011, 61(1): 81–87. DOI: 10.14429/dsj.61.411. [20] BURIAN W, ŻOCHOWSKI P, GMITRZUK M, et al. Protection effectiveness of perforated plates made of high strength steel [J]. International Journal of Impact Engineering, 2019, 126: 27–39. DOI: 10.1016/j.ijimpeng.2018.12.006. [21] 程月华, 吴昊, 谭可可, 等. 装甲钢/UHPC复合靶体抗侵彻性能试验与数值模拟研究 [J]. 爆炸与冲击, 2022, 42(5): 053302. DOI: 10.11883/bzycj-2021-0278.CHENG Y H, WU H, TAN K K, et al. Experimental and numerical studies on penetration resistance of armor steel/UHPC composite targets [J]. Explosion and Shock Waves, 2022, 42(5): 053302. DOI: 10.11883/bzycj-2021-0278. [22] Livermore Software Technology Corporation. LS-DYNA keyword user’s manual [Z]. Livermore: Livermore Software Technology Corporation, 2001. [23] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures [C]//Proceedings of the 7th International Symposium on Ballistics. Hague, 1983. [24] JOHNSON G R, COOK W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures [J]. Engineering Fracture Mechanics, 1985, 21(1): 31–48. DOI: 10.1016/0013-7944(85)90052-9. [25] STEINBERG D J. Equation of state and strength properties of selected materials [M]. Livermore: Lawrence Livermore National Laboratory, 1996. [26] IQBAL D, TIWARI V. Investigations on the influence of projectile shape on the transient and post impact response of thin sheet structures [J]. Thin-Walled Structures, 2019, 145: 106402. DOI: 10.1016/j.tws.2019.106402. -

下载:

下载: