Numerical simulation of explosive separation of mild detonating fuse based on coupling algorithm of smoothed particle hydrodynamics with finite element method

-

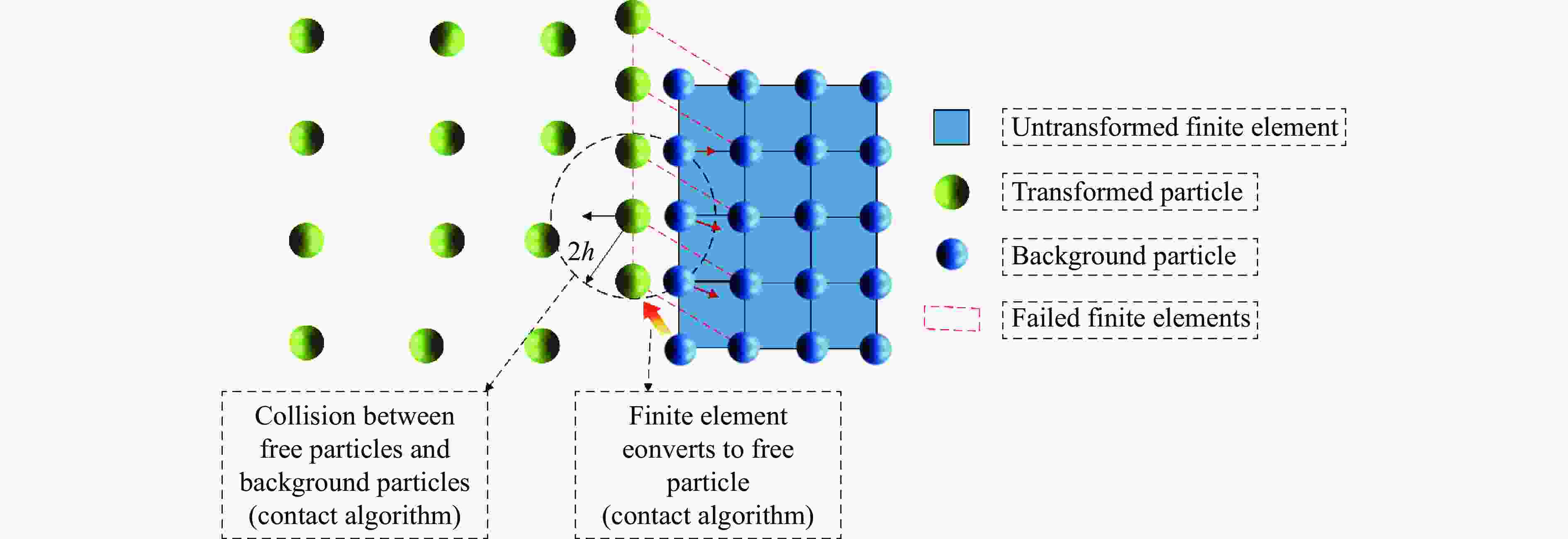

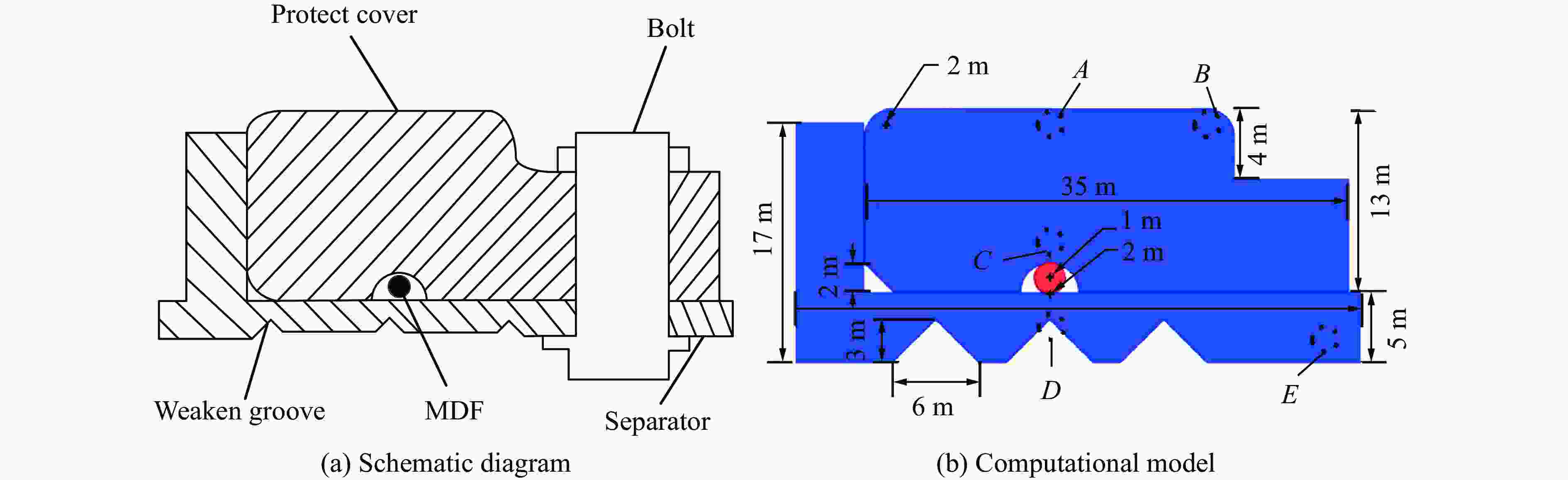

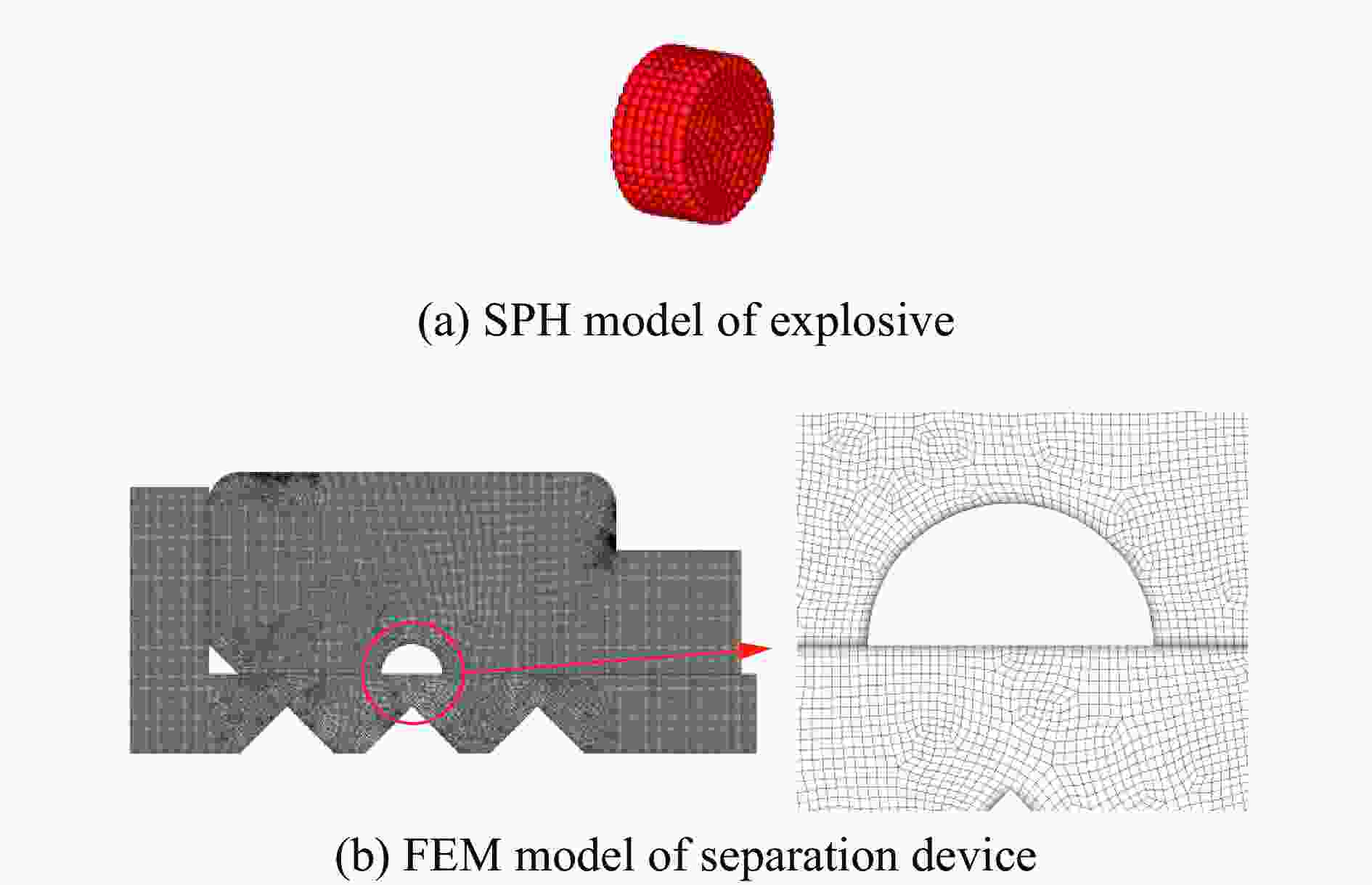

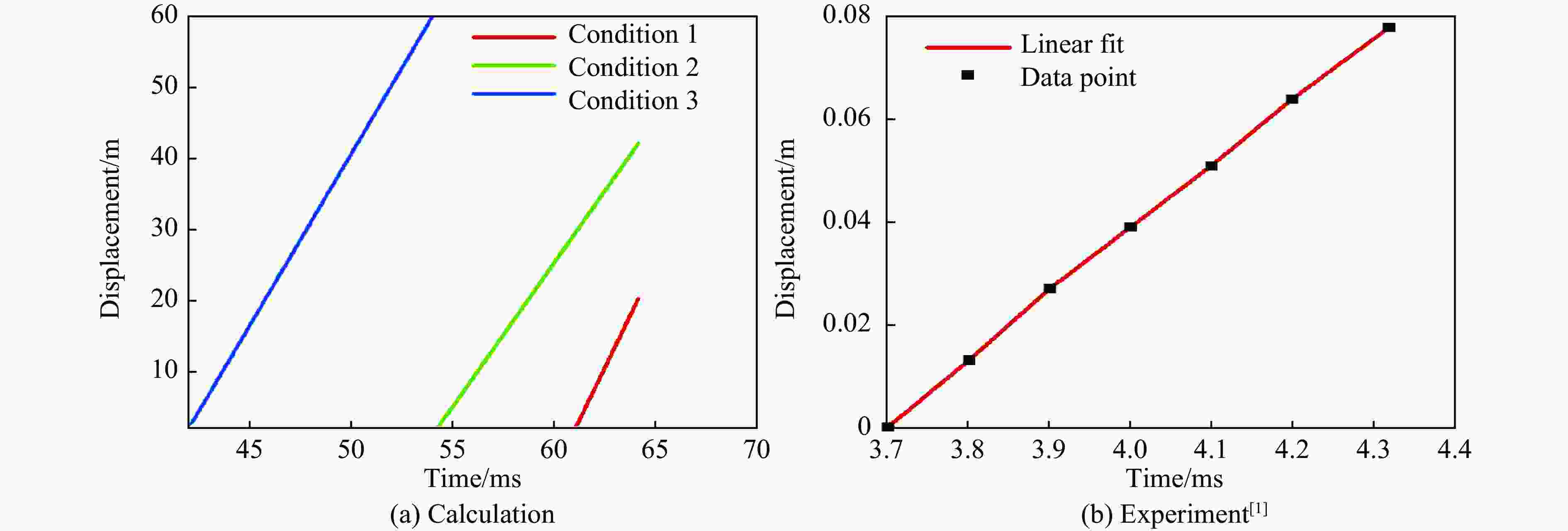

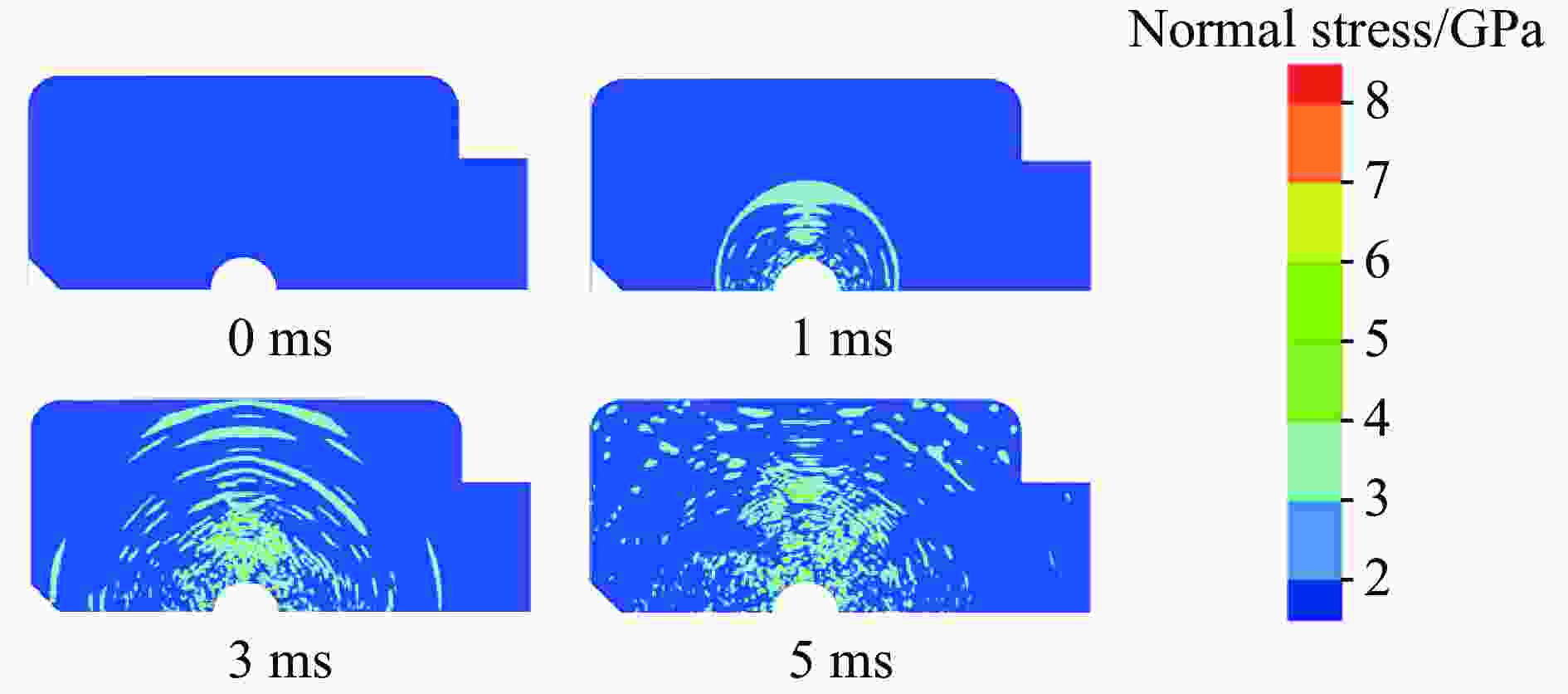

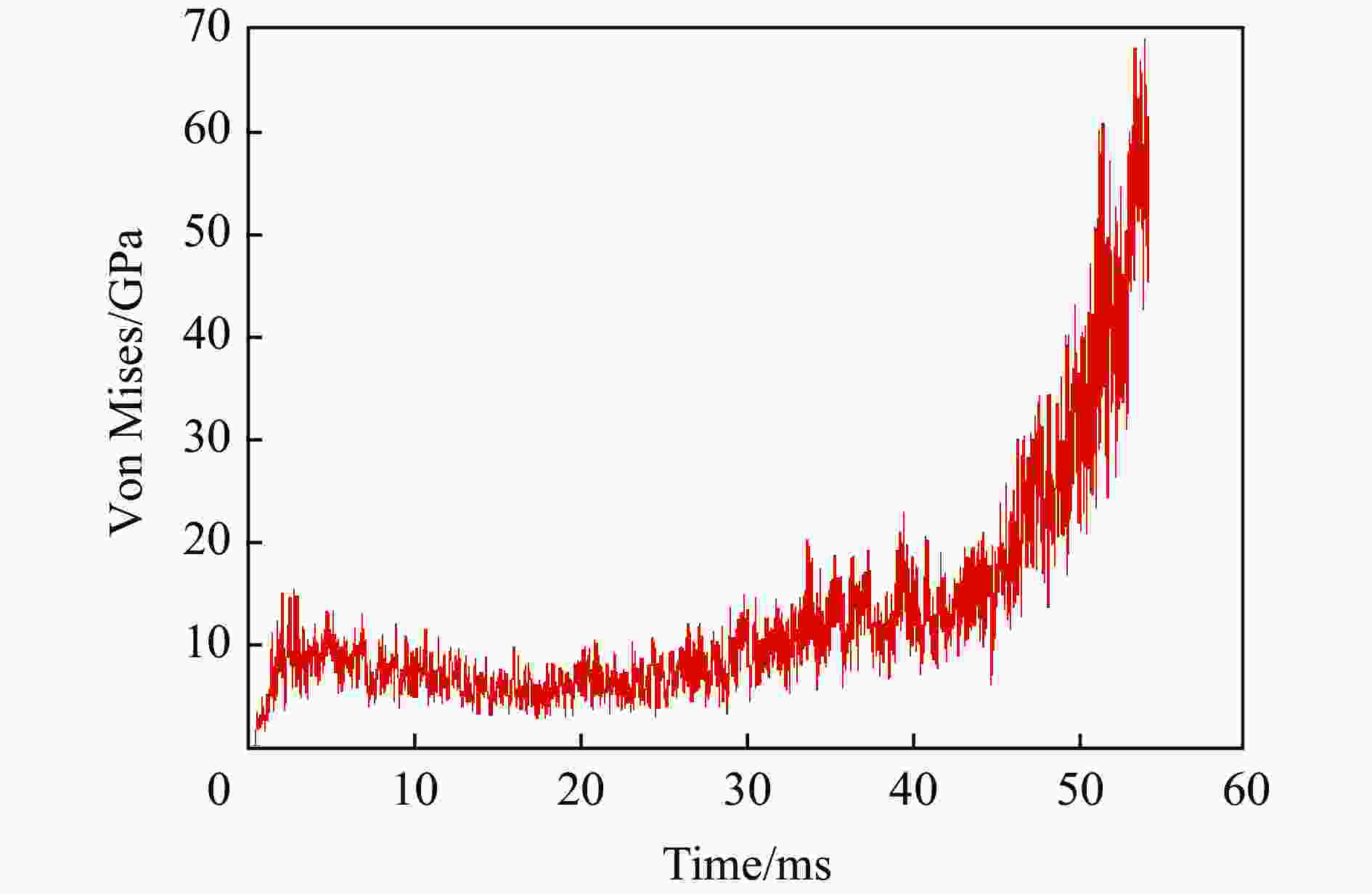

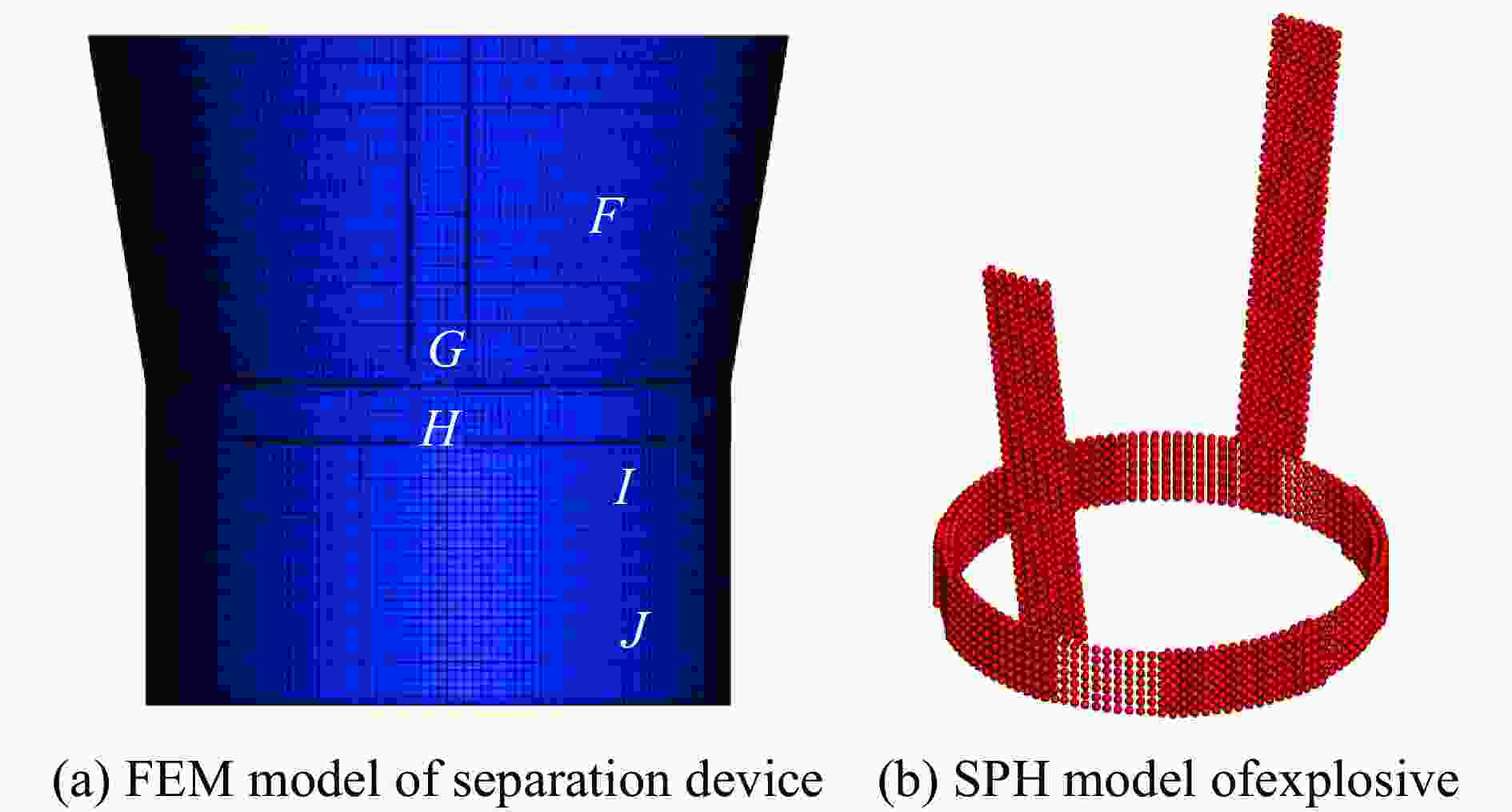

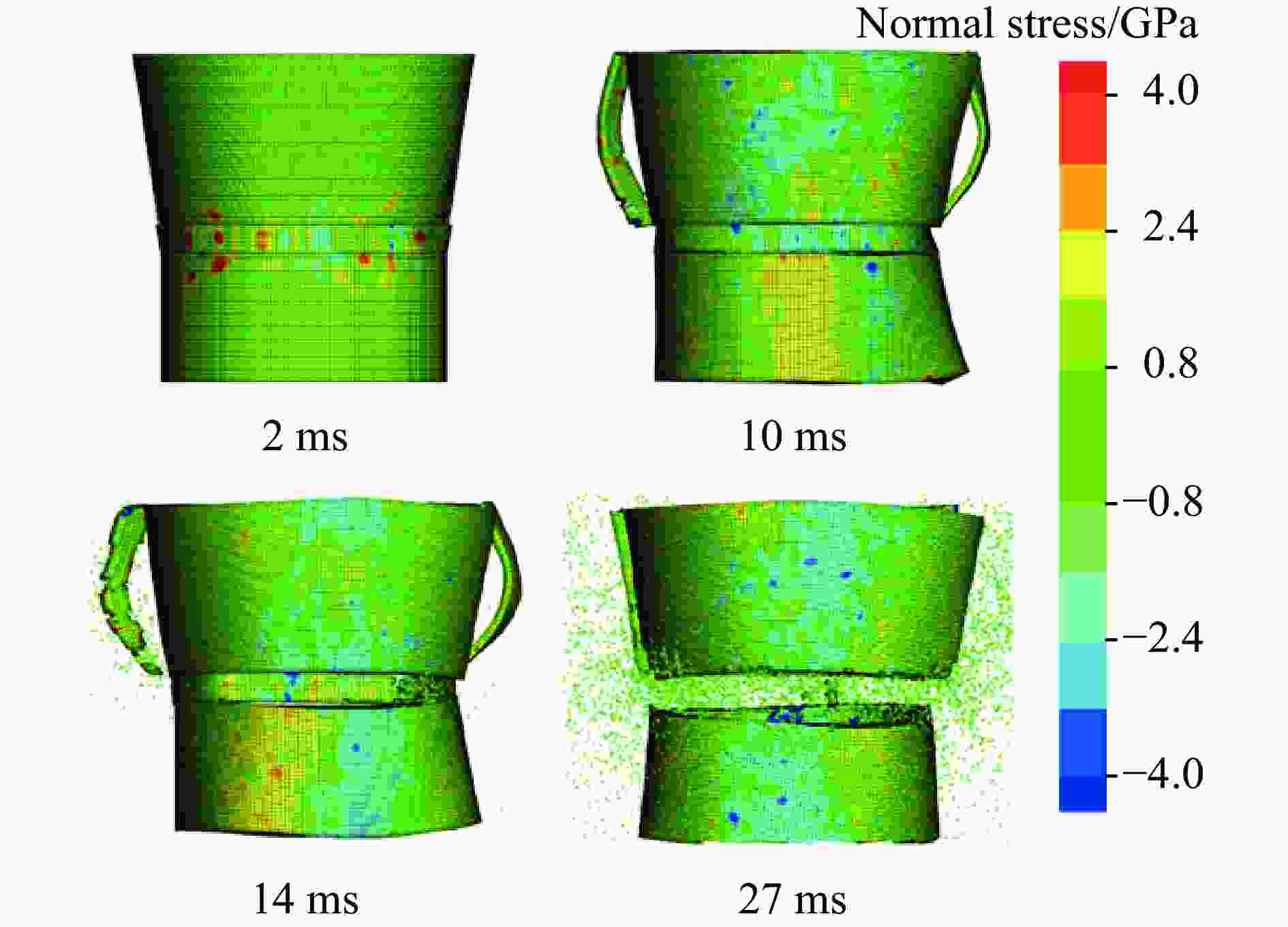

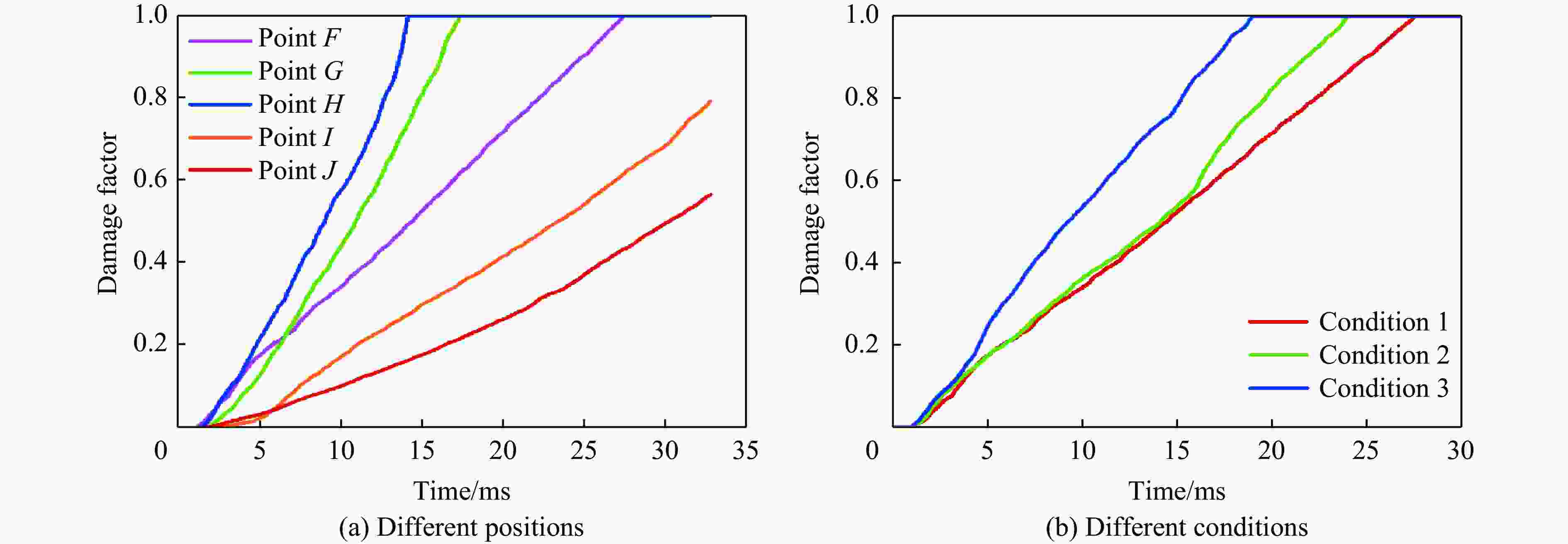

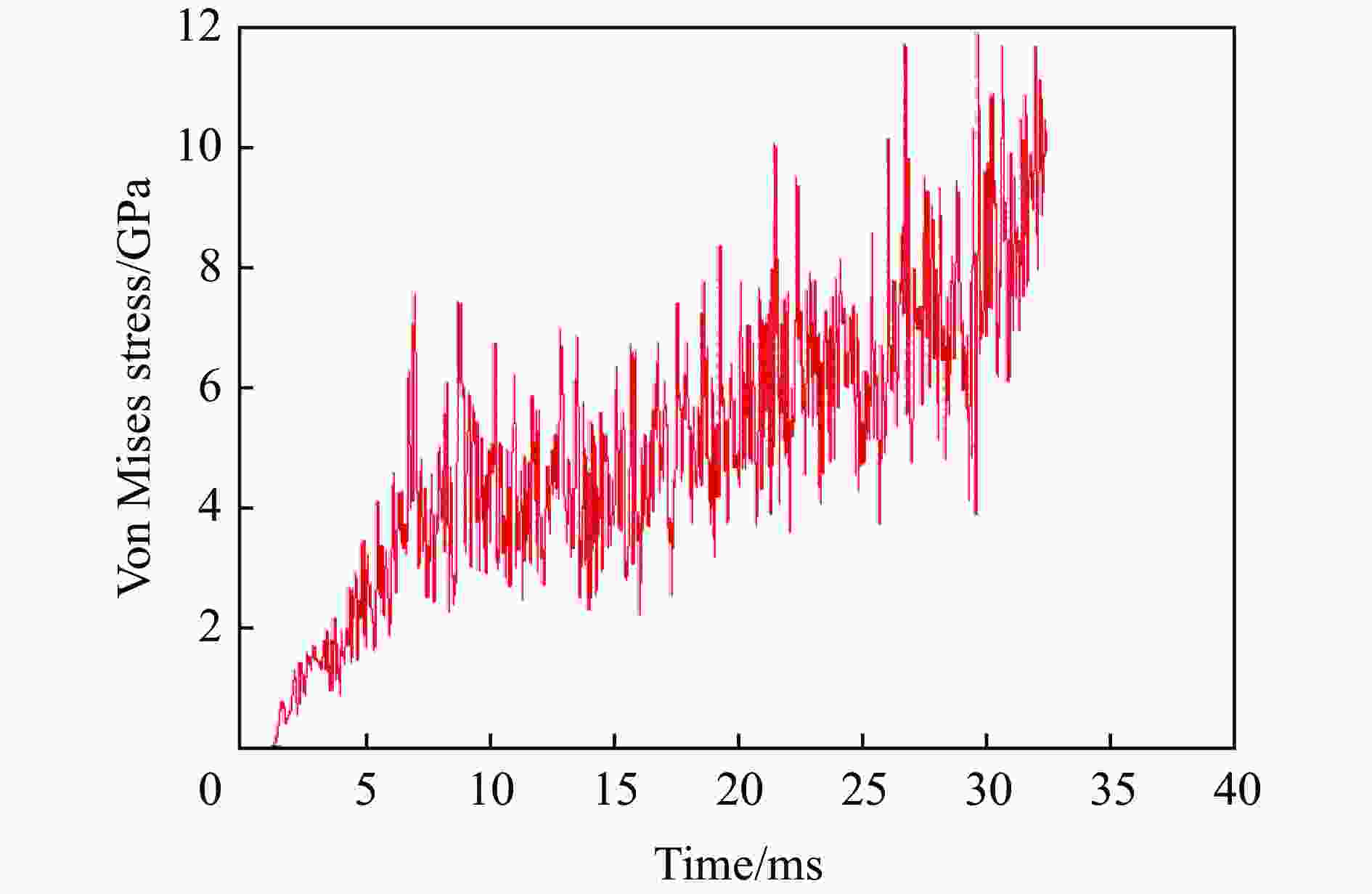

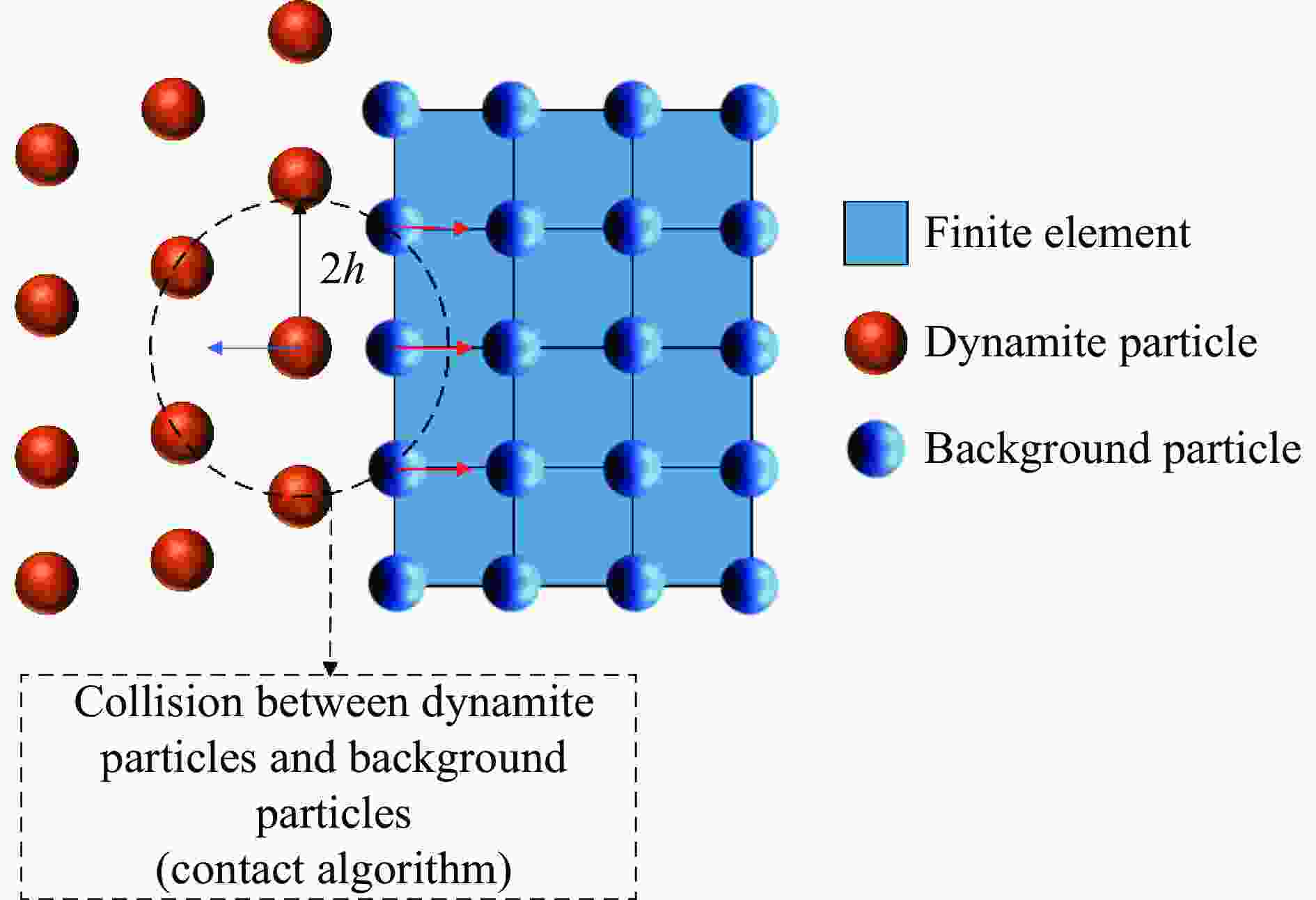

摘要: 为深入研究柔性导爆索在爆炸分离装置中的作用过程和机理,提出一种改进的光滑粒子流体动力学方法(smoothed particle hydrodynamics, SPH)与有限单元法( finite element method, FEM)耦合算法。新方法中不仅包含导爆索模拟的SPH方法与分离装置模拟的FEM方法之间的接触算法,同时将完全损伤失效后的单元采用转化算法动态转化成SPH粒子继续参与计算,转化后的粒子与未转化的有限单元之间采用接触算法计算。采用该方法对环型和平板型两种爆炸分离结构的分离过程进行了数值模拟,验证了新方法的准确性与问题适用性;分析了分离板的变形断裂及损伤碎片的飞溅过程,得到了分离装置表面不同时刻的应力分布、损伤因子的变化趋势、von Mises应力的变化趋势;探讨了炸药在不同比内能情况下单元的屈服损伤速度、碎片的飞溅位移速度。Abstract: Mild detonating fuse (MDF) explosive separation device is a widely used explosive separation device because of its relatively easy processing, simple structure, low cost and high reliability. In order to further study the action process and mechanism of flexible detonating cord in explosive separation device, an improved coupling algorithm of smooth particle hydrodynamics (SPH) and finite element method (FEM) is proposed in this paper. The new method is not limited to the contact algorithm between SPH method for MDF simulation and FEM method for separation device simulation; the element after complete damage failure is dynamically transformed into SPH particle by the transformation algorithm to continue its participation in the calculation, and the contact algorithm is used to calculate the relationship between the transformed particle and the untransformed finite element. By using this method, the separation process of two kinds of explosive separation structures with ring and plate shape is numerically simulated, and the accuracy and validity of the new method are verified. Then, the deformation and fracture of the separation plate and the spatter process of damage fragments are analyzed, while the stress distribution of the surface of the separation device at different time, the change trend of damage factor and the change trend of von Mises stress are obtained. Moreover, the yield damage velocity of the element and the spatter displacement velocity of fragments under various pecific internal energy of explosives are discussed. The results show that the stress at the weakening groove on the surface of the separation device is the largest, and the elements near the surface yield first; the von Mises stress shows an oscillating upward trend with time; with the increase of the initial specific internal energy of explosive, the yield damage speed of the element and the splash displacement speed of the fragments increase significantly.

-

Key words:

- mild detonating fuse /

- explosive separation /

- SPH-FEM /

- coupling method /

- yield damage

-

表 1 炸药的JWL状态方程参数

Table 1. Parameters of JWL equation of state for explosives

工况 材料 装药密度/(kg·m−3) 爆速/(m·s−1) A/GPa B/GPa R1 R2 w 比内能/(kJ·kg−1) 1 RDX 1500 8611 611.30 10.65 4.40 1.20 0.32 5450 2 HL15 1750 8611 972.27 38.23 5.25 1.73 0.48 10000 3 − 1950 8611 1172.27 40.23 5.25 1.73 0.48 15000 注:工况3的材料是人为添加的,旨在预测之后出现的更大含能材料。 表 2 分离装置的参数

Table 2. Parameters of separation device

材料 密度/(kg·m−3) 弹性模量/GPa μ A/MPa B/MPa C n 钢 7850 200 0.33 525 101 0.1739 0.081 m D1 D2 D3 D4 D5 g0/s−1 T0/K Tm/K Cp/(J·kg−1·K−1) 0.081 300 1.732 0.54 −0.0123 0 0.0005 300 1800 452 -

[1] 文学军. 线式爆炸分离碎片飞散安全性研究 [D]. 长沙: 国防科学技术大学, 2016.WEN X J. Separation security of fragments during linear explosive separation process [D]. Changsha: National University of Defense Technology, 2016. [2] 曹雷. 爆炸分离过程中保护罩结构能量分配及损伤特性研究 [D]. 长沙: 国防科学技术大学, 2016.CAO L. Study on energy distribution and damage property of protecting retainer during explosion separation [D]. Changsha: National University of Defense Technology, 2016. [3] 吴艳萍, 魏华男, 薛润华, 等. 柔性多点同步起爆装置设计与试验研究 [J]. 火工品, 2022(3): 14–17. DOI: 10.3969/j.issn.1003-1480.2022.03.004.WU Y P, WEI H N, XUE R H, et al. Design and experimental study of flexible multipoint synchronous initiation device [J]. Initiators & Pyrotechnics, 2022(3): 14–17. DOI: 10.3969/j.issn.1003-1480.2022.03.004. [4] 赵凯, 朱顺官, 张琳, 等. SY装药柔爆索的爆轰特性研究 [J]. 火工品, 2015(6): 10–13. DOI: 10.3969/j.issn.1003-1480.2015.06.003.ZHAO K, ZHU S G, ZHANG L, et al. Study on detonation characteristic of SY mild detonating cord [J]. Initiators & Pyrotechnics, 2015(6): 10–13. DOI: 10.3969/j.issn.1003-1480.2015.06.003. [5] 范新中, 苏晗, 杨小龙, 等. 一种航天线性分离装置装药量可靠性设计及可靠性评定方法 [J]. 导弹与航天运载技术, 2013(5): 63–65. DOI: 10.7654/j.issn.1004-7182.20130515.FAN X Z, SU H, YANG X L, et al. A reliability design and evaluation method for charge weight of aerospace linear separation devices [J]. Missiles and Space Vehicles, 2013(5): 63–65. DOI: 10.7654/j.issn.1004-7182.20130515. [6] 陈敏, 隋允康, 阳志光. 宇航火工分离装置爆炸分离数值模拟 [J]. 火工品, 2007, 16(5): 5–8. DOI: 10.3969/j.issn.1003-1480.2007.05.002.CHEN M, SUI Y K, YANG Z G. Numerical simulation of exploding separation for aerospace pyrotechnical actuated separation device [J]. Initiators & Pyrotechnics, 2007, 16(5): 5–8. DOI: 10.3969/j.issn.1003-1480.2007.05.002. [7] 王瑞峰, 卢芳云, 阳志光, 等. 保护罩破坏机理的分析及改进设计 [J]. 导弹与航天运载技术, 2007, 27(4): 17–20. DOI: 10.3969/j.issn.1004-7182.2007.04.005.WANG R F, LU F Y, YANG Z G, et al. Investigation on fracture mechanism of a retainer and its improvement design [J]. Missiles and Space Vehicles, 2007, 27(4): 17–20. DOI: 10.3969/j.issn.1004-7182.2007.04.005. [8] 宋保永, 卢红立, 阳志光, 等. 分离结构在冲击载荷作用下的破坏机理研究 [J]. 兵工学报, 2009, 30(S2): 102–106.SONG B Y, LU H L, YANG Z G, et al. Studies on fracture mechanism of explosive separation device subjected to impact loads [J]. Acta Armamentarii, 2009, 30(S2): 102–106. [9] 卢红立, 靳佳波, 侯金瑛, 等. 爆炸载荷作用下玻璃钢防护结构破坏分析 [J]. 兵工学报, 2016, 37(S1): 109–113.LU H L, JIN J B, HOU J Y, et al. Research on failure of fiberglass protective structure under explosive load [J]. Acta Armamentarii, 2016, 37(S1): 109–113. [10] 戈庆明, 渠弘毅, 王寅虎, 等. 柔性导爆索切割过程仿真及试验研究 [J]. 导弹与航天运载技术, 2020(6): 23–26. DOI: 10.7654/j.issn.1004-7182.20200605.GE Q M, QU H Y, WANG Y H, et al. Simulation and experiment of cutting ability of mild detonating fuse [J]. Missiles and Space Vehicles, 2020(6): 23–26. DOI: 10.7654/j.issn.1004-7182.20200605. [11] 王维国, 陈育民, 刘汉龙, 等. 基于SPH-FEM耦合法的土体爆炸效应数值研究 [J]. 岩土力学, 2013, 34(7): 2104–2110. DOI: 10.16285/j.rsm.2013.07.015.WANG W G, CHEN Y M, LIU H L, et al. Numerical simulation of explosion in soil based on a coupled SPH-FEM algorithm [J]. Rock and Soil Mechanics, 2013, 34(7): 2104–2110. DOI: 10.16285/j.rsm.2013.07.015. [12] WANG W, WU Y J, WU H, et al. Numerical analysis of dynamic compaction using FEM-SPH coupling method [J]. Soil Dynamics and Earthquake Engineering, 2021, 140: 106420. DOI: 10.1016/j.soildyn.2020.106420. [13] ZHONG H Q, LYU L, YU Z X, et al. Study on mechanical behavior of rockfall impacts on a shed slab based on experiment and SPH-FEM coupled method [J]. Structures, 2021, 33: 1283–1298. DOI: 10.1016/j.istruc.2021.05.021. [14] CHUZEL-MARMOT Y, ORTIZ R, Combescure A. Three dimensional SPH-FEM gluing for simulation of fast impacts on concrete slabs [J]. Computers & Structures, 2011, 89(23/24): 2484–2494. DOI: 10.1016/j.compstruc.2011.06.002. [15] 初文华, 张阿漫, 明付仁, 等. SPH-FEM耦合算法在爆炸螺栓解锁分离过程中的应用 [J]. 振动与冲击, 2012, 31(23): 197–202. DOI: 10.3969/j.issn.1000-3835.2012.23.036.CHU W H, ZHANG A M, MING F R, et al. Application of three-dimensional SPH-FEM coupling method in unlocking process of an explosion bolt [J]. Journal of Vibration and Shock, 2012, 31(23): 197–202. DOI: 10.3969/j.issn.1000-3835.2012.23.036. [16] 肖毅华, 胡德安, 韩旭, 等. 一种自适应轴对称FEM-SPH耦合算法及其在高速冲击模拟中的应用 [J]. 爆炸与冲击, 2012, 32(4): 384–392. DOI: 10.11883/1001-1455(2012)04-0384-09.XIAO Y H, HU D A, HAN X, et al. An adaptive axisymmetric FEM-SPH coupling algorithm and its application to high velocity impact simulation [J]. Explosion and Shock Waves, 2012, 32(4): 384–392. DOI: 10.11883/1001-1455(2012)04-0384-09. [17] 张志春, 强洪夫, 高巍然. 一种新型SPH-FEM耦合算法及其在冲击动力学问题中的应用 [J]. 爆炸与冲击, 2011, 31(3): 243–249. DOI: 10.11883/1001-1455(2011)03-0243-07.ZHANG Z C, QIANG H F, GAO W R. A new coupled SPH-FEM algorithm and its application to impact dynamics [J]. Explosion and Shock Waves, 2011, 31(3): 243–249. DOI: 10.11883/1001-1455(2011)03-0243-07. [18] 林晓东, 卢义玉, 汤积仁, 等. 基于SPH-FEM耦合算法的磨料水射流破岩数值模拟 [J]. 振动与冲击, 2014, 33(18): 170–176. DOI: 10.13465/j.cnki.jvs.2014.18.028.LIN X D, LU Y Y, TANG J R, et al. Numerical simulation of abrasive water jet breaking rock with SPH-FEM coupling algorithm [J]. Journal of Vibration and Shock, 2014, 33(18): 170–176. DOI: 10.13465/j.cnki.jvs.2014.18.028. [19] 胡英国, 卢文波, 陈明, 等. SPH-FEM耦合爆破损伤分析方法的实现与验证 [J]. 岩石力学与工程学报, 2015, 34(S1): 2740–2748. DOI: 10.13722/j.cnki.jrme.2014.0104.HU Y G, LU W B, CHEN M, et al. Implementation and verification of SPH-FEM coupling blasting damage analytical method [J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(S1): 2740–2748. DOI: 10.13722/j.cnki.jrme.2014.0104. [20] 米建宇, 黄飞, 李树清, 等. 基于SPH-FEM耦合算法的后混合磨料水射流冲击破岩数值模拟研究 [J]. 振动与冲击, 2021, 40(16): 132–139. DOI: 10.13465/j.cnki.jvs.2021.16.017.MI J Y, HUANG F, LI S Q, et al. Numerical simulation of rock breaking by rear-mixed abrasive water jet based on an SPH-FEM coupling algorithm [J]. Journal of Vibration and Shock, 2021, 40(16): 132–139. DOI: 10.13465/j.cnki.jvs.2021.16.017. [21] 方天成, 任福深, 刘汉旭, 等. 粒子浆液射流冲击下岩石动态损伤及破坏效应 [J]. 振动与冲击, 2021, 40(24): 107–118. DOI: 10.13465/j.cnki.jvs.2021.24.014.FANG T C, REN F S, LIU H X, et al. Dynamical response and failure effect of rock with particle slurry jet impact [J]. Journal of Vibration and Shock, 2021, 40(24): 107–118. DOI: 10.13465/j.cnki.jvs.2021.24.014. [22] 程兵, 汪海波, 宗琦. 基于SPH-FEM耦合法切缝药包爆破机理数值模拟 [J]. 含能材料, 2020, 28(4): 300–307. DOI: 10.11943/CJEM2018363.CHENG B, WANG H B, ZONG Q. Numerical simulation on blasting mechanism of slotted cartridge based on coupled SPH-FEM Algorithm [J]. Chinese Journal of Energetic Materials, 2020, 28(4): 300–307. DOI: 10.11943/CJEM2018363. [23] 刘赛, 张伟贵, 吕振华. 穿甲燃烧弹侵彻陶瓷复合装甲和玻璃复合装甲的FEM-SPH耦合计算模型 [J]. 爆炸与冲击, 2021, 41(1): 102–113. DOI: 10.11883/bzycj-2020-0069.LIU S, ZHANG W G, LYU Z H. An FEM-SPH coupled model for simulating penetration of armor-piercing bullets into ceramic composite armors and glass composite armors [J]. Explosion and Shock Waves, 2021, 41(1): 102–113. DOI: 10.11883/bzycj-2020-0069. [24] KARMAKAR S, SHAW A. Response of R. C. plates under blast loading using FEM-SPH coupled method [J]. Engineering Failure Analysis, 2021, 125: 105409. DOI: 10.1016/j.engfailanal.2021.105409. [25] BØRVIK T, LANGSETH M, HOPPERSTAD O S, et al. Ballistic penetration of steel plates [J]. International Journal of Impact Engineering, 1999, 22(9/10): 855–886. DOI: 10.1016/S0734-743X(99)00011-1. [26] 强洪夫. 光滑粒子流体动力学新方法及应用[M]. 北京: 科学出版社, 2017. -

下载:

下载: