| [1] |

GURNEY R W. The initial velocities of fragments from bombs, shells and grenades: BRL 405 [R]. Maryland: Army Ballistic Research Laboratory, 1943.

|

| [2] |

TAYLOR G I. The fragmentation of tubular bombs [J]. Advisory Council on Scientific Research and Technical Development, 1963, 5(1): 202–320.

|

| [3] |

HOGGATT C R, RECHT R F. Fracture behavior of tubular bombs [J]. Journal of Applied Physics, 1968, 39(3): 1856–1862. DOI: 10.1063/1.1656442.

|

| [4] |

胡八一, 董庆东, 韩长生, 等. 爆炸金属管绝热剪切断裂的细观研究 [J]. 爆炸与冲击, 1993, 13(4): 305–312.HU B Y, DONG Q D, HAN C S, et al. Mesoscopic study of adiabatic shear fracture of the metal tubes under internal explosive loading [J]. Explosion and Shock Waves, 1993, 13(4): 305–312.

|

| [5] |

金山, 汤铁钢, 孙学林, 等. 不同热处理条件下45钢柱壳的动态性能 [J]. 爆炸与冲击, 2006, 26(5): 423–428. DOI: 10.11883/1001-1455(2006)05-0423-06.JIN S, TANG T G, SUN X L, et al. Dynamic characteristics of 45 steel cylinder shell by different heat treatment conditions [J]. Explosion and Shock Waves, 2006, 26(5): 423–428. DOI: 10.11883/1001-1455(2006)05-0423-06.

|

| [6] |

GOTO D M, BECKER R, ORZECHOWSKI T J, et al. Investigation of the fracture and fragmentation of explosively driven rings and cylinders [J]. International Journal of Impact Engineering, 2008, 35(12): 1547–1556. DOI: 10.1016/j.ijimpeng.2008.07.081.

|

| [7] |

张世文, 刘仓理, 于锦泉. 微缺陷对圆管膨胀断裂的影响 [J]. 爆炸与冲击, 2008, 28(4): 316–323. DOI: 10.11883/1001-1455(2008)04-0316-08.ZHANG S W, LIU C L, YU J Q. Influences of microdefects on expanding fracture of a metal cylinder [J]. Explosion and Shock Waves, 2008, 28(4): 316–323. DOI: 10.11883/1001-1455(2008)04-0316-08.

|

| [8] |

潘顺吉, 俞鑫炉, 董新龙. 不同载荷下TA2钛合金柱壳爆炸碎裂的实验研究 [J]. 高压物理学报, 2017, 31(4): 382–388. DOI: 10.11858/gywlxb.2017.04.005.PAN S J, YU X L, DONG X L. Experimental study of fragmentation behavior of exploded TA2 alloy cylinders with varied charge [J]. Chinese Journal of High Pressure Physics, 2017, 31(4): 382–388. DOI: 10.11858/gywlxb.2017.04.005.

|

| [9] |

LIU M T, REN G W, FAN C, et al. Experimental and numerical studies on the expanding fracture behavior of an explosively driven 1045 steel cylinder [J]. International Journal of Impact Engineering, 2017, 109: 240–252. DOI: 10.1016/j.ijimpeng.2017.07.008.

|

| [10] |

吴思思, 董新龙, 俞鑫炉. 45钢柱壳爆炸膨胀断裂的SPH模拟分析 [J]. 爆炸与冲击, 2021, 41(10): 103101. DOI: 10.11883/bzycj-2021-0172.WU S S, DONG X L, YU X L. An investigating on explosive expanding fracture of 45 steel cylinders by SPH method [J]. Explosion and Shock Waves, 2021, 41(10): 103101. DOI: 10.11883/bzycj-2021-0172.

|

| [11] |

吴文苍, 董新龙, 庞振, 等. TA2钛合金开口柱壳外爆碎片分布研究 [J]. 力学学报, 2021, 53(6): 1795–1806. DOI: 10.6052/0459-1879-21-017.WU W C, DONG X L, PANG Z, et al. Study on fragments distribution of explosively driven cylinders for TA2 titanium alloy [J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(6): 1795–1806. DOI: 10.6052/0459-1879-21-017.

|

| [12] |

庞振, 董新龙, 吴文苍, 等. TA2钛金属柱壳外爆绝热剪切碎裂及微观组织演化 [J]. 稀有金属材料与工程, 2021, 50(12): 4334–4341.PANG Z, DONG X L, WU W C, et al. Multiple adiabatic shear fragmentation and microstructure evolution of explosive-driven TA2 pure titanium cylinders [J]. Rare Metal Materials and Engineering, 2021, 50(12): 4334–4341.

|

| [13] |

刘明涛, 汤铁钢. 爆炸加载下金属壳体膨胀断裂过程中的关键物理问题 [J]. 爆炸与冲击, 2021, 41(1): 011402. DOI: 10.11883/bzycj-2020-0351.LIU M T, TANG T G. Key physical problems in the expanding fracture of explosively driven metallic shells [J]. Explosion and Shock Waves, 2021, 41(1): 011402. DOI: 10.11883/bzycj-2020-0351.

|

| [14] |

LI W B, CHEN Z C, WANG X M, et al. Research on the intermediate phase of 40CrMnSiB steel shell under different heat treatments [J]. Defence Technology, 2021, 17(3): 1032–1041. DOI: 10.1016/j.dt.2020.06.009.

|

| [15] |

张世文, 李英雷, 陈艳, 等. 爆炸加载下金属柱壳破片软回收技术研究 [J]. 爆炸与冲击, 2021, 41(11): 114102. DOI: 10.11883/bzycj-2020-0449.ZHANG S W, LI Y L, CHEN Y, et al. Investigation on the technology of soft recovery of fragment produced by metal cylindrical shell subjected to explosive loading [J]. Explosion and Shock Waves, 2021, 41(11): 114102. DOI: 10.11883/bzycj-2020-0449.

|

| [16] |

MINSHALL S. Investigation of a polymorphic transition in iron at 130-kbar [J]. Physical Review, 1955, 98(1): 271.

|

| [17] |

BANCROFT D, PETERSON E L, MINSHALL S. Polymorphism of iron at high pressure [J]. Journal of Applied Physics, 1956, 27(3): 291–298. DOI: 10.1063/1.1722359.

|

| [18] |

JAMIESON J C, LAWSON A W. X-Ray diffraction studies in the 100 kilobar pressure range [J]. Journal of Applied Physics, 1962, 33(3): 776–780. DOI: 10.1063/1.1777167.

|

| [19] |

MEYERS M A. Dynamic behavior of materials [M]. New York: John Wiley & Sons, Inc, 1994. DOI: 10.1002/9780470172278.

|

| [20] |

DOBROMYSLOV A V, KOZLOV E A, TALUTS N I. High-strain-rate deformation of Armco iron induced by spherical and quasi-spherical converging shock waves and the mechanism of the α-ɛ transformation [J]. The Physics of Metals and Metallography, 2008, 106(5): 531–541. DOI: 10.1134/S0031918X08110136.

|

| [21] |

SHAO J L, DUAN S Q, HE A M, et al. Dynamic properties of structural transition in iron under uniaxial compression [J]. Journal of Physics: Condensed Matter, 2009, 21(24): 245703. DOI: 10.1088/0953-8984/21/24/245703.

|

| [22] |

GUNKELMANN N, BRINGA E M, KANG K, et al. Polycrystalline iron under compression: plasticity and phase transitions [J]. Physical Review B, 2012, 86(14): 144111. DOI: 10.1103/PhysRevB.86.144111.

|

| [23] |

WANG S J, SUI M L, CHEN Y T, et al. Microstructural fingerprints of phase transitions in shock-loaded iron [J]. Scientific Reports, 2013, 3: 1086. DOI: 10.1038/srep01086.

|

| [24] |

DOUGHERTY L M, GRAY Ⅲ G T, CERRETA E K, et al. Rare twin linked to high-pressure phase transition in iron [J]. Scripta Materialia, 2009, 60(9): 772–775. DOI: 10.1016/j.scriptamat.2009.01.014.

|

| [25] |

EPSHTEIN G N. Structure of metals deformed by explosion [M]. Moscow: Metallurgiya, 1988.

|

| [26] |

YAAKOBI B, BOEHLY T R, MEYERHOFER D D, et al. EXAFS measurement of iron bcc-to-hcp phase transformation in Nanosecond-Laser Shocks [J]. Physical Review Letters, 2005, 95(7): 075501. DOI: 10.1103/PhysRevLett.95.075501.

|

| [27] |

IVANOV A G, NOVIKOV S A. On rarefaction shocks in iron and steel [J]. Zh Eksp Teor Fiz, 1961, 40(6): 1880–1882.

|

| [28] |

ERKMAN J O. Smooth spalls and the polymorphism of iron [J]. Journal of Applied Physics, 1961, 32(5): 939–944. DOI: 10.1063/1.1736137.

|

| [29] |

IVANOV A G, NOVIKOV S A. Rarefaction shock waves in iron from explosive loading [J]. Combustion, Explosion, and Shock Waves, 1986, 22(3): 343–350. DOI: 10.1007/BF00750354.

|

| [30] |

ZUREK A K, FRANTZ C E, GRAY G T. In shock wave and high strain rate phenomena in materials [M]. Boca Raton: CRC Press, 1992.

|

| [31] |

VOLTZ C, ROY G. Study of spalling for high purity iron below and above shock induced α $\Leftrightarrow $ ε phase transition [J]. AIP Conference Proceedings, 2004, 706(1): 511–516. DOI: 10.1063/1.1780289. ε phase transition [J]. AIP Conference Proceedings, 2004, 706(1): 511–516. DOI: 10.1063/1.1780289.

|

| [32] |

VOLTZ C, BUY F, ROY G. Iron damage and spalling behavior below and above shock induced α $\Leftrightarrow $ ε phase transition [J]. AIP Conference Proceedings, 2006, 845(1): 678–681. DOI: 10.1063/1.2263413. ε phase transition [J]. AIP Conference Proceedings, 2006, 845(1): 678–681. DOI: 10.1063/1.2263413.

|

| [33] |

DE RESSÉGUIER T, HALLOUIN M. Effects of the α-ε phase transition on wave propagation and spallation in laser shock-loaded iron [J]. Physical Review B, 2008, 77(17): 174107. DOI: 10.1103/PhysRevB.77.174107.

|

| [34] |

ОРЛЕНКО Л П. Explosion physics [M]. 3rd ed. Translated by SUN C W. Beijing: Science Press, 2011.

|

| [35] |

BASHISTAKUMAR M, PUSHKAL B. Finite element analysis of orthogonal cutting forces in machining AISI 1020 steel using a carbide tip tool [J]. Journal of Engineering Sciences, 2018, 5(2): A1–A10. DOI: 10.21272/JES.2018.5(2).A1.

|

| [36] |

DOBRATZ B M. LLNL explosives handbook: properties of chemical explosives and explosives and explosive simulants: UCRL-52997 [R]. Livermore: Lawrence Livermore National Laboratory, 1981.

|

| [37] |

BROWN J M, MCQUEEN R G. Melting of iron under core conditions [J]. Geophysical Research Letters, 1980, 7(7): 533–536. DOI: 10.1029/GL007i007p00533.

|

| [38] |

JEANLOZ R, WENK H R. Convection and anisotropy of the inner core [J]. Geophysical Research Letters, 1988, 15(1): 72–75. DOI: 10.1029/gl015i001p00072.

|

| [39] |

SAXENA S K, SHEN G, LAZOR P. Experimental evidence for a new iron phase and implications for Earth’s core [J]. Science, 1993, 260(5112): 1312–1314. DOI: 10.1126/science.260.5112.1312.

|

| [40] |

WENK H R, MATTHIES S, HEMLEY R J, et al. The plastic deformation of iron at pressures of the Earth’s inner core [J]. Nature, 2000, 405(6790): 1044–1047. DOI: 10.1038/35016558.

|

| [41] |

SMITH C S. Metallographic studies of metals after explosive shock [J]. Transactions of the Metallurgical Society of AIME, 1958, 212: 574–589.

|

| [42] |

MIYAGI L, KUNZ M, KNIGHT J, et al. In situ phase transformation and deformation of iron at high pressure and temperature [J]. Journal of Applied Physics, 2008, 104(10): 103510. DOI: 10.1063/1.3008035.

|

| [43] |

ZARKEVICH N A, JOHNSON D D. Coexistence pressure for a martensitic transformation from theory and experiment: revisiting the bcc-hcp transition of iron under pressure [J]. Physical Review B, 2015, 91(17): 174104. DOI: 10.1103/PhysRevB.91.174104.

|

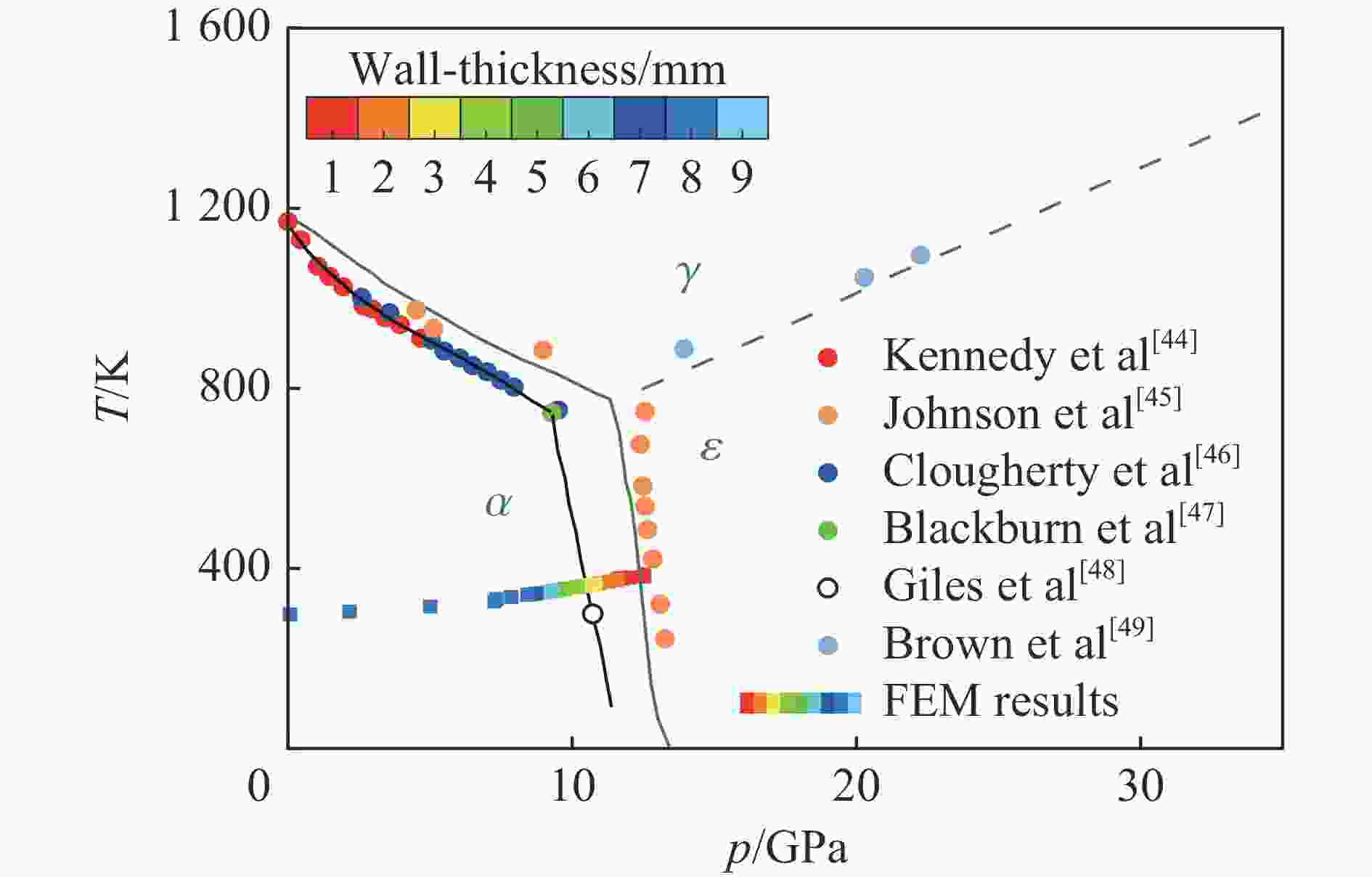

| [44] |

PAUL W, WARSCHAUER D M. Solids under pressure [M]. New York: McGraw-Hill, 1963.

|

| [45] |

JOHNSON P C, STEIN B A, DAVIS R S. Temperature dependence of shock-induced phase transformations in iron [J]. Journal of Applied Physics, 1962, 33(2): 557–561. DOI: 10.1063/1.1702465.

|

| [46] |

CLOUGHERTY E V, KAUFMAN L. In high pressure measurements [M]. Washington: Butterworths, 1963.

|

| [47] |

BLACKBURN L D, KAUFMAN L, COHEN M. Phase transformations in iron-ruthenium alloys under high pressure [J]. Acta Metallurgica, 1965, 13(5): 533–541. DOI: 10.1016/0001-6160(65)90104-5.

|

| [48] |

GILES P M, LONGENBACH M H, MARDER A R. High-pressure α $\rightleftarrows $ ε martensitic transformation in iron [J]. Journal of Applied Physics, 1971, 42(11): 4290–4295. DOI: 10.1063/1.1659768. ε martensitic transformation in iron [J]. Journal of Applied Physics, 1971, 42(11): 4290–4295. DOI: 10.1063/1.1659768.

|

| [49] |

BROWN J M, MCQUEEN R G. Phase transitions, Grüneisen parameter, and elasticity for shocked iron between 77 GPa and 400 GPa [J]. Journal of Geophysical Research: Solid Earth, 1986, 91(B7): 7485–7494. DOI: 10.1029/jb091ib07p07485.

|

| [50] |

LOREE T R, FOWLER C M, ZUKAS E G, et al. Dynamic polymorphism of some binary iron alloys [J]. Journal of Applied Physics, 1966, 37(4): 1918–1927. DOI: 10.1063/1.1708625.

|

| [51] |

王永刚. 延性金属动态拉伸断裂及其临界损伤度研究 [D]. 北京: 中国工程物理研究院, 2006.

|

| [52] |

DOBROMYSLOV A V, KOZLOV E A, LITVINOV B V, et al. High-rate deformation of Armco iron under loading by spherical converging shock waves [J]. Doklady Physics, 2007, 52(8): 418–421. DOI: 10.1134/s1028335807080046.

|

下载:

下载: