Experimental study on evolution of strain field of explosion stress wave passing through a heterogeneous interface based on the DIC method

-

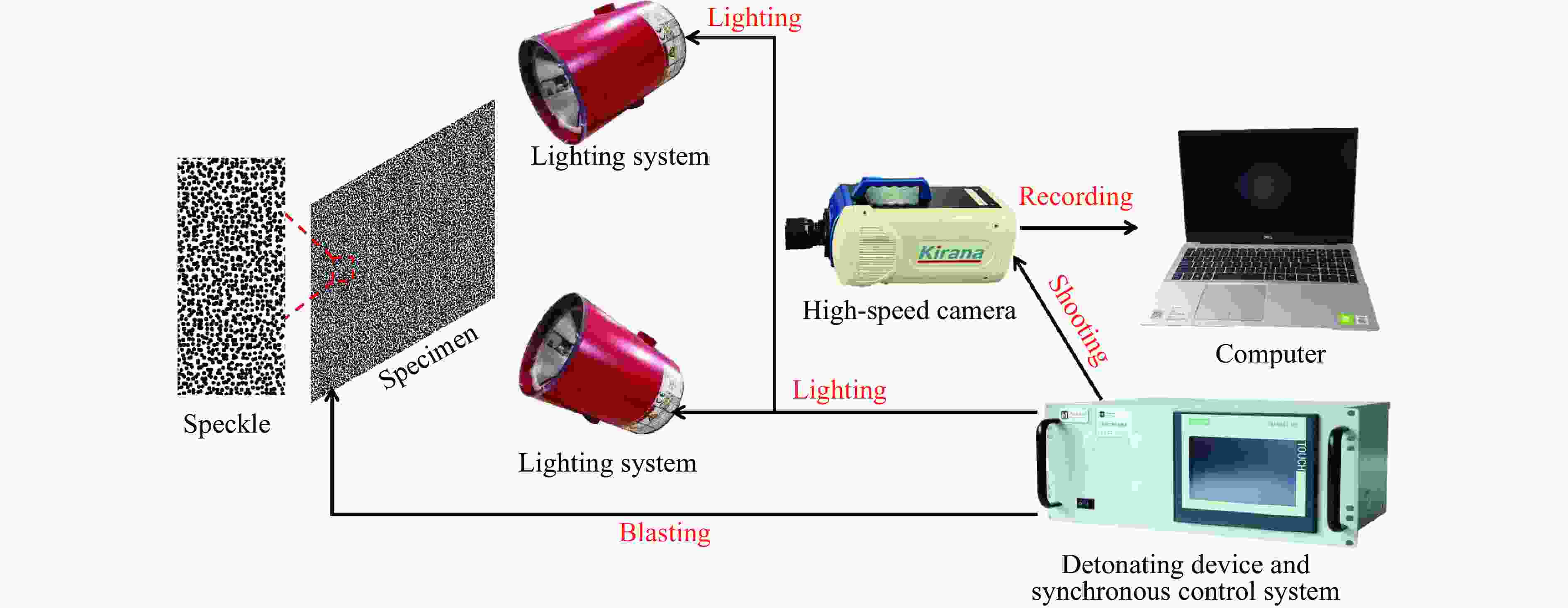

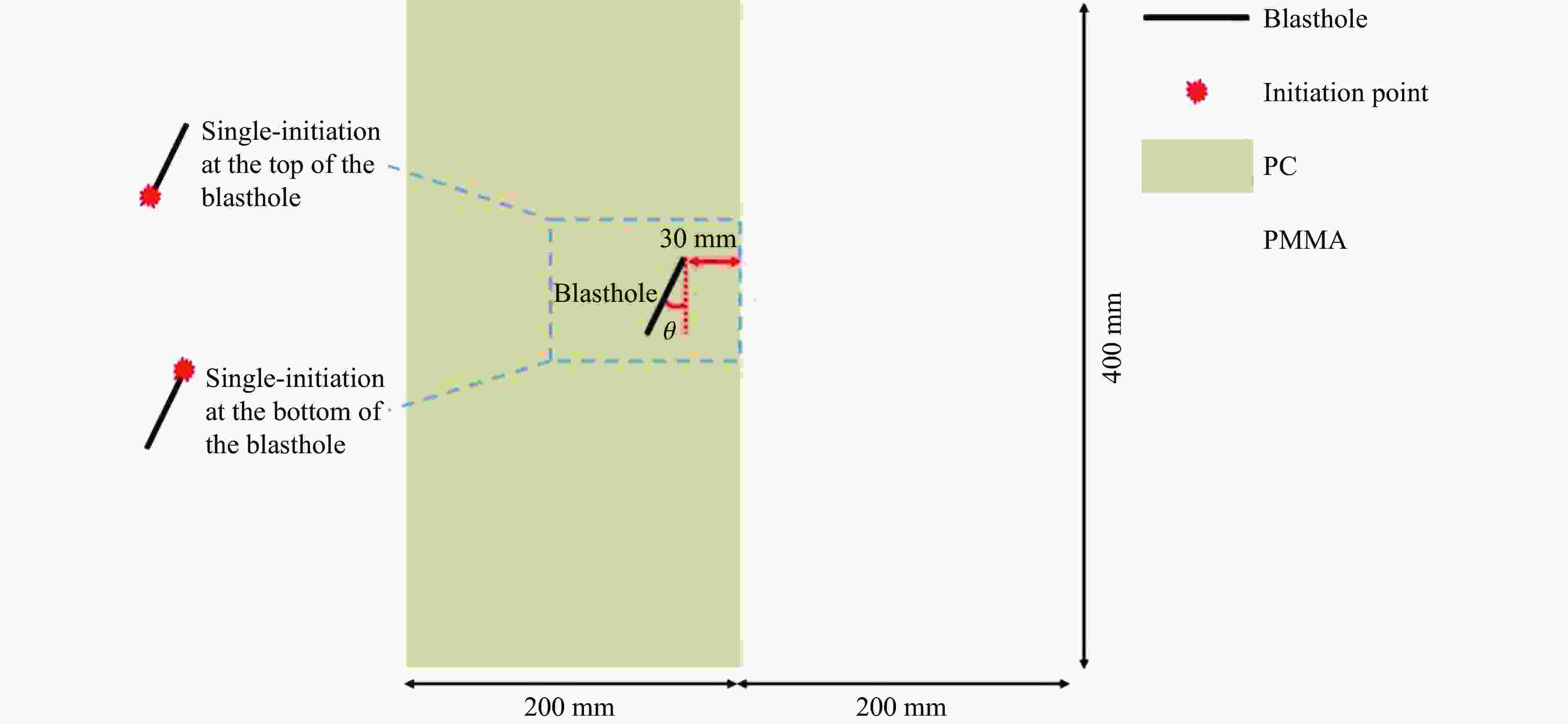

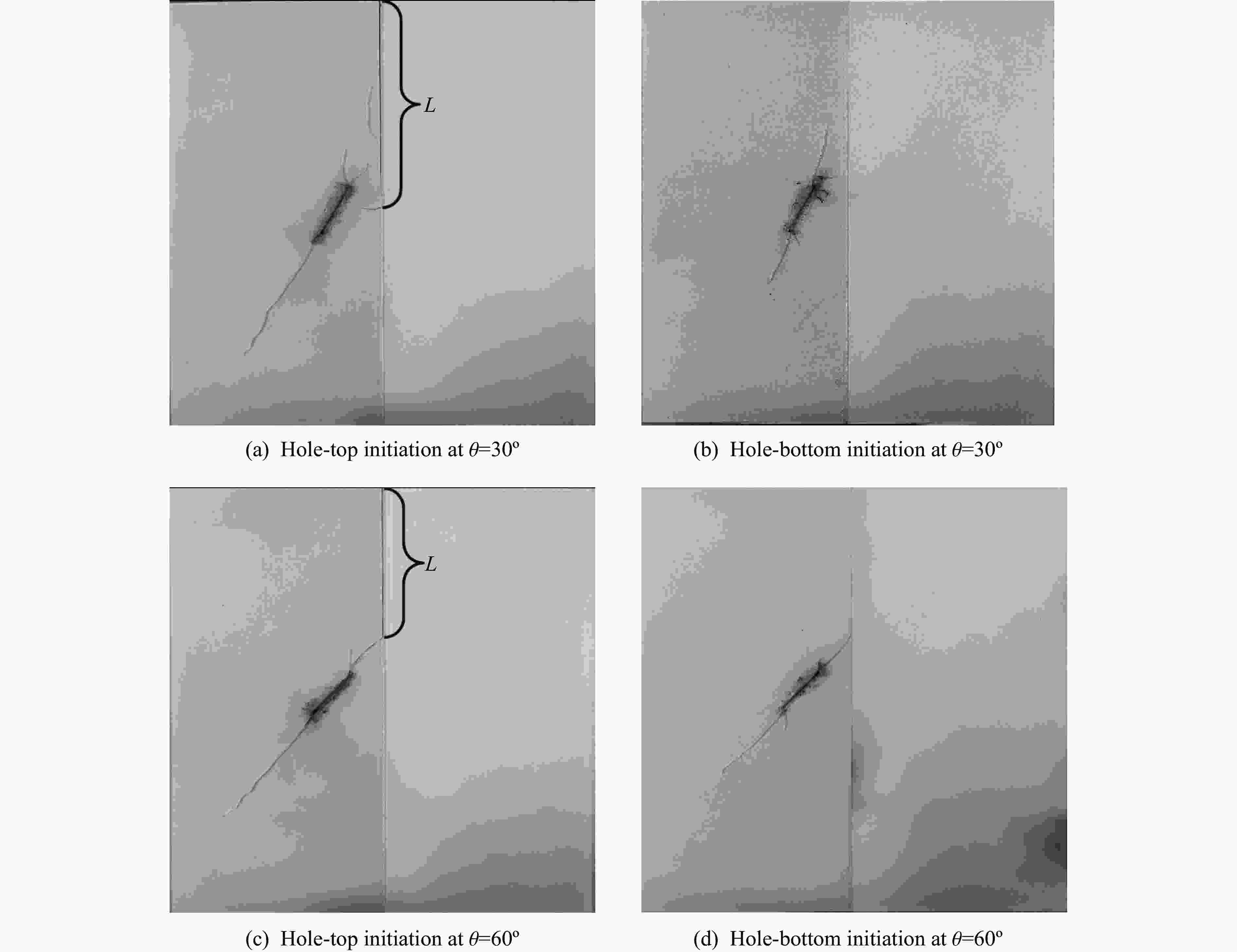

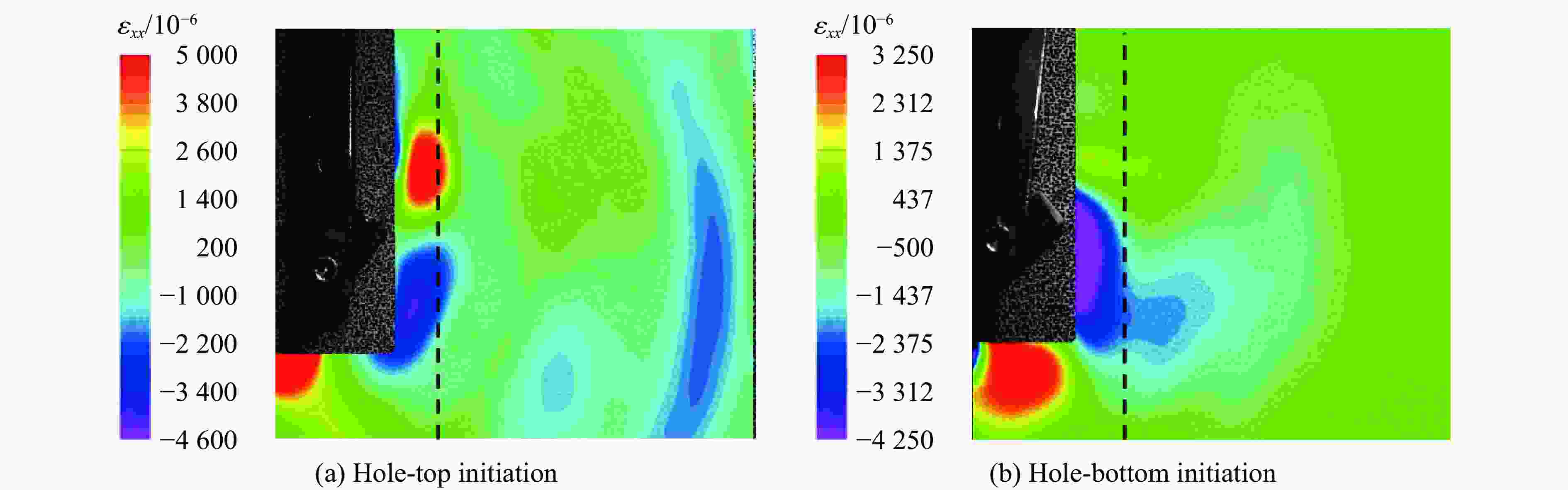

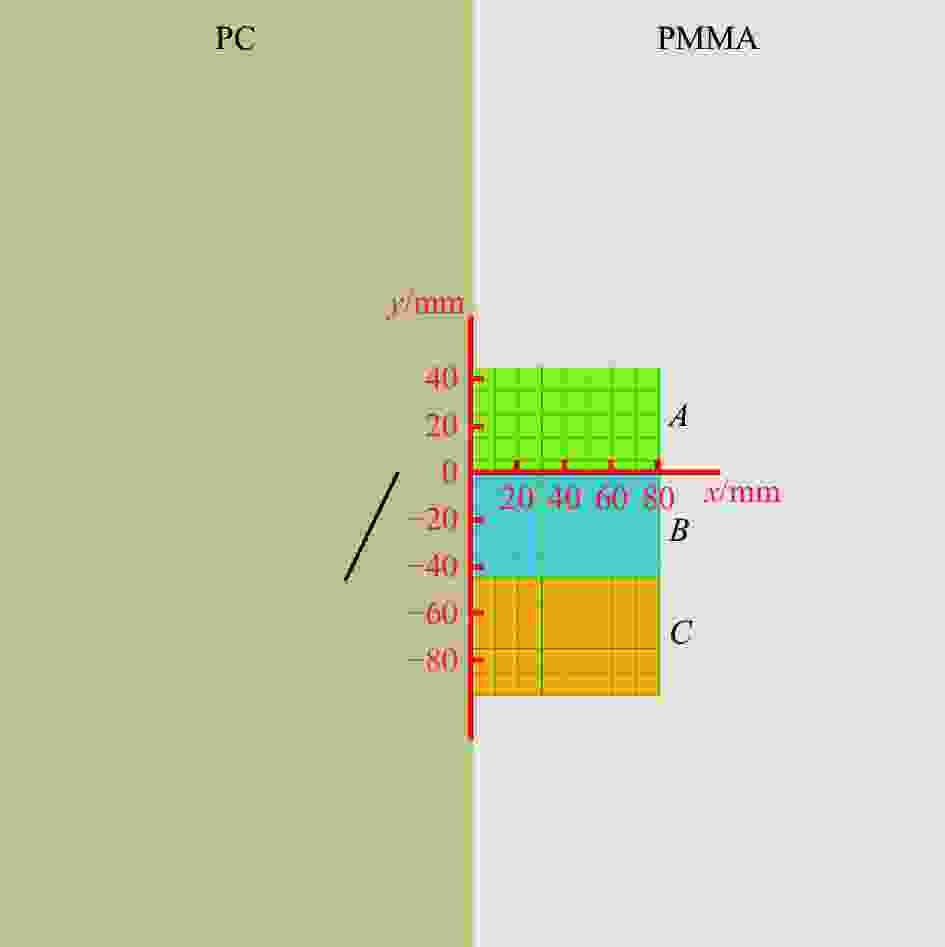

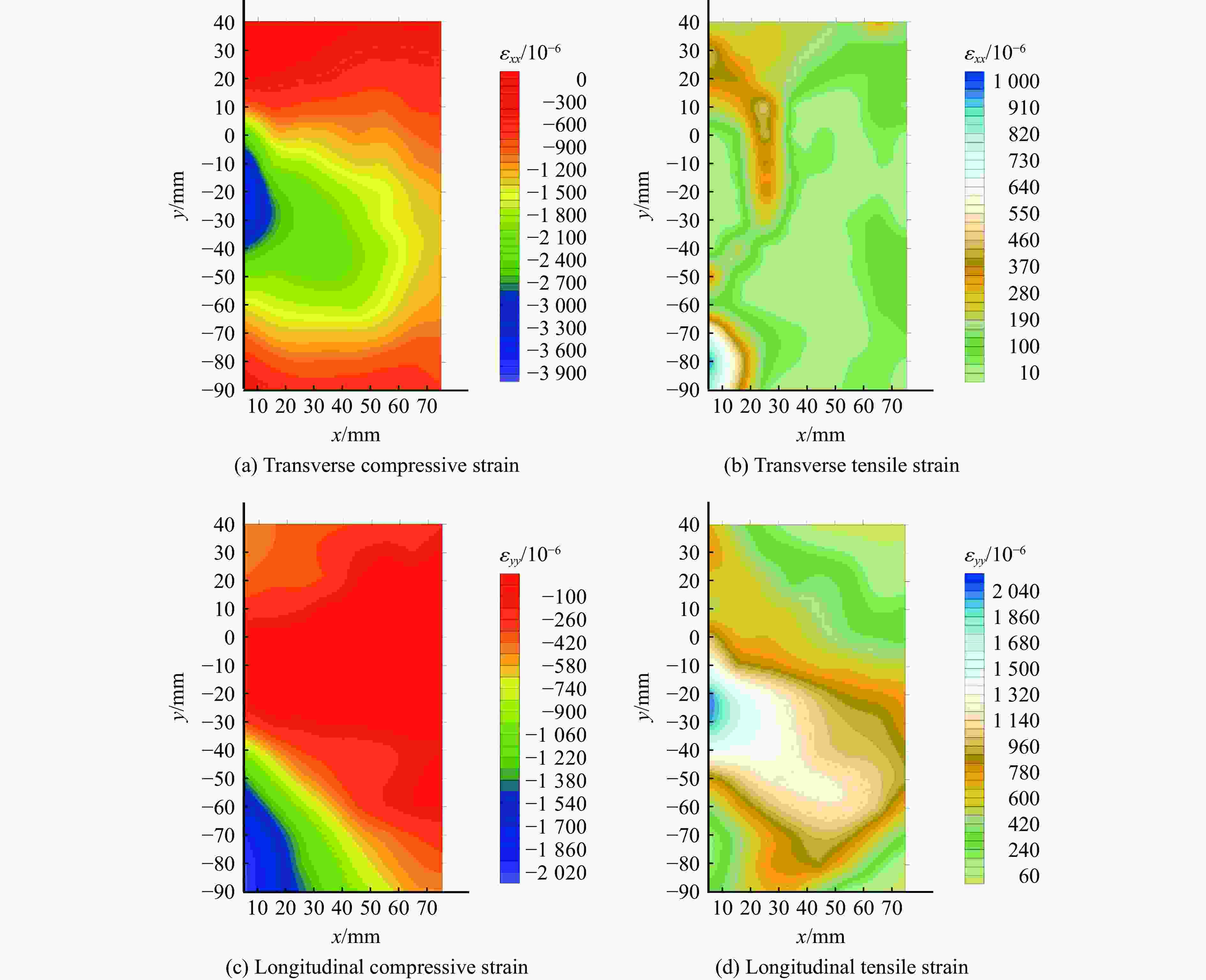

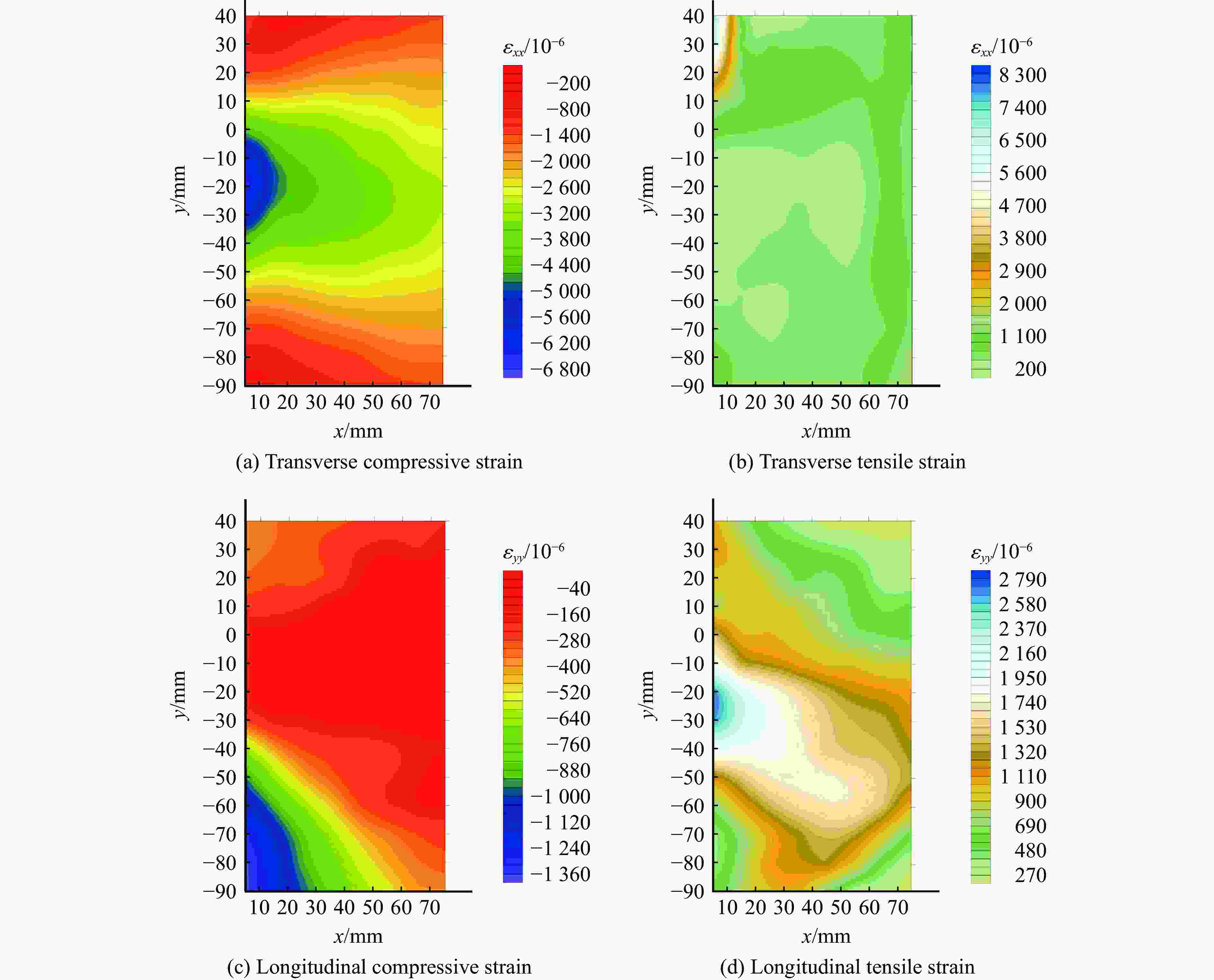

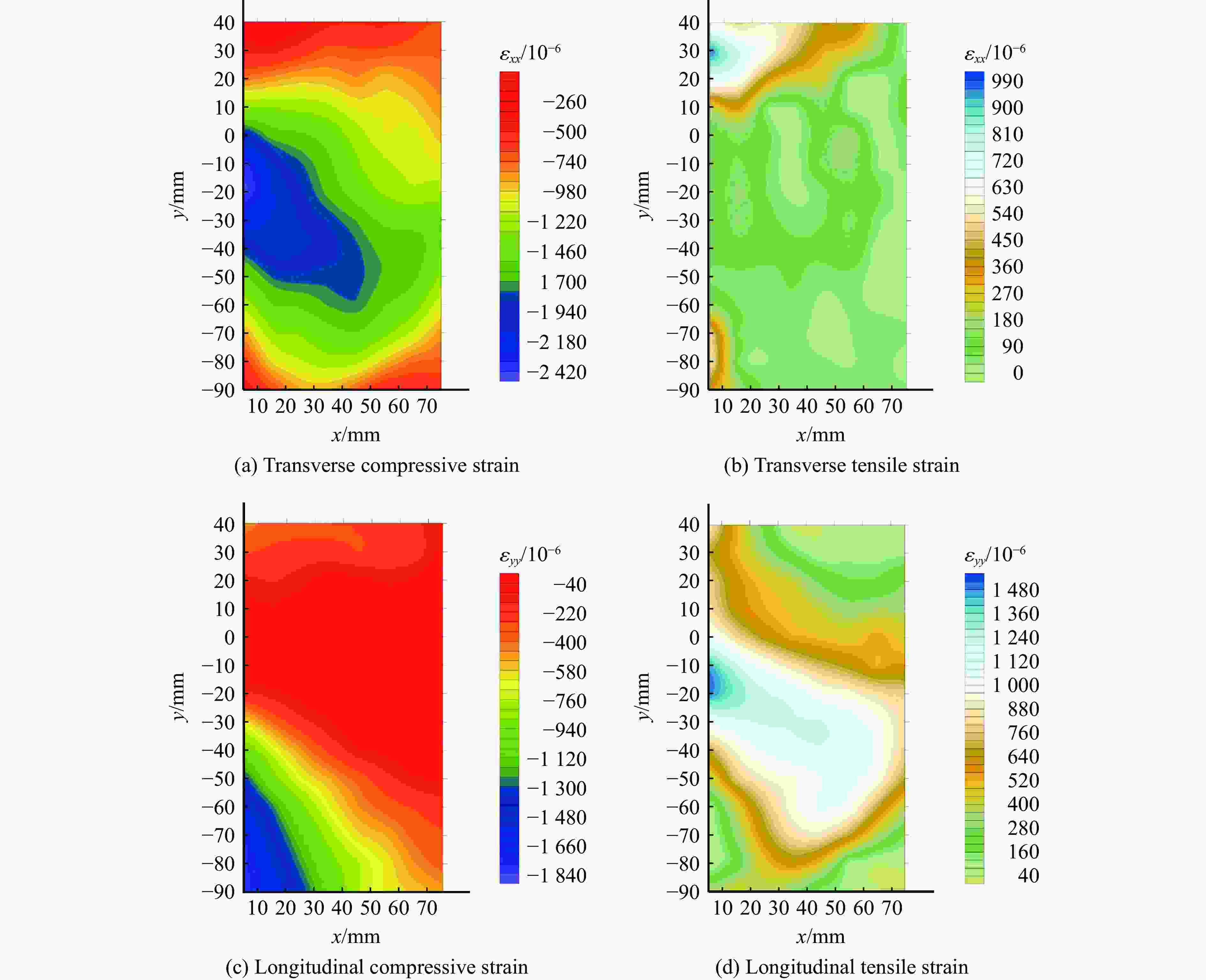

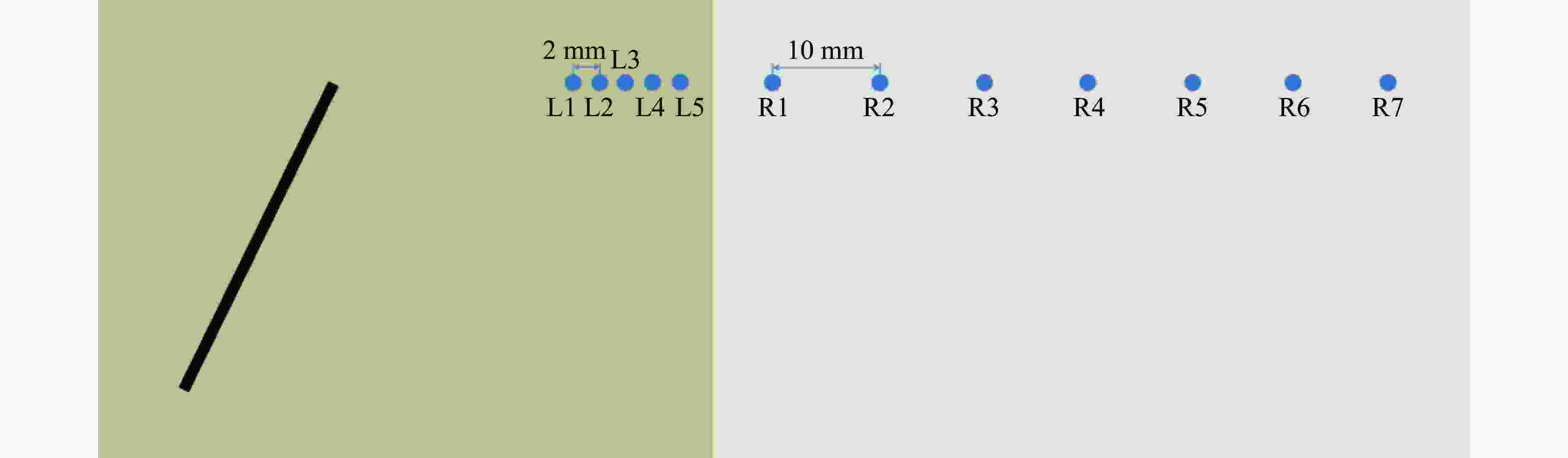

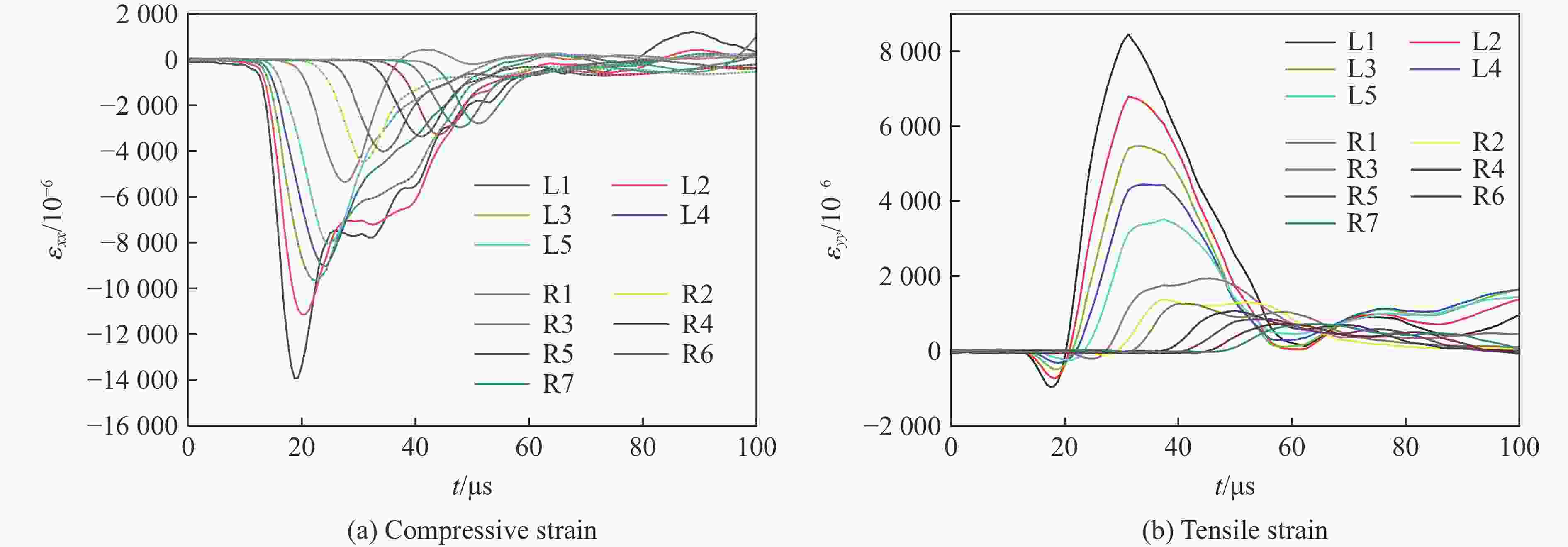

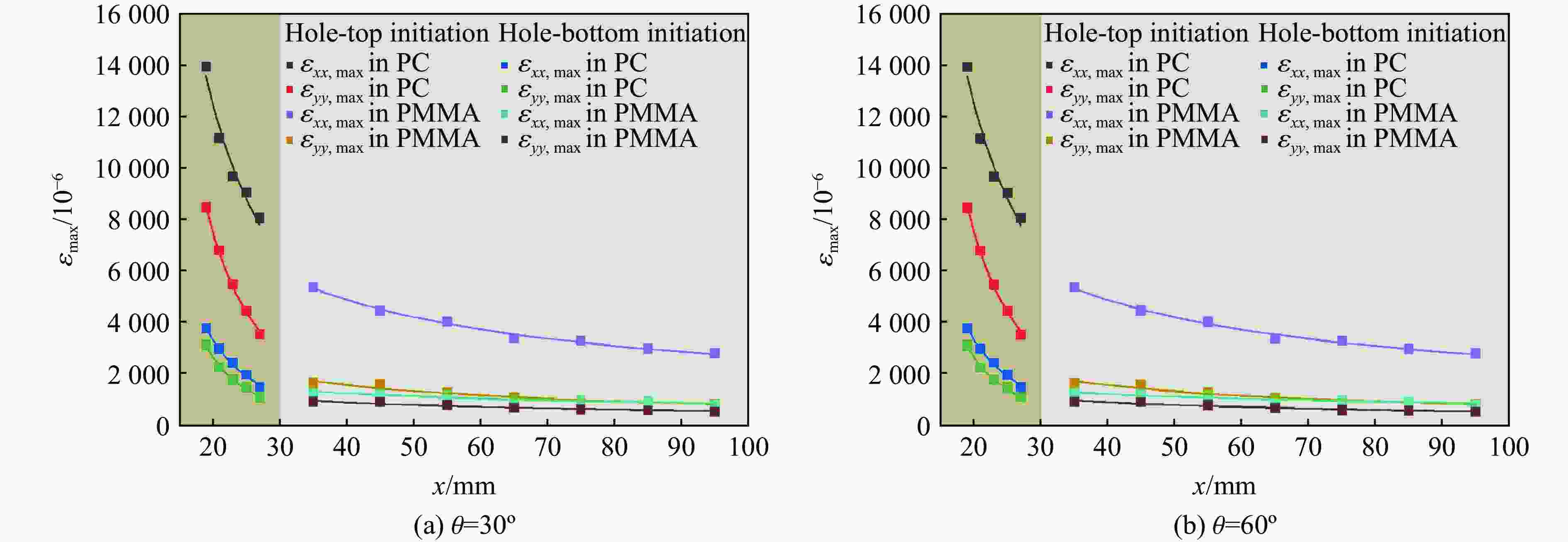

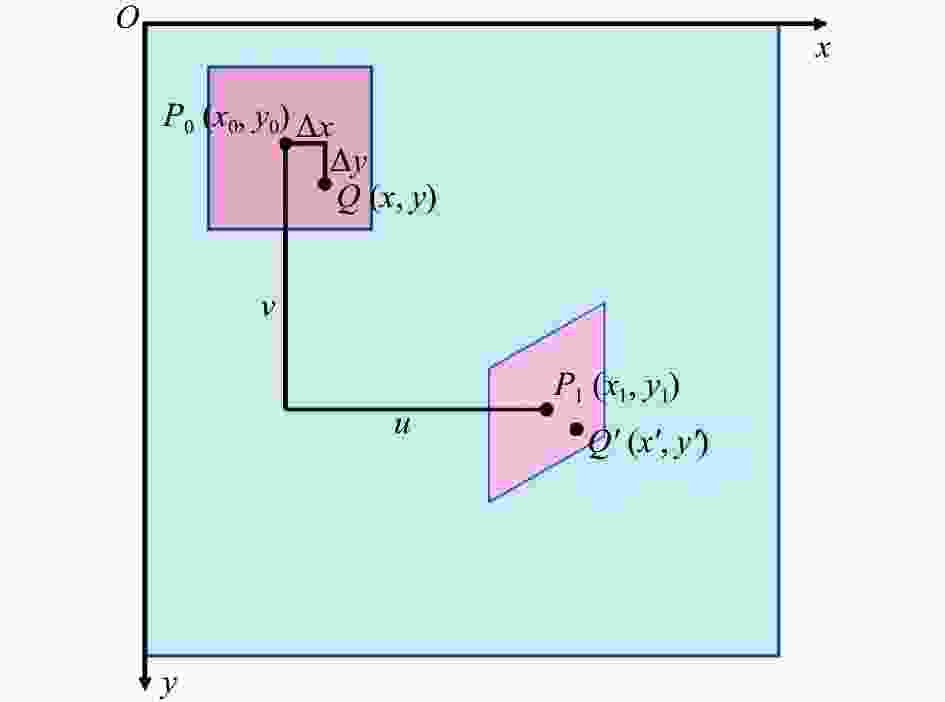

摘要: 采用氯仿粘结聚碳酸酯(polycarbonate, PC)板和聚甲基丙烯酸甲酯(polymethylmethacrylate, PMMA)板模拟含异质界面模型;在PC介质中布置柱状炮孔并与界面呈一定角度,根据炮孔端部与界面相对位置,分别于柱状炮孔两个端部设置起爆点,起爆点远离界面端部时定义为孔口起爆,靠近界面端部时定义为孔底起爆;借助数字图像相关实验系统,研究爆炸应力波通过异质界面后PMMA介质应变场演化过程及炮孔底部区域拉、压应变变化规律。实验结果表明,异质界面改变了爆炸应力波过界面后的传播形态。孔口起爆时,异质界面受爆破荷载作用后易形成应力集中区,界面处产生开裂,横向拉伸波作用是造成异质界面开裂的主要原因。起爆方式对过界面后介质PMMA的横/纵向拉、压应变场作用贡献不同,主要体现在应变场强度、拉/压应变场位置分布2个方面。在炮孔底部区域,起爆方式对应变场时程特性的影响主要体现在作用时效长短和应变强度2个方面。孔口起爆时,横/纵向应变体现出短时效、高强度的变化特征。就应变强度而言,起爆方式对横向压应变的影响显著强于其对纵向拉应变的影响。对空间分布特性影响主要体现在衰减程度,起爆方式对纵向应变衰减程度影响较大。无论采用何种起爆方式,爆炸应变场在PC介质中衰减速度较快,进入PMMA介质后衰减速度显著降低。Abstract: Chloroform was used to bond a polycarbonate (PC) plate and a polymethylmethacrylate (PMMA) plate to fabricate a model with a heterogeneous cemented interface. A cylinder blasthole was set in the PC plate with a certain angle to the interface. Base on the locations between the interface and the explosive initiation points, two kinds of initiation methods were used in the experiment. The one is the top initiation method, in which the initiation point is settled far away from the interface; and the other is the bottom initiation method, in which the initiation point is close to the interface. The digital image correlation (DIC) method was used to study the evolution of the strain field during the passage of the blast waves in the medium with the heterogeneous interface. The results show that the propagation pattern of the blast stress wave varies significantly after it passes through the interface. In the top initiation, a stress concentration zone is formed on the interface under blast loadings, and induce a crack initiate at the interface. The transverse tensile wave is the main reason for the cracking of the interface. Besides, it can be found that the initiation methods have different contributions to both the magnitude and the locations of the tensile/compressive strain in both the transverse and longitudinal directions. Moreover, in the bottom area of the borehole, the influence of the initiation method on the time-related characteristics of the strain field mainly has two aspects, namely, the duration time and the strain magnitude. And it is found that the transverse/longitudinal strain is of "short duration, high magnitude" variation characteristic for the top initiation. In terms of the strain magnitude, the influence of the initiation method on the transverse strain is much greater than it on the longitudinal strain. In addition, the initiation method can significantly influence the attenuation characteristics of the strain field, which is more obvious for the longitudinal strain field. In terms of the attenuation rate, the magnitude blast stress waves attenuated faster in the PC plate, whereas the blast stress waves attenuated slowly when it passed through the interface and propagated in the PMMA plate regardless of the initiation method.

-

材料 ρ/(kg·m−3) cp/(m∙s−1) cs/(m∙s−1) Ed/GPa Gd/GPa μd PC 1449 2125 1090 4.5 1.7 0.32 PMMA 1240 2320 1260 6.1 1.9 0.31 表 2 PC和PMMA介质中测点拉、压应变峰值

Table 2. Tensile and compressive strain peaks at measured points in PC and PMMA

介质 测点 x/mm θ=30º, 孔口起爆 θ=30º, 孔底起爆 θ=60º, 孔口起爆 θ=60º, 孔底起爆 εxx,max/10−6 εyy,max/10−6 εxx,max/10−6 εyy,max/10−6 εxx,max/10−6 εyy,max/10−6 εxx,max/10−6 εyy,max/10−6 PC L1 11 13927 8445 3756 3099 11485 7400 4344 2914 L2 9 11147 6784 2957 2243 9261 5991 3415 2230 L3 7 9650 5473 2426 1759 7498 4934 2548 1781 L4 5 9032 4438 1950 1462 6421 3986 1948 1522 L5 3 8053 3513 1463 1088 5614 3143 1457 1170 PMMA R1 5 5356 1630 1236 900 4284 1952 1256 970 R2 15 4444 1576 1205 890 3625 1630 1042 821 R3 25 4021 1257 1132 780 3368 1578 784 625 R4 35 3356 1062 959 678 2946 1461 739 518 R5 45 3275 942 960 593 2912 1211 649 490 R6 55 2957 823 913 559 2599 1049 639 451 R7 65 2789 812 778 511 2557 941 570 450 表 3 应变衰减指数和应变衰减程度

Table 3. Strain attenuation index and strain attenuation degree

起爆方式 应变 衰减函数 衰减指数 (εL4−εR1)/εL4 PC PMMA PC PMMA θ=30º,孔口起爆 εxx εmax=1.40x−1.57 εmax=56144x−0.66 1.57 0.66 0.4070 εyy εmax=1.01x−2.40 εmax=25613x−0.76 2.40 0.76 0.6327 θ=30º,孔底起爆 εxx εmax=5.98x−2.50 εmax=56144x−0.66 2.50 0.42 0.3662 εyy εmax=1.51x−2.89 εmax=25613x−0.76 2.89 0.58 0.3844 θ=60º,孔口起爆 εxx εmax=5.44x−2.09 εmax=27604x−0.52 2.09 0.52 0.3328 εyy εmax=6.94x−2.32 εmax=20396x−0.65 2.32 0.65 0.5103 θ=60º,孔底起爆 εxx εmax=2.76x−2.97 εmax=23138x−0.82 2.97 0.82 0.3552 εyy εmax=4.65x−2.50 εmax=22053x−0.88 2.50 0.88 0.3627 表 4 不同测点孔口起爆应变峰值与孔底起爆应变峰值的比值

Table 4. Ratios of strain peak of top initiation to strain peak of bottom initiation at different measuring points

θ/(º) 应变 应变峰值比 PC PMMA L1 L2 L3 L4 L5 R1 R2 R3 R4 R5 R6 R7 30 εxx 3.7 3.8 4.0 4.6 5.5 4.3 3.7 3.6 3.5 3.4 3.2 3.6 εyy 2.7 3.0 3.1 3.0 3.2 1.8 1.8 1.6 1.6 1.6 1.5 1.6 60 εxx 2.6 2.7 2.9 3.3 3.9 3.4 3.5 4.3 4.0 4.5 4.1 4.5 εyy 2.5 2.7 2.8 2.6 2.7 2.0 2.0 2.5 2.8 2.5 2.3 2.1 -

[1] 冷振东, 范勇, 卢文波, 等. 孔内双点起爆条件下的爆炸能量传输与破岩效果分析 [J]. 岩石力学与工程学报, 2019, 38(12): 2451–2462. DOI: 10.13722/j.cnki.jrme.2019.0474.LENG Z D, FAN Y, LU W B, et al. Explosion energy transmission and rock-breaking effect of in-hole dual initiation [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(12): 2451–2462. DOI: 10.13722/j.cnki.jrme.2019.0474. [2] 刘鑫, 杨军, 唐红亮. 同时起爆的双孔台阶模型试验研究 [J]. 岩石力学与工程学报, 2020, 39(12): 2460–2470. DOI: 10.13722/j.cnki.jrme.2020.0283.LIU X, YANG J, TANG H L. Experimental study on simultaneous initiation in double-hole bench model [J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(12): 2460–2470. DOI: 10.13722/j.cnki.jrme.2020.0283. [3] 高启栋, 靳军, 王亚琼, 等. 孔内起爆位置对爆破振动场分布的影响作用规律 [J]. 爆炸与冲击, 2021, 41(10): 105201. DOI: 10.11883/bzycj-2020-0352.GAO Q D, JIN J, WANG Y Q, et al. Acting law of in-hole initiation position on distribution of blast vibration field [J]. Explosion and Shock Waves, 2021, 41(10): 105201. DOI: 10.11883/bzycj-2020-0352. [4] 贾海鹏, 刘殿书, 陈斌, 等. 相邻隧道爆破振速分布规律研究 [J]. 矿业科学学报, 2019, 4(6): 506–514. DOI: 10.19606/j.cnki.jmst.2019.06.005.JIA H P, LIU D S, CHEN B, et al. Study on the vibration velocity distribution law of adjacent tunnel blasting [J]. Journal of Mining Science and Technology, 2019, 4(6): 506–514. DOI: 10.19606/j.cnki.jmst.2019.06.005. [5] 杨仁树, 苏洪. 爆炸荷载下含预裂缝的裂纹扩展实验研究 [J]. 煤炭学报, 2019, 44(2): 482–489. DOI: 10.13225/j.cnki.jccs.2018.0110.YANG R S, SU H. Experimental study on crack propagation with pre-crack under explosion load [J]. Journal of China Coal Society, 2019, 44(2): 482–489. DOI: 10.13225/j.cnki.jccs.2018.0110. [6] 杨仁树, 左进京, 肖成龙, 等. 爆炸载荷作用下静裂纹对运动裂纹扩展影响的实验研究 [J]. 振动与冲击, 2018, 37(13): 65–70,84. DOI: 10.13465/j.cnki.jvs.2018.13.010.YANG R S, ZUO J J, XIAO C L, et al. Tests for interaction between static crack and dynamic one under explosion loading [J]. Journal of Vibration and Shock, 2018, 37(13): 65–70,84. DOI: 10.13465/j.cnki.jvs.2018.13.010. [7] 许鹏, 陈程, 郭洋, 等. 含垂直层理介质在切缝药包爆破下裂纹扩展行为的试验研究 [J]. 矿业科学学报, 2019, 4(6): 498–505. DOI: 10.19606/j.cnki.jmst.2019.06.004.XU P, CHEN C, GUO Y, et al. Experimental study on crack propagation of slit charge blasting in media with vertical bedding plane [J]. Journal of Mining Science and Technology, 2019, 4(6): 498–505. DOI: 10.19606/j.cnki.jmst.2019.06.004. [8] 杨立云, 张蓝月, 丁晨曦, 等. 超高速数字图像相关实验系统及其在爆炸研究中的应用 [J]. 科技导报, 2018, 36(13): 58–64. DOI: 10.3981/j.issn.1000-7857.2018.13.008.YANG L Y, ZHANG L Y, DING C X, et al. Ultra high speed digital image correlation system and its application in blasting research [J]. Science & Technology Review, 2018, 36(13): 58–64. DOI: 10.3981/j.issn.1000-7857.2018.13.008. [9] 李二强, 冯吉利, 朱天宇, 等. 基于数字图像相关方法的层状板岩Ⅰ型断裂特性研究 [J]. 采矿与安全工程学报, 2021, 38(5): 979–987. DOI: 10.13545/j.cnki.jmse.2020.0375.LI E Q, FENG J L, ZHU T Y, et al. Examining type Ⅰ fracture characteristics in layered slates with digital image correlation [J]. Journal of Mining & Safety Engineering, 2021, 38(5): 979–987. DOI: 10.13545/j.cnki.jmse.2020.0375. [10] 孙强, 王启乾, 刘国有, 等. 基于超高速DIC方法的近距侧爆破地铁隧道应变场分析 [J]. 矿业科学学报, 2018, 3(1): 39–45. DOI: 10.19606/j.cnki.jmst.2018.01.005.SUN Q, WANG Q Q, LIU G Y, et al. Proximity side blasting based on ultra-high speed DIC method strain field analysis of subway tunnels [J]. Journal of Mining Science and Technology, 2018, 3(1): 39–45. DOI: 10.19606/j.cnki.jmst.2018.01.005. [11] DUTLER N, NEJATI M, VALLEY B, et al. On the link between fracture toughness, tensile strength, and fracture process zone in anisotropic rocks [J]. Engineering Fracture Mechanics, 2018, 201: 56–79. DOI: 10.1016/j.engfracmech.2018.08.017. [12] HOSDEZ J, LANGLOIS M, WITZ J F, et al. Plastic zone evolution during fatigue crack growth: digital image correlation coupled with finite elements method [J]. International Journal of Solids and Structures, 2019, 171: 92–102. DOI: 10.1016/j.ijsolstr.2019.04.032. [13] 齐飞飞, 张科, 谢建斌. 基于DIC技术的含不同节理密度类岩石试件破裂机制研究 [J]. 岩土力学, 2021, 42(6): 1669–1680. DOI: 10.16285/j.rsm.2020.1710.QI F F, ZHANG K, XIE J B. Fracturing mechanism of rock-like specimens with different joint densities based on DIC technology [J]. Rock and Soil Mechanics, 2021, 42(6): 1669–1680. DOI: 10.16285/j.rsm.2020.1710. [14] 杨立云, 刘振坤, 周莹莹, 等. 爆炸应力波在含层理介质中传播规律的实验研究 [J]. 爆破, 2018, 35(2): 1–5,11. DOI: 10.3963/j.issn.1001-487X.2018.02.001.YANG L Y, LIU Z K, ZHOU Y Y, et al. Study on propagation law of explosive stress wave in layered media [J]. Blasting, 2018, 35(2): 1–5,11. DOI: 10.3963/j.issn.1001-487X.2018.02.001. [15] 徐振洋, 杨军, 郭连军. 爆炸聚能作用下混凝土试件劈裂的高速3D DIC实验 [J]. 爆炸与冲击, 2016, 36(3): 400–406. DOI: 10.11883/1001-1455(2016)03-0400-07.XU Z Y, YANG J, GUO L J. Study of the splitting crack propagation morphology using high-speed 3D DIC [J]. Explosion and Shock Waves, 2016, 36(3): 400–406. DOI: 10.11883/1001-1455(2016)03-0400-07. [16] YANG R S, DING C X, YANG L Y, et al. Visualizing the blast-induced stress wave and blasting gas action effects using digital image correlation [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 112: 47–54. DOI: 10.1016/j.ijrmms.2018.10.007. [17] CHI L Y, ZHANG Z X, AALBERG A, et al. Fracture processes in granite blocks under blast loading [J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 853–868. DOI: 10.1007/s00603-018-1620-0. [18] 赵程, 鲍冲, 松田浩, 等. 数字图像技术在节理岩体裂纹扩展试验中的应用研究 [J]. 岩土工程学报, 2015, 37(5): 944–951. DOI: 10.11779/CJGE201505022.ZHAO C, BAO C, HIROSHI M, et al. Application of digital image correlation method in experimental research on crack propagation of brittle rock [J]. Chinese Journal of Geotechnical Engineering, 2015, 37(5): 944–951. DOI: 10.11779/CJGE201505022. [19] DING C X, YANG R S, FENG C. Stress wave superposition effect and crack initiation mechanism between two adjacent boreholes [J]. International Journal of Rock Mechanics and Mining Sciences, 2021, 138: 104622. DOI: 10.1016/j.ijrmms.2021.104622. [20] 李清, 张随喜, 万明华, 等. 长径比对束状炮孔端部裂纹力学特征影响的研究 [J]. 矿业科学学报, 2019, 4(2): 112–119. DOI: 10.19606/j.cnki.jmst.2019.02.003.LI Q, ZHANG S X, WAN M H, et al. Study on the influence of length- diameter ratio on the mechanical characteristics of cracks at the end of linear charges [J]. Journal of Mining Science and Technology, 2019, 4(2): 112–119. DOI: 10.19606/j.cnki.jmst.2019.02.003. [21] 向文飞, 舒大强, 朱传云. 起爆方式对条形药包爆炸应力场的影响分析 [J]. 岩石力学与工程学报, 2005, 24(9): 1624–1628. DOI: 10.3321/j.issn:1000-6915.2005.09.026.XIANG W F, SHU D Q, ZHU C Y. Impacts of detonating mode on blast stress field of linear explosive charge [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(9): 1624–1628. DOI: 10.3321/j.issn:1000-6915.2005.09.026. [22] 杨圣奇, 孙博文, 田文岭. 不同层理页岩常规三轴压缩力学特性离散元模拟 [J]. 工程科学学报, 2022, 44(3): 430–439. DOI: 10.13374/j.issn2095-9389.2020.10.12.005.YANG S Q, SUN B W, TIAN W L. Discrete element simulation of the mechanical properties of shale with different bedding inclinations under conventional triaxial compression [J]. Chinese Journal of Engineering, 2022, 44(3): 430–439. DOI: 10.13374/j.issn2095-9389.2020.10.12.005. [23] 丁晨曦. 爆炸动静破岩作用与高应力状态下爆破动力学行为研究 [D]. 北京: 中国矿业大学(北京), 2020. DOI: 10.27624/d.cnki.gzkbu.2020.000068.DING C X. Study on dynamic-staic rock fracture mechanism of blasting and blasting dynamic behavior under high stress condition [D]. Beijing, China: China University of Mining and Technology (Beijing), 2020. DOI: 10.27624/d.cnki.gzkbu.2020.000068. [24] 孙强, 李雪东, 姚腾飞, 等. 基于DIC的爆炸加载下脆性材料裂纹扩展规律的试验研究 [J]. 爆炸与冲击, 2019, 39(10): 103102. DOI: 10.11883/bzycj-2018-0308.SUN Q, LI X D, YAO T F, et al. Experimental study on crack propagation of brittle materials based on DIC under explosive loading [J]. Explosion and Shock Waves, 2019, 39(10): 103102. DOI: 10.11883/bzycj-2018-0308. [25] 左进京. 立井深孔分段掏槽与周边定向断裂损伤控制试验研究 [D]. 北京: 中国矿业大学(北京), 2020. DOI: 10.27624/d.cnki.gzkbu.2020.000069.ZUO J J. Experimental study on sectional cut blasting and directional fracture damage control of vertical shaft deep hole [D]. Beijing, China: China University of Mining and Technology (Beijing), 2020. DOI: 10.27624/d.cnki.gzkbu.2020.000069. [26] 赵勇, 肖成龙, 杨立云, 等. 动、静裂纹作用偏置效应的动焦散冲击实验 [J]. 爆炸与冲击, 2020, 40(7): 073201. DOI: 10.11883/bzycj-2019-0401.ZHAO Y, XIAO C L, YANG L Y, et al. Dynamic caustics experiments on offset effects between dynamic and static cracks [J]. Explosion and Shock Waves, 2020, 40(7): 073201. DOI: 10.11883/bzycj-2019-0401. -

下载:

下载: