Research on mechanism of shock fragmentation reaction of Zr-based bulk metallic glass fragment

-

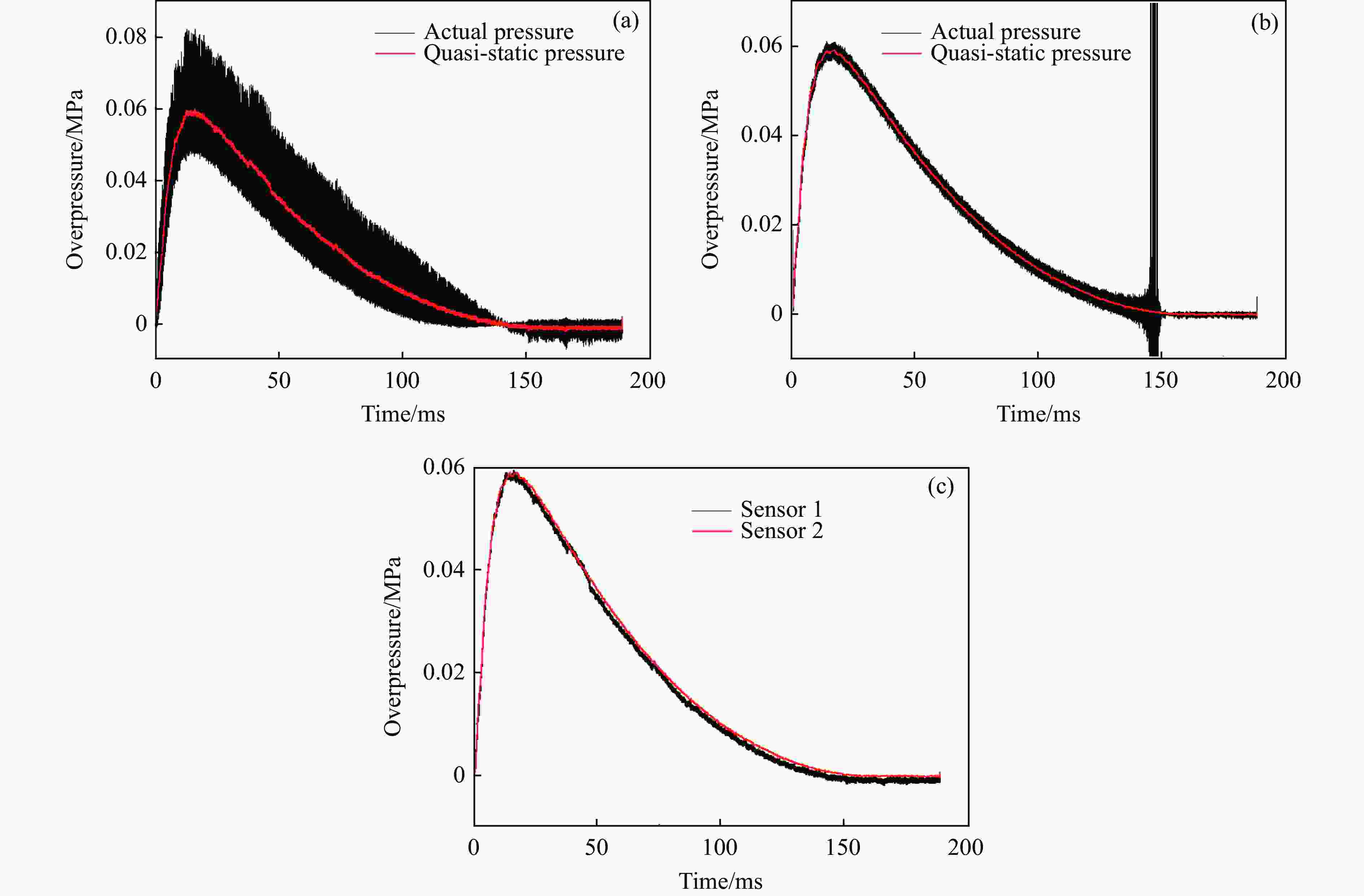

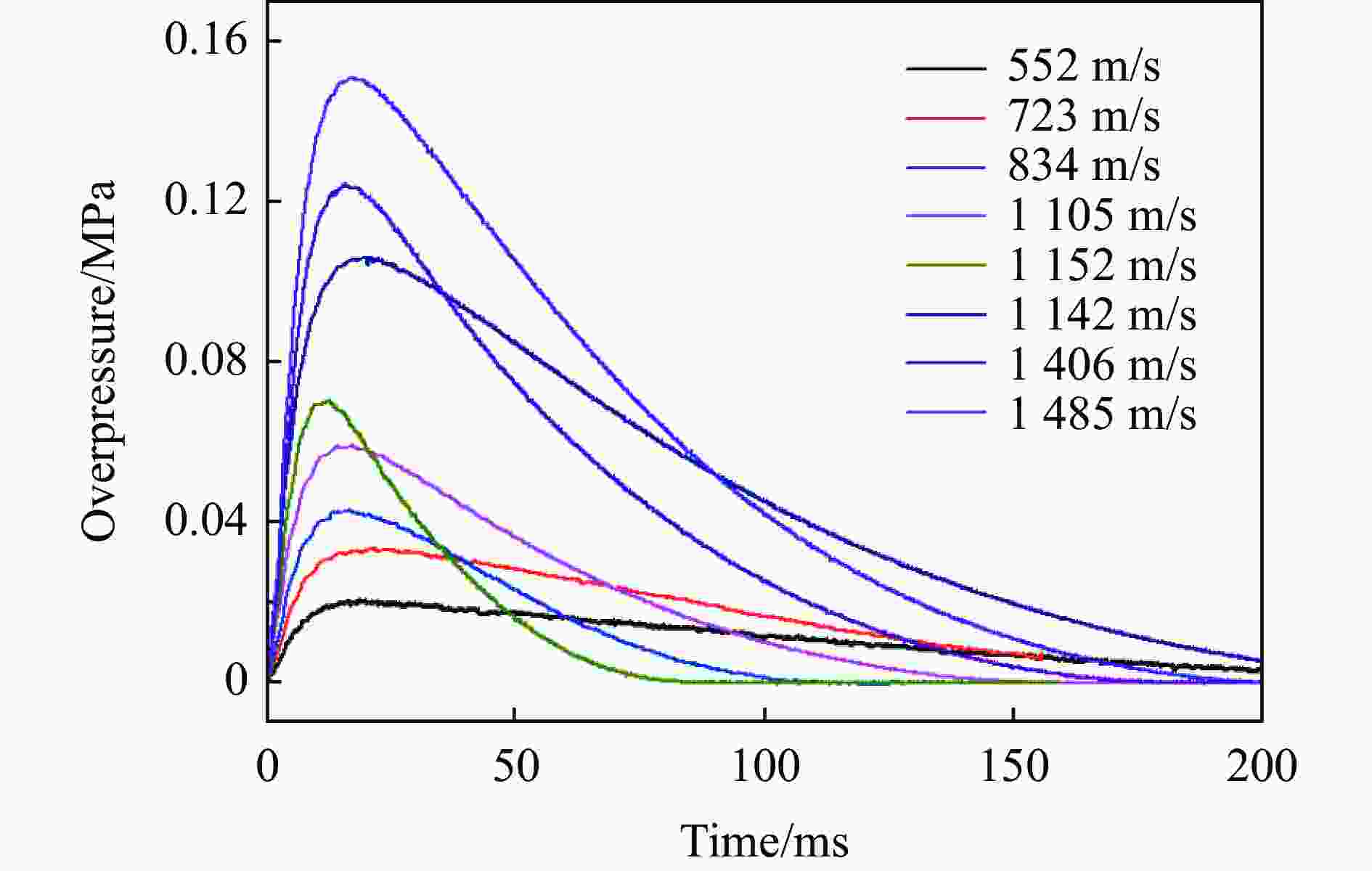

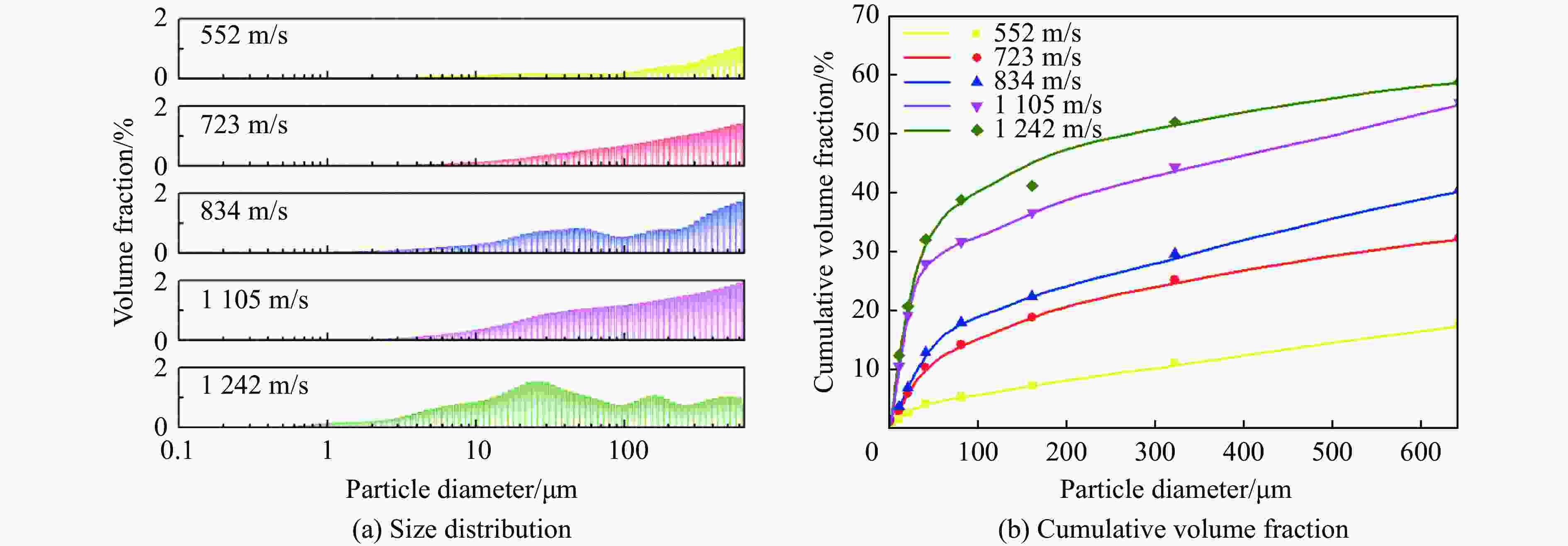

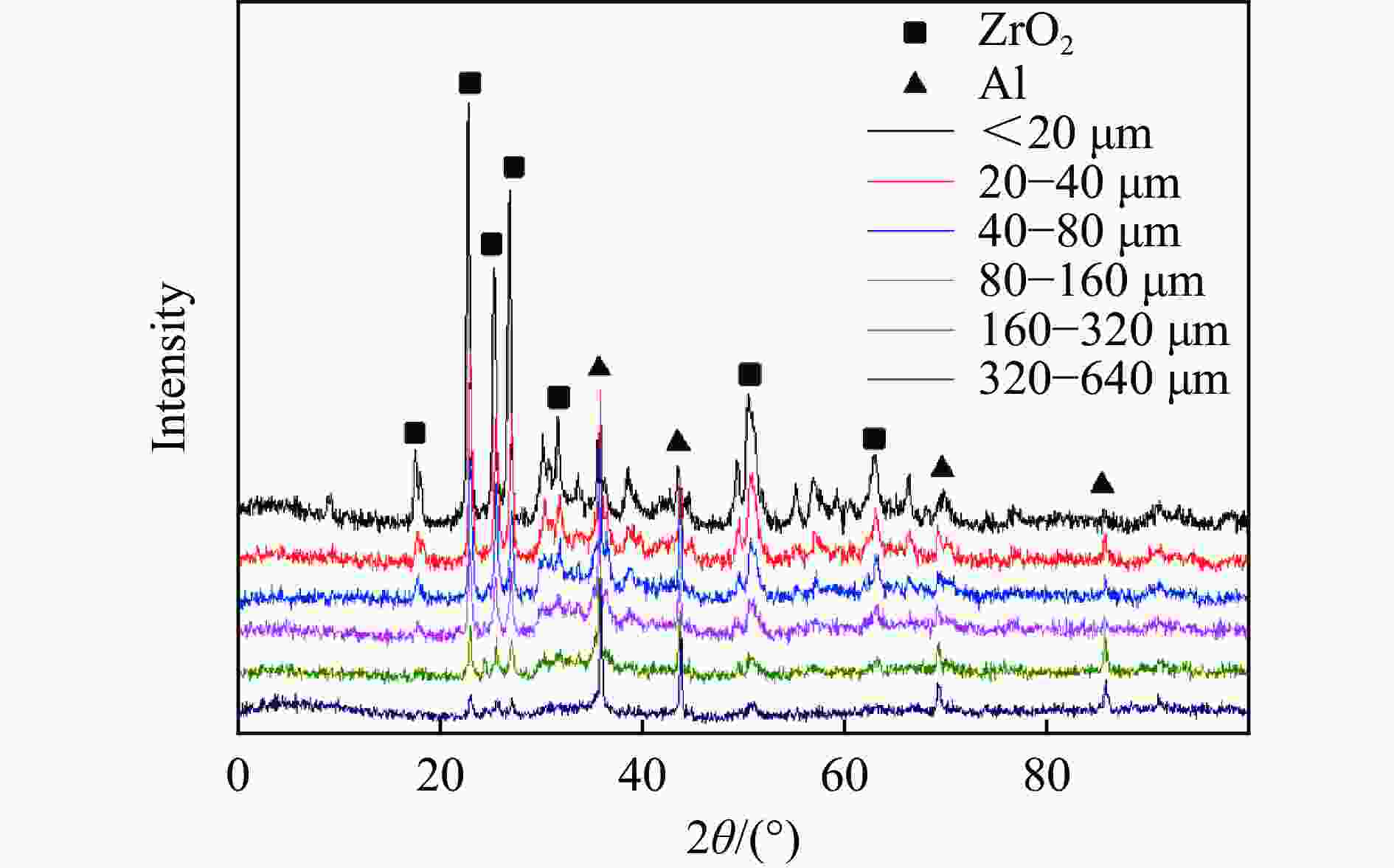

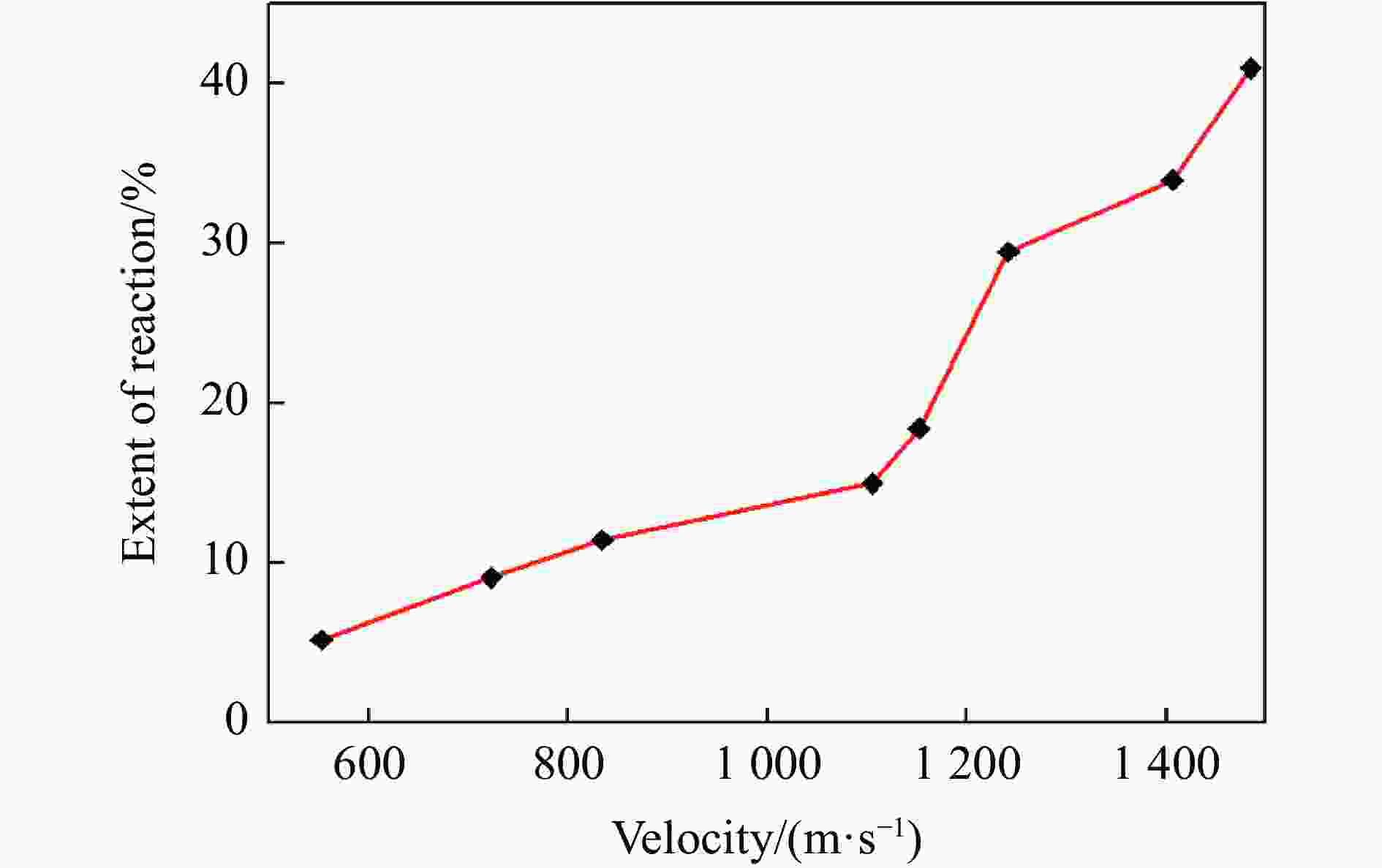

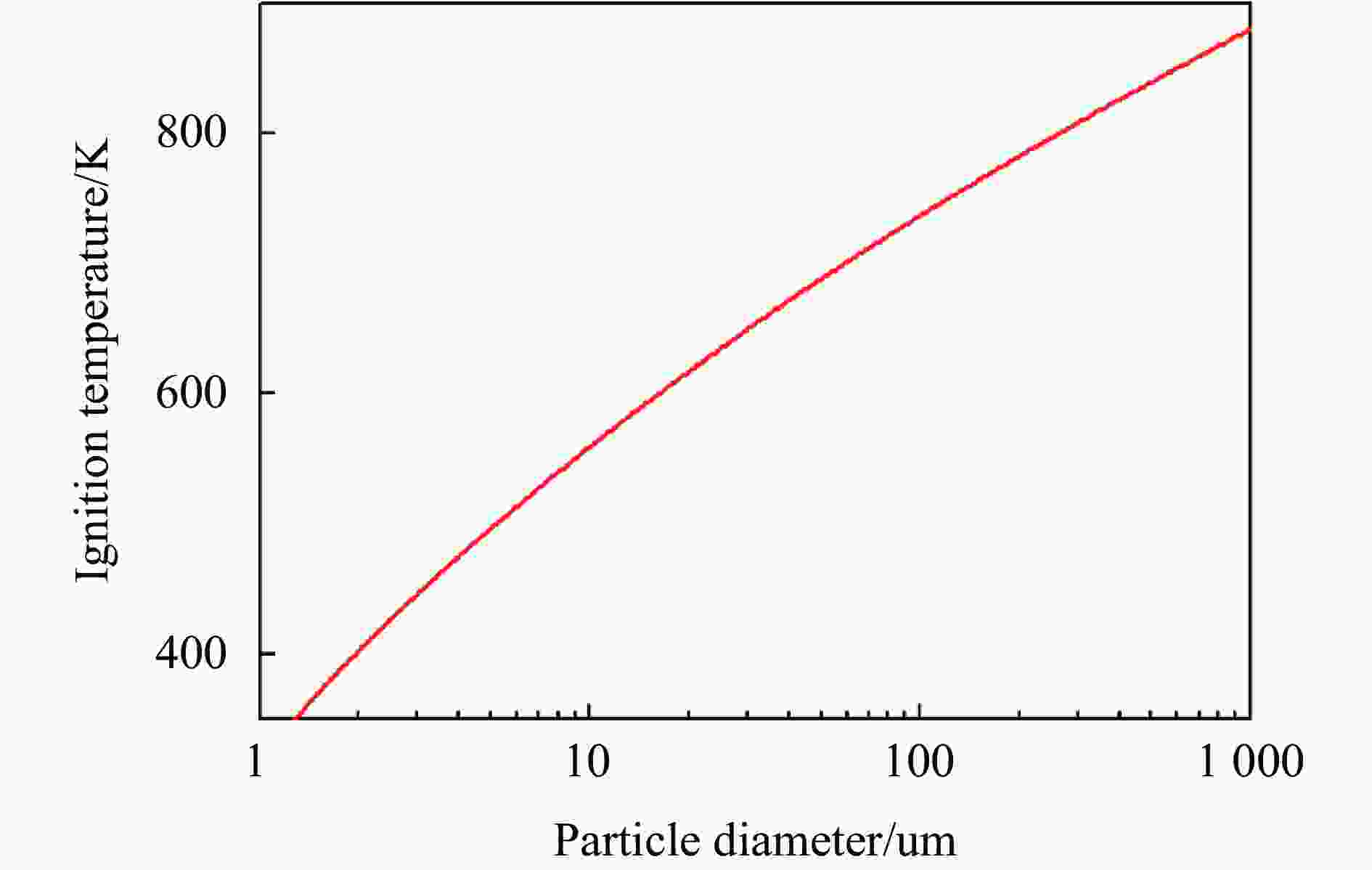

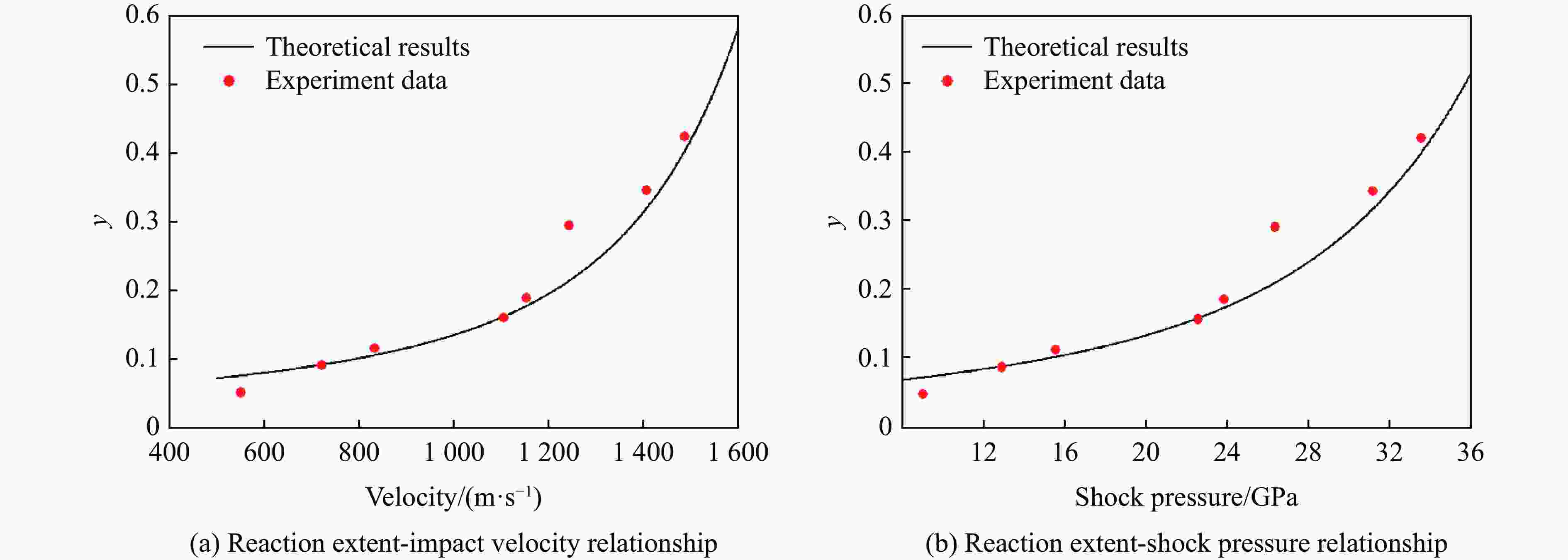

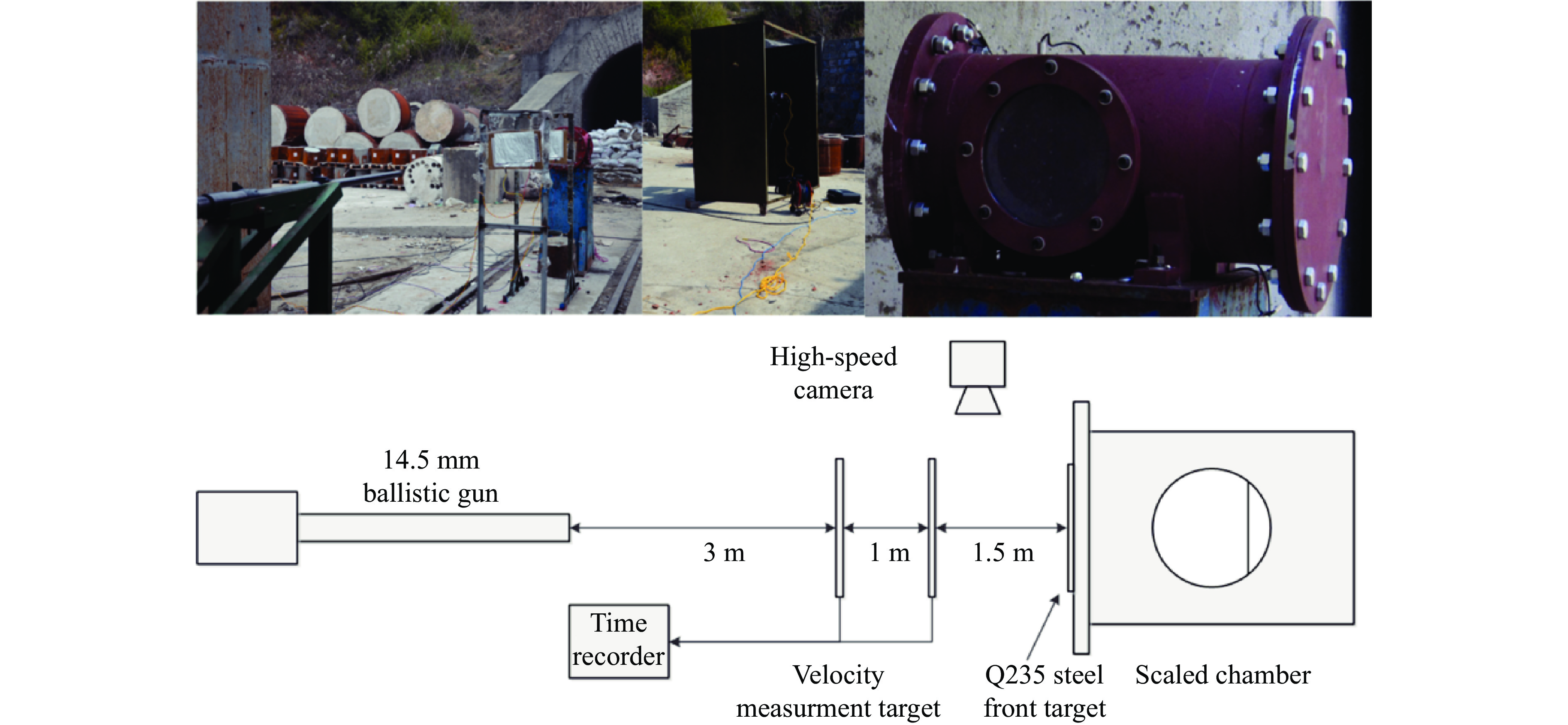

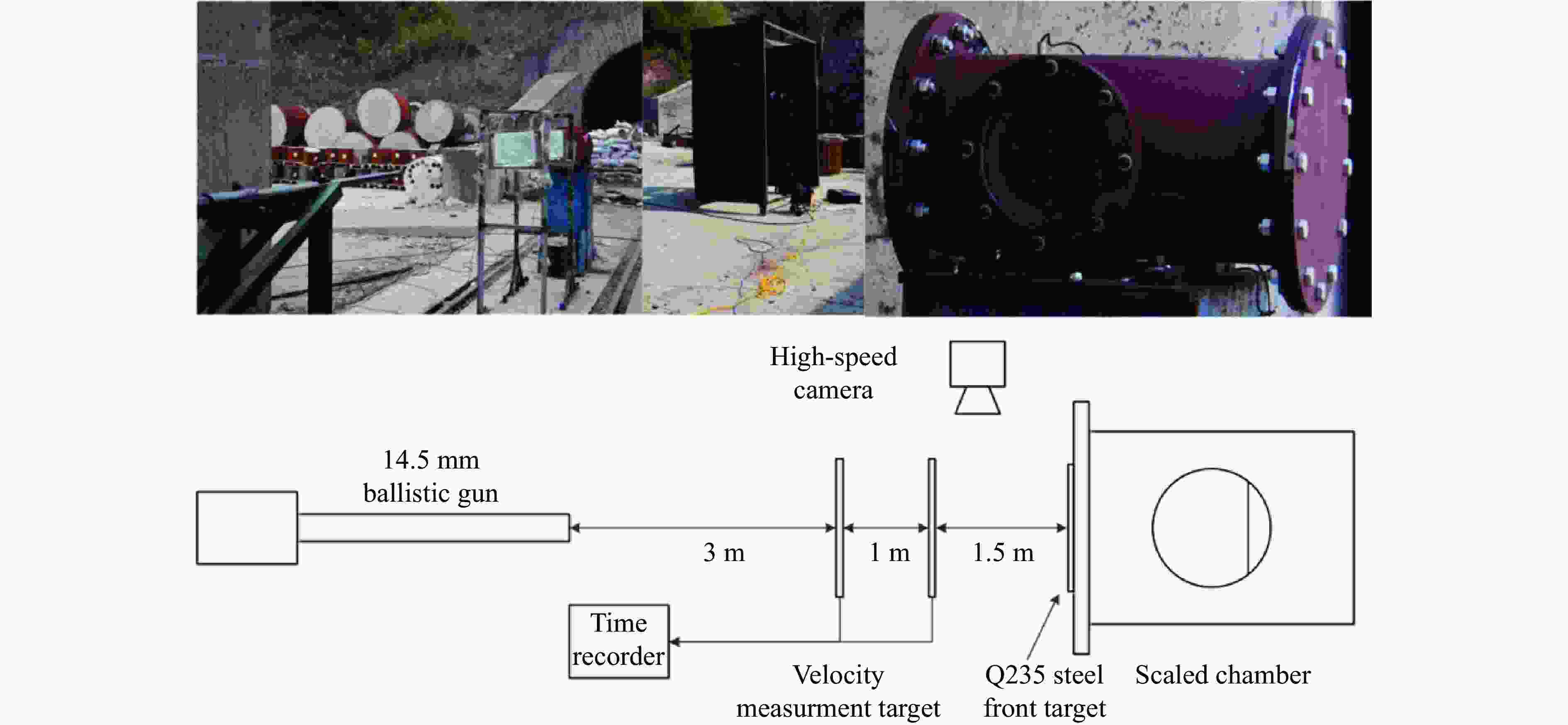

摘要: 为研究Zr基非晶合金破片的冲击破碎反应机制,进行了准密封箱冲击超压实验,测试了破片的碎片粒度,分析了碎片尺寸分布关系,并对不同粒径尺度的碎片进行了X射线衍射分析。实验结果表明,材料在冲击加载下的反应程度随着撞击速度的升高而增大;碎片分布符合分段式幂次律分布规律;材料冲击诱发的化学反应主要为Zr元素与空气中氧气的燃烧,其主要反应产物为ZrO2。基于冲击升温-碎片分布-碎片燃烧的冲击破碎反应理论模型能较好地解释冲击作用下Zr基非晶合金破片的反应规律,理论计算与实验结果吻合度较高。Abstract: Zr-based bulk metallic glasses are novel class of functional materials that comprehensively use chemical energy and kinetic energy to improve the damage effect of warhead. To investigate the mechanism of shock fragmentation reaction of Zr-based bulk metallic glass fragments, quasi-sealed venting chamber was used to measure the released energy of Zr62.5Nb3Cu14.5Ni14Al6 bulk metallic glass fragments under impact conditions. The fragments were driven by a 14.5 mm ballistic gun, with various levels of velocity, to impact the sealed chamber covered by 0.5 mm thick steel plates. High-speed camera was used to record the shock-fragmentation-reaction process through an observational window. The pressure in the chamber was measured by two pressure sensors installed in different positions on the inner wall of the chamber. The particle size of the fragment debris was measured by laser diffraction method and weighting method. And the debris with different particle sizes was analyzed by X-ray diffraction. According to one dimensional shock wave theory, the impact temperature of Zr-based bulk metallic glass was derived. Combined with the impact temperature, the fragment debris distribution model and metal particle ignition model, the shock-fragmentation-reaction theoretical model was developed to quickly calculate the extent of reaction of Zr-based bulk metallic glass fragments. The experiments results show that the reaction depth of material under impact loading increases with the increase of impact velocity. The distribution of debris conforms to the piecewise power law, and the size distribution of debris was fitted. The main chemical reaction induced by material impacting is the combustion of Zr and O2 in the air, and the main reaction product is ZrO2. Theoretical analysis results show that the shock-fragmentation-reaction theoretical model based on impact heating, debris distribution and debris combustion can explain the reaction law of Zr-based bulk metallic glass under impact loading well. And the theoretical calculation is in good agreement with the experimental results.

-

Key words:

- Zr-based bulk metallic glass /

- impact /

- fragmentation /

- reaction mechanism

-

表 1 超压峰值实验数据

Table 1. Experimental data of overpressure peak data

试验编号 v/(m·s−1) m/g $ {{\Delta }}p $/MPa 1 552 3.43 0.019 2 723 3.4 0.033 3 834 3.42 0.042 4 1105 3.49 0.058 5 1152 3.42 0.069 6 1242 3.36 0.105 7 1406 3.41 0.124 8 1485 3.47 0.151 表 2 实验数据及计算结果

Table 2. Results of calculation and experimental data

实验 v/(m·s−1) $ {{\Delta }}{E_{\text{C}}} $/kJ Ek/kJ $ {{\Delta }}Q $/kJ Qc/kJ y/% 1 552 1.67 0.16 1.52 29.32 5.17 2 723 2.90 0.27 2.64 29.06 9.08 3 834 3.70 0.36 3.34 29.23 11.42 4 1 105 5.10 0.64 4.47 29.83 14.97 5 1 152 6.07 0.68 5.39 29.23 18.44 6 1 242 9.24 0.78 8.46 28.72 29.47 7 1 406 10.91 1.01 9.90 29.15 33.97 8 1 485 13.29 1.15 12.24 29.66 40.93 -

[1] LUO P G, WANG Z C, JIANG C L, et al. Experimental study on impact-initiated characters of W/Zr energetic fragments [J]. Materials and Design, 2015, 84: 72–78. DOI: 10.1016/j.matdes.2015.06.107. [2] WANG C T, HE Y, JI C, et al. Investigation on shock-induced reaction characteristics of a Zr-based metallic glass [J]. Intermetallics, 2018, 93: 383–388. DOI: 10.1016/j.intermet.2017.11.004. [3] WEI H Y, YOO C S. Dynamic responses of reactive metallic structures under thermal and mechanical ignitions [J]. Journal of Materials Research, 2012, 27(21): 2705–2717. DOI: 10.1557/jmr.2012.302. [4] WEI H Y, YOO C S. Dynamic structural and chemical responses of energetic solids [J]. MRS Online Proceedings Library (OPL), 2012, 1405: 62–71. DOI: 10.1557/opl.2012.59. [5] JI C, HE Y, WANG C T, et al. Effect of dynamic fragmentation on the reaction characteristics of a Zr-based metallic glass [J]. Journal of Non-Crystalline Solids, 2019, 515: 149–156. DOI: 10.1016/j.jnoncrysol.2019.04.022. [6] GRADY D E. Fragment size distributions from the dynamic fragmentation of brittle solids [J]. International Journal of Impact Engineering, 2008, 35(12): 1557–1562. DOI: 10.1016/j.ijimpeng.2008.07.042. [7] GRADY D E. Length scales and size distributions in dynamic fragmentation [J]. International Journal of Fracture, 2010, 163(1/2): 85–99. DOI: 10.1007/s10704-009-9418-4. [8] ZHANG X F, SHI A S, QIAO L, et al. Experimental study on impact-initiated characters of multifunctional energetic structural materials [J]. Journal of Applied Physics, 2013, 113(8): 083508. DOI: 10.1063/1.4793281. [9] 谭华. 实验冲击波物理导引 [M]. 北京: 国防工业出版社, 2007: 4–87.TAN H. Introduction to experimental shock-wave physics [M]. Beijing: National Defense Industry Press, 2007: 4–87. [10] ZHANG X F, SHI A S, ZHANG J, et al. Thermochemical modeling of temperature controlled shock-induced chemical reactions in multifunctional energetic structural materials under shock compression [J]. Journal of Applied Physics, 2012, 111(12): 123501. DOI: 10.1063/1.4729048. [11] 张云峰. Zr基非晶合金破片特性及毁伤机理研究 [D]. 石家庄: 陆军工程大学, 2020: 29–84. [12] MOHAN S, TRUNOV M A, DREIZIN E L. Heating and ignition of metal particles in the transition heat transfer regime [J]. Journal of Heat Transfer, 2008, 130(10): 104505. DOI: 10.1115/1.2945881. [13] PHUOC T X, CHEN R H. Modeling the effect of particle size on the activation energy and ignition temperature of metallic nanoparticles [J]. Combustion and Flame, 2012, 159(1): 416–419. DOI: 10.1016/j.combustflame.2011.07.003. [14] MOHAN S, TRUNOV M A, DREIZIN E L. On possibility of vapor-phase combustion for fine aluminum particles [J]. Combustion and Flame, 2009, 156(11): 2213–2216. DOI: 10.1016/j.combustflame.2009.08.007. [15] HUANG Y, RISHA G A, YANG V, et al. Effect of particle size on combustion of aluminum particle dust in air [J]. Combustion and Flame, 2009, 156(1): 5–13. DOI: 10.1016/j.combustflame.2008.07.018. [16] 张云峰, 罗兴柏, 李晨, 等. 锆、铝颗粒活化能尺寸效应的理论模型 [J]. 稀有金属材料与工程, 2020, 49(12): 4097–4102.ZHANG Y F, LUO X B, LI C, et al. Analytical model for size effect of activation energy of zirconium and aluminum particles [J]. Rare Metal Materials and Engineering, 2020, 49(12): 4097–4102. [17] MAGLIA F, ANSELMI-TAMBURINI U, GENNARI S, et al. Dynamic behaviour and chemical mechanism in the self-propagating high-temperature reaction between Zr powders and oxygen gas [J]. Physical Chemistry Chemical Physics, 2001, 3(3): 489–496. DOI: 10.1039/B005678M. -

下载:

下载: