Mechanical properties of granite under impact compression after real-time high temperature

-

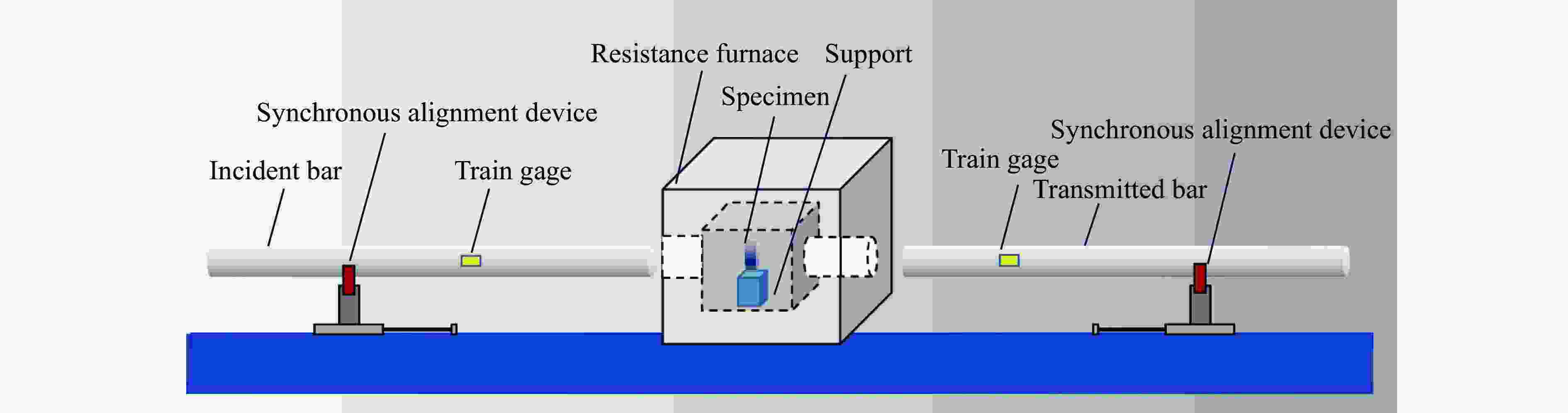

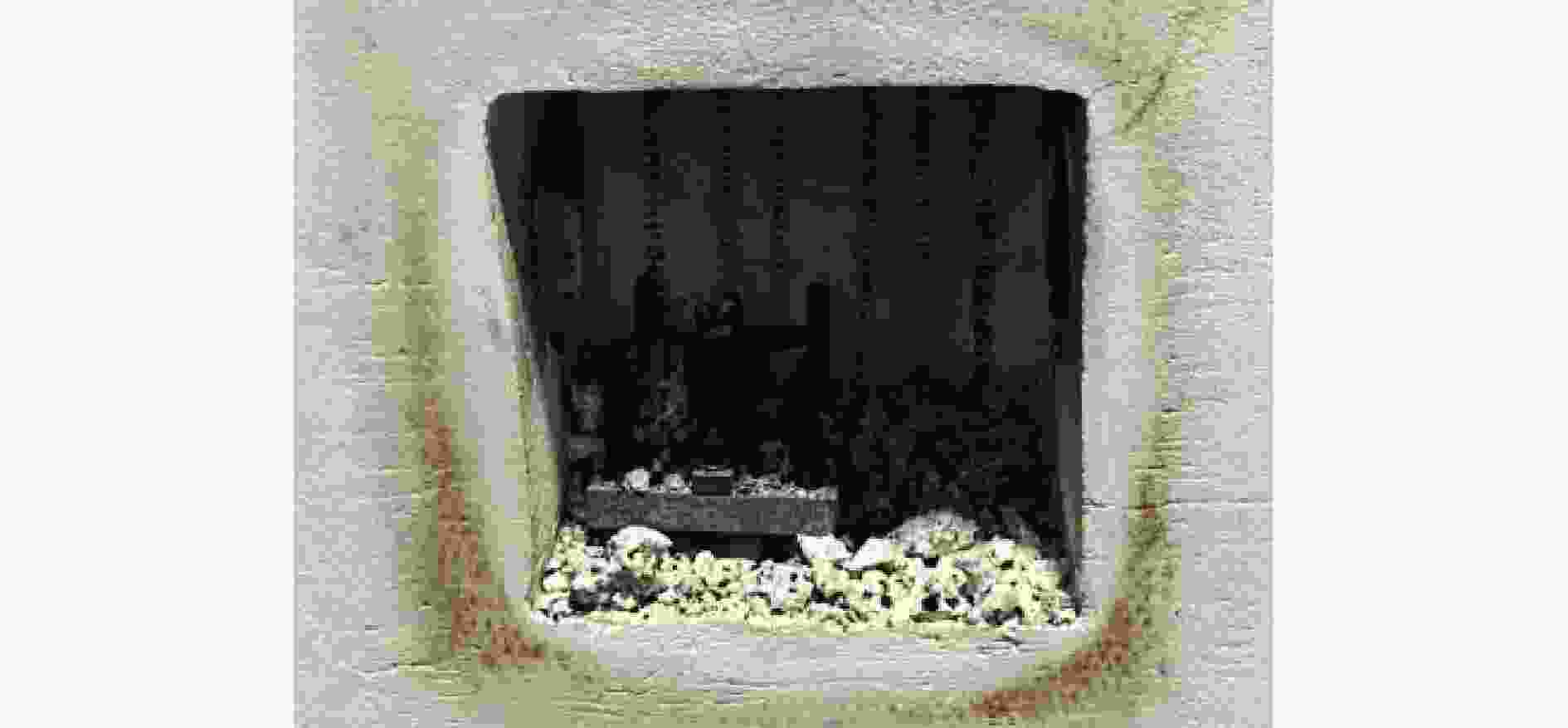

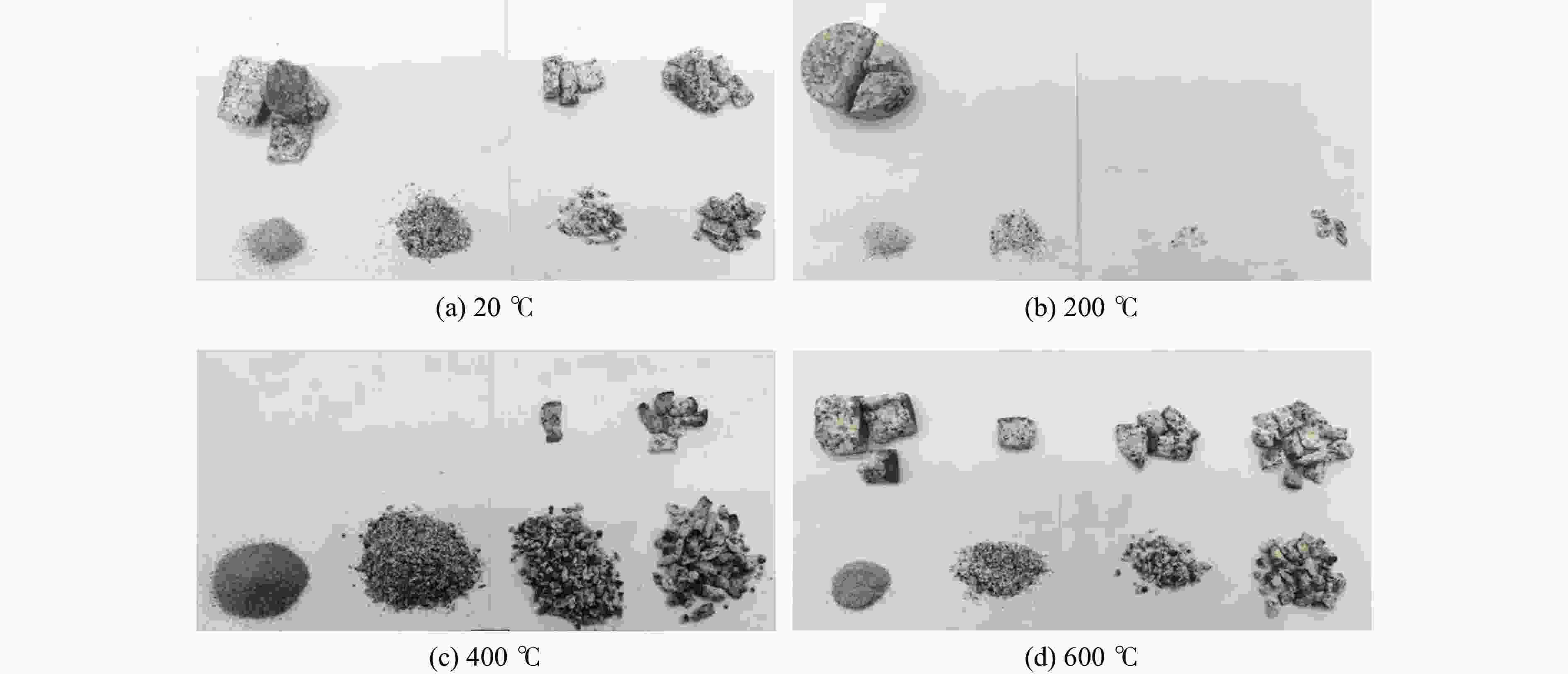

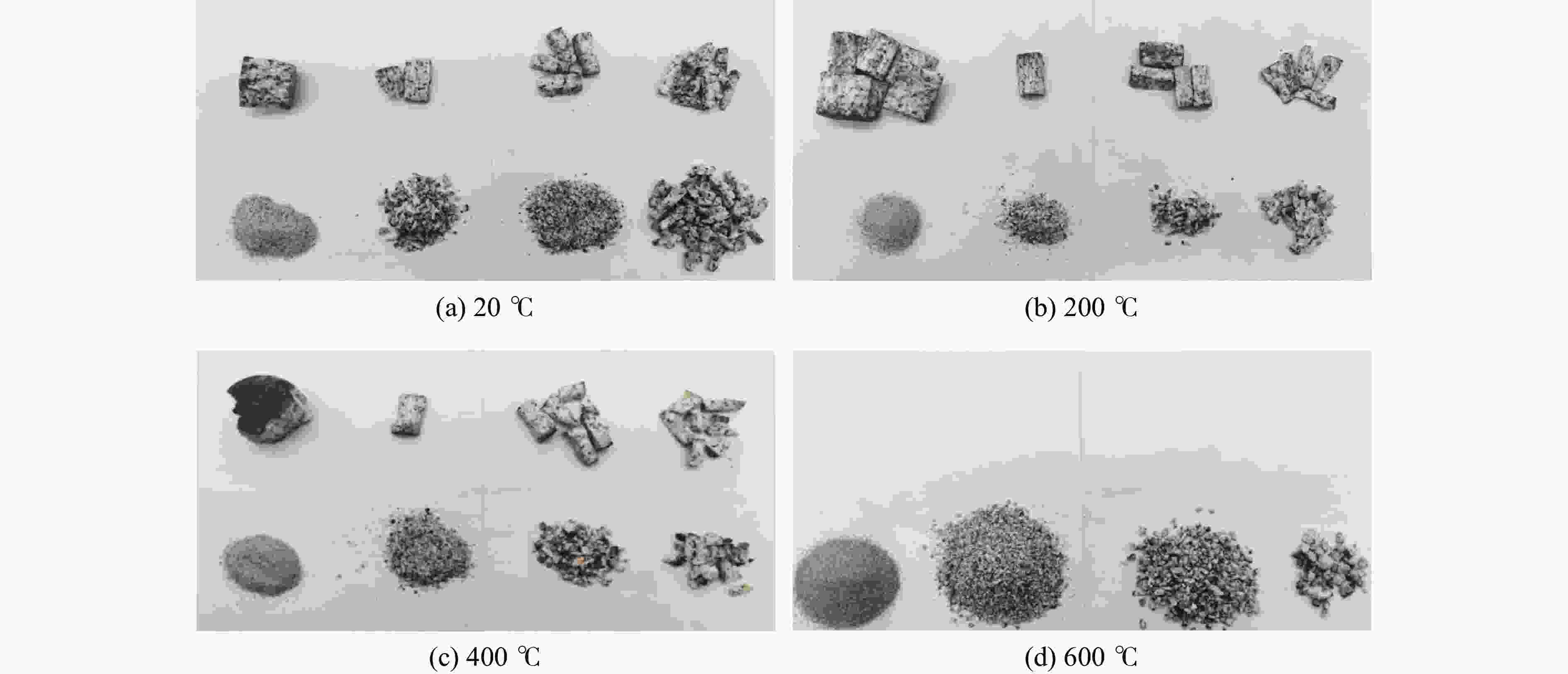

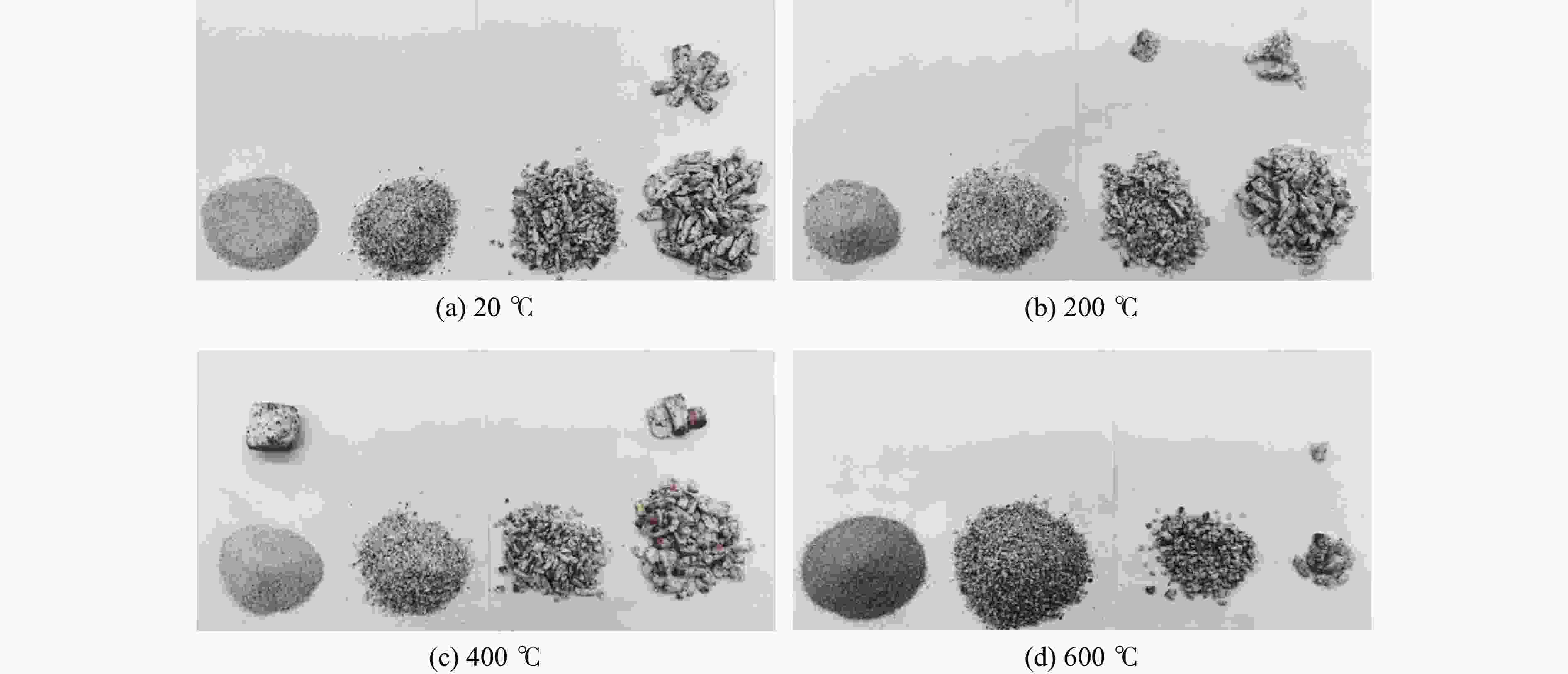

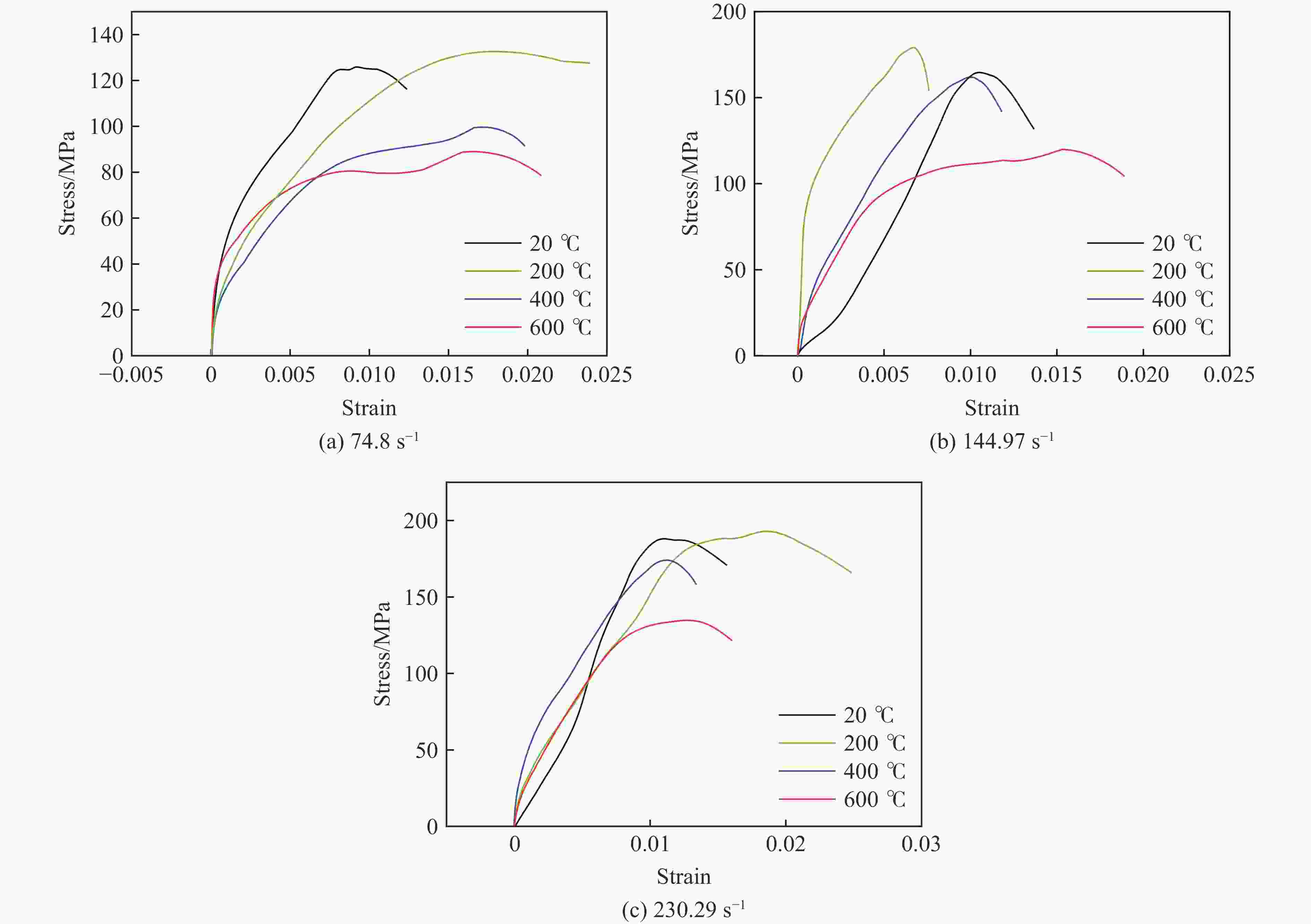

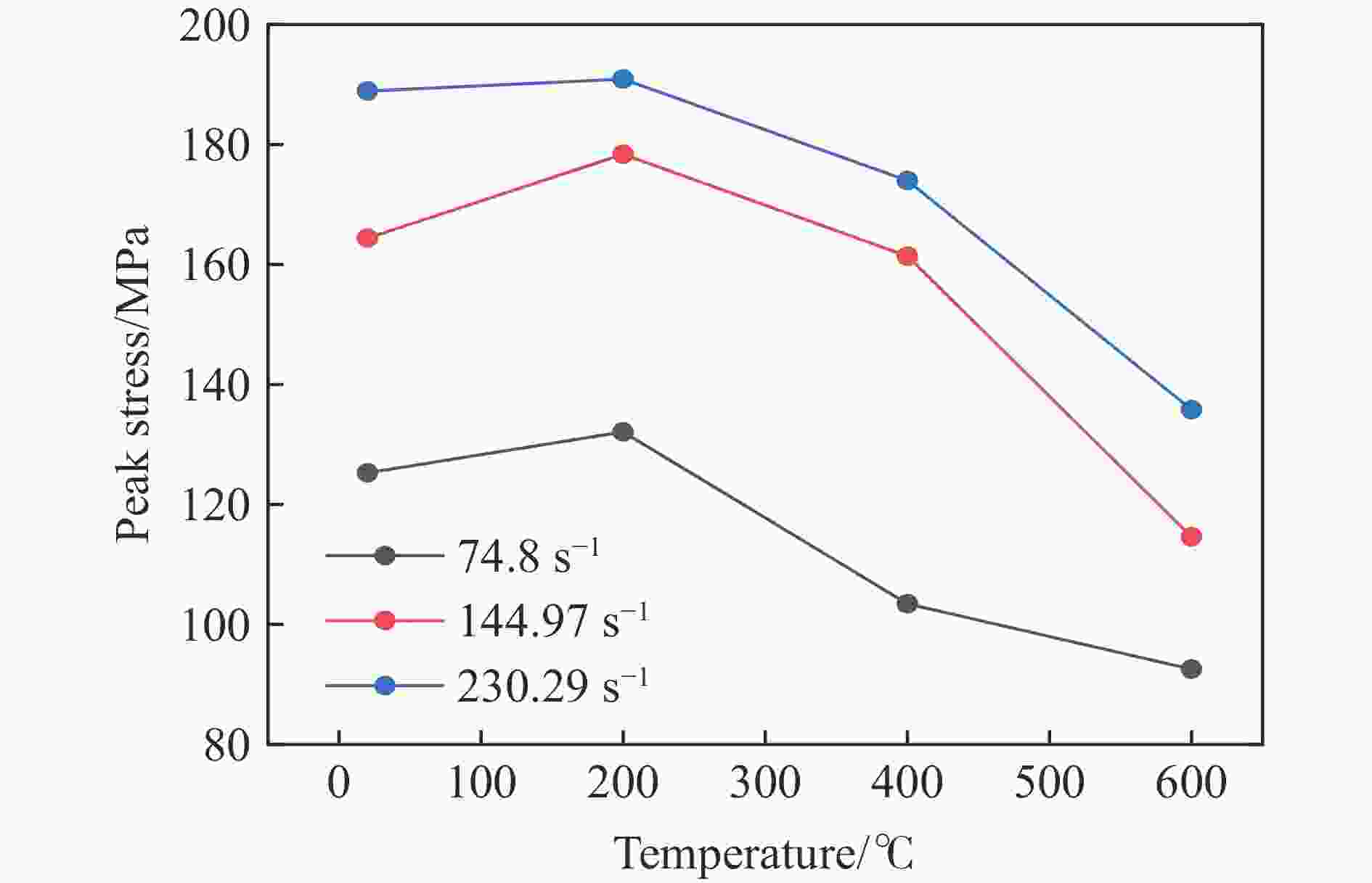

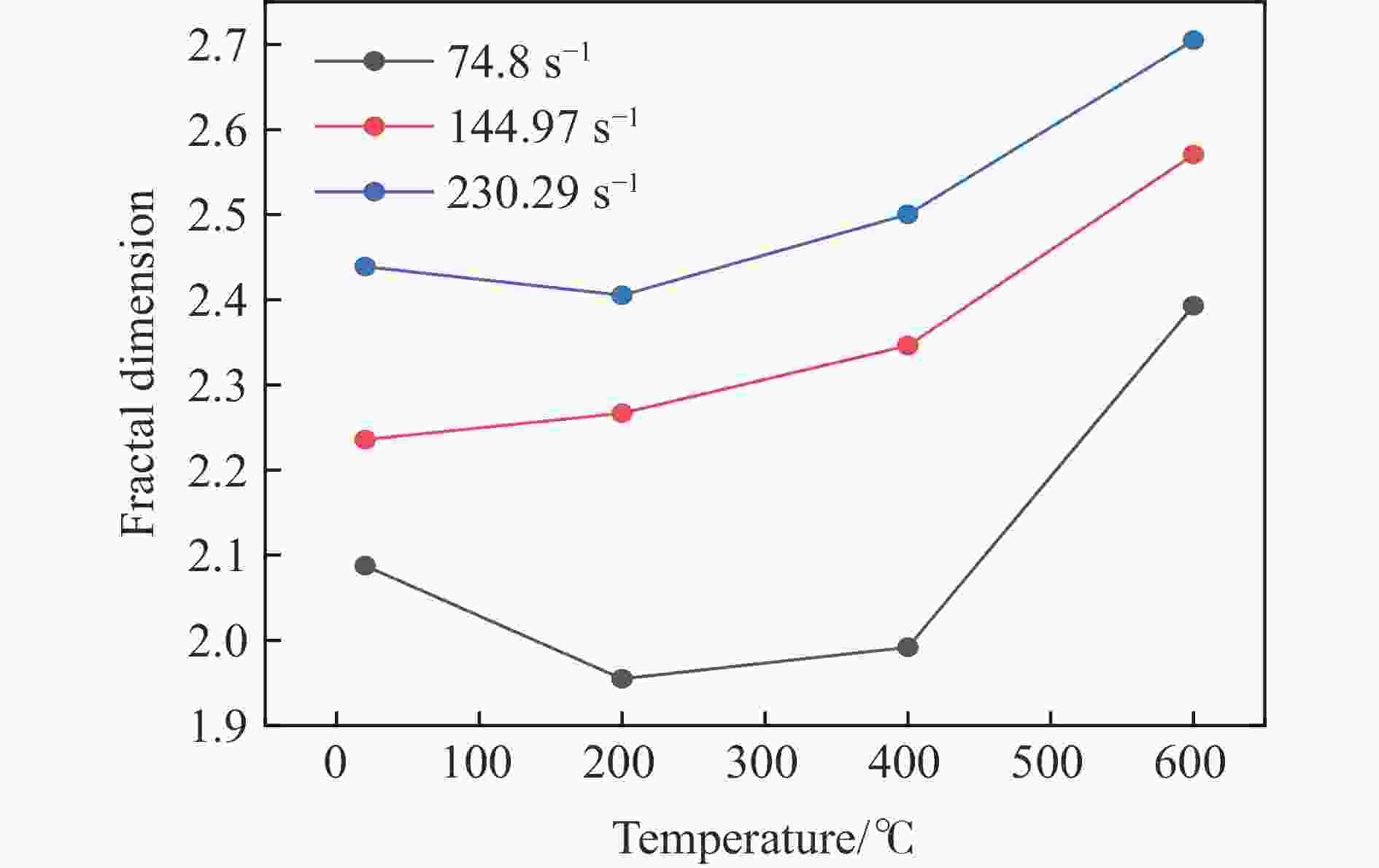

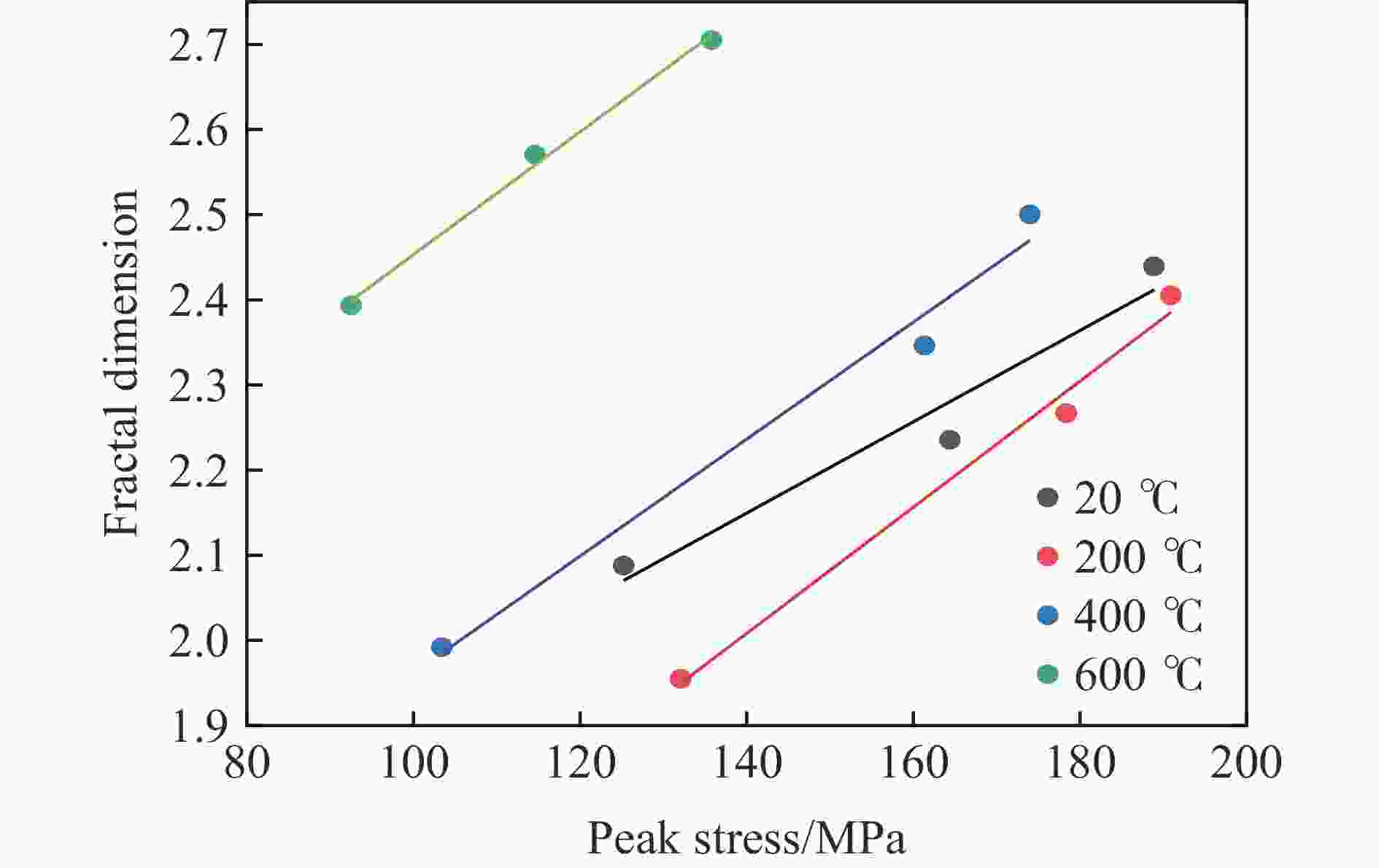

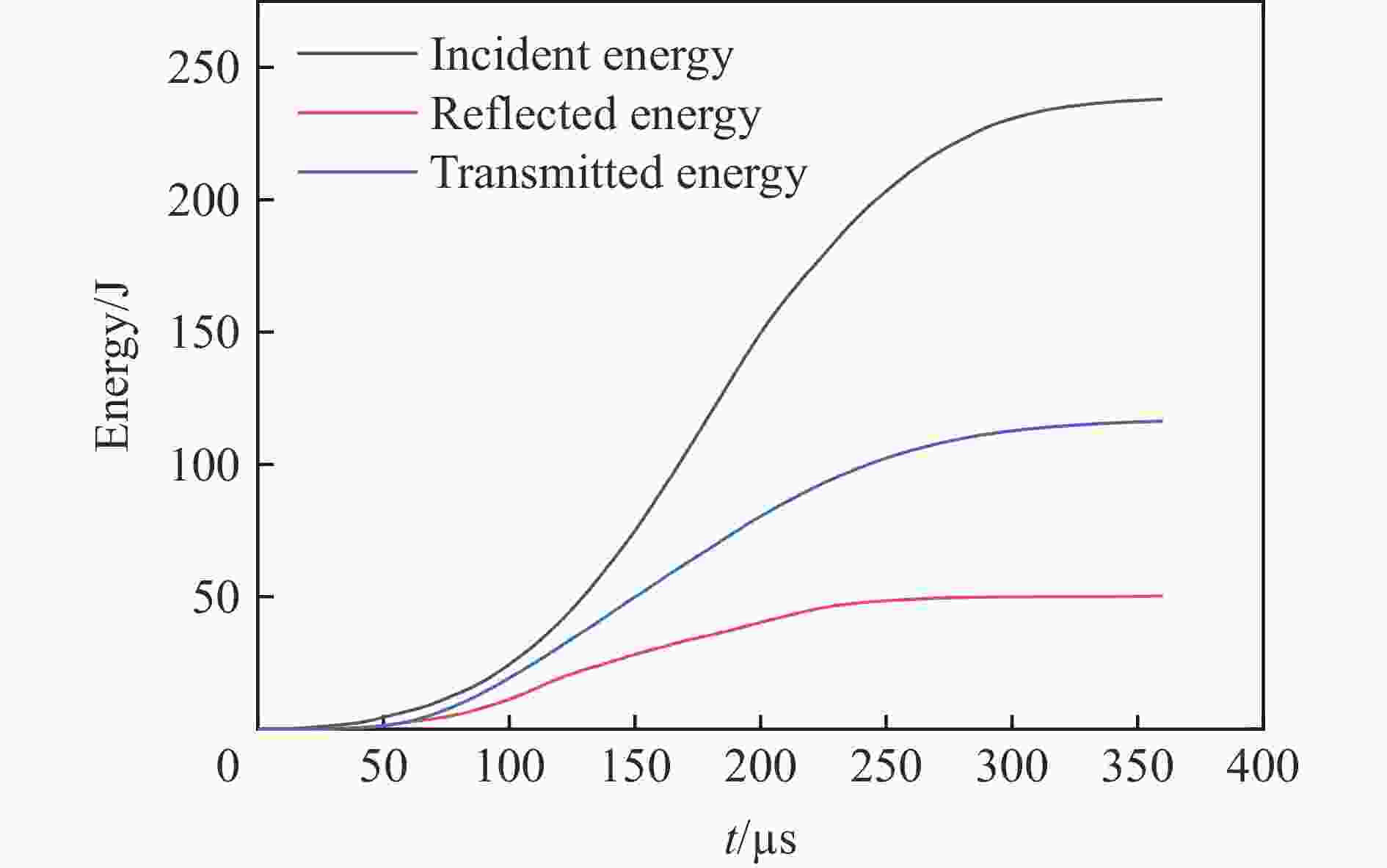

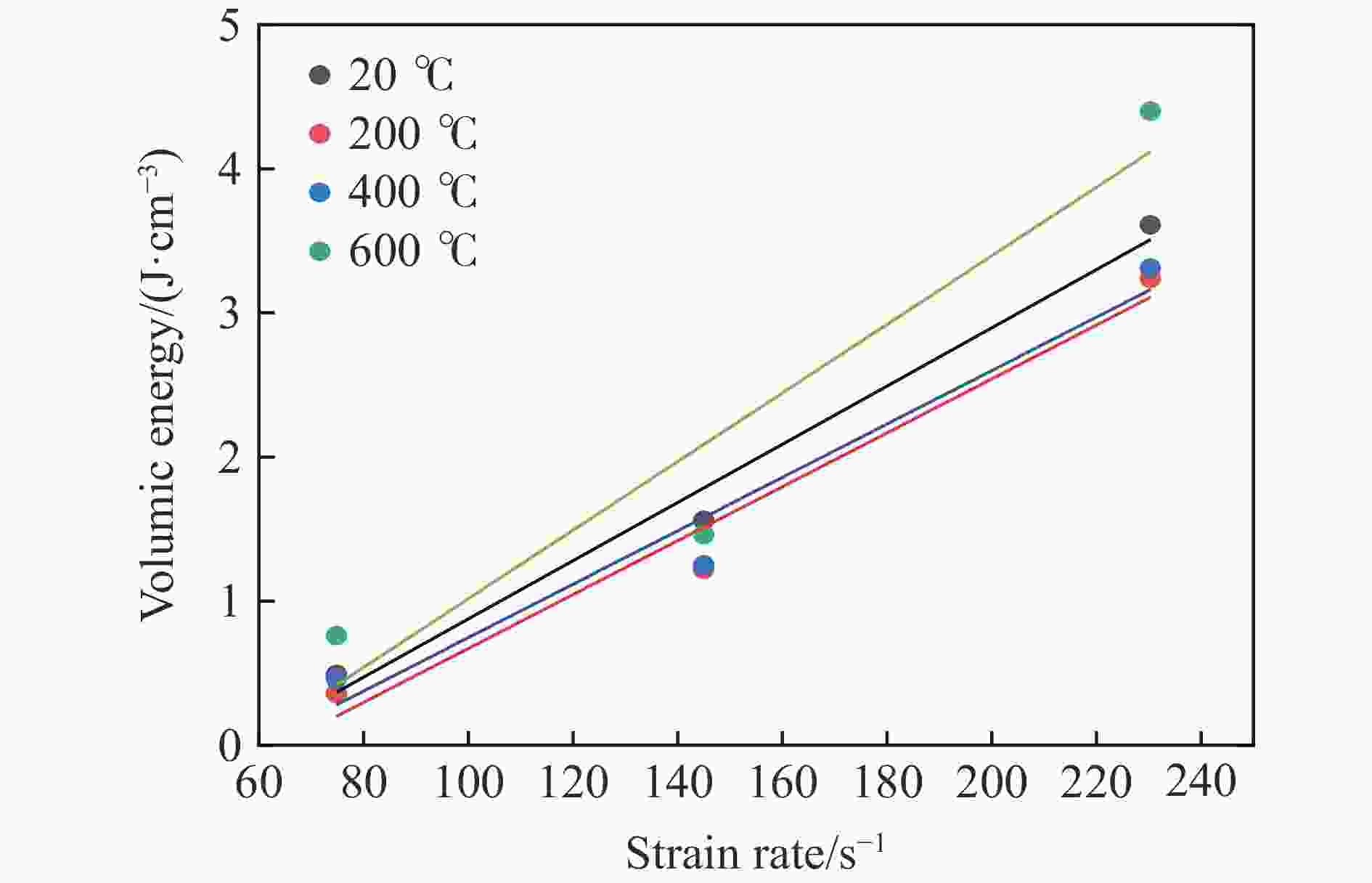

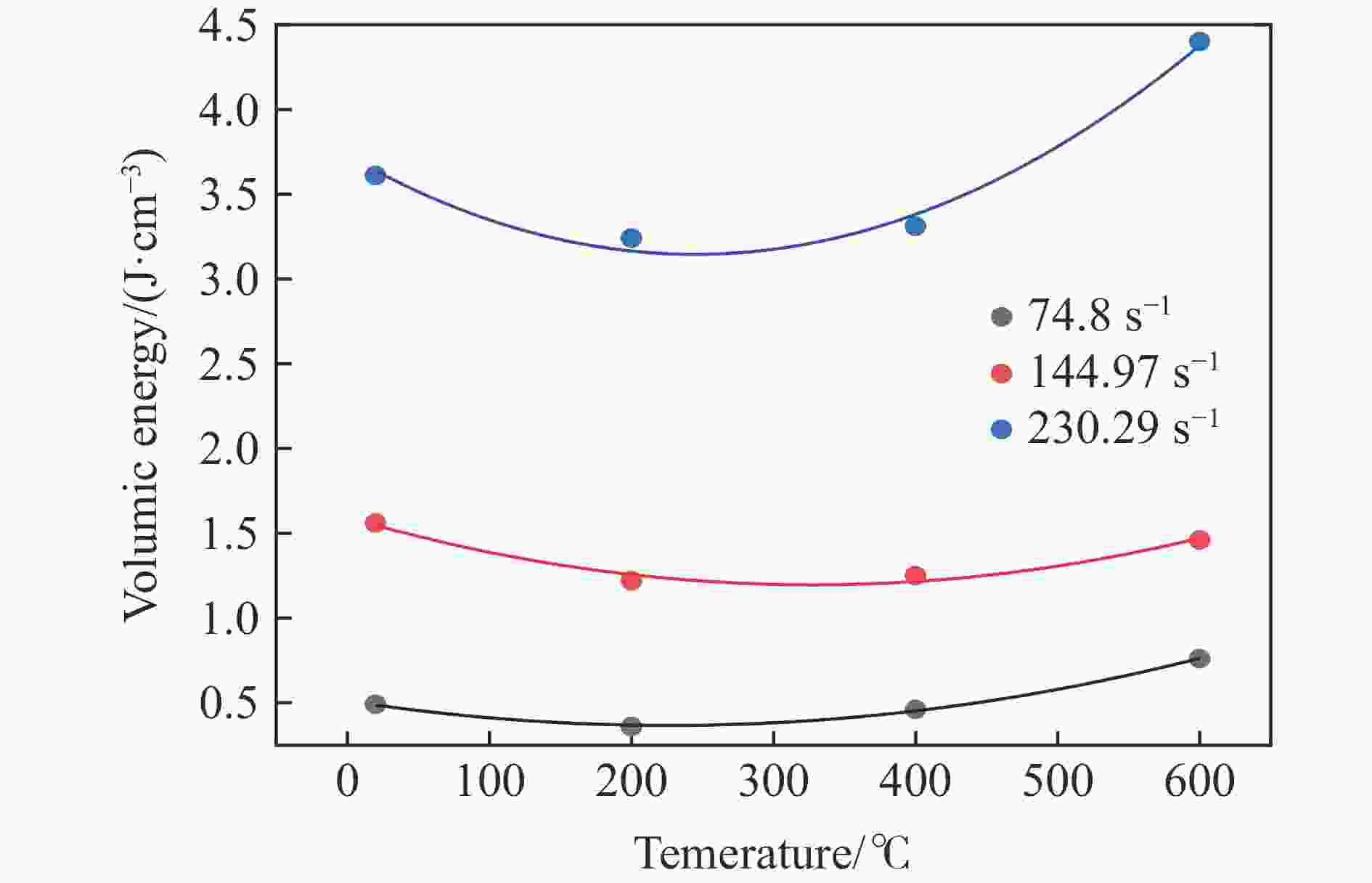

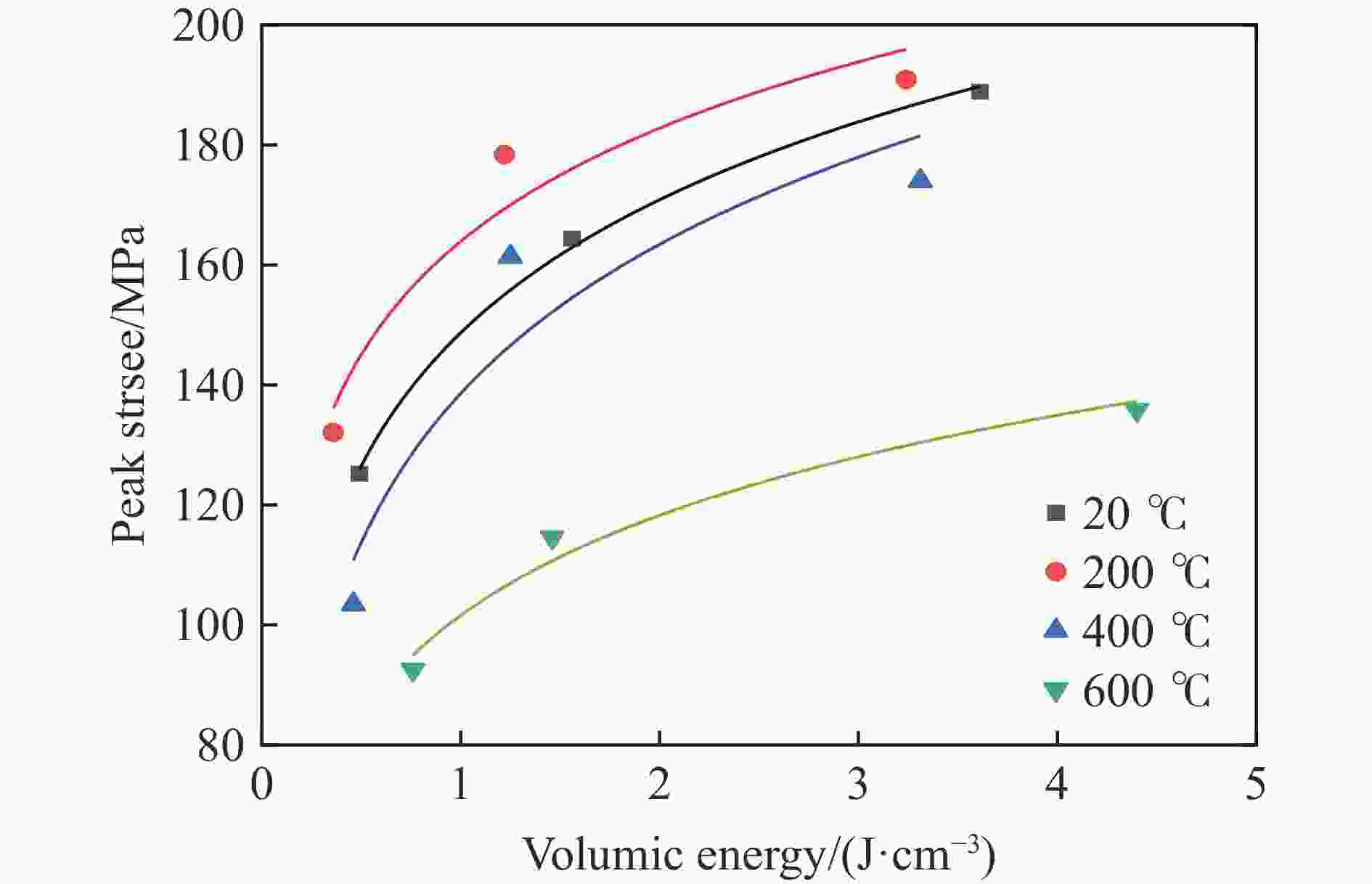

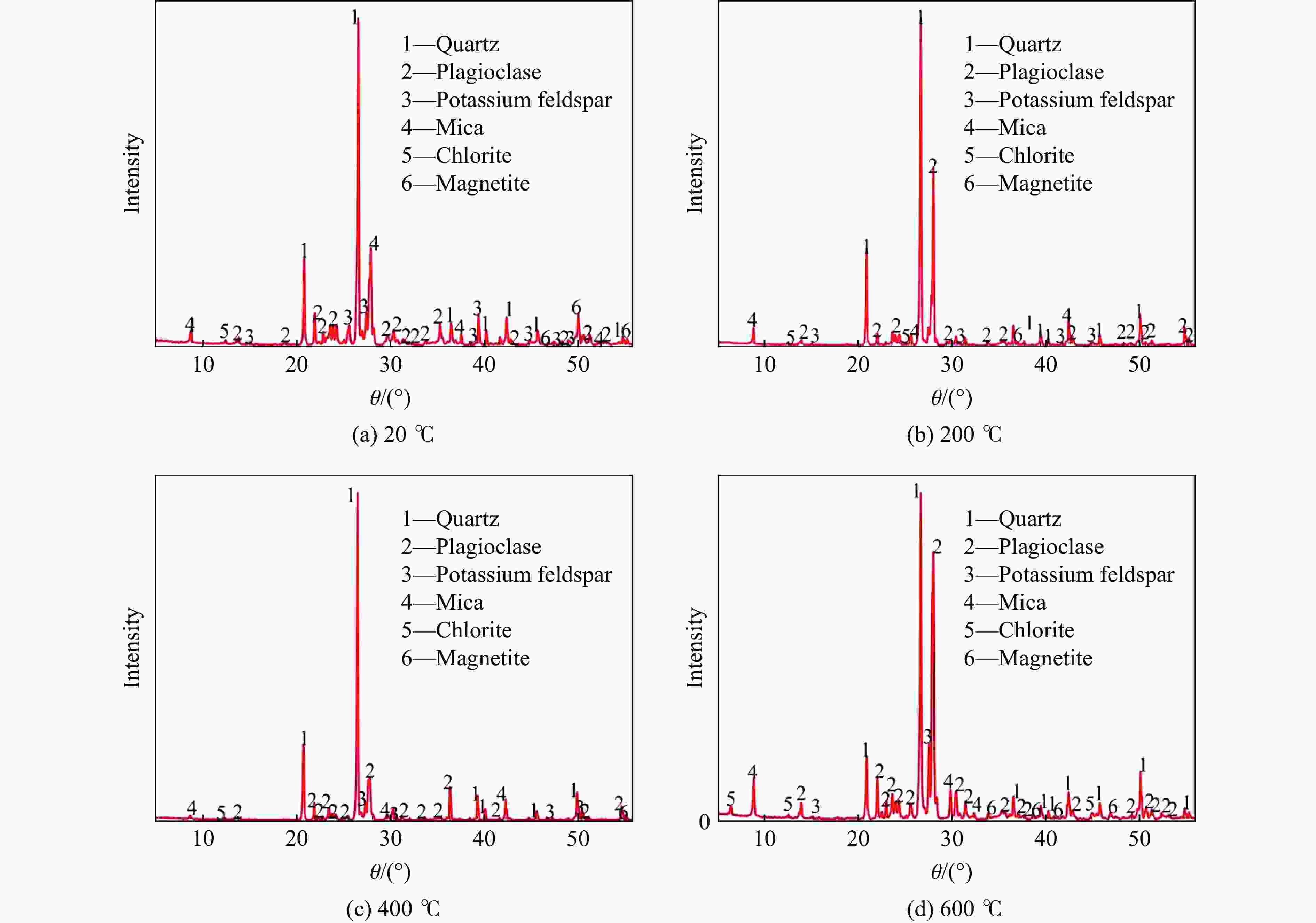

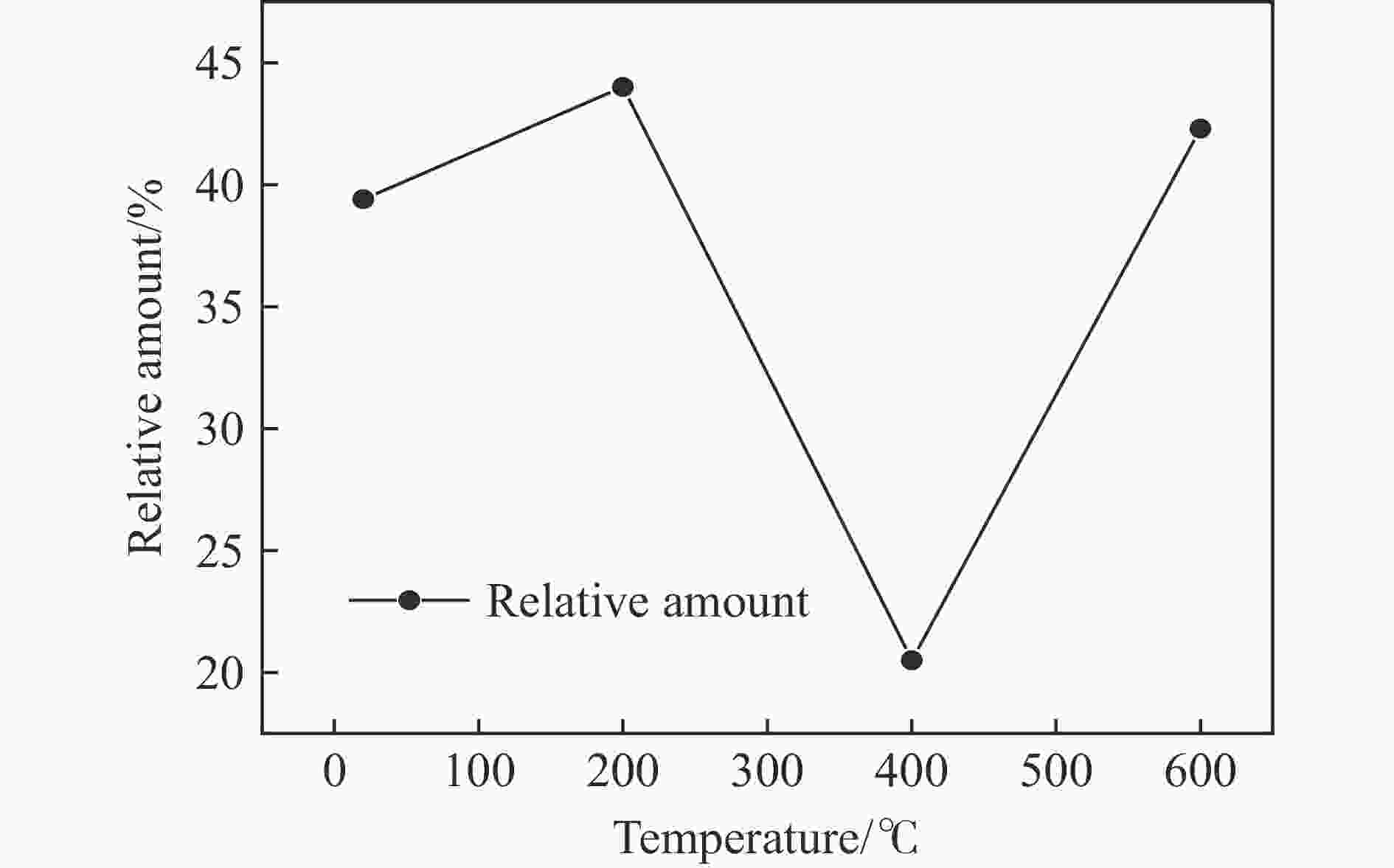

摘要: 为研究实时高温作用对花岗岩冲击力学特性的影响,以川藏铁路色季拉山施工区域加里东期花岗岩为研究对象,利用分离式霍普金森杆(SHPB)及同步箱式电阻炉,对20~800 ℃实时高温下的花岗岩试件进行冲击压缩试验,分析高温作用及加载应变率对试件破碎特征、动态抗压强度及能量吸收情况的影响,基于粉晶X射线衍射分析矿物成分变化与花岗岩动力学强度的内在关联。研究表明:20~400 ℃高温试件以脆性劈裂破坏为主,碎片形态呈纺锤形,两端尖锐,而600 ℃高温试件以塑性破坏为主,形状趋于圆钝;试件峰值应力随温度升高具有先增大后减小的变化趋势,200 ℃时达到强度阈值,随后持续降低;单位体积岩石耗散能与加载应变率呈线性正相关关系,与温度呈二次函数关系,与峰值应力呈指数关系,拟合效果良好;石英、云母和长石三种主要矿物成分的含量波动、相态变化等因素共同导致花岗岩动力学强度在200 ℃后逐步劣化。Abstract: The study of thermal-mechanical coupling mechanism is of great significance to deep rock engineering such as rock tunnel fire, nuclear waste treatment and geothermal development. To investigate the effect of high temperature on the impact mechanical properties of granite, the real-time high temperature impact compression test was carried out on the granite specimen at 20~800 ℃. The Caledonian granite in the construction area of Sejila Mountain on Sichuan-Tibet Railway was taken as the research object, real-time high temperature impact compression tests were carried out on the specimens under five different temperatures ( 20, 200, 400, 600 and 800 ℃) with three average loading rates ( 72.8, 144.97 and 230.29 s−1) by using the split Hopkinson pressure bar (SHPB) and synchronous box-type resistance furnace. The effects of high temperature and loading strain rate on the fracture characteristics, dynamic compressive strength and fractal dimension of the specimens were analyzed. The variation law of dissipated energy per unit volume was also studied and discussed. In addition, the intrinsic correlation between the change of mineral composition and the dynamic strength of granite was analyzed based on X-ray powder crystal diffraction. The results show that the brittle fracture of the specimens at 20 to 400 ℃ is dominant, and the fragments are spindle-shaped with sharp ends. The specimens at 600 ℃ are dominated by plastic failure, and their shapes tend to be round. The peak stress of specimens increases first and then decreases with the increase of temperature, reaches the strength threshold at 200 ℃, and then decreases continuously. The dissipated energy per unit volume of rock has a positive linear correlation with the loading strain rate and a quadratic function with the temperature, which shows a good fitting effect. The content fluctuation and phase change of the three main mineral components of quartz, mica and feldspar lead to the gradual deterioration of the dynamic strength of granite after 200 ℃.

-

Key words:

- real-time high temperature /

- granite /

- SHPB /

- energy dissipation /

- XRD

-

表 1 SHPB试验参数

Table 1. Parameters of the test

气压/MPa 冲击速率/(m∙s−1) 平均应变率/s−1 0.2 5.4 74.80 0.4 8.8 144.97 0.6 11.3 230.29 表 2 峰值应力

Table 2. Peak stress

平均应变率/s−1 试件峰值应力/MPa 20 ℃ 200 ℃ 400 ℃ 600 ℃ 800 ℃ 74.80 125.25 132.08 103.43 92.517 0 144.97 164.39 178.38 161.38 114.59 0 230.29 188.91 190.91 174.00 135.80 0 表 3 体积能量

Table 3. Volumic energy

$ \bar \varepsilon $/s−1 w/(J·cm−3) 20 ℃ 200 ℃ 400 ℃ 600 ℃ 800 ℃ 74.80 0.49 0.36 0.46 0.76 0.49 144.97 1.56 1.22 1.25 1.46 1.56 230.29 3.61 3.24 3.31 4.40 3.61 表 4 矿物成分的质量分数(%)

Table 4. Mass fraction (%) of the components

温度/℃ 石英 长石 云母 绿泥石 磁铁矿 20 53.4 32.2 7.2 2.2 5.0 200 52.5 35.6 8.4 1.7 0.5 400 77.4 17.1 3.4 1.4 0.7 600 33.3 50.0 13.2 1.5 0.6 -

[1] 闫治国, 朱合华, 梁利. 火灾高温下隧道衬砌管片力学性能试验 [J]. 同济大学学报(自然科学版), 2012, 40(6): 823–828. DOI: 10.3969/j.issn.0253-374x.2012.06.004.YAN Z G, ZHU H H, LIANG L. Experimental study on mechanical performance of lining segments in fire accidents [J]. Journal of Tongji University (Natural Science), 2012, 40(6): 823–828. DOI: 10.3969/j.issn.0253-374x.2012.06.004. [2] MARTÍN-GAMBOA M, IRIBARREN D, DUFOUR J. On the environmental suitability of high-and low-enthalpy geothermal systems [J]. Geothermics, 2015, 53: 27–37. DOI: 10.1016/j.geothermics.2014.03.012. [3] 杨丹. 三次采油化学驱油技术现状与未来展望 [J]. 化学工程与装备, 2021(1): 216–217. DOI: 10.19566/j.cnki.cn35-1285/tq.2021.01.099. [4] 唐红梅, 周云涛, 陈洪凯, 等. 地下工程爆破对危岩稳定性的影响 [J]. 爆炸与冲击, 2015, 35(2): 278–284. DOI: 10.11883/1001-1455(2015)02-0278-07.TANG H M, ZHOU Y T, CHEN H K, et al. Impact study on stability of unstable rock under underground construction blasting [J]. Explosion and Shock Waves, 2015, 35(2): 278–284. DOI: 10.11883/1001-1455(2015)02-0278-07. [5] 罗生银, 窦斌, 田红, 等. 自然冷却后与实时高温下花岗岩物理力学性质对比试验研究 [J]. 地学前缘, 2020, 27(1): 178–184. DOI: 10.13745/j.esf.2020.1.19.LUO S Y, DOU B, TIAN H, et al. Comparative experimental study on physical and mechanical properties of granite after natural cooling and under real-time high temperature [J]. Earth Science Frontiers, 2020, 27(1): 178–184. DOI: 10.13745/j.esf.2020.1.19. [6] 范飞林, 许金余. 大直径SHPB实验中的高温加载技术及其应用 [J]. 爆炸与冲击, 2013, 33(1): 54–60. DOI: 10.11883/1001-1455(2013)01-0054-07.FAN F L, XU J Y. High-temperature loading techniques in large-diameter SHPB experiment and its application [J]. Explosion and Shock Waves, 2013, 33(1): 54–60. DOI: 10.11883/1001-1455(2013)01-0054-07. [7] 寇绍全, ALM O. 微裂隙和花岗岩的抗拉强度 [J]. 力学学报, 1987, 19(4): 366–373. DOI: 10.6052/0459-1879-1987-4-1987-045.KOU S Q, ALM O. Microcracks and the tensile strength of granite [J]. Acta Mechanica Sinica, 1987, 19(4): 366–373. DOI: 10.6052/0459-1879-1987-4-1987-045. [8] 吴刚, 翟松韬, 王宇. 高温下花岗岩的细观结构与声发射特性研究 [J]. 岩土力学, 2015, 36(S1): 351–356. DOI: 10.16285/j.rsm.2015.S1.060.WU G, ZHAI S T, WANG Y. Research on characteristics of mesostructure and acoustic emission of granite under high temperature [J]. Rock and Soil Mechanics, 2015, 36(S1): 351–356. DOI: 10.16285/j.rsm.2015.S1.060. [9] 赵阳升, 孟巧荣, 康天合, 等. 显微CT试验技术与花岗岩热破裂特征的细观研究 [J]. 岩石力学与工程学报, 2008, 27(1): 28–34. DOI: 10.3321/j.issn:1000-6915.2008.01.005.ZHAO Y S, MENG Q R, KANG T H, et al. Micro-CT experimental technology and meso-investigation on thermal fracturing characteristics of granite [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(1): 28–34. DOI: 10.3321/j.issn:1000-6915.2008.01.005. [10] 赵阳升, 万志军, 张渊, 等. 岩石热破裂与渗透性相关规律的试验研究 [J]. 岩石力学与工程学报, 2010, 29(10): 1970–1976.ZHAO Y S, WAN Z J, ZHANG Y, et al. Experimental study of related laws of rock thermal cracking and permeability [J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(10): 1970–1976. [11] 张静华, 王靖涛, 赵爱国. 高温下花岗岩断裂特性的研究 [J]. 岩土力学, 1987, 8(4): 11–16. DOI: 10.16285/j.rsm.1987.04.005.ZHANG J H, WANG J T, ZHAO A G. Fracture properies of granite at high temperature [J]. Rock and Soil Mechanics, 1987, 8(4): 11–16. DOI: 10.16285/j.rsm.1987.04.005. [12] 王靖涛, 赵爱国, 黄明昌. 花岗岩断裂韧度的高温效应 [J]. 岩土工程学报, 1989, 11(6): 113–118. DOI: 10.3321/j.issn:1000-4548.1989.06.015.WANG J T, ZHAO A G, HUANG M C. Effect of high temperature on the fracture toughness of granite [J]. Chinese Journal of Geotechnical Engineering, 1989, 11(6): 113–118. DOI: 10.3321/j.issn:1000-4548.1989.06.015. [13] YIN T B, SHU R H, LI X B, et al. Comparison of mechanical properties in high temperature and thermal treatment granite [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(7): 1926–1937. DOI: 10.1016/S1003-6326(16)64311-X. [14] 尹土兵, 李夕兵, 殷志强, 等. 高温后砂岩静、动态力学特性研究与比较 [J]. 岩石力学与工程学报, 2012, 31(2): 273–279. DOI: 10.3969/j.issn.1000-6915.2012.02.006.YIN T B, LI X B, YIN Z Q, et al. Study and comparison of mechanical properties of sandstone under static and dynamic loadings after high temperature [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(2): 273–279. DOI: 10.3969/j.issn.1000-6915.2012.02.006. [15] 王超, 尹土兵. 实时高温下与热处理后砂岩动态拉伸特性研究 [J]. 工程爆破, 2021, 27(6): 9–17,51. DOI: 10.19931/j.EB.20210022.WANG C, YIN T B. Study on dynamic tensile properties of sandstone at real-time high temperatures and after thermal treatment [J]. Engineering Blasting, 2021, 27(6): 9–17,51. DOI: 10.19931/j.EB.20210022. [16] 许锡昌, 刘泉声. 高温下花岗岩基本力学性质初步研究 [J]. 岩土工程学报, 2000, 22(3): 332–335. DOI: 10.3321/j.issn:1000-4548.2000.03.014.XU X C, LIU Q S. A preliminary study on basic mechanical properties for granite at high temperature [J]. Chinese Journal of Geotechnical Engineering, 2000, 22(3): 332–335. DOI: 10.3321/j.issn:1000-4548.2000.03.014. [17] 王鹏, 许金余, 刘石, 等. 高温下砂岩动态力学特性研究 [J]. 兵工学报, 2013, 34(2): 203–208. DOI: 10.3969/j.issn.1000-1093.2013.02.012.WANG P, XU J Y, LIU S, et al. Research on dynamic mechanical properties of sandstone at high temperature [J]. Acta Armamentarii, 2013, 34(2): 203–208. DOI: 10.3969/j.issn.1000-1093.2013.02.012. [18] 平琦, 吴波, 吴明静, 等. 高温状态下岩石SHPB实验方法探究 [J]. 中国多媒体与网络教学学报(上旬刊), 2021(2): 205–207. [19] 刘石, 许金余. 高温作用对花岗岩动态压缩力学性能的影响研究 [J]. 振动与冲击, 2014, 33(4): 195–198. DOI: 10.3969/j.issn.1000-3835.2014.04.035.LIU S, XU J Y. Effect of high temperature on dynamic compressive mechanical properties of granite [J]. Journal of Vibration and Shock, 2014, 33(4): 195–198. DOI: 10.3969/j.issn.1000-3835.2014.04.035. [20] LI Y B, ZHAI Y, WANG C S, et al. Mechanical properties of Beishan granite under complex dynamic loads after thermal treatment [J]. Engineering Geology, 2020, 267: 105481. DOI: 10.1016/j.enggeo.2020.105481. [21] 尹土兵. 考虑温度效应的岩石动力学行为研究 [D]. 长沙: 中南大学, 2012.YIN T B. Study on dynamic behavior of rocks considering thermai, effect [D]. Changsha: Central South University, 2012. [22] 刘贵, 周永胜. 花岗岩剪切变形与矿物成分变化的高温高压实验 [J]. 地质通报, 2020, 39(11): 1840–1849.LIU G, ZHOU Y S. An experimental study of shear deformation and mineral composition changes of granite under the condition of high temperature and high pressure [J]. Geological Bulletin of China, 2020, 39(11): 1840–1849. [23] 张森, 舒彪, 梁铭, 等. 不同冷却方式下高温花岗岩细观损伤量化和机理分析 [J]. 煤田地质与勘探, 2022, 50(2): 106–114. DOI: 10.3969/j.issn.1001-1986.2022.02.013.ZHANG S, SHU B, LIANG M, et al. Quantification and mechanism analysis of meso-damage of high-temperature granite under different cooling modes [J]. Coal Geology & Exploration, 2022, 50(2): 106–114. DOI: 10.3969/j.issn.1001-1986.2022.02.013. [24] 王春, 熊宏威, 舒荣华, 等. 高温处理后含铜矽卡岩的动态力学特性及损伤破碎特征 [J]. 中国有色金属学报, 2022, 32(9): 2801–2818.WANG C, XIONG H W, SHU R H, et al. Dynamic mechanical characteristic and damage-fracture behavior of deep copper-bearing skarn after high temperature treatment [J]. The Chinese Journal of Nonferrous Metals, 2022, 32(9): 2801–2818. [25] 徐小丽, 高峰, 张志镇, 等. 实时高温下加载速率对花岗岩力学特性影响的试验研究 [J]. 岩土力学, 2015, 36(8): 2184–2192. DOI: 10.16285/j.rsm.2015.08.008.XU X L, GAO F, ZHANG Z Z, et al. Experimental study of the effect of loading rates on mechanical properties of granite at real-time high temperature [J]. Rock and Soil Mechanics, 2015, 36(8): 2184–2192. DOI: 10.16285/j.rsm.2015.08.008. [26] 张志镇, 高峰, 高亚楠, 等. 高温影响下花岗岩孔径分布的分形结构及模型 [J]. 岩石力学与工程学报, 2016, 35(12): 2426–2438. DOI: 10.13722/j.cnki.jrme.2016.0798.ZHANG Z Z, GAO F, GAO Y N, et al. Fractal structure and model of pore size distribution of granite under high temperatures [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(12): 2426–2438. DOI: 10.13722/j.cnki.jrme.2016.0798. [27] 席道瑛. 花岗岩中矿物相变的物性特征 [J]. 矿物学报, 1994, 14(3): 223–227. DOI: 10.16461/j.cnki.1000-4734.1994.03.003.XI D Y. Physical characteristics of mineral phase transition in the granite [J]. Acta Mineralogica Sinica, 1994, 14(3): 223–227. DOI: 10.16461/j.cnki.1000-4734.1994.03.003. [28] 许金余, 刘石. 大理岩冲击加载试验碎块的分形特征分析 [J]. 岩土力学, 2012, 33(11): 3225–3229. DOI: 10.16285/j.rsm.2012.11.005.XU J Y, LIU S. Research on fractal characteristics of marble fragments subjected to impact loading [J]. Rock and Soil Mechanics, 2012, 33(11): 3225–3229. DOI: 10.16285/j.rsm.2012.11.005. [29] ZHANG Z X, KOU S Q, JIANG L G, et al. Effects of loading rate on rock fracture: fracture characteristics and energy partitioning [J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37(5): 745–762. DOI: 10.1016/S1365-1609(00)00008-3. [30] 许金余, 吕晓聪, 张军, 等. 围压条件下岩石循环冲击损伤的能量特性研究 [J]. 岩石力学与工程学报, 2010, 29(S2): 4159–4165.XU J Y, LV X C, ZHANG J, et al. Research on energy properties of rock cyclical impact damage under confining pressure [J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(S2): 4159–4165. -

下载:

下载: