Critical vent area of a Comp-B warhead under fast cook-off

-

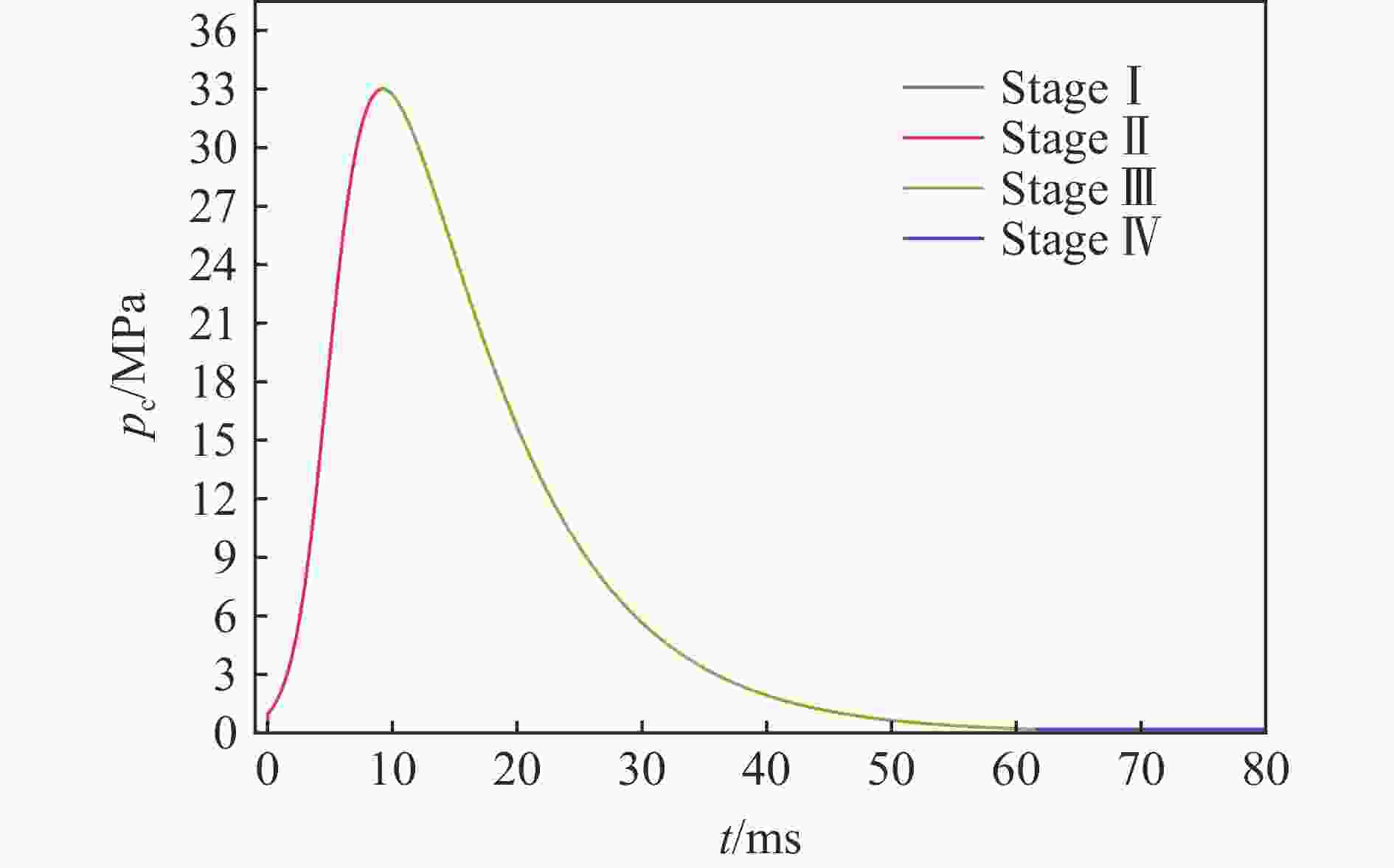

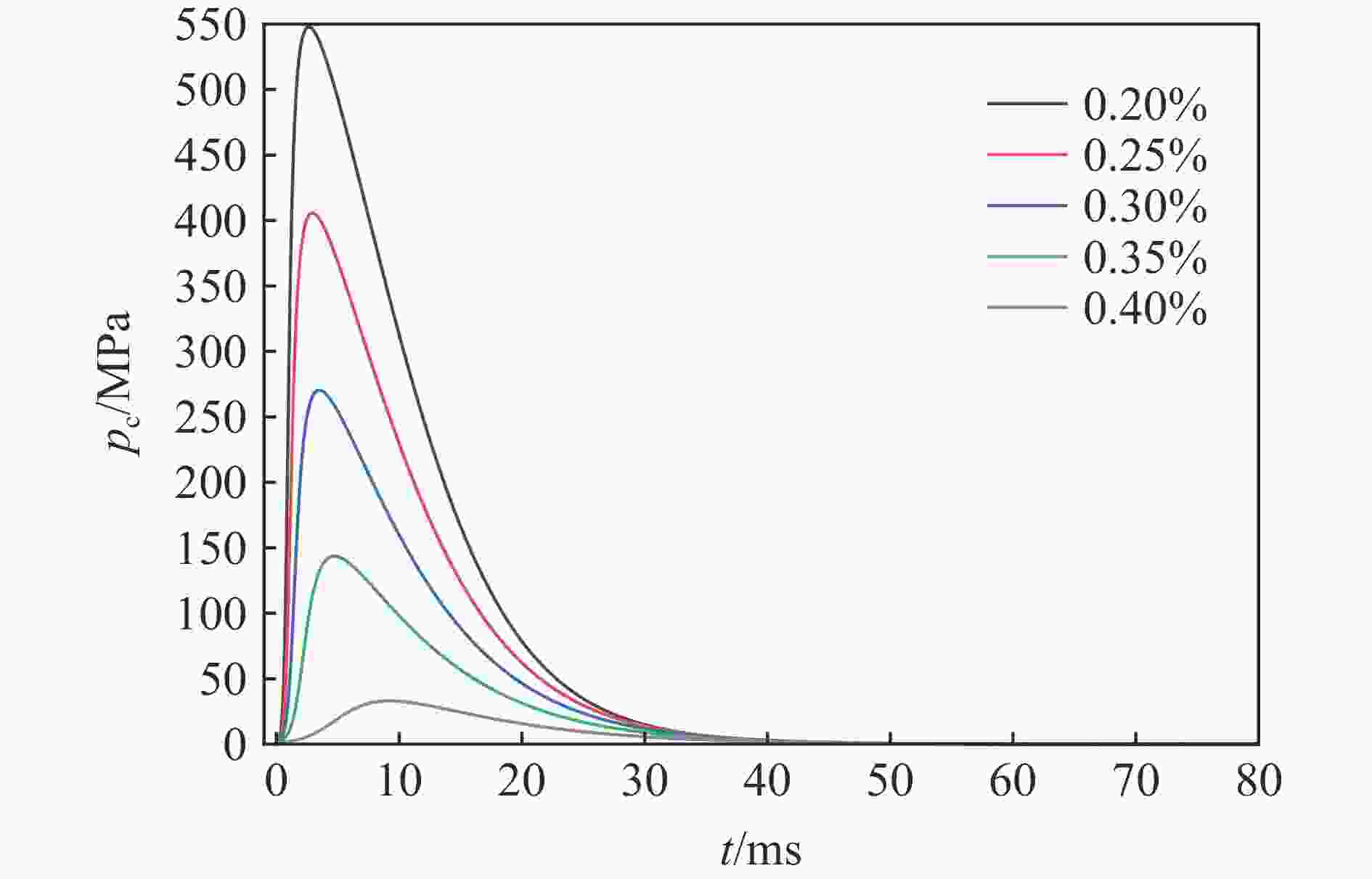

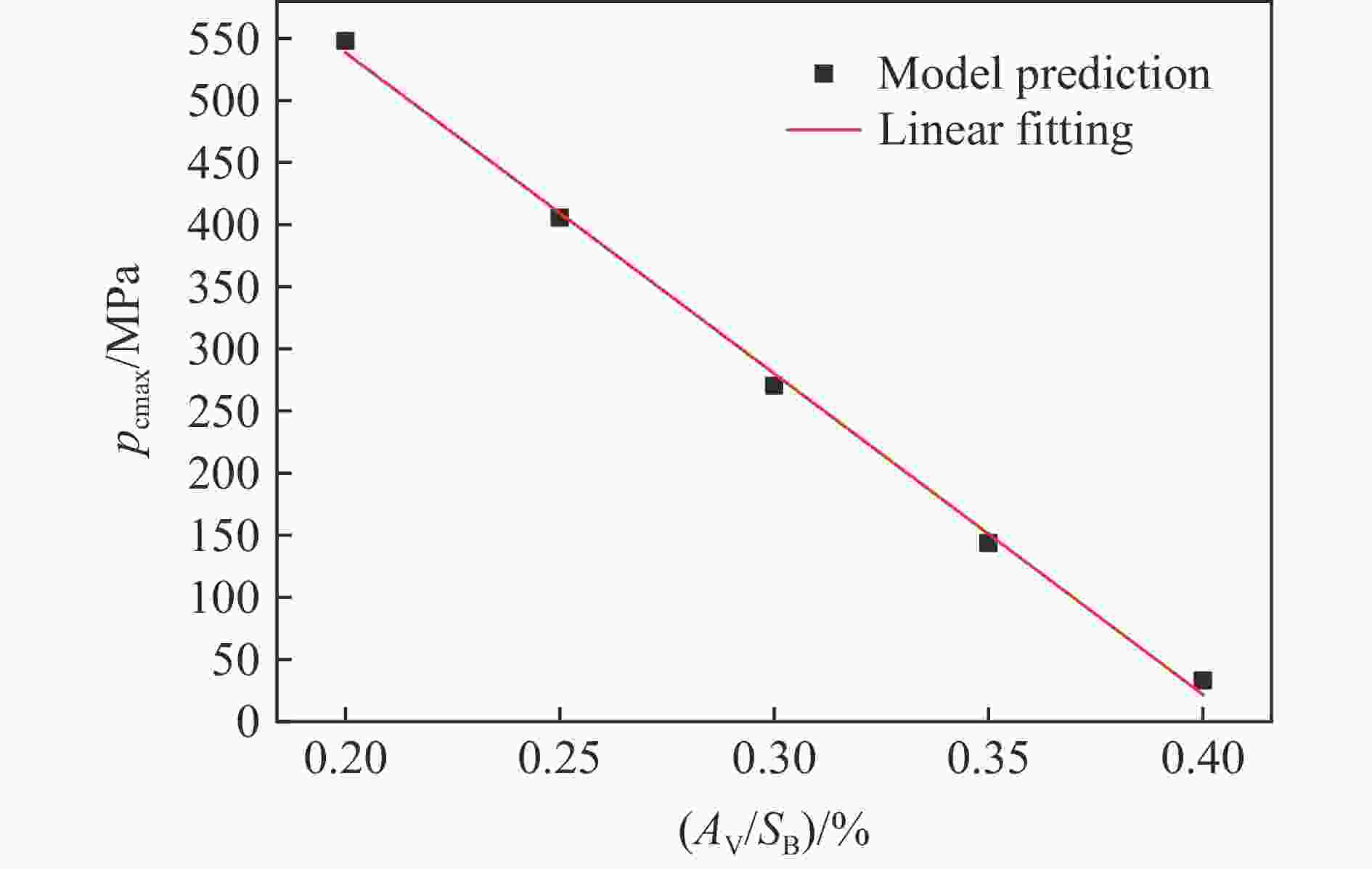

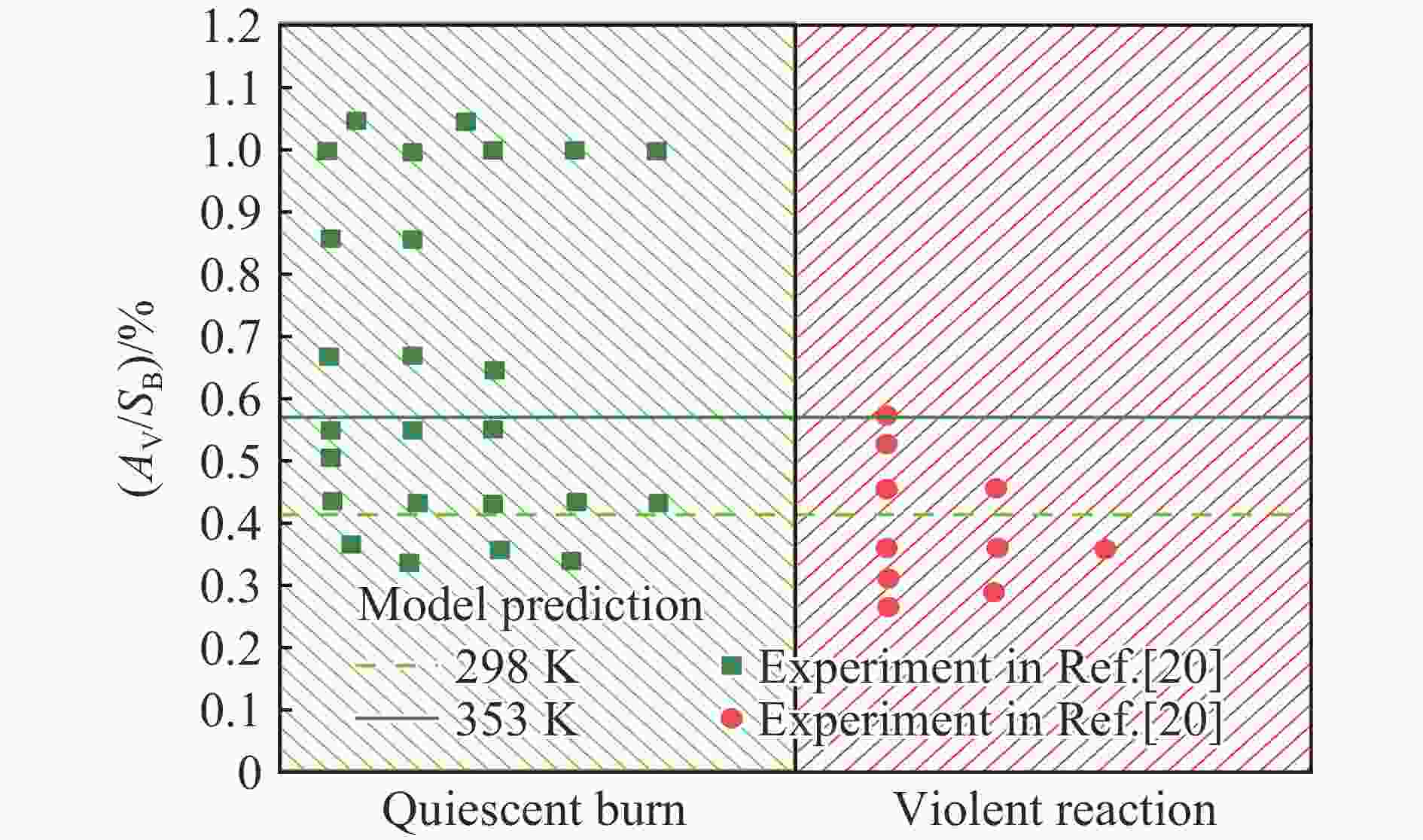

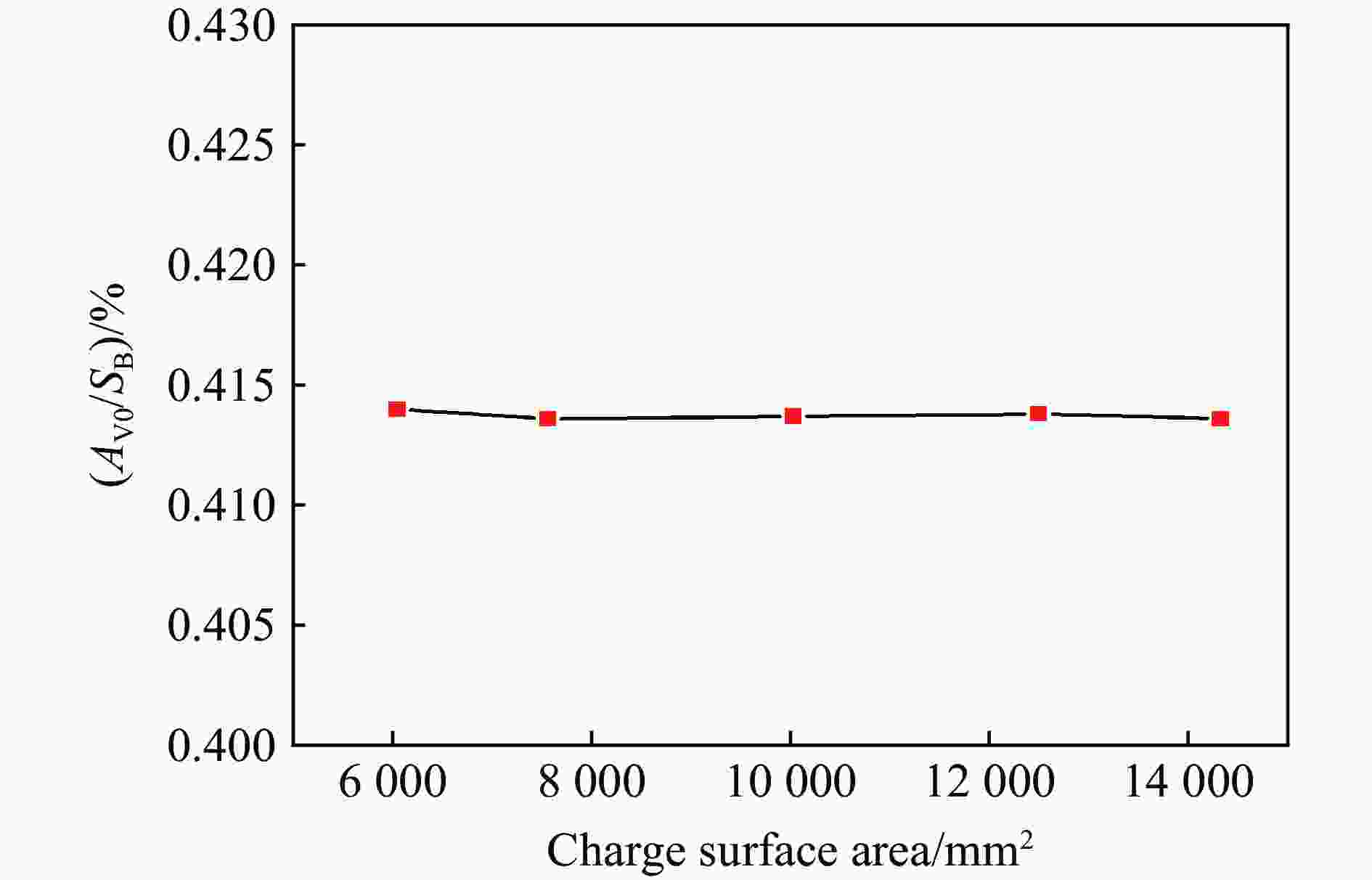

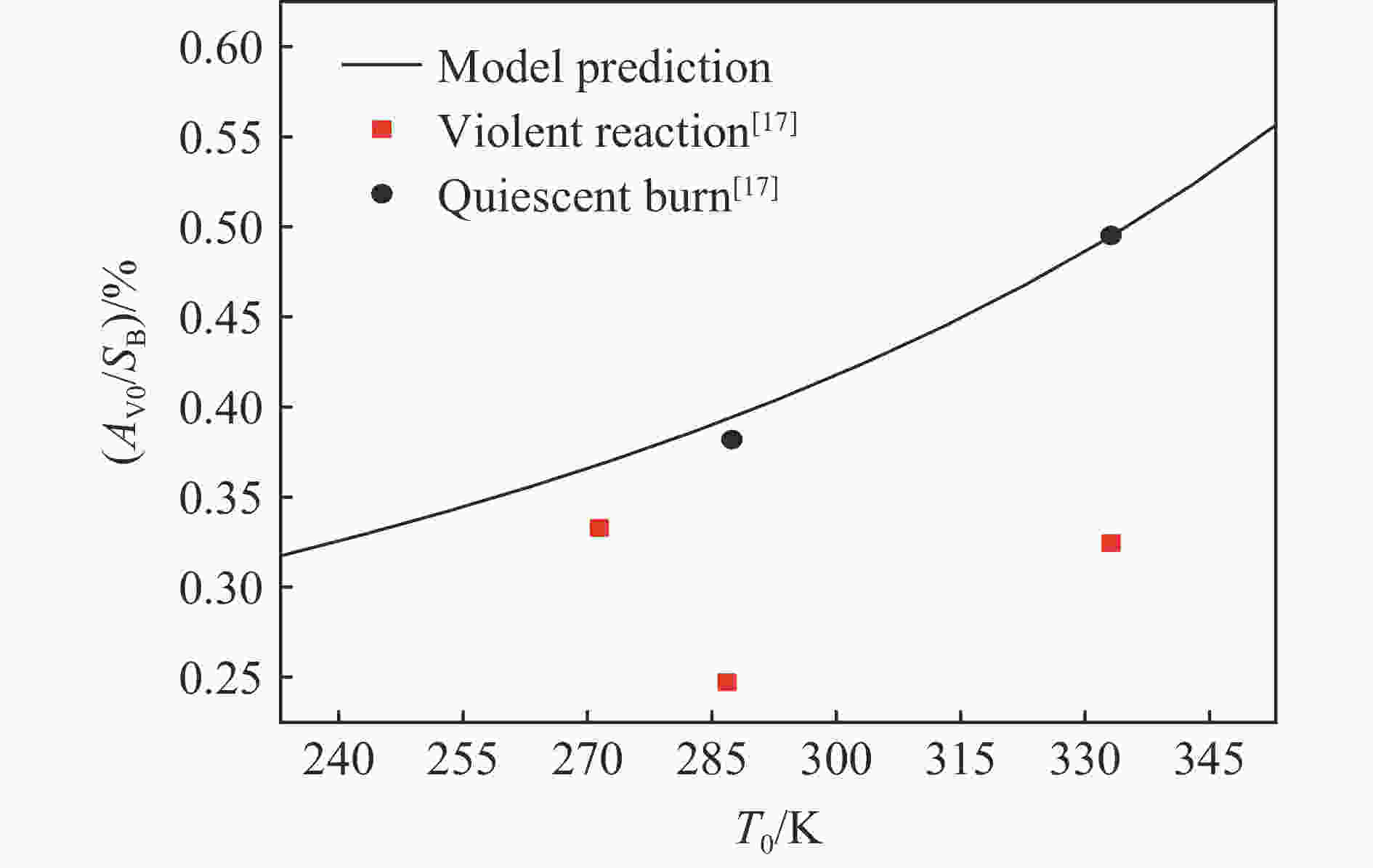

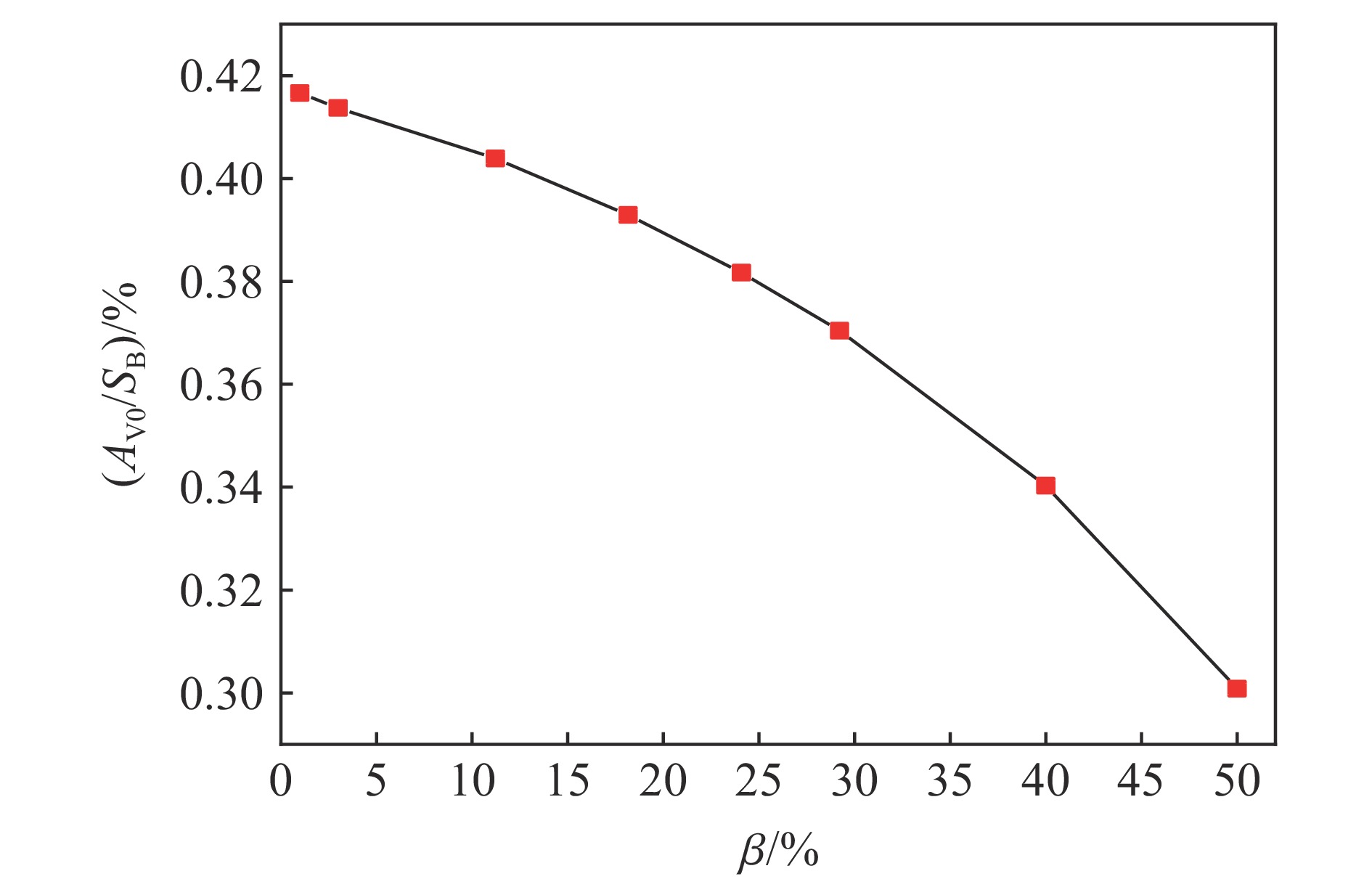

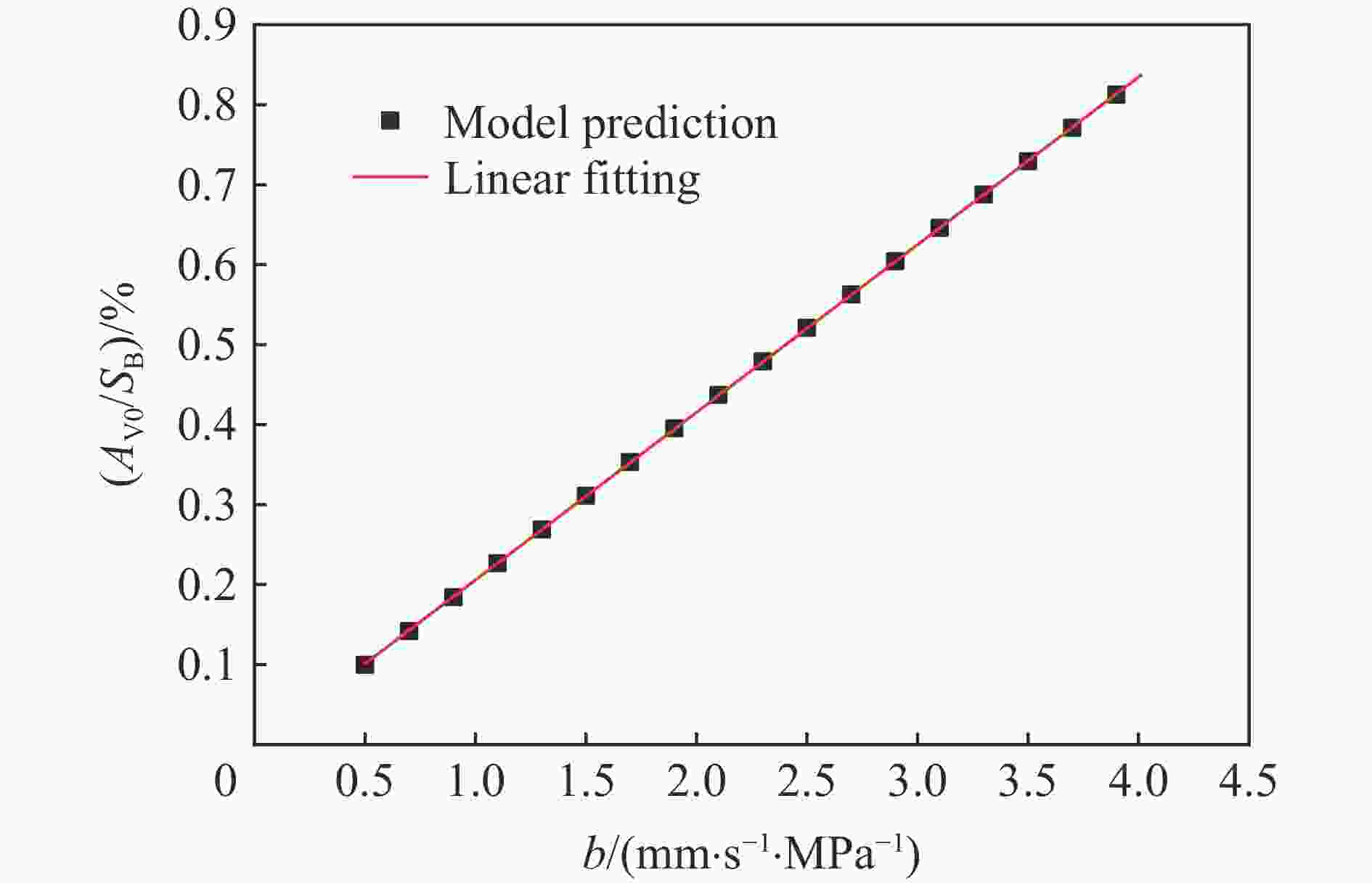

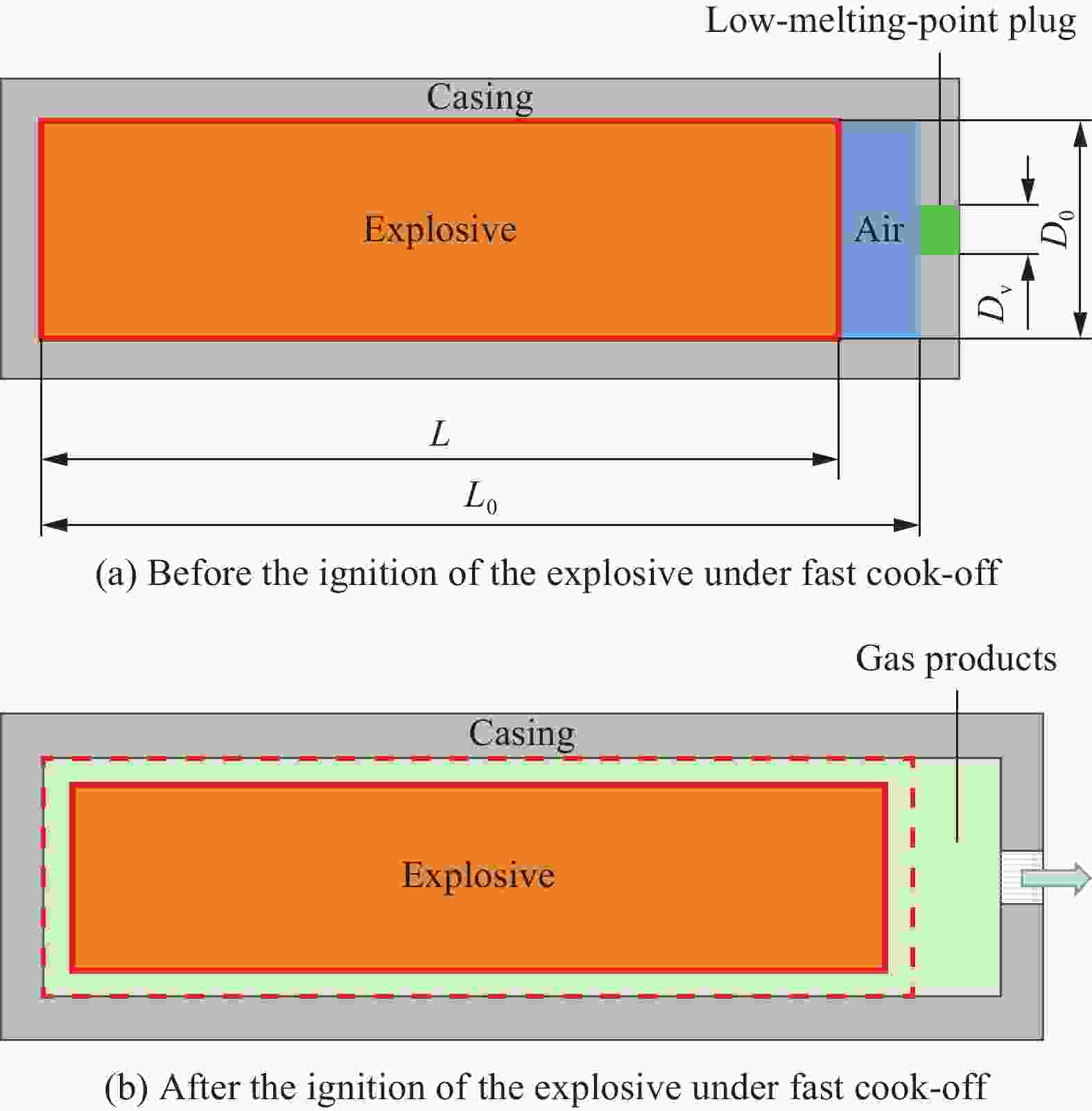

摘要: 为了确定战斗部装药在快速烤燃条件下能稳定燃烧的临界泄压面积,基于质量守恒定律和气体状态方程,建立了战斗部壳体内考虑炸药初始温度和排气孔排气的气体压力增长模型。以B炸药圆柱战斗部为研究对象,研究了炸药意外点火后能稳定燃烧的AV0/SB(临界泄压面积/炸药外表面积)确定方法,并与实验值进行了比较。结果表明,本文建立的模型能够很好地预测B炸药战斗部的临界泄压面积。研究了战斗部炸药装药表面积、炸药初始温度、空气体积占比和炸药燃速对AV0/SB的影响,并将不同温度的模型预测值与实验值进行了比较。结果表明:炸药装药表面积对AV0/SB基本没有影响;AV0/SB与温度和炸药燃速成正相关,与空气体积占比成负相关;不同温度的模型预测值AV0/SB与实验值吻合较好。Abstract: To determine the critical vent area over which a warhead can burn stably under the fast cook-off condition, the gas pressure rise inside the casing after the ignition of the warhead charge was studied under the fast cook-off stimulation based on the mass conservation law and state equation of gases. A gas pressure rise model was established in the current work by considering the initial temperature of the explosive and gas venting in a warhead. A composition B explosive (Comp-B) cylindrical warhead was used as the research object. The numerical calculation of the model was carried out to determine the AV0/SB ratio (critical vent area/external surface area of the explosive) at which the warhead could be in stable combustion after it was accidentally ignited. And the results were compared with experimental values. It is found that the change of pc (pressure inside the warhead casing) after the thermal stimulation and ignition of Comp-B occurred in four stages of Ⅰ-Ⅳ: increased sharply, increased rapidly, decreased slowly, and finally, leveled off. The peak pressure of the warhead decreased linearly with the increase of AV/SB. When AV/SB corresponding to the peak pressure (pcmax) of 10 MPa in the warhead was taken as the critical AV/SB ratio, AV/SB could better separate the stable combustion reaction from the explosion reaction inside the warhead. The effects of the warhead charge surface area, the explosive initial temperature, the air volume ratio, and the explosive burning rate on AV0/SB were investigated, and the model predictions at different temperatures were compared with the experimental results. The predicted values of AV0/SB agree well with the experimental results. It is found that the warhead charge surface area has little effect on AV0/SB, andAV0/SB is positively correlated with the temperature and burning rate of the explosive and negatively correlated with the air volume ratio. The proposed model can well predict the critical vent area of the Comp-B warhead. Therefore, the findings of this study provide a theoretical basis for the design of thermally stimulated venting structures of ammunition.

-

Key words:

- fast cook-off /

- critical vent area /

- initial temperature /

- burning rate /

- Comp-B

-

表 1 战斗部及装药尺寸参数

Table 1. Dimensional parameters of cylindrical charge structure

部位 直径/mm 长度/mm 战斗部内腔 27 108 炸药装药 27 104.76 空气 27 3.24 泄压孔 5.054 − 5.651 − 6.190 − 6.686 − 7.148 − 表 2 炸药性能参数

Table 2. Explosive performance parameters

α/(m∙s−1∙Pa−1) A B/K−1 M/(kg∙mol−1) TB/K k 0.01×10−6 12.04 0.0235 0.028 2500 1.27 表 3 不同炸药装药表面积的战斗部参数

Table 3. Cylindrical charge structure parameters for different explosive charge surface areas

序号 D0/mm L/mm L0/mm SB/mm2 1 27 104.76 108 10 031.16 2 17 104.76 108 6 048.88 3 37 104.76 108 14 327.60 4 27 75.66 78 7 562.81 5 27 133.86 138 12 499.51 表 4 不同空气体积占比的战斗部参数

Table 4. Parameters of cylindrical charge for different air volume ratios

序号 D0/mm L/mm L0/mm SB/mm2 β/% 1 27 104.76 108 10 031.16 3 2 27 104.76 105.82 10 031.16 1 3 27 104.76 118 10 031.16 11.22 4 27 104.76 128 10 031.16 18.16 5 27 104.76 138 10 031.16 24.09 6 27 104.76 148 10 031.16 29.22 7 27 104.76 174.6 10 031.16 40 8 27 104.76 209.52 10 031.16 50 -

[1] 许蕾, 张鹏. 国内外钝感弹药评估标准的发展与分析 [J]. 航天标准化, 2010(4): 35–37. DOI: 10.19314/j.cnki.1009-234x.2010.04.009.XU L, ZHANG P. Development and analysis of evaluation criteria for insensitive munitions at home and abroad [J]. Aerospace Standardization, 2010(4): 35–37. DOI: 10.19314/j.cnki.1009-234x.2010.04.009. [2] 黄亨建, 路中华, 刘晓波等. 欧美钝感弹药技术发展现状与趋势 [J]. 含能材料, 2017, 25(8): 618–621. DOI: 10.11943/j.issn.1006-9941.2017.08.00X.HUANG H J, LU Z H, LIU X B, et al. Development status and trend of insensitive ammunition technology in Europe and America [J]. Energetic Materials, 2017, 25(8): 618–621. DOI: 10.11943/j.issn.1006-9941.2017.08.00X. [3] 马晗晔, 王雨时, 王光宇. 国外不敏感炸药综述 [J]. 兵器装备工程学报, 2020, 41(5): 166–174. DOI: 10.11809/bqzbgcxb2020.05.032.MA H Y, WANG Y S, WANG G Y. Review of insensitive explosives abroad [J]. Journal of Ordnance Equipment Engineering, 2020, 41(5): 166–174. DOI: 10.11809/bqzbgcxb2020.05.032. [4] 梁斌, 钱立新, 牛公杰. 常规弹药热缓解技术研究初步分析 [C]//2014(第六届)含能材料与钝感弹药技术学术研讨会. 成都, 2014: 218–223.LIANG B, QIAN L X, NIU G J. Preliminary analysis on thermal mitigation technology of conventional ammunition [C]// Proceedings of the Symposium on Energetic Materials and Insensitive Ammunition Technology. Chengdu, Sichuan, China, 2014: 218–223. [5] 沈飞, 王胜强, 王辉. HMX基含铝炸药装药慢烤缓释结构设计及验证 [J]. 含能材料, 2019, 27(10): 861–866. DOI: 10.11943/CJEM2018273.SHEN F, WANG S Q, WANG H. Design and verification of slow-baking and sustained-release structure of HMX-based aluminum-containing explosive charge [J]. Energetic Materials, 2019, 27(10): 861–866. DOI: 10.11943/CJEM2018273. [6] 沈飞, 王胜强, 王辉. 不同约束条件下HMX基含铝炸药的慢烤响应特性 [J]. 火炸药学报, 2019, 42(4): 385–390. DOI: 10.14077/j.issn.1007-7812.2019.04.012.SHEN F, WANG S Q, WANG H. Slow-baking response characteristics of HMX-based aluminum-containing explosives under different constraints [J]. Chinese Journal of Explosives and Propellants, 2019, 42(4): 385–390. DOI: 10.14077/j.issn.1007-7812.2019.04.012. [7] 闫丽, 王雨时, 闻泉, 等. 国外钝感弹药技术新进展 [J]. 飞航导弹, 2017(8): 9–51. DOI: 10.16338/j.issn.1009-1319.2017.08.09.YAN L, WANG Y S, WEN Q, et al. New progress of foreign insensitive ammunition technology [J]. Airborne Missile, 2017(8): 9–51. DOI: 10.16338/j.issn.1009-1319.2017.08.09. [8] 徐瑞, 智小琦, 于永利, 等. 热刺激下不同结构引信的响应机理 [J]. 高压物理学报, 2021, 35(5): 127–137. DOI: 10.11858/gywlxb.20210720.XU R, ZHI X Q, YU Y L, et al. Response mechanism of fuzes with different structures under thermal stimulation [J]. Chinese Journal of High Voltage Physics, 2021, 35(5): 127–137. DOI: 10.11858/gywlxb.20210720. [9] 陈朗, 李贝贝, 马欣. DNAN炸药烤燃特征 [J]. 含能材料, 2016, 24(1): 6. DOI: 10.11943/j.issn.1006-9941.2016.01.004.CHEN L, LI B B, MA X. Cook-off characteristics of DNAN explosives [J]. Energetic Materials, 2016, 24(1): 6. DOI: 10.11943/j.issn.1006-9941.2016.01.004. [10] 吴松. 火烧环境下含炸药结构热响应行为的数值模拟研究[D]. 绵阳: 中国工程物理研究院, 2014. 51–63.WU S. Numerical simulation of thermal response behavior of explosive-containing structures in fire environment [D]. Mianyang, Sichuan, China: China Academy of Engineering Physics, 2014: 51–63. [11] 徐瑞. 热刺激下缓释结构与炸药响应烈度关系的研究[D]. 太原: 中北大学, 2021: 45–53. DOI: 10.27470/d.cnki.ghbgc.2021.000588.XU R. Study on the relationship between sustained-release structure and explosive response intensity under thermal stimulation [D]. Taiyuan, Shanxi, China: North University of China, 2021: 45–53. DOI: 10.27470/d.cnki.ghbgc.2021.000588. [12] ZHU M, WANG S G, HUANG H, et al. Numerical and experimental study on the response characteristics of warhead in the fast cook-off process [J]. Defence Technology, 2021, 17(4): 1444–1452. DOI: 10.3969/j.issn.2214-9147.2021.04.030. [13] 陈科全, 黄亨建, 路中华, 等. 一种弹体排气缓释结构设计方法与试验研究 [J]. 弹箭与制导学报, 2015, 35(4): 4. DOI: 10.15892/j.cnki.djzdxb.2015.04.004.CHEN K Q, HUANG H J, LU Z H, et al. Design method and experimental study of a slow-release structure for projectile exhaust [J]. Journal of Rocket and Guidance, 2015, 35(4): 4. DOI: 10.15892/j.cnki.djzdxb.2015.04.004. [14] 徐瑞, 智小琦, 王帅. 缓释结构对B炸药烤燃响应烈度的影响 [J]. 高压物理学报, 2021, 35(3): 035201. DOI: 10.11858/gywlxb.20200657.XU R, ZHI X Q, WANG S. Influence of sustained-release structure on the response intensity of B explosives [J]. Chinese Journal of High Pressure Physics, 2021, 35(3): 035201. DOI: 10.11858/gywlxb.20200657. [15] 邓海, 沈飞, 梁争峰, 等. 不同约束条件下B炸药的慢烤响应特性 [J]. 火炸药学报, 2018, 41(5): 6. DOI: 10.14077/j.issn.1007-7812.2018.05.008.DENG H, SHEN F, LIANG Z F, et al. Slow-baking response characteristics of B explosive under different constraints [J]. Chinese Journal of Explosives and Propellants, 2018, 41(5): 6. DOI: 10.14077/j.issn.1007-7812.2018.05.008. [16] BRADLEY D, MITCHESON A. The venting of gaseous explosions in spherical vessels. Ⅱ: theory and experiment [J]. Combustion and Flame, 1978, 32: 237–255. DOI: 10.1016/0010-2180(78)90098-6. [17] GRAHAM K J. Mitigation of fuel fire threat to large rocket motors by venting [R]. California, United States: Air Force Research Laboratory Edwards Air Force Base, 2010. [18] SAHIN H, NARIN B, FUNDA D. Development of a design methodology against fast cook-off threat for insensitive munitions [J]. Propellants, Explosives, Pyrotechnics, 2016, 41(3): 580–587. DOI: 10.1002/prep.201500333. [19] VETTER R F. Reduction of fuel fire cook-off hazard of rocket motors [R]. Naval Air Weapons Station China Lake, 1977. [20] MCCHRISTIAN L, CISTANO J, FOXX C, et al. Vulnerability of nuclear weapon systems to fire studies of burning explosives: RTD-TDR-63-3086 [R]. Chicago: Illinois Institute of Technology, 1963. [21] 周捷. 熔铸混合炸药慢速烤燃机理研究[D]. 太原: 中北大学, 2020. DOI: 10.27470/d.cnki.ghbgc.2020.000464.ZHOU J. Study on the slow roasting mechanism of molten-cast mixed explosives [D]. Taiyuan, Shanxi, China: North University of China, 2020. DOI: 10.27470/d.cnki.ghbgc.2020.000464. [22] 张俊, 刘荣忠, 郭锐, 等. 高速旋转飞行弹丸外弹道表面温度场研究 [J]. 兵工学报, 2013, 34(4): 425–430. DOI: 10.3969/j.issn.1000-1093.2013.04.007.ZHANG J, LIU R Z, GUO R, et al. Research on the temperature field of the outer ballistic surface of the high-speed rotating flying projectile [J]. Acta Armamentarii, 2013, 34(4): 425–430. DOI: 10.3969/j.issn.1000-1093.2013.04.007. [23] KOERNER J, MAIENSCHEIN J, BLACK K, et al. LX-17 deflagration at high pressures and temperatures: UCRL-CONF-225607 [R]. Livermore, California, United States: Lawrence Livermore National Laboratory, 2006. [24] GLASCOE E, MAIENSCHEIN J, BURNHAM A, et al. PBXN-9 ignition kinetics and deflagration rates: LLNL-PROC-403194 [R]. Livermore, California, United States: Lawrence Livermore National Laboratory, 2008. [25] GLASCOE E, SPRINGER H K, TRINGE J, et al. A comparison of deflagration rates at elevated pressures and temperatures with thermal explosion results [C]//17th Biennial International Conference of the APS Topical Group on Shock Compression of Condensed Matter. Chicago, Illinois, United States, 2011. [26] 潘文达. 俄国的炸药燃烧数据库 [J]. 火炸药学报, 1994(2): 35–37.PAN W D. Russian explosive combustion database [J]. Chinese Journal of Explosives and Propellants, 1994(2): 35–37. [27] 姚奎光, 赵学峰, 樊星, 等. 高压下PBX-1炸药的燃速-压力特性 [J]. 爆炸与冲击, 2020, 40(1): 011404. DOI: 10.11883/bzycj-2019-0347.YAO K G, ZHAO X F, FAN X, et al. Burning rate-pressure characteristics of PBX-1 explosive under high pressure [J]. Explosion and Shock Waves, 2020, 40(1): 011404. DOI: 10.11883/bzycj-2019-0347. -

下载:

下载: