Dynamic split tests of UHPFRC discs and failure mechanism analysis based on μXCT images

-

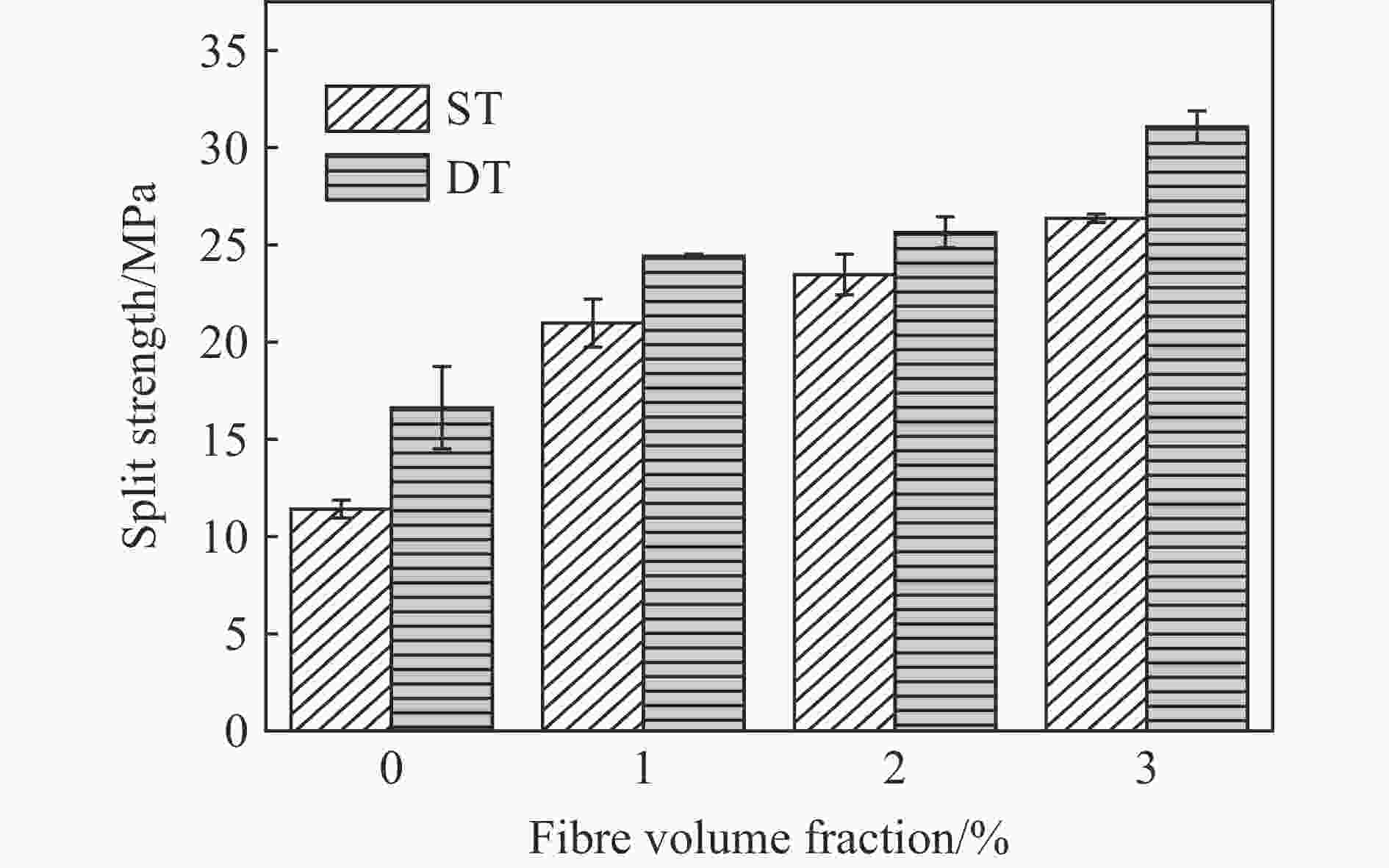

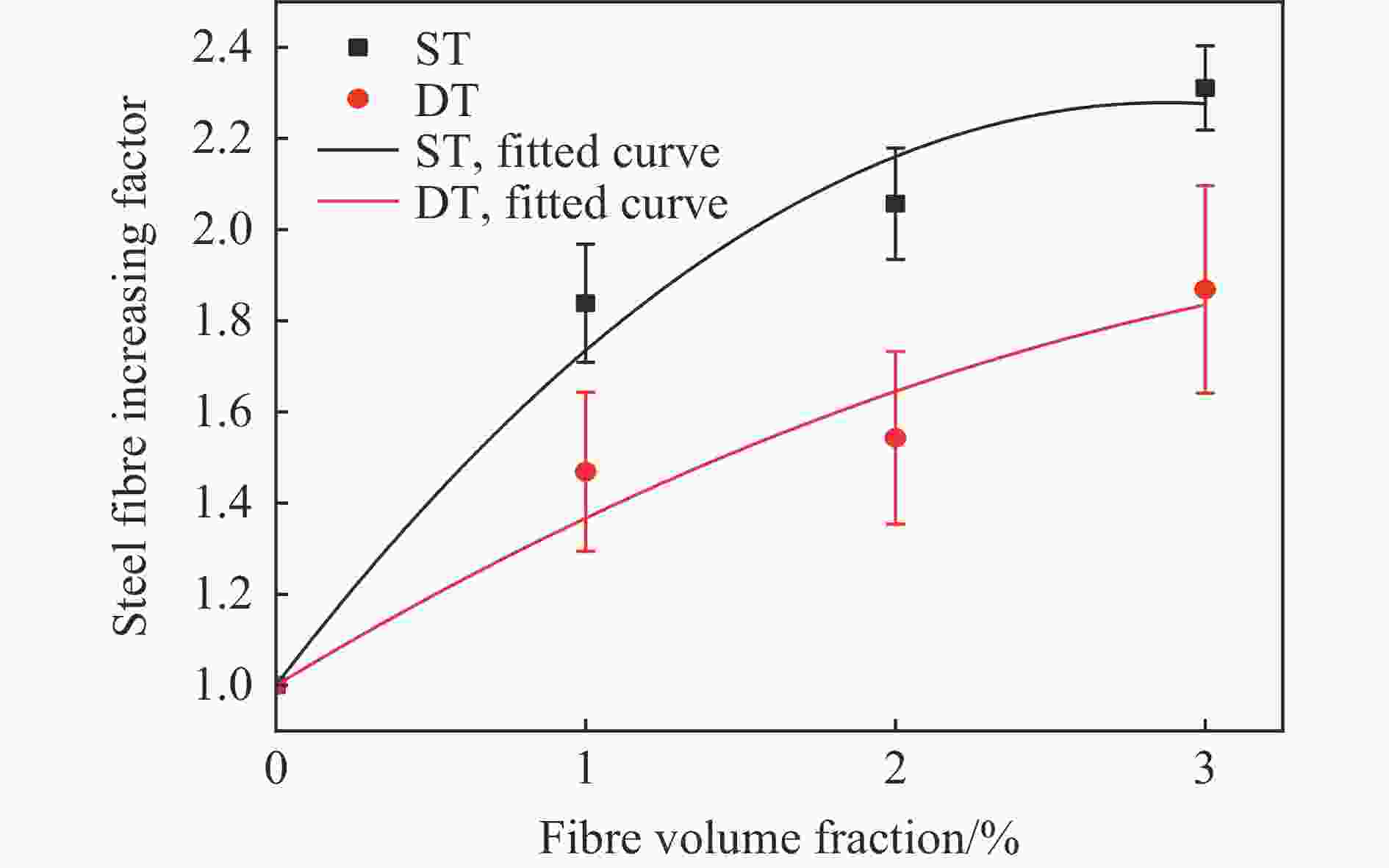

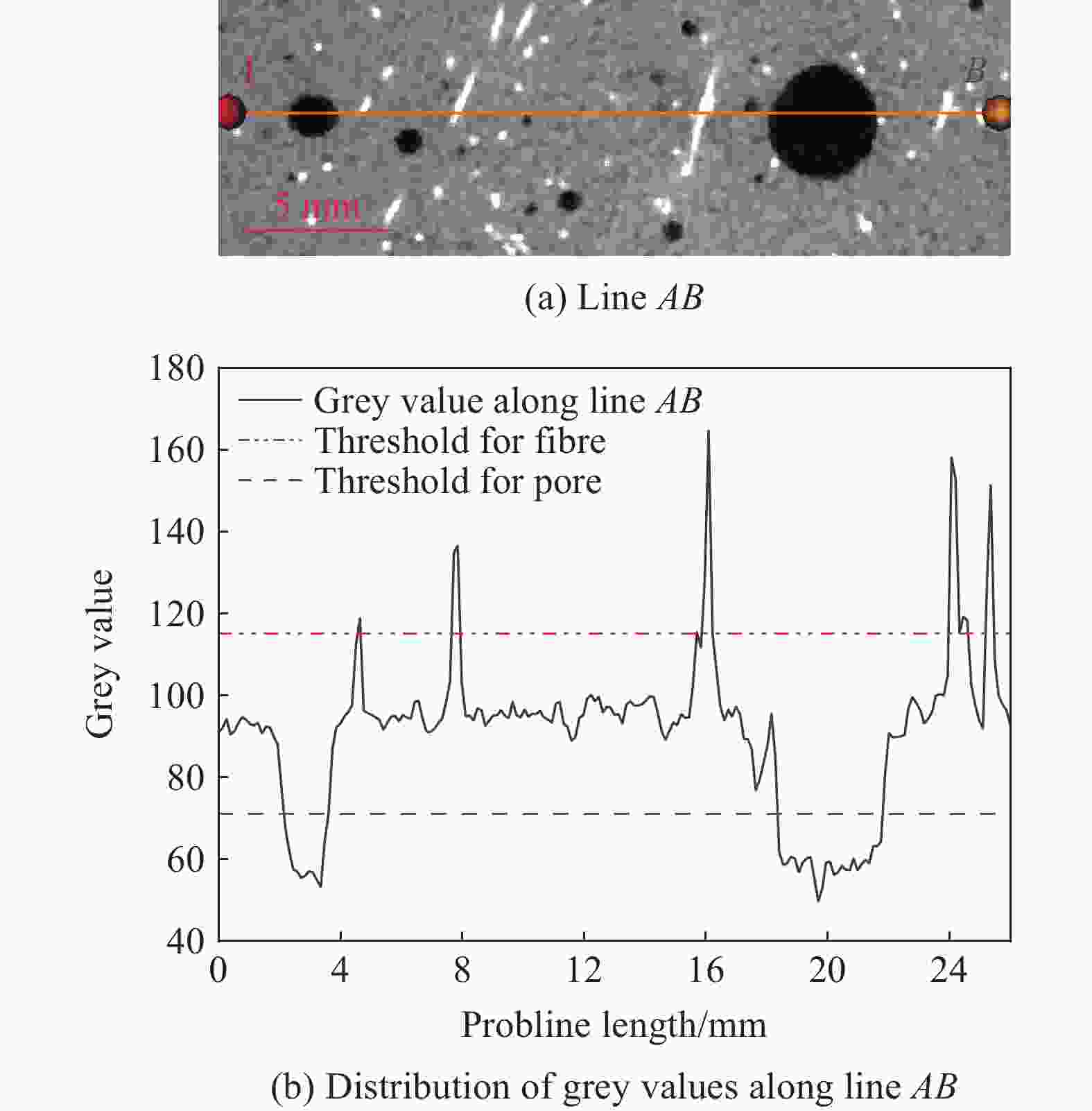

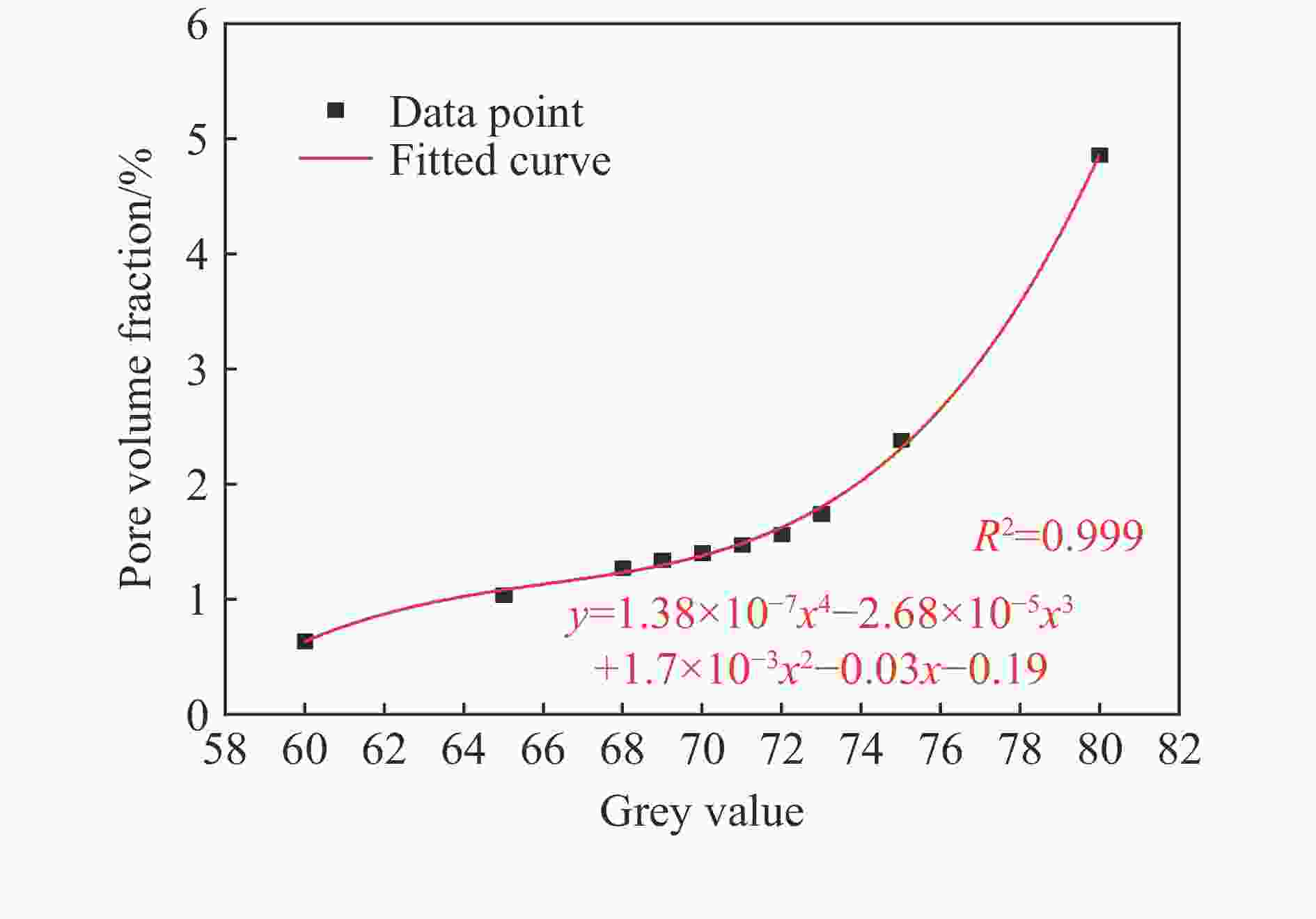

摘要: 采用分离式霍普金森压杆对钢纤维体积分数为0~3%的超高性能纤维增强混凝土(ultra high performance fibre reinforced concrete, UHPFRC)圆盘试件进行应变率为1.72~7.42 s−1的动态劈裂试验,使用高速摄像机结合数字图像相关(digital image correlation, DIC)法获得试件表面裂缝扩展全过程图像和应变演化过程,并对冲击前后试件进行微观X射线计算断层扫描(micro X-ray computed tomography, μXCT),获得分辨率为56.7 μm的三维内部图像,并进行统计和破坏机理分析。结果表明:(1)相比无纤维试件,掺入1%~3%的钢纤维,静、动劈裂强度分别提高84%~131%和47%~87%,动劈裂强度增强因子(即动静强度比值)为1.07~1.72;(2) DIC应变图像分析表明,无纤维试件裂缝集中、破坏快、能耗低;含纤维试件裂缝弥散程度大、能耗高、延性好,且随着纤维含量的提高而提升;(3) μXCT图像分析表明,试件中钢纤维体积分数为1.04%~2.47%,与设计基本一致,孔洞体积分数为0.98%~1.71%,纤维掺量的提高,降低了孔洞数量和总体积分数,但孔洞的平均体积和平均等效直径增大;裂缝桥连纤维数量的增加,减小了主裂缝的体积和平均宽度,提高了裂缝面的粗糙度和相对表面积,从而提高了试件的强度、能耗、韧性和延性。

-

关键词:

- 动态劈裂 /

- 超高性能纤维增强混凝土 /

- 微观X射线计算断层扫描 /

- 断裂机理 /

- 数字图像相关

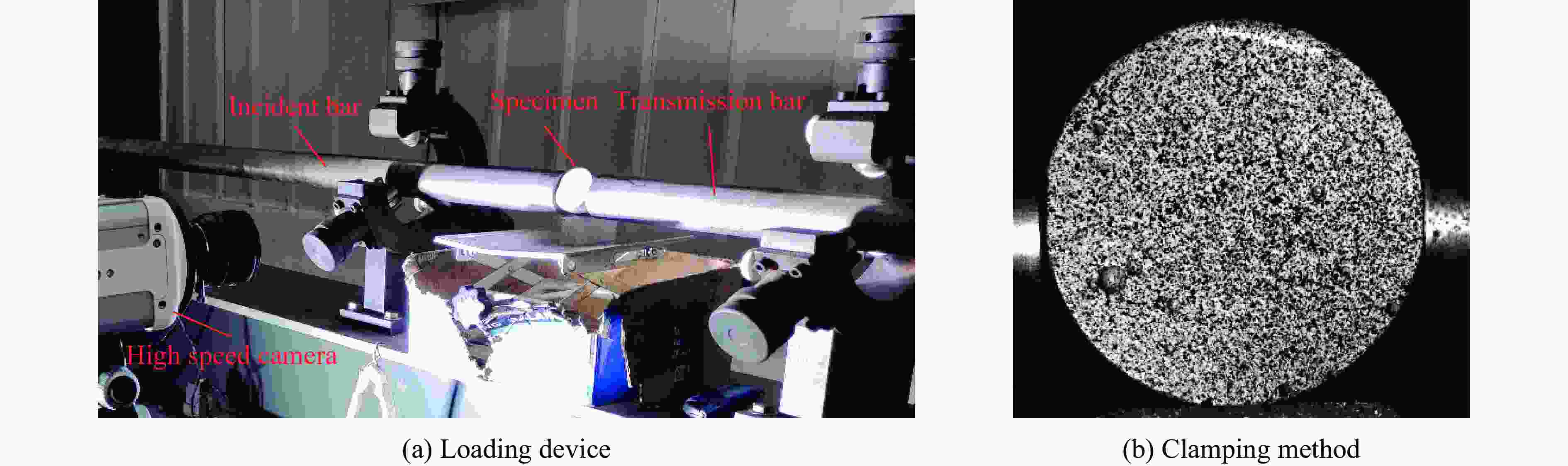

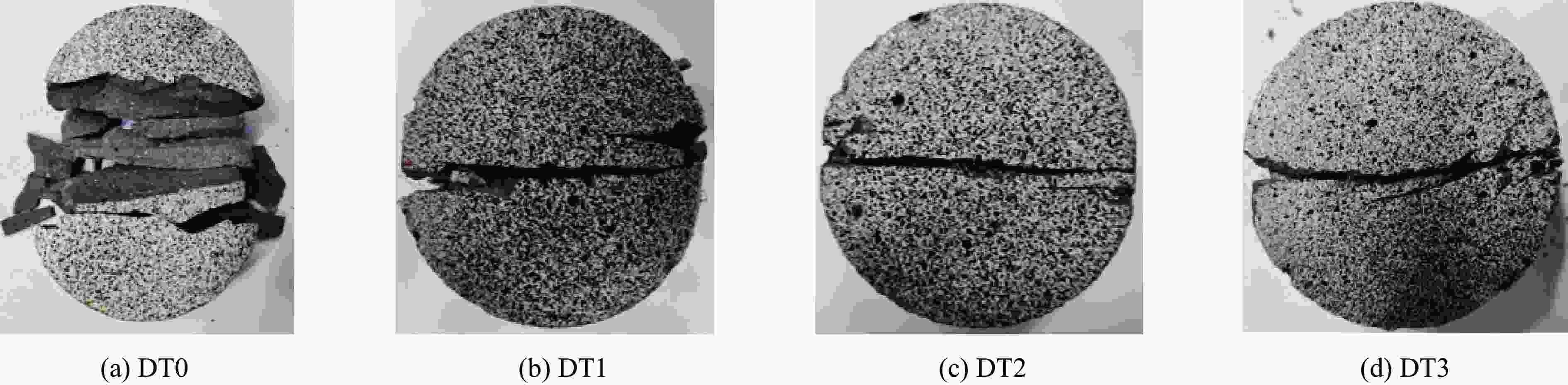

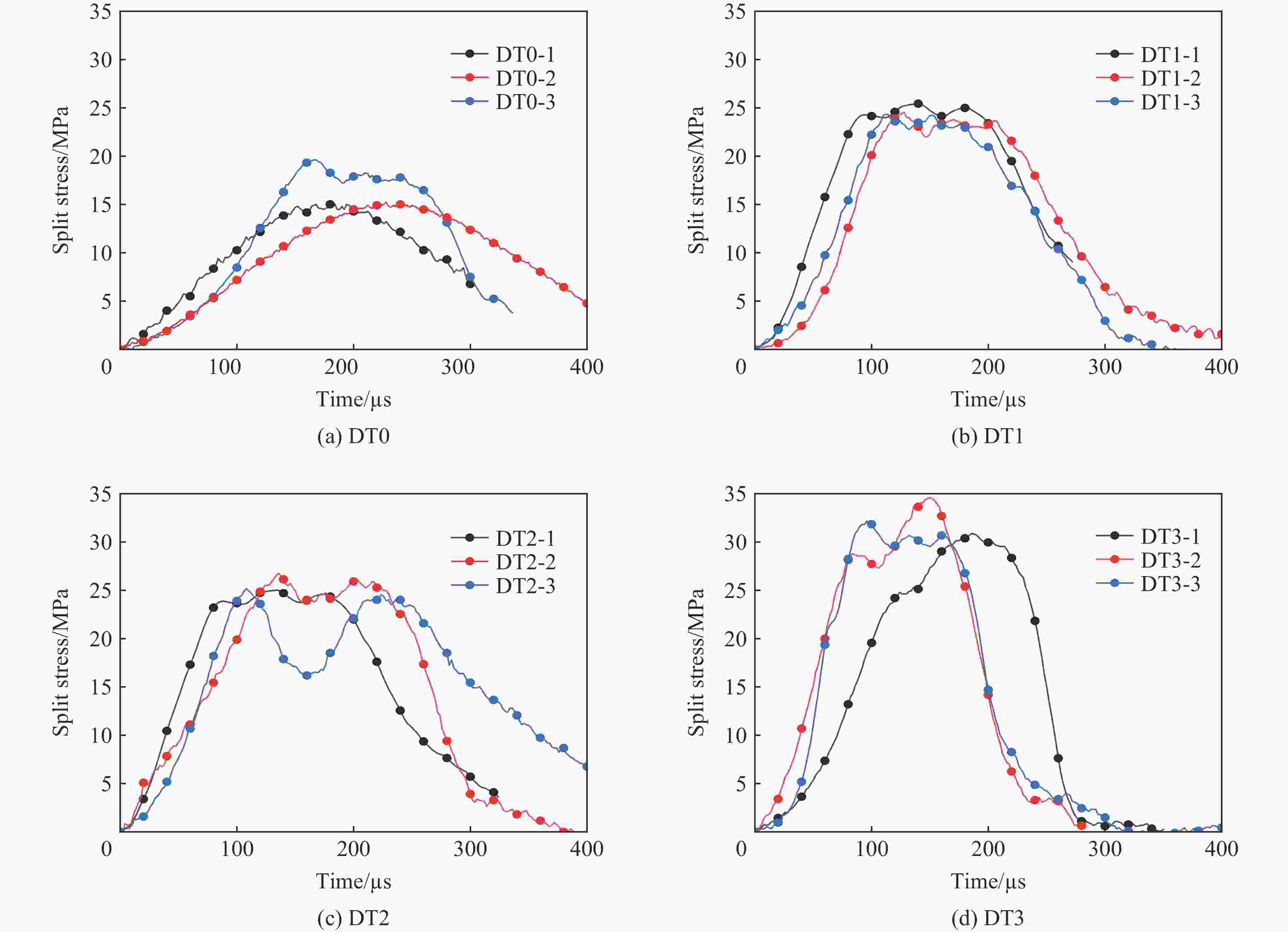

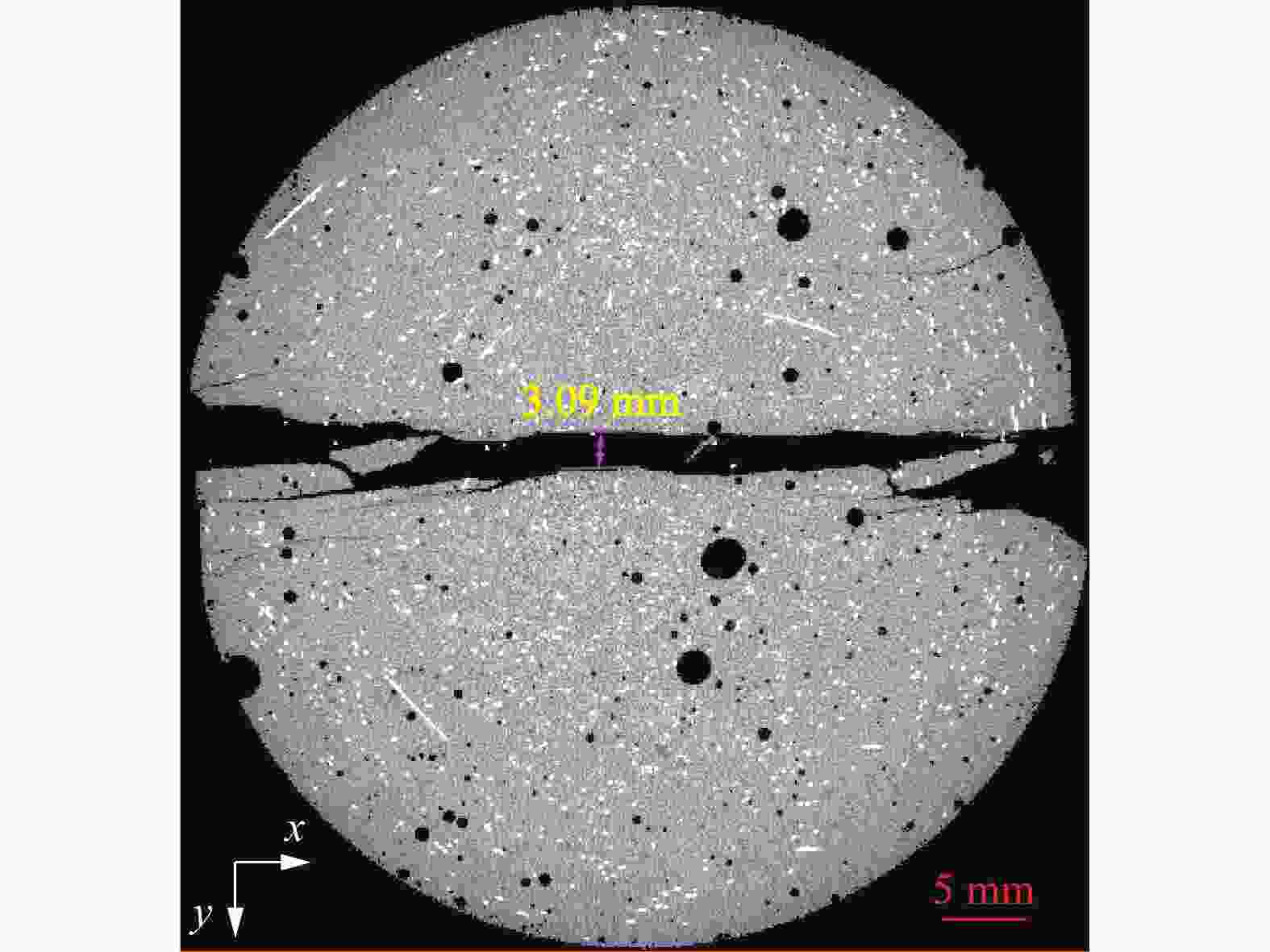

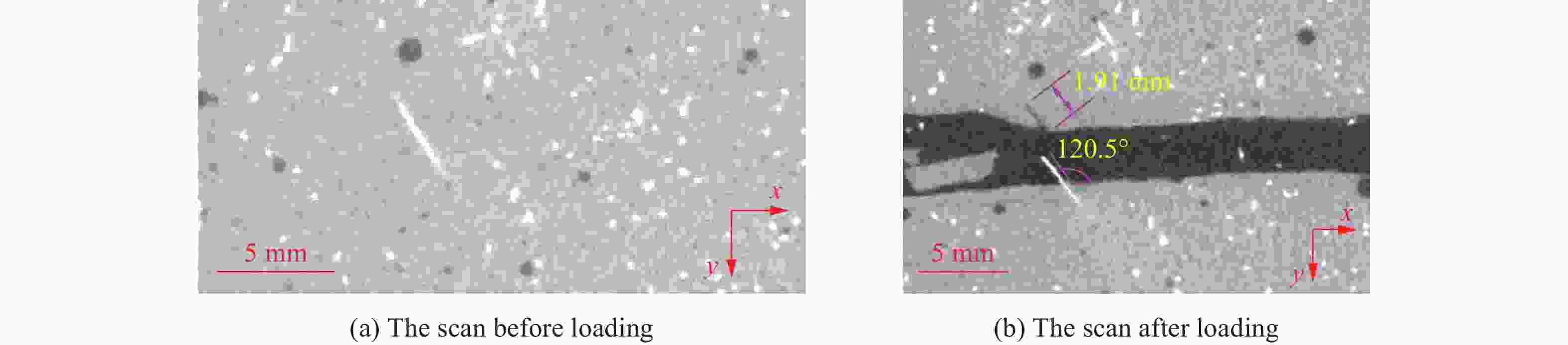

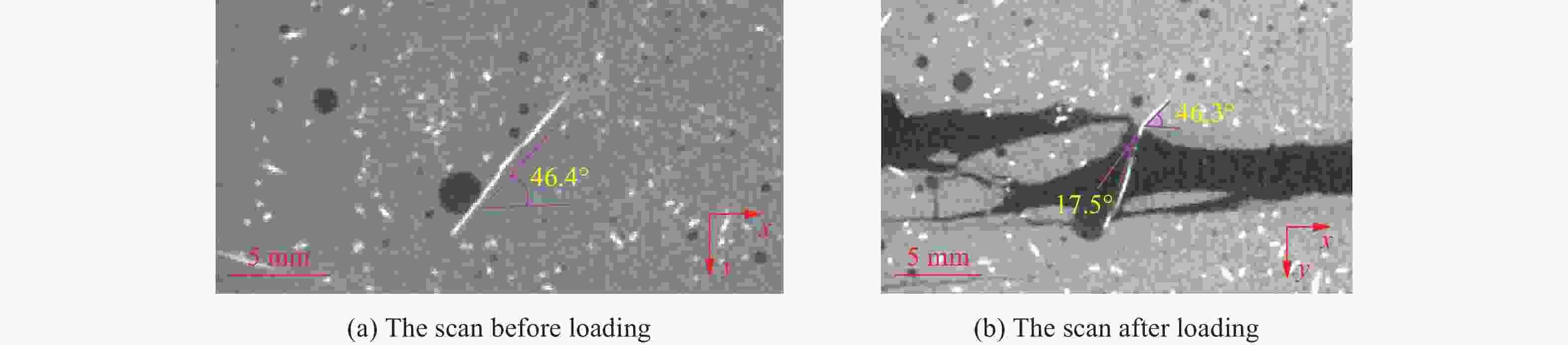

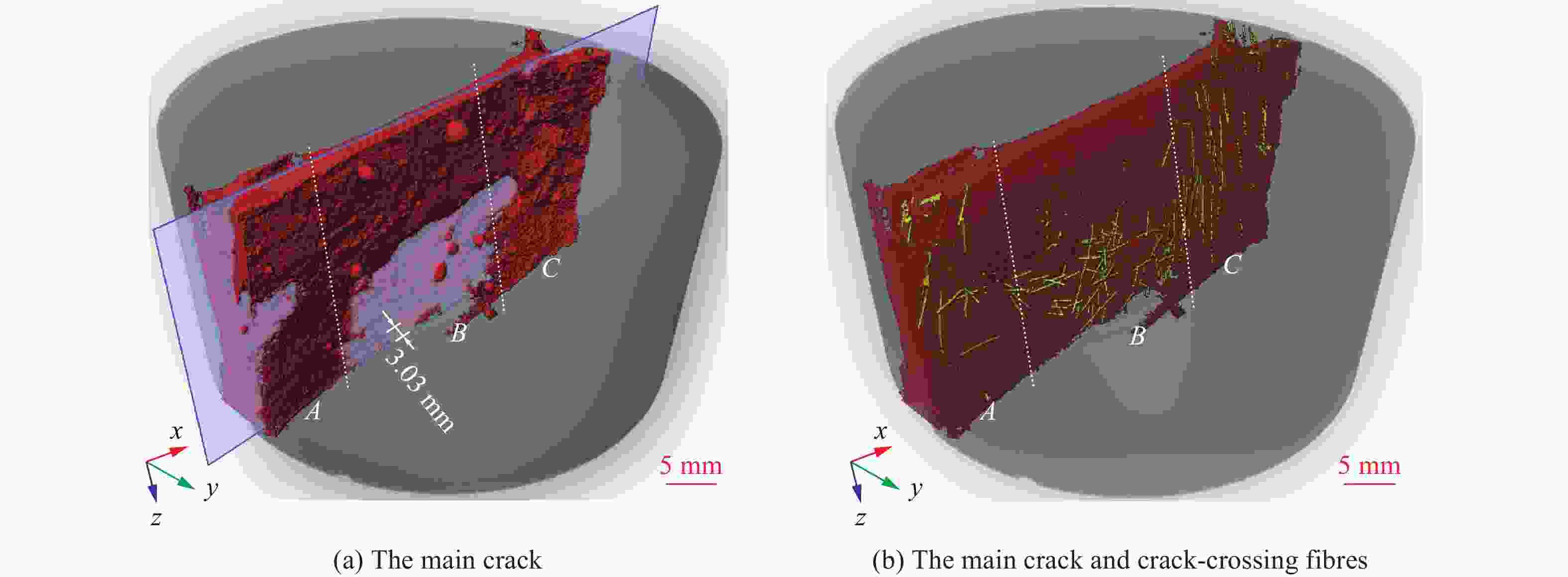

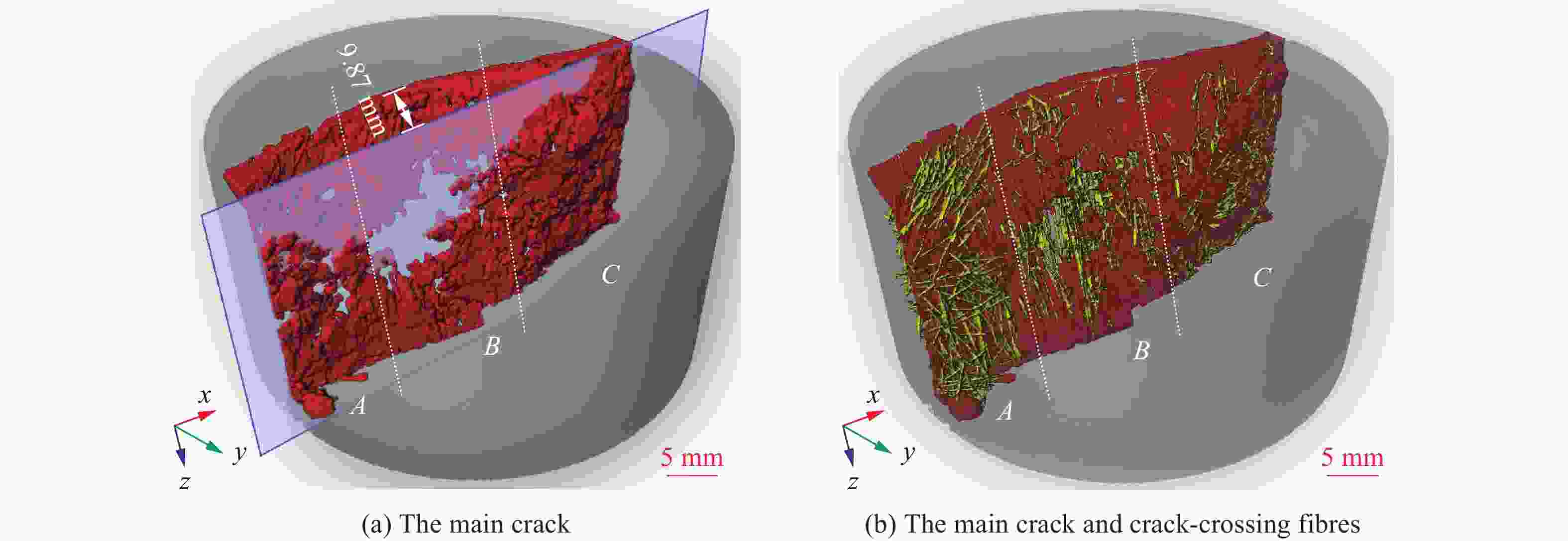

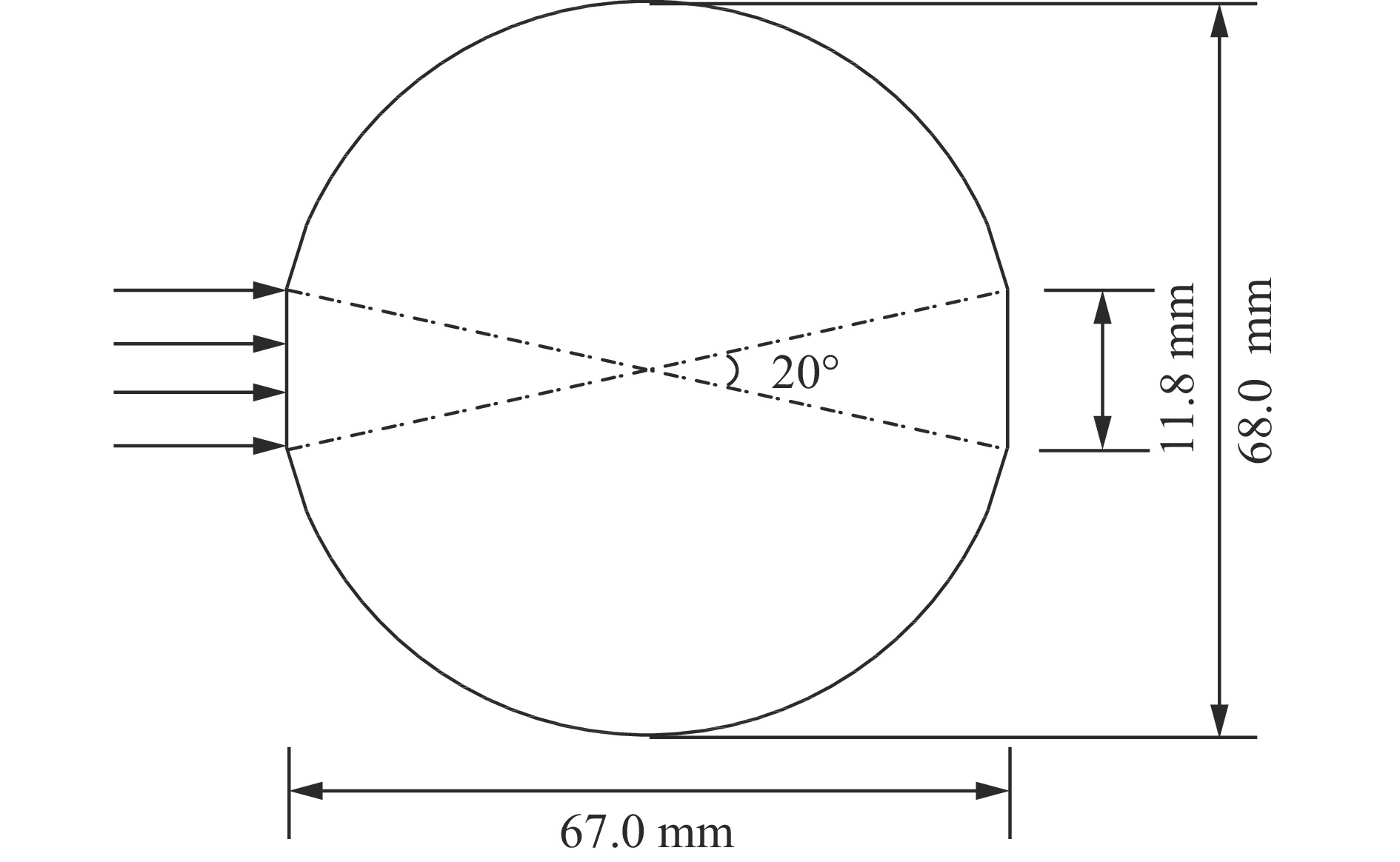

Abstract: In order to better investigate the dynamic tensile properties and damage mechanism of ultra-high performance fibre reinforced concrete (UHPFRC), dynamic split tests with the strain rates of 1.72-7.42 s-1 were carried out by a split Hopkinson pressure bar for UHPFRC discs with the fibre volume fractions of 0-3%. The surface crack propagation processes of the UHPFRC discs were captured by a high-speed camera and the images were analyzed by the digital image correlation (DIC) technique for strain evolution. Micro X-ray computed tomography (μXCT) scanning of the UHPFRC disc specimens before and after the dynamic tests was also conducted. The 3D images of the internal micro structures of the specimens with a voxel resolution of 56.7 μm were reconstructed, and they were then processed to statistically quantify the distribution, volume fractions and sizes of pores, fibres and cracks. Moreover, the dynamic failure mechanisms, such as pullout from the matrix, bending and breakage of steel fibres, crack propagation and merging in the mortar, etc., were visualized and analyzed. The main results obtained are as follows. (1) The addition of 1%-3% steel fibres raises the static and dynamic splitting strength by 84%-131% and 47%-87%, respectively. The dynamic increase factor (ratio of dynamic to static strength) is 1.07-1.72. (2) DIC images demonstrate that the fibres lead to more dispersed cracks, slower crack propagation, higher energy consumption and higher ductility. (3) The μXCT image analysis shows that the fibre volume fraction is 1.04%-2.47%, consistent with the designed proportion, while the porosity is 0.98%-1.71%. Fibres reduce the porosity and the number of pores, but increase their average volume and equivalent diameter. The increase of crack-bridging fibres reduces the volume and width of main cracks and raises the surface roughness and the relative surface area of cracks, resulting in the increase of strength, energy dissipation, toughness and ductility of specimens. The research data are useful for improvement of dynamic design guidelines and optimization for UHPFRC materials and structures. -

表 1 各组UHPFRC试件的配合比

Table 1. Mixing proportions of UHPFRC specimens for each test group

试件 钢纤维体积分数/% 配合比/(kg·m−3) 静力压缩 准静态劈裂 动态劈裂 水泥 硅灰 水 细砂 石英粉 减水剂 钢纤维 C0 ST0 DT0 0 1054 263 263 580 316 24 0 C1 ST1 DT1 1 1054 263 263 580 316 24 78 C2 ST2 DT2 2 1054 263 263 580 316 24 156 C3 ST3 DT3 3 1054 263 263 580 316 24 234 表 2 静力压缩试验结果

Table 2. Results of static compression tests

试件 钢纤维体积分数/% 峰值应变/% 峰值应力/MPa 弹性模量/GPa SC0 0 0.325±0.039 106.82±5.03 39.68±1.88 SC1 1 0.327±0.030 118.82±4.18 40.31±1.34 SC2 2 0.351±0.064 138.43±6.51 44.12±1.19 SC3 3 0.359±0.016 155.12±0.40 45.14±1.26 表 3 静力劈裂试验结果

Table 3. Results of static split tests

试件 钢纤维体积分数/% 劈裂强度/MPa 试件 钢纤维体积分数/% 劈裂强度/MPa ST0 0 11.41±0.46 ST2 2 23.47±1.04 ST1 1 20.98±1.23 ST3 3 26.37±0.22 表 4 动态劈裂试验结果

Table 4. Results of dynamic split tests

试件 $ \dot{\sigma } $/(GPa·s−1) $ \dot{\varepsilon } $/s−1 T/μs $ {\sigma }_{\mathrm{T}} $/MPa $ {\sigma }_{\mathrm{T},\mathrm{a}} $/MPa δt DT0-1 66.80 1.72 228 15.23 16.62 ± 2.12 1.33 DT0-2 89.40 2.30 168 15.02 1.32 DT0-3 118.13 3.04 166 19.61 1.72 DT1-1 258.37 6.41 94 24.29 24.41± 0.11 1.16 DT1-2 191.70 4.76 128 24.54 1.17 DT1-3 217.20 5.39 112 24.33 1.16 DT2-1 186.67 4.23 134 25.01 25.65± 0.79 1.07 DT2-2 233.08 5.28 108 25.17 1.07 DT2-3 196.76 4.46 136 26.76 1.14 DT3-1 177.31 3.93 170 30.14 31.06 ±0.83 1.14 DT3-2 334.93 7.42 96 32.15 1.22 DT3-3 166.04 3.68 186 30.88 1.17 表 5 试件DT0-3~DT3-3孔洞分布统计

Table 5. Statistics of pore distribution of specimens DT0-3-DT3-3

试件 孔洞体积

分数/%孔洞数目 孔洞平均

体积/mm3平均等效

直径/mm孔洞数目(占比) de=56.7~400 μm de=>400~800 μm de=>800~1600 μm de>1600 μm DT0-3 1.71 38671 0.053 0.466 27089

(70.05%)10012

(25.89%)1439

(3.72%)131

(0.34%)DT1-3 1.58 21384 0.089 0.554 12859

(60.13%)7389

(34.55%)983

(4.60%)153

(0.72%)DT2-3 1.20 15508 0.093 0.563 8847

(57.05%)5736

(36.99%)810

(5.22%)115

(0.74%)DT3-3 0.98 10158 0.101 0.579 6404

(63.04%)3134

(30.85%)548

(5.39%)72

(0.71%)表 6 裂缝及桥连纤维的统计分析

Table 6. Statistical analysis of cracks and bridged fibers

试件 桥连纤维

根数裂缝体积/

mm3裂缝表面积/

mm2相对表面积/

mm−1DT1-3 328 7118.97 10963.40 1.54 DT2-3 747 3234.73 6319.61 1.95 DT3-3 1 468 3081.81 6545.25 2.12 -

[1] RICHARD P, CHEYREZY M. Composition of reactive powder concretes [J]. Cement and Concrete Research, 1995, 25(7): 1501–1511. DOI: 10.1016/0008-8846(95)00144-2. [2] 徐海宾, 邓宗才, 陈春生, 等. 超高性能纤维混凝土梁抗剪性能试验研究 [J]. 土木工程学报, 2014, 47(12): 91–97. DOI: 10.15951/j.tmgcxb.2014.12.011.XU H B, DENG Z C, CHEN C S, et al. Experimental study on shear strength of ultra-high performance fiber reinforced concrete beams [J]. China Civil Engineering Journal, 2014, 47(12): 91–97. DOI: 10.15951/j.tmgcxb.2014.12.011. [3] MAGUREANU C, SOSA I, NEGRUTIU C, et al. Mechanical properties and durability of ultra-high-performance concrete [J]. Materials Journal, 2012, 109(2): 177–184. DOI: 10.14359/51683704. [4] YANG S L, MILLARD S G, SOUTSOS M N, et al. Influence of aggregate and curing regime on the mechanical properties of ultra-high performance fibre reinforced concrete (UHPFRC) [J]. Construction and Building Materials, 2009, 23(6): 2291–2298. DOI: 10.1016/j.conbuildmat.2008.11.012. [5] MILLARD S G, MOLYNEAUX T C K, BARNETT S J, et al. Dynamic enhancement of blast-resistant ultra high performance fibre-reinforced concrete under flexural and shear loading [J]. International Journal of Impact Engineering, 2010, 37(4): 405–413. DOI: 10.1016/j.ijimpeng.2009.09.004. [6] HABEL K, VIVIANI M, DENARIÉ E, et al. Development of the mechanical properties of an ultra-high performance fiber reinforced concrete (UHPFRC) [J]. Cement and Concrete Research, 2006, 36(7): 1362–1370. DOI: 10.1016/j.cemconres.2006.03.009. [7] 葛涛, 潘越峰, 谭可可, 等. 活性粉末混凝土抗冲击性能研究 [J]. 岩石力学与工程学报, 2007, 26(S1): 3553–3557. DOI: 10.3321/j.issn:1000-6915.2007.z1.148.GE T, PAN Y F, TAN K K, et al. Study on resistance of reactive powder concrete to impact [J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(S1): 3553–3557. DOI: 10.3321/j.issn:1000-6915.2007.z1.148. [8] 刘金涛. 基于纳米材料的活性粉末混凝土及其基本力学性能研究 [D]. 杭州: 浙江大学, 2016: 106–133.LIU J T. The mechanical properties of nanomaterials reinforced reactive powder concrete [D]. Hangzhou: Zhejiang University, 2016: 106–133. [9] 赖建中, 孙伟, 戎志丹. 活性粉末混凝土在多次冲击荷载下的力学行为 [J]. 爆炸与冲击, 2008, 28(6): 532–538. DOI: 10.11883/1001-1455(2008)06-0532-07.LAI J Z, SUN W, RONG Z D. Dynamic mechanical behaviour of reactive powder concrete subjected to repeated impact [J]. Explosion and Shock Waves, 2008, 28(6): 532–538. DOI: 10.11883/1001-1455(2008)06-0532-07. [10] 杜修力, 窦国钦, 李亮, 等. 纤维高强混凝土的动态力学性能试验研究 [J]. 工程力学, 2011, 28(4): 138–144.DU X L, DOU G Q, LI L, et al. Experimental study on dynamic mechanical properties of fiber reinforced high strength concrete [J]. Engineering Mechanics, 2011, 28(4): 138–144. [11] 谢磊, 李庆华, 徐世烺. 冲击荷载下免蒸养活性粉末混凝土分形特征研究 [J]. 工程力学, 2021, 38(3): 169–180. DOI: 10.6052/j.issn.1000-4750.2020.05.0298.XIE L, LI Q H, XU S L. Experimental study on fractal characteristics of steam free reactive powder concrete under impact load [J]. Engineering Mechanics, 2021, 38(3): 169–180. DOI: 10.6052/j.issn.1000-4750.2020.05.0298. [12] 焦楚杰, 孙伟, 高培正. 钢纤维超高强混凝土动态力学性能 [J]. 工程力学, 2006, 23(8): 86–89, 85. DOI: 10.3969/j.issn.1000-4750.2006.08.016.JIAO C J, SUN W, GAO P Z. Dynamic mechanical properties of steel-fiber reinforced ultra high strength concrete [J]. Engineering Mechanics, 2006, 23(8): 86–89, 85. DOI: 10.3969/j.issn.1000-4750.2006.08.016. [13] WANG Z L, LIU Y S, SHEN R F. Stress-strain relationship of steel fiber-reinforced concrete under dynamic compression [J]. Construction and Building Materials, 2008, 22(5): 811–819. DOI: 10.1016/j.conbuildmat.2007.01.005. [14] 任兴涛, 周听清, 钟方平, 等. 钢纤维活性粉末混凝土的动态力学性能 [J]. 爆炸与冲击, 2011, 31(5): 540–547. DOI: 10.11883/1001-1455(2011)05-0540-08.REN X T, ZHOU T Q, ZHONG F P, et al. Dynamic mechanical behavior of steel-fiber reactive powder concrete [J]. Explosion and Shock Waves, 2011, 31(5): 540–547. DOI: 10.11883/1001-1455(2011)05-0540-08. [15] 卢芳云, 陈荣, 林玉亮, 等. 霍普金森杆实验技术 [M]. 北京: 科学出版社, 2013: 151–167.LU F Y, CHEN R, LIN Y L, et al. Hopkinson bar techniques [M]. Beijing: Science Press, 2013: 151–167. [16] 焦楚杰, 蒋国平, 高乐. 钢纤维混凝土动态劈裂实验研究 [J]. 兵工学报, 2010, 31(4): 469–472.JIAO C J, JIANG G P, GAO L. Experimental research on the dynamic split properties of steel fiber reinforced concrete [J]. Acta Armamentarii, 2010, 31(4): 469–472. [17] 巫绪涛, 代仁强, 陈德兴, 等. 钢纤维混凝土动态劈裂试验的能量耗散分析 [J]. 应用力学学报, 2009, 26(1): 151–154.WU X T, DAI R Q, CHEN D X, et al. Energy dissipation analysis on dynamic splitting-tensile test of steel fiber reinforced concrete [J]. Chinese Journal of Applied Mechanics, 2009, 26(1): 151–154. [18] KHOSRAVANI M R, SILANI M, WEINBERG K. Fracture studies of ultra-high performance concrete using dynamic Brazilian tests [J]. Theoretical and Applied Fracture Mechanics, 2018, 93: 302–310. DOI: 10.1016/j.tafmec.2017.10.001. [19] PARK J K, KIM S W, KIM D J. Matrix-strength-dependent strain-rate sensitivity of strain-hardening fiber-reinforced cementitious composites under tensile impact [J]. Composite Structures, 2017, 162: 313–324. DOI: 10.1016/j.compstruct.2016.12.022. [20] CADONI E, FORNI D. Experimental analysis of the UHPFRCs behavior under tension at high stress rate [J]. The European Physical Journal Special Topics, 2016, 225(2): 253–264. DOI: 10.1140/epjst/e2016-02639-2. [21] 黄政宇, 秦联伟, 肖岩, 等. 级配钢纤维活性粉末混凝土的动态拉伸性能的试验研究 [J]. 铁道科学与工程学报, 2007, 4(4): 34–40. DOI: 10.3969/j.issn.1672-7029.2007.04.007.HUANG Z Y, QIN L W, XIAO Y, et al. Experimental investigation on the dynamic tensile behavior of graded steel-fiber RPC [J]. Journal of Railway Science and Engineering, 2007, 4(4): 34–40. DOI: 10.3969/j.issn.1672-7029.2007.04.007. [22] SU Y, LI J, WU C Q, et al. Effects of steel fibres on dynamic strength of UHPC [J]. Construction and Building Materials, 2016, 114: 708–718. DOI: 10.1016/j.conbuildmat.2016.04.007. [23] TRAN N T, KIM D J. Synergistic response of blending fibers in ultra-high-performance concrete under high rate tensile loads [J]. Cement and Concrete Composites, 2017, 78: 132–145. DOI: 10.1016/j.cemconcomp.2017.01.008. [24] TRAN N T, TRAN T K, KIM D J. High rate response of ultra-high-performance fiber-reinforced concretes under direct tension [J]. Cement and Concrete Research, 2015, 69: 72–87. DOI: 10.1016/j.cemconres.2014.12.008. [25] PYO S, EL-TAWIL S, NAAMAN A E. Direct tensile behavior of ultra high performance fiber reinforced concrete (UHP-FRC) at high strain rates [J]. Cement and Concrete Research, 2016, 88: 144–156. DOI: 10.1016/j.cemconres.2016.07.003. [26] 苗艳春, 张玉, SELYUTINA N, 等. 基于X-CT的高温后再生保温混凝土损伤分析 [J]. 复合材料学报, 2022, 39(6): 2829–2843. DOI: 10.13801/j.cnki.fhclxb.20210716.007.MIAO Y C, ZHANG Y, SELYUTINA N, et al. Damage analysis of meso-scale recycled aggregate thermal insulation concrete based on X-CT after high temperature [J]. Acta Materiae Compositae Sinica, 2022, 39(6): 2829–2843. DOI: 10.13801/j.cnki.fhclxb.20210716.007. [27] 覃茜, 徐千军. 基于CT图像的混凝土初始缺陷分布规律研究 [J]. 水利学报, 2016, 47(7): 959–966. DOI: 10.13243/j.cnki.slxb.20150935.QIN X, XU Q J. Statistics of the initial defects within concrete based on CT image [J]. Journal of Hydraulic Engineering, 2016, 47(7): 959–966. DOI: 10.13243/j.cnki.slxb.20150935. [28] NITKA M, TEJCHMAN J. A three-dimensional meso-scale approach to concrete fracture based on combined DEM with X-ray μCT images [J]. Cement and Concrete Research, 2018, 107: 11–29. DOI: 10.1016/j.cemconres.2018.02.006. [29] SUURONEN J P, KALLONEN A, EIK M, et al. Analysis of short fibres orientation in steel fibre-reinforced concrete (SFRC) by X-ray tomography [J]. Journal of Materials Science, 2013, 48(3): 1358–1367. DOI: 10.1007/s10853-012-6882-4. [30] BARNETT S J, LATASTE J F, PARRY T, et al. Assessment of fibre orientation in ultra high performance fibre reinforced concrete and its effect on flexural strength [J]. Materials and Structures, 2010, 43(7): 1009–1023. DOI: 10.1617/s11527-009-9562-3. [31] YANG Z J, QSYMAH A, PENG Y Z, et al. 4D characterisation of damage and fracture mechanisms of ultra high performance fibre reinforced concrete by in-situ micro X-Ray computed tomography tests [J]. Cement and Concrete Composites, 2020, 106: 103473. DOI: 10.1016/j.cemconcomp.2019.103473. [32] ZHANG X, YANG Z J, PANG M, et al. Ex-situ micro X-ray computed tomography tests and image-based simulation of UHPFRC beams under bending [J]. Cement and Concrete Composites, 2021, 123: 104216. DOI: 10.1016/j.cemconcomp.2021.104216. [33] American Society for Testing and Materials (ASTM). Standard test method for static modulus of elasticity and Poisson’s ratio of concrete in compression: ASTM C469/C469M—2010 [S]. Washington: ASTM, 2010. [34] 付应乾, 俞鑫炉, 董新龙, 等. 混凝土材料拉伸强度的应变率强化效应实验研究 [J]. 兵工学报, 2020, 41(1): 143–151. DOI: 10.3969/j.issn.1000-1093.2020.01.017.FU Y Q, YU X L, DONG X L, et al. An experimental investigation on the strain rate-dependent tensile strength of plain concretes [J]. Acta Armamentarii, 2020, 41(1): 143–151. DOI: 10.3969/j.issn.1000-1093.2020.01.017. [35] 赵昕. 超高韧性水泥基复合材料动态力学性能试验与理论研究 [D]. 杭州: 浙江大学, 2018: 84–107. DOI: 10.27461/d.cnki.gzjdx.2018.000077.ZHAO X. Experimental and theoretical study on the dynamic properties of ultra high toughness cementitious composites [D]. Hangzhou: Zhejiang University, 2018: 84–107. DOI: 10.27461/d.cnki.gzjdx.2018.000077. [36] 巫绪涛, 胡时胜, 陈德兴, 等. 钢纤维高强混凝土冲击压缩的试验研究 [J]. 爆炸与冲击, 2005, 25(2): 125–131. DOI: 10.11883/1001-1455(2005)02-0125-07.WU X T, HU S S, CHEN D X, et al. Impact compression experiment of steel fiber reinforced high strength concrete [J]. Explosion and Shock Waves, 2005, 25(2): 125–131. DOI: 10.11883/1001-1455(2005)02-0125-07. [37] 李庆华, 赵昕, 徐世烺. 纳米二氧化硅改性超高韧性水泥基复合材料冲击压缩试验研究 [J]. 工程力学, 2017, 34(2): 85–93. DOI: 10.6052/j.issn.1000-4750.2015.06.0477.LI Q H, ZHAO X, XU S L. Impact compression properties of nano-SiO2 modified ultra high toughness cementitious composites using a split Hopkinson pressure bar [J]. Engineering Mechanics, 2017, 34(2): 85–93. DOI: 10.6052/j.issn.1000-4750.2015.06.0477. [38] 宋力, 胡时胜. SHPB数据处理中的二波法与三波法 [J]. 爆炸与冲击, 2005, 25(4): 368–373. DOI: 10.11883/1001-1455(2005)04-0368-06.SONG L, HU S S. Two-wave and three-wave method in SHPB data processing [J]. Explosion and Shock Waves, 2005, 25(4): 368–373. DOI: 10.11883/1001-1455(2005)04-0368-06. [39] TEDESCO J W, ROSS C A, KUENNEN S T. Experimental and numerical analysis of high strain rate splitting-tensile tests [J]. Materials Journal, 1993, 90(2): 162–169. DOI: 10.14359/4013. [40] CHEN X D, WU S X, ZHOU J K. Experimental study on dynamic tensile strength of cement mortar using split Hopkinson pressure bar technique [J]. Journal of Materials in Civil Engineering, 2014, 26(6): 04014005. DOI: 10.1061/(ASCE)MT.1943-5533.0000926. [41] PETERS W H, RANSON W F. Digital imaging techniques in experimental stress analysis [J]. Optical Engineering, 1982, 21(3): 213427. DOI: 10.1117/12.7972925. [42] 方志, 周传波. 活性粉末混凝土动静弹性模量试验研究 [J]. 铁道学报, 2018, 40(9): 128–134. DOI: 10.3969/j.issn.1001-8360.2018.09.018.FANG Z, ZHOU C B. Experimental study on the elastic modulus of reactive powder concrete [J]. Journal of the China Railway Society, 2018, 40(9): 128–134. DOI: 10.3969/j.issn.1001-8360.2018.09.018. [43] QIN C, ZHANG C H. Numerical study of dynamic behavior of concrete by meso-scale particle element modeling [J]. International Journal of Impact Engineering, 2011, 38(12): 1011–1021. DOI: 10.1016/j.ijimpeng.2011.07.004. [44] QSYMAH A, SHARMA R, YANG Z, et al. Micro X-ray computed tomography image-based two-scale homogenisation of ultra high performance fibre reinforced concrete [J]. Construction and Building Materials, 2017, 130: 230–240. DOI: 10.1016/j.conbuildmat.2016.09.020. [45] YANG J, CHEN B C, NUTI C. Influence of steel fiber on compressive properties of ultra-high performance fiber-reinforced concrete [J]. Construction and Building Materials, 2021, 302: 124104. DOI: 10.1016/j.conbuildmat.2021.124104. [46] ZHONG C L, LIU M, ZHANG Y L, et al. Study on mechanical properties of hybrid polypropylene-steel fiber RPC and computational method of fiber content [J]. Materials, 2020, 13(10): 2243. DOI: 10.3390/ma13102243. -

下载:

下载: