| [1] |

叶建平, 史保生, 张春才. 中国煤储层渗透性及其主要影响因素 [J]. 煤炭学报, 1999, 24(2): 8–12. DOI: 10.3321/j.issn:0253-9993.1999.02.002.YE J P, SHI B S, ZHANG C C. Coal reservoir permeability and its controlled factors in China [J]. Journal of China Coal Society, 1999, 24(2): 8–12. DOI: 10.3321/j.issn:0253-9993.1999.02.002.

|

| [2] |

MOORE T A. Coalbed methane: a review [J]. International Journal of Coal Geology, 2012, 101: 36–81. DOI: 10.1016/j.coal.2012.05.011.

|

| [3] |

HAMAWAND I, YUSAF T, HAMAWAND S G. Coal seam gas and associated water: a review paper [J]. Renewable and Sustainable Energy Reviews, 2013, 22: 550–560. DOI: 10.1016/j.rser.2013.02.030.

|

| [4] |

WANG D K, LV R H, WEI J P, et al. An experimental study of the anisotropic permeability rule of coal containing gas [J]. Journal of Natural Gas Science and Engineering, 2018, 53: 67–73. DOI: 10.1016/j.jngse.2018.02.026.

|

| [5] |

傅雪海, 秦勇, 张万红, 等. 基于煤层气运移的煤孔隙分形分类及自然分类研究 [J]. 科学通报, 2005, 50(S1): 66–71. DOI: 10.3321/j.issn:0023-074X.2005.z1.009.FU X H, QIN Y, ZHANG W H, et al. Fractal classification and natural classification of coal pore structure based on migration of coal bed methane [J]. Chinese Science Bulletin, 2005, 50(S1): 66–71. DOI: 10.3321/j.issn:0023-074X.2005.z1.009.

|

| [6] |

LI B B, YANG K, XU P, et al. An experimental study on permeability characteristics of coal with slippage and temperature effects [J]. Journal of Petroleum Science and Engineering, 2019, 175: 294–302. DOI: 10.1016/j.petrol.2018.12.048.

|

| [7] |

吴飞鹏, 刘洪志, 任杨, 等. 燃爆冲击作用下岩石初始破坏区形成机制与主控因素 [J]. 爆炸与冲击, 2016, 36(5): 663–669. DOI: 10.11883/1001-1455(2016)05-0663-07.WU F P, LIU Z H, REN Y, et al. Formation mechanism and main controlling factors of rock’s initial damaged zone under explosive impact effect [J]. Explosion and Shock Waves, 2016, 36(5): 663–669. DOI: 10.11883/1001-1455(2016)05-0663-07.

|

| [8] |

牟恭雨, 罗宁, 申涛, 等. 聚能射流侵彻页岩储层损伤裂隙形成机制[J]. 爆炸与冲击, 2023, 43(3): 033301. DOI: 10.11883/bzycj-2022-0182.MU G Y, LUO N, SHEN T, et al. Mechanism of damage-induced fracture formation in shale reservoir penetrated by shaped charge jet [J]. Explosion and Shock Waves, 2023, 43(3): 033301. DOI: 10.11883/bzycj-2022-0182.

|

| [9] |

RAMULU M, CHAKRABORTY A K, SITHARAM T G. Damage assessment of basaltic rock mass due to repeated blasting in a railway tunnelling project-A case study [J]. Tunnelling and Underground Space Technology, 2009, 24(2): 208–221. DOI: 10.1016/j.tust.2008.08.002.

|

| [10] |

LI H B, XIA X, LI J C, et al. Rock damage control in bedrock blasting excavation for a nuclear power plant [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(2): 210–218. DOI: 10.1016/j.ijrmms.2010.11.016.

|

| [11] |

谢和平. 深部岩体力学与开采理论研究进展 [J]. 煤炭学报, 2019, 44(5): 1283–1305. DOI: 10.13225/j.cnki.jccs.2019.6038.XIE H P. Research review of the state key research development program of China: deep rock mechanics and mining theory [J]. Journal of China Coal Society, 2019, 44(5): 1283–1305. DOI: 10.13225/j.cnki.jccs.2019.6038.

|

| [12] |

鞠杨, 李业学, 谢和平, 等. 节理岩石的应力波动与能量耗散 [J]. 岩石力学与工程学报, 2006, 25(12): 2426–2434. DOI: 10.3321/j.issn:1000-6915.2006.12.007.JU Y, LI Y X, XIE H P, et al. Stress wave propagation and energy dissipation in jointed rocks [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(12): 2426–2434. DOI: 10.3321/j.issn:1000-6915.2006.12.007.

|

| [13] |

MA Y, PAN Z J, ZHONG N N, et al. Experimental study of anisotropic gas permeability and its relationship with fracture structure of Longmaxi Shales, Sichuan Basin, China [J]. Fuel, 2016, 180: 106–115. DOI: 10.1016/j.fuel.2016.04.029.

|

| [14] |

TAN Y L, PAN Z J, LIU J S, et al. Experimental study of permeability and its anisotropy for shale fracture supported with proppant [J]. Journal of Natural Gas Science and Engineering, 2017, 44: 250–264. DOI: 10.1016/j.jngse.2017.04.020.

|

| [15] |

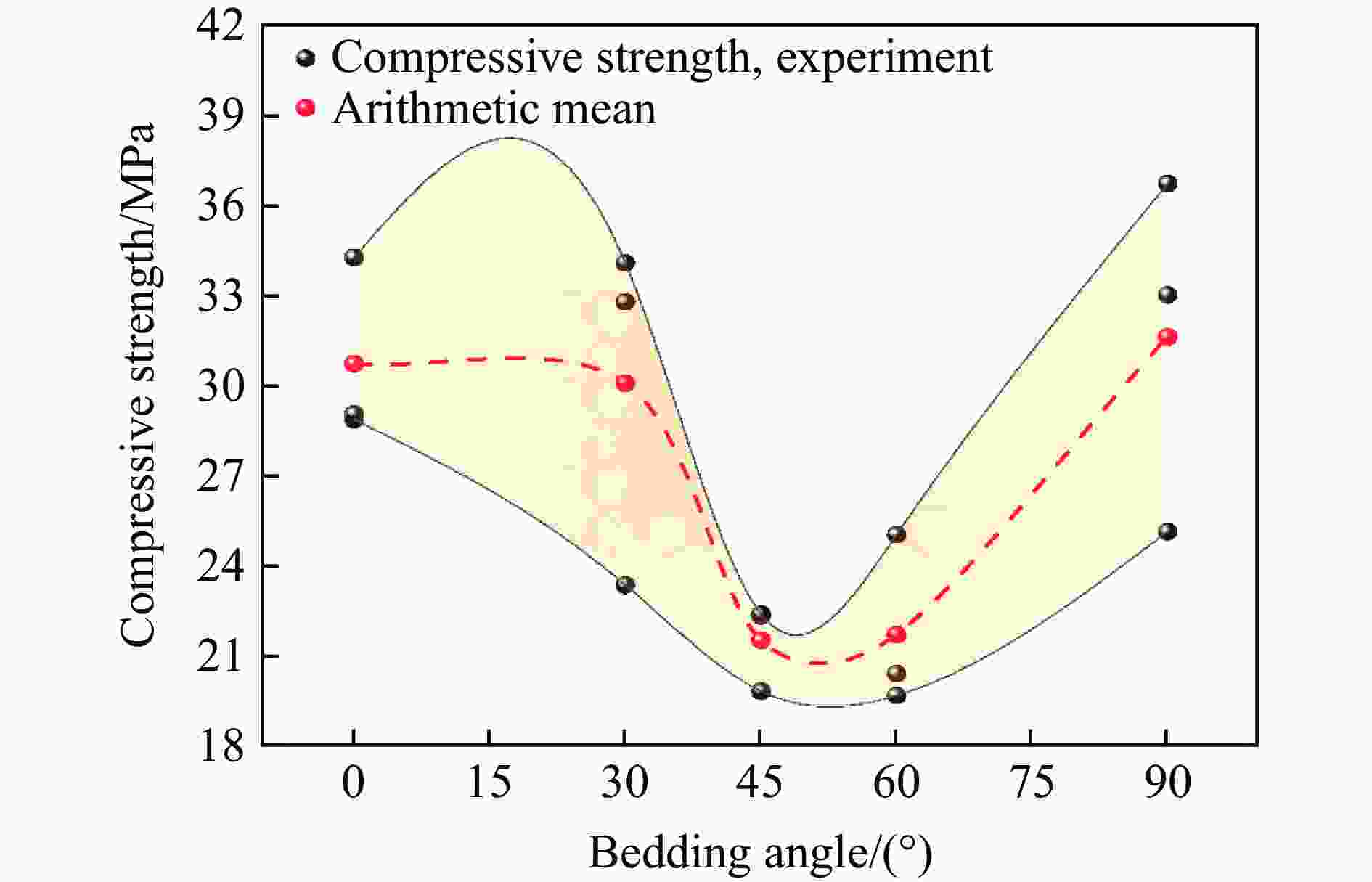

ZHAO Y X, ZHAO G F, JIANG Y D, et al. Effects of bedding on the dynamic indirect tensile strength of coal: laboratory experiments and numerical simulation [J]. International Journal of Coal Geology, 2014, 132: 81–93. DOI: 10.1016/j.coal.2014.08.007.

|

| [16] |

KONG X G, WANG E Y, LI S G, et al. Dynamic mechanical characteristics and fracture mechanism of gas-bearing coal based on SHPB experiments [J]. Theoretical and Applied Fracture Mechanics, 2020, 105: 102395. DOI: 10.1016/j.tafmec.2019.102395.

|

| [17] |

HAO X J, DU W S, ZHAO Y X, et al. Dynamic tensile behaviour and crack propagation of coal under coupled static-dynamic loading [J]. International Journal of Mining Science and Technology, 2020, 30(5): 659–668. DOI: 10.1016/j.ijmst.2020.06.007.

|

| [18] |

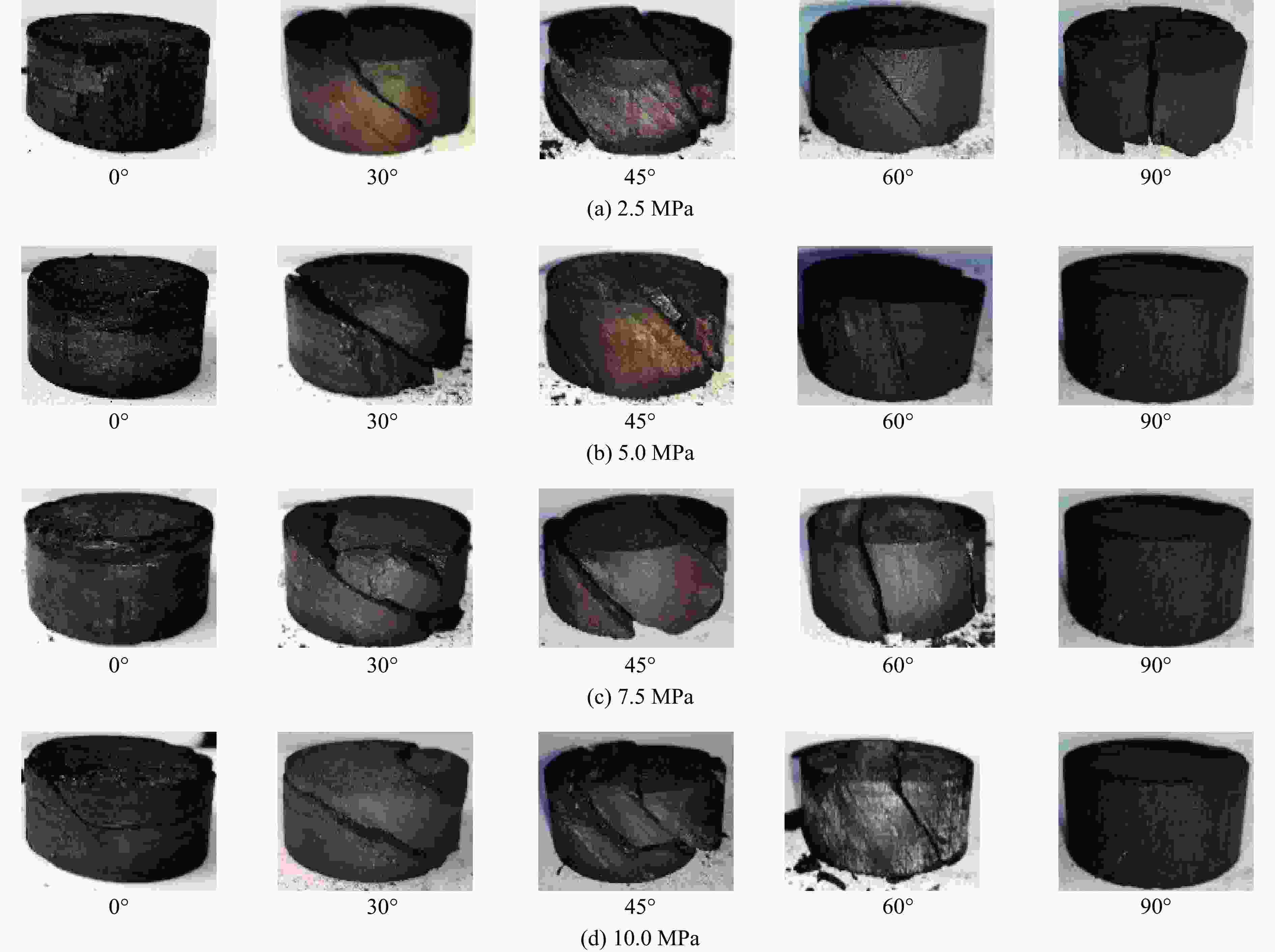

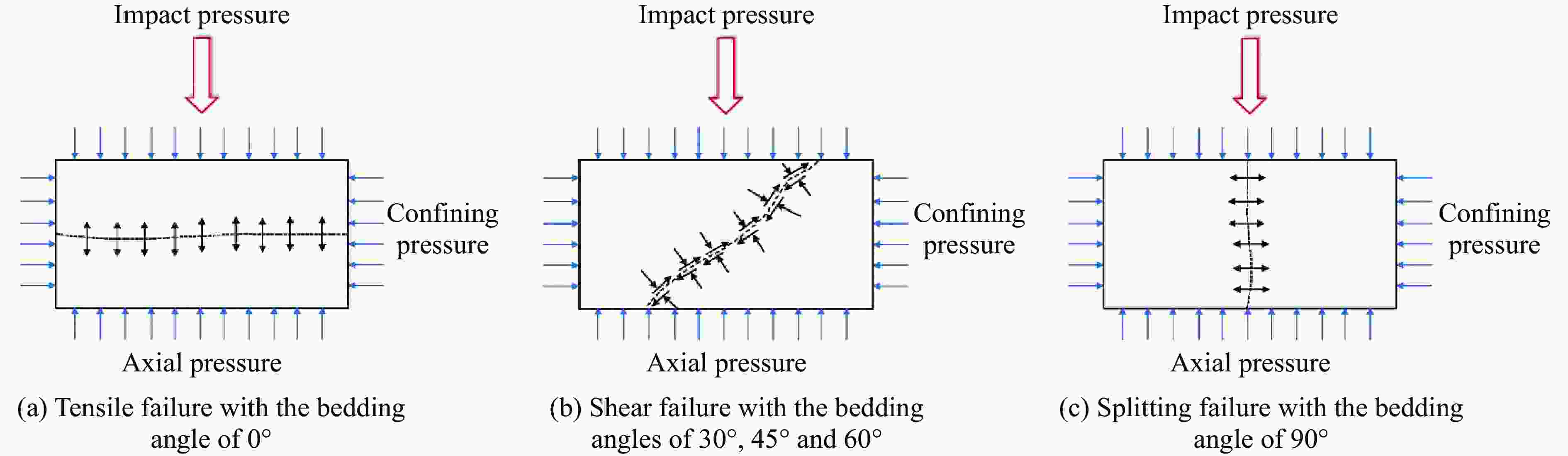

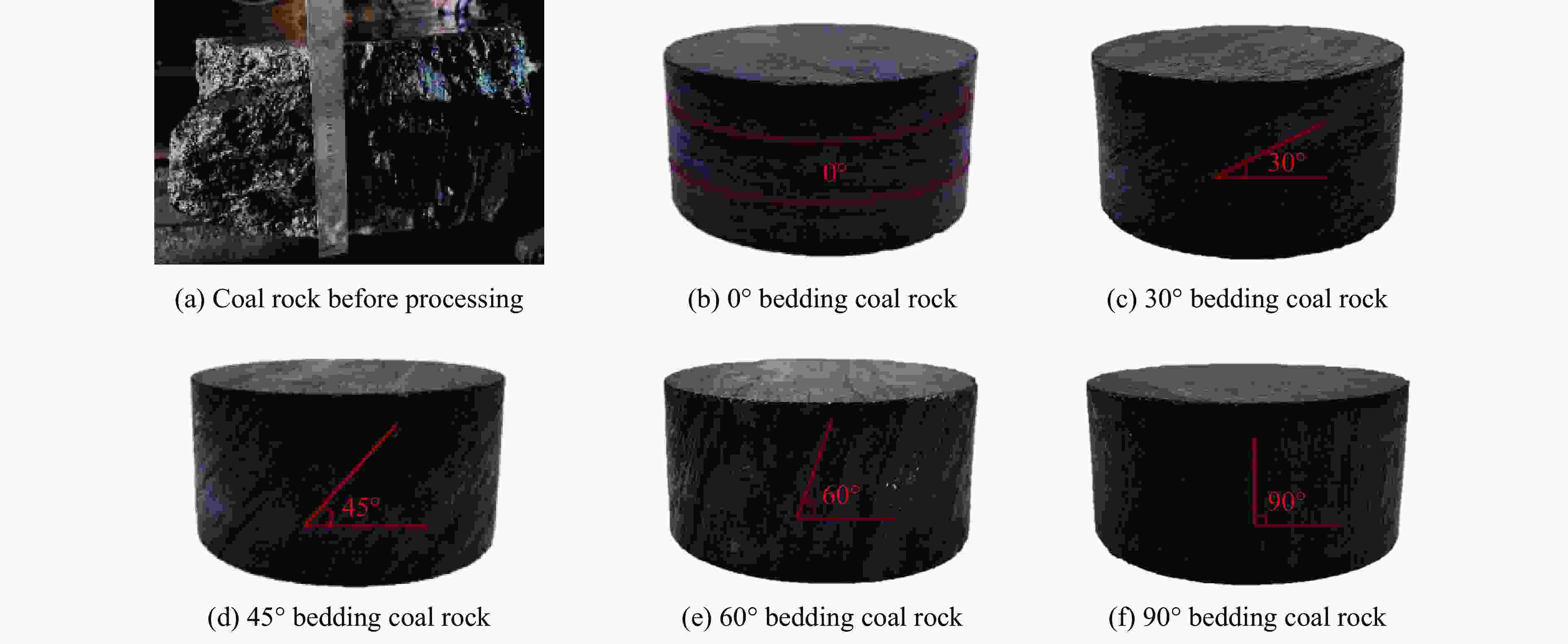

LIU X H, DAI F, ZHANG R, et al. Static and dynamic uniaxial compression tests on coal rock considering the bedding directivity [J]. Environmental Earth Sciences, 2015, 73(10): 5933–5949. DOI: 10.1007/s12665-015-4106-3.

|

| [19] |

CHEN Y L, ZHANG Y N, LI X L. Experimental study on influence of bedding angle on gas permeability in coal [J]. Journal of Petroleum Science and Engineering, 2019, 179: 173–179. DOI: 10.1016/j.petrol.2019.04.010.

|

| [20] |

ZHAO Y X, GONG S, HAO X J, et al. Effects of loading rate and bedding on the dynamic fracture toughness of coal: laboratory experiments [J]. Engineering Fracture Mechanics, 2017, 178: 375–391. DOI: 10.1016/j.engfracmech.2017.03.011.

|

| [21] |

WANG W, ZHAO Y X, TENG T, et al. Influence of bedding planes on mode Ⅰ and mixed-mode (Ⅰ-Ⅱ) dynamic fracture toughness of coal: analysis of experiments [J]. Rock Mechanics and Rock Engineering, 2021, 54(1): 173–189. DOI: 10.1007/s00603-020-02250-9.

|

| [22] |

FAN X R, LUO N, LIANG H L, et al. Dynamic breakage characteristics of shale with different bedding angles under the different ambient temperatures [J]. Rock Mechanics and Rock Engineering, 2021, 54(6): 3245–3261. DOI: 10.1007/s00603-021-02463-6.

|

| [23] |

王卫华, 李夕兵, 左宇军. 非线性法向变形节理对弹性纵波传播的影响 [J]. 岩石力学与工程学报, 2006, 25(6): 1218–1225. DOI: 10.3321/j.issn:1000-6915.2006.06.020.WANG W H, LI X B, ZUO Y J. Effects of single joint with nonlinear normal deformation on P-wave propagation [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(6): 1218–1225. DOI: 10.3321/j.issn:1000-6915.2006.06.020.

|

| [24] |

李业学, 谢和平, 朱哲明, 等. 应力波穿越分形节理时的透反射规律研究 [J]. 岩石力学与工程学报, 2009, 28(1): 120–129. DOI: 10.3321/j.issn:1000-6915.2009.01.016.LI Y X, XIE H P, ZHU Z M, et al. Study on rules of transmission and reflection of stress wave across fractal joint [J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(1): 120–129. DOI: 10.3321/j.issn:1000-6915.2009.01.016.

|

| [25] |

许金余, 范建设, 吕晓聪. 围压条件下岩石的动态力学特性 [M]. 西安: 西北工业大学出版社, 2012: 21–25.XU J Y, FAN J S, LYU X C. Dynamic mechanical properties of rock with the confining pressure [M]. Xi’an: Northwestern Polytechnical University Press, 2012: 21–25.

|

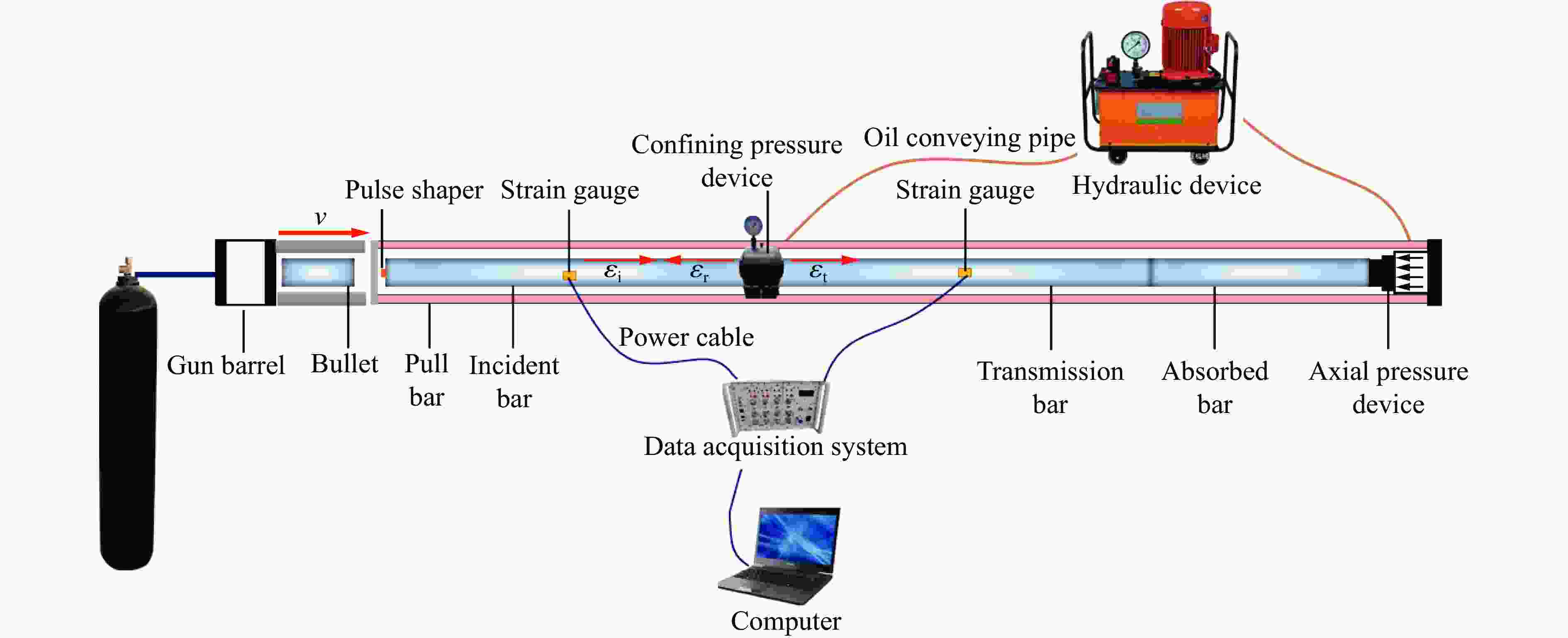

| [26] |

LEWANDOWSKI C M, COINVESTIGATOR N. Split Hopkinson (Kolsky) bar: design, testing and applications [M]. Springer, 2015: 6–12.

|

| [27] |

FAKHIMI A, AZHDARI P, KIMBERLEY J. Physical and numerical evaluation of rock strength in Split Hopkinson Pressure Bar testing [J]. Computers and Geotechnics, 2018, 102: 1–11. DOI: 10.1016/j.compgeo.2018.05.009.

|

| [28] |

FENG J J, WANG E Y, CHEN X, et al. Energy dissipation rate: an indicator of coal deformation and failure under static and dynamic compressive loads [J]. International Journal of Mining Science and Technology, 2018, 28(3): 397–406. DOI: 10.1016/j.ijmst.2017.11.006.

|

| [29] |

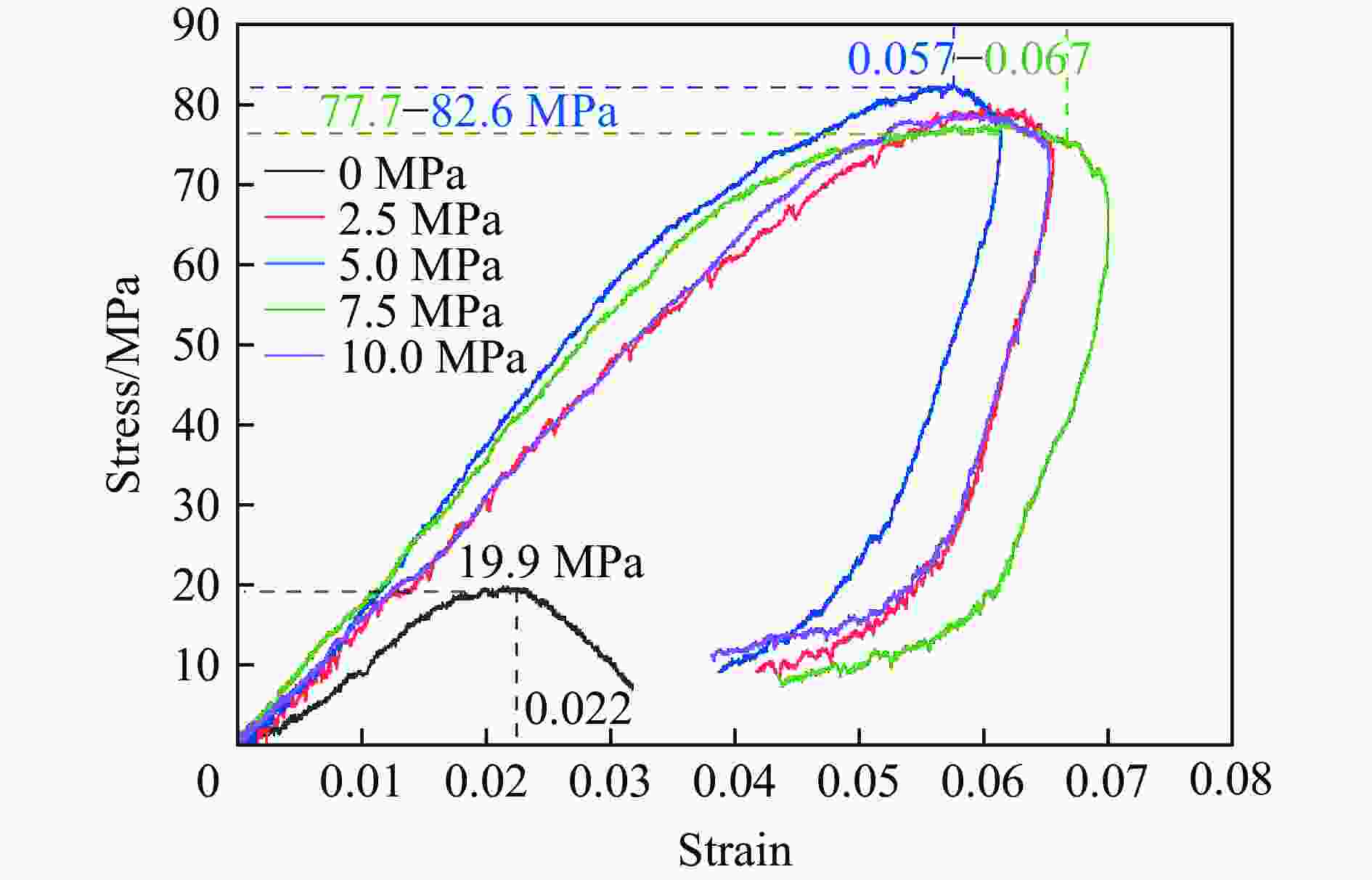

LUO N, SUO Y C, FAN X R, et al. Research on confining pressure effect of pore structure of coal-rich in coalbed methane under cyclic impact [J]. Energy Reports, 2022, 8: 7336–7348. DOI: 10.1016/j.egyr.2022.05.238.

|

| [30] |

SUO Y C, LUO N, CHAI Y B, et al. Experimental investigation of dynamic mechanical characteristics of inhomogeneous composite coal-sandstone combination for coalbed methane development [J]. Heliyon, 2022, 8: e11628. DOI: 10.1016/j.heliyon.2022.e11628.

|

| [31] |

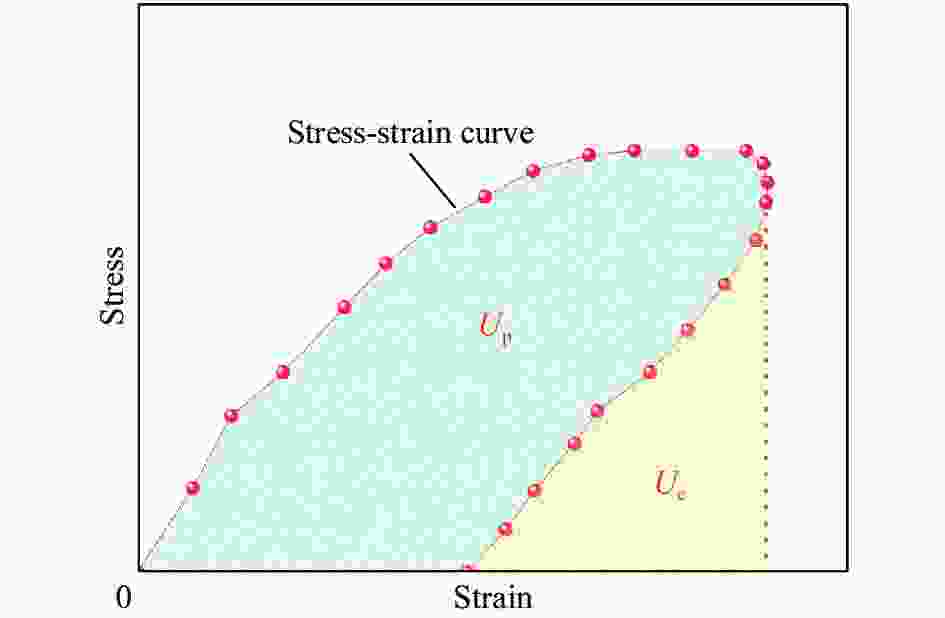

谢和平, 彭瑞东, 鞠杨, 等. 岩石破坏的能量分析初探 [J]. 岩石力学与工程学报, 2005, 24(15): 2603–2608. DOI: 10.3321/j.issn:1000-6915.2005.15.001.XIE H P, PENG R D, JU Y, et al. On energy analysis of rock failure [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(15): 2603–2608. DOI: 10.3321/j.issn:1000-6915.2005.15.001.

|

| [32] |

谢和平, 鞠杨, 黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则 [J]. 岩石力学与工程学报, 2005, 24(17): 3003–3010. DOI: 10.3321/j.issn:1000-6915.2005.17.001.XIE H P, JU, Y, LI L Y. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(17): 3003–3010. DOI: 10.3321/j.issn:1000-6915.2005.17.001.

|

| [33] |

黎立云, 徐志强, 谢和平, 等. 不同冲击速度下岩石破坏能量规律的实验研究 [J]. 煤炭学报, 2011, 36(12): 2007–2011. DOI: 10.13225/j.cnki.jccs.2011.12.012.LI L Y, XU Z Q, XIE H P, et al. Failure experimental study on energy laws of rock under differential dynamic impact velocities [J]. Journal of China Coal Society, 2011, 36(12): 2007–2011. DOI: 10.13225/j.cnki.jccs.2011.12.012.

|

| [34] |

刘晓辉, 薛洋, 周济芳, 等. 层理煤岩动态破坏能量变化规律及损伤特征 [J]. 地下空间与工程学报, 2021, 17(4): 1052–1062.LIU X H, XUE Y, ZHOU J F, et al. Dynamic failure energy change and damage characteristics of bedding coal rock [J]. Chinese Journal of Underground Space and Engineering, 2021, 17(4): 1052–1062.

|

| [35] |

周磊, 姜亚成, 朱哲明, 等. 动载荷作用下裂隙岩体的止裂机理分析 [J]. 爆炸与冲击, 2021, 41(5): 053102. DOI: 10.11883/bzycj-2020-0125.ZHOU L, JIANG Y C, ZHU Z M, et al. Mechanism study of preventing crack propagation of fractured rock under dynamic loads [J]. Explosion and Shock Waves, 2021, 41(5): 053102. DOI: 10.11883/bzycj-2020-0125.

|

| [36] |

杨国梁, 毕京九, 郭伟民, 等. 加载角度对层理页岩裂纹扩展影响的实验研究 [J]. 爆炸与冲击, 2021, 41(9): 093101. DOI: 10.11883/bzycj-2021-0097.YANG G L, BI J J, GUO W M, et al. Experimental study on the effect of loading angle on crack propagation in bedding shale [J]. Explosion and Shock Waves, 2021, 41(9): 093101. DOI: 10.11883/bzycj-2021-0097.

|

下载:

下载: