A review of sacrificial claddings in multilayer protective structure

-

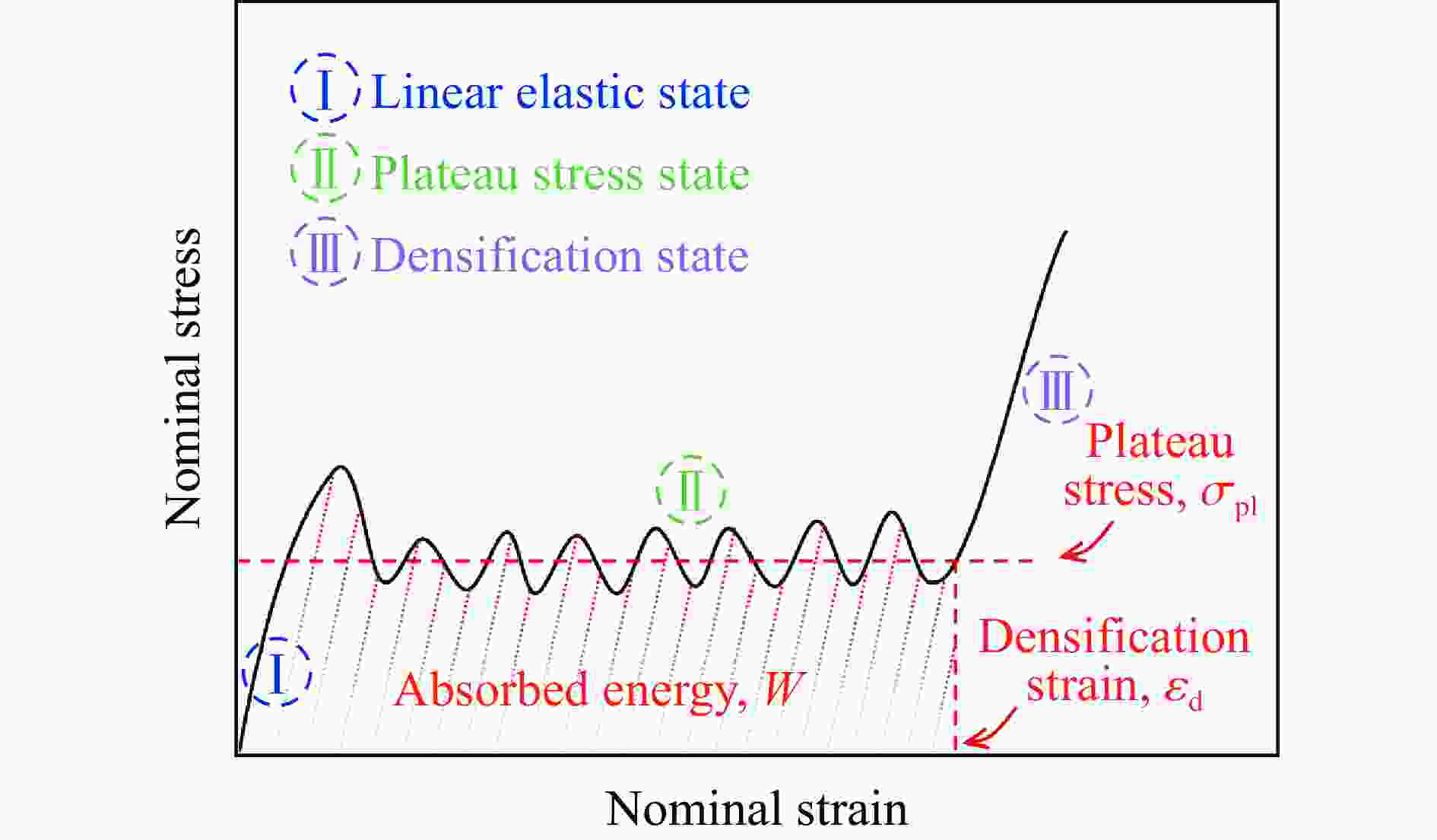

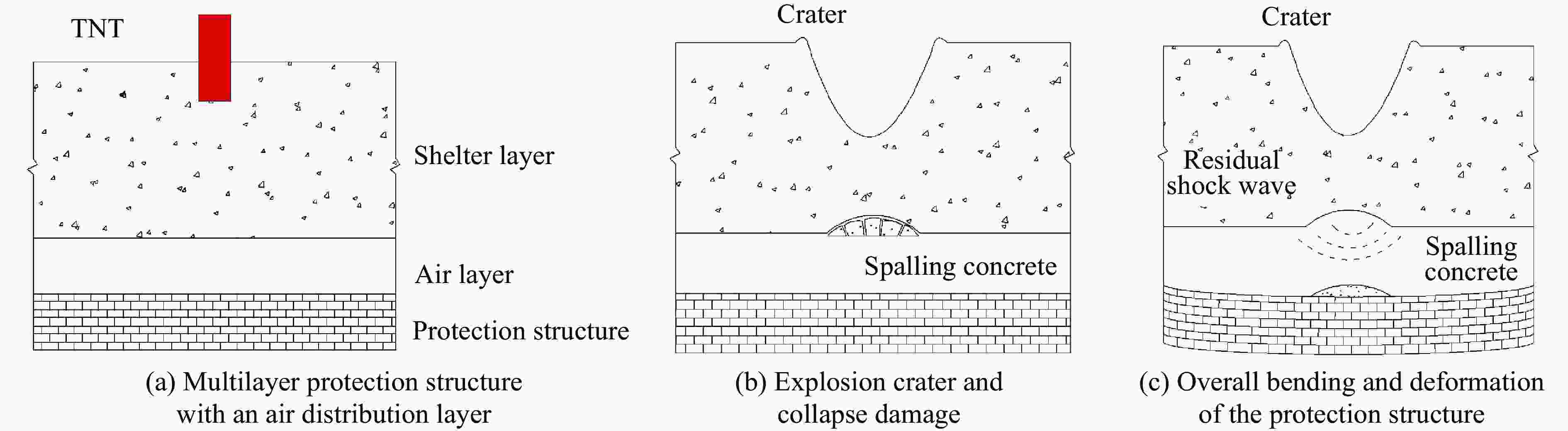

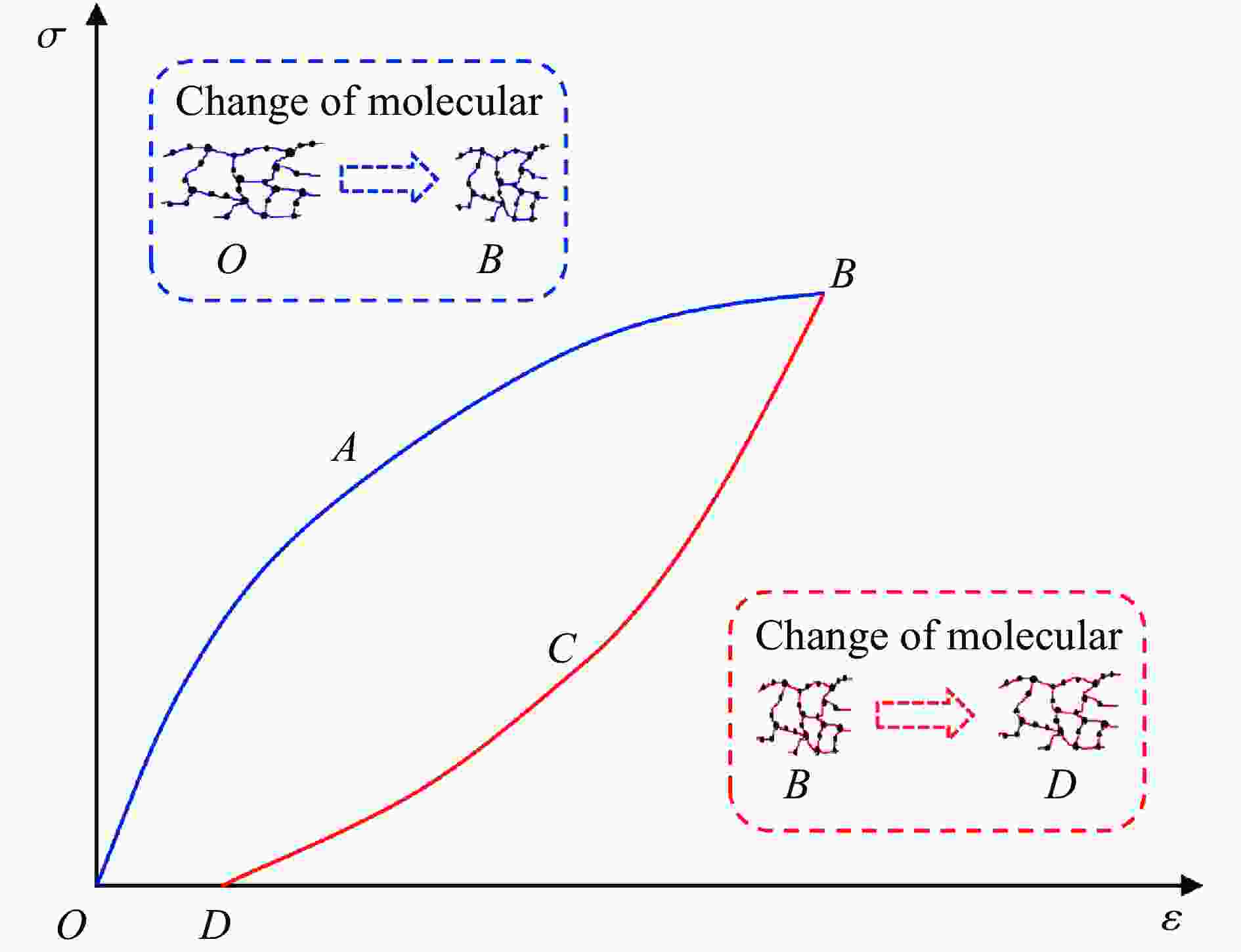

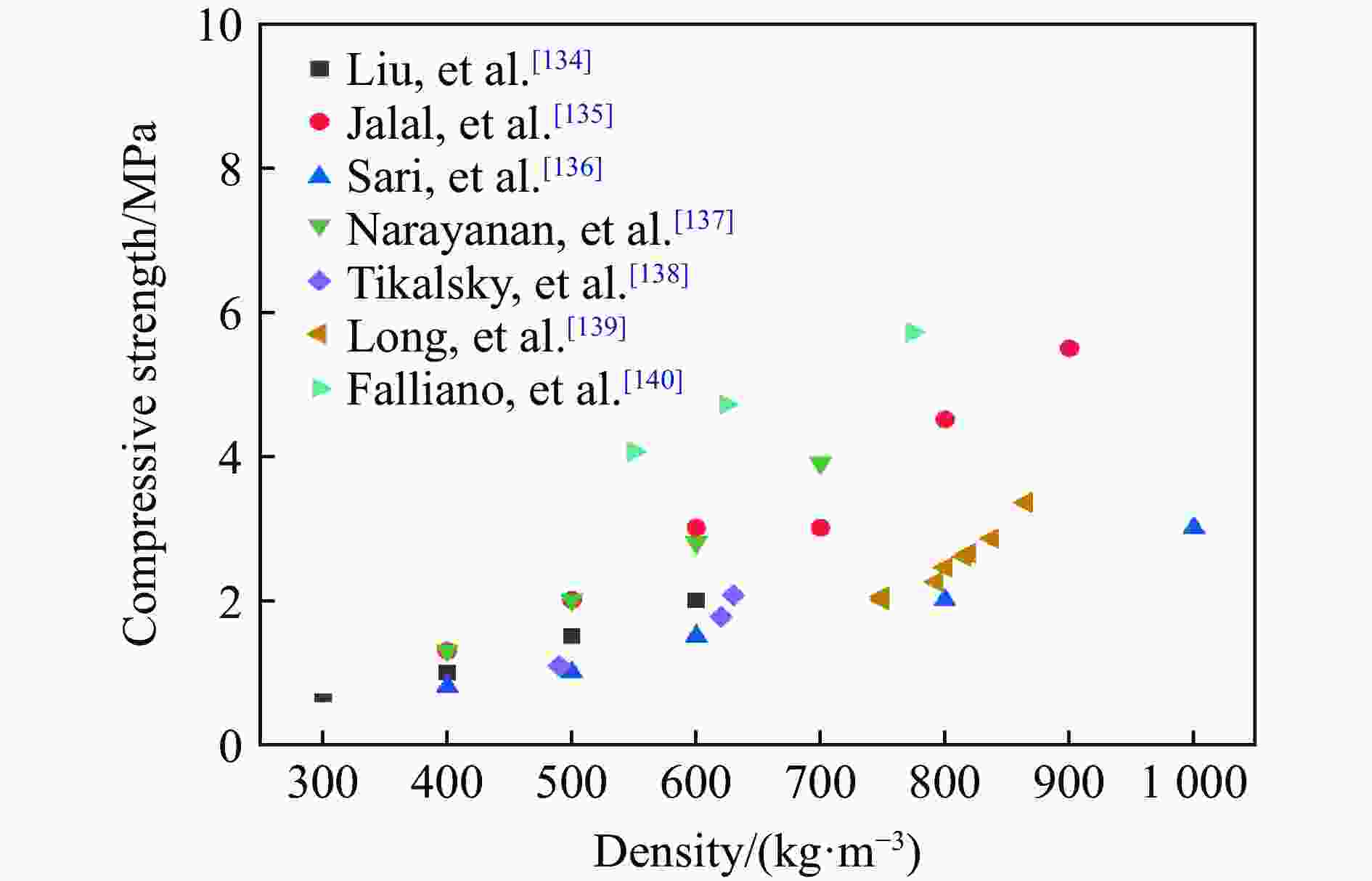

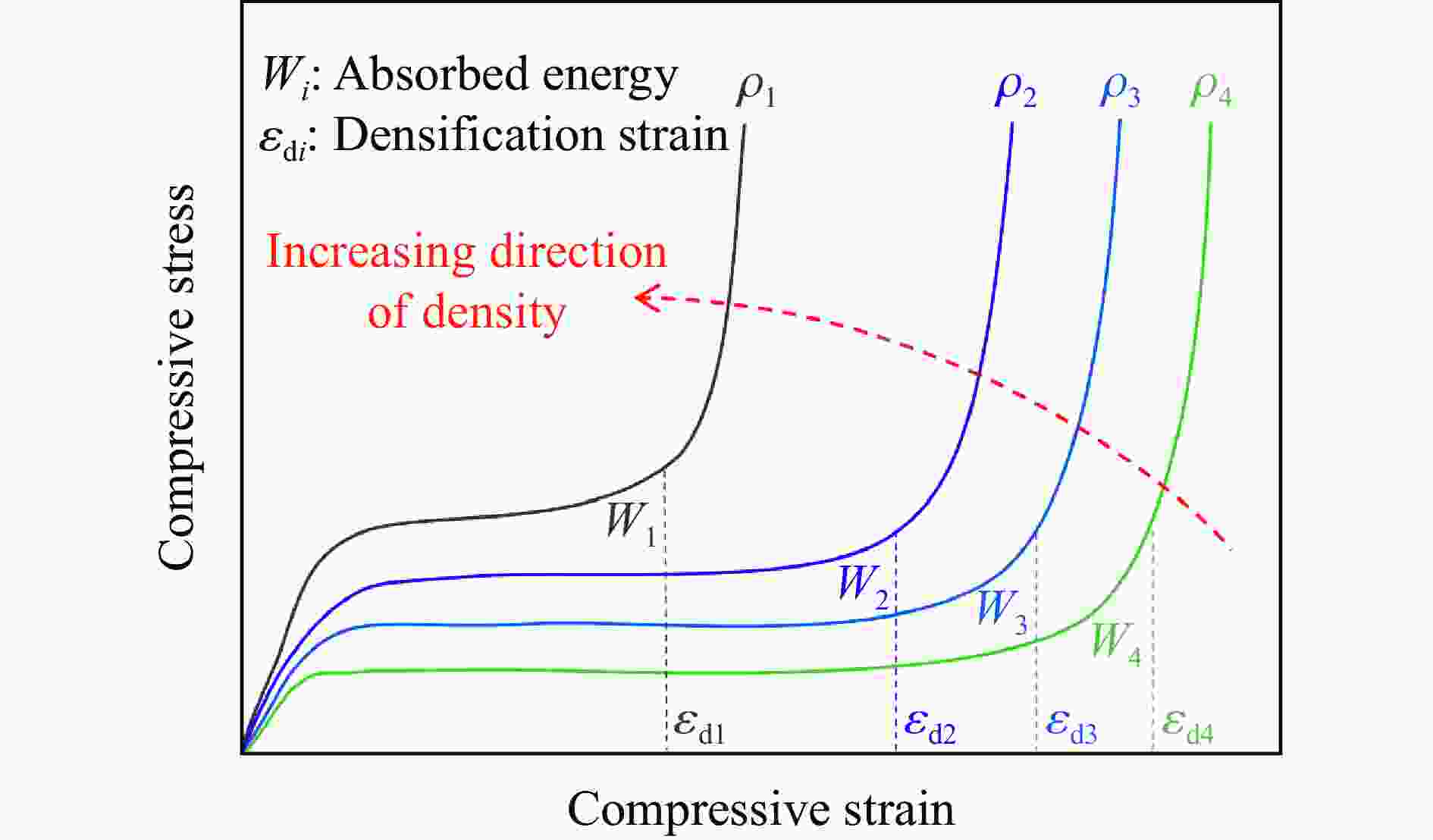

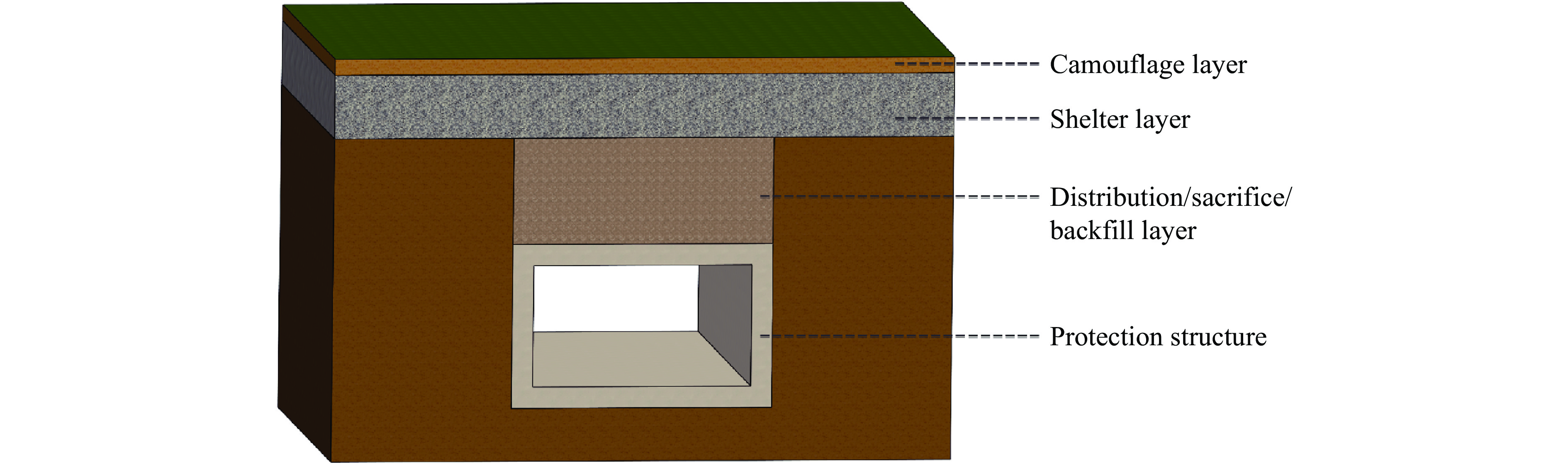

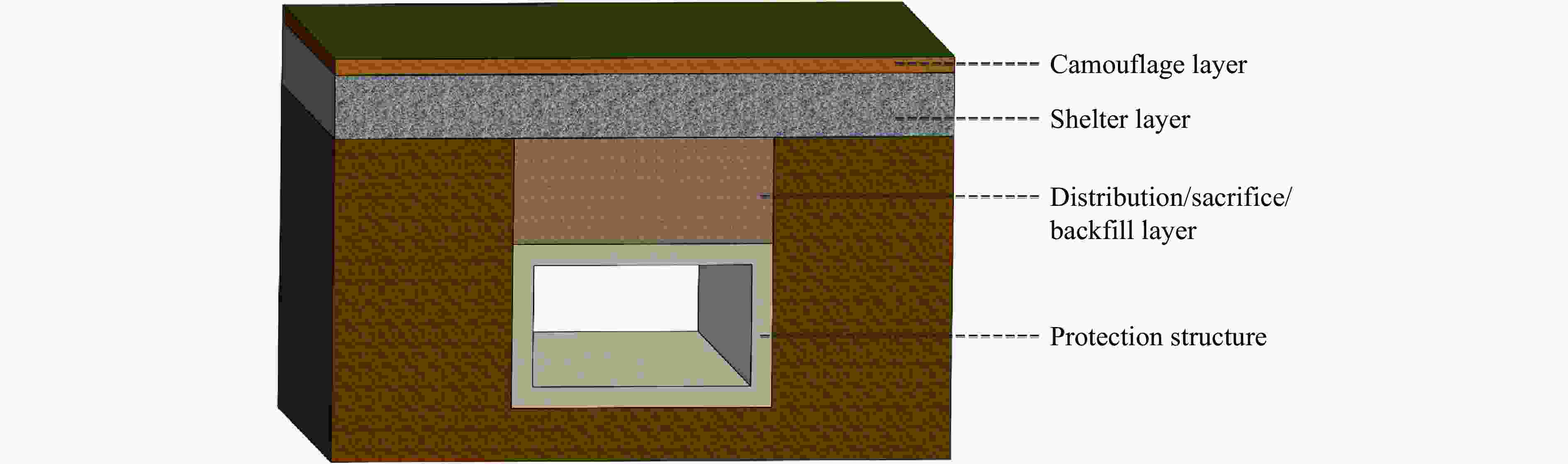

摘要: 成层式防护结构通常由伪装层、遮弹层、分散层和主体结构组成,现已被广泛应用于地面、浅埋以及坑道口部的防御工事中。其中分散层作为降低侵彻后爆炸毁伤效应的功能单元,其作用机理主要包括:借助波阻抗失配效应以降低向下部结构传播的能量占比、延长应力波传播路径;利用分层界面产生面波以改善荷载集中状态;通过基体材料不可逆塑性破坏以吸收耗散冲击波能量;增大结构阻尼以减轻主体结构震动效应。开展分散层的相关研究,对提高工程整体防护水平具有重要的现实意义。基于此,从分散层材料与结构型式两个方面较为系统地介绍了国内外成层式防护结构中分散层的研究现状,分析了分散层的结构及物性参数对其防护效能的影响,提出分散层选型及设计需关切的几点问题,并对目前分散层研究中存在的问题进行了探讨与展望,以期为今后分散层的研究发展提供参考。Abstract: The multilayer protective structure has been widely used in fortifications located above-ground, shallow burial, and tunnel entrances. And this type of structure usually consists of four parts: camouflage layer, shelter layer, sacrifice layer and protection structure. Among them, the sacrifice layer is the main functional unit to reduce the damage effect of strong explosion after penetration. Its action mechanism mainly includes: reducing the proportion of energy propagating to the substructure and extending the propagation path of stress wave by means of the wave impedance mismatch effect; using the layered interface to generate surface waves to reduce the load concentration; absorbing and dissipating shock wave energy through irreversible plastic failure of the matrix material; increasing the structural damping to reduce the vibration effect of the protection structure. Thus, it is of great practical significance to carry out relevant research to improve the overall level of engineering protection. Taking the materials and structure of sacrifice layer as clues, the current status of research on sacrifice layer in multilayer protective structure at home and abroad is systematically sorted out. On this basis, the influence of structural parameters such as the density, wave impedance, thickness, unit shapes and sizes, moisture content and other physical parameters of the sacrifice layer on the protective performance is analyzed. Moreover, several issues that need to be considered in the selection and design of the sacrifice layer are proposed. The perfect sacrifice layer should be economical, reliable, and have a low wave impedance, sufficient static compressive strength and a certain yield strength, which be able to undergo a large plastic deformation under the condition that the yield stress remains essentially constant. Finally, the problems existing in the current research on the sacrifice layer are discussed and prospected, in order to provide a reference for the research and development of the sacrifice layer in the future.

-

Table 1. Physical and mechanical parameters of the medium under the ground impact of explosion[9-10]

介质 波速c/(m·s−1) 波阻抗ρc /(kg·m-2·s-1) 衰减指数n 低相对密度松散干砂、黄土和砂砾 180 0.26×106 3.00~3.50 密实的不良级配干砂 274~396 0.57×106 2.50~2.75 相对密度接近100%的极密干砂 488 1.00×106 2.50 黏土、松散不良级配湿砂(含自由水) 152~183 0.28×106~0.34×106 3.00 湿的泥质黏土 213~274 0.41×106~0.57×106 2.75~3.00 砂质填土、回填土、潮湿黏土 300 0.50×106 2.75~3.00 密实的不良级配湿砂(含自由水) 305 0.50×106 2.75 潮湿黄土、粉土 300 0.63×106 2.75~3.00 地下水位以上的潮湿粉土 549 1.09×106 2.50 饱和土 550~1500 1.09×106~3.05×106 1.50~2.50 表 2 铺设泡沫混凝土分散层后结构层动态响应参数峰值衰减率

Table 2. Peak attenuation rate of dynamic response parameters of protection structure with foam concrete

工况 泡沫混凝土分散层 装药量/kg 结构层动态响应参数类型 峰值衰减率/% 数据来源 密度/(kg·m−3) 厚度/cm 1 450 6~10 44 压力峰值 79.1~89.9 文献[14] 2 475 3 0.014 54 文献[15] 3 610 15 0.2 48.9 文献[13] 4 788 20~120 306 23~28.8 文献[16] 5 799 5~15 − 20.1~40.5 文献[17] 6 788 40~120 − 加速度峰值 30.9~40.2 文献[18] 7 450 6~10 44 速度峰值 62.1~73.3 文献[14] 8 799 5~15 − 7.3~13.3 文献[17] 9 400 20 0.025~0.03 形变量峰值 66.7~83.7 文献[19] 10 475 2~4 0.014 11.9~23.9 文献[15] 11 799 15 − 8.3 文献[17] -

[1] 王年桥. 防护结构计算原理与设计 [M]. 南京: 中国人民解放军理工大学工程兵工程学院, 1998: 139–140.WANG N Q. Calculation principle of protective structure [M]. Nanjing: Engineering Institute of the Engineer Corps, PLA University of Science and Technology, 1998: 139–140. [2] ZHANG F L, POH L H, ZHANG M H. Resistance of cement-based materials against high-velocity small caliber deformable projectile impact [J]. International Journal of Impact Engineering, 2020, 144: 103629. DOI: 10.1016/j.ijimpeng.2020.103629. [3] SUN Y X, WANG X, JI C, et al. Experimental investigation on anti-penetration performance of polyurea-coated ASTM1045 steel plate subjected to projectile impact [J]. Defence Technology, 2021, 17(4): 1496–1513. DOI: 10.1016/j.dt.2020.08.005. [4] GURUPRASAD S, MUKHERJEE A. Layered sacrificial claddings under blast loading. Part I: analytical studies [J]. International Journal of Impact Engineering, 2000, 24(9): 957–973. DOI: 10.1016/S0734-743X(00)00004-X. [5] GURUPRASAD S, MUKHERJEE A. Layered sacrificial claddings under blast loading. Part Ⅱ: experimental studies [J]. International Journal of Impact Engineering, 2000, 24(9): 975–984. DOI: 10.1016/S0734-743X(00)00005-1. [6] 连志颖, 陆渝生, 邹同彬, 等. 用动光弹性法研究材料引入的分配层对应力波传播的影响 [J]. 实验力学, 2003, 18(4): 479–484. DOI: 10.3969/j.issn.1001-4888.2003.04.008.LIAN Z Y, LU Y S, ZOU T B, et al. A dynamic photoelastic analysis for the effect of different cushion layers on stress wave propagation in structure [J]. Journal of Experimental Mechanics, 2003, 18(4): 479–484. DOI: 10.3969/j.issn.1001-4888.2003.04.008. [7] ZHOU H Y, ZHAO Z Y, MA G W. Protection against blast load with cellular materials and structures [J]. International Journal of Aerospace and Lightweight Structures, 2012, 2(1): 53–76. DOI: 10.3850/S2010428612000220. [8] 钱七虎, 王明洋. 岩土中的冲击爆炸效应 [M]. 北京: 国防工业出版社, 2010: 1−43.QIAN Q H, WANG M Y. Impact and explosion effects in rock and soil [M]. Beijing: National Defense Industry Press, 2010: 1−43. [9] US Department of the Army. Fundamentals of protective design for conventional weapons: TM 5-855-1 [S]. Washington DC: US Department of the Army, 1986. [10] US Department of the Army. Structures to resist the effects of accidental explosions: TM5-1300 [S]. Washington: US Department of the Army, 1990. [11] 梁霍夫Г M. 岩土中爆炸动力学基础 [M]. 刘光寰, 王明洋, 译. 南京: 工程兵工程学院, 1993. [12] 刘飞, 任辉启, 王肖钧, 等. 典型分配层材料抗冲击性能对比研究 [J]. 防护工程, 2006, 28(5): 9–12.LIU F, REN H Q, WANG X J, et al. Comparative study on impact resistance of typical distribution layer materials [J]. Protective Engineering, 2006, 28(5): 9–12. [13] XUE Y L, TANG D G, LI Z Z, et al. A study on internal explosion testing of the “rigid-flexible-rigid” three-layer sealed structure [J]. Shock and Vibration, 2018, 2018: 1909872. DOI: 10.1155/2018/1909872. [14] ZHAO H L, YU H T, YUAN Y, et al. Blast mitigation effect of the foamed cement-base sacrificial cladding for tunnel structures [J]. Construction and Building Materials, 2015, 94: 710–718. DOI: 10.1016/j.conbuildmat.2015.07.076. [15] WANG X J, ZHANG X J, SONG L Y, et al. Mitigating confined blast response of buried steel box structure with foam concrete [J]. Thin-Walled Structures, 2021, 169: 108473. DOI: 10.1016/j.tws.2021.108473. [16] 袁英杰, 孙惠香, 陈卓. 爆炸荷载下泡沫混凝土减振层动力响应分析 [J]. 工程爆破, 2021, 27(4): 51–57. DOI: 10.19931/j.EB.20200167.YUAN Y J, SUN H X, CHEN Z. Analysis of dynamic response of foam concrete damping layer under explosive load [J]. Engineering Blasting, 2021, 27(4): 51–57. DOI: 10.19931/j.EB.20200167. [17] WANG G Y, DENG Z D, XU H L, et al. Application of foamed concrete backfill in improving antiexplosion performance of buried pipelines [J]. Journal of Materials in Civil Engineering, 2021, 33(4): 04021052. DOI: 10.1061/(ASCE)MT.1943-5533.0003630. [18] 李利莎, 谢清粮, 唐黎军, 等. 泡沫混凝土回填层减震性能影响因素分析 [J]. 爆破, 2015, 32(3): 166–171. DOI: 10.3963/j.issn.1001-487X.2015.03.030.LI L S, XIE Q L, TANG L J, et al. Influence factors of impact reduction performance of foamed concrete backfill layer [J]. Blasting, 2015, 32(3): 166–171. DOI: 10.3963/j.issn.1001-487X.2015.03.030. [19] TIAN X B, LI Q M, LU Z Y, et al. Experimental study of blast mitigation by foamed concrete [J]. International Journal of Protective Structures, 2016, 7(2): 179–192. DOI: 10.1177/2041419616633323. [20] 黄海健, 宫能平, 穆朝民, 等. 泡沫混凝土动态力学性能及本构关系 [J]. 建筑材料学报, 2020, 23(2): 466–472. DOI: 10.3969/j.issn.1007-9629.2020.02.033.HUANG H J, GONG N P, MU C M, et al. Dynamic mechanical properties and constitutive relation of foam concrete [J]. Journal of Building Materials, 2020, 23(2): 466–472. DOI: 10.3969/j.issn.1007-9629.2020.02.033. [21] BLANC L, SCHUNCK T, ECKENFELS D. Sacrificial cladding with brittle materials for blast protection [J]. Materials, 2021, 14(14): 3980. DOI: 10.3390/ma14143980. [22] 赵凯, 王肖钧, 刘飞, 等. 多孔材料中应力波的传播 [J]. 爆炸与冲击, 2011, 31(1): 107–112. DOI: 10.11883/1001-1455(2011)01-0107-06.ZHAO K, WANG X J, LIU F, et al. Propagation of stress wave in porous material [J]. Explosion and Shock Waves, 2011, 31(1): 107–112. DOI: 10.11883/1001-1455(2011)01-0107-06. [23] NIAN W M, SUBRAMANIAM K V L, ANDREOPOULOS Y. Experimental investigation on blast response of cellular concrete [J]. International Journal of Impact Engineering, 2016, 96: 105–115. DOI: 10.1016/j.ijimpeng.2016.05.021. [24] 赵武胜, 陈卫忠, 马少森, 等. 泡沫混凝土隧道减震层减震机制 [J]. 岩土力学, 2018, 39(3): 1027–1036. DOI: 10.16285/j.rsm.2016.0507.ZHAO W S, CHEN W Z, MA S S, et al. Isolation effect of foamed concrete layer on the seismic responses of tunnel [J]. Rock and Soil Mechanics, 2018, 39(3): 1027–1036. DOI: 10.16285/j.rsm.2016.0507. [25] WANG B, WANG P, CHEN Y S, et al. Blast responses of CFRP strengthened autoclaved aerated cellular concrete panels [J]. Construction and Building Materials, 2017, 157: 226–236. DOI: 10.1016/j.conbuildmat.2017.09.064. [26] CHEN Y S, WANG B, ZHANG B, et al. Polyurea coating for foamed concrete panel: an efficient way to resist explosion [J]. Defence Technology, 2020, 16(1): 136–149. DOI: 10.1016/j.dt.2019.06.010. [27] HAN B, XIANG T Y. Axial compressive stress-strain relation and Poisson effect of structural lightweight aggregate concrete [J]. Construction and Building Materials, 2017, 146: 338–343. DOI: 10.1016/j.conbuildmat.2017.04.101. [28] ABBAS A, ADIL M, AHMAD N, et al. Behavior of reinforced concrete sandwiched panels (RCSPs) under blast load [J]. Engineering Structures, 2019, 181: 476–490. DOI: 10.1016/j.engstruct.2018.12.051. [29] CUI C C, HUANG Q, LI D B, et al. Stress-strain relationship in axial compression for EPS concrete [J]. Construction and Building Materials, 2016, 105: 377–383. DOI: 10.1016/j.conbuildmat.2015.12.159. [30] BABU D S, BABU K G, TIONG-HUAN W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete [J]. Cement and Concrete Composites, 2006, 28(6): 520–527. DOI: 10.1016/j.cemconcomp.2006.02.018. [31] LIU N, CHEN B. Experimental study of the influence of EPS particle size on the mechanical properties of EPS lightweight concrete [J]. Construction and Building Materials, 2014, 68: 227–232. DOI: 10.1016/j.conbuildmat.2014.06.062. [32] BABU K G, BABU D S. Behaviour of lightweight expanded polystyrene concrete containing silica fume [J]. Cement and Concrete Research, 2003, 33(5): 755–762. DOI: 10.1016/S0008-8846(02)01055-4. [33] 胡俊. EPS混凝土力学性能及抗爆、抗震性能研究 [D]. 合肥: 中国科学技术大学, 2012.HU J. Research on mechanical properties and anti-explosion、seismic performance of EPS concrete [D]. Hefei: University of Science and Technology of China, 2012. [34] 白二雷, 许金余, 高志刚. 冲击荷载作用下EPS混凝土动态性能研究 [J]. 振动与冲击, 2012, 31(13): 53–57. DOI: 10.13465/j.cnki.jvs.2012.13.010.BAI E L, XU J Y, GAO Z G. Dynamic mechanical property of expanded polystyrene concrete under impact loading [J]. Journal of Vibration and Shock, 2012, 31(13): 53–57. DOI: 10.13465/j.cnki.jvs.2012.13.010. [35] LIU Y P, MA D P, JIANG Z Y, et al. Dynamic response of expanded polystyrene concrete during low speed impact [J]. Construction and Building Materials, 2016, 122: 72–80. DOI: 10.1016/j.conbuildmat.2016.06.059. [36] 巫绪涛, 胡俊, 谢思发. EPS混凝土的动态劈裂强度和能量耗散 [J]. 爆炸与冲击, 2013, 33(4): 369–374. DOI: 10.11883/1001-1455(2013)04-0369-06.WU X T, HU J, XIE S F. Dynamic splitting-tensile strength and energy dissipation property of EPS concrete [J]. Explosion and Shock Waves, 2013, 33(4): 369–374. DOI: 10.11883/1001-1455(2013)04-0369-06. [37] 石文博, 缪林昌, 王佳奇, 等. 循环荷载作用下不同配比EPS轻质混凝土阻尼比变化规律 [J]. 东南大学学报(自然科学版), 2016, 46(1): 179–183. DOI: 10.3969/j.issn.1001-0505.2016.01.029.SHI W B, MIAO L C, WANG J Q, et al. Damping behavior of lightweight expanded polystyrene concrete under dynamic cyclic loading [J]. Journal of Southeast University (Natural Science Edition), 2016, 46(1): 179–183. DOI: 10.3969/j.issn.1001-0505.2016.01.029. [38] COLANGELO F, ROVIELLO G, RICCIOTTI L, et al. Mechanical and thermal properties of lightweight geopolymer composites [J]. Cement and Concrete Composites, 2018, 86: 266–272. DOI: 10.1016/j.cemconcomp.2017.11.016. [39] 江水德, 任辉启, 赵大勇, 等. 空气夹层结构抗爆炸局部破坏设计方法 [J]. 防护工程, 2004, 26(1): 1–6.JIANG S D, REN H Q, ZHAO D Y, et al. Design method for anti-explosion local damage of air sandwich structure [J]. Protective Engineering, 2004, 26(1): 1–6. [40] YU X, CHEN L, FANG Q, et al. Blast mitigation effect of the layered concrete structure with an air gap: a numerical approach [J]. International Journal of Protective Structures, 2018, 9(4): 432–460. DOI: 10.1177/2041419618766951. [41] 王新武, 卫明山, 丁巧爱, 等. 支撑式薄板夹层结构抗爆性能试验研究 [J]. 武汉理工大学学报, 2010, 32(9): 309–313. DOI: 10.3963/j.issn.1671-4431.2010.09.071.WANG X W, WEI M S, DING Q A, et al. Experimental study on thin plates sandwich structure with braced subjected to blast loads [J]. Journal of Wuhan University of Technology, 2010, 32(9): 309–313. DOI: 10.3963/j.issn.1671-4431.2010.09.071. [42] 颜海春, 艾德武, 袁正如, 等. 空气隔层成层式结构抗常规武器设计荷载分析 [J]. 地下空间与工程学报, 2012, 8(4): 802–806,856. DOI: 10.3969/j.issn.1673-0836.2012.04.025.YAN H C, AI D W, YUAN Z R, et al. On the load analysis of resistance to conventional weapons under the circumstances of air buffer application [J]. Chinese Journal of Underground Space and Engineering, 2012, 8(4): 802–806,856. DOI: 10.3969/j.issn.1673-0836.2012.04.025. [43] 方建辉, 刘元, 周兆鹏, 等. 遮弹板不贯穿情况下爆炸冲击波在空气分散层中的传播规律研究 [J]. 防护工程, 2012, 34(2): 14–19.FANG J H, LIU Y, ZHOU Z P, et al. Experimental research on propagation rule of the explosive shock wave in air dispersion layer with burster layer not perforated [J]. Protective Engineering, 2012, 34(2): 14–19. [44] 颜海春, 方秦, 范俊余, 等. 成层式结构中顶板上常规武器爆炸动荷载的数值分析 [J]. 防护工程, 2007, 29(1): 40–44.YAN H C, FANG Q, FAN J Y, et al. Numerical analysis of dynamic loads of conventional weapons on top slabs in multilayer structures [J]. Protective Engineering, 2007, 29(1): 40–44. [45] 黄旭. 增加缓冲层的人防工程成层式防护结构抗冲击性能研究 [D]. 南京: 东南大学, 2019. DOI: 10.27014/d.cnki.gdnau.2019.001422.HUANG X. Study on impact resistance of layered protection structure for civil air defense engineering with buffer layer [D]. Nanjing: Southeast University, 2019. DOI: 10.27014/d.cnki.gdnau.2019.001422. [46] 李永池, 姚磊, 沈俊, 等. 空穴的绕射隔离效应和对后方应力波的削弱作用 [J]. 爆炸与冲击, 2005, 25(3): 193–199. DOI: 10.11883/1001-1455(2005)03-0193-07.LI Y C, YAO L, SHEN J, et al. Insulation effect of the cavity on stress wave [J]. Explosion and Shock Waves, 2005, 25(3): 193–199. DOI: 10.11883/1001-1455(2005)03-0193-07. [47] 穆朝民, 齐娟. 地下防护层中空穴形状对爆炸波衰减作用的影响 [J]. 岩土力学, 2011, 32(12): 3773–3779. DOI: 10.3969/j.issn.1000-7598.2011.12.039.MU C M, QI J. Attenuation effects of cavity shape on blast wave in underground defense layer [J]. Rock and Soil Mechanics, 2011, 32(12): 3773–3779. DOI: 10.3969/j.issn.1000-7598.2011.12.039. [48] WANG Z L, WANG J G, LI Y C, et al. Attenuation effect of artificial cavity on air-blast waves in an intelligent defense layer [J]. Computers and Geotechnics, 2006, 33(2): 132–141. DOI: 10.1016/j.compgeo.2006.02.002. [49] LI X Y, LI Y C, ZHAO K, et al. Mechanical properties of sialic foamed ceramic and applications in defense structure [J]. Chinese Physics Letters, 2014, 31(8): 086201. DOI: 10.1088/0256-307X/31/8/086201. [50] 任新见, 张庆明, 刘瑞朝. 成层式结构泡沫空心球分配层抗爆性能试验研究 [J]. 振动与冲击, 2015, 34(21): 100–104. DOI: 10.13465/j.cnki.jvs.2015.21.018.REN X J, ZHANG Q M, LIU R C. Tests for anti-blast performance of layered structures with hollow foam spheres as distribution layers [J]. Journal of Vibration and Shock, 2015, 34(21): 100–104. DOI: 10.13465/j.cnki.jvs.2015.21.018. [51] 赵凯, 罗文超, 王肖钧. 粘土质泡沫陶瓷力学性能实验研究 [J]. 振动与冲击, 2012, 31(21): 50–53,67. DOI: 10.3969/j.issn.1000-3835.2012.21.011.ZHAO K, LUO W C, WANG X J. Tests for mechanical behavior of clay ceramic foam [J]. Journal of Vibration and Shock, 2012, 31(21): 50–53,67. DOI: 10.3969/j.issn.1000-3835.2012.21.011. [52] 孙晓旺, 李永池, 叶中豹, 等. 新型空壳颗粒材料在人防工程中应用的实验研究 [J]. 爆炸与冲击, 2017, 37(4): 643–648. DOI: 10.11883/1001-1455(2017)04-0643-06.SUN X W, LI Y C, YE Z B, et al. Experimental study of a novel shelly cellular material used in civil defense engineering [J]. Explosion and Shock Waves, 2017, 37(4): 643–648. DOI: 10.11883/1001-1455(2017)04-0643-06. [53] 张春晓, 何翔, 刘国权, 等. 泡沫陶瓷球壳与高黏弹沥青热压复合板材研制及其抗爆性能试验研究 [J]. 工程力学, 2017, 34(S1): 320–325. DOI: 10.6052/j.issn.1000-4750.2016.03.S029.ZHANG C X, HE X, LIU G Q, et al. The development of ceramic foam spherical shell with high viscoelastic asphalt hot pressing composite plate and research on antiknock performance test [J]. Engineering Mechanics, 2017, 34(S1): 320–325. DOI: 10.6052/j.issn.1000-4750.2016.03.S029. [54] SEVIN E. Ground shock isolation of buried structures: AFSWC-TR-59-47 [R]. New Mexico: Air Force Special Weapons Center, Kirtland Air Force Base, 1959. [55] 徐畅, 崔传安, 王在晖. 聚氨酯泡沫分配层在成层式防护层中的数值模拟 [J]. 防护工程, 2016, 38(6): 44–47.XU C, CUI C A, WANG Z H. Numerical simulation of the polyurethane foam distribution layer in the multilayer protective layer [J]. Protective Engineering, 2016, 38(6): 44–47. [56] MAZEK S A, MOSTAFA A A. Impact of a shock wave on a structure strengthened by rigid polyurethane foam [J]. Structural Engineering and Mechanics, 2013, 48(4): 569–585. DOI: 10.12989/sem.2013.48.4.569. [57] DE A, MORGANTE A N, ZIMMIE T F. Numerical and physical modeling of geofoam barriers as protection against effects of surface blast on underground tunnels [J]. Geotextiles and Geomembranes, 2016, 44(1): 1–12. DOI: 10.1016/j.geotexmem.2015.06.008. [58] 陈网桦, 冯伟, 彭金华, 等. 空气及半硬质聚氨酯泡沫塑料中爆炸波传播特性的研究 [J]. 火炸药学报, 2001, 24(4): 41–42,45. DOI: 10.3969/j.issn.1007-7812.2001.04.020.CHEN W H, FENG W, PENG J H, et al. Experimental investigation of propagation properties of blast waves in air and in semi-rigid polyurethane foam [J]. Chinese Journal of Explosives & Propellants, 2001, 24(4): 41–42,45. DOI: 10.3969/j.issn.1007-7812.2001.04.020. [59] MOSTAFA H E, EL-DAKHAKHNI W W, MEKKY W F. Use of reinforced rigid polyurethane foam for blast hazard mitigation [J]. Journal of Reinforced Plastics and Composites, 2010, 29(20): 3048–3057. DOI: 10.1177/0731684410363184. [60] CODINA R, AMBROSINI D, DE BORBÓN F. Alternatives to prevent the failure of RC members under close-in blast loadings [J]. Engineering Failure Analysis, 2016, 60: 96–106. DOI: 10.1016/j.engfailanal.2015.11.038. [61] SHERWOOD B S. Underground explosion test [J]. The Military Engineer, 1951, 43(294): 268–275. [62] VAILE JR R B. Isolation of structures from ground shock: operation plumbbob: WT-1424 [R]. Menlo Park: Stanford Research Institute, 1957. [63] ZHANG B, NIAN X Z, JIN F N, et al. Failure analyses of flexible ultra-high molecular weight polyethylene (UHMWPE) fiber reinforced anti-blast wall under explosion [J]. Composite Structures, 2018, 184: 759–774. DOI: 10.1016/j.compstruct.2017.10.037. [64] CHEN Y, CHEN F, DU Z P, et al. Protective effect of polymer coating on the circular steel plate response to near-field underwater explosions [J]. Marine Structures, 2015, 40: 247–266. DOI: 10.1016/j.marstruc.2014.11.005. [65] CHEN Y, ZHANG Z Y, WANG Y, et al. Crush dynamics of square honeycomb thin rubber wall [J]. Thin-Walled Structures, 2009, 47(12): 1447–1456. DOI: 10.1016/j.tws.2009.07.007. [66] CHEN Y, TONG Z P, HUA H X, et al. Experimental investigation on the dynamic response of scaled ship model with rubber sandwich coatings subjected to underwater explosion [J]. International Journal of Impact Engineering, 2009, 36(2): 318–328. DOI: 10.1016/j.ijimpeng.2007.12.015. [67] CHEN Y, WANG Y, ZHANG Z Y, et al. Experimental research on the responses of neoprene coated cylinder subjected to underwater explosions [J]. Journal of Offshore Mechanics and Arctic Engineering, 2013, 135(1): 011102. DOI: 10.1115/1.4006761. [68] 金泽宇. 抗冲覆盖层水下爆炸计算方法研究 [D]. 上海: 上海交通大学, 2017.JIN Z Y. Computational method study on shock mitigation coatings subjected to underwater explosion [D]. Shanghai: Shanghai Jiaotong University, 2017. [69] 梅松华, 盛谦, 崔臻, 等. 黏弹性阻尼减震层的吸能特性试验研究 [J]. 岩土工程学报, 2022, 44(6): 997–1005. DOI: 10.11779/CJGE202206003.MEI S H, SHENG Q, CUI Z, et al. Experimental study on energy absorption property of viscoelasticity damping layer [J]. Chinese Journal of Geotechnical Engineering, 2022, 44(6): 997–1005. DOI: 10.11779/CJGE202206003. [70] 高光发, 李永池, 赵凯, 等. 柱壳结构的弥散效应及对应力波的削弱作用 [J]. 振动与冲击, 2011, 30(12): 195–200. DOI: 10.3969/j.issn.1000-3835.2011.12.038.GAO G F, LI Y C, ZHAO K, et al. Dispersion and attenuation effects on stress waves in defense layer with cylindrical shell embedded [J]. Journal of Vibration and Shock, 2011, 30(12): 195–200. DOI: 10.3969/j.issn.1000-3835.2011.12.038. [71] 杨旭东, 许佳丽, 邹田春, 等. 泡沫铝填充金属薄壁管复合结构的研究进展 [J]. 材料导报, 2019, 33(21): 3637–3643. DOI: 10.11896/cldb.18080101.YANG X D, XU J L, ZOU T C, et al. Advances in the composite structure of aluminum foam filled metal thin-walled tube [J]. Materials Reports, 2019, 33(21): 3637–3643. DOI: 10.11896/cldb.18080101. [72] KARAGIOZOVA D, JONES N. On the mechanics of the global bending collapse of circular tubes under dynamic axial load: dynamic buckling transition [J]. International Journal of Impact Engineering, 2008, 35(5): 397–424. DOI: 10.1016/j.ijimpeng.2007.04.002. [73] 吴明泽, 张晓伟, 张庆明. 材料和内边界约束对薄壁圆管轴向压缩吸能特性的影响研究 [J]. 应用力学学报, 2020, 37(4): 1415–1421. DOI: 10.11776/cjam.37.04.D037.WU M Z, ZHANG X W, ZHANG Q M. Effects of material properties and inner-constraints on the energy absorption of thin-walled circular tube under axial compression [J]. Chinese Journal of Applied Mechanics, 2020, 37(4): 1415–1421. DOI: 10.11776/cjam.37.04.D037. [74] GUILLOW S R, LU G, GRZEBIETA R H. Quasi-static axial compression of thin-walled circular aluminium tubes [J]. International Journal of Mechanical Sciences, 2001, 43(9): 2103–2123. DOI: 10.1016/S0020-7403(01)00031-5. [75] WU S Y, LI G Y, SUN G Y, et al. Crashworthiness analysis and optimization of sinusoidal corrugation tube [J]. Thin-Walled Structures, 2016, 105: 121–134. DOI: 10.1016/j.tws.2016.03.029. [76] SALEHGHAFFARI S, TAJDARI M, PANAHI M, et al. Attempts to improve energy absorption characteristics of circular metal tubes subjected to axial loading [J]. Thin-Walled Structures, 2010, 48(6): 379–390. DOI: 10.1016/j.tws.2010.01.012. [77] 高光发, 李永池, 黄瑞源, 等. 平面冲击载荷下不同形式含柱壳结构的防护性能 [J]. 土木建筑与环境工程, 2012, 34(1): 7–11,28. DOI: 10.11835/j.issn.1674-4764.2012.01.003.GAO G F, LI Y C, HUANG R Y, et al. Protection performance of the various structures with cylindrical shells under plane impact loadings [J]. Journal of Civil and Environmental Engineering, 2012, 34(1): 7–11,28. DOI: 10.11835/j.issn.1674-4764.2012.01.003. [78] ASHBY M F, EVANS T, FLECK N A, et al. Metal foams: a design guide [M]. Oxford: Butterworth-Heinemann, 2000: 119. [79] HANSSEN A G, ENSTOCK L, LANGSETH M. Close-range blast loading of aluminium foam panels [J]. International Journal of Impact Engineering, 2002, 27(6): 593–618. DOI: 10.1016/S0734-743X(01)00155-5. [80] 余同希, 卢国兴, 张雄. 能量吸收: 结构与材料的力学行为和塑性分析 [M]. 北京: 科学出版社, 2019: 240−243.YU T X, LU G X, ZHANG X. Energy absorption: mechanical behavior and plasticity analysis of structures and materials [M]. Beijing: Science Press, 2019: 240−243. [81] 王永刚, 胡时胜, 王礼立. 爆炸荷载下泡沫铝材料中冲击波衰减特性的实验和数值模拟研究 [J]. 爆炸与冲击, 2003, 23(6): 516–522.WANG Y G, HU S S, WANG L L. Shock attenuation in aluminum foams under explosion loading [J]. Explosion and Shock Waves, 2003, 23(6): 516–522. [82] 程和法, 黄笑梅, 薛国宪, 等. 冲击波在泡沫铝中的传播和衰减特性 [J]. 材料科学与工程学报, 2004, 22(1): 78–81. DOI: 10.3969/j.issn.1673-2812.2004.01.021.CHENG H F, HUANG X M, XUE G X, et al. Propagation and attenuation characteristic of shock wave in aluminum foam [J]. Journal of Materials Science & Engineering, 2004, 22(1): 78–81. DOI: 10.3969/j.issn.1673-2812.2004.01.021. [83] XIA Y, WU C Q, LI Z X. Optimized design of foam cladding for protection of reinforced concrete members under blast loading [J]. Journal of Structural Engineering, 2015, 141(9): 06014010. DOI: 10.1061/(asce)st.1943-541x.0001190. [84] WU C Q, SHEIKH H. A finite element modelling to investigate the mitigation of blast effects on reinforced concrete panel using foam cladding [J]. International Journal of Impact Engineering, 2013, 55: 24–33. DOI: 10.1016/j.ijimpeng.2012.11.006. [85] KOSTOPOULOS V, KALIMERIS G D, GIANNAROS E. Blast protection of steel reinforced concrete structures using composite foam-core sacrificial cladding [J]. Composites Science and Technology, 2022: 109330 [2022-02-13]. DOI: 10.1016/j.compscitech.2022.109330. [86] XIA Y, WU C Q, ZHANG F R, et al. Numerical analysis of foam-protected RC members under blast loads [J]. International Journal of Protective Structures, 2014, 5(4): 367–390. DOI: 10.1260/2041-4196.5.4.367. [87] WU C Q, ZHOU Y. Simplified analysis of foam cladding protected reinforced concrete slabs against blast loadings [J]. International Journal of Protective Structures, 2011, 2(3): 351–365. DOI: 10.1260/2041-4196.2.3.351. [88] 高海莹, 刘中宪, 杨烨凯, 等. 泡沫铝防护钢筋混凝土板的抗爆性能 [J]. 爆炸与冲击, 2019, 39(2): 023101. DOI: 10.11883/bzycj-2018-0284.GAO H Y, LIU Z X, YANG Y K, et al. Blast-resistant performance of aluminum foam-protected reinforced concrete slabs [J]. Explosion and Shock Waves, 2019, 39(2): 023101. DOI: 10.11883/bzycj-2018-0284. [89] LI Z Q, ZHANG J J, FAN J H, et al. On crushing response of the three-dimensional closed-cell foam based on Voronoi model [J]. Mechanics of Materials, 2014, 68: 85–94. DOI: 10.1016/j.mechmat.2013.08.009. [90] MA G W, YE Z Q. Analysis of foam claddings for blast alleviation [J]. International Journal of Impact Engineering, 2007, 34(1): 60–70. DOI: 10.1016/j.ijimpeng.2005.10.005. [91] ZHAO S Y, SIQUEIRA G, DRDOVA S, et al. Additive manufacturing of silica aerogels [J]. Nature, 2020, 584(7821): 387–392. DOI: 10.1038/s41586-020-2594-0. [92] KATTI A, SHIMPI N, ROY S, et al. Chemical, physical, and mechanical characterization of isocyanate cross-linked amine-modified silica aerogels [J]. Chemistry of Materials, 2006, 18(2): 285–296. DOI: 10.1021/cm0513841. [93] LUO H, CHURU G, FABRIZIO E F, et al. Synthesis and characterization of the physical, chemical and mechanical properties of isocyanate-crosslinked vanadia aerogels [J]. Journal of Sol-Gel Science and Technology, 2008, 48(1): 113–134. DOI: 10.1007/s10971-008-1788-y. [94] 杨杰, 李树奎, 闫丽丽, 等. 二氧化硅气凝胶的防爆震性能及机理研究 [J]. 物理学报, 2010, 59(12): 8934–8940. DOI: 10.7498/aps.59.8934.YANG J, LI S K, YAN L L, et al. Protective performance and protective mechanism of SiO2 aerogel under explosive loading [J]. Acta Physica Sinica, 2010, 59(12): 8934–8940. DOI: 10.7498/aps.59.8934. [95] 杨杰, 李树奎, 王富耻. 以气凝胶为夹层的复合结构抗弹性能研究 [J]. 兵工学报, 2012, 33(8): 921–926.YANG J, LI S K, WANG F C. Research on the anti-bullet performance of composite structure with aerogel interlayer [J]. Acta Armamentarii, 2012, 33(8): 921–926. [96] 王礼立. 应力波基础 [M]. 2版. 北京: 国防工业出版社, 2005.WANG L L. Foundation of stress waves [M]. 2nd ed. Beijing: National Defense Industry Press, 2005. [97] RANDALL J P, MEADOR M A B, JANA S C. Tailoring mechanical properties of aerogels for aerospace applications [J]. Acs Applied Materials & Interfaces, 2011, 3(3): 613–626. DOI: 10.1021/am200007n. [98] 李砚召, 王肖钧, 吴祥云, 等. 分配层分层结构对核爆炸荷载的防护效果试验研究 [J]. 中国科学技术大学学报, 2009, 39(9): 931–935.LI Y Z, WANG X J, WU X Y, et al. Test study on layered structure’s defense effect of distribution layer against nuclear explosive loadings [J]. Journal of University of Science and Technology of China, 2009, 39(9): 931–935. [99] 王超申, 康道辉, 游世辉, 等. 爆炸载荷下地下巷道分配层结构的对比分析 [J]. 计算力学学报, 2020, 37(3): 377–383. DOI: 10.7511/jslx20190506001.WANG C S, KANG D H, YOU S H, et al. Comparative analysis of distribution layer structure of underground tunnels under explosive loading [J]. Chinese Journal of Computational Mechanics, 2020, 37(3): 377–383. DOI: 10.7511/jslx20190506001. [100] 张勇. 聚氨酯泡沫铝复合结构抗爆吸能试验及数值模拟分析 [J]. 爆炸与冲击, 2022, 42(4): 045101. DOI: 10.11883/bzycj-2021-0182.ZHANG Y. Testing and numerical simulation of the antiknock energy absorption of polyurethane foam aluminum composite structure [J]. Explosion and Shock Waves, 2022, 42(4): 045101. DOI: 10.11883/bzycj-2021-0182. [101] 毛勇建, 李玉龙. 杆中嵌入薄板的应力波传播行为 [J]. 固体力学学报, 2008, 29(3): 239–244. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2008.03.004.MAO Y J, LI Y L. Stress wave propagation through a thin plate sandwiched between two bars [J]. Chinese Journal of Solid Mechanics, 2008, 29(3): 239–244. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2008.03.004. [102] MAHBOD M, ASGARI M. Energy absorption analysis of a novel foam-filled corrugated composite tube under axial and oblique loadings [J]. Thin-Walled Structures, 2018, 129: 58–73. DOI: 10.1016/j.tws.2018.03.023. [103] LI G Y, ZHANG Z S, SUN G Y, et al. Crushing analysis and multiobjective optimization for functionally graded foam-filled tubes under multiple load cases [J]. International Journal of Mechanical Sciences, 2014, 89: 439–452. DOI: 10.1016/j.ijmecsci.2014.10.001. [104] HANSSEN A G, LANGSETH M, HOPPERSTAD O S. Static and dynamic crushing of square aluminium extrusions with aluminium foam filler [J]. International Journal of Impact Engineering, 2000, 24(4): 347–383. DOI: 10.1016/S0734-743X(99)00169-4. [105] ELAHI S A, ROUZEGAR J, NIKNEJAD A, et al. Theoretical study of absorbed energy by empty and foam-filled composite tubes under lateral compression [J]. Thin-Walled Structures, 2017, 114: 1–10. DOI: 10.1016/j.tws.2017.01.029. [106] DARVIZEH A, DARVIZEH M, ANSARI R, et al. Effect of low density, low strength polyurethane foam on the energy absorption characteristics of circumferentially grooved thick-walled circular tubes [J]. Thin-Walled Structures, 2013, 71: 81–90. DOI: 10.1016/j.tws.2013.04.014. [107] TOKSOY A K, GÜDEN M. Partial Al foam filling of commercial 1050H14 Al crash boxes: the effect of box column thickness and foam relative density on energy absorption [J]. Thin-Walled Structures, 2010, 48(7): 482–494. DOI: 10.1016/j.tws.2010.02.002. [108] IMBALZANO G, LINFORTH S, NGO T D, et al. Blast resistance of auxetic and honeycomb sandwich panels: comparisons and parametric designs [J]. Composite Structures, 2018, 183: 242–261. DOI: 10.1016/j.compstruct.2017.03.018. [109] ZHU F, WANG Z H, LU G X, et al. Analytical investigation and optimal design of sandwich panels subjected to shock loading [J]. Materials & Design, 2009, 30(1): 91–100. DOI: 10.1016/j.matdes.2008.04.027. [110] FLECK N A, DESHPANDE V S. The resistance of clamped sandwich beams to shock loading [J]. Journal of Applied Mechanics, 2004, 71(3): 386–401. DOI: 10.1115/1.1629109. [111] LI Y, REN X B, ZHANG X Q, et al. Deformation and failure modes of aluminum foam-cored sandwich plates under air-blast loading [J]. Composite Structures, 2021, 258: 113317. DOI: 10.1016/j.compstruct.2020.113317. [112] HOU S J, SHU C F, ZHAO S Y, et al. Experimental and numerical studies on multi-layered corrugated sandwich panels under crushing loading [J]. Composite Structures, 2015, 126: 371–385. DOI: 10.1016/j.compstruct.2015.02.039. [113] CHEN D, JING L, YANG F. Optimal design of sandwich panels with layered-gradient aluminum foam cores under air-blast loading [J]. Composites Part B:Engineering, 2019, 166: 169–186. DOI: 10.1016/j.compositesb.2018.11.125. [114] 李勇, 程远胜, 张攀, 等. 空中爆炸载荷下梯度波纹夹层板抗爆性能仿真研究 [J]. 兵工学报, 2017, 38(6): 1131–1139. DOI: 10.3969/j.issn.1000-1093.2017.06.012.LI Y, CHENG Y S, ZHANG P, et al. Numerical research on blast-resistant performance of graded corrugated sandwich plates under air blast loading [J]. Acta Armamentarii, 2017, 38(6): 1131–1139. DOI: 10.3969/j.issn.1000-1093.2017.06.012. [115] LI Z J, CHEN W S, HAO H. Blast mitigation performance of cladding using square dome-shape kirigami folded structure as core [J]. International Journal of Mechanical Sciences, 2018, 145: 83–95. DOI: 10.1016/j.ijmecsci.2018.06.035. [116] CHEN G C, CHENG Y S, ZHANG P, et al. Blast resistance of metallic double arrowhead honeycomb sandwich panels with different core configurations under the paper tube-guided air blast loading [J]. International Journal of Mechanical Sciences, 2021, 201: 106457. DOI: 10.1016/j.ijmecsci.2021.106457. [117] XU F X, ZHANG X, ZHANG H. A review on functionally graded structures and materials for energy absorption [J]. Engineering Structures, 2018, 171: 309–325. DOI: 10.1016/j.engstruct.2018.05.094. [118] HOU S J, HAN X, SUN G Y, et al. Multiobjective optimization for tapered circular tubes [J]. Thin-Walled Structures, 2011, 49(7): 855–863. DOI: 10.1016/j.tws.2011.02.010. [119] ZHANG X, ZHANG H, WANG Z. Bending collapse of square tubes with variable thickness [J]. International Journal of Mechanical Sciences, 2016, 106: 107–116. DOI: 10.1016/j.ijmecsci.2015.12.006. [120] LAKES R. Materials with structural hierarchy [J]. Nature, 1993, 361(6412): 511–515. DOI: 10.1038/361511a0. [121] MA G W, YE Z Q. Energy absorption of double-layer foam cladding for blast alleviation [J]. International Journal of Impact Engineering, 2007, 34(2): 329–347. DOI: 10.1016/j.ijimpeng.2005.07.012. [122] 张鹏飞, 刘志芳, 李世强. 内爆炸载荷下梯度泡沫铝夹芯管的动态响应 [J]. 爆炸与冲击, 2020, 40(7): 071402. DOI: 10.11883/bzycj-2019-0418.ZHANG P F, LIU Z F, LI S Q. Dynamic response of sandwich tubes with graded foam aluminum cores under internal blast loading [J]. Explosion and Shock Waves, 2020, 40(7): 071402. DOI: 10.11883/bzycj-2019-0418. [123] ZHOU J, GUAN Z W, CANTWELL W J. The impact response of graded foam sandwich structures [J]. Composite Structures, 2013, 97: 370–377. DOI: 10.1016/j.compstruct.2012.10.037. [124] WANG E H, GARDNER N, SHUKLA A. The blast resistance of sandwich composites with stepwise graded cores [J]. International Journal of Solids and Structures, 2009, 46(18/19): 3492–3502. DOI: 10.1016/j.ijsolstr.2009.06.004. [125] LIANG M Z, LI Z B, LU F Y, et al. Theoretical and numerical investigation of blast responses of continuous-density graded cellular materials [J]. Composite Structures, 2017, 164: 170–179. DOI: 10.1016/j.compstruct.2016.12.065. [126] LAN X K, FENG S S, HUANG Q, et al. Blast response of continuous-density graded cellular material based on the 3D Voronoi model [J]. Defence Technology, 2018, 14(5): 433–440. DOI: 10.1016/j.dt.2018.06.003. [127] 蔡正宇, 丁圆圆, 王士龙, 等. 梯度多胞牺牲层的抗爆炸分析 [J]. 爆炸与冲击, 2017, 37(3): 396–404. DOI: 10.11883/1001-1455(2017)03-0396-09.CAI Z Y, DING Y Y, WANG S L, et al. Anti-blast analysis of graded cellular sacrificial cladding [J]. Explosion and Shock Waves, 2017, 37(3): 396–404. DOI: 10.11883/1001-1455(2017)03-0396-09. [128] 周宏元, 贾昆程, 王小娟, 等. 负泊松比三明治结构填充泡沫混凝土的面内压缩性能 [J]. 复合材料学报, 2020, 37(8): 2005–2014. DOI: 10.13801/j.cnki.fhclxb.20191207.001.ZHOU H Y, JIA K C, WANG X J, et al. In-plane compression properties of negative Poisson's ratio sandwich structure filled with foam concrete [J]. Acta Materiae Compositae Sinica, 2020, 37(8): 2005–2014. DOI: 10.13801/j.cnki.fhclxb.20191207.001. [129] 杨德庆, 吴秉鸿, 张相闻. 星型负泊松比超材料防护结构抗爆抗冲击性能研究 [J]. 爆炸与冲击, 2019, 39(6): 065102. DOI: 10.11883/bzycj-2018-0060.YANG D Q, WU B H, ZHANG X W. Anti-explosion and shock resistance performance of sandwich defensive structure with star-shaped auxetic material core [J]. Explosion and Shock Waves, 2019, 39(6): 065102. DOI: 10.11883/bzycj-2018-0060. [130] QI C, REMENNIKOV A, PEI L Z, et al. Impact and close-in blast response of auxetic honeycomb-cored sandwich panels: experimental tests and numerical simulations [J]. Composite Structures, 2017, 180: 161–178. DOI: 10.1016/j.compstruct.2017.08.020. [131] KEARSLEY E P, WAINWRIGHT P J. The effect of porosity on the strength of foamed concrete [J]. Cement and Concrete Research, 2002, 32(2): 233–239. DOI: 10.1016/S0008-8846(01)00665-2. [132] 刘飞, 王辉明, 晏麓晖, 等. 炸弹邻近爆炸对浅埋结构人防工程的毁伤效应 [J]. 兵工学报, 2021, 42(3): 625–632. DOI: 10.3969/j.issn.1000-1093.2021.03.019.LIU F, WANG H M, YAN L H, et al. Damage effect of shallow buried civil air defense engineering structures under nearby blast loading [J]. Acta Armamentarii, 2021, 42(3): 625–632. DOI: 10.3969/j.issn.1000-1093.2021.03.019. [133] ICHINO H, BEPPU M, WILLIAMSON E B, et al. Effects of EPS density on blast mitigation performance in underground protective structures [J]. International Journal of Impact Engineering, 2022, 164: 104189. DOI: 10.1016/j.ijimpeng.2022.104189. [134] 柳厚祥, 郑智雄. 高地应力软岩公路隧道泡沫混凝土卸压机理及支护结构研究 [J]. 中国公路学报, 2016, 29(11): 122–129. DOI: 10.3969/j.issn.1001-7372.2016.11.016.LIU H X, ZHENG Z X. Research on mechanism of pressure relief and supporting structure of foam concrete in high geostress soft rock highway tunnel [J]. China Journal of Highway and Transport, 2016, 29(11): 122–129. DOI: 10.3969/j.issn.1001-7372.2016.11.016. [135] JALAL M D, TANVEER A, JAGDEESH K, et al. Foam concrete [J]. International Journal of Civil Engineering Research, 2017, 8(1): 1–14. [136] SARI K A M, SANI A R M. Applications of foamed lightweight concrete [J]. MATEC Web of Conferences, 2017, 97: 01097. DOI: 10.1051/matecconf/20179701097. [137] NARAYANAN N, RAMAMURTHY K. Structure and properties of aerated concrete: a review [J]. Cement and Concrete Composites, 2000, 22(5): 321–329. DOI: 10.1016/S0958-9465(00)00016-0. [138] TIKALSKY P J, POSPISIL J, MACDONALD W. A method for assessment of the freeze-thaw resistance of preformed foam cellular concrete [J]. Cement and Concrete Research, 2004, 34(5): 889–893. DOI: 10.1016/j.cemconres.2003.11.005. [139] LONG W W, WANG J S. Study on compressive strength and moisture content of different grades density of foam concrete [C]//Proceedings of the 2015 International Conference on Material Science and Applications. Atlantis Press. 2014: 167−172. [140] FALLIANO D, De DOMENICO D, RICCIARDI G, et al. Experimental investigation on the compressive strength of foamed concrete: effect of curing conditions, cement type, foaming agent and dry density [J]. Construction and Building Materials, 2018, 165: 735–749. DOI: 10.1016/j.conbuildmat.2017.12.241. [141] 马立秋. 爆炸荷载下城市浅埋隧道动力离心模型试验和数值研究 [D]. 北京: 清华大学, 2010.MA L Q. Centrifugal modeling and numerical research for urban shallow-buried tunnel under blasting [D]. Beijing: Tsinghua University, 2010. [142] 李永池. 波动力学 [M]. 合肥: 中国科学技术大学出版社, 2015.LI Y C. Wave mechanics [M]. Hefei: Press of University of Science and Technology of China, 2015. [143] LI Q M, MENG H. Attenuation or enhancement - a one-dimensional analysis on shock transmission in the solid phase of a cellular material [J]. International Journal of Impact Engineering, 2002, 27(10): 1049–1065. DOI: 10.1016/S0734-743X(02)00016-7. [144] CRAWFORD R E, HIGGINS C J, BULTMANN E H. The air force manual for design and analysis of hardened structures [M]. Washington: Air Force Weapons Laboratory, 1987: 341−346. [145] DING Y Y, WANG S L, ZHAO K, et al. Blast alleviation of cellular sacrificial cladding: a nonlinear plastic shock model [J]. International Journal of Applied Mechanics, 2016, 8(4): 1650057. DOI: 10.1142/S1758825116500575. [146] 穆朝民, 任辉启, 李永池, 等. 爆炸波在高饱和度饱和土中传播规律的研究 [J]. 岩土力学, 2010, 31(3): 875–880. DOI: 10.16285/j.rsm.2010.03.051.MU C M, REN H Q, LI Y C, et al. Propagation laws of blast wave in saturated soils with high saturation degree [J]. Rock and Soil Mechanics, 2010, 31(3): 875–880. DOI: 10.16285/j.rsm.2010.03.051. [147] WANG Z L, LI Y C. Further study on effect of concrete defense layer on evolution mechanism of stress-waves [J]. Theoretical and Applied Fracture Mechanics, 2007, 47(1): 15–25. DOI: 10.1016/j.tafmec.2006.10.002. [148] NIA A A, HAMEDANI J H. Comparative analysis of energy absorption and deformations of thin walled tubes with various section geometries [J]. Thin-Walled Structures, 2010, 48(12): 946–954. DOI: 10.1016/j.tws.2010.07.003. [149] 王展光, 徐玉红, 何德坪. 球形孔泡沫纯铝准静态压缩性能 [J]. 兵器材料科学与工程, 2008, 31(4): 15–19. DOI: 10.3969/j.issn.1004-244X.2008.04.004.WANG Z G, XU Y H, HE D P. Quasi-static compressive property of spherical pores Al foam [J]. Ordnance Material Science and Engineering, 2008, 31(4): 15–19. DOI: 10.3969/j.issn.1004-244X.2008.04.004. [150] ZHANG J X, QIN Q H, WANG T J. Compressive strengths and dynamic response of corrugated metal sandwich plates with unfilled and foam-filled sinusoidal plate cores [J]. Acta Mechanica, 2013, 224(4): 759–775. DOI: 10.1007/s00707-012-0770-5. [151] LI Z X, MA W, YAO S G, et al. Crashworthiness performance of corrugation- reinforced multicell tubular structures [J]. International Journal of Mechanical Sciences, 2021, 190: 106038. DOI: 10.1016/j.ijmecsci.2020.106038. -

下载:

下载: