Investigation of combustion characteristics of a new aluminum-containing propellant based on optical diagnosis

-

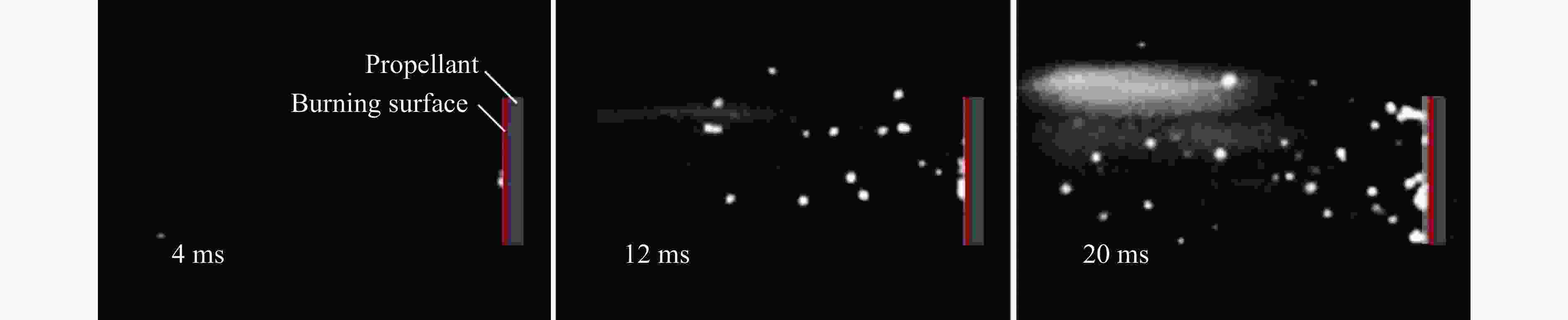

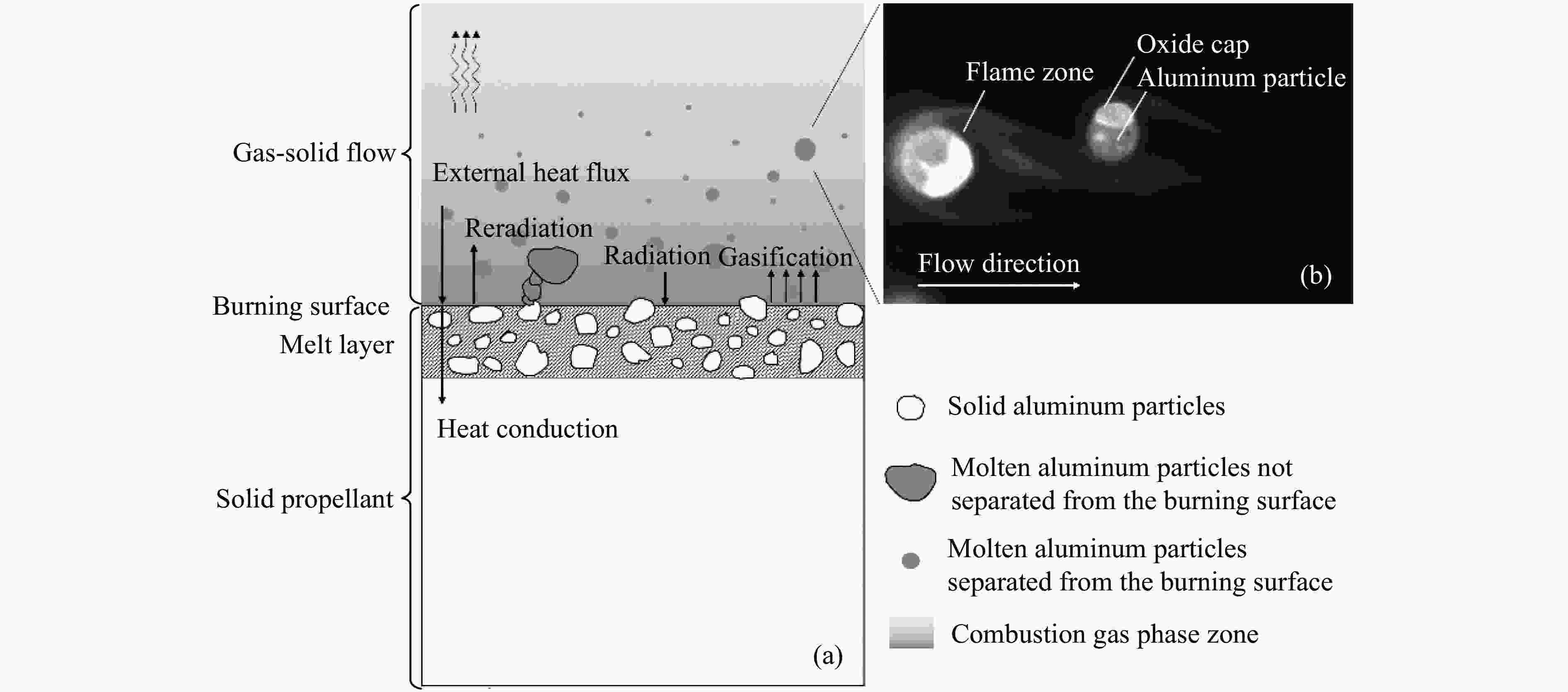

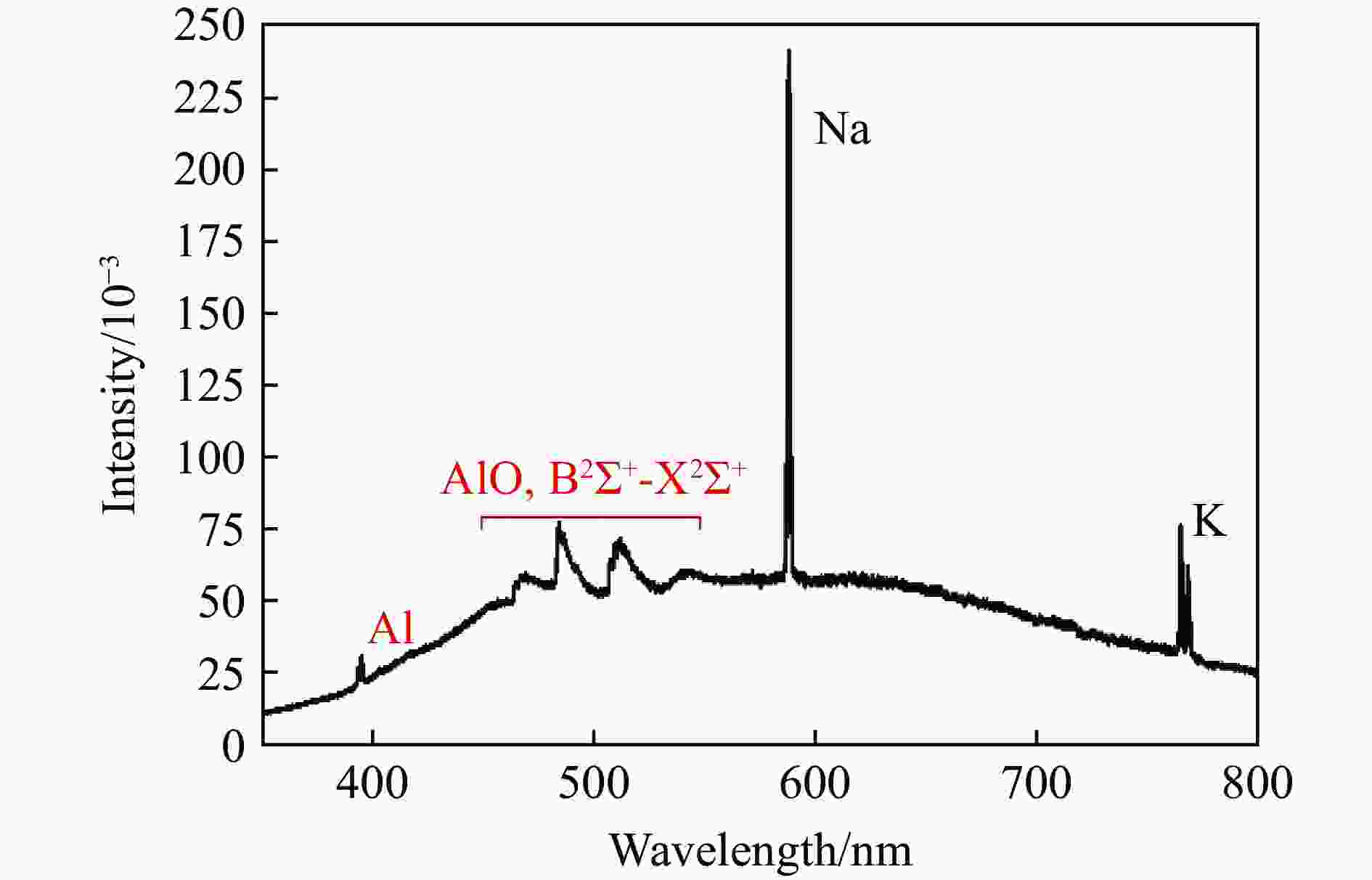

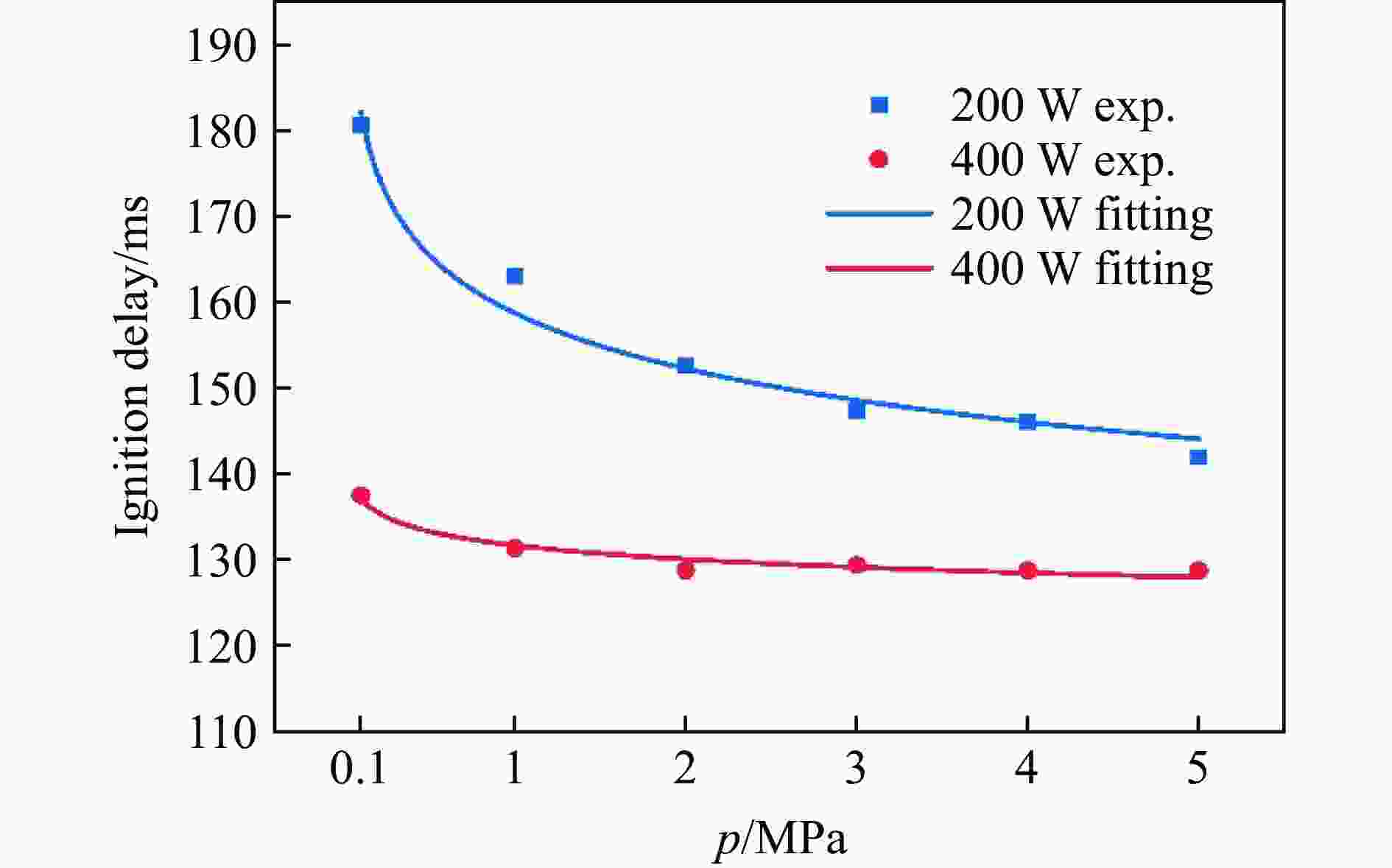

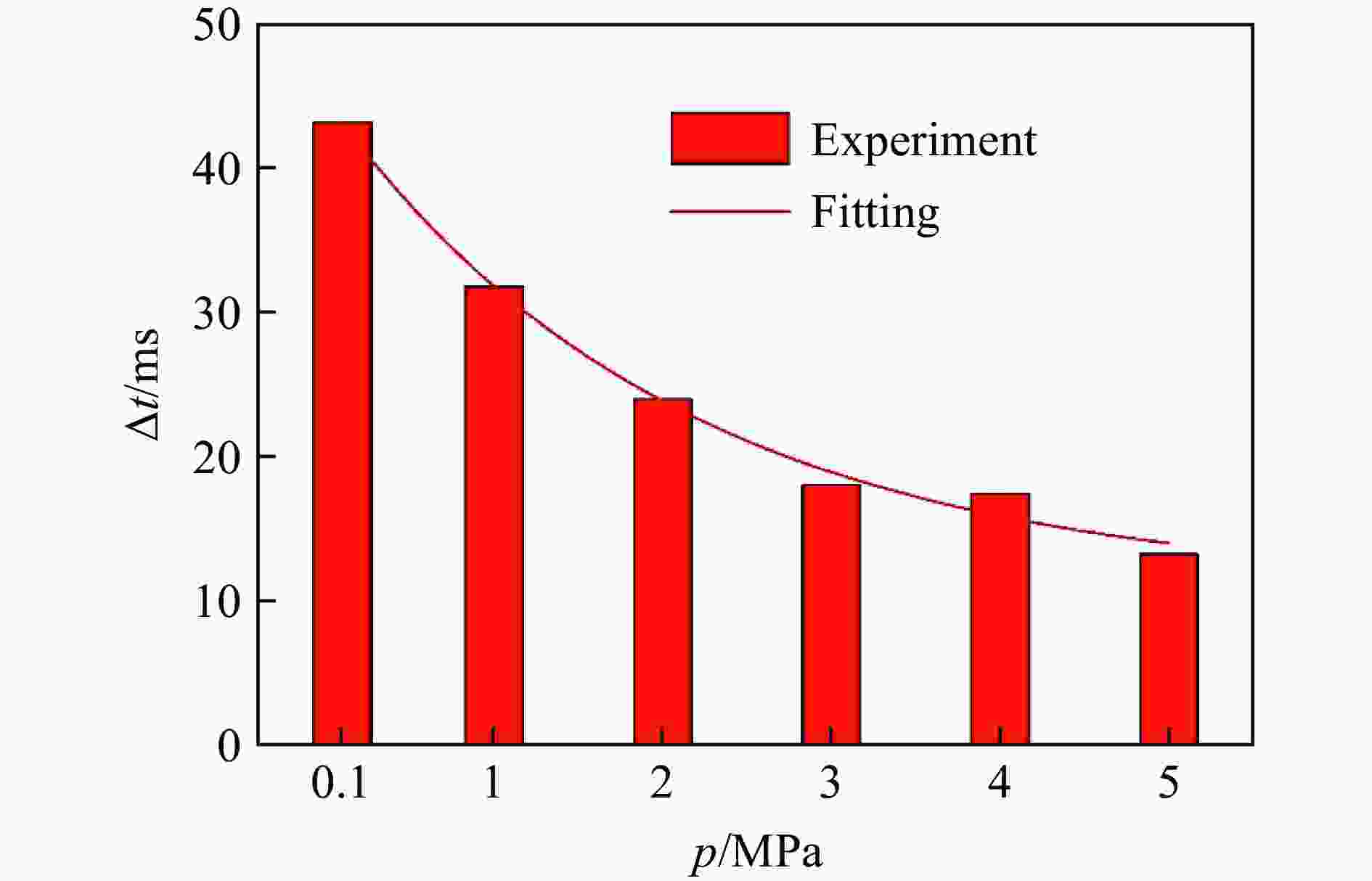

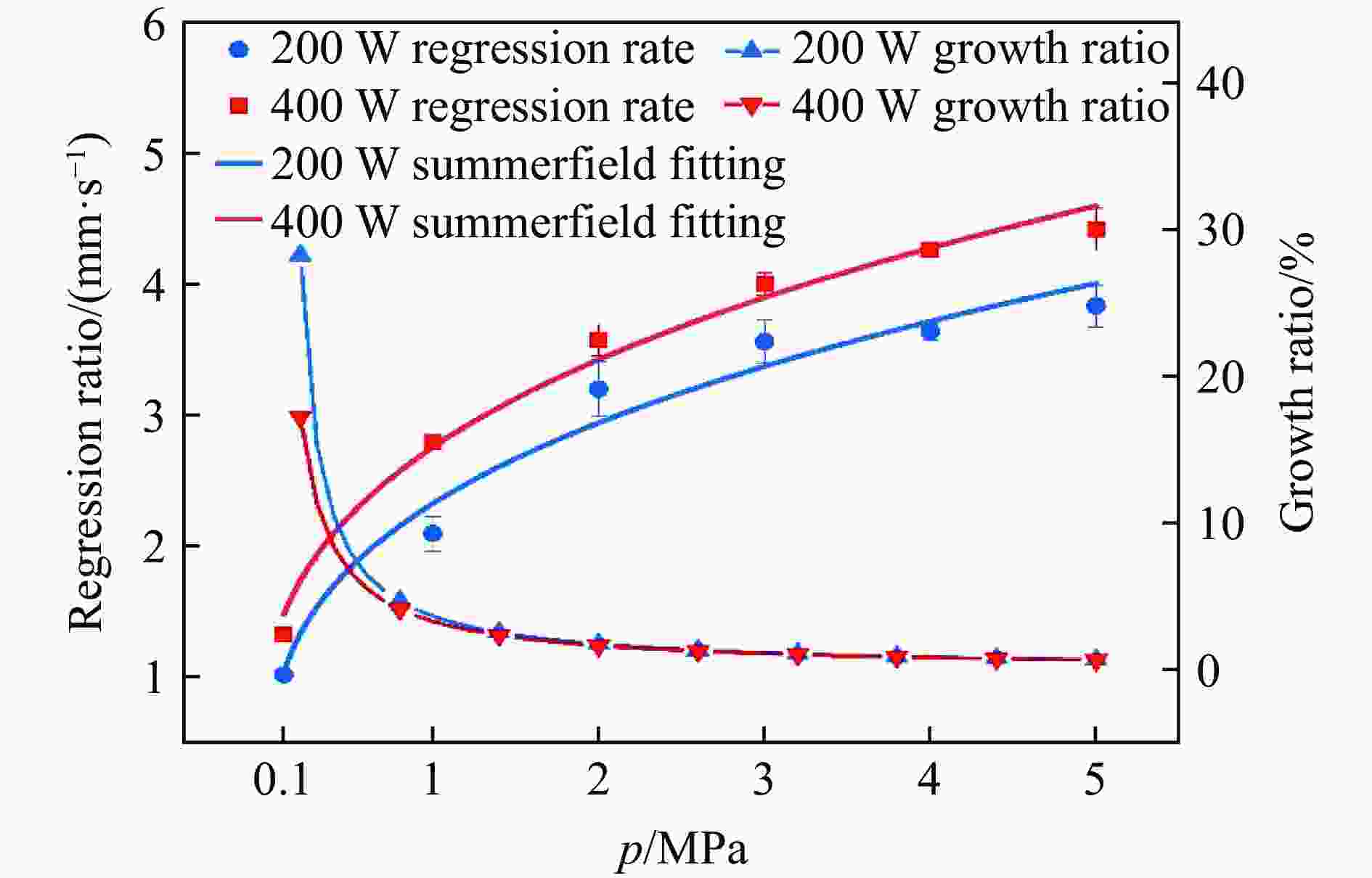

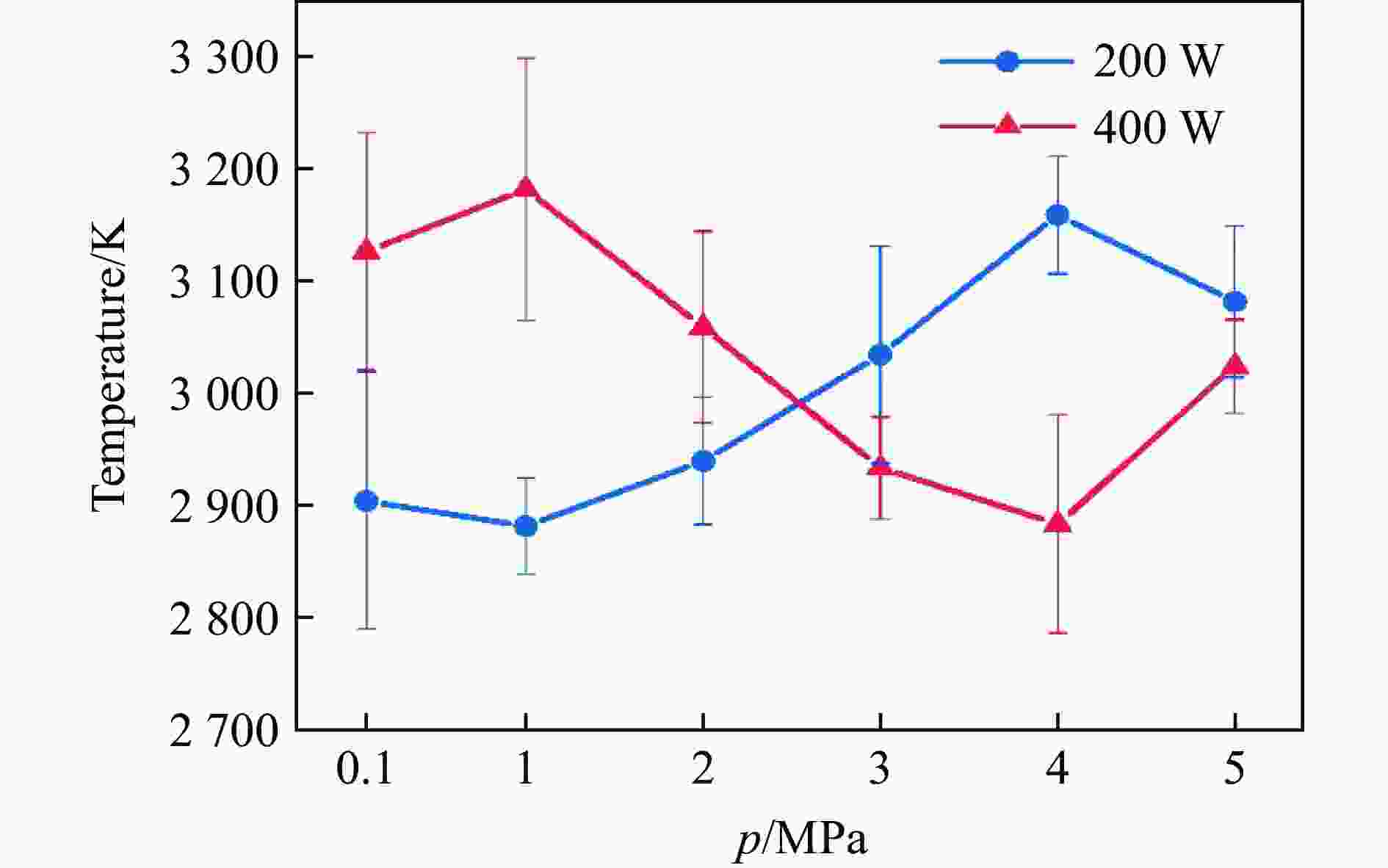

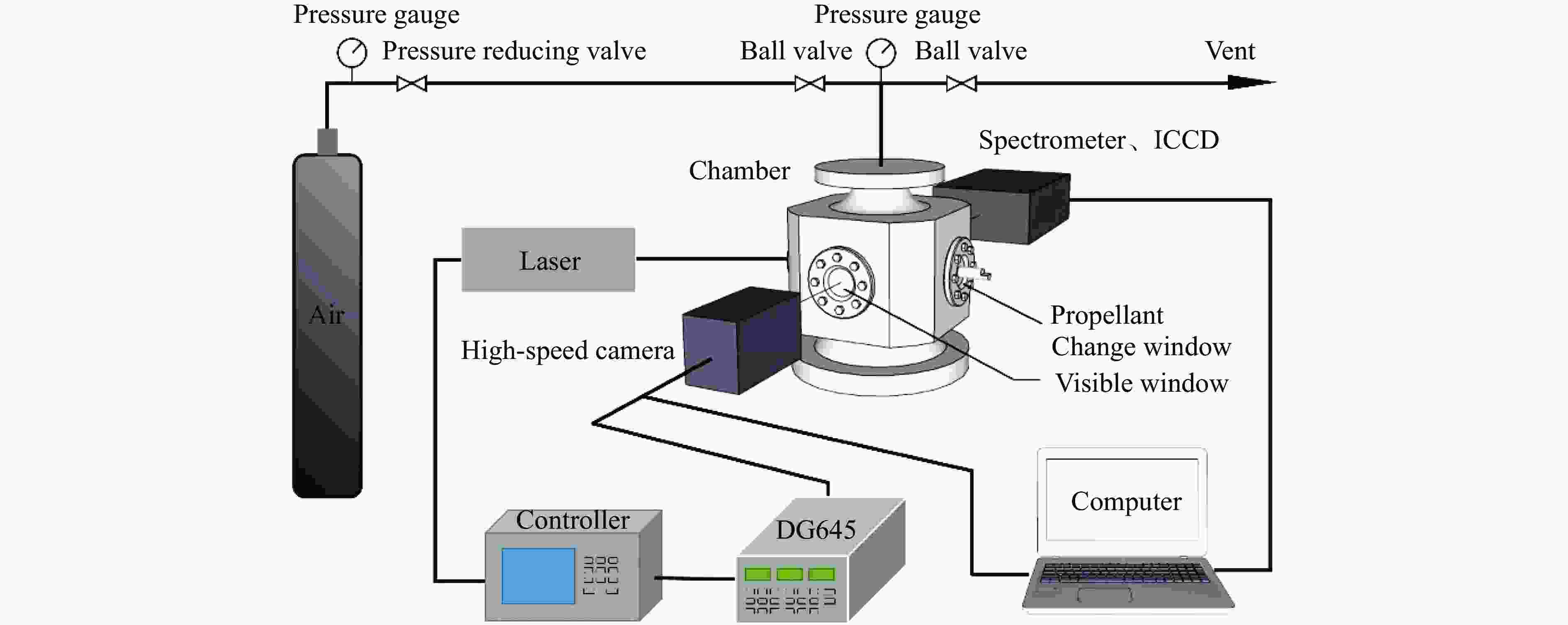

摘要: 为探究某新型含铝固体推进剂燃烧特性和规律,在模拟固体发动机的高压条件下,采用可调功率激光器结合高速摄影、发射光谱等光学诊断技术对该新型含铝固体推进剂开展了系统的点火及燃烧过程研究。通过对该推进剂的点火延迟、退移速率、燃烧温度以及团聚物颗粒尺寸的定量测量和分析,明确了该推进剂的点火延迟量级;证实此推进剂的退移速率严格遵循Summerfield燃速公式;判断出其最高燃烧温度高于3 300 K,且随压力增大而升高;通过对燃烧过程中发光凝聚相产物面积的量化分析得出推进剂产物中团聚物粒径尺寸受环境参数的影响规律。Abstract: In order to investigate the combustion characteristics of a new aluminum-containing solid propellant, the ignition and combustion process of the propellant at elevated pressure for simulating the solid propellant rocket engine were systematically studied by using a variable power fiber-laser and optical diagnostic techniques. The near-infrared fiber laser was employed to ignite the propellant slices placed in a high-pressure optical tank which was designed and manufactured for simulating solid propellant rocket engine conditions. The successive images of the laser-ignition and combustion process were captured by a high-speed camera while the optical emission spectroscopy was recorded with fiber-based spectrometers. Therewith, the regression rate, the ignition delay, and agglomerate particle size of the propellant were determined from the quantitative measurement and analysis of the former, likewise, the combustion temperatures were deduced by the latter. Accordingly, the maximum combustion temperature, the magnitude of the ignition delay, and rules of regression rate were mastered, as well as their dependence on laser power and ambient pressure. Firstly, the analysis of emission spectra shows that the maximum combustion temperature of this propellant should be higher than 3 300 K which grows with pressure. It reveals that the fundamental mechanisms of the propellant receding rate and ignition delay are affected by the ambient pressure from the perspective of chemical reaction dynamics. Meantime, the exponential decay law of ignition delay is determined while its formation mechanism is explored, based on the real-time monitoring of the propellant burning surface with high spatial and temporal resolution. Furthermore, it is also found that the regression rate of this propellant increases rapidly at low pressure, but appears to be saturated gradually when the ambient pressure exceeds 4 MPa. Whereafter, it is confirmed that the receding rate rules strictly follow the Summerfield burning rate equation. Finally, through the quantitative analysis of the luminous area of agglomerates in the combustion process, the effects of the agglomerate particle size in the propellant product by environmental parameters are concluded.

-

Key words:

- solid propellant /

- aluminum /

- laser ignition /

- combustion characteristics /

- optical diagnosis

-

表 1 激光点火的实验参数

Table 1. Experimental parameters of laser ignition

序号 点火功率/W 点火时间/ms 环境压力/MPa 1 200 200 0.1, 1, 2, 3, 4, 5 2 400 200 0.1, 1, 2, 3, 4, 5 表 2 不同点火延迟时间

$t ({\rm{ms}}) $ 随压力$p ({\rm{MPa}}) $ 变化规律公式Table 2. Formula of variation of ignition delay time

$t ({\rm{ms}}) $ with pressure$p ({\rm{MPa}}) $ 点火功率/W 拟合公式 R2 200 t = 0.16 p−0.060 0.97 400 t = 0.13 p−0.018 0.96 表 3 燃速公式的参数

Table 3. Parameters of burning rate formula

激光功率/W as bs R2 200 0.00458 0.42468 0.99371 400 −0.01364 0.37591 0.99777 -

[1] 《固体火箭技术》编辑部. 2021年固体推进动力领域发展综述 [J]. 固体火箭技术, 2022, 45(2): 167–180. DOI: 10.7673/j.issn.1006-2793.2022.02.001.Editorial Department of JSRT. Development review of solid propulsion technology in 2021 [J]. Journal of Solid Rocket Technology, 2022, 45(2): 167–180. DOI: 10.7673/j.issn.1006-2793.2022.02.001. [2] 田维平, 王立武, 王伟. 固体火箭发动机技术发展和面临的关键技术问题 [J]. 固体火箭技术, 2021, 44(1): 4–8. DOI: 10.7673/j.issn.1006-2793.2021.01.002.TIAN W P, WANG L W, WANG W. Technological development and key technical problems in solid rocket motors [J]. Journal of Solid Rocket Technology, 2021, 44(1): 4–8. DOI: 10.7673/j.issn.1006-2793.2021.01.002. [3] 刘继宁, 李苗苗, 陶锴, 等. 固体推进剂铝基燃料高效燃烧的研究进展 [J]. 上海航天, 2019, 36(S1): 1–6. DOI: 10.19328/j.cnki.1006-1630.2019.S1.001.LIU J N, LI M M, TAO K, et al. Research progress on high combustion performance of aluminum based fuel in solid propellant [J]. Aerospace Shanghai, 2019, 36(S1): 1–6. DOI: 10.19328/j.cnki.1006-1630.2019.S1.001. [4] GILL R J, BADIOLA C, DREIZIN E L. Combustion times and emission profiles of micron-sized aluminum particles burning in different environments [J]. Combustion and Flame, 2010, 157(11): 2015–2023. DOI: 10.1016/j.combustflame.2010.02.023. [5] MOHAN S, FURET L, DREIZIN E L. Aluminum particle ignition in different oxidizing environments [J]. Combustion and Flame, 2010, 157(7): 1356–1363. DOI: 10.1016/j.combustflame.2009.11.010. [6] BADIOLA C, GILL R J, DREIZIN E L. Combustion characteristics of micron-sized aluminum particles in oxygenated environments [J]. Combustion and Flame, 2011, 158(10): 2064–2070. DOI: 10.1016/j.combustflame.2011.03.007. [7] TAO H. Shock wave ignition of aluminum particles [J]. Journal De Physique Ⅳ, 2002, 12(7): 105–112. DOI: 10.1051/jp4:20020272. [8] 胡栋, 叶松, 吴旌贺, 等. 铝粉点火微观机理的光谱研究 [J]. 高压物理学报, 2006, 20(3): 237–242. DOI: 10.11858/gywlxb.2006.03.003.HU D, YE S, WU J H, et al. The spectro-studies on micro-mechanism of shock ignition for aluminium [J]. Chinese Journal of High Pressure Physics, 2006, 20(3): 237–242. DOI: 10.11858/gywlxb.2006.03.003. [9] ROBERTS T A, BURTON R L, KRIER H. Ignition and combustion of aluminummagnesium alloy particles in O2 at high pressures [J]. Combustion and Flame, 1993, 92(1/2): 125–143. DOI: 10.1016/0010-2180(93)90203-F. [10] FOELSCHE R O, BURTON R L, KRIER H. Ignition and combustion of aluminum particles in H2/O2/N2 combustion products [J]. Journal of Propulsion and Power, 1998, 14(6): 1001–1008. DOI: 10.2514/2.5365. [11] BELYAEV A F, FROLOV Y V, KOROTKOV A I. Combustion and ignition of particles of finely dispersed aluminum [J]. Combustion, Explosion and Shock Waves, 1971, 4(3): 182–185. DOI: 10.1007/BF00750857. [12] FRIEDMAN R, MAČEK A. Combustion studies of single aluminum particles [J]. Symposium (International) on Combustion, 1963, 9(1): 703–712. DOI: 10.1016/S0082-0784(63)80078-8. [13] TAKAHASHI K, OIDE S, KUWAHARA T. Agglomeration characteristics of aluminum particles in AP/AN composite propellants [J]. Propellants, Explosives, Pyrotechnics, 2013, 38(4): 555–562. DOI: 10.1002/prep.201200187. [14] ANAND K V, ROY A, MULLA I, et al. Experimental data and model predictions of aluminium agglomeration in ammonium perchlorate-based composite propellants including plateau-burning formulations [J]. Proceedings of the Combustion Institute, 2013, 34(2): 2139–2146. DOI: 10.1016/j.proci.2012.07.024. [15] 刘佩进, 白俊华, 杨向明, 等. 固体火箭发动机燃烧室凝相粒子的收集与分析 [J]. 固体火箭技术, 2008, 31(5): 461–463, 479. DOI: 10.3969/j.issn.1006-2793.2008.05.009.LIU P J, BAI J H, YANG X M, et al. Collection and analysis on the condensed-phase particles in the chamber of SRM [J]. Journal of Solid Rocket Technology, 2008, 31(5): 461–463, 479. DOI: 10.3969/j.issn.1006-2793.2008.05.009. [16] 曹向宇. 固体推进剂中铝颗粒温度测量方法及燃烧特性试验研究 [D]. 长沙: 国防科技大学, 2018: 51–52. DOI: 10.27052/d.cnki.gzjgu.2018.001156.CAO X Y. Experimental study on temperature measurement and combustion characteristics of aluminum particles in solid propellant [D]. Changsha: National University of Defense Technology, 2018: 51–52. DOI: 10.27052/d.cnki.gzjgu.2018.001156. [17] 郝海霞, 裴庆, 赵凤起, 等. 固体推进剂激光点火性能研究综述 [J]. 含能材料, 2009, 17(4): 491–498. DOI: 10.3969/j.issn.1006-9941.2009.04.028.HAO H X, PEI Q, ZHAO F Q, et al. Summarization of laser ignition characteristics of solid propellants [J]. Chinese Journal of Energetic Materials, 2009, 17(4): 491–498. DOI: 10.3969/j.issn.1006-9941.2009.04.028. [18] 敖文, 刘佩进, 吕翔, 等. 固体推进剂燃烧过程铝团聚研究进展 [J]. 宇航学报, 2016, 37(4): 371–380. DOI: 10.3873/j.issn.1000-1328.2016.04.001.AO W, LIU P J, LV X, et al. Review of aluminum agglomeration during the combustion of solid propellants [J]. Journal of Astronautics, 2016, 37(4): 371–380. DOI: 10.3873/j.issn.1000-1328.2016.04.001. [19] BECKSTEAD M W, LIANG Y, PUDDUPPAKKAM K V. Numerical simulation of single aluminum particle combustion: Review [J]. Combustion, Explosion, and Shock Waves, 2005, 41(6): 622–638. DOI: 10.1007/s10573-005-0077-0. [20] BUCHER P, YETTER R A, DRYER F L, et al. PLIF species and ratiometric temperature measurements of aluminum particle combustion in O2, CO2 and N2O oxidizers, and comparison with model calculations [J]. Symposium (International) on Combustion, 1998, 27(2): 2421–2429. DOI: 10.1016/S0082-0784(98)80094-5. [21] 张炜, 朱慧. 铝镁贫氧推进剂低压燃烧性能表征方法研究 [J]. 含能材料, 2002, 10(3): 125–127. DOI: 10.3969/j.issn.1006-9941.2002.03.009.ZHANG W, ZHU H. Characterization methods of combustion properties of aluminum-magnesium fuel-rich propellant at low pressure [J]. Chinese Journal of Energetic Materials, 2002, 10(3): 125–127. DOI: 10.3969/j.issn.1006-9941.2002.03.009. [22] 张林, 张志杰, 李岩峰. 双波段比色测温技术的应用 [J]. 现代电子技术, 2019, 42(8): 1–5. DOI: 10.16652/j.issn.1004-373x.2019.08.001.ZHANG L, ZHANG Z J, LI Y F. Application of dual-waveband colorimetric temperature measurement technology [J]. Modern Electronics Technique, 2019, 42(8): 1–5. DOI: 10.16652/j.issn.1004-373x.2019.08.001. [23] 闫白, 郝晓剑, 周汉昌. 基于比色法的纯镁及镁合金燃点测试系统 [J]. 激光与光电子学进展, 2013, 50(11): 112301. DOI: 10.3788/LOP50.112301.YAN B, HAO X J, ZHOU H C. Ignition test system of pure magnesium and magnesium alloys based on colorimetric method [J]. Laser & Optoelectronics Progress, 2013, 50(11): 112301. DOI: 10.3788/LOP50.112301. -

下载:

下载: