Effect of the specimen shape on microstructure of the adiabatic shear band in bearing steel

-

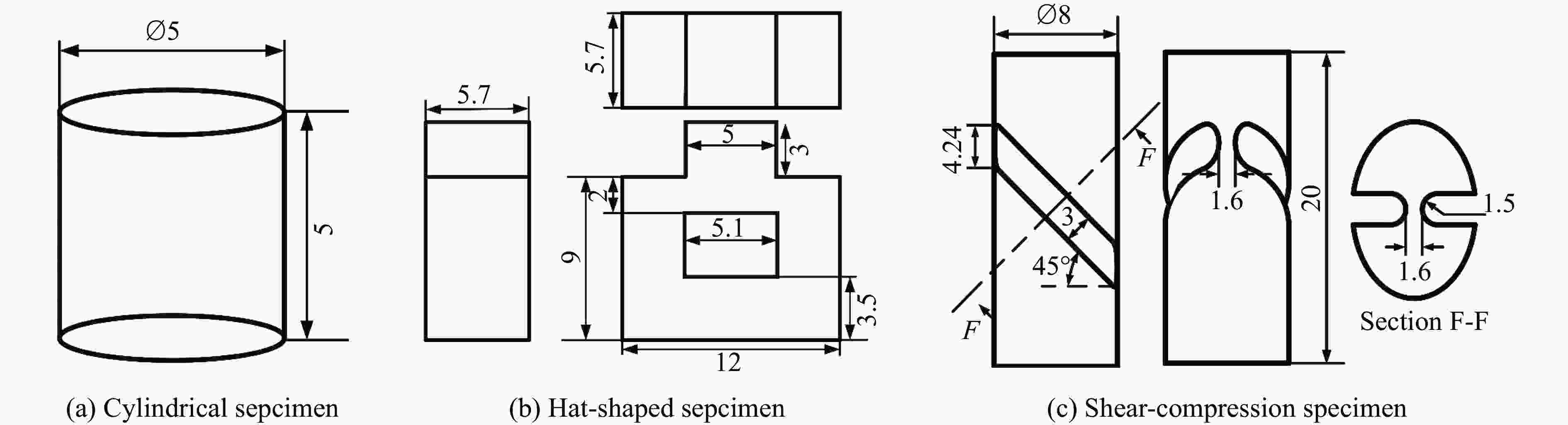

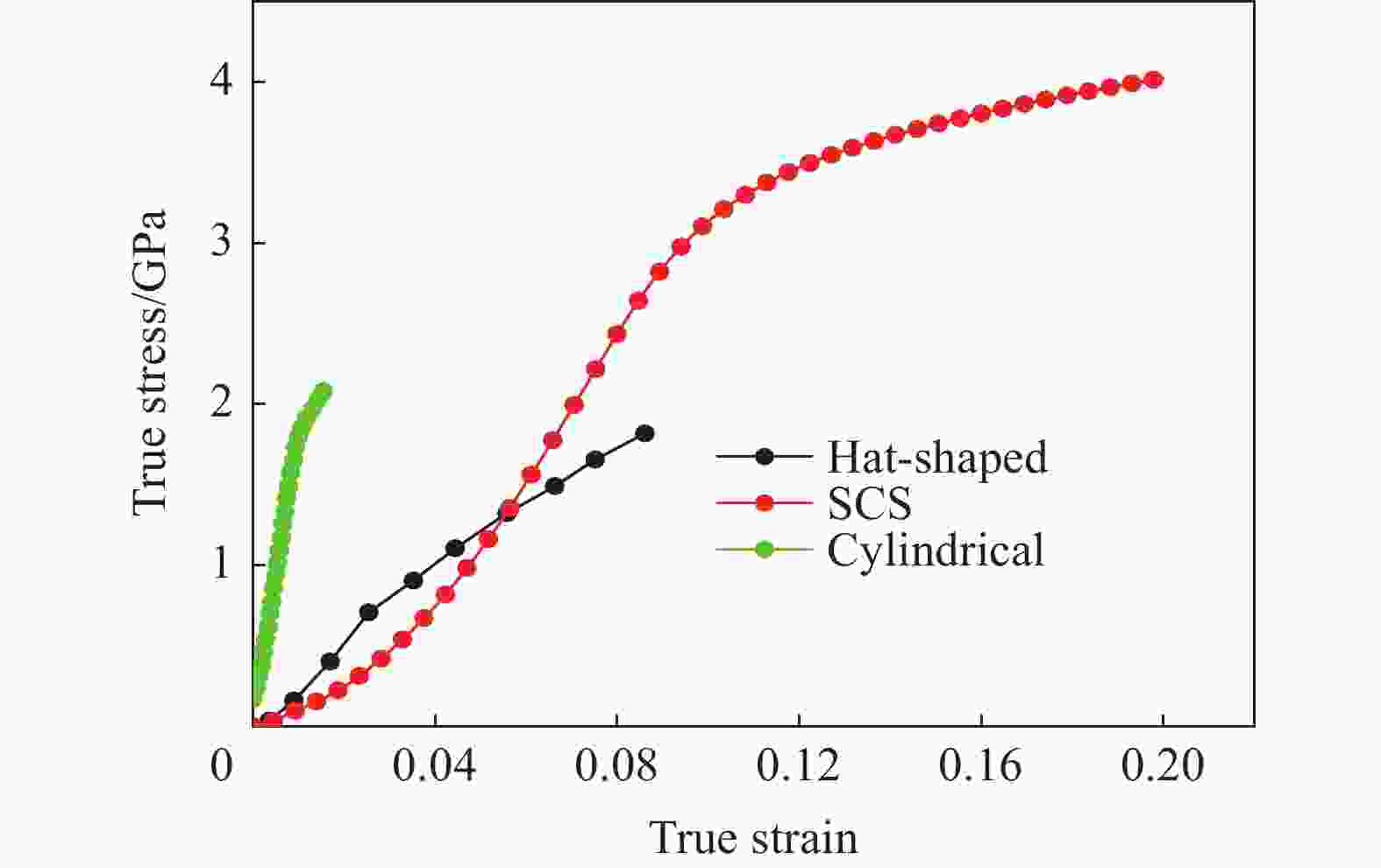

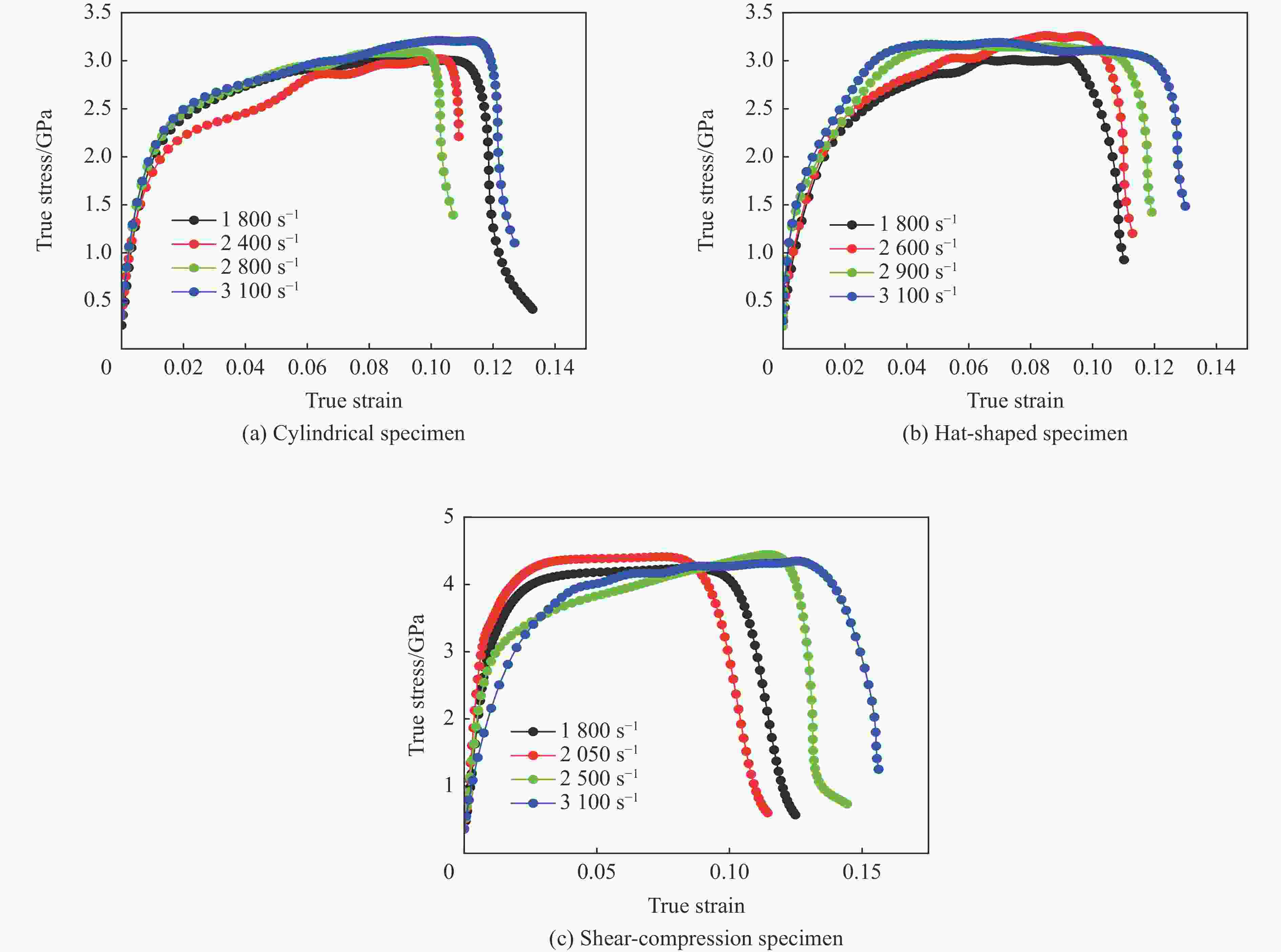

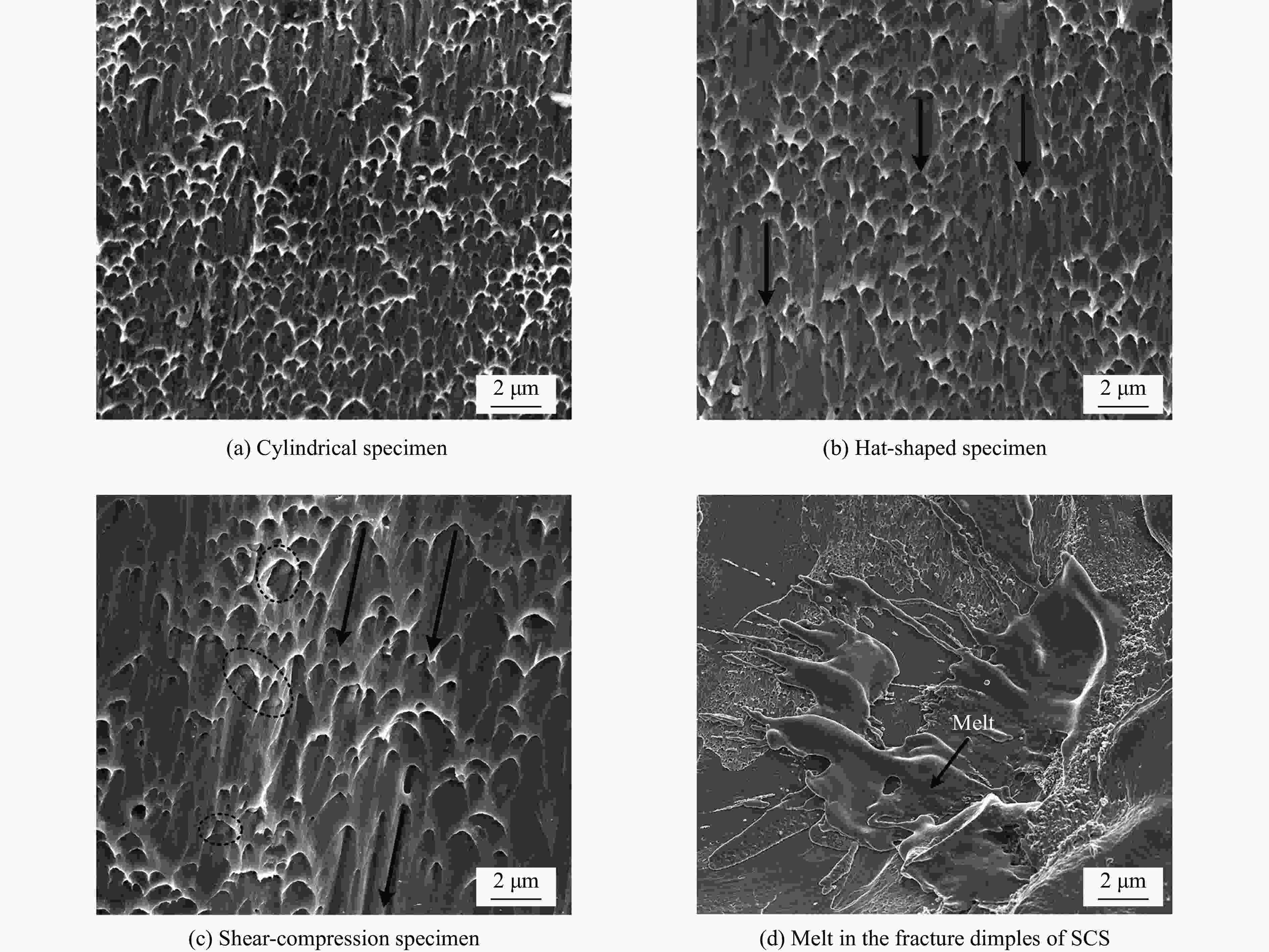

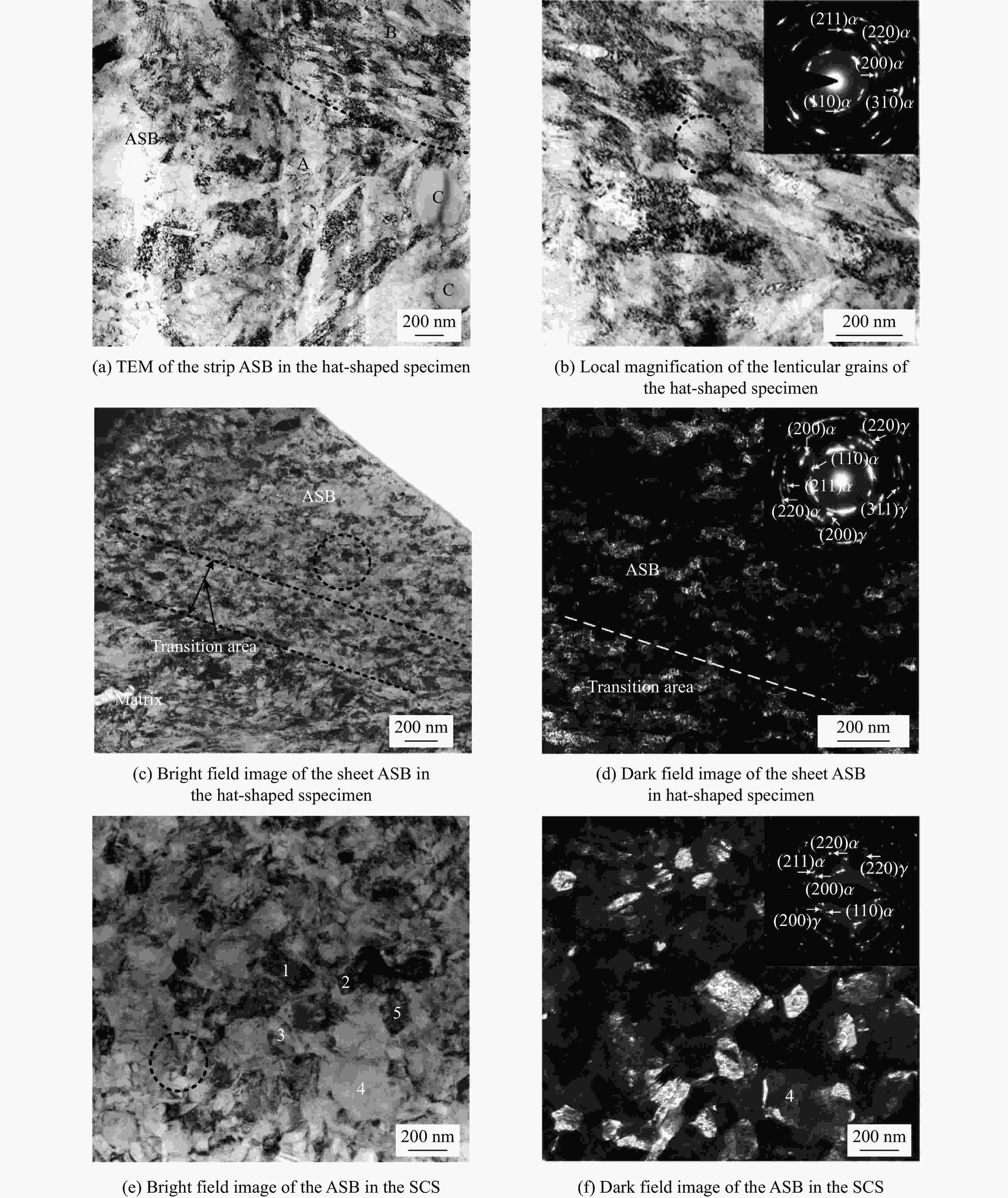

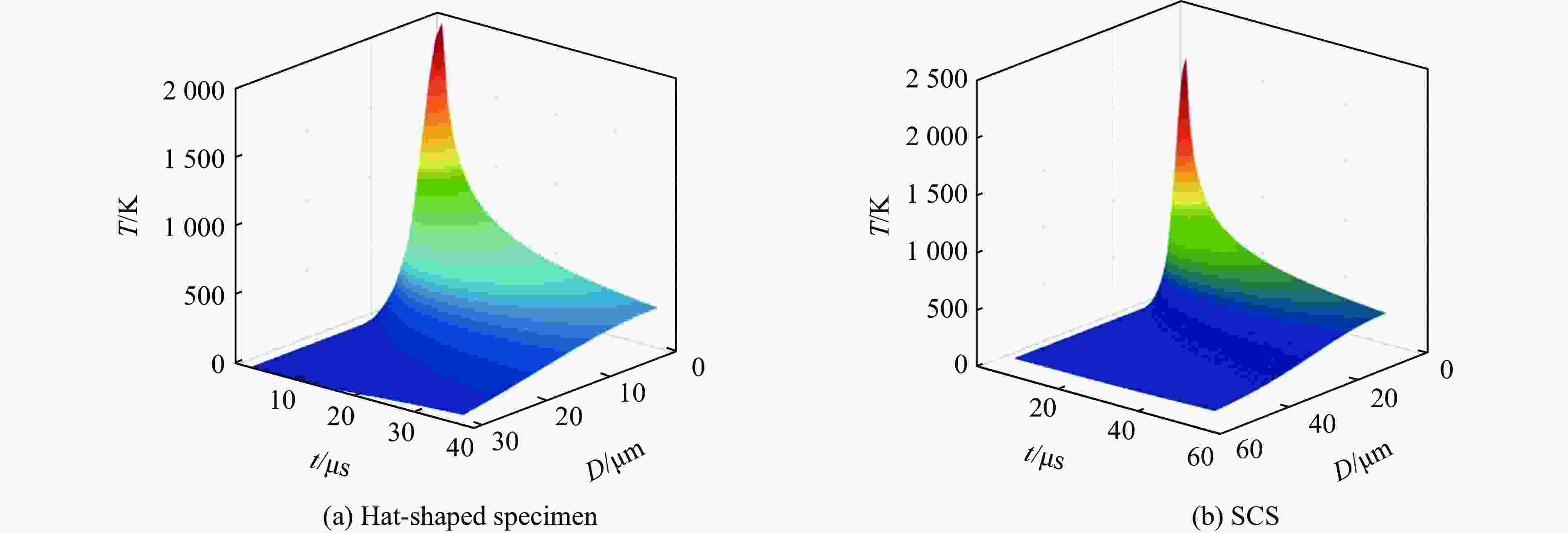

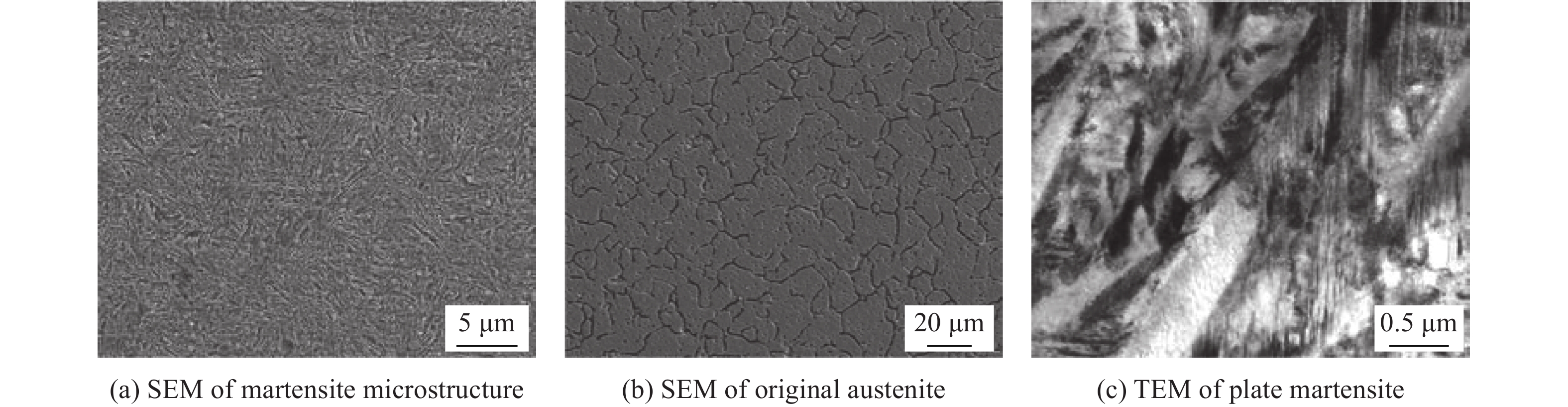

摘要: 绝热剪切带(ASB)的微观组织受试样几何形状的影响。对圆柱、帽形和剪切压缩型三种不同形状的试样进行分离式霍普金森压杆高速冲击试验,研究试样形状对轴承钢绝热剪切带的形成和微观组织的影响。结果表明,在应变率为1800~3100 s-1的范围内,材料对应变率的敏感性很低。圆柱试样呈现明显的应变硬化,而帽形试样和剪切压缩型试样(SCS)在不同应变率下分别出现应变硬化和无应变硬化的特征,但流变应力并未因应变硬化而提高。试样形状对ASB的微观形貌和组织有很大影响。圆柱试样上产生了窄且细长的ASB,只发生了应变诱发的晶粒细化,属于形变ASB;帽形试样和SCS则形成大片状的ASB,由等轴晶组成,且发生了体心立方体(BCC)马氏体转变为面心立方体(FCC)奥氏体的相变,属于相变ASB。尤其是SCS中ASB的等轴晶,有非常清晰的晶界,是典型的动态再结晶晶粒。温升计算结果显示,圆柱试样ASB的温升远低于奥氏体相变温度,而帽形试样和SCS的温升高于马氏体的熔点,导致局部熔融。Abstract: The microstructure of adiabatic shear band (ASB) is influenced by the specimen geometric shape. High-speed impact tests were performed on specimens of three different shapes of cylinder, hat-shaped, and shear-compression by a split Hopkinson pressure bar, to study the effect of the specimen shape on the formation and microstructure of the adiabatic shear band in the bearing steel. The results show that at the strain rate from 1800 to 3100 s-1, the flow stress remains almost the same with increasing the strain rate in three different shapes of sepcimens, indicating that the material shows low strain rate sensitivity. At high strain rates, the cylindrical specimen exhibits a strong strain hardening, while the hat-shaped specimen and the shear-compression specimen (SCS) show both strain hardening and no strain hardening features at different strain rates, but their flow stresses are not increased due to hardening effect. The fracture surface of the cylindrical specimen presents a large number of dense and tiny elliptical dimples. The number of dimples is greatly reduced on the hat-shaped specimen. The dimple, however, has a width that is twice of that of the cylindrical specimen. There is a distinct shearing path of carbides. In contrast, the SCS has even fewer but much larger dimples, with the width of 1.6 μm, twice of the hat-shaped specimen, and the shearing path of carbides reaches 7 μm. Local melting occurs on both the hat-shaped specimen and SCS, especially the SCS, a massive melting is displayed. A long and narrow ASB was produced in the cylindrical specimen, and only strain-induced grain refinement occurred in the ASB, which belongs to the deformed ASB. Large patch of ASBs is generated in the hat-shaped specimen and SCS. The ASBs consist of equiaxed grains and belong to the transformed ASB as the phase transformation from martensite to austenite occurred. In particular, the equiaxed grains in the ASB of the SCS have very clear grain boundaries, which are typical dynamic recrystallization grains. It can conclude that the shape of the specimen has a great influence on the microscopic morphologies and microstructures of ASB. The cylindrical specimen is in a typical compressive stress state, while the hat-shaped specimen and SCS are in complicated stress dominated by shear. The temperature rise int the ASB of the cylindrical specimen is much lower than the austenite transformation temperature, while it is higher than the melting point of martensite in the hat-shaped specimen and SCS, leading to local melting and microstructural change.

-

Key words:

- bearing steel /

- adiabatic shear band (ASB) /

- phase transformation /

- equiaxed grain

-

表 1 三种形状试样的罗德参数、应力三轴度和最大剪切应力

Table 1. Rhodes parameters, stress triaxiality and maximum shear stress of three shape specimens

试样类型 Lode参数 应力三轴度 最大剪切应力/MPa 圆柱 −1 −0.33 0.0015 帽型 0.47 −0.58 1897 SCS 0.58 −0.43 2625 -

[1] MEYERS M A, XU Y B, XUE Q, et al. Microstructural evolution in adiabatic shear localization in stainless steel [J]. Acta Materialia, 2003, 51(5): 1307–1325. DOI: 10.1016/S1359-6454(02)00526-8. [2] XU Y B, ZHANG J H, BAI Y L, et al. Shear localization in dynamic deformation: microstructural evolution [J]. Metallurgical and Materials Transactions A, 2008, 39(4): 811–843. DOI: 10.1007/s11661-007-9431-z. [3] 寿先涛, 郑必举, 樊晓都, 等. 高强度马氏体35CrMo钢的绝热剪切特性 [J]. 金属热处理, 2018, 43(10): 36–39. DOI: 10.13251/j.issn.0254-6051.2018.10.008.SHOU X T, ZHENG B J, FAN X D, et al. Adiabatic shear characteristic of high strength martensitic 35CrMo steel [J]. Heat Treatment of Metals, 2018, 43(10): 36–39. DOI: 10.13251/j.issn.0254-6051.2018.10.008. [4] 王琳, 杜文文, 姚春发, 等. 等温处理对新型高强钢力学性能和绝热剪切行为的影响 [J]. 北京理工大学学报, 2016, 36(12): 1315–1320. DOI: 10.15918/j.tbit1001-0645.2016.12.020.WANG L, DU W W, YAO C F, et al. Isothermal heat treatment on mechanical properties and adiabatic shear behavior of a new high-strength steel [J]. Transactions of Beijing Institute of Technology, 2016, 36(12): 1315–1320. DOI: 10.15918/j.tbit1001-0645.2016.12.020. [5] 范昌增, 许泽建, 何晓东, 等. 加载速率对40Cr钢Ⅱ型动态断裂特性的影响 [J]. 爆炸与冲击, 2021, 41(8): 083101. DOI: 10.11883/bzycj-2021-0029.FANG C Z, XU Z J, HE X D, et al. Effect of loading rate on the mode Ⅱ dynamic fracture characteristics of 40Cr steel [J]. Explosion and Shock Waves, 2021, 41(8): 083101. DOI: 10.11883/bzycj-2021-0029. [6] 金婷, 杨平. 高锰钢帽型样品在高速冲击下的剪切行为 [J]. 爆炸与冲击, 2017, 37(1): 150–156. DOI: 10.11883/1001-1455(2017)01-0150-07.JIN T, YANG P. Shear behaviors of hat-shaped high manganese steel specimens under high-speed impact [J]. Explosion and Shock Waves, 2017, 37(1): 150–156. DOI: 10.11883/1001-1455(2017)01-0150-07. [7] LI S X, ZHAO P C, HE Y N, et al. Microstructural evolution associated with shear location of AISI 52100 under high strain rate loading [J]. Materials Science and Engineering: A, 2016, 662: 46–53. DOI: 10.1016/j.msea.2016.03.050. [8] GONG X, FAN J L, HUANG B Y, et al. Microstructure characteristics and a deformation mechanism of fine-grained tungsten heavy alloy under high strain rate compression [J]. Materials Science and Engineering: A, 2010, 527(29/30): 7565–7570. DOI: 10.1016/j.msea.2010.07.102. [9] YAN N, LI Z Z, XU Y B, et al. Shear localization in metallic materials at high strain rates [J]. Progress in Materials Science, 2021, 119: 100755. DOI: 10.1016/j.pmatsci.2020.100755. [10] PEIRS J, TIRRY W, AMIN-AHMADI B, et al. Microstructure of adiabatic shear bands in Ti6Al4V [J]. Materials Characterization, 2013, 75: 79–92. DOI: 10.1016/j.matchar.2012.10.009. [11] JO M C, KIM S, SUH D W, et al. Effect of tempering conditions on adiabatic shear banding during dynamic compression and ballistic impact tests of ultra-high-strength armor steel [J]. Materials Science and Engineering: A, 2020, 792: 139818. DOI: 10.1016/j.msea.2020.139818. [12] OWOLABI G M, BOLLING D T, ODESHI A G, et al. The effects of specimen geometry on the plastic deformation of AA 2219-T8 aluminum alloy under dynamic impact loading [J]. Journal of Materials Engineering and Performance, 2017, 26(12): 5837–5846. DOI: 10.1007/s11665-017-3061-4. [13] ZHU S X, GUO Y Z, CHEN H S, et al. Formation of adiabatic shear band within Ti-6Al-4V: effects of stress state [J]. Mechanics of Materials, 2019, 137: 103102. DOI: 10.1016/j.mechmat.2019.103102. [14] PEIRS J, VERLEYSEN P, DEGRIECK J, et al. The use of hat-shaped specimens to study the high strain rate shear behaviour of Ti-6Al-4V [J]. International Journal of Impact Engineering, 2010, 37(6): 703–714. DOI: 10.1016/j.ijimpeng.2009.08.002. [15] LI J R, YU J L, WEI Z G. Influence of specimen geometry on adiabatic shear instability of tungsten heavy alloys [J]. International Journal of Impact Engineering, 2003, 28(3): 303–314. DOI: 10.1016/S0734-743X(02)00022-2. [16] DOROGOY A, RITTEL D. Dynamic large strain characterization of tantalum using shear-compression and shear-tension testing [J]. Mechanics of Materials, 2017, 112: 143–153. DOI: 10.1016/j.mechmat.2017.06.003. [17] SU Y S, LI S X, YANG G N, et al. Shear instability and considerably localized melting in quasi-static compression [J]. Materials Characterization, 2020, 160: 110081. DOI: 10.1016/j.matchar.2019.110081. [18] ROGERS H C. Adiabatic plastic deformation [J]. Annual Review of Materials Science, 1979, 9: 283–311. DOI: 10.1146/annurev.ms.09.080179.001435. [19] LI N, WANG Y D, PENG R L, et al. Localized amorphism after high-strain-rate deformation in TWIP steel [J]. Acta Materialia, 2011, 59(16): 6369–6377. DOI: 10.1016/j.actamat.2011.06.048. [20] OSOVSKI S, RITTEL D, LANDAU P, et al. Microstructural effects on adiabatic shear band formation [J]. Scripta Materialia, 2012, 66(1): 9–12. DOI: 10.1016/j.scriptamat.2011.09.014. [21] RITTEL D, ZHANG L H, OSOVSKI S. The dependence of the Taylor-Quinney coefficient on the dynamic loading mode [J]. Journal of the Mechanics and Physics of Solids, 2017, 107: 96–114. DOI: 10.1016/j.jmps.2017.06.016. [22] SAKAI T, BELYAKOV A, KAIBYSHEV R, et al. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions [J]. Progress in Materials Science, 2014, 60: 130–207. DOI: 10.1016/j.pmatsci.2013.09.002. [23] XIE H X, MA T, YU T, et al. Body-centered-cubic to face-centered-cubic phase transformation of iron under compressive loading along [100] direction [J]. Materials Today Communications, 2021, 26: 101961. DOI: 10.1016/j.mtcomm.2020.101961. [24] IVANISENKO Y, MACLAREN I, SAUVAGE X, et al. Shear-induced α→γ transformation in nanoscale Fe-C composite [J]. Acta Materialia, 2006, 54(6): 1659–1669. DOI: 10.1016/j.actamat.2005.11.034. [25] JIANG G H, LI S X, PU J B, et al. Phase transformation in the subsurface of case carbonitrided bearing steels under rolling contact fatigue [J]. Tribology International, 2022, 169: 107468. DOI: 10.1016/j.triboint.2022.107468. [26] MEYER L W, STASKEWITSCH E, BURBLIES A. Adiabatic shear failure under biaxial dynamic compression/shear loading [J]. Mechanics of Materials, 1994, 17(2/3): 203–214. DOI: 10.1016/0167-6636(94)90060-4. -

下载:

下载: