On impact properties of Mo-ZrC gradient metal ceramics

-

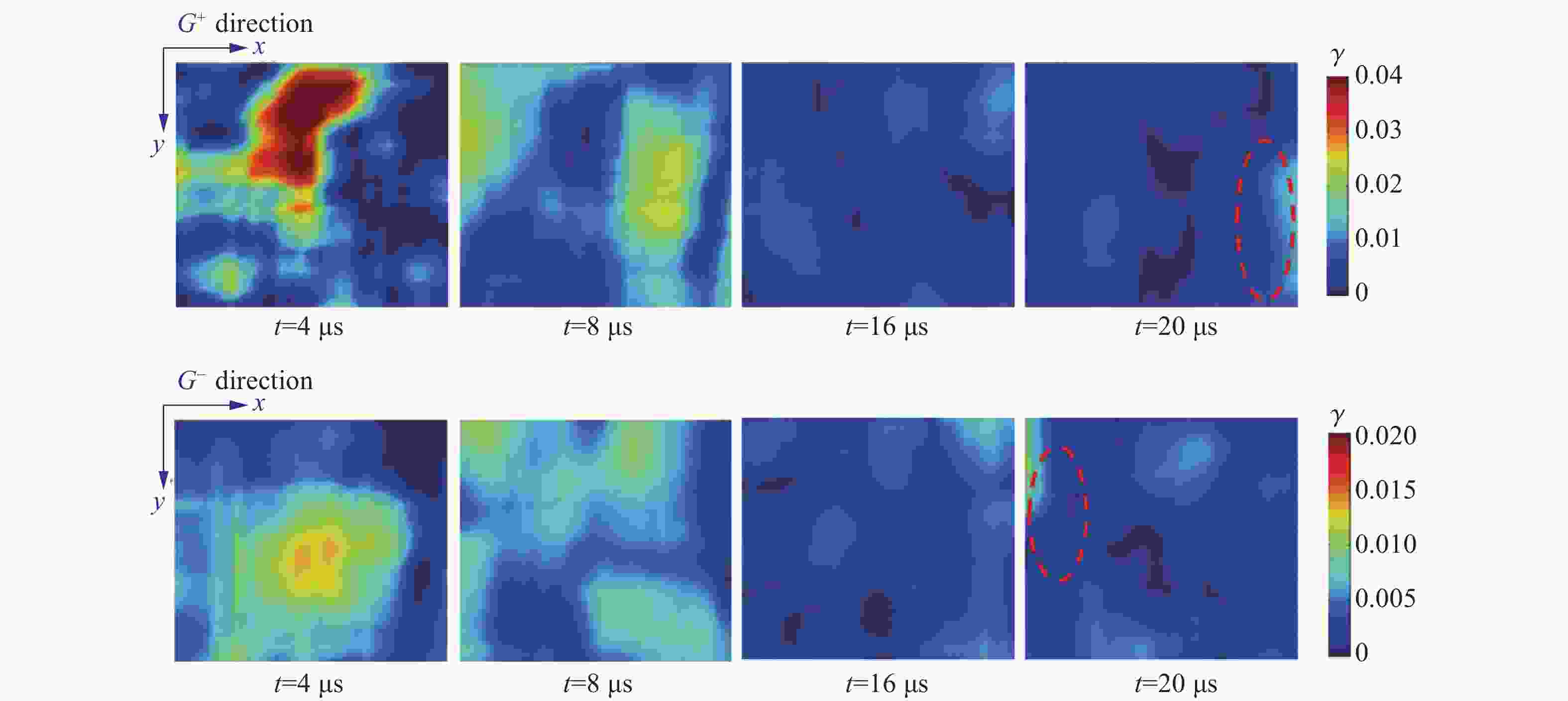

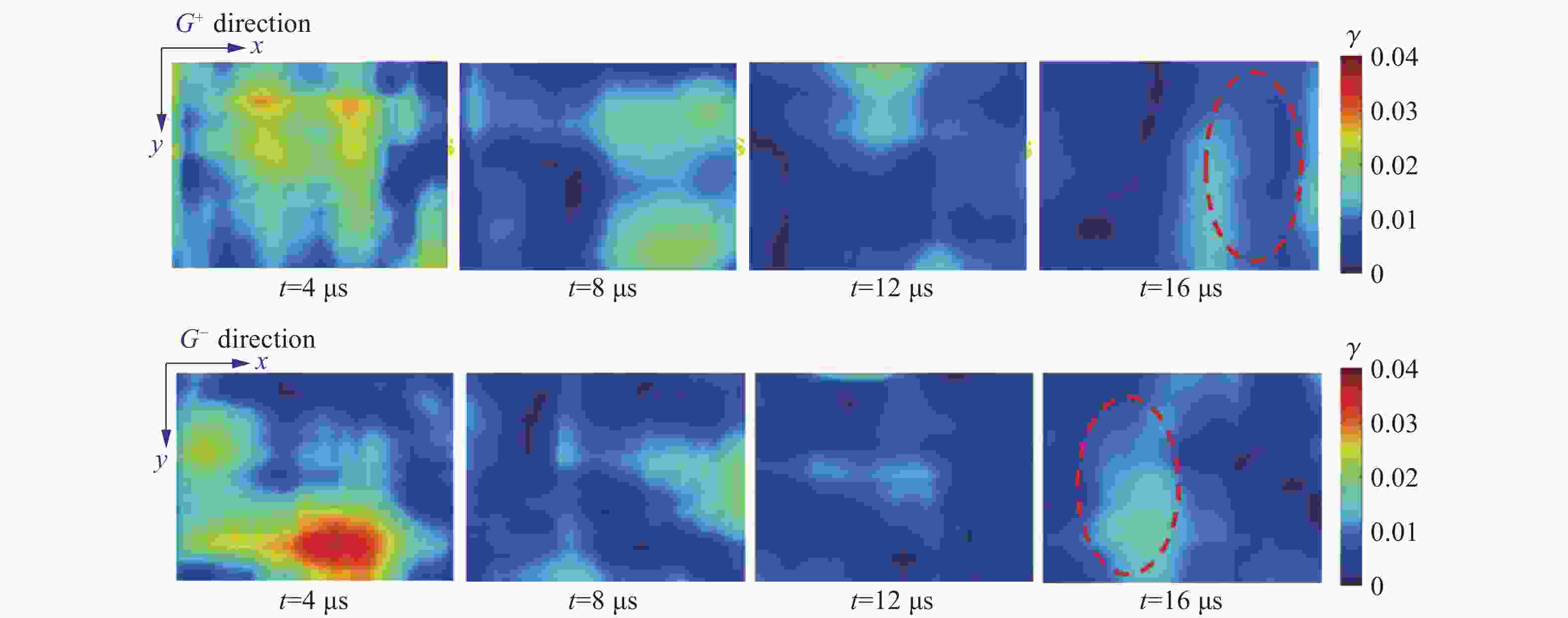

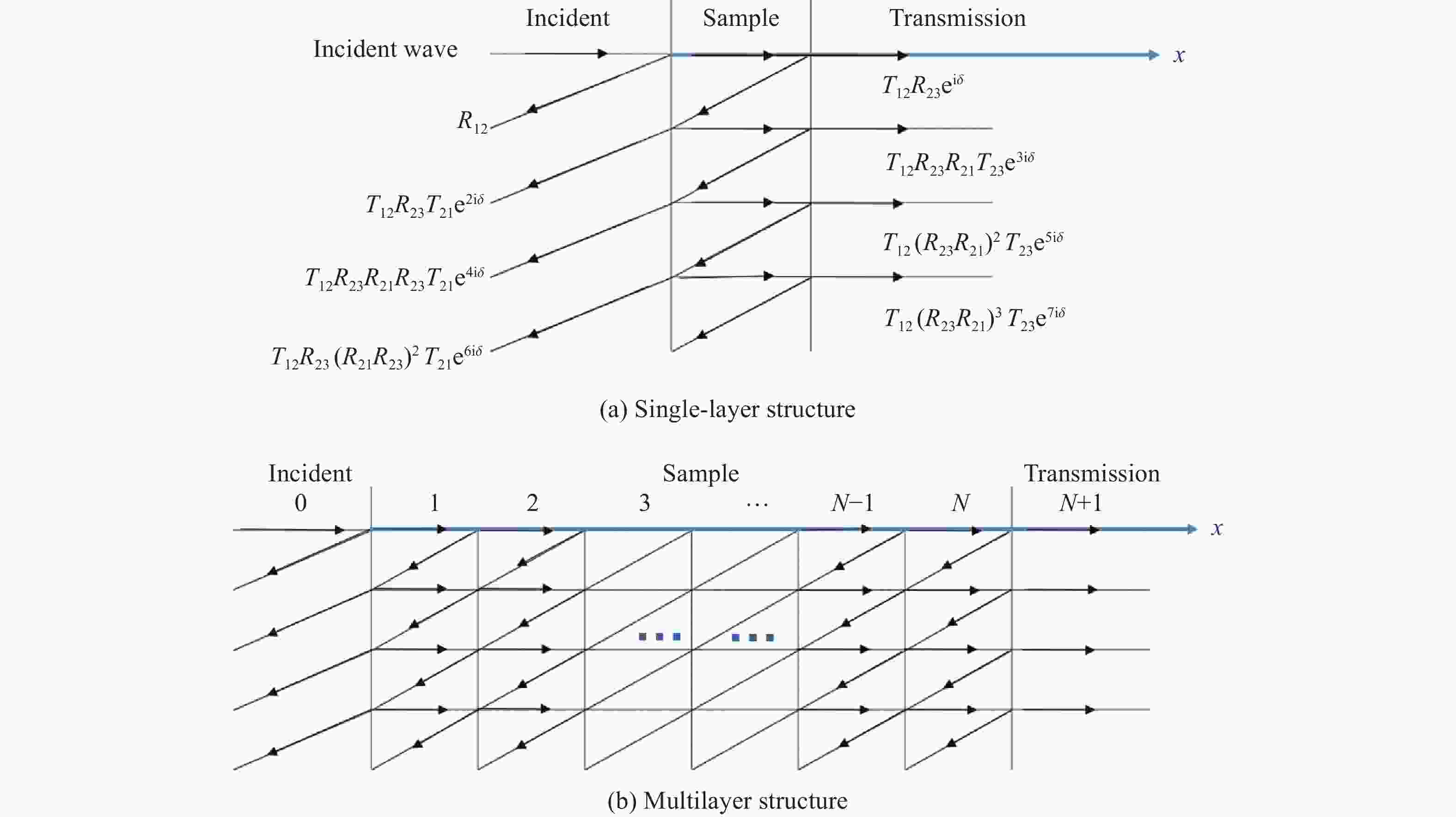

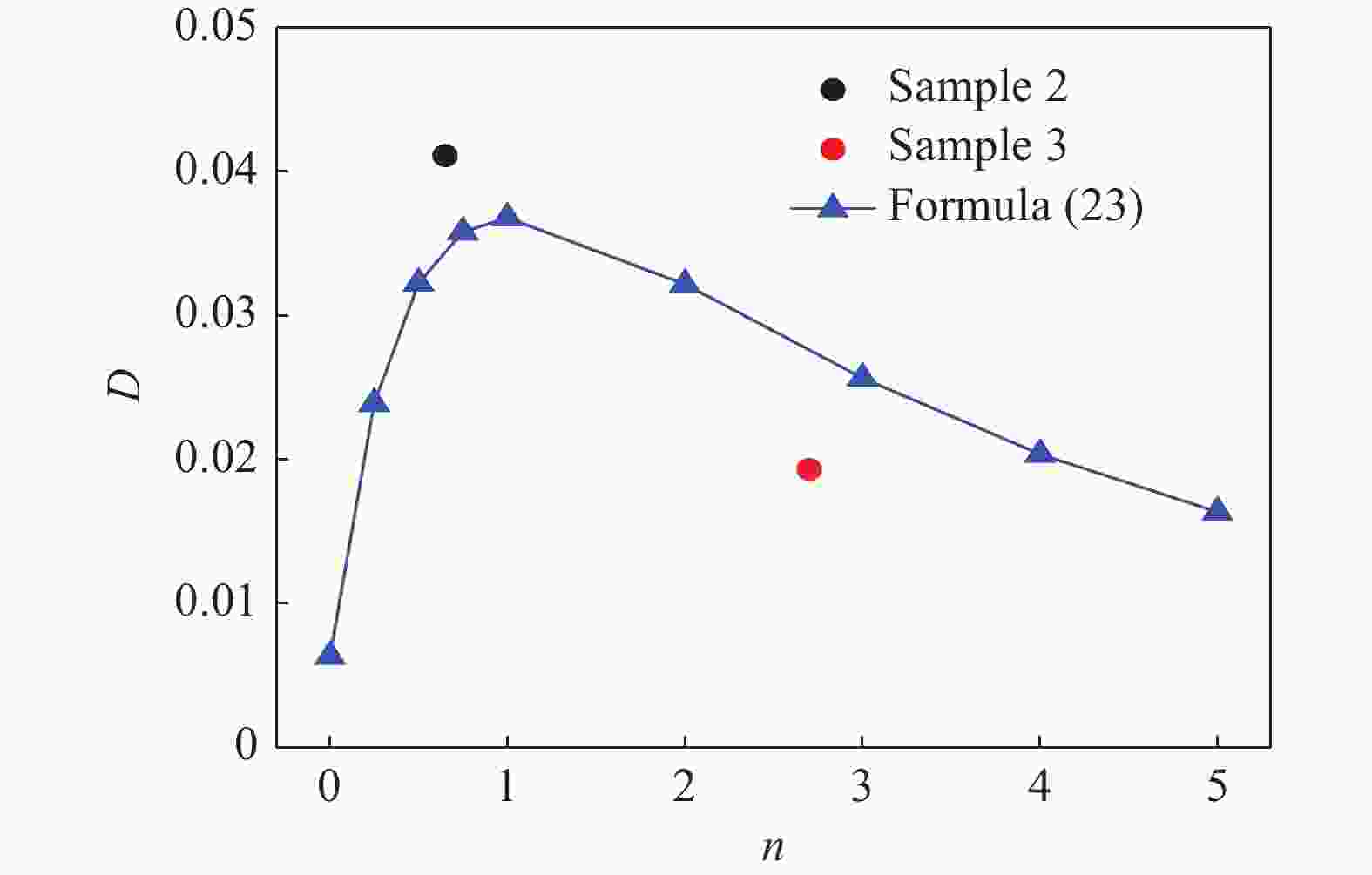

摘要: 分层梯度材料特定的梯度变化能有效增强材料性能。为研究梯度结构、冲击方向对分层梯度材料冲击响应的影响,利用分离式霍普金森压杆结合高速摄影技术对Mo-ZrC分层梯度金属陶瓷进行了动态压缩实验,基于数字图像相关技术讨论了梯度结构、冲击方向对金属陶瓷材料破坏模式的影响,利用Mori-Tanaka理论计算得到金属陶瓷等效性质,结合应力波理论研究波在分层梯度复合材料中的传播规律。结果表明:(1) 相同加载条件下,梯度结构对材料的强度、韧性和破坏产物的完整性具有重要影响,在冲击过程中,样品响应可以分为压紧阶段、裂纹成核发展阶段和贯穿阶段,对于不同梯度结构和冲击方向,样品在加载过程中呈现出不同的破坏时序和失效模式;(2) 利用数字图像相关方法跟踪分层梯度陶瓷的局部变形发展,分析发现局部增量达到临界状态后,局部变形发展转化为微裂纹的形成和累积,最终导致整体性破碎失效;(3) 通过分层梯度材料一维应力波传播理论推导得到,改变冲击梯度方向对应力波透反射系数存在一定影响,不同梯度结构设计对改变冲击梯度方向敏感性不同,且存在极值情况。

-

关键词:

- 冲击动力学 /

- Mo-ZrC金属陶瓷 /

- 分层结构 /

- 应力波传播

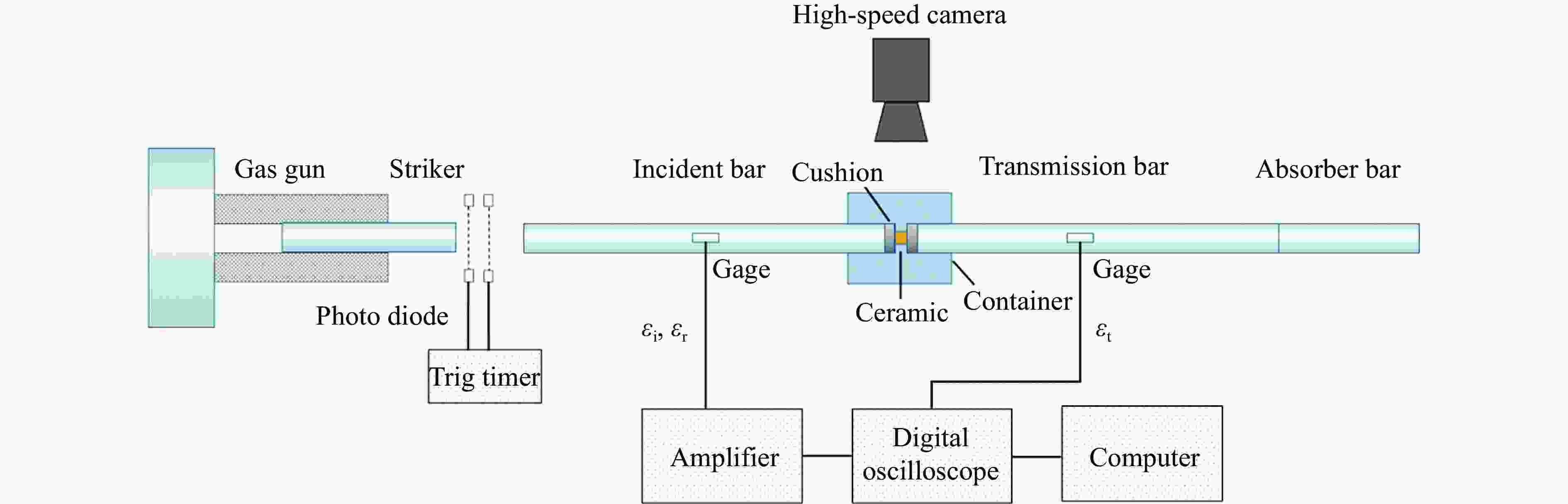

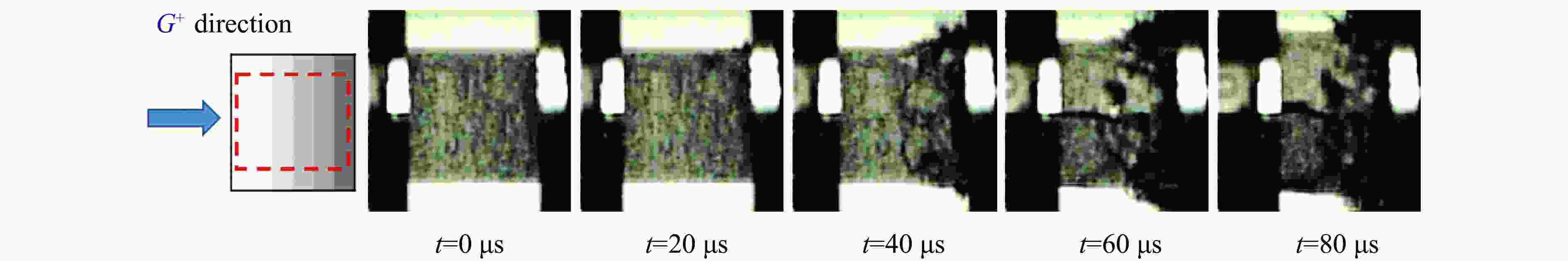

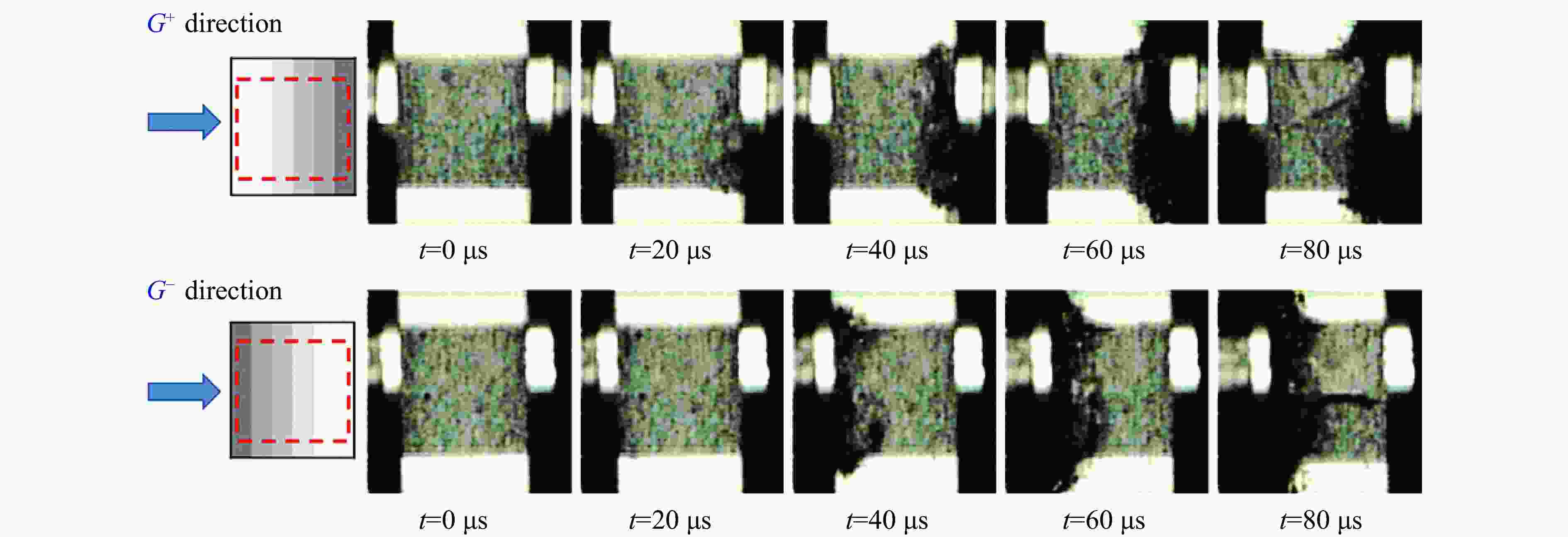

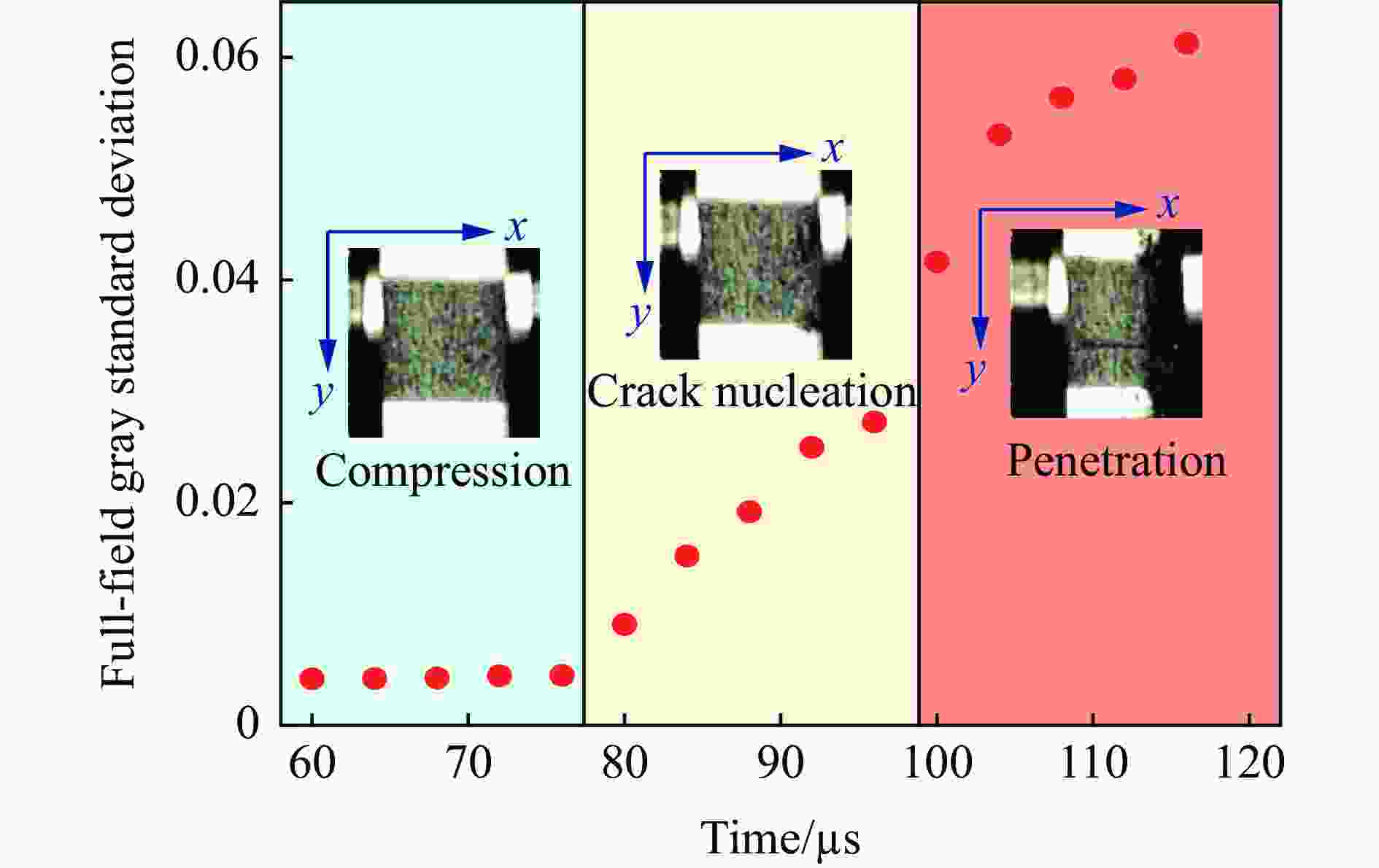

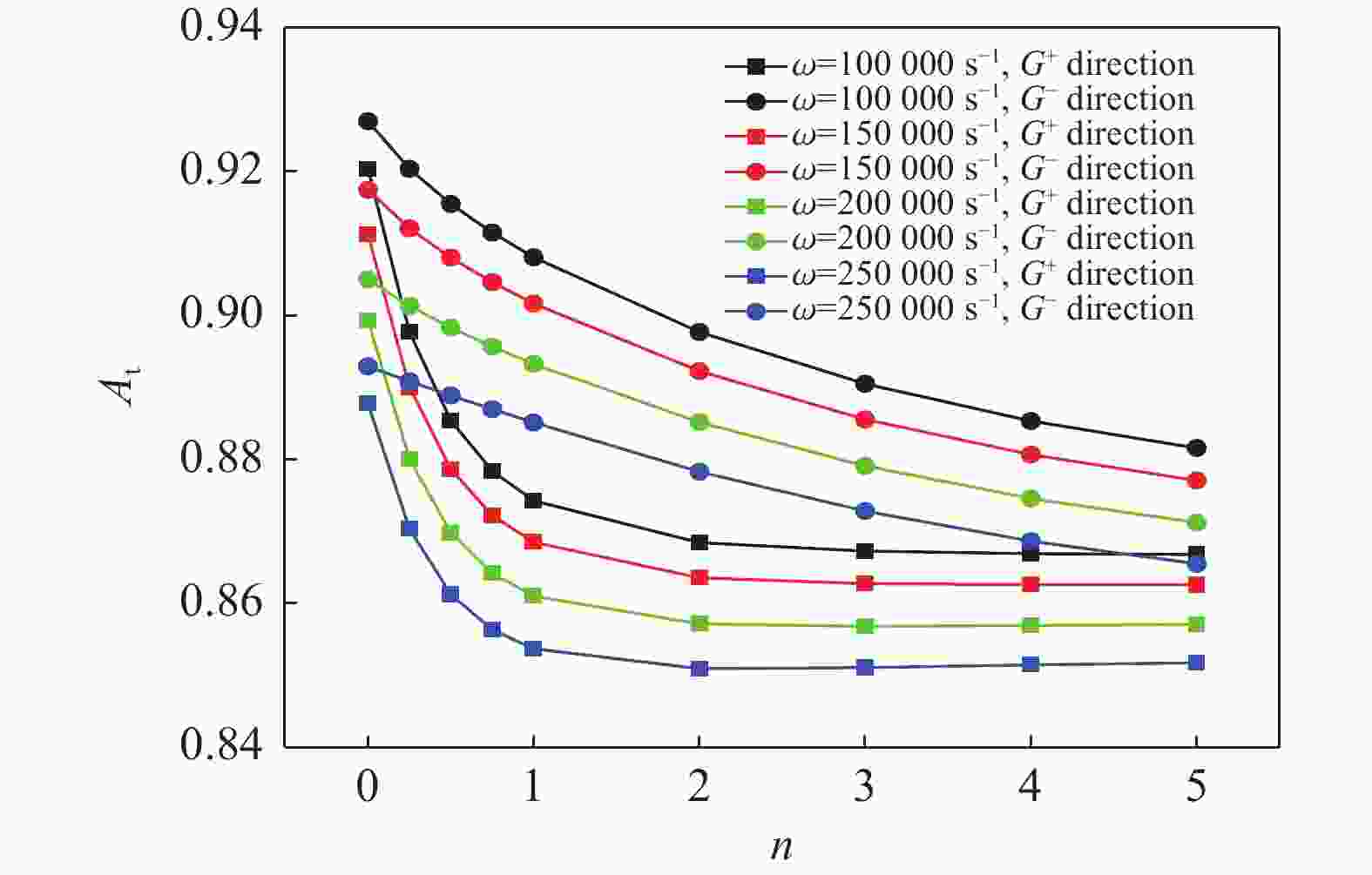

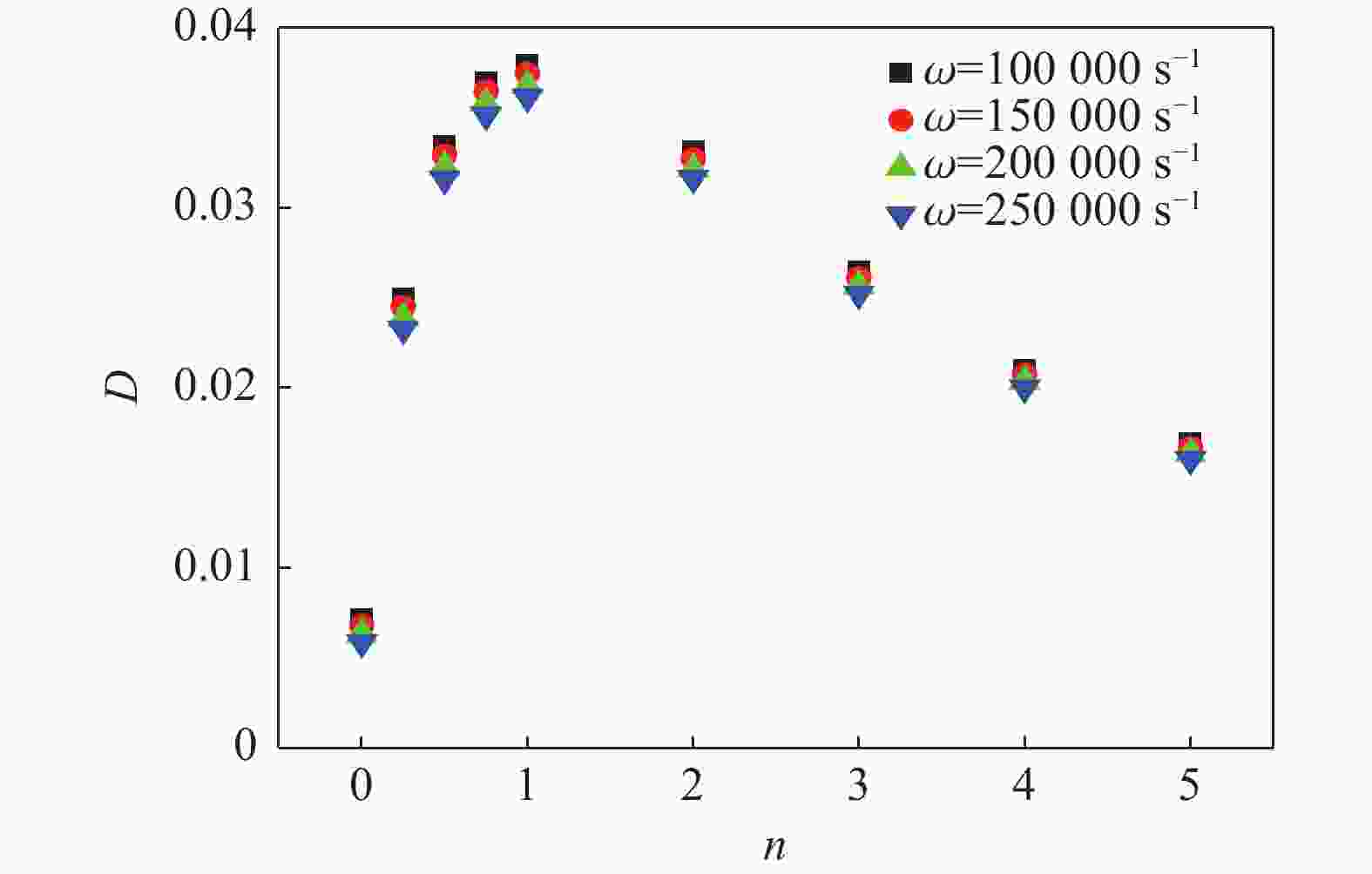

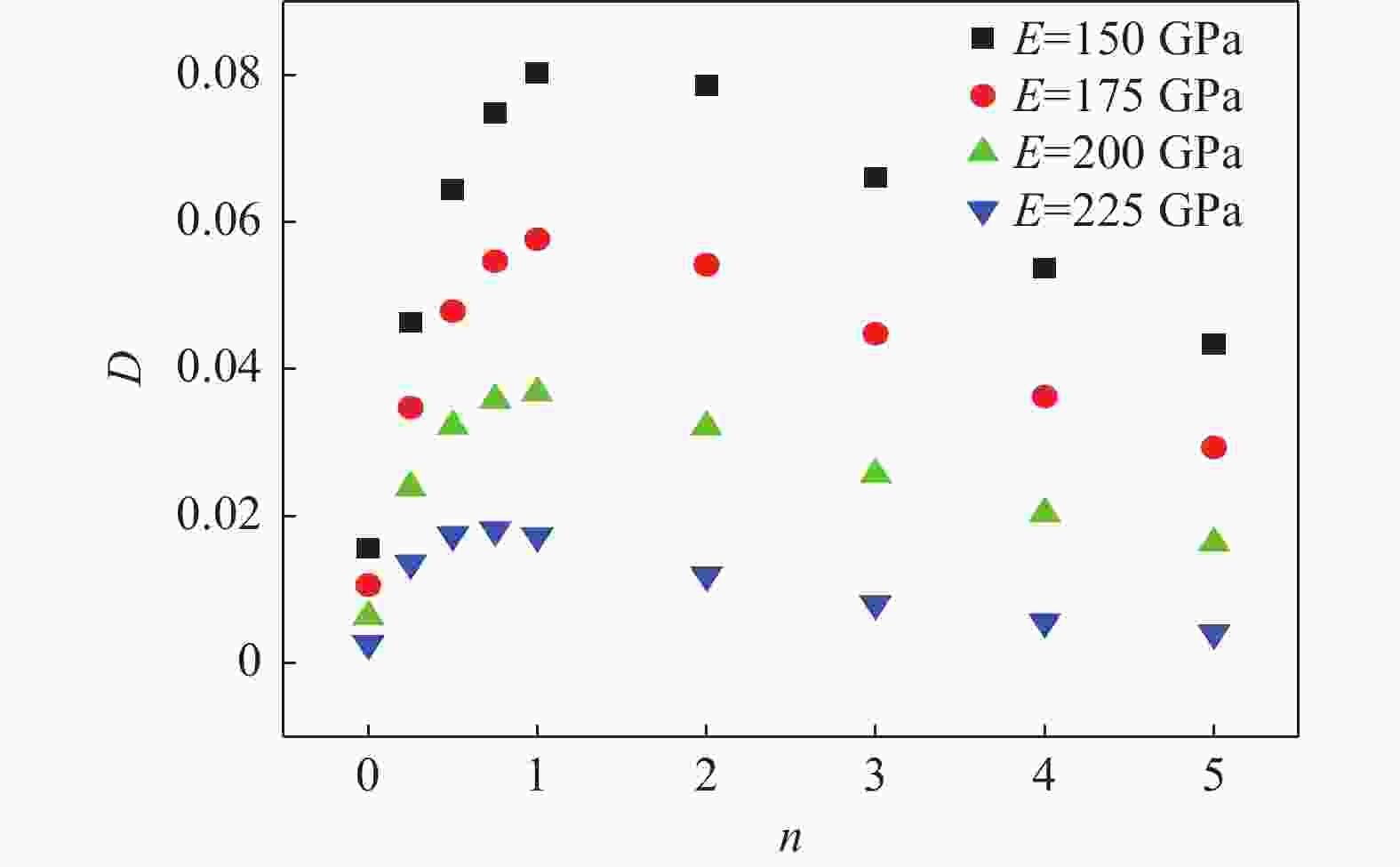

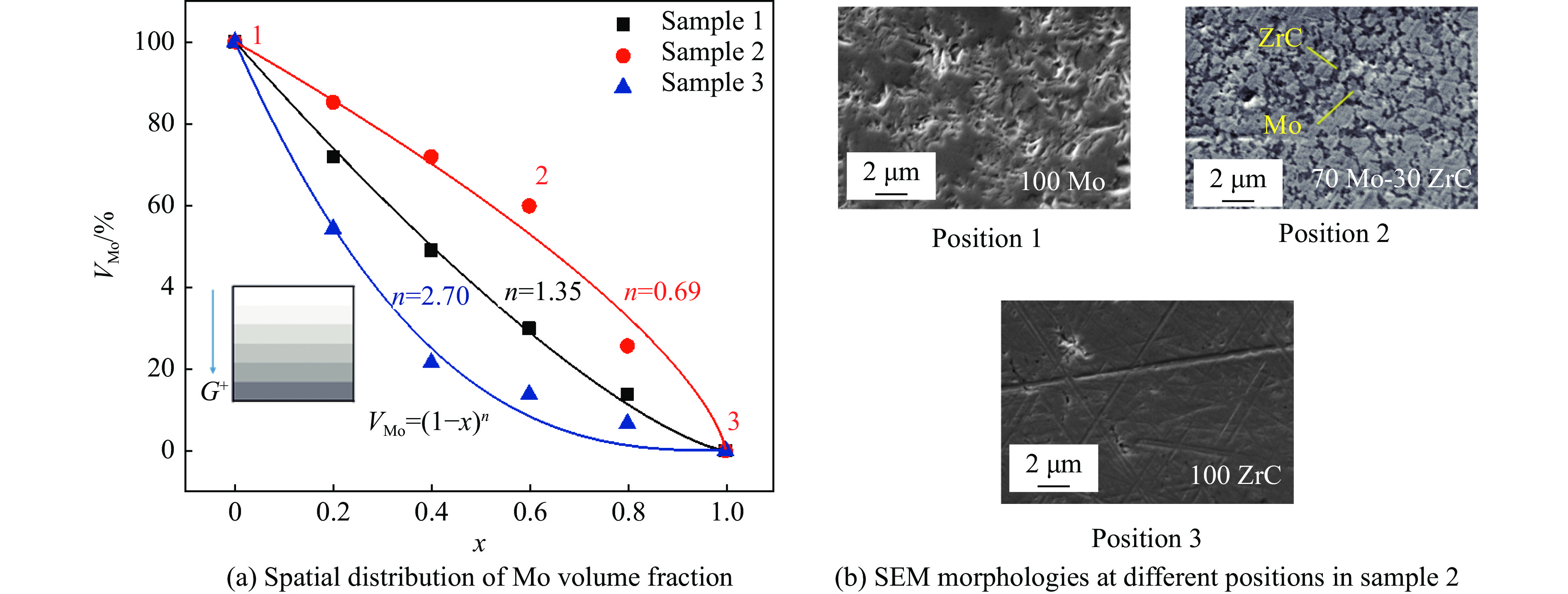

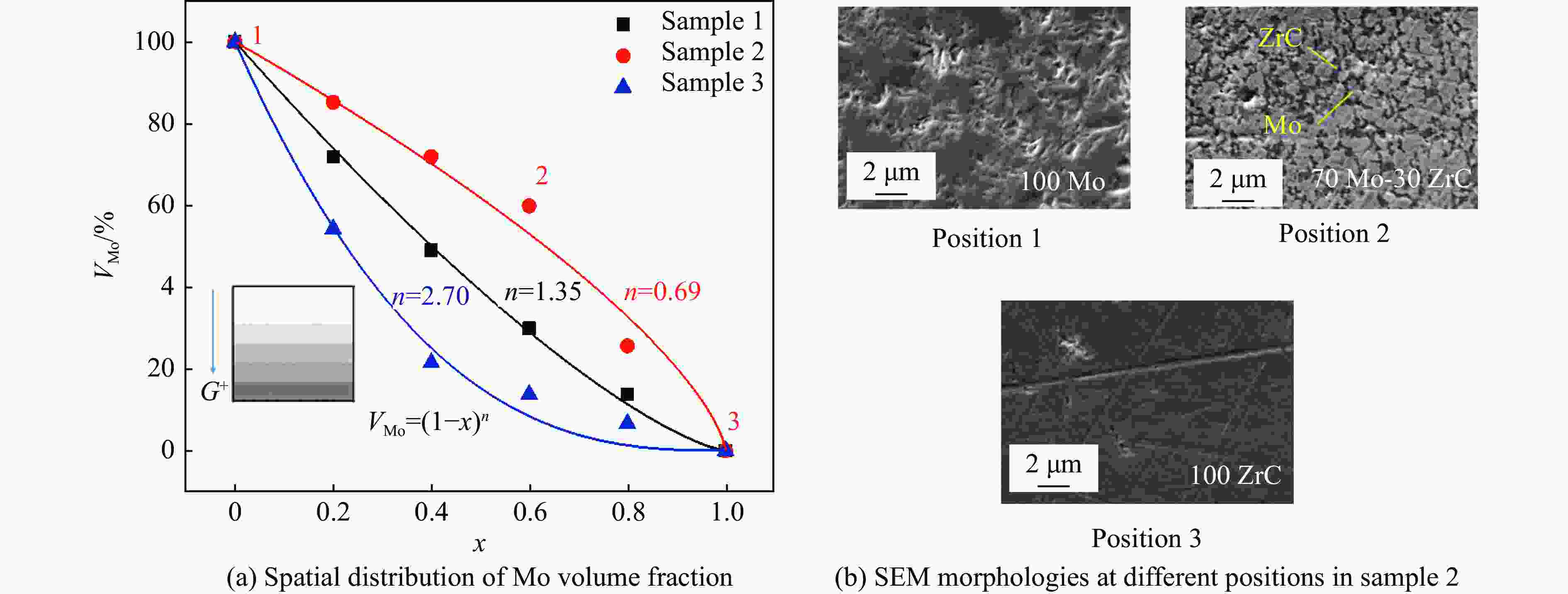

Abstract: Molybdenum (Mo) and zirconium carbide (ZrC) ceramic possess high strength and good wear resistance. Specific gradient changes of layered gradient structure can effectively take advantage of the two materials. To study the effects of gradient structure and impact direction on the dynamic responses of Mo-ZrC layered gradient cermet, the low-speed dynamic compression test of layered gradient cermet was launched by the split Hopkinson pressure bar device combined with high-speed photography technology, and three kinds of samples with different graded structures were pre-designed and sintered. Based on the digital image correlation (DIC) technology, the effects of gradient structure and impact direction on the failure modes of layered gradient cermet were discussed in detail. The propagation of the one-dimensional stress wave in the layered gradient composite was analyzed according to the equivalent properties of each layer of graded cermet calculated by the Mori-Tanaka theory. Results show as follows. (1) Under the same loading condition, the layered gradient structure has an important influence on material strength and integrity of the damaged product. Samples with a higher overall metal content exhibit better performance. In the process of impaction, the dynamic impaction responses can divide into three stages: compression, crack nucleation, and penetration. According to the results of high-speed photography, different gradient structure and direction of impact damage present different temporal and modes. (2) With the help of the calculation results based on the DIC method, the local deformation development of layered gradient cermet is tracked. When the local incremental development reaches a critical state, the local deformation development turns to the formation and accumulation of micro-cracks, which would lead to overall failure eventually. (3) Based on the one-dimensional stress wave propagation theory of layered gradient materials, the changing of impact direction influences the permeability and reflection coefficient of the stress wave, different gradient structure design shows sensitivity difference to the impact direction change, and there are extreme values.-

Key words:

- impact dynamics /

- Mo-ZrC cermet /

- layered structure /

- stress wave propagation

-

材料 密实度 密度/(kg·m−3) 模量/GPa 波速/(m·s−1) 泊松比 熔点/℃ Mo 0.95 10200 279 5230 0.32 3400 ZrC 0.98 6510 390 7740 0.191 2620 表 2 Mo-ZrC梯度金属陶瓷梯度结构

Table 2. Gradient structure of Mo-ZrC gradient metal ceramics

层编号 质量分数/% 样品 1 样品 2 样品 3 Mo ZrC Mo ZrC Mo ZrC 1 100 0 100 0 100 0 2 80 20 90 10 65 35 3 60 40 80 20 30 70 4 40 60 70 30 20 80 5 20 80 35 65 10 90 6 0 100 0 100 0 100 -

[1] UDUPA G, RAO S S, GANGADHARAN K V. Functionally graded composite materials: an overview [J]. Procedia Materials Science, 2014, 5: 1291–1299. DOI: 10.1016/j.mspro.2014.07.442. [2] SALEH B, JIANG J H, FATHI R, et al. 30 years of functionally graded materials: an overview of manufacturing methods, Applications and Future Challenges [J]. Composites Part B: Engineering, 2020, 201: 108376. DOI: 10.1016/j.compositesb.2020.108376. [3] LARSON R A, PALAZOTTO A N, GARDENIER H E. Impact response of titanium and titanium boride monolithic and functionally graded composite plates [J]. AIAA Journal, 2009, 47(3): 676–691. DOI: 10.2514/1.38577. [4] QI Q, JI W, LI Q N, et al. Integrated preparation and enhanced performance of high-melting-point ZrC-Mo multilayer graded materials [J]. Ceramics International, 2022, 48(14): 20769–20777. DOI: 10.1016/j.ceramint.2022.04.057. [5] LI Y, RAMESH K T, CHIN E S C. Dynamic characterization of layered and graded structures under impulsive loading [J]. International Journal of Solids and structures, 2001, 38(34/35): 6045–6061. DOI: 10.1016/S0020-7683(00)00364-4. [6] WU T, HU Y, LENG Y L, et al. In situ observation of fracture in homogeneous and functionally graded 6061Al/SiCp composites [J]. Materials Science and Engineering: A, 2022, 830: 142279. DOI: 10.1016/j.msea.2021.142279. [7] JIA M Y, CHEN F, WU Y Q, et al. Microstructure and shear fracture behavior of Mo/AlN/Mo symmetrical compositionally graded materials [J]. Materials Science and Engineering: A, 2022, 834: 142591. DOI: 10.1016/j.msea.2021.142591. [8] KEDIR N, KIRK C D, GUO Z R, et al. Real-time visualization of impact damage in monolithic silicon carbide and fibrous silicon carbide ceramic composite [J]. International Journal of Impact Engineering, 2019, 129: 168–179. DOI: 10.1016/j.ijimpeng.2019.01.012. [9] ZHU B, CAI Y J. A strain rate-dependent enhanced continuum model for elastic-plastic impact response of metal-ceramic functionally graded composites [J]. International Journal of Impact Engineering, 2019, 133: 103340. DOI: 10.1016/j.ijimpeng.2019.103340. [10] MOVAHEDI N, FIEDLER T, TAŞDEMIRCI A, et al. Impact loading of functionally graded metal syntactic foams [J]. Materials Science and Engineering: A, 2022, 839: 142831. DOI: 10.1016/j.msea.2022.142831. [11] KOOHBOR B, KIDANE A. Design optimization of continuously and discretely graded foam materials for efficient energy absorption [J]. Materials and Design, 2016, 102: 151–161. DOI: 10.1016/j.matdes.2016.04.031. [12] XIAO D B, DONG Z C, LI Y, et al. Compression behavior of the graded metallic auxetic reentrant honeycomb: experiment and finite element analysis [J]. Materials Science and Engineering: A, 2019, 758: 163–171. DOI: 10.1016/j.msea.2019.04.116. [13] KOOHBOR B, RAVINDRAN S, KIDANE A. In situ deformation characterization of density-graded foams in quasi-static and impact loading conditions [J]. International Journal of Impact Engineering, 2021, 150: 103820. DOI: 10.1016/j.ijimpeng.2021.103820. [14] CHEN X, CHANDRA N. The effect of heterogeneity on plane wave propagation through layered composites [J]. Composites Science and Technology, 2004, 64(10/11): 1477–1493. DOI: 10.1016/j.compscitech.2003.10.024. [15] BRUCK H A. A one-dimensional model for designing functionally graded materials to manage stress waves [J]. International Journal of solids and Structures, 2000, 37(44): 6383–6395. DOI: 10.1016/S0020-7683(99)00236-X. [16] KATOH Y, VASUDEVAMURTHY G, NOZAWA T, et al. Properties of zirconium carbide for nuclear fuel applications [J]. Journal of Nuclear Materials, 2013, 441(1/2/3): 718–742. DOI: 10.1016/j.jnucmat.2013.05.037. [17] LANDWEHR S E, HILMAS G E, FAHRENHOLTZ W G, et al. Microstructure and mechanical characterization of ZrC-Mo cermets produced by hot isostatic pressing [J]. Materials Science and Engineering: A, 2008, 497(1/2): 79–86. DOI: 10.1016/j.msea.2008.07.017. [18] CHENG J Y, NEMAT-NASSER S, GUO W G. A unified constitutive model for strain-rate and temperature dependent behavior of molybdenum [J]. Mechanics of Materials, 2001, 33(11): 603–616. DOI: 10.1016/S0167-6636(01)00076-X. [19] LI Y, FENG Z Y, HAO L, et al. A review on functionally graded materials and structures via additive manufacturing: from multi-scale design to versatile functional properties [J]. Advanced Materials Technologies, 2020, 5(6): 1900981. DOI: 10.1002/admt.201900981. [20] HUANG J Y, LU L, FAN D, et al. Heterogeneity in deformation of granular ceramics under dynamic loading [J]. Scripta Materialia, 2016, 111: 114–118. DOI: 10.1016/j.scriptamat.2015.08.028. [21] GRADY D E, KIPP M E. Continuum modelling of explosive fracture in oil shale [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1980, 17(3): 147–157. DOI: 10.1016/0148-9062(80)91361-3. [22] 徐松林, 刘永贵, 席道瑛. 岩石物理与动力学原理 [M]. 北京: 科学出版社, 2019: 159–163.XU S L, LIU Y G, XI D Y. Rock physics and dynamics principle [M]. Beijing, China: Science Press, 2019: 159–163. [23] 李毅, 苗春贺, 徐松林, 等. 梯度密度黏弹性材料的波传播研究 [J]. 爆炸与冲击, 2021, 41(1): 013202. DOI: 10.11883/bzycj-2020-0313.LI Y, MIAO C H, XU S L, et al. Wave propagation in density-graded viscoelastic material [J]. Explosion and Shock Waves, 2021, 41(1): 013202. DOI: 10.11883/bzycj-2020-0313. -

下载:

下载: