Practical engineering calculation models for rigid projectile penetrating and perforating into concrete target

-

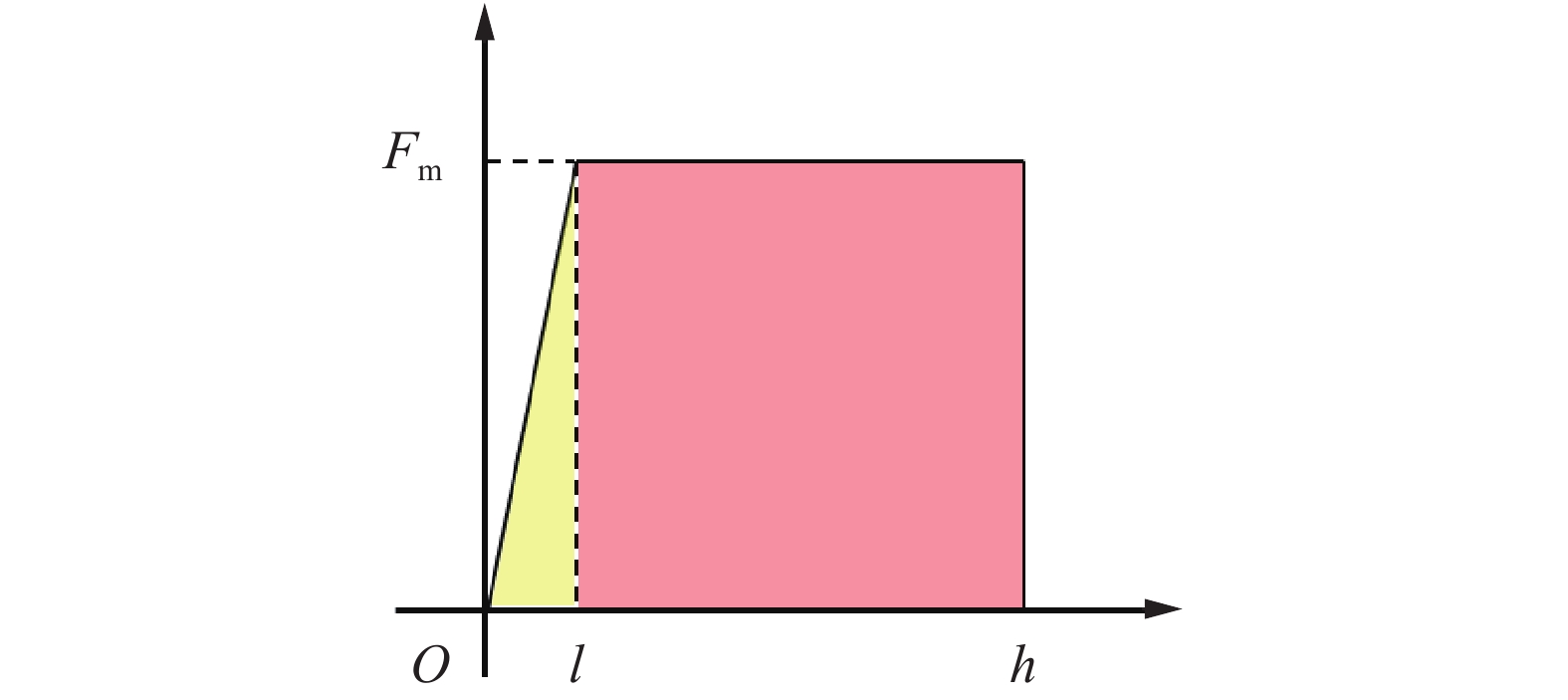

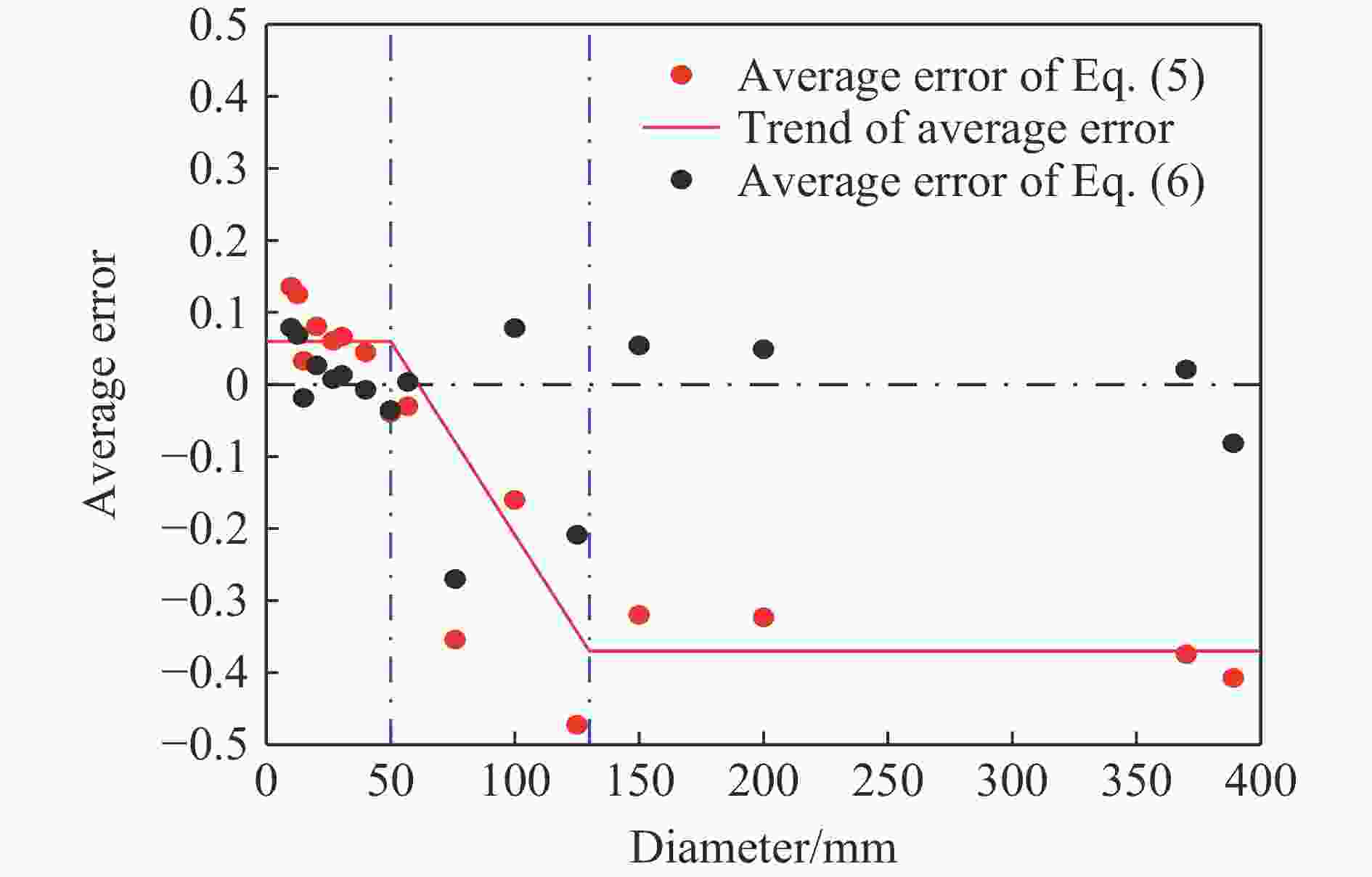

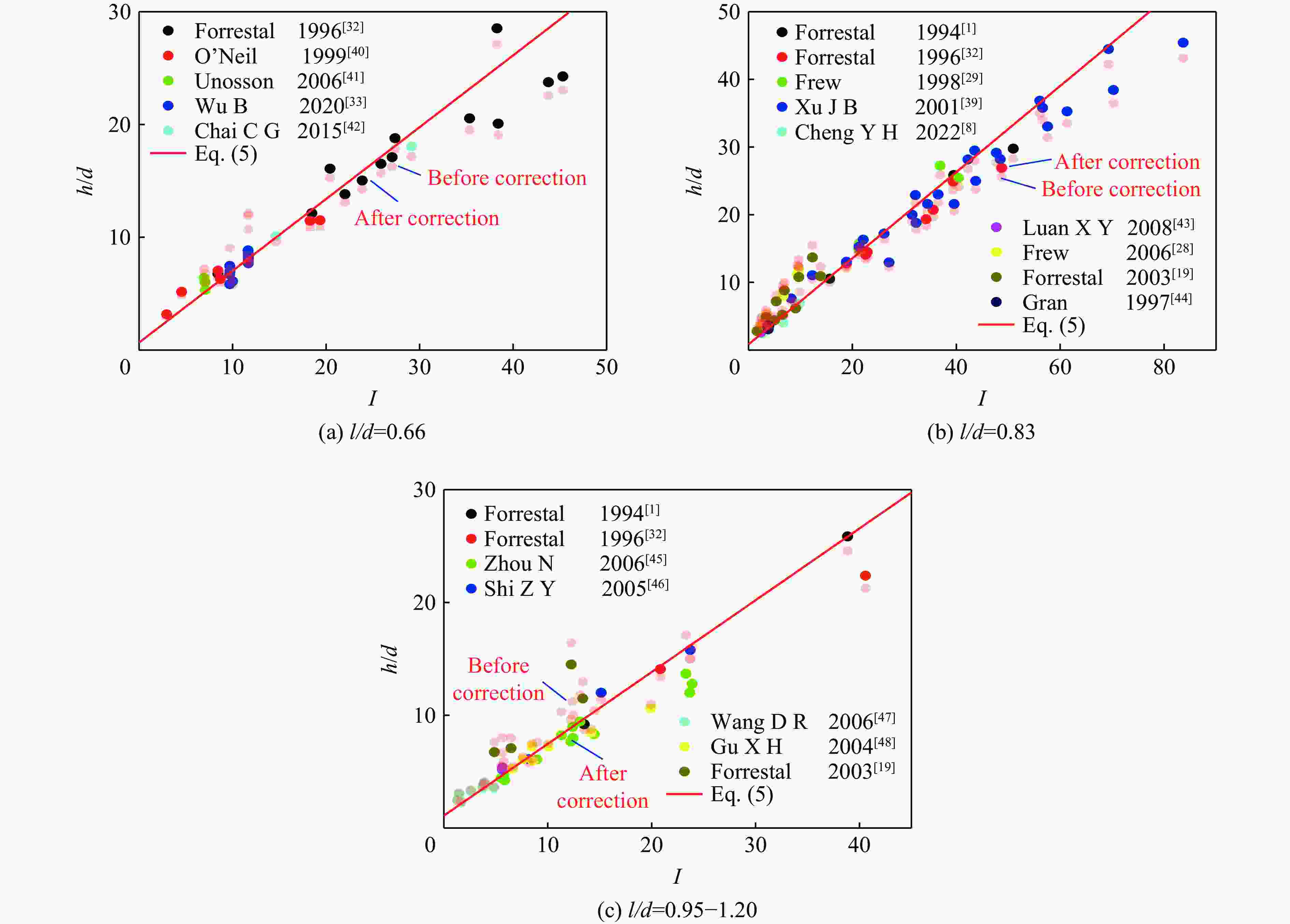

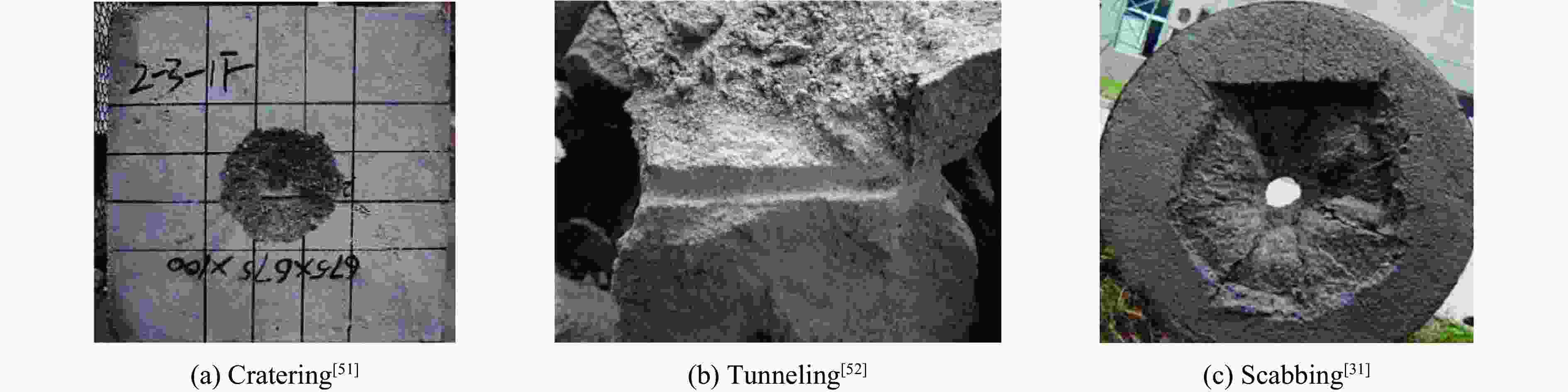

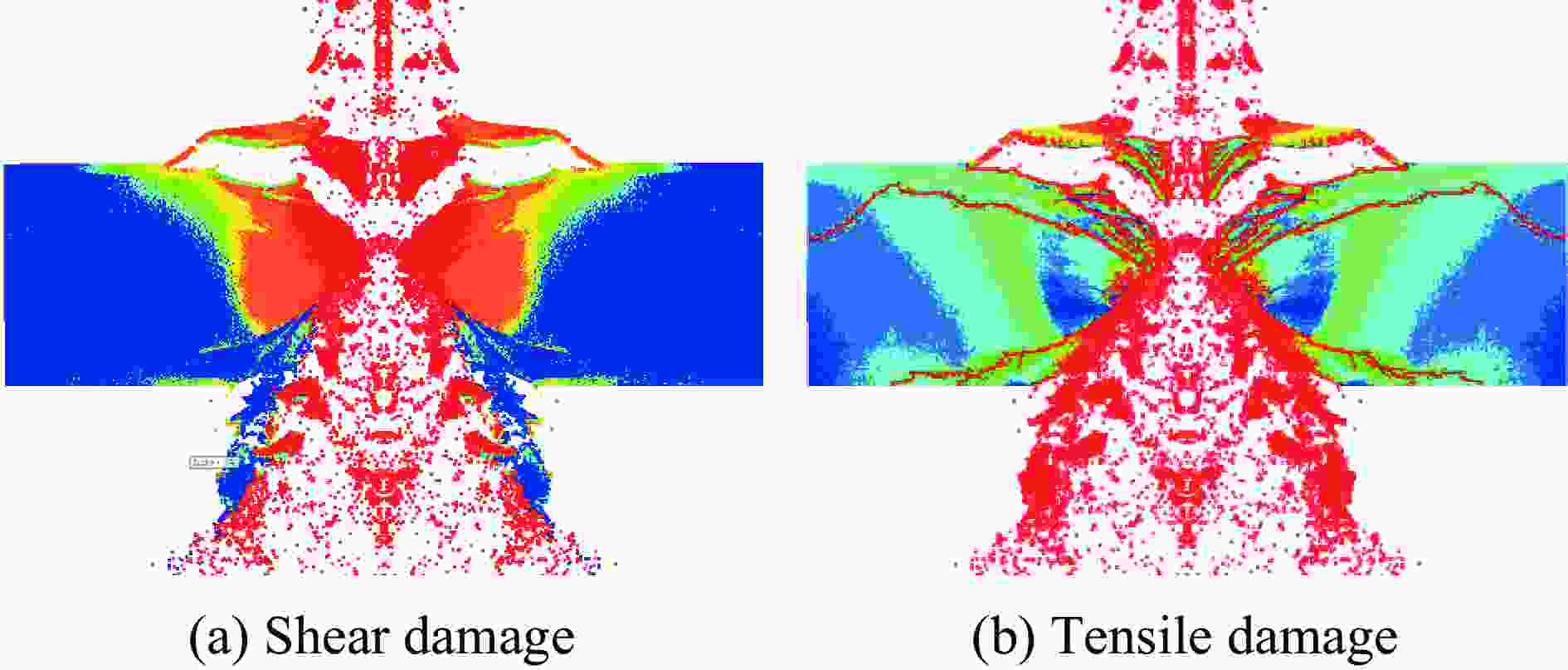

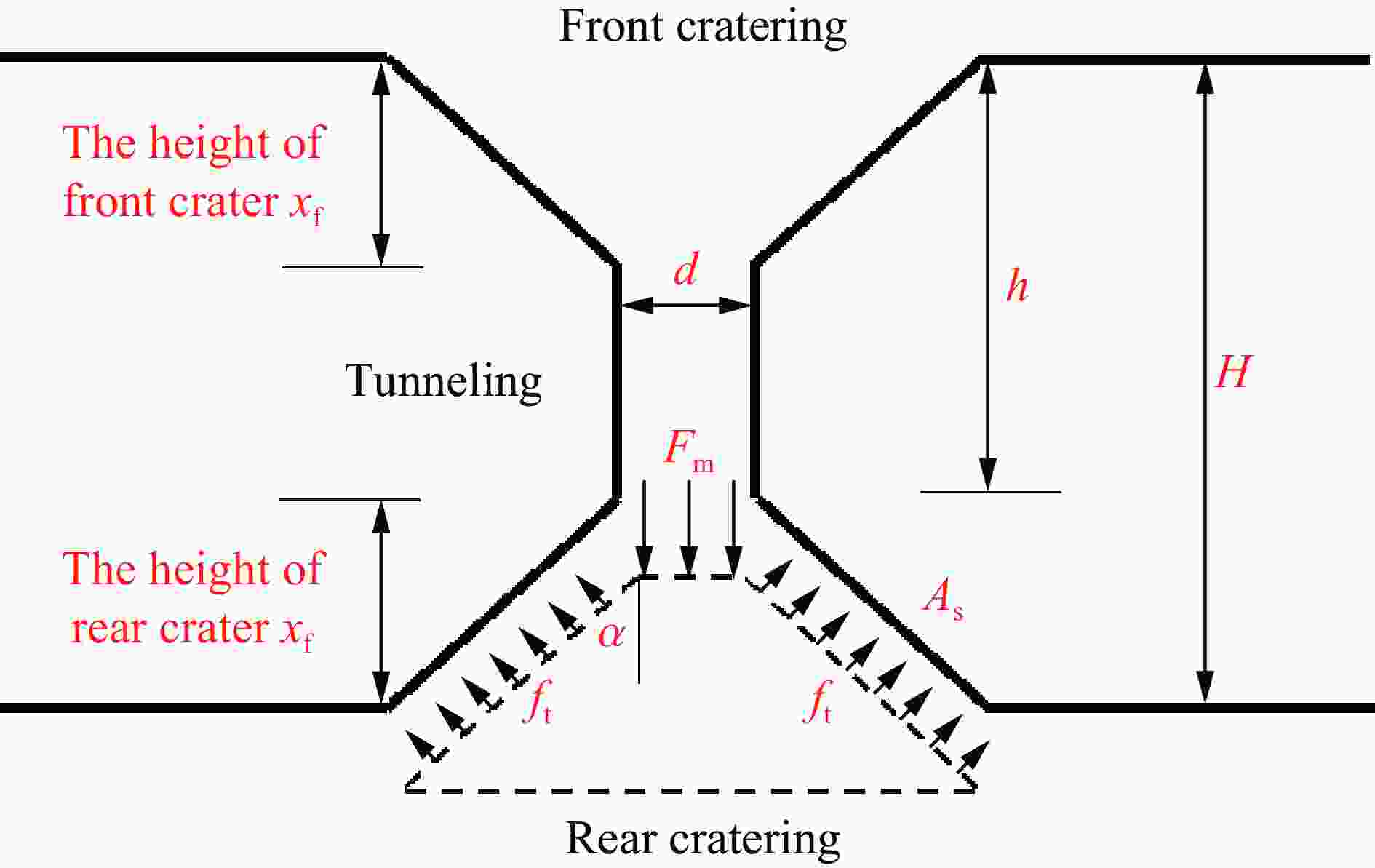

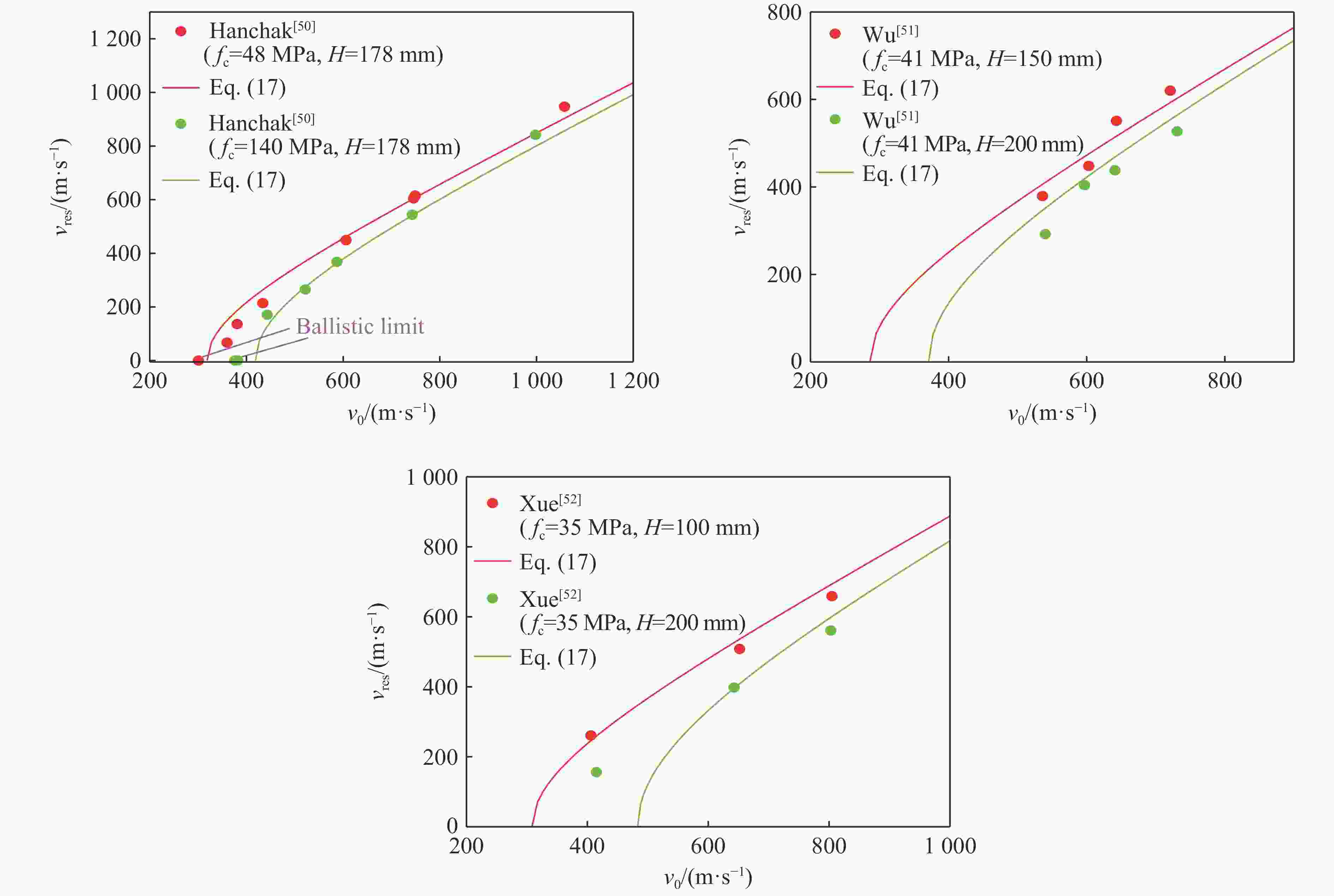

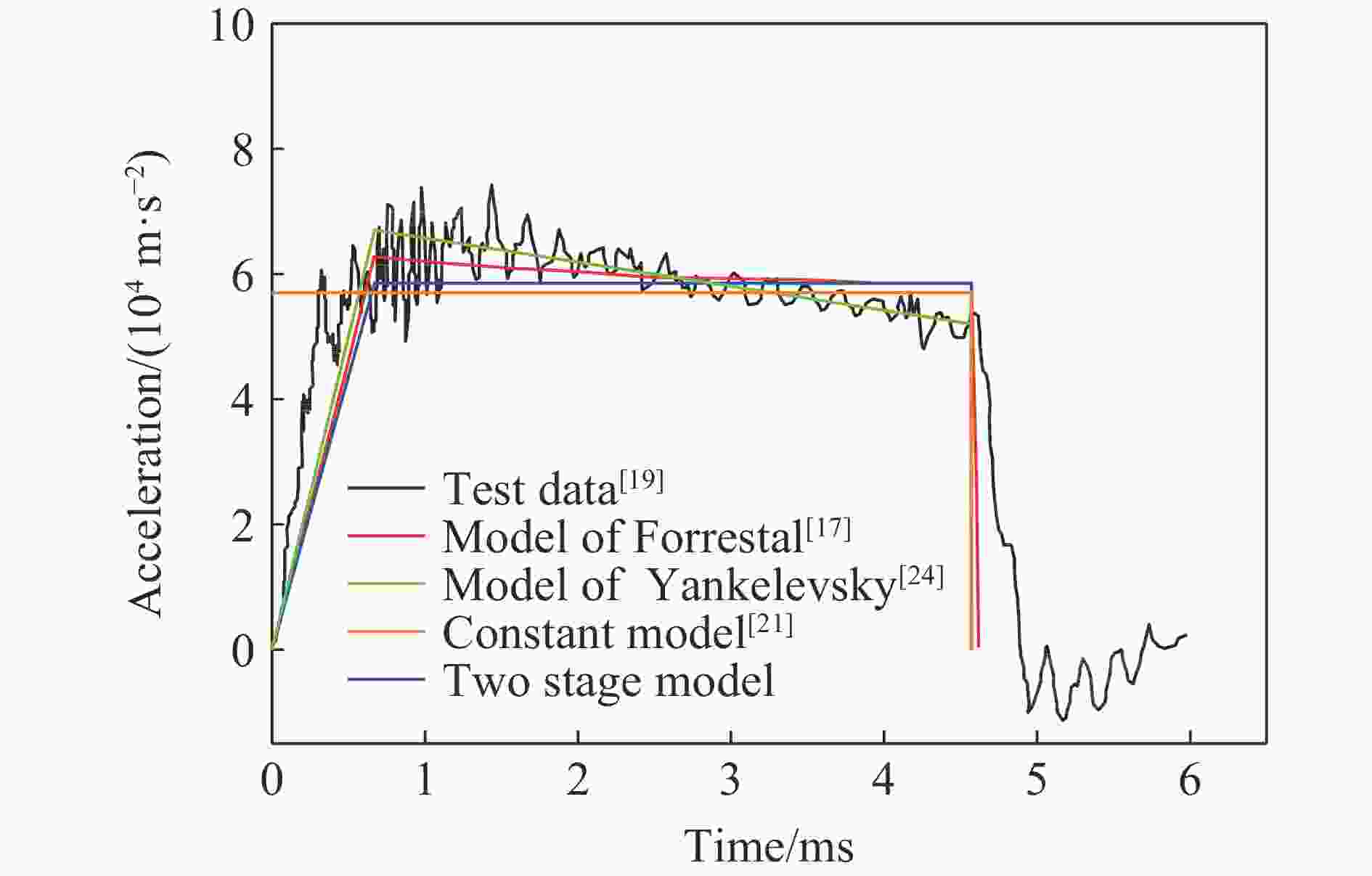

摘要: 准确计算钻地弹对混凝土材料的侵彻深度和临界贯穿厚度是防护工程领域重点关注的问题。现有侵彻深度计算公式对于大口径钻地弹的预测精度较差,且临界贯穿厚度的计算方法缺乏理论依据。针对上述问题,基于145组刚性卵弹侵彻混凝土试验数据和32组贯穿混凝土试验数据,对刚性卵弹侵彻和贯穿混凝土靶体的实用化计算模型进行了研究。首先基于对刚性弹侵彻混凝土靶体的阻力分析,提出线性上升-恒定的两阶段阻力模型,建立了考虑尺寸效应影响的侵彻深度实用化计算模型,通过与15组大口径、大长径比的侵彻试验数据及ACE和NDRC公式的对比分析,验证了提出公式的可靠性和优越性;然后基于后坑由拉伸破坏引起的基本假定,给出了临界贯穿厚度、弹道极限和残余速度的计算模型;最后通过与现有的贯穿试验数据对比分析,验证了计算模型的正确性。Abstract: Accurate predictions of the penetration depth and critical perforation thickness of earth penetration weapons into concrete materials are key issues in the field of protective engineering. However, the widely-used formulas have limited predictive accuracy for penetration depth when earth penetration weapons have a large diameter and a high aspect ratio, and are lack of theoretical basis for critical perforation thickness. To resolve the two issues above, the engineering calculation models of rigid ogive-nose shape projectile penetrating and/or perforating into concrete targets are investigated in this paper on the basis of 145 sets of penetration data and 32 sets of perforation data. Firstly, based on the resistance analysis of rigid projectile penetrating into concrete target, a two-stage resistance model is proposed, and then a practical calculation model of penetration depth with the consideration of scaling effect is proposed. The reliability of the proposed model is verified by comparing it with 15 sets of penetration data with large diameter and high aspect ratio as well as the predictions by widely-used ACE formula and NDRC formula. The results show that the average errors of the proposed formula, ACE formula and NDRC formula are 5.5%, 15.7% and 24.9%, respectively. Secondly, based on the assumption that the scabbing is caused by the tensile failure of concrete, a formula for the scabbing height is derived based on the force equilibrium between the stress produced by the projectile and the tensile strength of concrete target. Then, the formulas for the critical perforation thickness, ballistic limit and residual velocity are deduced, which are validated by the relevant experimental data. Besides, the coefficients of concrete targets in preventing perforation for four typical earth penetration weapons are compared and analyzed. The accuracy of proposed calculation models for penetration depth and critical perforation thickness shows a great improvement, providing reliable reference for engineering design.

-

Key words:

- rigid projectile /

- concrete target /

- penetration /

- perforation

-

表 1 弹径修正系数取值表

Table 1. Correction factor for projectile diameter

弹径/mm <40 60 80 100 >130 λd 0.95 1.05 1.15 1.25 1.55 表 2 大口径弹体侵彻混凝土靶体试验数据及各公式预测误差

Table 2. Test data and formulas error for projectile penetrating into concrete targets with large projectile diameters

来源 弹重/kg 弹径/mm 弹头长/mm 强度/MPa 初速度/(m·s−1) 试验侵深/mm 公式误差/% ACE NDRC 本文公式 周宁等[45] 25 100 193.6 35 456 1000 −7.21 −19.41 11.09 25 100 193.6 35 310 590 −8.13 −23.32 −1.95 25 100 193.6 35 387 750 −1.82 −16.62 11.20 25 100 193.6 35 455 1100 −15.91 −26.99 0.60 25 100 193.6 35 468 1190 −19.10 −29.44 −2.21 程月华等[8] 17.3 100 165.0 40 503 860 −17.64 −24.98 3.18 17.3 100 165.0 100 357 350 −14.59 −18.28 3.79 20.1 105 162.0 40 325 515 −19.10 −28.29 −9.88 145.0 203 335.4 100 360 870 −19.71 −25.81 6.56 874.0 370 571.0 100 325 1400 −11.27 −19.78 2.07 吴飚等[33] 25.62 100 132.3 40 450 1070.0 −18.23 −28.90 −5.40 25.62 100 132.3 60 450 906.0 −20.13 −29.42 −5.59 89.99 152 201.1 40 450 1810.3 −19.99 −31.27 5.41 214.35 203 268.5 40 450 2468.5 −16.88 −29.17 3.23 王德荣等[47] 307 300 540 176 320 740 −25.99 −21.24 9.92 表 3 后坑高度预测值和试验值的对比

Table 3. Comparison of scabbing depth predicted by Eq. (11) with test data

来源 靶体厚度/mm 靶体抗压强度/MPa 靶体抗拉强度/MPa 阻力系数 后坑角度/(°) 无量纲后坑高度 试验值 公式(11) 误差/% Hanchak等[50] 178 48 4 10.06 65 2.33d 2.34d 0.43 178 140 5 5.62 2.33d 2.70d −15.88 Wu等[51] 200 41 3.71* 10.96 65 2.57d 2.34d 8.95 200 2.37d 1.27 200 1.98d −18.18 200 2.17d −7.83 150 2.57d 8.95 150 2.77d 15.52 150 2.57d 8.95 150 2.37d 1.27 Li等[31] 300 34.26 3.22* 12.08 65 2.03d 2.42d −19.21 400 2.84d 14.79 500 3.83d 36.81 600 4.77d 49.27 700 4.25d 43.06 注:*表示在试验中未实际测量靶体的抗拉强度,是通过规范[58]估计得到。 -

[1] FORRESTAL M J, ALTMAN B S, CARGILE J D, et al. An empirical equation for penetration depth of ogive-nose projectiles into concrete targets [J]. International Journal of Impact Engineering, 1994, 15(4): 395–405. DOI: 10.1016/0734-743X(94)80024-4. [2] KONG X Z, WU H, FANG Q, et al. Rigid and eroding projectile penetration into concrete targets based on an extended dynamic cavity expansion model [J]. International Journal of Impact Engineering, 2017, 100: 13–22. DOI: 10.1016/j.ijimpeng.2016.10.005. [3] LI Q M, CHEN X W. Dimensionless formulae for penetration depth of concrete target impacted by a non-deformable projectile [J]. International Journal of Impact Engineering, 2003, 28(1): 93–116. DOI: 10.1016/S0734-743X(02)00037-4. [4] YARIN A L, RUBIN M B, ROISMAN I V. Penetration of a rigid projectile into an elastic-plastic target of finite thickness [J]. International Journal of Impact Engineering, 1995, 16(5/6): 801–831. DOI: 10.1016/0734-743X(95)00019-7. [5] LI Q M, REID S R, WEN H M, et al. Local impact effects of hard missiles on concrete targets [J]. International Journal of Impact Engineering, 2005, 32(1/2/3/4): 224–284. DOI: 10.1016/j.ijimpeng.2005.04.005. [6] 王安宝, 邓国强, 张磊, 等. 混凝土侵彻公式的合理性分析 [J]. 防护工程, 2020, 42(6): 1–7. DOI: 10.3969/j.issn.1674-1854.2020.06.001.WANG A B, DENG G Q, ZHANG L, et al. Analysis on the rationality of concrete penetration formula [J]. Protective Engineering, 2020, 42(6): 1–7. DOI: 10.3969/j.issn.1674-1854.2020.06.001. [7] 张爽. 弹体侵彻/贯穿钢筋混凝土靶机理与弹道轨迹研究 [D]. 北京:北京理工大学, 2018. DOI: 10.26948/d.cnki.gbjlu.2018.000162.ZHANG S. Investigation on the mechanism and trajectory of projectile penetrating / perforating reinforced concrete target [D]. Beijing: Beijing Institute of Technology, 2018. DOI: 10.26948/d.cnki.gbjlu.2018.000162. [8] 程月华, 姜鹏飞, 吴昊, 等. 考虑尺寸效应的典型钻地弹侵彻混凝土深度分析 [J]. 爆炸与冲击, 2022, 42(6): 063302. DOI: 10.11883/bzycj-2021-0373.CHENG Y H, JIANG P F, WU H, et al. On penetration depth of typical earth-penetrating projectiles into concrete targets considering the scaling effect [J]. Explosion and Shock Waves, 2022, 42(6): 063302. DOI: 10.11883/bzycj-2021-0373. [9] 龚自明, 方秦, 张亚栋, 等. 混凝土靶体侵彻不贯穿系数的试验研究 [J]. 兵工学报, 2009,30 (9): 1181–1186. DOI: 10.3321/j.issn:1000-1093.2009.09.006.GONG Z M, FANG Q, ZHANG Y D, et al. Experimental investigation into coefficients of concrete targets to prevent perforation [J]. Acta Armamentarii, 2009,30 (9): 1181–1186. DOI: 10.3321/j.issn:1000-1093.2009.09.006. [10] WALTER T A, WOLDE-TINSAE A M. Turbine missile perforation of reinforced concrete [J]. Journal of Structural Engineering, 1984, 110(10): 2439–2455. DOI: 10.1061/(ASCE)0733-9445(1984)110:10(2439). [11] ACE. Fundamentals of protective structures: report AT120 AT1207821[R]. Office of the Chief of Engineers, Army Corps of Engineers, 1946. [12] NDRC. Effects of impact and explosion. summary technical report of division 2, vol. 1[S]. Washington D C: National Defence Research Committee, 1946. [13] LI Q M, REID S R, AHMAD-ZAIDI A M. Critical impact energies for scabbing and perforation of concrete target [J]. Nuclear Engineering and Design, 2006, 236(11): 1140–1148. DOI: 10.1016/j.nucengdes.2005.10.017. [14] CHEN X W, LI X L. Modeling of normal perforation of reinforced concrete slabs by a rigid projectile [J]. Transactions of Tianjin University, 2006,12 (S1): 107–111. [15] CHEN X W, FAN S C, LI Q M. Oblique and normal perforation of concrete targets by a rigid projectile [J]. International Journal of Impact Engineering, 2004, 30(6): 617–637. DOI: 10.1016/j.ijimpeng.2003.08.003. [16] PENG Y, WU H, FANG Q, et al. A note on the deep penetration and perforation of hard projectiles into thick targets [J]. International Journal of Impact Engineering, 2015, 85: 37–44. DOI: 10.1016/j.ijimpeng.2015.06.013. [17] FORRESTAL M J, TZOU D Y. A spherical cavity-expansion penetration model for concrete targets [J]. International Journal of Solids and Structures, 1997, 34(31/32): 4127–4146. DOI: 10.1016/S0020-7683(97)00017-6. [18] CHEN X W, LI Q M. Deep penetration of a non-deformable projectile with different geometrical characteristics [J]. International Journal of Impact Engineering, 2002, 27(6): 619–637. DOI: 10.1016/S0734-743X(02)00005-2. [19] FORRESTAL M J, FREW D J, HICKERSON J P, et al. Penetration of concrete targets with deceleration-time measurements [J]. International Journal of Impact Engineering, 2003, 28(5): 479–497. DOI: 10.1016/S0734-743X(02)00108-2. [20] ROSENBERG Z, DEKEL E. The penetration of rigid long rods–revisited [J]. International Journal of Impact Engineering, 2009, 36(4): 551–564. DOI: 10.1016/j.ijimpeng.2008.06.001. [21] ROSENBERG Z, DEKEL E. The deep penetration of concrete targets by rigid rods-revisited [J]. International Journal of Protective Structures, 2010, 1(1): 125–144. DOI: 10.1260/2041-4196.1.1.125. [22] ROSENBERG Z, DEKEL E, KOSITSKI R. A comment on “constant deceleration approach for the penetration analysis of rigid projectiles into concrete targets [J]. International Journal of Protective Structures, 2020, 11(3): 411–414. DOI: 10.1177/2041419620939117. [23] ROSENBERG Z, KOSITSKI R, DEKEL E. Comment on: “rigid and eroding projectile penetration into concrete targets based on an extended cavity expansion model [J]. International Journal of Impact Engineering, 2017, 100(104): A1–A3. DOI: 10.1016/j.ijimpeng.2017.03.004. [24] YANKELEVSKY D Z, FELDGUN V R. Constant deceleration approaches for penetration analysis of rigid projectile into concrete [J]. International Journal of Protective Structures, 2020, 11(4): 515–532. DOI: 10.1177/2041419620914646. [25] YANKELEVSKY D Z, FELDGUN V R. Response and closure to: a comment on “Constant deceleration approach for the penetration analysis of rigid projectiles into concrete targets [J]. International Journal of Protective Structures, 2020, 11(3): 415–420. DOI: 10.1177/2041419620939106. [26] 陈小伟, 李继承. 刚性弹侵彻深度和阻力的比较分析 [J]. 爆炸与冲击, 2009, 29(6): 584–589. DOI: 10.11883/1001-1455(2009)06-0584-06.CHEN X W, LI J C. Analysis on the penetration depth and resistive force in the deep penetration of a rigid projectile [J]. Explosion and Shock Waves, 2009, 29(6): 584–589. DOI: 10.11883/1001-1455(2009)06-0584-06. [27] KONG X Z, WU H, FANG Q, et al. Response to: comment on “rigid and eroding projectile penetration into concrete targets based on an extended cavity expansion model” by Kong et al. Int. J. Impact Eng. 2017 by Z. Rosenberg et al [J]. International Journal of Impact Engineering, 2017, 100(104): 150–153. DOI: 10.1016/j.ijimpeng.2017.03.003. [28] FREW D J, FORRESTAL M J, CARGILE J D. The effect of concrete target diameter on projectile deceleration and penetration depth [J]. International Journal of Impact Engineering, 2006, 32(10): 1584–1594. DOI: 10.1016/j.ijimpeng.2005.01.012. [29] FREW D J, HANCHAK S J, GREEN M L, et al. Penetration of concrete targets with ogive-nose steel rods [J]. International Journal of Impact Engineering, 1998, 21(6): 489–497. DOI: 10.1016/S0734-743X(98)00008-6. [30] TELAND J A, SJØL H. Penetration into concrete by truncated projectiles [J]. International Journal of Impact Engineering, 2004, 30(4): 447–464. DOI: 10.1016/S0734-743X(03)00073-3. [31] LI J Z, LV Z J, ZHANG H S, et al. Perforation experiments of concrete targets with residual velocity measurements [J]. International Journal of Impact Engineering, 2013, 57: 1–6. DOI: 10.1016/j.ijimpeng.2013.01.007. [32] FORRESTAL M J, FREW D J, HANCHAK S J, et al. Penetration of grout and concrete targets with ogive-nose steel projectiles [J]. International Journal of Impact Engineering, 1996, 18(5): 465–476. DOI: 10.1016/0734-743X(95)00048-F. [33] 吴飚, 任辉启, 陈力, 等. 弹体侵彻混凝土尺度效应试验研究与理论分析 [J]. 防护工程, 2020, 42(2): 1–10. DOI: 10.3969/j.issn.1674-1854.2020.02.001.WU B, REN H Q, CHEN L, et al. Experimental study and theoretical analysis of size effect on projectile penetrating concrete [J]. Protective Engineering, 2020, 42(2): 1–10. DOI: 10.3969/j.issn.1674-1854.2020.02.001. [34] WU H, LI Y C, FANG Q, et al. Scaling effect of rigid projectile penetration into concrete target: 3D mesoscopic analyses [J]. Construction and Building Materials, 2019, 208: 506–524. DOI: 10.1016/j.conbuildmat.2019.03.040. [35] 彭永, 卢芳云, 方秦, 等. 弹体侵彻混凝土靶体的尺寸效应分析 [J]. 爆炸与冲击, 2019, 39(11): 113301. DOI: 10.11883/bzycj-2018-0402.PENG Y, LU F Y, FANG Q, et al. Analyses of the size effect for projectile penetrations into concrete targets [J]. Explosion and Shock Waves, 2019, 39(11): 113301. DOI: 10.11883/bzycj-2018-0402. [36] CANFIELD J A, CLATOR I G. Development of a scaling law and techniques to investigate penetration in concrete [M]. United States Naval Weapons Laboratory, 1966. [37] ANDERSON JR C E, MULLIN S A, KUHLMAN C J. Computer simulation of strain-rate effects in replica scale model penetration experiments [J]. International Journal of Impact Engineering, 1993, 13(1): 35–52. DOI: 10.1016/0734-743X(93)90107-I. [38] HUANG X, KONG X, HU J, et al. Scaling the failure of concrete gravity dam subjected to underwater explosion shock loading [J]. Ocean Engineering, 2022, 261: 112176. DOI: 10.1016/j.oceaneng.2022.112176. [39] 徐建波. 长杆射弹对混凝土的侵彻特性研究 [D]. 长沙:国防科学技术大学, 2001. DOI: 10.7666/d.y480203.XU J B. Investigations on long projectiles penetrating into concrete targets [D]. Changsha: National University of Defense Technology, 2001. DOI: 10.7666/d.y480203. [40] O’NEIL E F, NEELEY B D, CARGILE J D. Tensile properties of very-high-strength concrete for penetration-resistant structures [J]. Shock and Vibration, 1999, 6(5/6): 237–245. DOI: 10.1155/1999/415360. [41] UNOSSON M, NILSSON L. Projectile penetration and perforation of high performance concrete: experimental results and macroscopic modelling [J]. International Journal of Impact Engineering, 2006, 32(7): 1068–1085. DOI: 10.1016/j.ijimpeng.2004.11.003. [42] 柴传国. 异形头部弹体对混凝土靶的侵彻效应研究 [D]. 北京:北京理工大学, 2014. DOI: CNKI:CDMD:1.1014.086790.CHAI C G. Study on the mechanism of penetration into concrete of nose headed projectile [D]. Beijing: Beijing Institute of Technology, 2014. [43] 栾晓岩, 贺虎成, 耿忠, 等. 弹丸侵彻混凝土的试验与仿真 [J]. 系统仿真学报, 2008, 20(13): 3571–3573. DOI: 10.16182/j.cnki.joss.2008.13.016.LUAN X Y, HE H C, GENG Z, et al. Simulation and experiment of projectile penetrating into concrete [J]. Journal of System Simulation, 2008, 20(13): 3571–3573. DOI: 10.16182/j.cnki.joss.2008.13.016. [44] GRAN J K, FREW D J. In-target radial stress measurements from penetration experiments into concrete by ogive-nose steel projectiles [J]. International Journal of Impact Engineering, 1997, 19(8): 715–726. DOI: 10.1016/S0734-743X(97)00008-0. [45] 周宁, 任辉启, 沈兆武, 等. 弹丸侵彻混凝土和钢筋混凝土的实验 [J]. 中国科学技术大学学报, 2006, 36(10): 1021–1027. DOI: 10.3969/j.issn.0253-2778.2006.10.001.ZHOU N, REN H Q, SHEN Z W, et al. Experimental on the projectile penetration concrete targets and reinforced concrete targets [J]. Journal of University of Science and Technology of China, 2006, 36(10): 1021–1027. DOI: 10.3969/j.issn.0253-2778.2006.10.001. [46] 石志勇, 汤文辉, 赵国民, 等. 混凝土靶中侵彻深度的相似性研究 [J]. 弹道学报, 2005, 17(1): 62–66. DOI: 10.3969/j.issn.1004-499X.2005.01.012.SHI Z Y, TANG W H, ZHAO G M, et al. Similarity study of the penetration depth for the concrete targets [J]. Journal of Ballistics, 2005, 17(1): 62–66. DOI: 10.3969/j.issn.1004-499X.2005.01.012. [47] 王德荣, 葛涛, 周泽平, 等. 钢纤维超高强活性混凝土(RPC)抗侵彻计算方法研究 [J]. 爆炸与冲击, 2006, 26(4): 367–372. DOI: 10.11883/1001-1455(2006)04-0367-06.WANG D R, GE T, ZHOU Z P, et al. Investigation of calculation method for anti-penetration of reactive power steel fiber concrete (RPC) [J]. Explosion and Shock Waves, 2006, 26(4): 367–372. DOI: 10.11883/1001-1455(2006)04-0367-06. [48] 顾晓辉, 王晓鸣, 陈惠武, 等. 动能侵彻体垂直侵彻半无限厚混凝土靶的试验研究 [J]. 实验力学, 2004, 19(1): 103–108. DOI: 10.3969/j.issn.1001-4888.2004.01.019.GU X H, WANG X M, CHEN H W, et al. Experimental study on the kinetic energy penetrations against semi-infinite concrete targets at normal incidence [J]. Journal of Experimental Mechanics, 2004, 19(1): 103–108. DOI: 10.3969/j.issn.1001-4888.2004.01.019. [49] DANCYGIER A N. Rear face damage of normal and high-strength concrete elements caused by hard projectile impact [J]. Structural Journal, 1998, 95(3): 291–304. DOI: 10.14359/547. [50] HANCHAK S J, FORRESTAL M J, YOUNG E R, et al. Perforation of concrete slabs with 48 MPa (7 ksi) and 140 MPa (20 ksi) unconfined compressive strengths [J]. International Journal of Impact Engineering, 1992, 12(1): 1–7. DOI: 10.1016/0734-743X(92)90282-X. [51] WU H, FANG Q, PENG Y, et al. Hard projectile perforation on the monolithic and segmented RC panels with a rear steel liner [J]. International Journal of Impact Engineering, 2015, 76: 232–250. DOI: 10.1016/j.ijimpeng.2014.10.010. [52] 薛建锋, 张鹏, 刘涛, 等. 不同靶板厚度对混凝土靶的抗侵彻性能研究 [J]. 兵器材料科学与工程, 2017, 40(5): 59–63. DOI: 10.14024/j.cnki.1004-244x.20170907.005.XUE J F, ZHANG P, LIU T, et al. Penetrating performance of concrete target with different thickness [J]. Ordnance Material Science and Engineering, 2017, 40(5): 59–63. DOI: 10.14024/j.cnki.1004-244x.20170907.005. [53] ZHANG S B, KONG X, FANG Q, et al. Numerical prediction of dynamic failure in concrete targets subjected to projectile impact by a modified Kong-Fang material model [J]. International Journal of Impact Engineering, 2020, 144: 103633. DOI: 10.1016/j.ijimpeng.2020.103633. [54] WANG Y, KONG X, FANG Q, et al. Modelling damage mechanisms of concrete under high confinement pressure [J]. International Journal of Impact Engineering, 2021, 150: 103815. DOI: 10.1016/j.ijimpeng.2021.103815. [55] 武海军, 黄风雷, 金乾坤, 等. 弹体贯穿钢筋混凝土数值模拟 [J]. 爆炸与冲击, 2003, 23(6): 545–550.WU H J, HUANG F L, JIN Q K, et al. Numerical simulation on perforation of reinforced concrete targets [J]. Explosion and Shock Waves, 2003, 23(6): 545–550. [56] 邓国强, 董军, 杨秀敏. 弹丸冲击下钢筋混凝土板的局部破坏形态分析 [C]//第十三届全国结构工程学术会议, 2004. [57] KONG X, FANG Q, CHEN L, et al. A new material model for concrete subjected to intense dynamic loadings [J]. International Journal of Impact Engineering, 2018, 120: 60–78. DOI: 10.1016/j.ijimpeng.2018.05.006. [58] 中华人民共和国住房和城乡建设部.GB/T 50107-2010, 混凝土强度检验评定标准 [S]. [59] 甄建伟, 曹凌宇, 孙福. 弹药毁伤效应数值仿真技术 [M]. 北京: 北京理工大学出版社, 2018. [60] 严平, 谭波, 苗润, 等. 战斗部及其毁伤原理 [M]. 北京: 国防工业出版社, 2020. -

下载:

下载: