Performance deterioration behavior of photovoltaic cells subjected to massive-particles impact environment

-

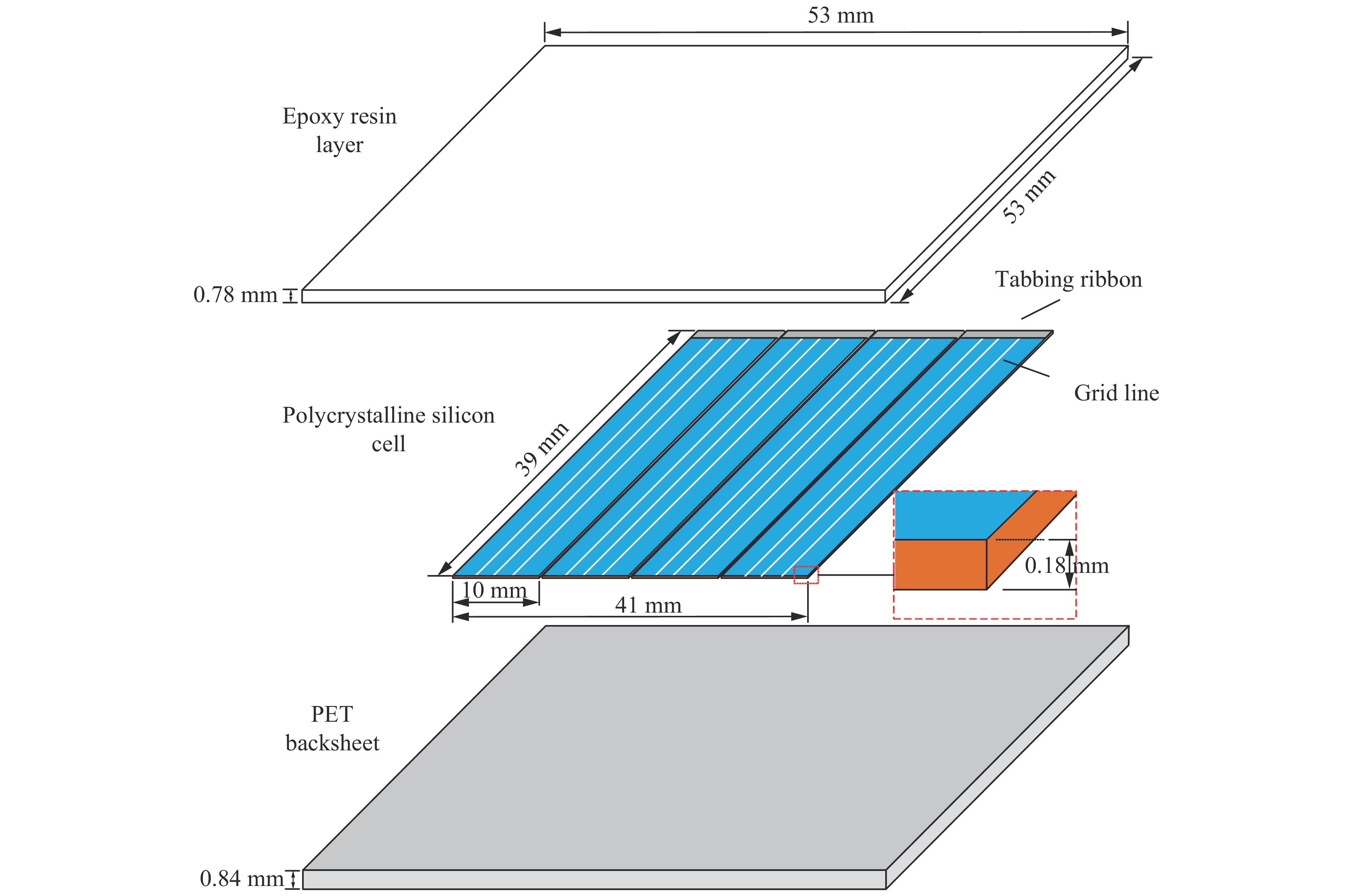

摘要: 光伏电池由于具有较高的光电转化效率,在沙漠等太阳能充足的地方被广泛应用。但在沙尘长期冲击的环境下,光伏电池内部结构易出现累积损伤,使光电转化效率大幅降低。因此,研究颗粒群冲击条件下光伏电池的力-电行为具有重要意义。基于分离式霍普金森压杆,发展了一种驱动较大尺寸颗粒群高速冲击的实验方法,并系统测量了不同冲击条件下,多晶硅光伏电池的损伤行为与光电转化性能衰减规律。研究结果表明,随着颗粒直径、冲击速度和数密度的增加,光伏电池的光电转换效率快速降低;颗粒冲击后光伏电池表现出三种典型的损伤模式,并给出了对应的应力阈值条件。基于实验测试结果,发展了多晶硅光伏电池颗粒群冲击损伤诱导光电转化性能退化模型,为沙砾冲击环境下光伏电池光电性能衰减规律提供了有效的预测方法。Abstract: Photovoltaic cells have been widely used in desert areas and other solar-rich environments due to the relatively high solar energy to electricity conversion efficiency. Under the long-term dust impact condition in the desert dust environment, the internal structures of photovoltaic cells are prone to damage, resulting in a significant deterioration of photoelectric conversion efficiency. Therefore, it is of great significance to understand the photoelectric response of photovoltaic cells subjected to massive particles impact. Firstly, a millimeter-scale high-speed particle impact experimental method was developed based on split Hopkinson pressure bar (SHPB) facility. The experimental results showed that the damage of the photovoltaic cell was mainly caused by the first impact, leading to the damage characteristics including shear microcracking, brittle fracture and delamination. Then, the critical stresses corresponding to the three failure modes were analyzed in terms of the initial impact kinetic energy. The first failure mode assumes that high-speed particles behave as fluids, so impulsive compressive stresses are used in the model. The damage in the second failure mode comes from high contact stresses on the impacted surface. The damage in the third mode of failure comes from bending stresses. The photovoltaic performance degradation of the photovoltaic cells after impact under different particle velocities, diameters, and number densities were investigated, showing that the photoelectric conversion efficiency of the photovoltaic cells decreased significantly with the increase of the particle size, the impact velocity, and the number density. Finally, a damage-induced photovoltaic performance degradation (DPPD) model under sand and gravel impact conditions is established to quantitatively describe the influence of impact parameters on the photovoltaic conversion efficiency, in which the two-dimensional damage factor D is proposed to represent the average damage level of the damaged area. The results of the DPPD model are in agreement with the experimental results, validating the applicability of the model for predicting accurately the photovoltaic cell photovoltaic performance under massive sand and gravel impact environment.

-

表 1 光伏电池冲击前后光电测试结果

Table 1. Light-electricity conversion performance of the photovoltaic cells before and after impact

测试编号 颗粒直径/mm 冲击速度m/s 颗粒数 输出功率变化/% 光电转化效率/% 损伤特征 1 3 0 0 0 19.0 完好 2 3 30 5 0 19.0 完好 3 3 40 5 −0.8 18.8 微裂纹 4 3 45 5 −3.2 18.4 微裂纹 5 3 55 5 −6.1 17.8 明显断裂 6 3 45 1 −0.8 18.8 微裂纹 7 3 55 1 −1.4 18.7 明显断裂 8 3 65 1 −2.2 18.6 分层脱胶 9 3 65 10 −22.2 14.7 分层脱胶 10 3 65 15 −30.0 13.3 分层脱胶 11 2 65 10 −0.1 19.0 微裂纹 12 2 87 10 −9.9 17.2 明显断裂 13 2 122 10 −27.0 13.9 分层脱胶 14 2 84 15 −12.3 16.7 明显断裂 15 2 128 15 −36.0 12.3 分层脱胶 16 1 128 100 −2.3 19.0 完好 17 3 45 5 −12.5 16.6 明显断裂 2 87 10 18 3 65 10 −23.0 14.6 分层脱胶 2 -

[1] 李靖琳. 硅晶体光伏电池输出特性的建模与仿真研究 [D]. 沈阳: 沈阳农业大学, 2018: 34–45.LI J L. Modeling and simulation of output characteristics of silicon crystal photovoltaic cells [D]. Shenyang: Shenyang Agricultural University, 2018: 34–45. [2] 黄仕相. 光面晶体硅表面质量对其光生伏特效应的影响研究 [D]. 福建泉州: 华侨大学, 2021: 2–9.HUANG S X. Study on the influence of the surface quality of smooth crystalline silicon on its photovoltaic effect [D]. Quanzhou, Fujian: Huaqiao University, 2021: 2–9. [3] YUAN Y C, WU C W. Thermal analysis of film photovoltaic cell subjected to dual laser beam irradiation [J]. Applied Thermal Engineering, 2015, 88: 410–417. DOI: 10.1016/j.applthermaleng.2015.01.054. [4] 张彦, 马梓焱, 袁成清, 等. 环境因素对光伏组件表面的损伤及其防护技术的研究现状 [J]. 腐蚀与防护, 2020, 41(6): 7–13. DOI: 10.11973/fsyfh-202006002.ZHANG Y, MA Z Y, YUAN C Q, et al. Research progress of environmental factors on surface damage of PV modules and their protection technology [J]. Corrosion & Protection, 2020, 41(6): 7–13. DOI: 10.11973/fsyfh-202006002. [5] 赵明智, 苗一鸣, 张旭, 等. 沙漠沙尘粒径对太阳电池输出特性影响的实验研究 [J]. 太阳能学报, 2019, 40(5): 1247–1252. DOI: 10.19912/j.0254-0096.2019.05.009.ZHAO M Z, MIAO Y M, ZHANG X, et al. Experimental study on influence of different dust particle size on output characteristics of solar panel [J]. Acta Energiae Solaris Sinica, 2019, 40(5): 1247–1252. DOI: 10.19912/j.0254-0096.2019.05.009. [6] ALNASER N W, AL OTHMAN M J, DAKHEL A A, et al. Comparison between performance of man-made and naturally cleaned PV panels in a middle of a desert [J]. Renewable and Sustainable Energy Reviews, 2018, 82: 1048–1055. DOI: 10.1016/j.rser.2017.09.058. [7] FIGGIS B, AHMED E, AHZI S, et al. Review of PV soiling particle mechanics in desert environments [J]. Renewable and Sustainable Energy Reviews, 2017, 76: 872–881. DOI: 10.1016/j.rser.2017.03.100. [8] MASSI P A, MELLIT A, DE PIERI D, et al. A comparison between BNN and regression polynomial methods for the evaluation of the effect of soiling in large scale photovoltaic plants [J]. Applied Energy, 2013, 108: 392–401. DOI: 10.1016/j.apenergy.2013.03.023. [9] JAVED W, WUBULIKASIMU Y, FIGGIS B, et al. Characterization of dust accumulated on photovoltaic panels in Doha, Qatar [J]. Solar Energy, 2017, 142: 123–135. DOI: 10.1016/j.solener.2016.11.053. [10] CHEN J X, PAN G B, OUYANG J, et al. Study on impacts of dust accumulation and rainfall on PV power reduction in East China [J]. Energy, 2020, 194: 116915. DOI: 10.1016/j.energy.2020.116915. [11] MEMICHE M, BOUZIAN C, BENZAHIA A, et al. Effects of dust, soiling, aging, and weather conditions on photovoltaic system performances in a Saharan environment—case study in Algeria [J]. Global Energy Interconnection, 2020, 3(1): 60–67. DOI: 10.1016/j.gloei.2020.03.004. [12] GHOLAMI A, KHAZAEE I, KHAZAEE S, et al. Experimental investigation of dust deposition effects on photo-voltaic output performance [J]. Solar Energy, 2018, 159: 346–352. DOI: 10.1016/j.solener.2017.11.010. [13] HACHICHA A A, AL-SAWAFTA I, SAID Z. Impact of dust on the performance of solar photovoltaic (PV) systems under united Arab emirates weather conditions [J]. Renewable Energy, 2019, 141: 287–297. DOI: 10.1016/j.renene.2019.04.004. [14] TIPPABHOTLA S K, RADCHENKO I, SONG W J R, et al. From cells to laminate: probing and modeling residual stress evolution in thin silicon photovoltaic modules using synchrotron X-ray micro-diffraction experiments and finite element simulations [J]. Progress in Photovoltaics: Research and Applications, 2017, 25(9): 791–809. DOI: 10.1002/pip.2891. [15] XIAO K L, WU X Q, WU C W, et al. Residual stress analysis of thin film photovoltaic cells subjected to massive micro-particle impact [J]. RSC Advances, 2020, 10(23): 13470–13479. DOI: 10.1039/C9RA10082B. [16] XIAO K L, WU X Q, SONG X, et al. Study on performance degradation and damage modes of thin-film photovoltaic cell subjected to particle impact [J]. Scientific Reports, 2021, 11(1): 782. DOI: 10.1038/S41598-020-80879-W. [17] HASSANI-GANGARAJ M, VEYSSET D, NELSON K A, et al. Melt-driven erosion in microparticle impact [J]. Nature Communications, 2018, 9(1): 5077. DOI: 10.1038/s41467-018-07509-y. [18] WIESE S, KRAEMER F, BETZL N, et al. Interconnection technologies for photovoltaic modules-analysis of technological and mechanical problems [C]//Proceedings of the 2010 11th International Thermal, Mechanical & Multi-Physics Simulation, and Experiments in Microelectronics and Microsystems. Bordeaux: IEEE, 2010: 1–6. DOI: 10.1109/ESIME.2010.5464518. [19] FRAGA M M, DE OLIVEIRA CAMPOS B L, DE ALMEIDA T B, et al. Analysis of the soiling effect on the performance of photovoltaic modules on a soccer stadium in Minas Gerais, Brazil [J]. Solar Energy, 2018, 163: 387–397. DOI: 10.1016/j.solener.2018.02.025. [20] DE MOURA M F S F, MARQUES A T. Prediction of low velocity impact damage in carbon–epoxy laminates [J]. Composites Part A: Applied Science and Manufacturing, 2002, 33(3): 361–368. DOI: 10.1016/S1359-835X(01)00119-1. [21] LIAO B B, LIU P F. Finite element analysis of dynamic progressive failure properties of GLARE hybrid laminates under low-velocity impact [J]. Journal of Composite Materials, 2018, 52(10): 1317–1330. DOI: 10.1177/0021998317724216. [22] WU X Q, YIN Q Y, WEI Y P, et al. Effects of imperfect experimental conditions on stress waves in SHPB experiments [J]. Acta Mechanica Sinica, 2015, 31(6): 827–836. DOI: 10.1007/s10409-015-0439-0. [23] WU X Q, WANG X, WEI Y P, et al. An experimental method to measure dynamic stress-strain relationship of materials at high strain rates [J]. International Journal of Impact Engineering, 2014, 69: 149–156. DOI: 10.1016/j.ijimpeng.2014.02.016. [24] ZARMAI M T, EKERE N N, ODUOZA C F, et al. Evaluation of thermo-mechanical damage and fatigue life of solar cell solder interconnections [J]. Robotics and Computer-Integrated Manufacturing, 2017, 47: 37–43. DOI: 10.1016/j.rcim.2016.12.008. [25] ESFAHANI S N, ASGHARI S, RASHID-NADIMI S. A numerical model for soldering process in silicon solar cells [J]. Solar Energy, 2017, 148: 49–56. DOI: 10.1016/j.solener.2017.03.065. [26] KOISSIN V, SKVORTSOV V, SHIPSHA A. Stability of the face layer of sandwich beams with sub-interface damage in the foam core [J]. Composite Structures, 2007, 78(4): 507–518. DOI: 10.1016/j.compstruct.2005.11.012. [27] PAPARGYRI L, THERISTIS M, KUBICEK B, et al. Modelling and experimental investigations of microcracks in crystalline silicon photovoltaics: a review [J]. Renewable Energy, 2020, 145: 2387–2408. DOI: 10.1016/j.renene.2019.07.138. [28] TORENBEEK E, WITTENBERG H. Flight physics: essentials of aeronautical disciplines and technology, with historical notes [M]. Dordrecht: Springer Science & Business Media, 2009. [29] BOEDONI P G. Stress waves in solids [M]. Courier Corporation, 1963. [30] WU Z L, WU C W, CHEN G N, et al. On a novel method of impact by a front-end-coated bullet to evaluate the interface adhesion between film and substrate [J]. Progress in Organic Coatings, 2010, 68(1/2): 19–22. DOI: 10.1016/j.porgcoat.2009.07.013. [31] TIMOSHENKO S, WOINOWSKY-KRIEGER S. Theory of plates and shells [M]. New York: McGraw-Hill, 1959. [32] NYARKO F K A, TAKYI G, EFFAH F B. Impact of the constitutive behaviour of the encapsulant on thermo-mechanical damage in (c-Si) solar PV modules under thermal cycling [J]. Scientific African, 2021, 12: E00767. DOI: 10.1016/j.sciaf.2021.e00767. [33] 袁锦龙. 多晶硅的破碎机理及破碎装置的设计 [D]. 湖南株洲: 湖南工业大学, 2020: 34–35.YUAN J L. Crushing mechanism of polysilicon and design of crushing device [D]. Zhuzhou, Hunan: Hunan University of Technology, 2020: 34–35. [34] 张行. 断裂与损伤力学 [M]. 2版. 北京: 北京航空航天大学出版社, 2009: 45–50.ZHANG X. Mechanics of fracture and damage [M]. 2nd ed. Beijing: Beihang University Press, 2009: 45–50. [35] 周越松, 梁森, 王得盼, 等. 阻尼材料/纤维层合板复合靶板抗冲击性能研究 [J]. 兵器装备工程学报, 2022, 43(1): 243–248. DOI: 10.11809/bqzbgcxb2022.01.038.ZHOU Y S, LIANG S, WANG D P, et al. Impact resistance behavior of damping material/fiber laminate composite target [J]. Journal of Ordnance Equipment Engineering, 2022, 43(1): 243–248. DOI: 10.11809/bqzbgcxb2022.01.038. [36] 季晨. 基于非局部理论的复合材料层合板损伤演化研究 [D]. 哈尔滨: 哈尔滨工业大学, 2016: 24.JI C. Research on damage evolution of laminates based on nonlocal theory [D]. Harbin: Harbin Institute of Technology, 2016: 24. -

下载:

下载: