Protective effect of polymer layer on reinforced concrete slabs under an underwater contact explosion

-

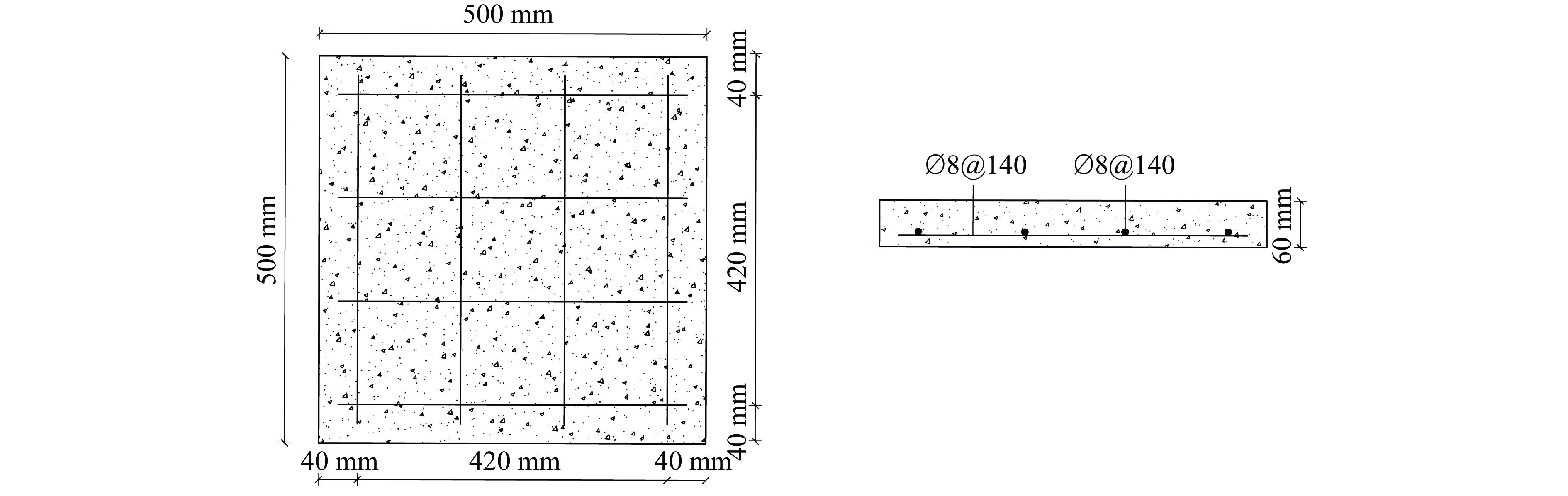

摘要: 为研究多孔材料高聚物对水下混凝土结构的抗爆防护性能,对含高聚物防护层的钢筋混凝土板开展了水下爆炸实验,并设置了对照组。利用AUTODYN有限元程序建立了含高聚物防护层的钢筋混凝土板水下爆炸全耦合模型,并通过数值模拟结果与实验的对比,验证了所建模型的可靠性。在此基础上,通过数值模拟,进一步分析了前置钢板对高聚物层防护性能的提升效果。以钢筋混凝土板跨中残余位移为指标,参数化分析了起爆药量和复合结构层厚比对高聚物层水下防护效果的影响规律。结果表明:水下爆炸下,高聚物防护层能够有效降低混凝土结构的毁伤程度;在高聚物层外侧布置钢质薄板,可以更好地发挥高聚物层的吸能效果,对钢筋混凝土板起到更好的防护效果,且当高聚物层与前置钢板层厚度比为20时,防护效果最佳。Abstract: In order to study the anti-explosion protection performance of porous polymers on underwater concrete structures, underwater explosion experiments were carried out on reinforced concrete slabs with a polymer protective layer, and an ordinary reinforced concrete slab was set as a comparing subject. A fully coupled model of underwater explosion of reinforced concrete slab with polymer protective layer was established by the AUTODYN finite element program, while the reliability of the proposed model was verified by the comparison of the calculatied results with experimental ones. Thus, the propagation characteristics of explosion load in water and the damage results of the structure can be better simulated by this model. In addition, the effect of the front steel plate on the enhancement of the protection performance of the polymer layer was further analyzed by numerical simulation. The front steel plate can evenly exert the pressure generated by the explosion load on the inner core layer, so that the polymer layer can display a better energy-absorbing effect. Taking the mid-span residual displacement of the reinforced concrete slab as an index, the influences of the amount of detonating charge and the layer thickness ratio of the composite structure on the underwater protection effect of the polymer layer are analyzed parametrically. The results show that the damage degree of the concrete structure under underwater explosion can be reduced by the polymer protective layer; arranging the steel thin plate on the outside of the polymer layer can improve the energy-absorbing effect of the polymer layer and provide better protection to the reinforced concrete slab; and the protection effect is the best when the ratio of the polymer layer to the front steel plate layer thickness is 20. The research results can provide a reference for the subsequent studies and application of polymer materials in the protection of underwater engineering structures.

-

Key words:

- underwater explosion /

- polymer /

- composite structure /

- reinforced concrete slab /

- protective performance

-

表 1 试件损伤程度

Table 1. Degree of damage to specimens

试件 迎爆面破坏区域 是否发生冲切破坏 整体性 承载能力 RC板 140 mm×130 mm 是 一般 较差 P-RC板 否 较好 较好 密度$ {\rho }_{0} $/(g·cm−3) 体积模量A1/GPa 剪切模量G/GPa 抗压强度fc/MPa 抗拉强度ft/fc 抗剪强度fs/fc 2.75 35.27 22.06 35 0.1 0.18 失效面常数A 残余失效面常数B 残余失效面指数M 损伤常数D1 损伤常数D2 侵蚀应变 1.60 1.60 0.61 0.04 1.00 2.0 密度$ {\rho }_{0} $/(g·cm−3) 体积模量A1/GPa 剪切模量G/MPa 抗压强度fc/MPa 抗拉强度ft/fc 抗剪强度fs/fc 0.2 2.2 20.78 4.5 0.598 0.694 失效面常数A 残余失效面常数B 残余失效面指数M 损伤常数D1 损伤常数D2 侵蚀应变 0.61 1.60 0.61 0.04 1.00 0.60 ρ/(g·cm−3) D/(m·s−1) A/GPa B/GPa ${p_{{\mathrm{CJ}}}}$/GPa R1 R2 ω E/GPa 1.05 3850 209.70 3.50 3.70 5.76 1.29 0.39 4.20 表 5 复合防护层不同层厚比

Table 5. Different layer thickness ratios of composite protective layers

工况 高聚物层厚度h1/mm 前置钢板厚度h2/mm 层厚比(h1/h2) 工况 高聚物层厚度h1/mm 前置钢板厚度h2/mm 层厚比(h1/h2) 1 60 2.0 30.0 6 40 3.0 13.3 2 60 2.5 24.0 7 50 3.0 16.7 3 60 3.0 20.0 8 70 3.0 23.3 4 60 3.5 17.1 9 80 3.0 26.7 5 60 4.0 15.0 -

[1] 张社荣, 孔源, 王高辉. 水下和空中爆炸时混凝土重力坝动态响应对比分析 [J]. 振动与冲击, 2014, 33(17): 47–54. DOI: 10.13465/j.cnki.jvs.2014.17.009.ZHANG S R, KONG Y, WANG G H. Dynamic responses of a concrete gravity dam subjected to underwater and air explosions [J]. Journal of Vibration and Shock, 2014, 33(17): 47–54. DOI: 10.13465/j.cnki.jvs.2014.17.009. [2] 李凌锋, 韦灼彬, 唐廷, 等. 爆炸荷载下沉箱重力式码头模型毁伤效应 [J]. 爆炸与冲击, 2019, 39(1): 012202. DOI: 10.11883/bzycj-2017-0406.LI L F, WEI Z B, TANG T, et al. Damage effect of caisson gravity wharf model under explosive loading [J]. Explosion and Shock Waves, 2019, 39(1): 012202. DOI: 10.11883/bzycj-2017-0406. [3] YANG G D, WANG G H, LU W B, et al. Cross-section shape effects on anti-knock performance of RC columns subjected to air and underwater explosions [J]. Ocean Engineering, 2019, 181(6): 252–266. DOI: 10.1016/j.oceaneng.2019.04.031. [4] ZHAO X H, WANG G H, LU W B, et al. Experimental investigation of RC slabs under air and underwater contact explosions [J]. European Journal of Environmental and Civil Engineering, 2021, 25(1): 190–204. DOI: 10.1080/19648189.2018.1528892. [5] 孔祥清, 赵倩, 曲艳东, 等. 空中和水下爆炸时钢筋混凝土板动态响应对比分析 [J]. 科技导报, 2016, 34(18): 279–286.KONG X Q, ZHAO Q, QU Y D, et al. Dynamic responses of a concrete slab subjected to air and underwater explosions [J]. Science and Technology Review, 2016, 34(18): 279–286. [6] 刘超, 孙启鑫, 李会驰. 近爆作用下钢筋混凝土π梁防护性能的数值模拟 [J]. 振动与冲击, 2022, 41(4): 223–231. DOI: 10.13465/j.cnki.jvs.2022.04.029.LIU C, SUN Q X, LI H C. Numerical simulation for protective of reinforced concrete π beams under close-in explosion [J]. Journal of Vibration and Shock, 2022, 41(4): 223–231. DOI: 10.13465/j.cnki.jvs.2022.04.029. [7] 石少卿, 张湘冀, 刘颖芳, 等. 硬质聚氨酯泡沫塑料抗爆炸冲击作用的研究 [J]. 振动与冲击, 2005, 24(5): 59–61. DOI: 10.3969/j.issn.1000-3835.2005.05.017.SHI S Q, ZHANG X J, LIU Y F, et al. The study on explosion shock resistance of rigid polyurethane foam plastics [J]. Journal of Vibration and Shock, 2005, 24(5): 59–61. DOI: 10.3969/j.issn.1000-3835.2005.05.017. [8] 刘佳, 崔传安, 徐畅. 爆炸波在硬质聚氨酯泡沫中的衰减特性模拟 [J]. 兵器装备工程学报, 2017, 38(9): 164–167. DOI: 10.11809/scbgxb2017.09.035.LIU J, CUI C A, XU C. Simulation of explosive wave attenuation characteristics in rigid polyurethane foam [J]. Journal of Ordnance Equipment Engineering, 2017, 38(9): 164–167. DOI: 10.11809/scbgxb2017.09.035. [9] CODINA R, AMBROSINI D, BORBÓN B F. Alternatives to prevent the failure of RC members under close-in blast loadings [J]. Engineering Failure Analysis, 2016, 60(2): 96–106. DOI: 10.1016/j.engfailanal.2015.11.038. [10] KOSTOPOULOS V, KALIMERIS G D, GIANNAROS E. Blast protection of steel reinforced concrete structures using composite foam-core sacrificial cladding [J]. Composites Science and Technology, 2022: 109330. DOI: 10.1016/J.COMPSCITECH.2022.109330. [11] 夏志成, 张建亮, 王曦浩, 等. 钢板夹芯防爆墙防护效应的影响因素 [J]. 工程爆破, 2016, 22(6): 1–7. DOI: 10.3969/j.issn.1006-7051.2016.06.001.XIA Z C, ZHANG J L, WANG X H, et al. Influencing factors of protective effect of steel plate sandwich explosion proof wall [J]. Engineering Blasting, 2016, 22(6): 1–7. DOI: 10.3969/j.issn.1006-7051.2016.06.001. [12] 邹广平, 孙杭其, 唱忠良, 等. 聚氨酯/钢夹芯结构爆炸载荷下动力学响应的数值模拟 [J]. 爆炸与冲击, 2015, 35(6): 907–912. DOI: 10.11883/1001-1455(2015)06-0907-06.ZOU G P, SUN H Q, CHANG Z L, et al. Numerical simulation on dynamic response of polyurethane/steel sandwich structure under blast loading [J]. Explosion and Shock Waves, 2015, 35(6): 907–912. DOI: 10.11883/1001-1455(2015)06-0907-06. [13] 李姝妍, 王在成, 毛亮, 等. 活性破片战斗部用缓冲结构应力衰减特性研究 [J]. 兵器材料科学与工程, 2020, 43(5): 43–49. DOI: 10.14024/j.cnki.1004-244x.20200701.001.LI S Y, WANG Z C, MAO L, et al. Study on stress attenuation characteristics of buffer structure of reactive fragment warhead [J]. Ordnance Material Science and Engineering, 2020, 43(5): 43–49. DOI: 10.14024/j.cnki.1004-244x.20200701.001. [14] 刘宏杰, 王伟力, 苗润, 等. 基于环形切割串联战斗部隔爆结构的优化设计 [J]. 弹箭与制导学报, 2019, 39(4): 73–76. DOI: 10.15892/j.cnki.djzdxb.2019.04.018.LIU H J, WANG W L, MIAO R, et al. Optimization design of flameproof structure based on annular cutting tandem warhead [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2019, 39(4): 73–76. DOI: 10.15892/j.cnki.djzdxb.2019.04.018. [15] WANG Z Y, DU M R, FANG H Y, et al. Influence of different corrosion environments on mechanical properties of a roadbed rehabilitation polyurethane grouting material under uniaxial compression [J]. Construction and Building Materials, 2021, 301: 124092. DOI: 10.1016/J.CONBUILDMAT.2021.124092. [16] 林沛元, 郭潘峰, 郭成超, 等. 钢板、高聚物、土不同材料界面剪切特性试验研究[J]. 岩土工程学报, 2023,45(1): 1–11.LIN P Y, GUO P F, GUO C C, et al. Experimental study on interfacial shear properties of steel plate, polymer and soil [J]. Chinese Journal of Geotechnical Engineering, 2023,45(1): 1–11. [17] 孙文彬. 钢筋混凝土板的爆炸荷载试验研究 [J]. 辽宁工程技术大学学报(自然科学版), 2009, 28(2): 217–220. DOI: 10.3969/j.issn.1008-0562.2009.02.016.SUN W B. Experimental studies on reinforced concrete (RC) slabs subjected to blast loads [J]. Journal of Liaoning Technical University (Natural Science), 2009, 28(2): 217–220. DOI: 10.3969/j.issn.1008-0562.2009.02.016. [18] WANG Z Q, LU Y, HAO H, et al. A full coupled numerical analysis approach for buried structures subjected to subsurface blast [J]. Computers & Structures, 2005, 83(4/5): 339–356. DOI: 10.1016/j.compstruc.2004.08.014. [19] WANG W, ZhANG D, LU F Y, et al. Experimental study and numerical simulation of the damage mode of a square reinforced concrete slab under close-in explosion [J]. Engineering Failure Analysis, 2013, 27. DOI: 10.1016/j.engfailanal.2012.07.010. [20] 赵浩楠, 方宏远, 赵小华, 等. 接触爆炸作用下高聚物复合板毁伤特性分析 [J]. 爆炸与冲击, 2023, 43(5): 052201. DOI: 10.11883/bzycj-2022-0161.HAO H N, FANG H Y, ZHAO X H, et al. Analysis on the blast resistance of polymer composite slabs under contact explosions [J]. Explosion and Shock Waves, 2023, 43(5): 052201. DOI: 10.11883/bzycj-2022-0161. [21] LI M J, DU M R, WANG F M, et al. Study on the mechanical properties of polyurethane (PU) grouting material of different geometric sizes under uniaxial compression [J]. Construction and Building Materials, 2020, 259: 119797. DOI: 10.1016/j.conbuildmat.2020.119797. [22] 石明生. 高聚物注桨材料特性与堤坝定向劈裂注桨机理研究[D]. 大连: 大连理工大学, 2011: 22–61. [23] LIU Z D, ZHAO X H, LIU D, et al. Comparative study on blast damage features of reinforced concrete slabs with polyurethane sacrificial cladding based on different numerical simulation methods [J]. Polymers, 2022, 14(18): 3857. DOI: 10.3390/polym14183857. [24] 杨广栋, 王高辉, 李麒, 等. 爆炸冲击下水底隧道的动态响应及毁伤模式研究 [J]. 振动与冲击, 2022, 41(4): 150–158. DOI: 10.13465/j.cnki.jvs.2022.04.020.YANG G D, WANG G H, LI Q, et al. Dynamic response and damage patterns of underwater tunnel subjected to blast loads [J]. Journal of Vibration and Shock, 2022, 41(4): 150–158. DOI: 10.13465/j.cnki.jvs.2022.04.020. [25] 郑欣颖, 李海涛, 张弛, 等. 乳化炸药水下爆炸载荷输出特性实验研究 [J]. 高压物理学报, 2022, 36(4): 045101. DOI: 10.11858/gywlxb.20220502.ZHENG X Y, LI H T, ZHANG C, et al. Experimental study on load output characteristics of emulsified explosive in underwater explosion [J]. Chinese Journal of High Pressure Physics, 2022, 36(4): 045101. DOI: 10.11858/gywlxb.20220502. [26] 孙远翔, 田俊宏, 张之凡, 等. 含铝炸药近场水下爆炸冲击波的实验及数值模拟 [J]. 振动与冲击, 2020, 39(14): 171–178, 193. DOI: 10.13465/j.cnki.jvs.2020.14.025.SUN Y X, TIAN J H, ZHANG Z F, et al. Experiment and numerical simulation study on the near-field underwater explosion of aluminized explosive [J]. Journal of Vibration and Shock, 2020, 39(14): 171–178, 193. DOI: 10.13465/j.cnki.jvs.2020.14.025. [27] 赵春风, 何凯城, 卢欣, 等. 弧形双钢板混凝土组合板抗爆性能数值研究 [J]. 爆炸与冲击, 2022, 42(2): 025101. DOI: 10.11883/bzycj-2021-0205.ZHAO C F, HE K C, LU X, et al. Numerical study of blast resistance of curved steel-concrete-steel composite slabs [J]. Explosion and Shock Waves, 2022, 42(2): 025101–. DOI: 10.11883/bzycj-2021-0205. [28] ZHAO L, YU H T, YUAN Y, et al. Blast mitigation effect of the foamed cement-base sacrificial cladding for tunnel structures [J]. Construction and Building Materials, 2015, 94(9): 710–718. DOI: 10.1016/j.conbuildmat.2015.07.076. -

下载:

下载: