| [1] |

龙文武. 泡沫混凝土力学性能及其数值模拟 [D]. 湖南衡阳: 南华大学, 2016: 10–21.LONG W W. Mechanical properties of foamed concrete and its numerical simulation [D]. Hengyang, Hunan, China: University of South China, 2016: 10–21.

|

| [2] |

谷亚新, 王延钊, 王小萌. 不同工艺泡沫混凝土的研究进展 [J]. 混凝土, 2013(12): 148–152. DOI: 10.3969/j.issn.1002-3550.2013.12.042.GU Y X, WANG Y Z, WANG X M. Research progress of foam concrete in different process [J]. Concrete, 2013(12): 148–152. DOI: 10.3969/j.issn.1002-3550.2013.12.042.

|

| [3] |

熊耀清, 姚谦峰. 轻质多孔混凝土受压应力-应变全曲线试验研究 [J]. 四川建筑科学研究, 2010, 36(2): 228–232. DOI: 10.3969/j.issn.1008-1933.2010.02.059.XIONG Y Q, YAO Q F. Experimental study on the total stress-strain curve of porous lightweight concrete [J]. Sichuan Building Science, 2010, 36(2): 228–232. DOI: 10.3969/j.issn.1008-1933.2010.02.059.

|

| [4] |

龚独明. 轻质高强泡沫混凝土的制备与性能研究 [D]. 长沙: 长沙理工大学, 2013: 11–35.GONG D M. Study on preparation and performance of the light-weight and high-strength foamed concrete [D]. Changsha, Hunan, China: Changsha University of Science and Technology, 2013: 11–35.

|

| [5] |

周明杰, 王娜娜, 赵晓艳, 等. 泡沫混凝土的研究和应用最新进展 [J]. 混凝土, 2009(4): 104–107. DOI: 10.3969/j.issn.1002-3550.2009.04.031.ZHOU M J, WANG N N, ZHAO X Y, et al. Latest development of research and application on foam concrete [J]. Concrete, 2009(4): 104–107. DOI: 10.3969/j.issn.1002-3550.2009.04.031.

|

| [6] |

扈士凯, 李应权, 徐洛屹, 等. 国外泡沫混凝土工程应用进展 [J]. 混凝土世界, 2010(4): 48–50. DOI: 10.3969/j.issn.1674-7011.2010.04.012.HU S K, LI Y Q, XU L Y, et al. Foam concrete engineering application development abroad [J]. China Concrete, 2010(4): 48–50. DOI: 10.3969/j.issn.1674-7011.2010.04.012.

|

| [7] |

周小华. 承重保温型复合墙体的设计与研究 [D]. 广州: 华南理工大学, 2011: 8–25.ZHOU X H. Design and research on load-bearing and thermal insulation sandwich composite wall [D]. Guangzhou, Guangdong, China: South China University of Technology, 2011: 8–25.

|

| [8] |

丁曼. 防水性泡沫混凝土研究 [D]. 长沙: 湖南大学, 2011: 10–14.DING M. A study on the property of foam concrete with water repellents [D]. Changsha, Hunan, China: Hunan University, 2011: 10–14.

|

| [9] |

吴江龙, 周新刚. 钢丝网泡沫混凝土轻质墙板 [J]. 新型建筑材料, 1998, 25(5): 36–37.WU J L, ZHOU X G. Steel mesh foam concrete lightweight wallboard [J]. New Building Material, 1998, 25(5): 36–37.

|

| [10] |

何书明. 泡沫混凝土本构关系的研究 [D]. 长春: 吉林建筑大学, 2014: 5–10.HE S M. Study on the constitutive relationship of foam concrete [D]. Changchun, Jilin, China: Jilin Jianzhu University, 2014: 5–10.

|

| [11] |

刘子全, 王波, 李兆海, 等. 泡沫混凝土的研究开发进展 [J]. 混凝土, 2008(12): 24–26. DOI: 10.3969/j.issn.1002-3550.2008.12.008.LIU Z Q, WANG B, LI Z H, et al. Research and development progress on foamed concrete [J]. Concrete, 2008(12): 24–26. DOI: 10.3969/j.issn.1002-3550.2008.12.008.

|

| [12] |

郭宁. 新型泡沫混凝土复合砌块的应用研究 [D]. 长沙: 长沙理工大学, 2013: 6–8.GUO N. A research on the use of new form of mixed sandwich foam concrete block [D]. Changsha, Hunan, China: Changsha University of Science and Technology, 2013: 6–8.

|

| [13] |

ZHAO H L, YU H T, YUAN Y, et al. Blast mitigation effect of the foamed cement-base sacrificial cladding for tunnel structures [J]. Construction and Building Materials, 2015, 94: 710–718. DOI: 10.1016/j.conbuildmat.2015.07.076.

|

| [14] |

WU C Q, SHEIKH H. A finite element modelling to investigate the mitigation of blast effects on reinforced concrete panel using foam cladding [J]. International Journal of Impact Engineering, 2013, 55: 24–33. DOI: 10.1016/j.ijimpeng.2012.11.006.

|

| [15] |

董永香, 黄晨光, 段祝平. 多层介质对应力波传播特性影响分析 [J]. 高压物理学报, 2005, 19(1): 59–65. DOI: 10.11858/gywlxb.2005.01.011.DONG Y X, HUANG C G, DUAN Z P. Analysis on the influence of multi-layered media on stress wave propagation [J]. Chinese Journal of High Pressure Physics, 2005, 19(1): 59–65. DOI: 10.11858/gywlxb.2005.01.011.

|

| [16] |

赵凯. 分层防护层对爆炸波的衰减和弥散作用研究 [D]. 合肥: 中国科学技术大学, 2007: 2–8.ZHAO K. The attenuation and dispersion effects on explosive wave of layered protective engineering [D]. Hefei, Anhui, China: University of Science and Technology of China, 2007: 2–8.

|

| [17] |

SHEN J, REN X J. Experimental investigation on transmission of stress waves in sandwich samples made of foam concrete [J]. Defence Technology, 2013, 9(2): 110–114. DOI: 10.3969/j.issn.1672-002X.2013.02.007.

|

| [18] |

李砚召, 王肖钧, 吴祥云, 等. 分配层分层结构对核爆炸荷载的防护效果试验研究 [J]. 中国科学技术大学学报, 2009, 39(9): 931–935.LI Y Z, WANG X J, WU X Y, et al. Test study on layered structure’s defense effect of distribution layer against nuclear explosive loadings [J]. Journal of University of Science and Technology of China, 2009, 39(9): 931–935.

|

| [19] |

张景飞, 冯明德, 陈金刚. 泡沫混凝土抗爆性能的试验研究 [J]. 混凝土, 2010(10): 10–12. DOI: 10.3969/j.issn.1002-3550.2010.10.004.ZHANG J F, FENG M D, CHEN J G. Study on the knock characteristic of foam concrete [J]. Concrete, 2010(10): 10–12. DOI: 10.3969/j.issn.1002-3550.2010.10.004.

|

| [20] |

高全臣, 刘殿书, 王代华, 等. 泡沫混凝土复合防护结构的抗爆性能试验研究 [C]//第六届全国工程结构安全防护学术会议论文集. 北京: 中国力学学会, 2007: 120–123.GAO Q C, LIU D S, WANG D H, et al. Experimental study on anti-knock performance of foam concrete composite protective structure [C]//Proceedings of the 6th National Academic Conference on Safety Protection of Engineering Structures. Beijing, China: Chinese Society of Theoretical and Applied Mechanics, 2007: 120–123.

|

| [21] |

杜玉兰, 王代华, 刘殿书, 等. 含泡沫混凝土层复合结构抗爆性能试验研究 [C]//首届全国水工抗震防灾学术会议论文集. 北京: 中国水力发电工程学会, 2006: 85–89.DU Y L, WANG D H, LIU D S, et al. Experimental research on the characteristics of anti-blast compound structures including foam concrete [C]//Proceedings of the First National Academic Conference on Earthquake Resistance and Disaster Prevention of Hydraulic Engineering. Beijing: China Society for Hydropower Engineering, 2006: 85–89.

|

| [22] |

王代华, 刘殿书, 杜玉兰, 等. 含泡沫吸能层防护结构爆炸能量分布的数值模拟研究 [J]. 爆炸与冲击, 2006, 26(6): 562–567. DOI: 10.11883/1001-1455(2006)06-0562-06.WANG D H, LIU D S, DU Y L, et al. Numerical simulation of anti-blasting mechanism and energy distribution of composite protective structure with foam concrete [J]. Explosion and Shock Waves, 2006, 26(6): 562–567. DOI: 10.11883/1001-1455(2006)06-0562-06.

|

| [23] |

唐德高, 王昆明, 贺虎成, 等. 泡沫混凝土回填层在坑道中的耗能作用 [J]. 解放军理工大学学报(自然科学版), 2006, 7(4): 365–370. DOI: 10.3969/j.issn.1009-3443.2006.04.013.TANG D G, WANG K M, HE H C, et al. Energy dissipation mechanism of foamed concrete backfill layers in underground tunnels [J]. Journal of PLA University of Science and Technology, 2006, 7(4): 365–370. DOI: 10.3969/j.issn.1009-3443.2006.04.013.

|

| [24] |

SKEWS B W, ATKINS M D, SEITZ M W. The impact of a shock wave on porous compressible foams [J]. Journal of Fluid Mechanics, 1993, 253: 245–265. DOI: 10.1017/S0022112093001788.

|

| [25] |

HANSSEN A G, ENSTOCK L, LANGSETH M. Close-range blast loading of aluminium foam panels [J]. International Journal of Impact Engineering, 2002, 27(6): 593–618. DOI: 10.1016/S0734-743X(01)00155-5.

|

| [26] |

周宏元, 李永胜, 王小娟, 等. 地冲击作用下基于泡沫混凝土的地下结构柔性防护 [J]. 北京工业大学学报, 2020, 46(6): 533–539. DOI: 10.11936/bjutxb2020010013.ZHOU H Y, LI Y S, WANG X J, et al. Flexible protection of underground structures with foam concrete subjected to ground shocks [J]. Journal of Beijing University of Technology, 2020, 46(6): 533–539. DOI: 10.11936/bjutxb2020010013.

|

| [27] |

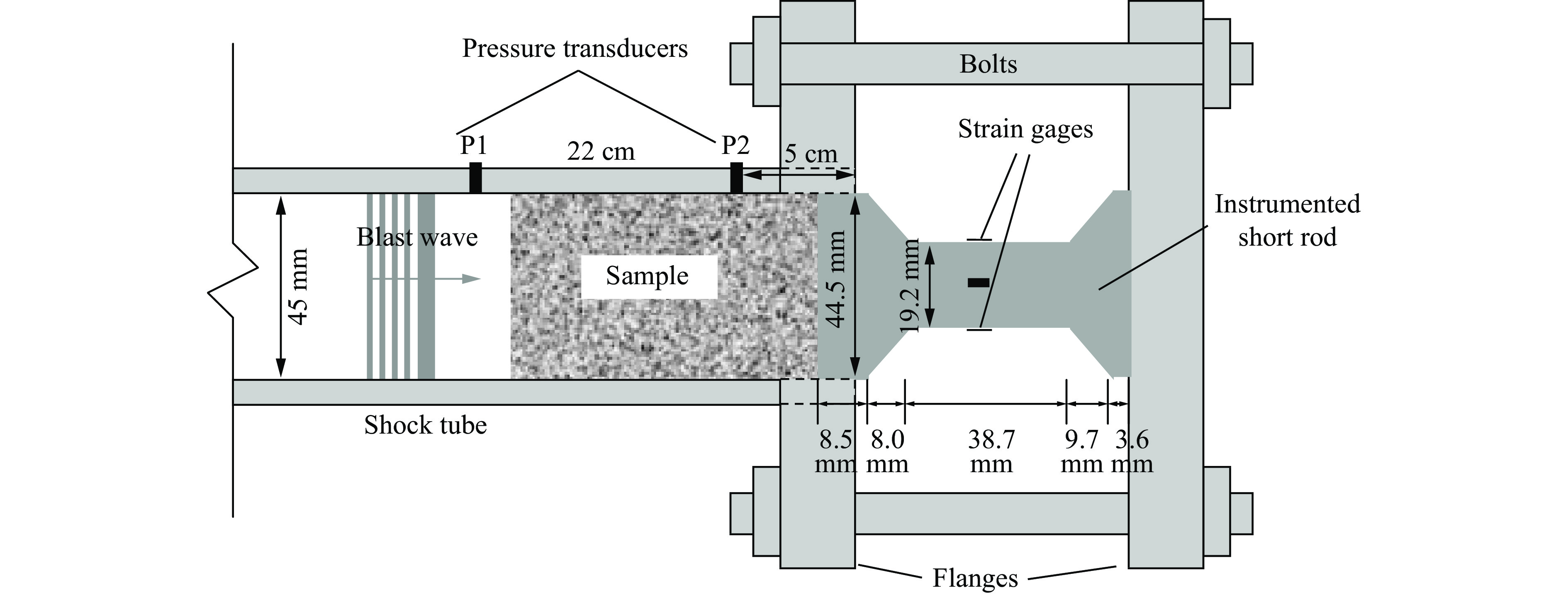

NIAN W M, SUBRAMANIAM K V L, ANDREOPOULOS Y. Experimental investigation on blast response of cellular concrete [J]. International Journal of Impact Engineering, 2016, 96: 105–115. DOI: 10.1016/j.ijimpeng.2016.05.021.

|

| [28] |

LI Q M, MENG H. Attenuation or enhancement-a one-dimensional analysis on shock transmission in the solid phase of a cellular material [J]. International Journal of Impact Engineering, 2002, 27(10): 1049–1065. DOI: 10.1016/S0734-743X(02)00016-7.

|

| [29] |

HALLQUIST J. LS-DYNA keyword user's manual, version: 970 [M]. Livermore, USA: Livermore Software Technology Corporation, 2003.

|

| [30] |

LEE M Y, BRONOWSKI D R, HARDY R D. Laboratory constitutive characterization of cellular concrete: SAND2004-1030 [R]. Albuquerque, USA: Sandia National Laboratories, 2004. DOI: 10.2172/918757.

|

| [31] |

GIBSON L J, ASHBY M F. Cellular solids: structure and properties [M]. 2nd ed. Cambridge, UK: Cambridge University Press, 1997: 110–122. DOI: 10.1017/CBO9781139878326.

|

| [32] |

中华人民共和国住房和城乡建设部. 泡沫混凝土: JG/T 266–2011 [S]. 北京: 中国标准出版社, 2011: 2–11.Ministry of Housing and Urban-Rural Development of the Peopleʼs Republic of China. Foamed concrete: JG/T 266–2011 [S]. Beijing, China: Standards Press of China, 2011: 2–11.

|

下载:

下载: