Dynamic tensile mechanical properties and constitutive equation of Kevlar29 yarn

-

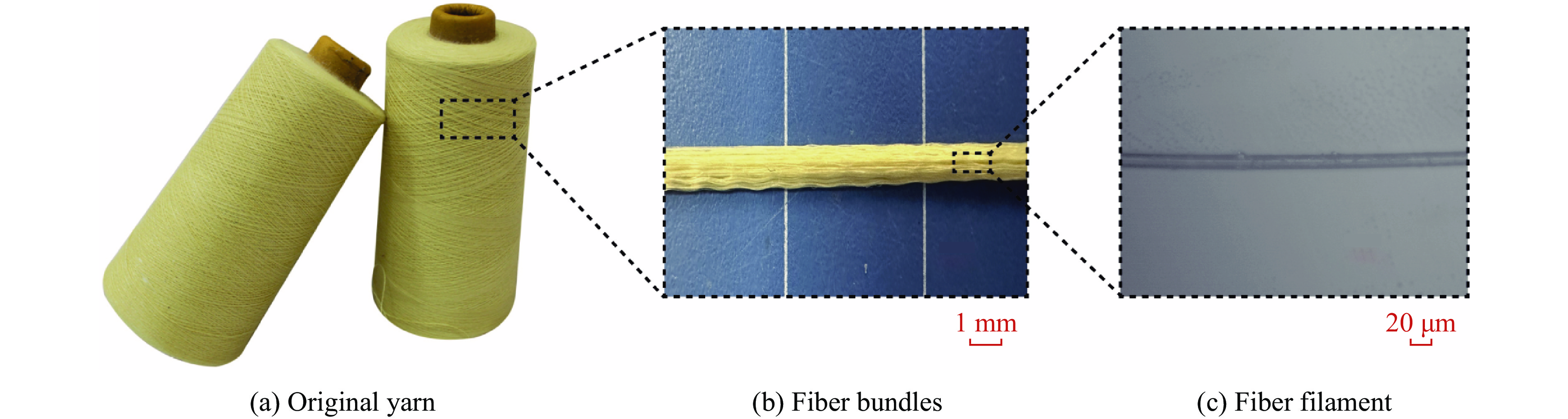

摘要: 为了能够清晰地表征芳纶纱线在不同应变率下的力学行为,进行了Kevlar29纱线的准静态和动态拉伸试验,结合分离式霍普金森拉杆理论和运动目标追踪法,获得了Kevlar29纱线在不同应变率下的应力-应变曲线,分析了纱线动态拉伸的变形与断裂过程,揭示了Kevlar29纱线力学性能的应变率效应;通过最小二乘法拟合得到了基于纱线应变率效应的黏弹性本构方程,分析了三元件和五元件本构模型的差异及适用性。结果表明:随着应变率升高,Kevlar29纱线的断裂应变减小,拉伸强度和韧性先增大后减小,拉伸模量先增大后趋于稳定;五元件黏弹性本构模型能够较好地表征纱线力学性能的应变率效应。Abstract: In order to clearly characterize the mechanical behavior of Kevlar29 yarn at different strain rates, this paper reports quasi-static and dynamic tensile tests on Kevlar29 yarn. Combined with the split Hopkinson tensile bar (SHTB) theory and motion target tracking method, the stress-strain curves of Kevlar29 yarn at different strain rates are accurately obtained, and then the deformation and fracture process of yarn dynamic tension are analyzed, revealing the strain rate effect of Kevlar29 yarn mechanical properties. Based on the strain rate effect of yarn, a viscoelastic constitutive equation is obtained through the least squares fitting method, and the differences and applicability between the three-element and five-element constitutive models are analyzed. The results show that when the strain is calculated by identifying the coordinates of the marker points on the yarn by the motion target tracking method, it is more accurate than the strain calculated directly from the waveform measured by SHTB. The quasi-static mechanical properties and dynamic mechanical properties of Kevlar29 yarn differ significantly, e.g., the dynamic tensile modulus and tensile strength are higher than those of quasi-static, and the dynamic fracture strain is smaller than that of quasi-static. In the strain rate range of 0.001–700 s−1, with the increase of strain rate, the breaking strain of Kevlar29 yarn decreases, and the tensile strength, tensile modulus and toughness all increase first, but at higher strain rates, the tensile strength (higher than 497.5 s−1) and toughness (higher than 330.7 s−1) decrease, while the tensile modulus (higher than 330.7 s−1) tends to be stable. The viscoelastic constitutive equation can better characterize the strain rate effect of the mechanical properties of Kevlar29 yarn, but the viscoelastic constitutive model cannot reflect the nonlinear stress-strain relationship of the yarn before fracture. Relatively speaking, the fitting effect of the five-element viscoelastic model is better than that of the three-element viscoelastic model.

-

表 1 三元件黏弹性本构模型参数

Table 1. Parameters for the three-element viscoelastic model

E1/GPa E2/GPa η2/(MPa·s) 82.5 54.7 2.218 表 2 五元件黏弹性本构模型参数

Table 2. Parameters for the five-element viscoelastic model

E1/GPa E2/GPa E3/GPa η2/(MPa·s) η3/(MPa·s) C1 82.5 43.7 42.3 1.326 0.989 1416 -

[1] WANG H X, HAZELL P J, SHANKAR K, et al. Tensile properties of ultra-high-molecular-weight polyethylene single yarns at different strain rates [J]. Journal of Composite Materials, 2020, 54(11): 1453–1466. DOI: 10.1177/0021998319883416. [2] WANG Y, XIA Y M. Experimental and theoretical study on the strain rate and temperature dependence of mechanical behaviour of Kevlar fibre [J]. Composites Part A: Applied Science and Manufacturing, 1999, 30(11): 1251–1257. DOI: 10.1016/S1359-835X(99)00035-4. [3] RUSSELL B P, KARTHIKEYAN K, DESHPANDE V S, et al. The high strain rate response of ultra high molecular-weight polyethylene: from fibre to laminate [J]. International Journal of Impact Engineering, 2013, 60: 1–9. DOI: 10.1016/j.ijimpeng.2013.03.010. [4] ZHOU Y X, WANG Y, XIA Y M, et al. Tensile behavior of carbon fiber bundles at different strain rates [J]. Materials Letters, 2010, 64(3): 246–248. DOI: 10.1016/j.matlet.2009.10.045. [5] DOORAKI B F, NEMES J A, BOLDUC M. Study of parameters affecting the strength of yarns [J]. Journal de Physique Ⅳ (Proceedings), 2006, 134: 1183–1188. DOI: 10.1051/jp4:2006134180. [6] ZHU D, MOBASHER B, ERNI J, et al. Strain rate and gage length effects on tensile behavior of Kevlar 49 single yarn [J]. Composites Part A: Applied Science and Manufacturing, 2012, 43(11): 2021–2029. DOI: 10.1016/j.compositesa.2012.06.007. [7] 陈思颖, 黄晨光, 段祝平. 几种高性能纤维束的冲击动力学性能实验研究 [J]. 爆炸与冲击, 2003, 23(4): 355–359.CHEN S Y, HUANG C G, DUAN Z P. Experimental study on the dynamic properties of high strength fiber clusters [J]. Explosion and Shock Waves, 2003, 23(4): 355–359. [8] 朱德举, 欧云福, 张晓彤, 等. Kevlar® 29纤维多尺度力学行为的试验研究和有限元模拟 [J]. 工程力学, 2016, 33(9): 242–249, 256. DOI: 10.6052/j.issn.1000-4750.2015.02.0123.ZHU D J, OU Y F, ZHANG X T, et al. Experimental study and finite element modeling of the multi-scale mechanical behavior of Kevlar® 29 fibers [J]. Engineering Mechanics, 2016, 33(9): 242–249, 256. DOI: 10.6052/j.issn.1000-4750.2015.02.0123. [9] TAPIE E, SHIM V P W, GUO Y B. Influence of weaving on the mechanical response of aramid yarns subjected to high-speed loading [J]. International Journal of Impact Engineering, 2015, 80: 1–12. DOI: 10.1016/j.ijimpeng.2014.12.010. [10] NILAKANTAN G, KEEFE M, BOGETTI T A, et al. Multiscale modeling of the impact of textile fabrics based on hybrid element analysis [J]. International Journal of Impact Engineering, 2010, 37(10): 1056–1071. DOI: 10.1016/j.ijimpeng.2010.04.007. [11] YANG Y F, LIU Y C, XUE S N, et al. Multi-scale finite element modeling of ballistic impact onto woven fabric involving fiber bundles [J]. Composite Structures, 2021, 267: 113856. DOI: 10.1016/j.compstruct.2021.113856. [12] ZHOU Y, YAO W T, ZHANG Z W, et al. The effect of cumulative damage on the ballistic performance of plain weaves [J]. Composite Structures, 2022, 297: 115978. DOI: 10.1016/j.compstruct.2022.115978. [13] NILAKANTAN G. Filament-level modeling of Kevlar KM2 yarns for ballistic impact studies [J]. Composite Structures, 2013, 104: 1–13. DOI: 10.1016/j.compstruct.2013.04.001. [14] HA-MINH C, IMAD A, KANIT T, et al. Numerical analysis of a ballistic impact on textile fabric [J]. International Journal of Mechanical Sciences, 2013, 69: 32–39. DOI: 10.1016/j.ijmecsci.2013.01.014. [15] ROYLANCE D. Wave propagation in a viscoelastic fiber subjected to transverse impact [J]. Journal of Applied Mechanics, 1973, 40(1): 143–148. DOI: 10.1115/1.3422914. [16] TAYLOR W J, VINSON J R. Modeling ballistic impact into flexible materials [J]. AIAA Journal, 1990, 28(12): 2098–2103. DOI: 10.2514/3.10527. [17] SHIM V P W, TAN V B C, TAY T E. Modelling deformation and damage characteristics of woven fabric under small projectile impact [J]. International Journal of Impact Engineering, 1995, 16(4): 585–605. DOI: 10.1016/0734-743X(94)00063-3. [18] KOH A C P, SHIM V P W, TAN V B C. Dynamic behaviour of UHMWPE yarns and addressing impedance mismatch effects of specimen clamps [J]. International Journal of Impact Engineering, 2010, 37(3): 324–332. DOI: 10.1016/j.ijimpeng.2009.10.008. [19] GUO Y B, SHIM V P W, TAN B W F. Dynamic tensile properties of magnesium nanocomposite [J]. Materials Science Forum, 2012, 706: 780–785. DOI: 10.4028/www.scientific.net/MSF.706-709.780. -

下载:

下载: