The law of gas explosion and gas-liquid coupling in urban underground drainage pipelines

-

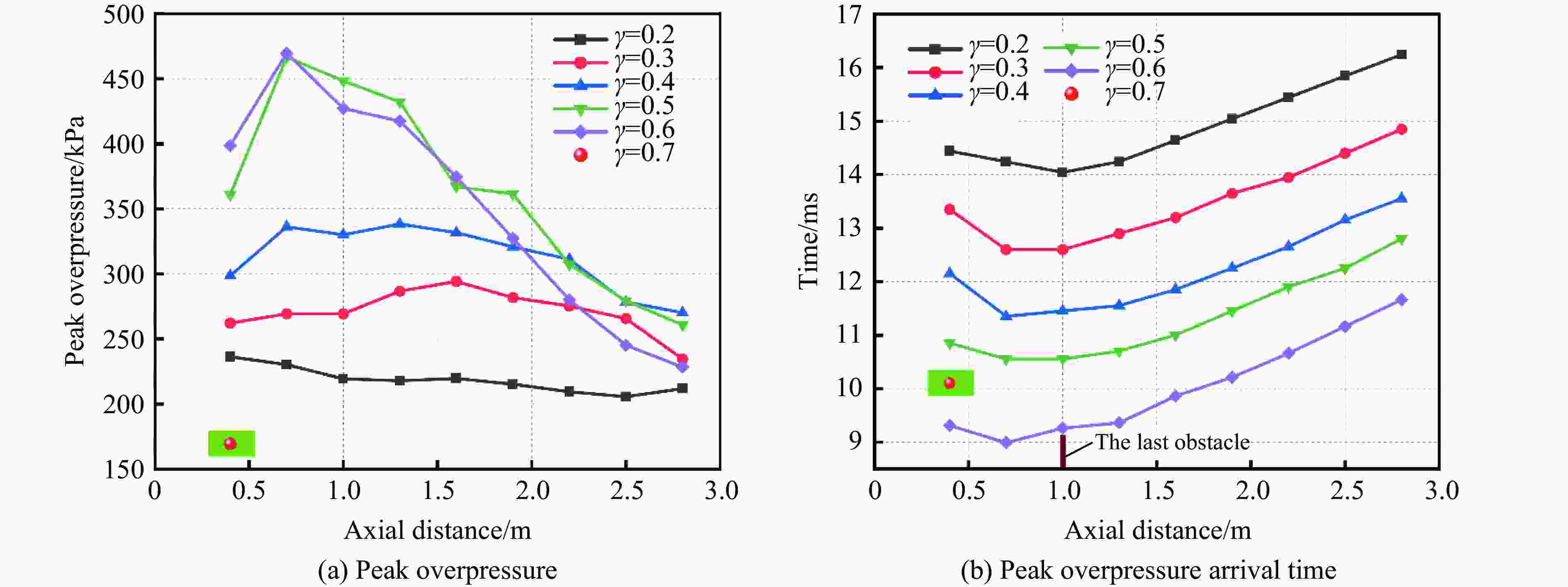

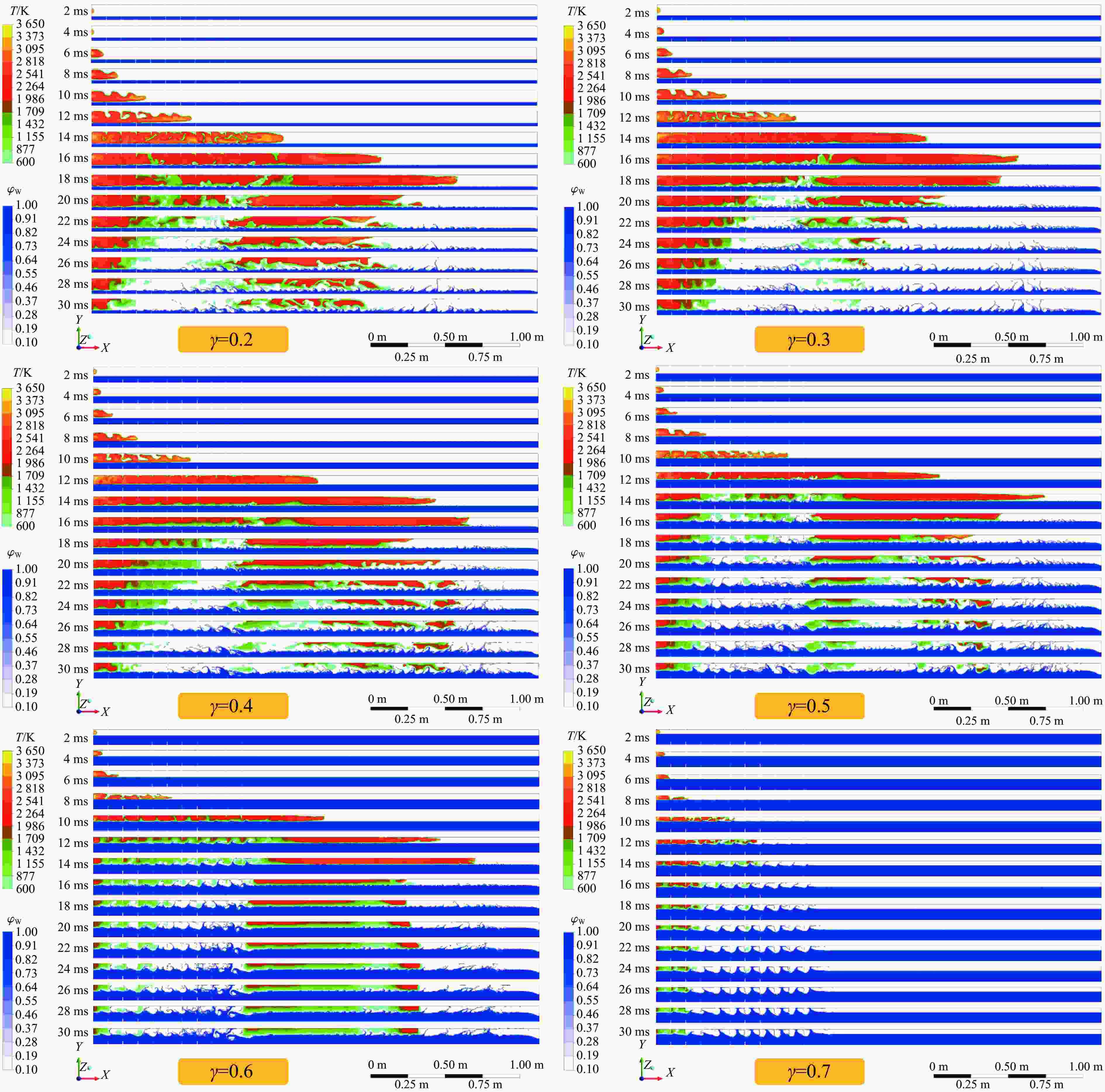

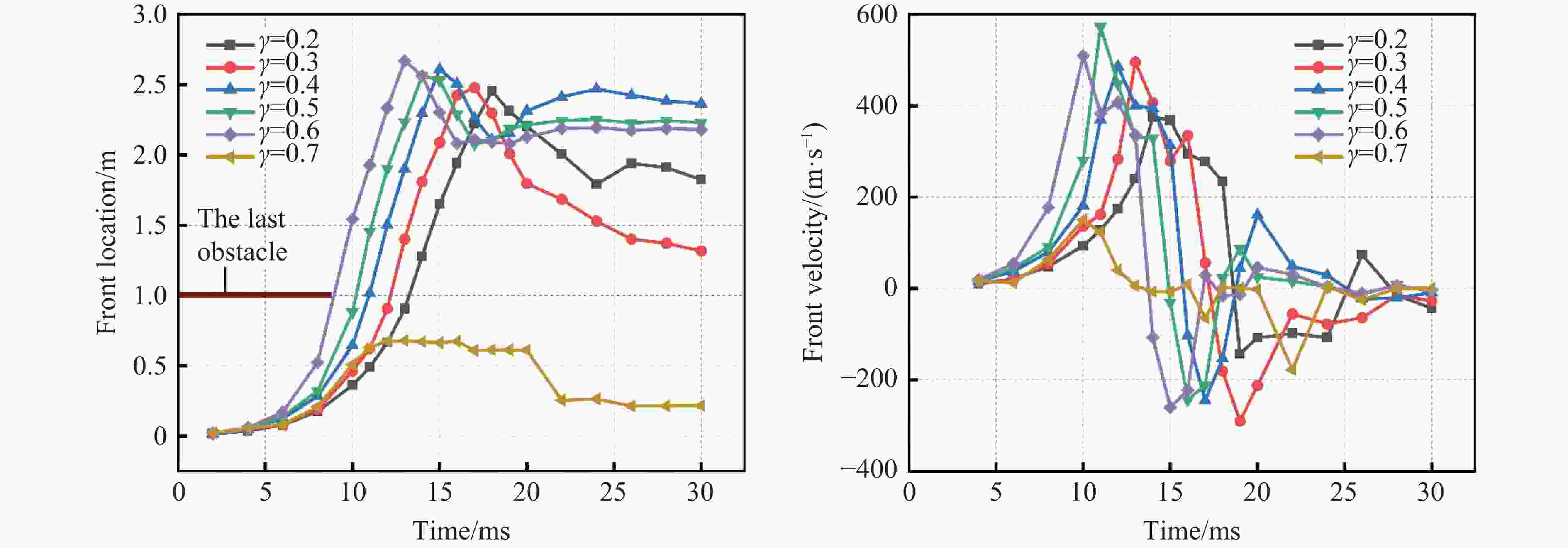

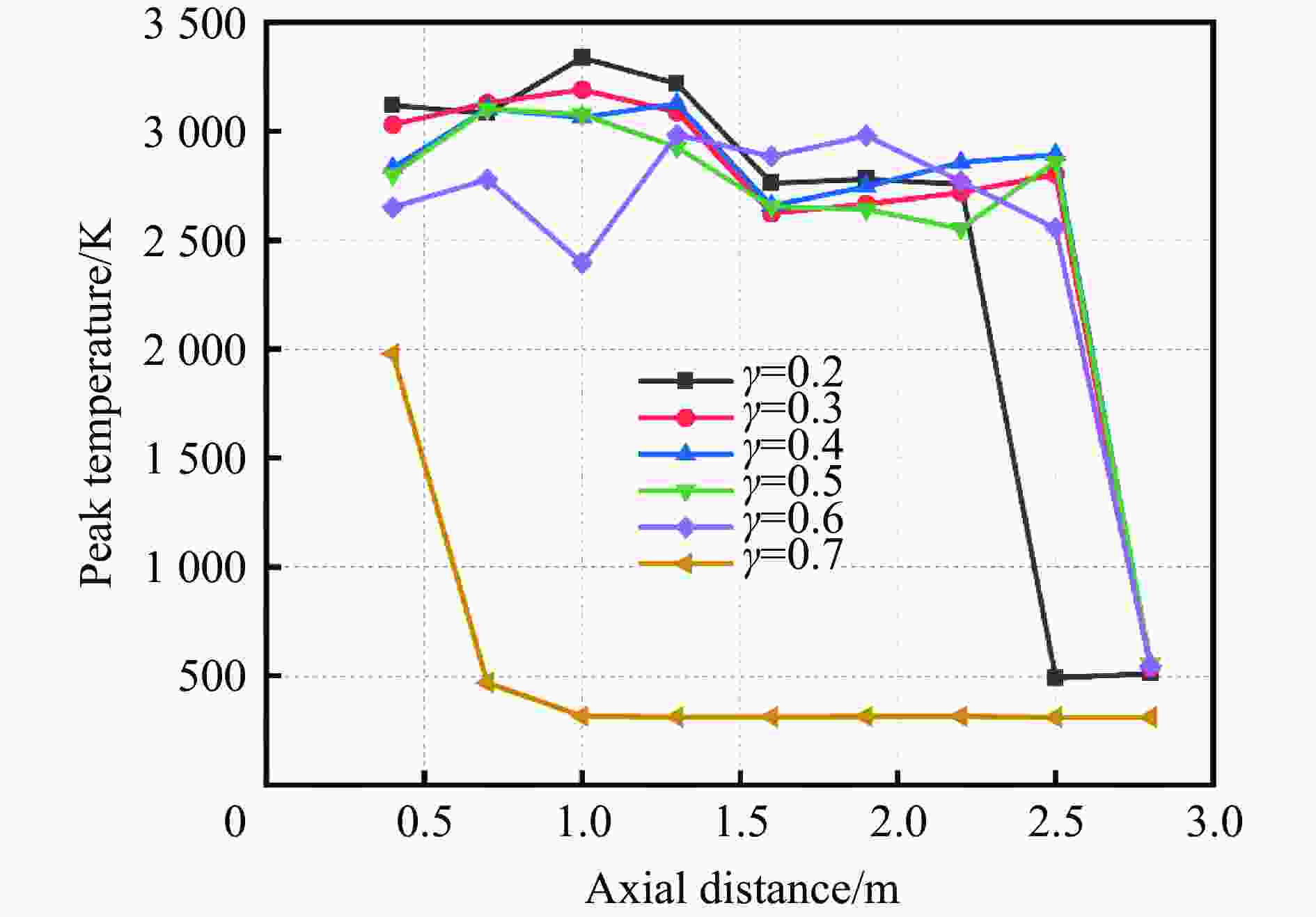

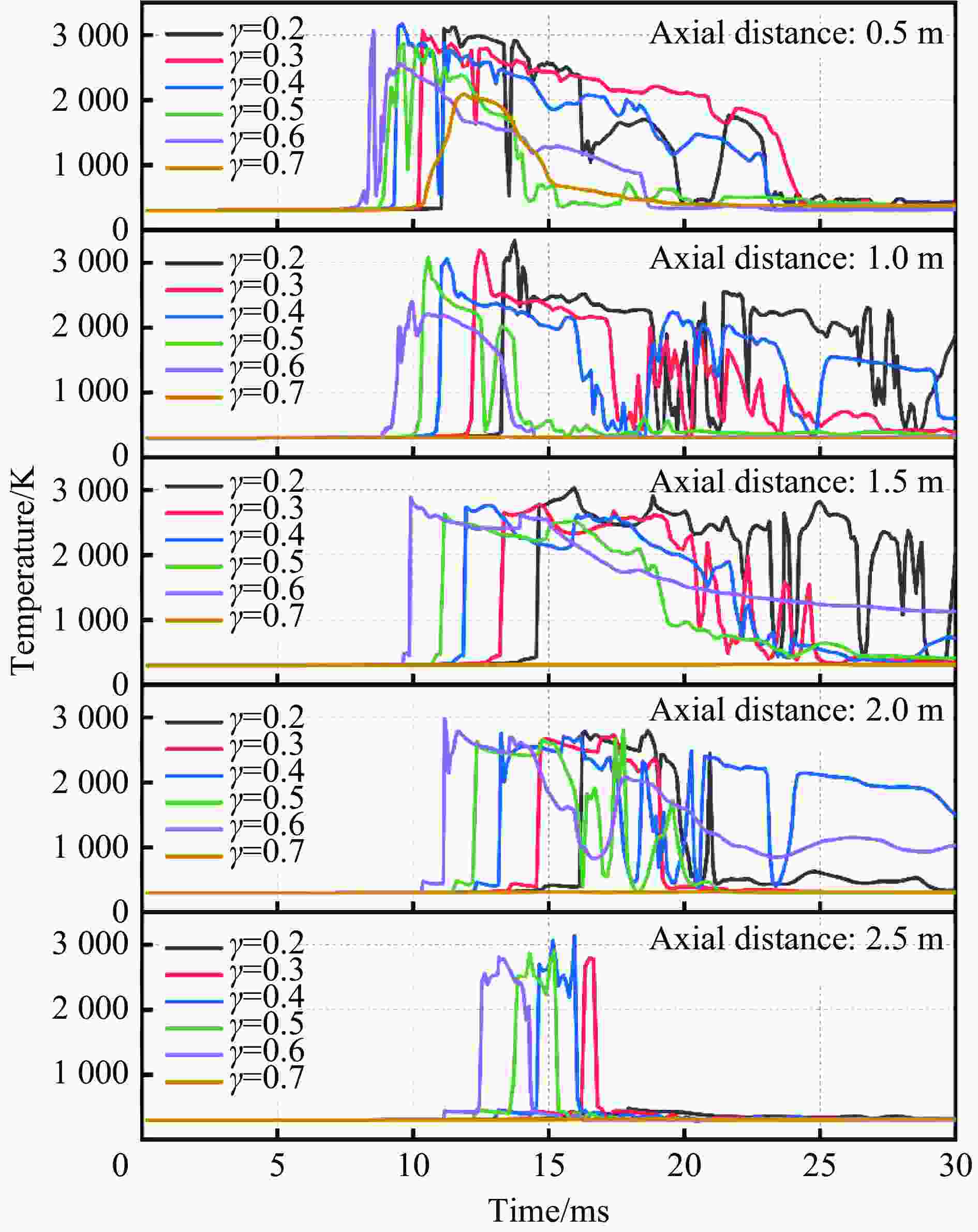

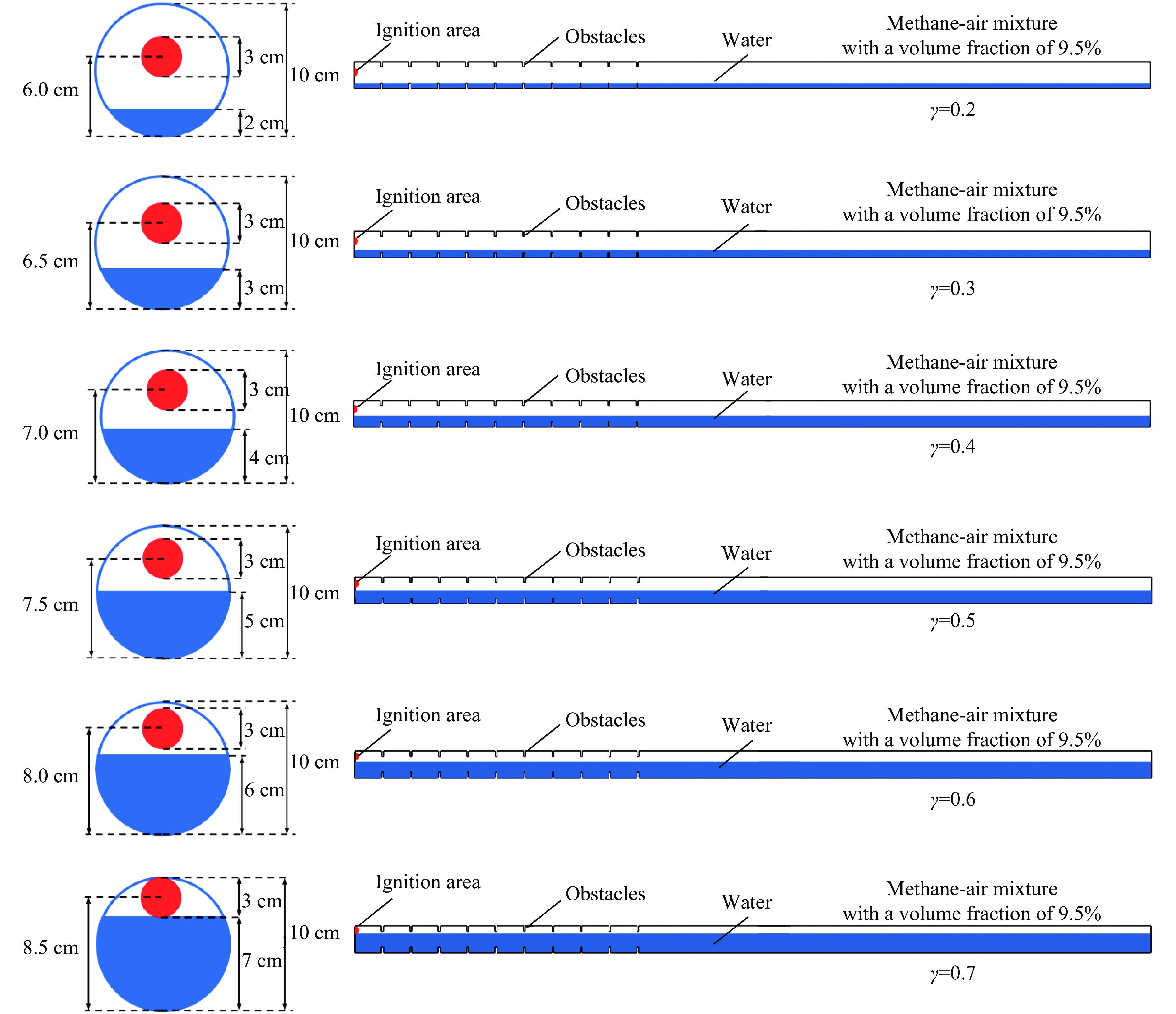

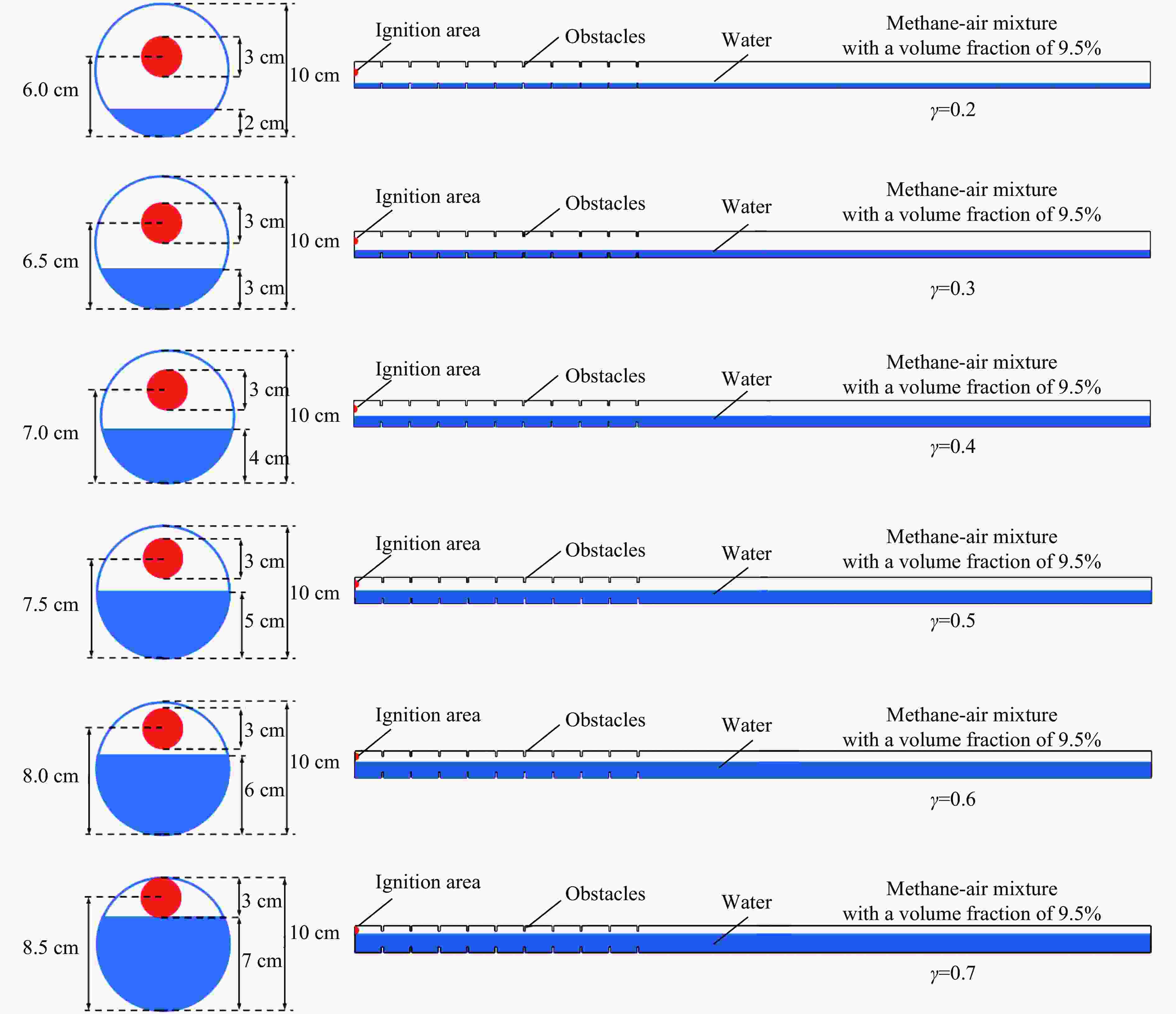

摘要: 为研究城市地下排水管道中燃气爆炸传播特性和气-液两相耦合作用规律,基于气-液两相流理论和计算流体力学方法,对不同水深率下的天然气/空气混合物的爆炸-加速-衰减过程进行了数值模拟。研究结果表明:当水深率小于0.7时,随着水深率的增加,气相空间的长径比增大,燃料燃烧加剧,火焰的加速现象逐渐显著,导致峰值超压逐渐增大,超压峰值显现时间逐渐缩短,且峰值超压沿轴向的提升效果更加显著;当水深率达到0.7时,火焰在管道内的传播明显受阻,水震荡产生的波动及细水柱迅速占据了有限的气相空间,阻断了火焰的自维持传播,使得爆炸超压仅在点火源附近显现。不同水深率条件下,管道中相同区域内,同一时刻水面被扬起的高度和气相区域的速度场不同,被卷扬起的低温液体对其相邻区域的高温火焰形成降温和阻断,之后由于气体的宏观流动,与液面相邻的低温气体流动至管道内高温区域,进而造成管道内火焰温度降低,同时,水的震荡和细水柱的飞扬大大降低了爆炸超压风险。Abstract: There are frequent gas explosion accidents in urban rain and sewage drainage pipes, which pose a serious threat to people’s lives and property safety. To study the propagation characteristics of gas explosion and the law of gas-liquid two-phase coupling in urban underground drainage pipes, based on the gas-liquid two-phase flow theory and computational fluid dynamics method, a numerical simulation study of the explosion-acceleration-decay process of gas/air mixture under different water depth ratio was conducted. The results show that when the water depth ratio is less than 0.7, as the water depth ratio increases, the long-diameter ratio of the gas phase space increases, the fuel combustion intensifies, and the flame acceleration phenomenon gradually becomes significant, which leads to a gradual increase in peak overpressure, a gradual reduction in peak overpressure time, and a more significant effect of peak overpressure along the axial direction. When the water depth ratio reaches 0.7, the propagation of the flame in the pipeline is blocked, and the fluctuation caused by the water shock and the fine water column quickly occupy a small gas phase space, blocking the continuous propagation of the flame, which makes the explosion overpressure appear only near the ignition source. Under different water depth ratios, in the same zone of the pipeline and at the same moment, the height of the water being rolled up and the velocity field of the gas phase region is different, and the cryogenic liquid is rolled up to cool and block the high-temperature flame in the adjacent zone. Then, due to the macroscopic flow of the gas, the cryogenic gas adjacent to the liquid surface flows to the high-temperature region in the pipeline, resulting in a decrease in the flame temperature in the pipeline. The shock of water and the flying of fine water columns greatly reduce the risk of explosion overpressure. The research results provide a scientific basis for the explosion protection of urban gas lifelines.

-

表 1 水深率不同时管道内不同测点处的温度峰值

Table 1. Temperature peak at different measuring points in the pipeline under different water depth ratios

水深率 不同测点的温度峰值/K 0.4 m 0.7 m 1.0 m 1.3 m 1.6 m 1.9 m 2.2 m 2.5 m 2.8 m 0.2 3 117.6 3 082.4 3 336.6 3 216.4 2 760.8 2 778.5 2 757.1 490.8 510.9 0.3 3 029.9 3 128.6 3 190.2 3 086.7 2 622.4 2 664.6 2 717.9 2 801.7 536.2 0.4 2 832.4 3 102.3 3 062.2 3 126.8 2 657.6 2 745.1 2 856.3 2 892.2 557.7 0.5 2 800.9 3 102.2 3 077.3 2 925.4 2 652.6 2 641.6 2 552.3 2 860.3 556.1 0.6 2 650.7 2 777.9 2 395.2 2 983.2 2 883.8 2 978.6 2 770.4 2 552.8 547.0 0.7 1 978.3 469.3 316.2 312.3 313.2 313.8 314.9 310.9 310.7 -

[1] 程方明, 南凡, 肖旸, 等. CF3I和CO2抑制甲烷-空气爆炸实验研究 [J]. 爆炸与冲击, 2022, 42(6): 065402. DOI: 10.11883/bzycj-2021-0386.CHENG F M, NAN F, XIAO C, et al. Experimental study on the suppression of methane-air explosion by CF3I and CO2 [J]. Explosion and Shock Waves, 2022, 42(6): 065402. DOI: 10.11883/bzycj-2021-0386. [2] ZHANG Z W, HOU L F, YUAN M Q, et al. Optimization monitoring distribution method for gas pipeline leakage detection in underground spaces [J]. Tunnelling and Underground Space Technology, 2020, 104: 103545. DOI: 10.1016/j.tust.2020.103545. [3] CHEN C H, SHEEN Y N, WANG H Y. Case analysis of catastrophic underground pipeline gas explosion in Taiwan [J]. Engineering Failure Analysis, 2016, 65: 39–47. DOI: 10.1016/j.engfailanal.2016.03.013. [4] ZHU Y, QIAN X M, LIU Z Y, et al. Analysis and assessment of the Qingdao crude oil vapor explosion accident: lessons learnt [J]. Journal of Loss Prevention in the Process Industries, 2015, 33: 289–303. DOI: 10.1016/j.jlp.2015.01.004. [5] KINDRACKI J, KOBIERA A, RARATA G, et al. Influence of ignition position and obstacles on explosion development in methane-air mixture in closed vessels [J]. Journal of Loss Prevention in the Process Industries, 2007, 20(4): 551–561. DOI: 10.1016/j.jlp.2007.05.010. [6] 郑永辉, 魏继锋. 水介质初始参数设置对水下爆炸载荷的影响 [J]. 爆炸与冲击, 2022, 42(5): 053201. DOI: 10.11883/bzycj-2021-0485.ZHENG Y H, WEI J F. Effect of initial parameter setting of water on load characteristics of underwater explosion [J]. Explosion and Shock Waves, 2022, 42(5): 053201. DOI: 10.11883/bzycj-2021-0485. [7] CAO Y, LI B, XIE L F, et al. Experimental and numerical study on pressure dynamic and venting characteristic of methane-air explosion in the tube with effect of methane concentration and vent burst pressure [J]. Fuel, 2022, 316: 123311. DOI: 10.1016/j.fuel.2022.123311. [8] 文彦博, 胡亮亮, 秦健, 等. 近场水下爆炸气泡脉动及水射流的实验与数值模拟研究 [J]. 爆炸与冲击, 2022, 42(5): 053203. DOI: 10.11883/bzycj-2021-0206.WEN Y B, HU L L, QIN J, et al. Experimental study and numerical simulation on bubble pulsation and water jet in near-field underwater explosion [J]. Explosion and Shock Waves, 2022, 42(5): 053203. DOI: 10.11883/bzycj-2021-0206. [9] ZHU Y F, WANG D M, SHAO Z L, et al. Investigation on the overpressure of methane-air mixture gas explosions in straight large-scale tunnels [J]. Process Safety and Environmental Protection, 2020, 135: 101–112. DOI: 10.1016/j.psep.2019.12.022. [10] WANG L Q, MA H H, SHEN Z W, et al. Experimental investigation of methane-oxygen detonation propagation in tubes [J]. Applied Thermal Engineering, 2017, 123: 1300–1307. DOI: 10.1016/j.applthermaleng.2017.05.045. [11] AKKERMAN V, BYCHKOV V, PETCHENKO A, et al. Accelerating flames in cylindrical tubes with nonslip at the walls [J]. Combustion and Flame, 2006, 145(1/2): 206–219. DOI: 10.1016/j.combustflame.2005.10.011. [12] KUNDU S K, ZANGANEH J, ESCHEBACH D, et al. Explosion characteristics of methane-air mixtures in a spherical vessel connected with a duct [J]. Process Safety and Environmental Protection, 2017, 111: 85–93. DOI: 10.1016/j.psep.2017.06.014. [13] STARKE R, ROTH P. An experimental investigation of flame behavior during explosions in cylindrical enclosures with obstacles [J]. Combustion and Flame, 1989, 75(2): 111–121. DOI: 10.1016/0010-2180(89)90090-4. [14] IBRAHIM S S, MASRI A R. The effects of obstructions on overpressure resulting from premixed flame deflagration [J]. Journal of Loss Prevention in the Process Industries, 2001, 14(3): 213–221. DOI: 10.1016/S0950-4230(00)00024-3. [15] WANG C, HUANG F L, KWASI E, et al. Effect of concentration and obstacles on flame velocity and overpressure of methane-air mixture [J]. Journal of Loss Prevention in the Process Industries, 2016, 43: 302–310. DOI: 10.1016/j.jlp.2016.05.021. [16] 余明高, 杨勇, 裴蓓, 等. N2双流体细水雾抑制管道瓦斯爆炸实验研究 [J]. 爆炸与冲击, 2017, 37(2): 194–200. DOI: 10.11883/1001-1455(2017)02-0194-07.YU M G, YANG Y, PEI B, et al. Experimental study of methane explosion suppression by nitrogen twin-fluid water mist [J]. Explosion and Shock Waves, 2017, 37(2): 194–200. DOI: 10.11883/1001-1455(2017)02-0194-07. [17] 贾海林, 翟汝鹏, 李第辉, 等. 三种盐类超细水雾抑制管道内甲烷-空气预混气爆炸的差异性 [J]. 爆炸与冲击, 2020, 40(8): 082201. DOI: 10.11883/bzycj-2019-0456.JIA H L, ZHAI R P, LI D H, et al. Differences of premixed methane-air explosion in pipelines suppressed by three ultrafine water mists containing different salts [J]. Explosion and Shock Waves, 2020, 40(8): 082201. DOI: 10.11883/bzycj-2019-0456. [18] WANG F H, YU M G, WEN X P, et al. Suppression of methane/air explosion in pipeline by water mist [J]. Journal of Loss Prevention in the Process Industries, 2017, 49: 791–796. DOI: 10.1016/j.jlp.2017.02.005. [19] JING Q, WANG D, LIU Q M, et al. Inhibition effect and mechanism of ultra-fine water mist on CH4/air detonation: quantitative research based on CFD technology [J]. Process Safety and Environmental Protection, 2021, 148: 75–92. DOI: 10.1016/j.psep.2020.10.007. [20] LI H T, CHEN X K, SHU C M, et al. Experimental and numerical investigation of the influence of laterally sprayed water mist on a methane-air jet flame [J]. Chemical Engineering Journal, 2019, 356: 554–569. DOI: 10.1016/j.cej.2018.09.051. [21] LIANG Y T, ZENG W. Numerical study of the effect of water addition on gas explosion [J]. Journal of Hazardous Materials, 2010, 174(1/2/3): 386–392. DOI: 10.1016/j.jhazmat.2009.09.064. [22] LI X C, ZHANG H, BAI S, et al. Analysis of the effect mechanism of water and CH4 concentration on gas explosion in confined space [J]. Journal of Saudi Chemical Society, 2021, 25(11): 101363. DOI: 10.1016/j.jscs.2021.101363. [23] ZHANG Q, FU L Y, LI Z Y, et al. Coupling mechanism of natural gas deflagration flame and continuous water in closed pipeline [J]. Process Safety and Environmental Protection, 2020, 143: 177–185. DOI: 10.1016/j.psep.2020.07.004. [24] ZHANG Q, QIAN X M, FU L Y, et al. Shock wave evolution and overpressure hazards in partly premixed gas deflagration of DME/LPG blended multi-clean fuel [J]. Fuel, 2020, 268: 117368. DOI: 10.1016/j.fuel.2020.117368. [25] CHEN Y Y, QIAN X M, ZHANG Q, et al. Study on the effects of initial pressure and temperature on the explosion characteristics of DME-blended LPG mixtures in an obstructed confined pipeline [J]. Fuel, 2019, 257: 116047. DOI: 10.1016/j.fuel.2019.116047. [26] 许晓元, 孙金华, 刘晅亚. 具有体积分数梯度的连通装置甲烷-空气爆炸特性数值模拟 [J]. 爆炸与冲击, 2021, 41(4): 045401. DOI: 10.11883/bzycj-2020-0086.XU X Y, SUN J H, LIU X Y. Numerical simulation of methane-air explosion in a connected device with volume fraction gradient [J]. Explosion and Shock Waves, 2021, 41(4): 045401. DOI: 10.11883/bzycj-2020-0086. [27] 马晓丽. 故障树分析法在中缅长输原油管道失效风险评价的应用 [J]. 新疆石油天然气, 2014, 10(3): 119–124, 9. DOI: 10.3969/j.issn.1673-2677.2014.03.023.MA X L. The application of china-burma long distance oil pipeline failure risk assessmentin the fault tree analysis [J]. Xinjiang Oil and Gas, 2014, 10(3): 119–124, 9. DOI: 10.3969/j.issn.1673-2677.2014.03.023. [28] ZHOU G, MA Y, KONG Y, et al. Study on explosion dynamics and kinetic mechanism of DME/H2 blended gas at typical fuel-lean/rich concentrations [J]. Case Studies in Thermal Engineering, 2022, 40: 102444. DOI: 10.1016/j.csite.2022.102444. [29] ZHANG Q, ZHOU G, HU Y, et al. Risk evaluation and analysis of a gas tank explosion based on a vapor cloud explosion model: a case study [J]. Engineering Failure Analysis, 2019, 101: 22–35. DOI: 10.1016/j.engfailanal.2019.03.003. [30] 申亮. 天然气高压管道泄漏爆炸后果评价 [J]. 新疆石油天然气, 2013, 9(1): 90–95. DOI: 10.3969/j.issn.1673-2677.2013.01.020.SHEN L. Evaluation on explosion consequence caused by leakage of high-pressure nature gas pipeline [J]. Xinjiang Oil and Gas, 2013, 9(1): 90–95. DOI: 10.3969/j.issn.1673-2677.2013.01.020. [31] 徐岩, 李永泉, 郭晓燕, 等. 基于YOLOv3-tiny的火焰目标检测算法 [J]. 山东科技大学学报, 2022, 41(6): 95–103. DOI: 10.16452/j.cnki.sdkjzk.2022.06.010.XU Y, LI Y Q, GUO X Y, et al. Flame object detection algorithm based on YOLOv3-tinys [J]. Journal of Shandong University of Science and Technology (Natural Science), 2022, 41(6): 95–103. DOI: 10.16452/j.cnki.sdkjzk.2022.06.010. [32] 潘旭海, 徐进, 蒋军成. 圆柱形薄壁储罐对爆炸冲击波动力学响应的模拟分析 [J]. 化工学报, 2008, 59(3): 796–801. DOI: 10.3321/j.issn:0438-1157.2008.03.041.PAN X H, XU J, JIANG J C. Simulation analysis of dynamic response of thin-wall cylindrical tank to shock wave [J]. Journal of Chemical Industry and Engineering, 2008, 59(3): 796–801. DOI: 10.3321/j.issn:0438-1157.2008.03.041. [33] 冯丽, 郝海清, 王凯. 矿井立井防爆盖泄压复位技术及动力学相应规律研究 [J]. 山东科技大学学报, 2022, 4(3): 51–57. DOI: 10.16425/j.cnki.sdkjzk.2022.03.006.FENG L, HAO H Q, WANG K. Study on pressure relief and reset technology and dynamic response law of mine shaft explosion-proof covers [J]. Journal of Shandong University of Science and Technology (Natural Science), 2022, 4(3): 51–57. DOI: 10.16425/j.cnki.sdkjzk.2022.03.006. [34] ZHOU G, KONG Y, QIAN X M, et al. Explosion dynamics and sensitivity analysis of blended LPG/DME clean fuel promoted by H2 in a confined elongated space [J]. Fuel, 2023, 331: 125816. DOI: 10.1016/j.fuel.2022.125816. [35] SONG Y F, ZHANG Q, WU W W. Interaction between gas explosion flame and deposited dust [J]. Process Safety and Environmental Protection, 2017, 111(1989): 775–784. DOI: 10.1016/j.psep.2017.09.004. [36] DIANAT M, SKARYSZ M, GARMORY A. A coupled level set and volume of fluid method for automotive exterior water management applications [J]. International Journal of Multiphase Flow, 2017, 91: 19–38. DOI: 10.1016/j.ijmultiphaseflow.2017.01.008. [37] ZHOU G, LIU Y W, KONG Y, et al. Numerical analysis of dust pollution evolution law caused by ascensional/descensional ventilation in fully mechanized coal mining face based on DPM-DEM model [J]. Journal of Environmental Chemical Engineering, 2022, 10(3): 107732. DOI: 10.1016/j.jece.2022.107732. [38] 皇新宇, 纪强, 张宪堂, 等. 地应力作用下四孔掏槽爆破破岩机理数值模拟研究 [J]. 山东科技大学学报, 2022, 41(2): 61–69. DOI: 10.16452/j.cnki.dkjzk.2022.02.007.HUANG X Y, JI Q, ZHANG X T, et al. Numerical simulation research on rock breaking mechanism of four-hole cut blasting under ground stress [J]. Journal of Shandong University of Science and Technology (Natural Science), 2022, 41(2): 61–69. DOI: 10.16452/j.cnki.dkjzk.2022.02.007. [39] YANG Y, YANG S G, FANG Q, et al. Large-scale experimental and simulation study on gas explosion venting load characteristics of urban shallow buried pipe trenches [J]. Tunnelling and Underground Space Technology, 2022, 123(1): 104409. DOI: 10.1016/j.tust.2022.104409. [40] ZELDOVICH Y B, RAIZER Y P. Physics of shock waves and high-temperature hydrodynamic phenomena [J]. Journal of Quantitative Spectroscopy and Radiative Transfer, 2003, 76(2): 235–236. DOI: 10.1016/S0022-4073(02)00065-1. -

下载:

下载: