Stress wave separation based on standard Hopkinson pressure bar set-up and unlimited duration of experiment data processing

-

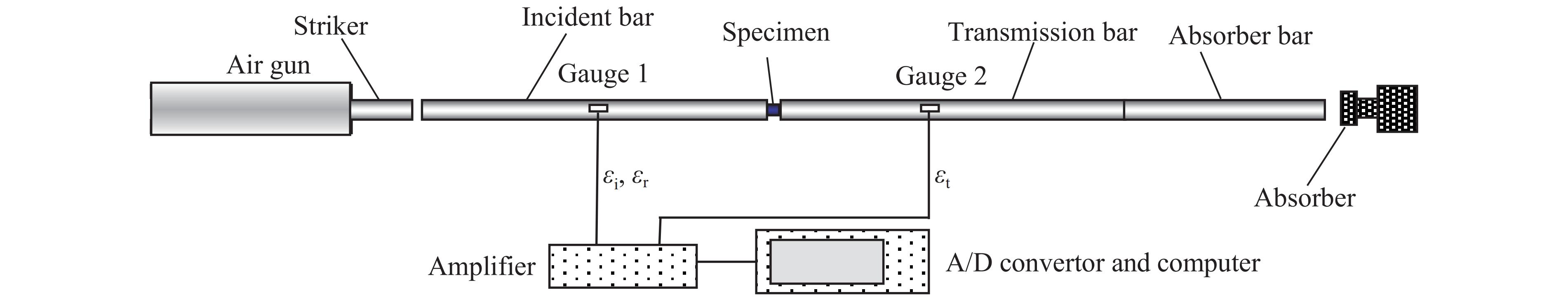

摘要: 在经典一维应力波理论基础上以及试件受力平衡假定成立的条件下,提出了一种在标准霍普金森压杆实验配置下实现杆中左、右行应力波分离的新方法,可简单有效地解决常规霍普金森压杆在长时实验时左、右行波信号重叠的问题,从而保证实验中的全部应变测试数据都可以加以利用,显著提高了霍普金森压杆的测试能力。给出了新的基于杆中左、右行应力波信号的实验数据处理公式。作为霍普金森压杆实验中经典数据处理公式的扩展,在测试信号不需要进行波分离处理的情况下,新的数据处理公式等同于经典公式。利用ABAQUS 有限元软件对霍普金森压杆实验进行了数值模拟,采用虚拟实验的方式,利用模拟测试点的应变信号进行了多种实验条件下的数据处理,对该应力波分离方法的有效性及误差进行了验证与评价。数值模拟结果表明,该应力波分离方法可以给出很好的数据处理结果。在标准霍普金森压杆上进行了部分实验并利用新的波分离方法及公式对数据进行处理,所得结果令人满意。Abstract: Based on the classical one-dimensional stress wave theory and the assumption of force equilibrium of the specimen, a new method for separating left-going and right-going stress waves on the standard Hopkinson pressure bar set-up is proposed. It can solve the problem of left-going and right-going stress wave signal overlapping in a standard Hopkinson pressure bar used for a long-duration experiment effectively and with simplicity. By introducing virtual strain measuring points at the specimen end of the incident bar and the free end of the transmission bar, the separation problem of stress waves in each bar which using only one strain gage is transformed into the two-point wave separation problem and then the separation of the left and right traveling stress waves is conveniently accomplished. In principle, this new method allows unlimited duration of test data analysis thus the overall experimental process can be analyzed. It thereby significantly enhances the test ability of the standard Hopkinson pressure bar. New experimental data processing formulas based on the left-going and right-going stress wave signals are presented. They are actually the generalizations of the classical data processing formulas. These new formula are equivalent to the classical formulas when the wave separation processing is unnecessary. Full model simulations of the split Hopkinson pressure bar experiment were carried out on the ABAQUS/Explicit finite element simulation platform. The simulated strain signals at the test positions then are processed in the way of virtual experiment under various experimental conditions. Based on this, the effectiveness and errors are verified or evaluated. The simulation result shows that this new stress wave separation method can give a good data processing result. Some experiments were carried out on a standard Hopkinson pressure bar apparatus with a 1-m-length incident bar and a 1-m-length transmission bar. The new wave separation technique and data process formulas were used. For the 2014 aluminum alloy test, the specimen stress and deformation progresses was clearly captured for the first and second loading process. For the aluminum foam test, a quasi-direct impact technique was used to achieve long-time continuous loading on the specimen and the experiment result was complete, clean and satisfactory.

-

Key words:

- Hopkinson pressure bar /

- wave signal overlapping /

- wave separation /

- data processing

-

表 1 试件材料常数及J-C模型参数

Table 1. Parameters of materials and J-C model for specimens

材料 密度/(kg·m−3) 模量/GPa 泊松比 A/MPa B/MPa n m Tm/K T0/K C 弹簧钢 7 850 206 0.295 无氧铜 8 960 124 0.340 90 292 0.31 1.09 1 356 298 0.025 表 2 压杆、试件及整形器的几何参数、单元尺寸及材料

Table 2. Geometries, element sizes and materials of bars, specimens and shaper

部件 直径/mm 长度(厚度)/mm 最大网格尺寸/mm 材料 $\varnothing $16 mm入射、透射杆 16.0 1 000.0 1.00 弹簧钢 $\varnothing $16 mm撞击杆 16.0 300.0 1.00 弹簧钢 $\varnothing $50 mm入射、透射杆 50.0 1 600.0 2.50 弹簧钢 $\varnothing $50 mm撞击杆 50.0 1 600.0 2.50 弹簧钢 无氧铜试件 8.0 6.0 0.80 无氧铜 泡沫铝试件 30.0 15.0 1.50 泡沫铝 脉冲整形片 6.4 0.5, 1.0 0.25 无氧铜 -

[1] GRAY G T Ⅲ. Classic split Hopkinson pressure bar testing [M] // ASM Handbook, Mechanical Testing and Evaluation. Ohio: ASM International, 2000: 463–476. DOI: 10.31399/asm.hb.v08.a0003296. [2] SONG B, SYN C J, GRUPIDO C L, et al. A long split Hopkinson pressure bar (LSHPB) for intermediate-rate characterization of soft materials [J]. Experimental Mechanics, 2008, 48(6): 809–815. DOI: 10.1007/s11340-007-9095-z. [3] ZHAO H, GARY G. A new method for the separation of waves: application to the SHPB technique for an unlimited duration of measurement [J]. Journal of the Mechanics and Physics of Solids, 1997, 45(7): 1185–1202. DOI: 10.1016/s0022-5096(96)00117-2. [4] PERONI M, SOLOMOS G, BABCSAN N. Development of a Hopkinson bar apparatus for testing soft materials: application to a closed-cell aluminum foam [J]. Materials, 2016, 9(1): 27. DOI: 10.3390/ma9010027. [5] GILAT A, SEIDT J D, MATRKA T A, et al. A new device for tensile and compressive testing at intermediate strain rates [J]. Experimental Mechanics, 2019(59): 725–731. DOI: 10.1007/s11340-019-00488-1. [6] LUNDBERG B, HENCHOZ A. Analysis of elastic waves from two-point strain measurement [J]. Experimental Mechanics, 1977, 17(6): 213–218. DOI: 10.1007/BF02324491. [7] YANAGIHARA N. New measuring method of impact force [J]. Bulletin of JSME, 1978, 21(157): 1085–1088. DOI: 10.1299/jsme1958.21.1085. [8] 姜清辉, 赵统武, 刘清泉. 两点应变测量法测试冲击力 [J]. 山东科技大学学报(自然科学版), 2000, 19(2): 29–32. DOI: 10.3969/j.issn.1672-3767.2000.02.008.JIANG Q H, ZHAO T W, LIU Q Q. Test of impact force by using two-point strain measuring method [J]. Journal of Shandong University of Science and Technology (Natural Science), 2000, 19(2): 29–32. DOI: 10.3969/j.issn.1672-3767.2000.02.008. [9] 巫绪涛, 胡时胜, 张芳荣. 两点应变测量法在SHPB测量技术上的运用 [J]. 爆炸与冲击, 2003, 23(4): 309–312.WU X T, HU S S, ZHANG F R. Application of two-point strain measurement to the SHPB technique [J]. Explosion and Shock Waves, 2003, 23(4): 309–312. [10] LIU J G, SI Y, et al. Experimental investigation on the dynamic behavior of metal foam: from yield to densification [J]. International Journal of Impact Engineering, 2018(114): 69–77. DOI: 10.1016/j.ijimpeng.2017.12.016. [11] OTHMAN R. The Kolsky-Hopkinson bar machine: selected topics [M]. Switzerland: Springer, 2018: 183–203. DOI: 10.1007/978-3-319-71919-1. [12] JACQUELIN E, HAMELIN P. Force recovered from three recorded strains [J]. International Journal of Solids and Structures, 2003, 40(1): 73–88. DOI: 10.1016/S0020-7683(02)00544-9. [13] OTHMAN R. Comparison of three methods to separate waves in the processing of long-time Hopkinson bar experiments [J]. International Journal of Mechanical Engineering and Technology, 2014, 5(11): 114–119. [14] GARY G. Testing with bars from dynamic to quasi-static [M] // LODYGOWSKI T, RUSINEK A. Constitutive Relations under Impact Loadings. Vienna: Springer. 2014, 552: 1–58. DOI: 10.1007/978-3-7091-1768-2_1. [15] PARK S W, ZHOU M. Separation of elastic waves in split Hopkinson bars using one-point strain measurements [J]. Experimental Mechanics, 1999, 39(4): 287–294. DOI: 10.1007/BF02329807. [16] CHEN W, SONG B. Split Hopkinson (Kolsky) bar: design, testing and applications [M]. New York: Springer, 2011. DOI: 10.1007/978-1-4419-7982-7. [17] SONG B, CHEN W, LU W Y. Mechanical characterization at intermediate strain rates for rate effects on an epoxy syntactic foam [J]. International Journal of Mechanical Sciences, 2007, 49(12): 1336–1343. DOI: 10.1016/j.ijmecsci.2007.04.003. [18] GARY G, MOHR D. Modified Kolsky formulas for an increased measurement duration of SHPB systems [J]. Experimental Mechanics, 2013, 53(4): 713–717. DOI: 10.1007/s11340-012-9664-7. [19] 金属材料高应变速率室温压缩试验方法: GBT 34108—2017 [S]. 北京: 中国标准出版社, 2021.Test method for high strain rate compression of metallic materials at room temperature: GBT 34108—2017 [S]. Beijing: Standard Press of China, 2021. [20] 宋力, 胡时胜. SHPB数据处理中的二波法与三波法 [J]. 爆炸与冲击, 2005, 25(4): 368–373. DOI: 10.3321/j.issn:1001-1455.2005.04.014.SONG L, HU S S. Two-wave and tri-wave method in SHPB data treatment [J]. Explosion and Shock Waves, 2005, 25(4): 368–373. DOI: 10.3321/j.issn:1001-1455.2005.04.014. [21] MOHR D, GARY G, LUNDBERG B. Evaluation of stress-strain curve estimates in dynamic experiments [J]. International Journal of Impact Engineering, 2010, 37(2): 161–169. DOI: 10.1016/j.ijimpeng.2009.09.007. [22] MENG H, LI Q M. An SHPB set-up with reduced time-shift and pressure bar length [J]. International Journal of Impact Engineering, 2003, 28(6): 677–696. DOI: 10.1016/S0734-743X(02)00124-0. [23] BUSSAC M N, COLLET P, GARY G, et al. An optimization method for separating and rebuilding one-dimensional dispersive waves from multi-point measurements. application to elastic or viscoelastic bars [J]. Journal of the Mechanics and Physics of Solids, 2002, 50(2): 321–349. DOI: 10.1016/S0022-5096(01)00057-6. [24] MENG H, LI Q M. Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments [J]. International Journal of Impact Engineering, 2003, 28(5): 537–555. DOI: 10.1016/S0734-743X(02)00073-8. [25] BARR A D, RIGBY S E, CLAYTON M. Correction of higher mode Pochhammer-Chree dispersion in experimental blast loading measurements [J]. International Journal of Impact Engineering, 2020, 139(1914): 103526. DOI: 10.1016/j.ijimpeng.2020.103526. [26] XU A, VODENITCHAROVA T, KABIR K, et al. Finite element analysis of indentation of aluminium foam and sandwich panels with aluminium foam core [J]. Materials Science and Engineering: A, 2014(599): 125–133. DOI: 10.1016/j.msea.2014.01.080. [27] LINDHOLM U S. Some experiments with the split Hopkinson pressure bar [J]. Journal of the Mechanics and Physics of Solids, 1964, 12(5): 317–335. DOI: 10.1016/0022-5096(64)90028-6. [28] 张科, 唐志平. TiNi柱壳在不同约束下的横向冲击实验 [J]. 爆炸与冲击, 2015, 35(3): 296–303. DOI: 10.11883/1001-1455-(2015)03-0296-08.ZHANG K, TANG Z P. Experimental study of TiNi tubes under radial impact with without lateral constrain [J]. Explosion and Shock Waves, 2015, 35(3): 296–303. DOI: 10.11883/1001-1455-(2015)03-0296-08. [29] 宋力, 梁浩哲. 三波法在霍普金森压杆实验中的应用 [C] // 第七届全国爆炸力学实验技术学术会议论文集. 浙江宁波, 2012: 95–100.SONG L, LIANG H Z. The application of tri-wave method in SHPB test [C] // Proceedings of the 7th National Conference on Experimental Technology of Explosion Mechanics. Ningbo, Zhejiang, China, 2012: 95–100. [30] BUTTON, NANTES V. Principles of measurement and transduction of biomedical variables [M]. US: Academic Press, 2015. DOI: 10.1016/C2013-0-14261-4. [31] CLEVELAND, WILLIAM S. Robust locally weighted regression and smoothing scatterplots [J]. Journal of the American Statistical Association, 1979, 74(368): 829–36. DOI: 10.2307/2286407. [32] NEMAT-NASSER S, ISAACS J B, STARRETT J E. Hopkinson techniques for dynamic recovery experiments [C] // Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences. 1991, 435(1894): 371–391. DOI: 10.1098/rspa.1991.0150. -

下载:

下载: