| [1] |

COMPTON B G, LEWIS J A. 3D-Printing of lightweight cellular composites [J]. Advanced Materials, 2014, 26(34): 5930–5935. DOI: 10.1002/adma.201401804.

|

| [2] |

ZOK F W, RATHBUN H, HE M, et al. Structural performance of metallic sandwich panels with square honeycomb cores [J]. Philosophical Magazine, 2005, 85: 3207–34. DOI: 10.1080/14786430500073945.

|

| [3] |

CADMAN J, CHEN Y H, ZHOU S W, et al. Creating biomaterials inspired by the microstructure of cuttlebone [J]. Materials Science Forum, 2010, 654: 2229–2232. DOI: 10.4028/www.scientific.net/MSF.654-656.2229.

|

| [4] |

SHERRARD K M. Cuttlebone morphology limits habitat depth in eleven species of sepia (cephalopoda: sepiidae) [J]. The Biological Bulletin, 2000, 198(3): 404–414. DOI: 10.2307/1542696.

|

| [5] |

ROCHA J, LEMOS A F, AGATHOPOULOS S, et al. Scaffolds for bone restoration from cuttlefish [J]. Bone, 2005, 37(6): 850–857. DOI: 10.1016/j.bone.2005.06.018.

|

| [6] |

JIAN S, WANG Y, ZHOU W, et al. Topology optimization-guided lattice composites and their mechanical characterizations [J]. Composites Part B: Engineering, 2019, 60: 402–411. DOI: 10.1016/j.compositesb.2018.12.027.

|

| [7] |

RIVERA J, HASSEII M S, RESTREPO D, et al. Publisher correction: Toughening mechanisms of the elytra of the diabolical ironclad beetle [J]. Nature, 590(7844): E21. DOI: 10.1038/s41586-020-03106-6.

|

| [8] |

DENTON E J, GILPIN-BROWN J B. The buoyancy of the cuttlefish, sepia officinalis [J]. Journal of the Marine Biological Association of the United Kingdom, 1961, 41(2): 319–342. DOI: 10.1017/s0025315400023948.

|

| [9] |

ROCHA J H G, LEMOS A F, AGATHOPOULOS S, et al. Hydrothermal growth of hydroxyapatite scaffolds from aragonitic cuttlefish bones [J]. Journal of Biomedical Materials Research Part A, 2006, 77(1): 160–168. DOI: 10.1002/jbm.a.30566.

|

| [10] |

BIRCHALL J D, THOMAS N L. On the architecture and function of cuttlefish bone [J]. Journal of Materials Science, 1983, 18(7): 2081–2086. DOI: 10.1007/bf00555001.

|

| [11] |

CADMAN J, ZHOU S, CHEN Y, et al. Characterization of cuttlebone for a biomimetic design of cellular structures [J]. Acta Mechanica Sinica, 2010, 26(1): 27–35. DOI: 10.1007/s10409-009-0310-2.

|

| [12] |

WARD P D, BOLETZKY S V. Shell implosion depth and implosion morphologies in three species of sepia (cephalopoda) from the Mediterranean Sea [J]. Journal of the Marine Biological Association of the United Kingdom, 1984, 64: 955–966. DOI: 10.1017/s0025315400047366.

|

| [13] |

BOLETZKY S V. Biology of early life stages in cephalopod molluscs [J]. Advances in Marine Biology, 2003, 44: 143–203. DOI: 10.1016/S0065-2881(03)44003-0.

|

| [14] |

YANG T, JIA Z, CHEN H S, et al. Mechanical design of the highly porous cuttlebone: a bioceramic hard buoyancy tank for cuttlefish [J]. Proceedings of the National Academy of Sciences of the United States of America, 2020, 117(38): 23450–23459. DOI: 10.1073/pnas.2009531117.

|

| [15] |

EDWARD L, JIA Z, YANG T, et al. Multiscale mechanical design of the lightweight, stiff, and damage-tolerant cuttlebone: a computational study [J]. Acta Biomaterialia, 2022, 154: 312–323. DOI: 10.1016/j.actbio.2022.09.057.

|

| [16] |

MAO A, ZHAO N, LIANG Y, et al. Mechanically efficient cellular materials inspired by cuttlebone [J]. Advanced Materials, 2021, 33(15): 2007348. DOI: 10.1002/adma.202007348.

|

| [17] |

YANG C, LI Q M. Advanced lattice material with high energy absorption based on topology optimization [J]. Mechanics of Materials, 2020, 148(10): 103536. DOI: 10.1016/j.mechmat.2020.103536.

|

| [18] |

谢慕原, 李鹏飞, 徐汉祥, 等. 基于内壳生长纹的浙江海域曼氏无针乌贼生长特性 [J]. 浙江海洋大学学报(自然科学版), 2022, 41(4): 279–285. DOI: 10.3969/j.issn.1008-830X.2022.04.001.XIE M Y, LI P F, XU H X, et al. Growth characteristics of sepiella maindroni based on growth increments of cuttlebone in coastal water of Zhejiang [J]. Journal of Zhejiang Ocean University (Natural Science Edition), 2022, 41(4): 279–285. DOI: 10.3969/j.issn.1008-830X.2022.04.001.

|

| [19] |

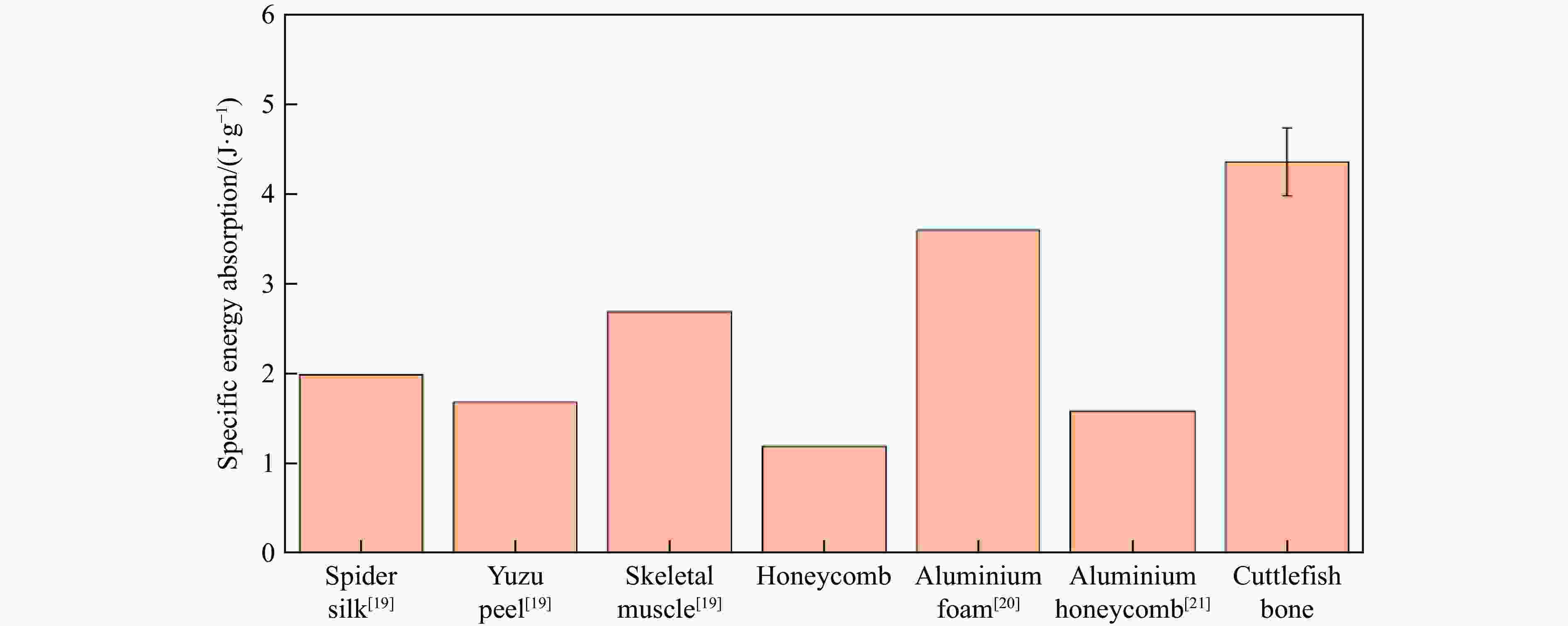

QI C, JIANG F, YANG S. Advanced honeycomb designs for improving mechanical properties: A review [J]. Composites, Part B. Engineering, 2021, 227: 109393. DOI: 10.1016/j.compositesb.2021.109393.

|

| [20] |

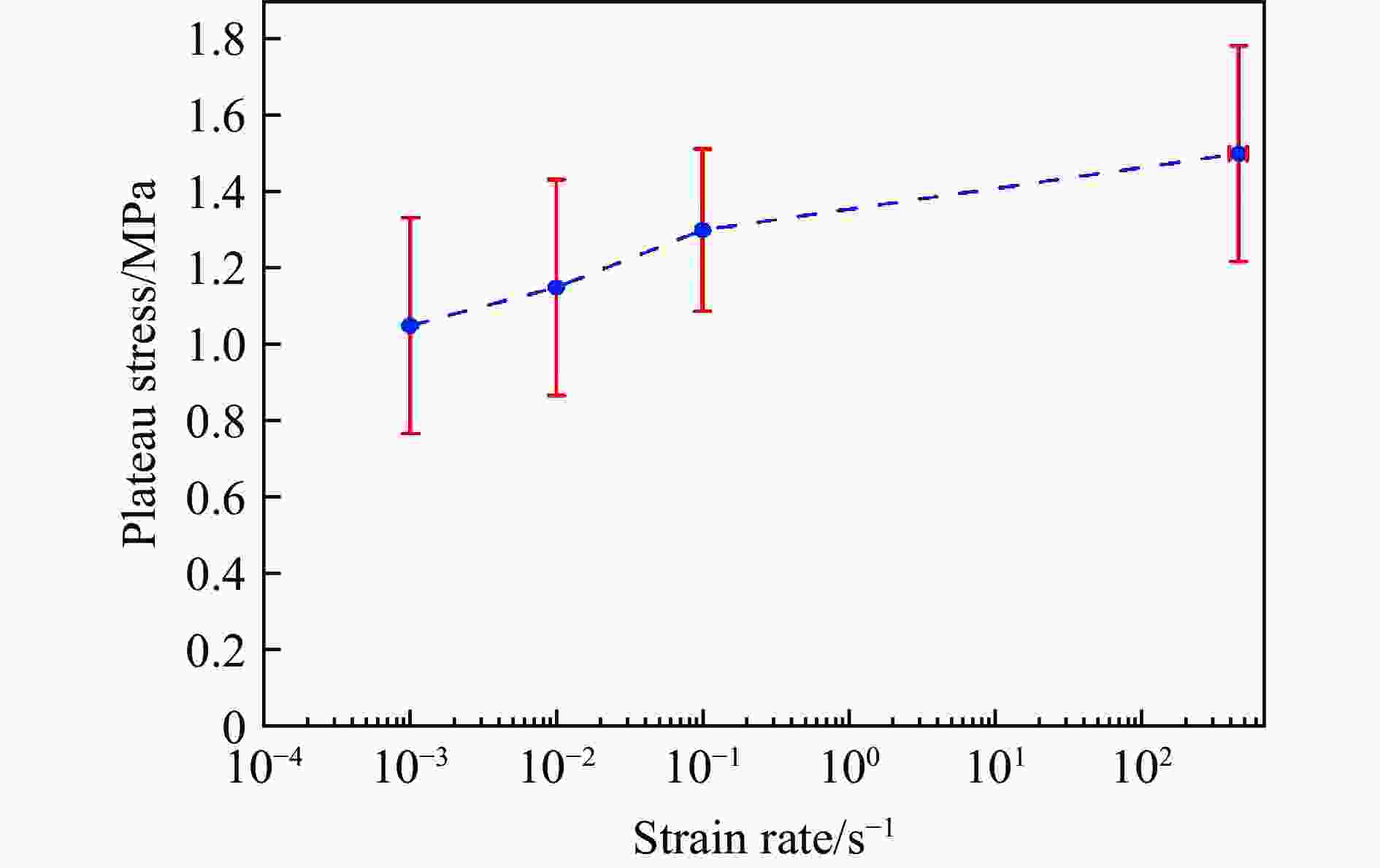

曾斐, 潘艺, 胡时胜. 泡沫铝缓冲吸能评估及其特性 [J]. 爆炸与冲击, 2002, 22(4): 358–362.ZENG F, PAN Y, HU S S. Evaluation of cushioning properties and energy-absorption capability of foam aluminium [J]. Explosion and Shock Waves, 2002, 22(4): 358–362.

|

| [21] |

宋玉环, 肖久梅. 聚氨酯/蜂窝铝复合材料的缓冲吸能特性研究[C]//北京力学会学术年会, 北京, 2016: 442–443.

|

| [22] |

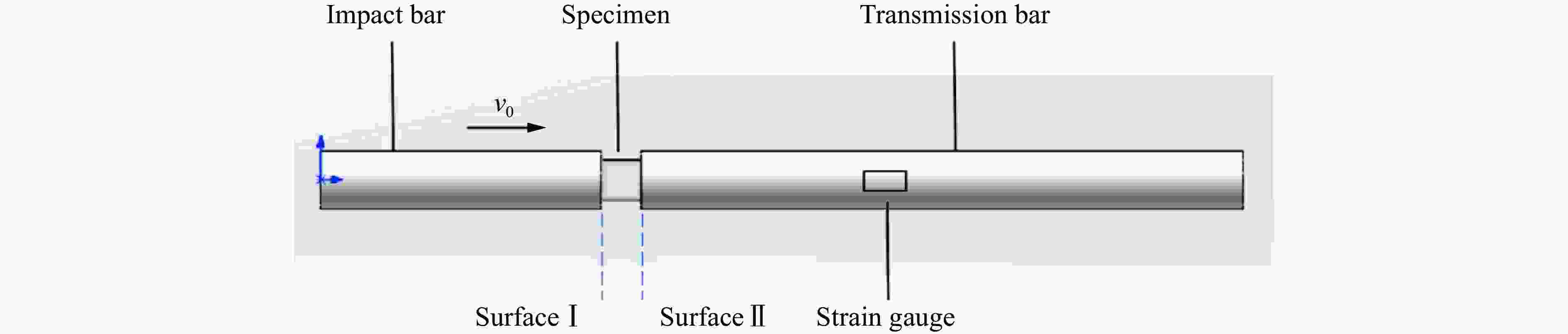

陈浩, 郭鑫, 宋力. 直接撞击式大变形霍普金森压杆实验技术 [J]. 宁波大学学报(理工版), 2018, 31(4): 70–73. DOI: 10.3969/j.issn.1001-5132.2018.04.012.CHEN H, GUO X, SONG L. A direct impact Hopkinson pressure bar technique for material testing in large deformation [J]. Journal of Ningbo University (Natural Science & Engineering Edition), 2018, 31(4): 70–73. DOI: 10.3969/j.issn.1001-5132.2018.04.012.

|

| [23] |

PARK S. W, ZHOU M. Separation of elastic waves in split Hopkinson bars using one-point strain measurements [J]. Experimental Mechanics, 1999, 39(4): 287–294. DOI: 10.1007/bf02329807.

|

| [24] |

PIYUSH U, PRAVEER S, NAVIN K. Effect of organic matrix alteration on strain rate dependent mechanical behavior of cortical bone [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2022, 125: 104910. DOI: 10.1016/j.jmbbm.2021.104910.

|

下载:

下载: