A numerical study of the impact mechanism of bottom gap on charge launch safety

-

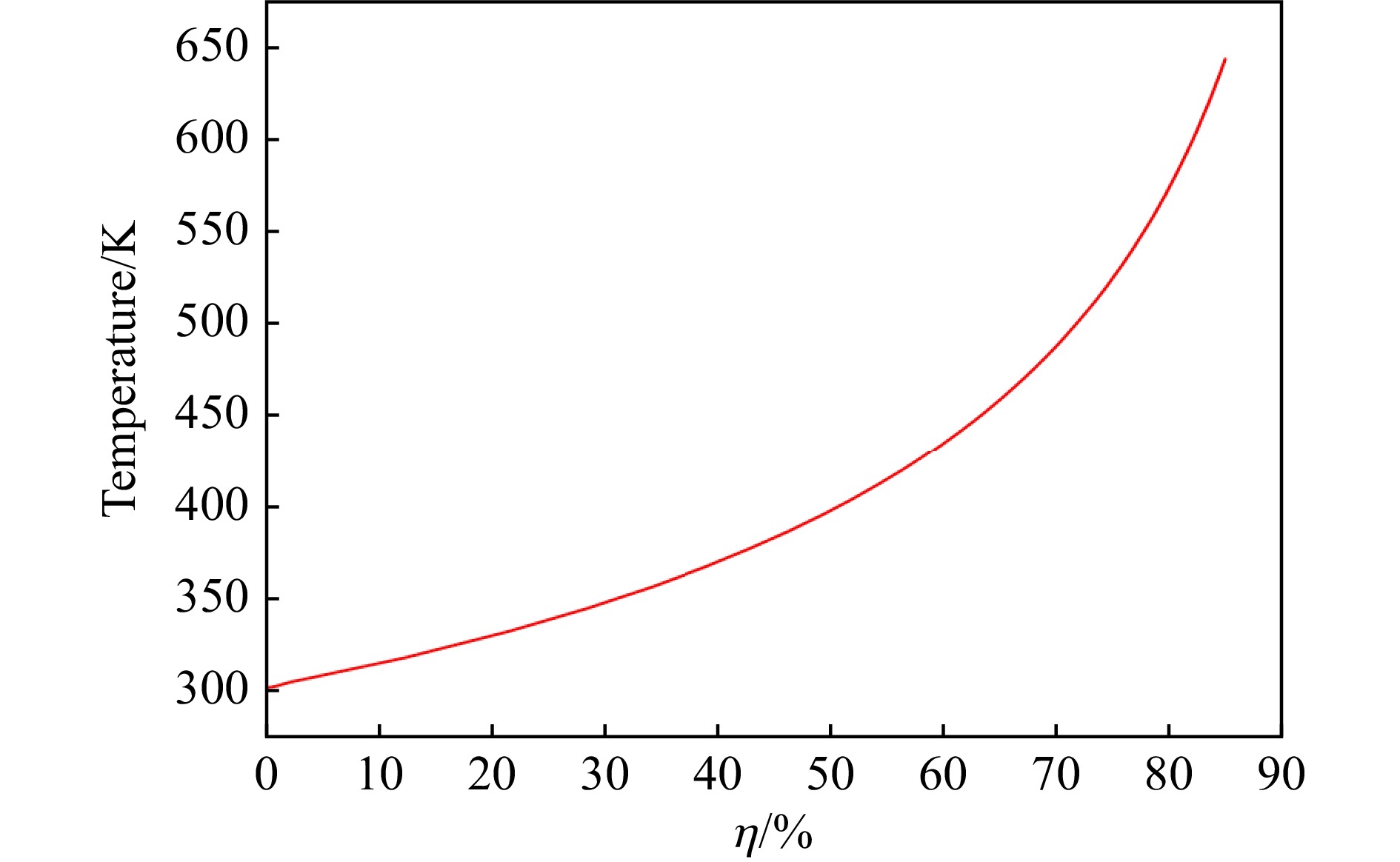

摘要: 为研究底隙对装药发射安全性的影响机理,基于物质点法建立了冲击载荷下受底隙影响的热-力-固耦合装药燃烧模型。该模型模拟的PBX装药底部温度与实验结果基本一致,验证了模型的正确性。采用该模型模拟了不同底隙厚度时Composition B(COM B)装药的炮弹发射过程,分析了装药温度变化规律。结果表明:发射过程中,COM B装药温度从底部到顶部逐步降低,装药底部最可能出现点火反应;装药底部温度随着底隙厚度的增加而升高。弹底载荷峰值为324.7 MPa时,COM B装药处于安全状态的底隙厚度不超过0.062 cm。底隙中的空气在发射过程中被压缩,其温度极速升高,导致相邻的装药底部易出现点火反应。Abstract: The issue of charge launch safety under the environment of high rifling pressure, high overload and high initial velocity has been one of the research hot topics. To investigate the impact mechanism of bottom gap on charge launch safety, a thermo-mechanical-solid coupling combustion model of the charge affected by bottom gap under impact loads based on the material point method is established. In this procedure, the formula for calculating temperature of air in the bottom gap during adiabatic compression is deduced, the relationship between the compression amount and the air temperature is quantitatively analyzed, the criteria and equation of state of the multi-material hybrid is constructed, and the calculation method of the temperature at the charge bottom affected by bottom gap in the launch process is established. The launch process of PBX charge with different bottom gap thicknesses is simulated by using the model, and the bottom temperature variation of PBX charge under different conditions are consistent with the experimental results, which verifies the correctness of the model. This model is then used to simulate the launch process of Composition B (COM B) charge with different bottom gap thickness in the launch environment, and the bottom temperature variation of charge is analyzed. The simulation results show that the charge temperature decreases gradually from the bottom to the top in the launch process and the area most likely to experience an ignition reaction is located at the charge bottom. The bottom temperature of COM B charge increases with the increase of the bottom gap thickness. The thickness of the bottom gap shall not be greater than 0.062 cm when the charge is in the launch safety state under the action of loading peak value of 324.7 MPa, which means that the presence of bottom gap seriously affects charge launch safety. From the simulation results, it is clear that the air in the bottom gap can be compressed in the launch process, and its temperature can rise rapidly; while in turn, it transfers heat to the charge bottom adjacent to the air, causing the temperature of the charge bottom to rise and making the charge bottom more susceptible to ignition reactions. The combustion model provides a theoretical basis for studying the charge launch safety.

-

Key words:

- bottom gap /

- charge /

- launch safety /

- material point method

-

名称 ρ1/(kg·m−3) cp1/(J·kg−1·K−1) λ1/(W·m−1·K−1) Q1/(J·kg−1) Z1/s−1 Ea1·R−1/K μd1 COM B 1717 1780 0.246 5.82×106 2.01×1018 2.7×104 0.2 PBX 1842 1810 0.5 5.6×106 5.5×1019 2.652×104 0.24 ρ/(kg·m−3) AJC/MPa BJC/MPa nJC CJC mJC Tmelt/K 7830 792 510 0.26 0.014 1.03 1793 名称 ρ/(kg·m−3) A/GPa B/GPa R1 R2 W/(MPa·K−1) COM B 1717 7.781×104 −5.031 11.3 1.13 2.2229 PBX 1842 9.522×105 −5.944 14.1 1.41 2.4656 ρst,0/(kg·m−3) C0/(m·s−1) s Γ 7830 4610 1.73 1.67 表 5 不同底隙厚度时PBX装药的点火情况

Table 5. Ignition situation of PBX charge with different bottom gap thicknesses

表 6 不同底隙厚度时COM B装药的点火情况

Table 6. Ignition situations of COM Bwith different bottom gap thicknesses

δ/cm 装药底部温度

峰值/K高温点 高温区域 点火情况 0 379.30 G5 装药底部 未点火 0.055 491.39 G5 装药底部 未点火 0.062 514.39 G5 装药底部 未点火 0.063 >750.00 G5 装药底部 点火 -

[1] 杨京广, 余永刚. 随行装药方案提高大口径火炮初速的数值预测 [J]. 爆炸与冲击, 2008, 28(2): 161–165. DOI: 10.11883/1001-1455(2008)02-0161-05.YANG J G, YU Y G. Velocity prediction of big caliber gun based on traveling charge scheme [J]. Explosion and Shock Waves, 2008, 28(2): 161–165. DOI: 10.11883/1001-1455(2008)02-0161-05. [2] 彭嘉诚, 蒋建伟, 廖伟. 高速旋转弹丸炸药装药在膛内运动中底层温度的数值模拟 [J]. 兵工学报, 2020, 41(9): 1783–1791. DOI: 10.3969/j.issn.1000-1093.2020.09.010.PENG J C, JIANG J W, LIAO W. Bottom temperature simulation of explosive charge in high-speed rotating projectile in internal ballistic process [J]. Acta Armamentarii, 2020, 41(9): 1783–1791. DOI: 10.3969/j.issn.1000-1093.2020.09.010. [3] 张雯浩, 余永刚. 基于流固耦合的燃气冲刷烧蚀内膛特性分析 [J]. 爆炸与冲击, 2023, 43(3): 034201. DOI: 10.11883/bzycj-2022-0390.ZHANG W H, YU Y G. Analysis of gas-eroding barrel characteristics based on fluid-solid interaction [J]. Explosion and Shock Waves, 2023, 43(3): 034201. DOI: 10.11883/bzycj-2022-0390. [4] LI C, RUI X T, WANG Y, et al. A novel method for gas generation law calculation of fractured propellant charge [J]. Propellants, Explosives, Pyrotechnics, 2018, 43(9): 898–903. DOI: 10.1002/prep.201800025. [5] 贠来峰, 芮筱亭, 王国平, 等. DCD格式在破碎发射药床两相流内弹道计算中的应用 [J]. 爆炸与冲击, 2010, 30(3): 295–300. DOI: 10.11883/1001-1455(2010)03-0295-06.YUN L F, RUI X T, WANG G P, et al. Application of DCD scheme to computation of two-phase flow interior ballistics for fractured propellant bed [J]. Explosion and Shock Waves, 2010, 30(3): 295–300. DOI: 10.11883/1001-1455(2010)03-0295-06. [6] ZHAO X, RUI X T, LI C, et al. Evaluation and prediction methods for launch safety of propellant charge based on support vector regression [J]. Applied Soft Computing, 2021, 109: 107527. DOI: 10.1016/j.asoc.2021.107527. [7] LIU W, WANG G P, RUI X T, et al. A hotspot model for PBX explosive charge ignition in a launch environment [J]. Combustion Science and Technology, 2022, 194(10): 1954–1972. DOI: 10.1080/00102202.2020.1849166. [8] GUO H F, ZHANG F, ZHAO C Z, et al. Influence of particle size of explosive on ignition mechanism under low velocity impact [J]. Propellants, Explosives, Pyrotechnics, 2021, 46(1): 46–51. DOI: 10.1002/prep.202000121. [9] 王世英, 胡焕性. B炸药装药发射安全性落锤模拟加载实验研究 [J]. 爆炸与冲击, 2003, 23(3): 275–278.WANG S Y, HU H X. Drop hammer simulation study on launch safety of composite B [J]. Explosion and Shock Waves, 2003, 23(3): 275–278. [10] 王燕, 芮筱亭, 宋振东, 等. 初始堆积对发射药床底部挤压应力的影响 [J]. 爆炸与冲击, 2014, 34(5): 560–566. DOI: 10.11883/1001-1455(2014)05-0560-07.WANG Y, RUI X T, SONG Z D, et al. Effect of original packing on compression stress at the bottom of propellant bed [J]. Explosion and Shock Waves, 2014, 34(5): 560–566. DOI: 10.11883/1001-1455(2014)05-0560-07. [11] ROY S, JOHNSON B P, ZHOU X, et al. Hot spot ignition and growth from tandem micro-scale simulations and experiments on plastic-bonded explosives [J]. Journal of Applied Physics, 2022, 131(20): 205901. DOI: 10.1063/5.0085356. [12] YANG K, WU Y Q, HUANG F L. Damage and hotspot formation simulation for impact-shear loaded PBXs using combined microcrack and microvoid model [J]. European Journal of Mechanics: A/Solids, 2020, 80: 103924. DOI: 10.1016/j.euromechsol.2019.103924. [13] LONG Y, CHEN J. Theoretical study of the critical dynamic behaviors for pore collapse in explosive [J]. Modelling and Simulation in Materials Science and Engineering, 2021, 29(5): 055009. DOI: 10.1088/1361-651X/abfd1c. [14] LI X, LIU Y Z, SUN Y. Dynamic mechanical damage and non-shock initiation of a new polymer bonded explosive during penetration [J]. Polymers, 2020, 12(6): 1342. DOI: 10.3390/polym12061342. [15] MA X, MA Q P, LI T, et al. A modified set of constitutive models for polymer-bonded explosives that consider heterogeneity of initial cracks and failure of damaged granules [J]. Propellants, Explosives, Pyrotechnics, 2022, 47(11): e202200032. DOI: 10.1002/prep.202200032. [16] MA X, ZHANG K, SHANG H L, et al. Measuring crack growth and rise in temperature around a cylindrical defect in explosive simulants under low-pressure and long-pulse loadings [J]. Propellants, Explosives, Pyrotechnics, 2020, 45(10): 1654–1661. DOI: 10.1002/prep.202000057. [17] LIU R, CHEN P W, ZHANG X T, et al. Non-shock ignition probability of octahydro-1, 3, 5, 7-tetranitro-tetrazocine-based polymer bonded explosives based on microcrack stochastic distribution [J]. Propellants, Explosives, Pyrotechnics, 2020, 45(4): 568–580. DOI: 10.1002/prep.201900313. [18] LIU R, WANG X J, CHEN P W, et al. The role of tension-compression asymmetrical microcrack evolution in the ignition of polymer-bonded explosives under low-velocity impact [J]. Journal of Applied Physics, 2021, 129(17): 175108. DOI: 10.1063/5.0046011. [19] 张瑞华, 芮筱亭, 赵宏立, 等. 基于离散单元法的发射装药挤压破碎模拟实验 [J]. 爆炸与冲击, 2021, 41(6): 062301. DOI: 10.11883/bzycj-2020-0157.ZHANG R H, RUI X T, ZHAO H L, et al. Simulational experiment on compression and fracture of propellant charge based on the discrete element method [J]. Explosion and Shock Waves, 2021, 41(6): 062301. DOI: 10.11883/bzycj-2020-0157. [20] LI C, RUI X T, GU J J, et al. Influences of the random stacking and charge’s diameter on compression and fracture process of propellant charge [J]. Propellants, Explosives, Pyrotechnics, 2022, 47(1): e202100177. DOI: 10.1002/prep.202100177. [21] WANG Y, RUI X, LI C, et al. Analysis on affecting factors of the fragmentation degree of propellant charge [C]//1st International Conference on Mechanical System Dynamics. Nanjing, China: IET, 2022: 647–651. DOI: 10.1049/icp.2022.1890. [22] 周培毅, 徐更光, 张景云, 等. 改性B炸药装药发射安全性实验研究 [J]. 火炸药学报, 1999, 22(4): 34–35. DOI: 10.3969/j.issn.1007-7812.1999.04.010.ZHOU P Y, XU G G, ZHANG J Y, et al. The experimental study of lunching safety of modified Comp-B explosive charge [J]. Chinese Journal of Explosives & Propellants, 1999, 22(4): 34–35. DOI: 10.3969/j.issn.1007-7812.1999.04.010. [23] 肖玮, 李亮亮, 苏健军, 等. TNT在热和撞击加载作用下的点火性能 [J]. 火炸药学报, 2013, 36(2): 38–41. DOI: 10.14077/j.issn.1007-7812.2013.02.009.XIAO W, LI L L, SU J J, et al. Ignition performances of TNT under temperature and impact loading actions [J]. Chinese Journal of Explosives & Propellants, 2013, 36(2): 38–41. DOI: 10.14077/j.issn.1007-7812.2013.02.009. [24] LIU W, WANG G P, RUI X T, et al. A test method for launch safety of explosive charge accurately simulating launch overload [J]. Journal of Energetic Materials, 2022: 1-21. DOI: 10.1080/07370652.2022.2108165. [25] 李文彬, 王晓鸣, 赵国志, 等. 装药底隙对弹底应力及发射安全性影响研究 [J]. 弹道学报, 2001, 13(3): 64–67, 72. DOI: 10.3969/j.issn.1004-499X.2001.03.013.LI W B, WANG X M, ZHAO G Z, et al. The research of the effect of base gap on the stress of explosives and the lunching safety [J]. Journal of Ballistics, 2001, 13(3): 64–67, 72. DOI: 10.3969/j.issn.1004-499X.2001.03.013. [26] 陈力, 丁雁生. 炸药装药撞击起爆低速气炮模拟实验系统 [C]//第三届全国爆炸力学实验技术交流会论文集. 黄山: 中国科学技术大学冲击动力学实验室, 2004: 280–284. [27] 高玉玲, 肖玮, 杜振华. 在撞击作用下炸药装药的底隙制作研究 [J]. 火炸药学报, 2001, 24(3): 35–36. DOI: 10.3969/j.issn.1007-7812.2001.03.012.GAO Y L, XIAO W, DU Z H. Research on the making of base-gap of the explosive under impact in steel sleeve [J]. Chinese Journal of Explosives & Propellants, 2001, 24(3): 35–36. DOI: 10.3969/j.issn.1007-7812.2001.03.012. [28] 周培毅, 徐更光, 王廷增. 炸药装药在后座冲击条件下的点火模型研究 [J]. 火炸药学报, 2000, 23(1): 1–5. DOI: 10.3969/j.issn.1007-7812.2000.01.001.ZHOU P Y, XU G G, WANG T Z. Ignition models of explosive charge subjected to setback impact [J]. Chinese Journal of Explosives & Propellants, 2000, 23(1): 1–5. DOI: 10.3969/j.issn.1007-7812.2000.01.001. [29] YU Y C, YAN H, CHEN W D, et al. Finite volume method for the launch safety of energetic materials [J]. Shock and Vibration, 2021, 2021: 9609557. DOI: 10.1155/2021/9609557. [30] 李德聪, 陈力, 丁雁生. 装药弹体侵彻混凝土厚靶中的炸药摩擦起爆模型 [J]. 爆炸与冲击, 2009, 29(1): 13–17. DOI: 10.11883/1001-1455(2009)01-0013-05.LI D C, CHEN L, DING Y S. A model of explosion induced by friction in the process of loaded projectiles penetrating into concrete targets [J]. Explosion and Shock Waves, 2009, 29(1): 13–17. DOI: 10.11883/1001-1455(2009)01-0013-05. [31] 赵泽灏, 张金龙, 董宇红. 多孔介质传热模型在多孔壁湍流中的适用性 [J]. 空气动力学学报, 2023, 41(0): 1–10. DOI: 10.7638/kqdlxxb-2023.0084.ZHAO Z H, ZHANG J L, DONG Y H. Heat transfer models for porous media in porous-walled turbulent flows [J]. Acta Aerodynamica Sinica, 2023, 41(0): 1–10.DOI: 10.7638/kqdlxxb-2023.0084. [32] CHEN W D, MA J X, SHI Y Q, et al. A mesoscopic numerical analysis for combustion reaction of multi-component PBX explosives [J]. Acta Mechanica, 2018, 229(5): 2267–2286. DOI: 10.1007/s00707-017-2098-7. [33] MCCLELLAND M A, GLASCOE E A, NICHOLS A L, et al. ALE3D simulation of incompressible flow, heat transfer, and chemical decomposition of Comp B in slow cookoff experiments: DE-AC52-07NA27344 [R]. Livermore: Lawrence Livermore National Laboratory, 2014. [34] HOBBS M L, KANESHIGE M J, ANDERSON M U. Cookoff of a melt-castable explosive (compb-B): SAND2012-10207C [R]. Albuquerque: Sandia National Laboratory, 2012. [35] 马敬鑫. 基于物质点法的非均质炸药燃烧细观响应机理研究 [D]. 哈尔滨: 哈尔滨工程大学, 2021: 55–68. DOI: 10.27060/d.cnki.ghbcu.2021.000050.MA J X. Mechanism research of combustion reaction of multi-component explosives at mesoscale based on material point method [D]. Harbin: Harbin Engineering University, 2021: 55–68. DOI: 10.27060/d.cnki.ghbcu.2021.000050. [36] CHEN W D, SHI Y Q, YAN H, et al. A stochastic material point method for probabilistic dynamics and reliability [J]. Computational Mechanics, 2019, 63(5): 1069–1082. DOI: 10.1007/s00466-018-1667-5. [37] CHEN W D, WU S B, MA J X, et al. Numerical simulation of the deflagration to detonation transition behavior in explosives based on the material point method [J]. Combustion and Flame, 2022, 238: 111920. DOI: 10.1016/j.combustflame.2021.111920. [38] TARVER C M. Jones-Wilkins-Lee unreacted and reaction product equations of state for overdriven detonations in octogen- and triaminotrinitrobenzene-based plastic-bonded explosives [J]. The Journal of Physical Chemistry A, 2020, 124(7): 1399–1408. DOI: 10.1021/acs.jpca.9b10804. -

下载:

下载: