An experimental study on temperature field evolution of carbon dioxide blasting jets

-

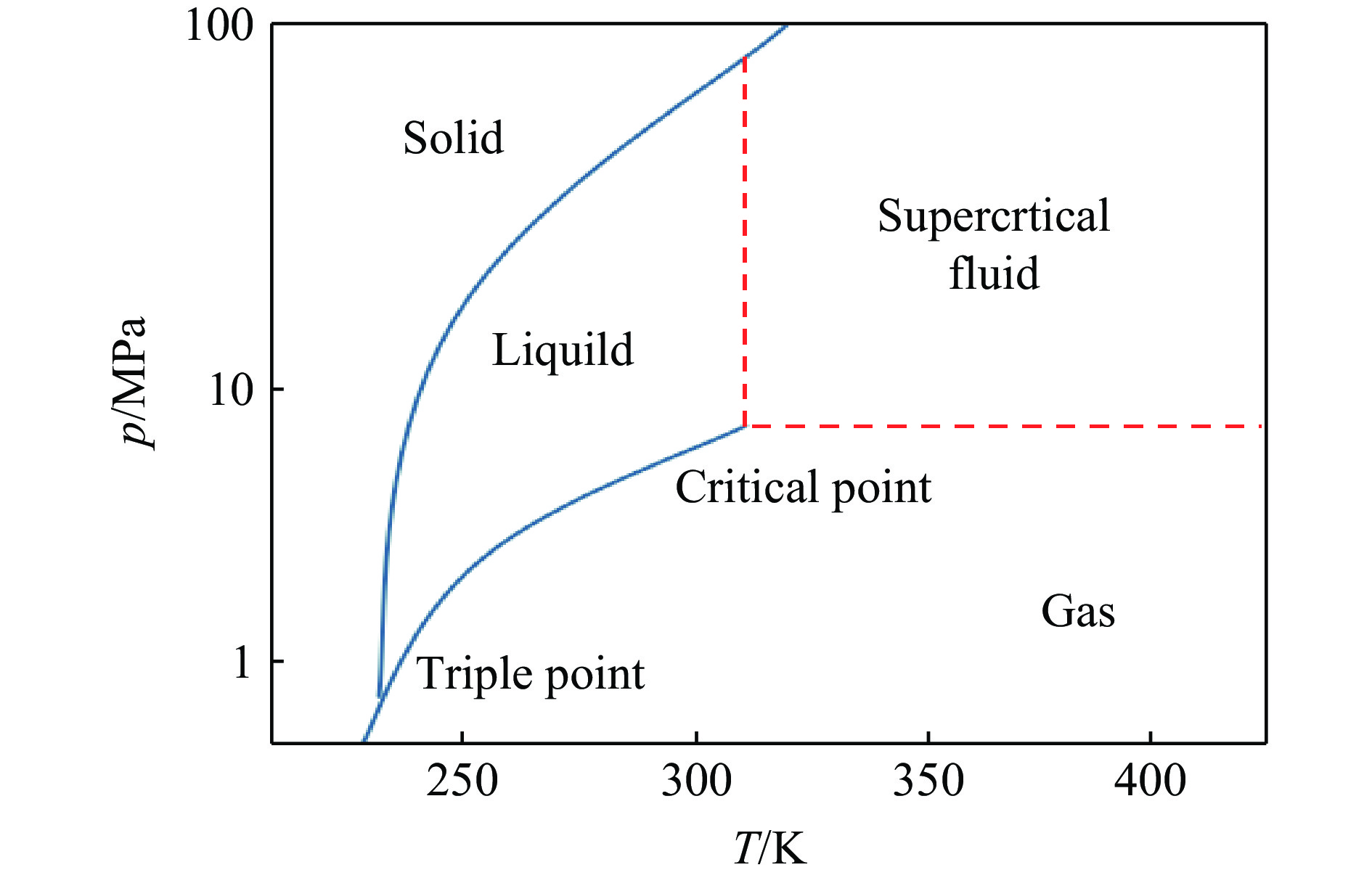

摘要: 为了研究二氧化碳爆破射流温度场的演化规律,构建了二氧化碳爆破红外热成像实验系统,开展了二氧化碳爆破实验,分析了二氧化碳爆破射流的空间发展和温度演变过程。研究结果表明:在出现超温现象之前,二氧化碳射流的温度梯度分别为外圈最高、内圈稍低,核心区域温度最低;当出现超温现象时,射流的温度梯度分别为外圈最低、内圈稍高,核心区域温度最高;射流周围的环境温度呈现先降低,后升高的现象。初始泄能压力越高,二氧化碳爆破射流的温度峰值越高,最高温度达到了133.7 ℃,到达温度峰值所需的时间越长;初始泄能压力越低,温度谷值越低,最低温度为−3.4 ℃,到达温度谷值所需的时间越短;射流温度的峰值基本出现在二氧化碳爆破器泄能的初始阶段,随后小幅度上升,再跌入谷值。射流升温的主要阶段在管内,二氧化碳爆破射流的温度总体呈现先上升后下降的趋势。Abstract: In order to study the evolution law of the temperature field of carbon dioxide blasting jet, an infrared thermal imaging test system of carbon dioxide blasting was constructed, which enabled the space development and temperature evolution of the carbon dioxide blasting jet being analyzed through carbon dioxide blasting experiment. This paper will first introduce the principle of carbon dioxide blasting technology and the structure of carbon dioxide blasting device, and expound the physical properties of carbon dioxide. Through the operation of Span-Wagner equation of state, the relationship between temperature and pressure of carbon dioxide is revealed, and then the temperature-pressure relationship curve is drawn. Secondly, the evolution cloud map of jet temperature field is analyzed, showing that before the overtemperature phenomenon, the temperature gradient of the jet is the highest in the outer ring, slightly lower in the inner ring, and the lowest in the core region. While overtemperature occurs, the temperature gradient of the carbon dioxide jet is the lowest in the outer ring, slightly higher in the inner ring, and the highest in the core region. Therefore, the ambient temperature around the jet decreases first and then increases during the carbon dioxide explosion. Finally, the temperature-time curve of the jet is studied. One the one hand, the higher the initial discharge pressure, the higher the peak temperature of the carbon dioxide blasting jet, and the longer the time required to reach the peak temperature, with the highest temperature in the test reaching 133.7 ℃. While the lower the initial energy release pressure, the lower the temperature valley value, the shorter the time required to reach the temperature valley value, with the lowest temperature in the test being −3.4 ℃. On the other hand, the peak of jet temperature basically appears in the initial stage of blasting energy discharge, and then the temperature rises slightly, followed by the temperature drop to the valley value. The main stage of jet heating is in the pipe, and the study shows that the temperature of carbon dioxide blasting jet generally presents a trend of first rising followed by decreasing.

-

Key words:

- carbon dioxide /

- jet /

- temperature field /

- infrared thermal imaging /

- equation of state

-

表 1 实验参数

Table 1. Experimental parameters

实验 二氧化碳爆破器 爆破片

材质爆破片厚度/

mm爆破片抗剪

强度/MPa额定液态二氧化碳

充装压力/MPa额定液态二氧化

碳充装量/g额定发热

剂量/g1 MZL300-95/1300 Q235 4 200 10 1500 400 2 MZL300-95/1300 Q235 5 250 10 1500 400 3 MZL300-95/1300 Q235 6 300 10 1500 400 表 2 实验结果

Table 2. Experimental results

实验 爆破片抗剪

强度/MPa环境温度/℃ 峰值温度/℃ 峰值温度与环境

温度之差/℃到达峰值温度

的时间/ms谷值温度/

℃谷值温度与峰值

温度之差/℃到达谷值温度

的时间/ms1 200 30.1 41.3 11.2 80.1 −3.4 44.7 129.5 2 250 21.4 53.5 32.1 89.3 2.1 51.4 134.2 3 300 20.5 133.7 113.2 97.4 10.2 123.5 133.7 -

[1] LU T K, WANG Z F, YANG H M, et al. Improvement of coal seam gas drainage by under panel cross strata stimulation using highly pressurized gas [J]. International Journal of Rock Mechanics and Mining Sciences, 2015, 77: 300–312. DOI: 10.1016/j.ijrmms.2015.03.034. [2] 张东明, 白鑫, 尹光志, 等. 低渗煤层液态CO2相变定向射孔致裂增透技术及应用 [J]. 煤炭学报, 2018, 43(7): 1938–1950. DOI: 10.13225/j.cnki.jccs.2018.0281.ZHANG D M, BAI X, YIN G Z, et al. Research and application on technology of increased permeability by liquid CO2 phase change directional jet fracturing in low-permeability coal seam [J]. Journal of China Coal Society, 2018, 43(7): 1938–1950. DOI: 10.13225/j.cnki.jccs.2018.0281. [3] PERERA M S A, RANJITH P G, VIETE D R. Effects of gaseous and supercritical carbon dioxide saturation on the mechanical properties of bituminous coal from the Southern Sydney Basin [J]. Applied Energy, 2013, 110(1): 73–81. DOI: 10.1016/j.apenergy.2013.03.069. [4] 周盛涛, 罗学东, 蒋楠, 等. 二氧化碳相变致裂技术研究进展与展望 [J]. 工程科学学报, 2021, 43(7): 883–893. DOI: 10.13374/j.issn2095-9389.2020.11.05.006.ZHOU S T, LUO X D, JIANG N, et al. A review on fracturing technique with carbon dioxide phase transition [J]. Chinese Journal of Engineering, 2021, 43(7): 883–893. DOI: 10.13374/j.issn2095-9389.2020.11.05.006. [5] 李启月, 刘小雄, 吴正宇, 等. 液态CO2相变破岩技术在地铁基坑开挖中的应用 [J]. 铁道科学与工程学报, 2018, 15(1): 163–169. DOI: 10.19713/j.cnki.43-1423/u.2018.01.021.LI Q Y, LIU X X, WU Z Y, et al. Application of liquid CO2 phase change rock breaking technology in metro foundation pit excavation [J]. Journal of Railway Science and Engineering, 2018, 15(1): 163–169. DOI: 10.19713/j.cnki.43-1423/u.2018.01.021. [6] WANG X F , HU S B , WANG E Y, et al. Experimental research and energy analysis of a new type of dry ice powder pneumatic rock breaking technology [J]. International Journal of Mining Science and Technology, 2023, 33(4): 423–435. DOI: 10.1016/j.ijmst.2022.12.010. [7] 倪昊. 煤矿竖井二氧化碳“二阶二段”筒形掏槽爆破技术及应用研究[J/OL]. 煤炭科学技术[2023-06-19]. https://doi.org/10.13199/j.cnki.cst.2023-0468.NI H. Research on the technology and application of carbon dioxide two-step barrel cut blasting in coal mine shaft [J]. Coal Science and Technology [2023-06-19]. https://doi.org/10.13199/j.cnki.cst.2023-0468. [8] 曹运兴, 张军胜, 田林, 等. 低渗煤层定向多簇气相压裂瓦斯治理技术研究与实践 [J]. 煤炭学报, 2017, 42(10): 2631–2641. DOI: 10.13225/j.cnki.jccs.2017.0500.CAO Y X , ZHANG J S, TIAN L, et al. Research and application of CO gas fracturing for gas control in low permeability coal seams [J]. Journal of China Coal Society, 2017, 42(10): 2631–2641. DOI: 10.13225/j.cnki.jccs.2017.0500. [9] 谢晓锋, 李夕兵, 李启月, 等. 液态CO2相变破岩桩井开挖技术 [J]. 中南大学学报(自然科学版), 2018, 49(8): 2031–2038. DOI: 10.11817/j.issn.1672−7207.2018.08.025.XIE X F, LI X B, LI Q Y, et al. Liquid CO2 phase-transforming rock fracturing technology in pile-well excavation [J]. Journal of Central South University (Science and Technology), 2018, 49(8): 2031–2038. DOI: 10.11817/j.issn.1672−7207.2018.08.025. [10] 周西华, 门金龙, 宋东平, 等. 液态CO2液态CO2爆破煤层增透最优钻孔参数研究 [J]. 岩石力学与工程学报, 2016, 35(3): 524–529. DOI: 10.13722/j.cnki.jrme.2015.0319.ZHOU X H, MEN J L, SONG D P, et al. Research on optimal borehole parameters of antireflection in coal seam by liquid CO2 blasting [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(3): 524–529. DOI: 10.13722/j.cnki.jrme.2015.0319. [11] DAVIES B, HAWKES I. The mechanics of blasting stratausing the cardox and air blasting systems [M]. London: London Toothill Press, 1984: 461–467. [12] 张东明, 白鑫, 尹光志, 等. 低渗煤层液态CO2相变射孔破岩及裂隙扩展力学机理 [J]. 煤炭学报, 2018, 43(11): 3154–3168. DOI: 10.13225/j.cnki.jccs.2018.0946.ZHANG D M, BAI X, YIN G Z, et al. Mechanism of breaking and fracture expansion of liquid CO2 phase change jet fracturing in low-permeability coal seam [J]. Journal of China Coal Society, 2018, 43(11): 3154–3168. DOI: 10.13225/j.cnki.jccs.2018.0946. [13] 白鑫, 张东明, 王艳, 等. 液态CO2相变射流压力变化及其煤岩致裂规律 [J]. 中国矿业大学学报, 2020, 49(4): 661–670. DOI: 10.13247/j.cnki.jcumt.001171.BAI X, ZHANG D M, WANG Y, et al. Pressure variation and coal fracturing law of liquid CO2 phase transition jet [J]. Journal of China University of Mining and Technology, 2020, 49(4): 661–670. DOI: 10.13247/j.cnki.jcumt.001171. [14] 孙可明, 辛利伟, 吴迪, 等. 初应力条件下超临界CO2气爆致裂规律模拟研究 [J]. 振动与冲击, 2018, 37(12): 232–238. DOI: 10.13465/j.cnki.jvs.2018.12.035.SUN K M, XIN L W, WU D, et al. Simulation of fracture law of supercritical CO2 explosion under initial stress condition [J]. Journal of Vibration and Shock, 2018, 37(12): 232–238. DOI: 10.13465/j.cnki.jvs.2018.12.035. [15] 孙可明, 辛利伟, 吴迪, 等. 初应力条件下超临界CO2气爆致裂规律研究 [J]. 固体力学学报, 2017, 38(5): 473–482. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2017.05.011.SUN K M, XIN L W, WU D, et al. Mechanism of fracture caused by supercritical CO2 explosion under the impact of initial stress [J]. Chinese Journal of Solid Mechanics, 2017, 38(5): 473–482. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2017.05.011. [16] 周科平, 柯波, 李杰林, 等. 液态CO2爆破系统压力动态响应及爆炸能量分析 [J]. 爆破, 2017, 34(3): 7–13. DOI: 10.3963/j.issn.1001-487X.2017.03.002.ZHOU K P, KE B, LI J L, et al. Pressure dynamic response and explosion energy of liquid carbon dioxide blasting system [J]. Blasting, 2017, 34(3): 7–13. DOI: 10.3963/j.issn.1001-487X.2017.03.002. [17] KOLLÉ J, MARVIN M. Jet-assisted coiled tubing drilling with supercritical carbon dioxide [C]// ASME Proceedings of ETCE /OMAE 2000 Joint Energy Conference. New Orleans, New York, USA, 2000. [18] DU Y K, WANG R H, NI H J, et al. Determination of rock-breaking performance of high-pressure supercritical carbon dioxide jet [J]. Journal of Hydrodynamics, Series B, 2012, 24(4): 554–560. DOI: 10.1016/S1001-6058(11)60277-1. [19] LI M K, NI H J, WANG R H, et al. Comparative simulation research on the stress characteristics of supercritical carbon dioxide jets, nitrogen jets and water jets [J]. Engineering Applications of Computational Fluid Mechanics, 2017, 11(1): 357–370. DOI: 10.1080/19942060.2017.1293565. [20] WANG H Z, LI G S, TIAN S C, et al. Flow field simulation of supercritical carbon dioxide jet: comparison and sensitivity analysis [J]. Journal of Hydrodynamics, 2015, 27(2): 210–215. DOI: 10.1016/S1001-6058(15)60474-7. [21] 李木坤, 王刚, 程卫民, 等. 超临界二氧化碳射流破岩的热流固耦合机理 [J]. 石油勘探与开发, 2021, 48(6): 1258–1268. DOI: 10.11698/PED.2021.06.18.LI M K, WANG G, CHENG W M, et al. Heat-fluid-solid coupling mechanism of supercritical carbon dioxide jet in rock-breaking [J]. Petroleum Exploration and Development, 2021, 48(6): 1258–1268. DOI: 10.11698/PED.2021.06.18. [22] 王海柱, 沈忠厚, 李根生. 超临界CO2钻井井筒压力温度耦合计算 [J]. 石油勘探与开发, 2011, 38(1): 97–102.WANG H Z, SHEN Z H, LI G S. Well bore temperature and pressure coupling calculation of drilling with supercritical carbon dioxide [J]. Petroleum Exploration and Development, 2011, 38(1): 97–102. [23] 程宇雄, 李根生, 王海柱, 等. 超临界二氧化碳喷射压裂井筒流体相态控制 [J]. 石油学报, 2014, 35(6): 1182–1187. DOI: 10.7623/syxb201406016.CHENG Y X, LI G S, WANG H Z, et al. Phase control of well bore fluid during supercritical CO2 jet fractureing [J]. Acta Petrolei Sinica, 2014, 35(6): 1182–1187. DOI: 10.7623/syxb201406016. [24] 沈维道, 童均耕. 工程热力学 [M]. 4版. 北京: 高等教育出版社, 2007: 31–32. [25] 童景山. 化工热力学 [M]. 北京: 清华大学出版社, 1995: 27–28. [26] 童景山. 流体的热物理性质 [M]. 北京: 中国石化出版社, 1996: 15–16. [27] FENGHOUR A, WAKEHAM W A, VESOVIC V. The viscosity of carbon dioxide [J]. Journal of Physical and Chemical Reference Data, 1998, 27(1): 31–44. DOI: 10.1063/1.556013. [28] 波林B E, 普劳斯尼茨J M, 奥康奈尔J P. 气液物性估算手册 [M]. 赵红玲, 译. 北京: 化学工业出版社, 2006: 79–80. [29] 孙小辉, 孙宝江, 王志远. 超临界二氧化碳压裂裂缝温度场模型 [J]. 石油学报, 2015, 36(12): 1586–1592. DOI: 10.7623/syxb201512014.SUN X H, SUN B J, WANG Z Y. Fissure temperature field model of supercritical CO2 fracturing [J]. Acta Petrolei Sinica, 2015, 36(12): 1586–1592. DOI: 10.7623/syxb201512014. [30] ZHANG B J, HOU Y J. A theoretical form of the Martin-Hou equation of statet [J]. Science in China Series B: Chemistry,, 1999, 42(1): 9–95. DOI: 10.1007/bf02883042. [31] SPAN R, WAGNER W. A new equation of state for carbon dioxide covering the fluid region from the triple-point temperature to 1100 K at pressures up to 800 MPa [J]. Journal of Physical and Chemical Reference Data, 1996, 25(6): 1509–1596. DOI: 10.1063/1.555991. [32] 霍中刚. 二氧化碳致裂器深孔预裂爆破煤层增透新技术 [J]. 煤炭科学技术, 2015, 43(2): 80–83. DOI: 10.13199/j.cnki.cst.2015.02.018.HUO Z G. New technology of carbon dioxide fracturer applied to deep borehole pre-cracking blasting for seam permeability improvement [J]. Coal Science and Technology, 2015, 43(2): 80–83. DOI: 10.13199/j.cnki.cst.2015.02.018. [33] 刘旭, 孙玉利, 张桂冠, 等. 液氮射流冲击冷却聚二甲基硅氧烷的温度场仿真和实验研究 [J]. 中国机械工程, 2022, 33(18): 2161–2171. DOI: 10.3969/j.issn.1004-132X.2022.18.002.LIU X, SUN Y L, ZHANG G G, et al. Simulation and experimental research about temperature fields of PDMS cooled by liquid nitrogen jet impingement [J]. China Mechanical Engineering, 2022, 33(18): 2161–2171. DOI: 10.3969/j.issn.1004-132X.2022.18.002. [34] 王宏, 符彬, 刘桂生, 等. 用热像仪测试发动机燃气流场温度 [J]. 固体火箭技术, 2003, 26(2): 65–67. DOI: 10.3969/j.issn.1006-2793.2003.02.018.WANG H, FU B, LIU G S, et al. Temperature test of motor combustion gas flow field with thermographic instrument [J]. Journal of Solid Rocket Technology, 2003, 26(2): 65–67. DOI: 10.3969/j.issn.1006-2793.2003.02.018. [35] 杜玉昆, 陈晓红, 王瑞和, 等. 超临界二氧化碳粒子射流破岩性能分析 [J]. 中国石油大学学报(自然科学版), 2019, 43(2): 85–90. DOI: 10.3969/j.issn.16735005.2019.02.010.DU Y K, CHEN X H, WANC R H, et al. Analysis on rock-reaking property of supercritical carbon dioxide particles jet [J]. Journal of China University of Petroleum (Edition of Natural Science), 2019, 43(2): 85–90. DOI: 10.3969/j.issn.16735005.2019.02.010. [36] 杜玉昆, 王瑞和, 倪红坚, 等. 超临界二氧化碳射流破岩试验 [J]. 中国石油大学学报(自然科学版), 2012, 36(4): 93–96. DOI: 10.3969/j.issn.16735005.2012.04.017.DU Y K, WANG R H, NI H J, et al. Rock-breaking experiment with supercritical carbon dioxide jet [J]. Journal of China University of Petroleum (Edition of Natural Science), 2012, 36(4): 93–96. DOI: 10.3969/j.issn.16735005.2012.04.017. -

下载:

下载: