Voltage transient characteristics and microscopic mechanism of tantalum capacitors under impact load

-

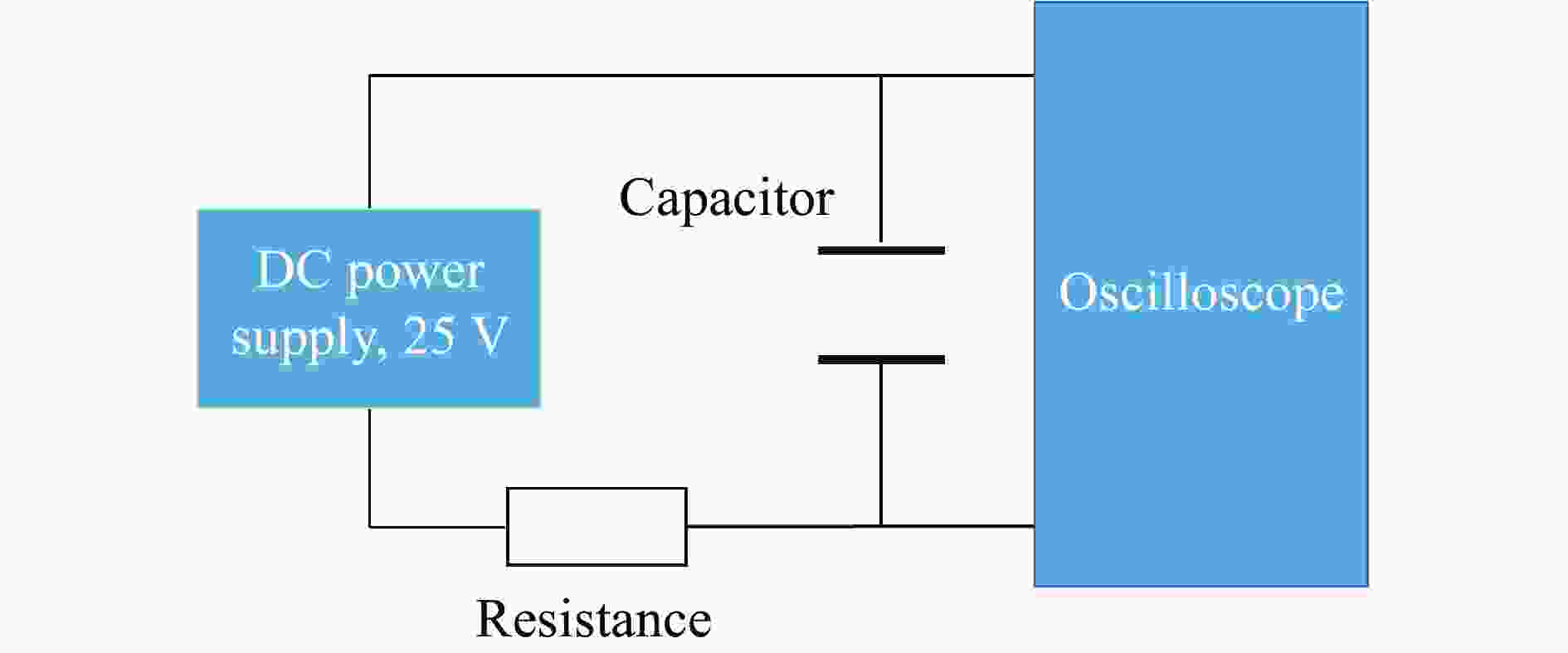

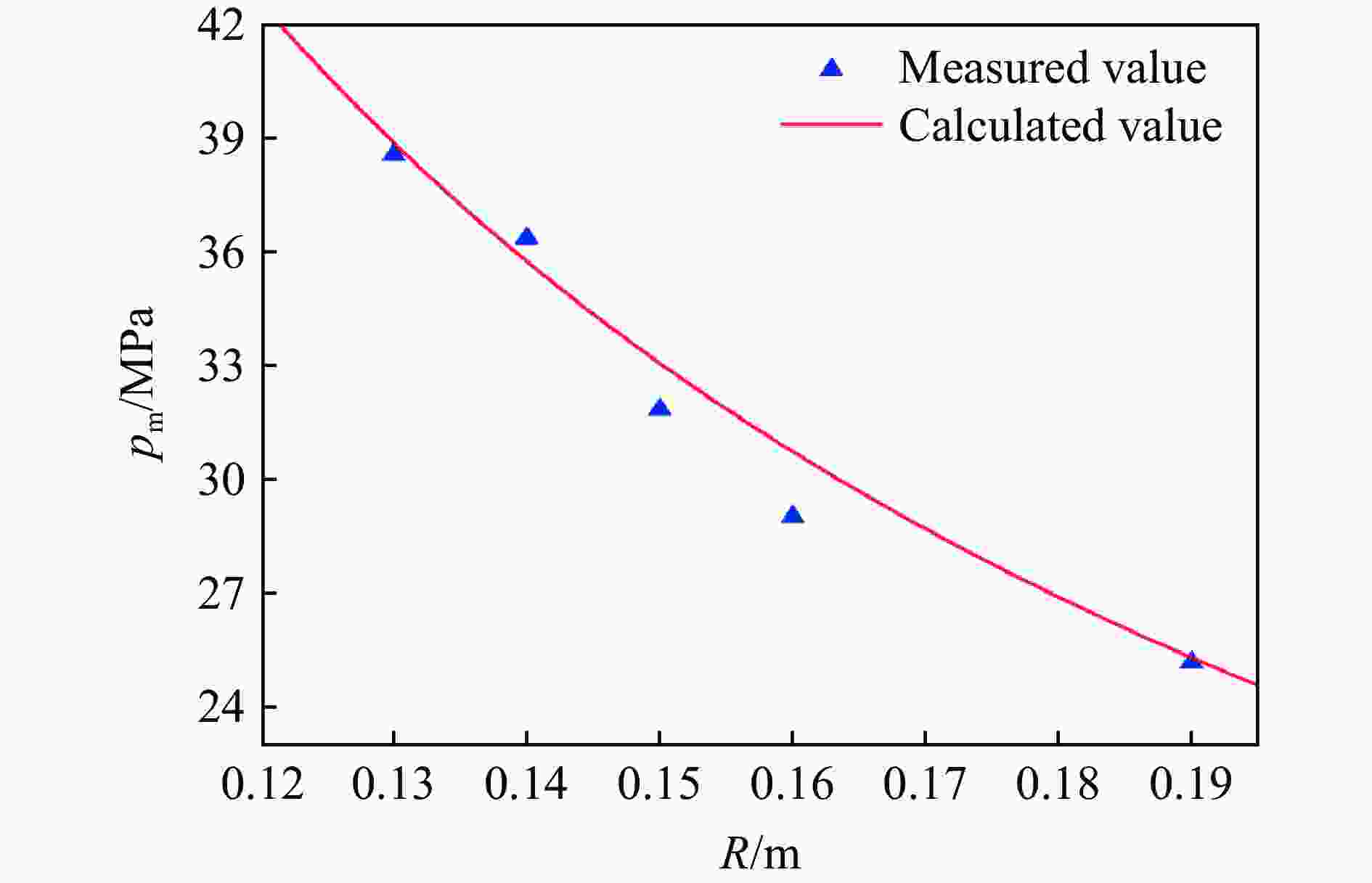

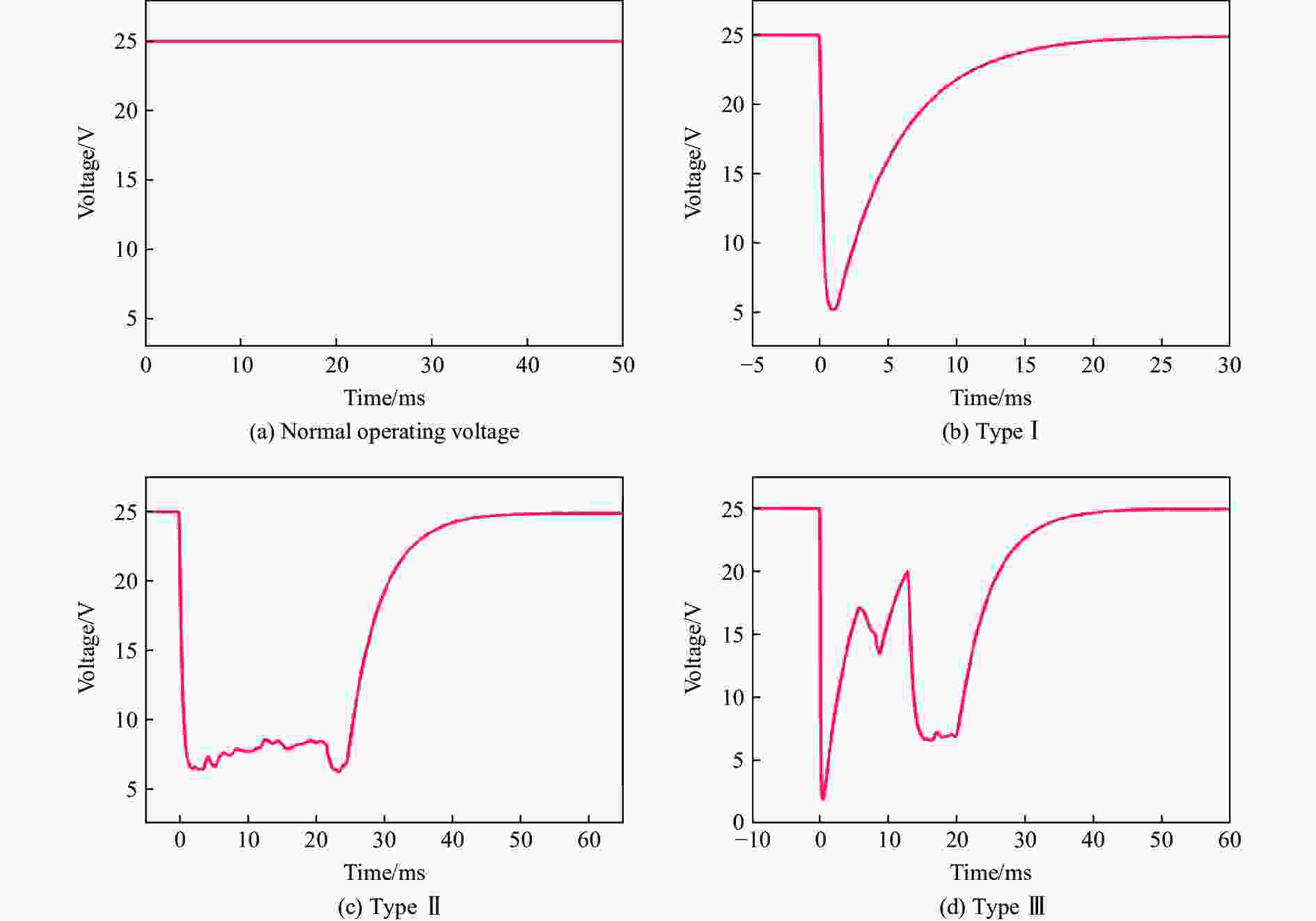

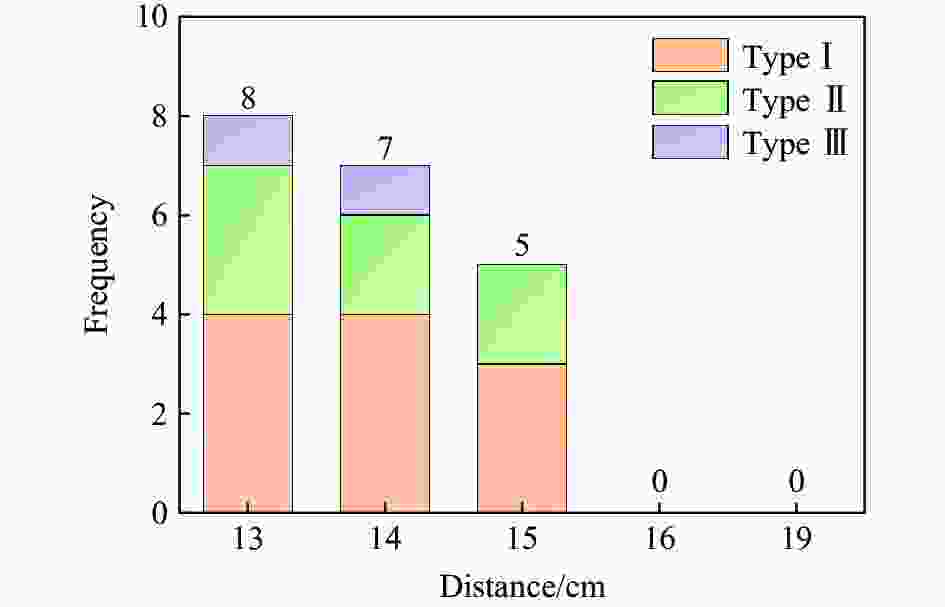

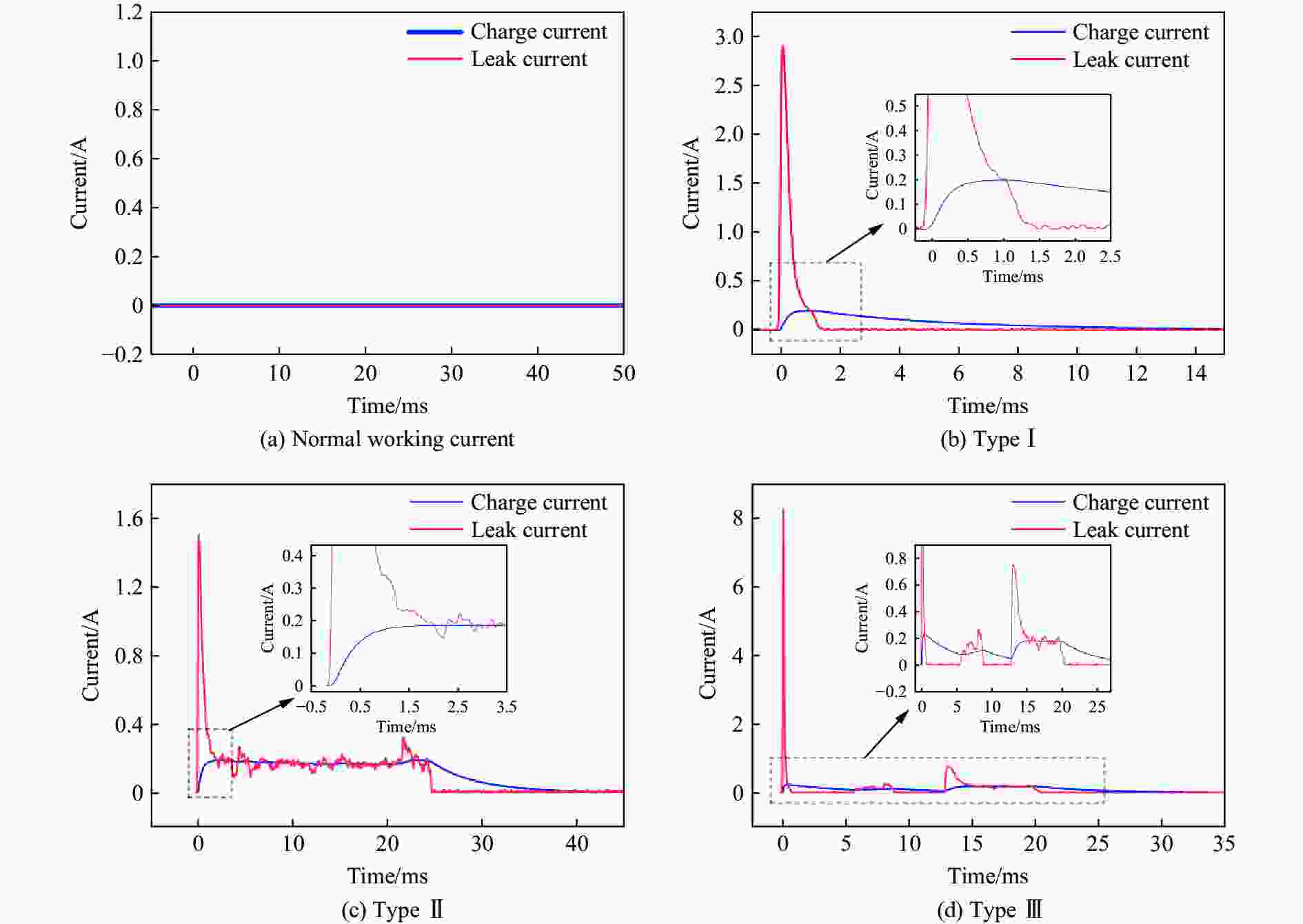

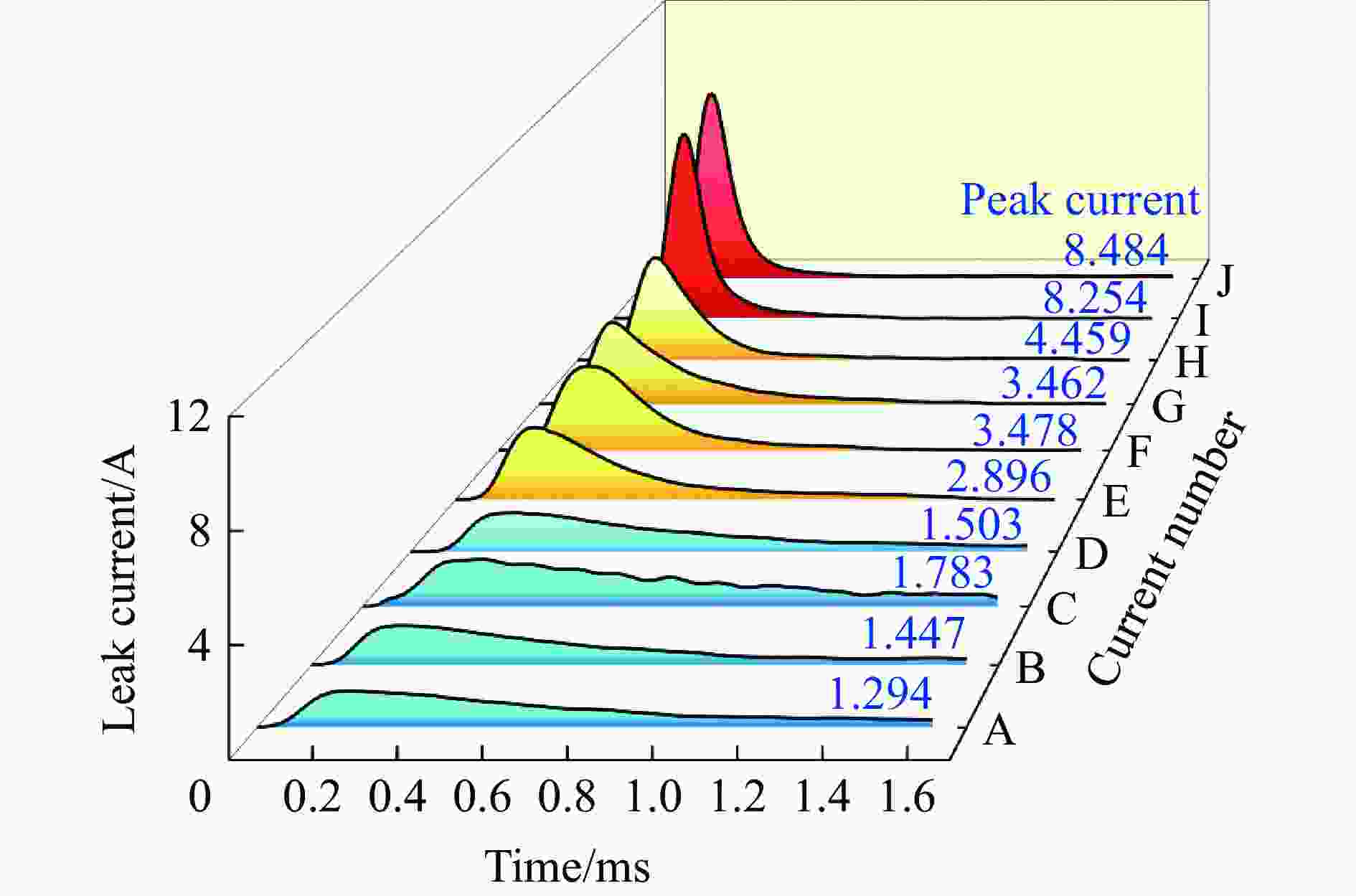

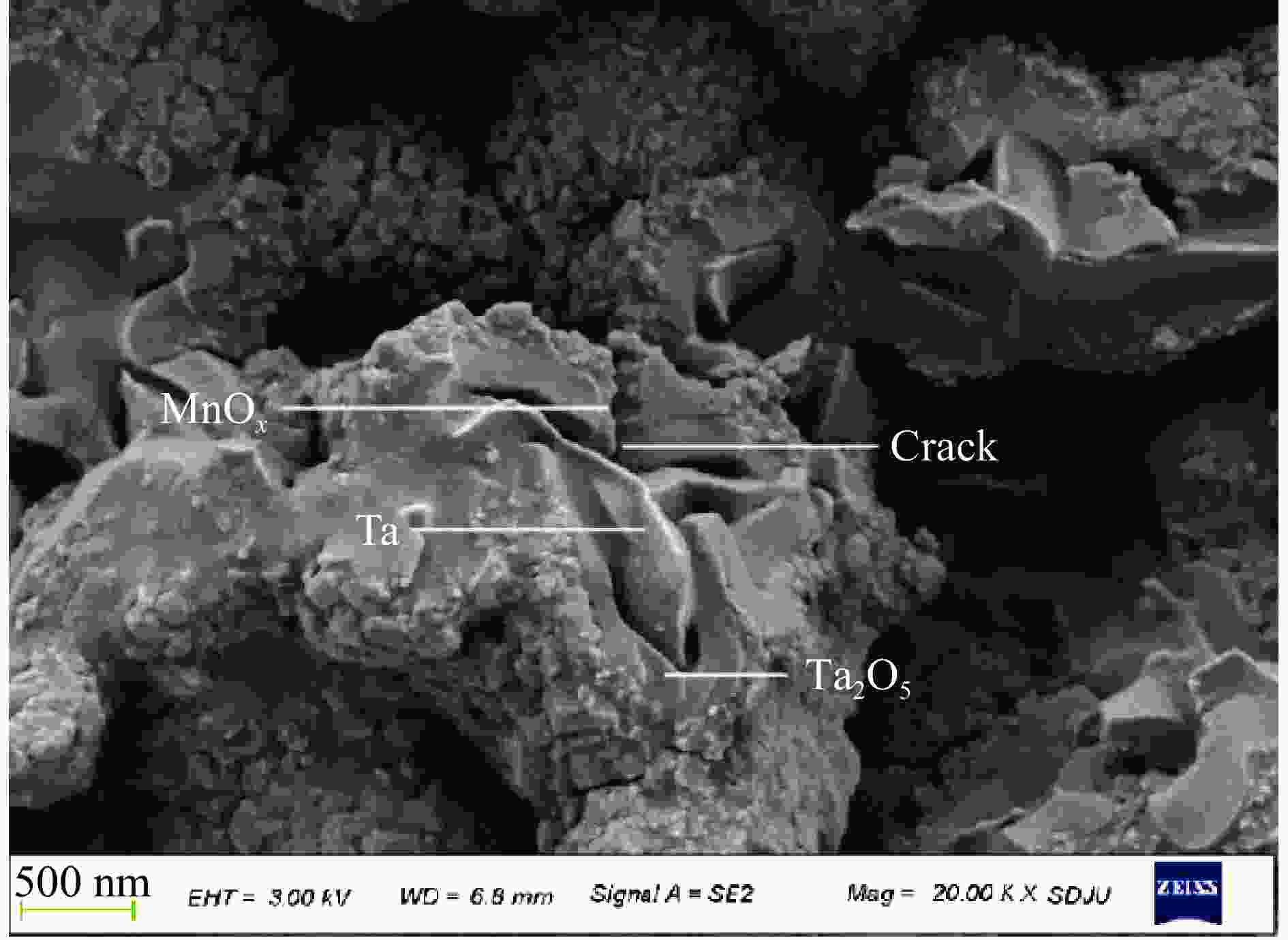

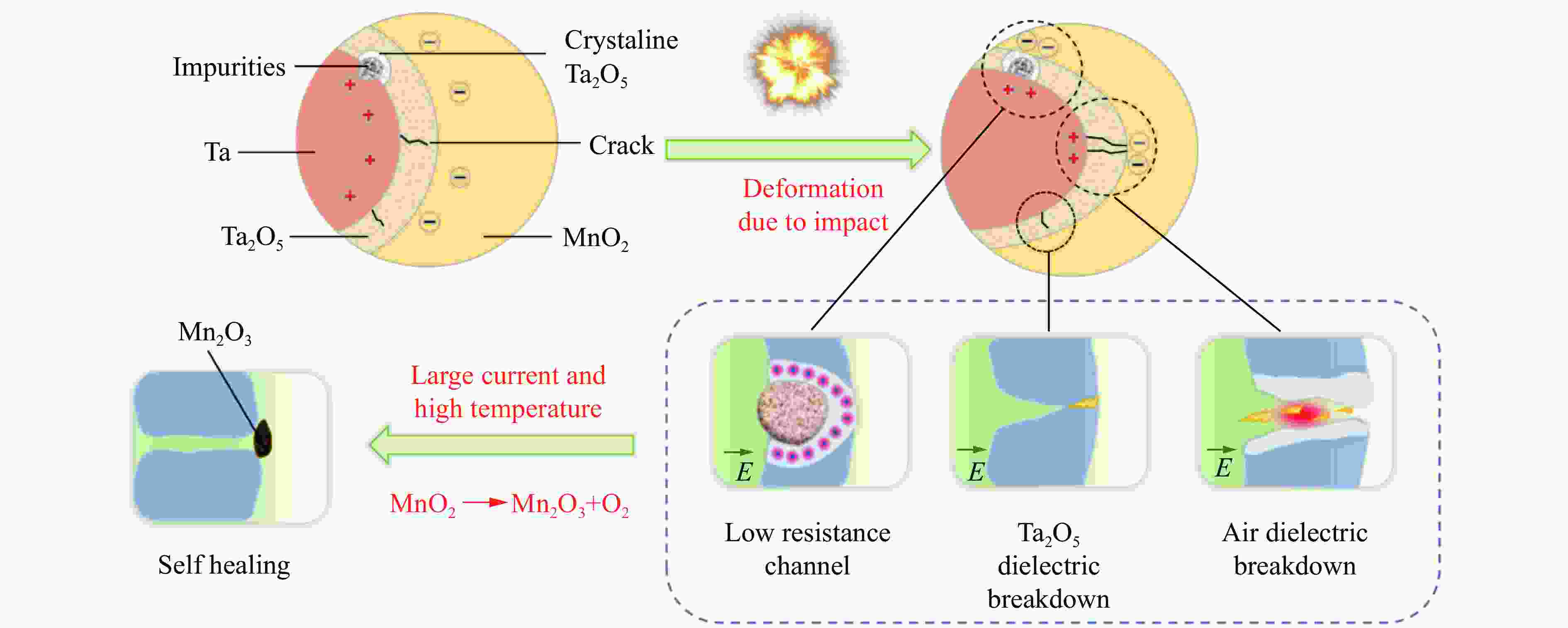

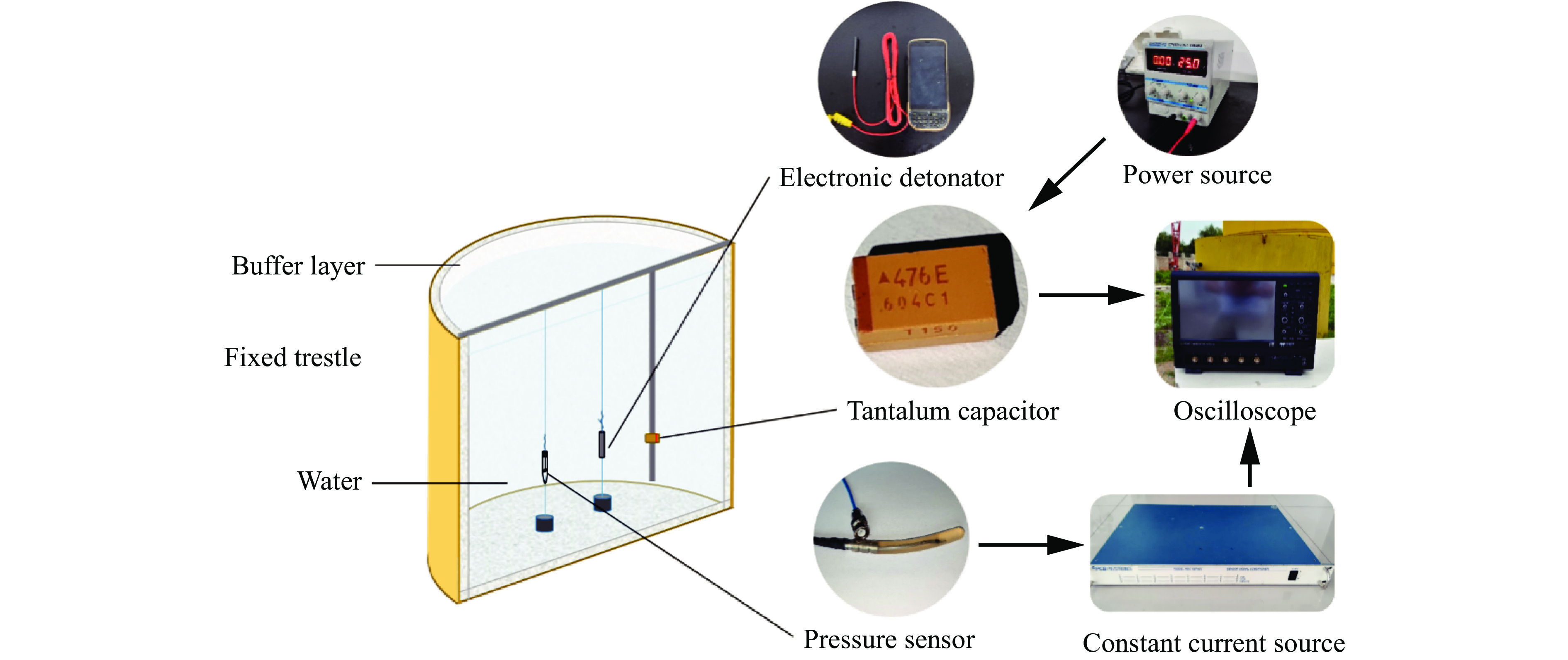

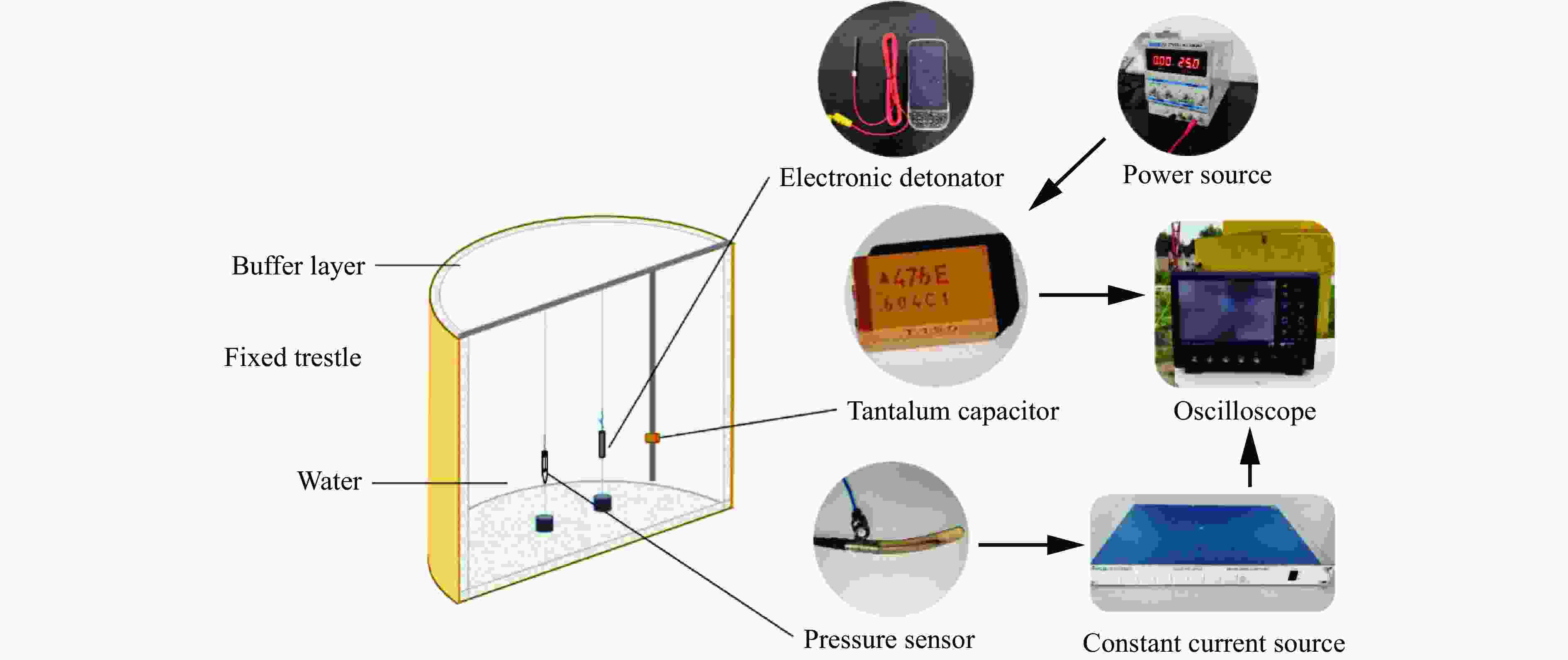

摘要: 为探究钽电容在冲击载荷作用下的失效机制,设计并开展了5组不同强度的钽电容水下爆炸冲击实验,研究了冲击载荷作用下钽电容的电压瞬变特性,通过漏电、充电电流变化分析了钽电容的失效模式,利用扫描电镜观察钽电容的微观结构,讨论了冲击载荷作用下钽电容的失效机理。结果表明:钽电容受冲击后发生短路失效,电压大幅度降低,在自愈完成后电压缓慢上升。随着冲击波超压的增大,钽电容失效的概率增大,钽电容失效的临界超压约为32 MPa。不同类型的电压变化对应不同的失效模式,包括击穿后瞬间自愈、击穿后缓慢自愈和多次击穿自愈。不同类型电压变化的初始漏电电流峰值有较大差别,Ⅰ类电流峰值为2.5~5 A,Ⅱ类为1~2 A,Ⅲ类为8~9 A,且峰值越大,峰宽越小。冲击载荷作用下钽电容的微观失效机理与其氧化膜的瑕疵相关,机理包括氧化膜中微裂缝扩展使得局部电场强度超过击穿场强造成击穿、氧化膜较薄区域下方的杂质及晶态膜突出形成导电通道、贯穿型裂缝形成后气体电离导致的击穿。Abstract: To investigate the failure mechanism of tantalum capacitors under shock loads, shock experiments were conducted on tantalum capacitors using shock waves generated by underwater explosions with an electronic detonator. Five groups of experiments with different shock intensities were designed by varying the distance between the capacitor and the electronic detonator. The transient voltage characteristics of tantalum capacitors under different intensity shock loads were studied. The voltage variations of tantalum capacitors were explained based on the changes in internal leakage current and external charging current, and the failure modes of tantalum capacitors were analyzed. Scanning electron microscopy was utilized to observe the microstructure of damaged areas in tantalum capacitors and the micro-failure mechanisms of tantalum capacitors under shock loads were discussed. The results indicate that tantalum capacitors experience short-circuit failures after shocks, with a significant decrease in voltage initially, followed by a slow rise and self-recovery. As the shock wave overpressure increases, the probability of tantalum capacitor failure increases, with a critical overpressure threshold of approximately 32 MPa. Different types of voltage variations correspond to different failure modes, including instant self-recovery after breakdown, slow self-recovery after breakdown, and repetitive breakdown with self-recovery. Different types of voltage variations exhibit significant differences in the peak values of initial leakage currents, with the first type ranging from 2.5 A to 5 A, the second type ranging from 1 A to 2 A, and the third type ranging from 8 A to 9 A. Moreover, larger peak values of leakage currents result in narrower peak widths. The micro-failure mechanisms of tantalum capacitors under shock loads include the propagation of microcracks within the oxide film leading to excessive local electric field strength and breakdown, impurities and surrounding crystalline oxide film protruding to form conductive channels in the region of thinner oxide film, and the formation of through-cracks followed by gas ionization leading to breakdown.

-

Key words:

- tantalum capacitor /

- shock loading /

- underwater explosion /

- electronic detonator

-

表 1 电容参数

Table 1. Capacitor parameters

电容类型 耐压/V 容值/μF 封装规格 阳极材料 阴极材料 介电层 数量 贴片钽电容 25 47 7343 Ta MnO2 Ta2O5 50 表 2 不同距离下的冲击波超压

Table 2. Shock wave overpressures at different distances

距离/cm 冲击波超压/MPa 冲击波超压平均值/MPa 第1次测量 第2次测量 第3次测量 13 38.627 38.045 38.557 38.410 14 36.157 37.219 36.358 36.578 15 31.974 32.312 31.845 32.044 16 30.146 29.418 29.022 29.529 19 24.719 25.767 25.057 25.181 -

[1] 杨文, 岳彩新, 宋家良, 等. 工业电子雷管抗冲击性能试验研究 [J]. 火工品, 2022(2): 16–19. DOI: 10.3969/j.issn.1003-1480.2022.02.004.YANG W, YUE C X, SONG J L, et al. Experimental research on the impact resistance of industrial electronic detonators [J]. Initiators and Pyrotechnics, 2022(2): 16–19. DOI: 10.3969/j.issn.1003-1480.2022.02.004. [2] 刘忠民, 杨年华, 石磊, 等. 电子雷管小孔距爆破拒爆试验研究 [J]. 爆破器材, 2021, 50(5): 39–42, 49. DOI: 10.3969/j.issn.1001-8352.2021.05.007.LIU Z M, YANG N H, SHI L, et al. Experimental study on misfire in small hole-space blasting of electronic detonator [J]. Explosive Materials, 2021, 50(5): 39–42, 49. DOI: 10.3969/j.issn.1001-8352.2021.05.007. [3] TEVEROVSKY A. Effect of mechanical stresses on characteristics of chip tantalum capacitors [J]. IEEE Transactions on Device and Materials Reliability, 2007, 7(3): 399–406. DOI: 10.1109/TDMR.2007.907289. [4] 程融, 张永录. 某型电子干扰弹引信用固体钽电容器失效分析 [J]. 国防技术基础, 2009(8): 28–30.CHEN R, ZHANG Y L. Some electronic countermeasure ball blasting fuse uses the solid tantalum capacitor failure analysis [J]. Technology Foundation of National Defence, 2009(8): 28–30. [5] 李长龙, 高世桥, 牛少华, 等. 高冲击下引信用固态钽电容的参数变化 [J]. 爆炸与冲击, 2018, 38(2): 419–425. DOI: 10.11883/bzycj-2016-0222.LI C L, GAO S Q, NIU S H, et al. Parameters variation of solid tantalum capacitors used in fuze under high- g shock [J]. Explosion and Shock Waves, 2018, 38(2): 419–425. DOI: 10.11883/bzycj-2016-0222. [6] 李长龙, 高世桥, 牛少华, 等. 高冲击环境对引信用储能电容性能的影响 [J]. 兵工学报, 2016, 37(S2): 16–22.LI C L, GAO S Q, NIU S H, et al. Effect of high- g shock environment on performances of energy-storage capacitors used in fuse [J]. Acta Armamentarii, 2016, 37(S2): 16–22. [7] 贾丰州, 牛少华, 孙远程, 等. 冲击载荷作用下的固体钽电容力-电响应特性 [J]. 探测与控制学报, 2022, 44(5): 20–25.JIA F Z, NIU S H, SUN Y C, et al. Solid tantalum capacitance force-electrical response characteristics of impact load [J]. Journal of Detection and Control, 2022, 44(5): 20–25. [8] COLE R H. Underwater explosions[M]. New Jersey: Princeton University Press, 1948. [9] TEVEROVSKY A. Breakdown and self-healing in tantalum capacitors [J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2021, 28(2): 663–671. DOI: 10.1109/TDEI.2020.009240. [10] TEVEROVSKY A. Scintillation and surge current breakdown voltages in solid tantalum capacitors [J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2009, 16(4): 1134–1142. DOI: 10.1109/TDEI.2009.5211867. [11] VERMILYEA D A. The effect of metal surface condition on the anodic oxidation of tantalum [J]. Acta Metallurgica, 1954, 2(3): 476–481. DOI: 10.1016/0001-6160(54)90069-3. [12] 潘齐凤. 片式钽电容器浪涌电流失效研究[D]. 成都: 电子科技大学, 2012. [13] EZHILVALAVAN S, TSENG T Y. Conduction mechanisms in amorphous and crystalline Ta2O5 thin films [J]. Journal of Applied Physics, 1998, 83(9): 4797–4801. DOI: 10.1063/1.367272. [14] MIYAIRI K. Electrical breakdown and electroluminescence in tantalum pentoxide films [C]//Conference on Electrical Insulation and Dielectric Phenomena. Ottawa, ON, Canada: Institute of Electrical and Electronics Engineers, 2002. DOI: 10.1109/CEIDP.1988.26332. [15] JACOB K T, KUMAR A, RAJITHA G, et al. Thermodynamic data for Mn3O4, Mn2O3 and MnO2 [J]. High Temperature Materials and Processes, 2012, 30(4): 459–472. DOI: 10.1515/HTMP.2011.069. -

下载:

下载: