A constitutive model for ceramic materials including microstructural features and damage factor

-

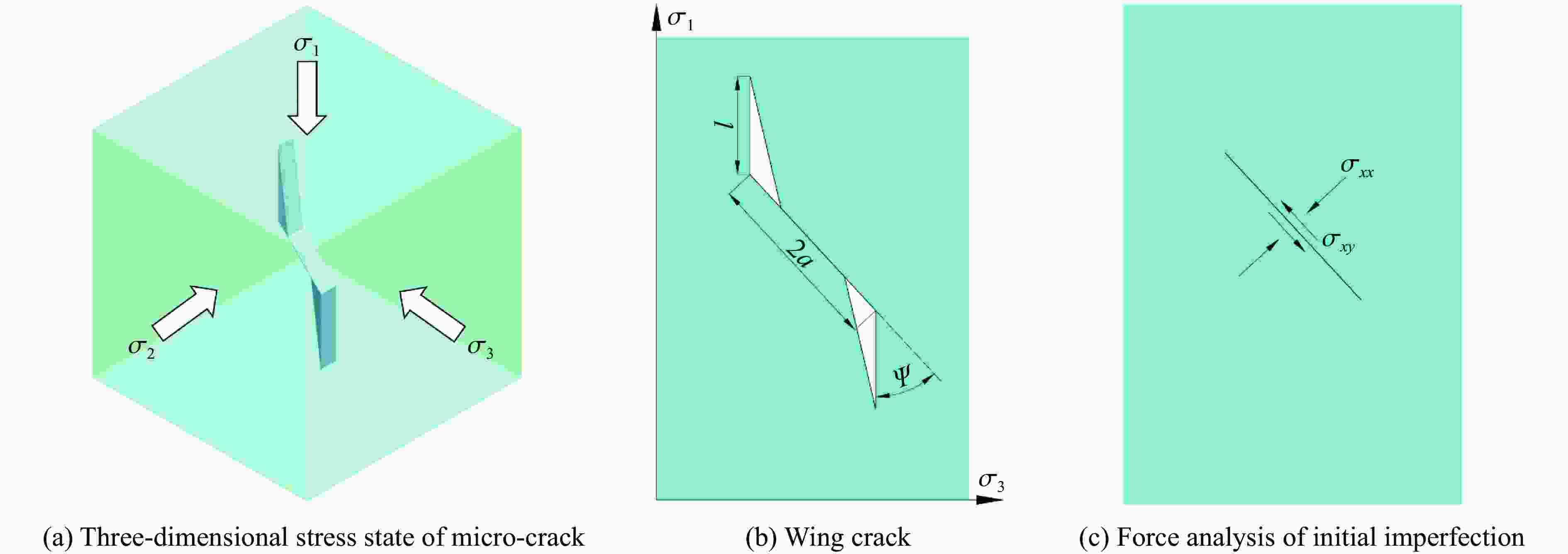

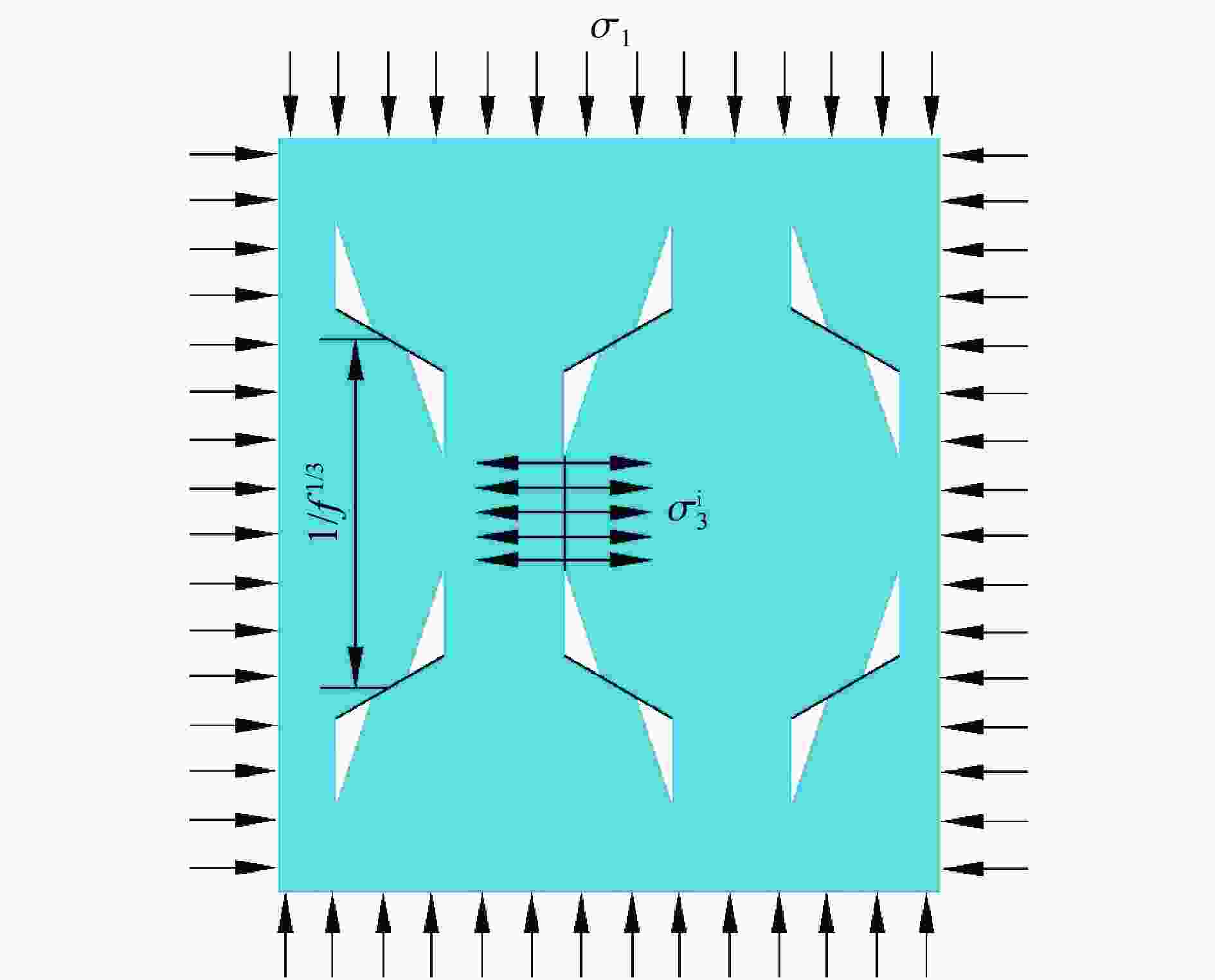

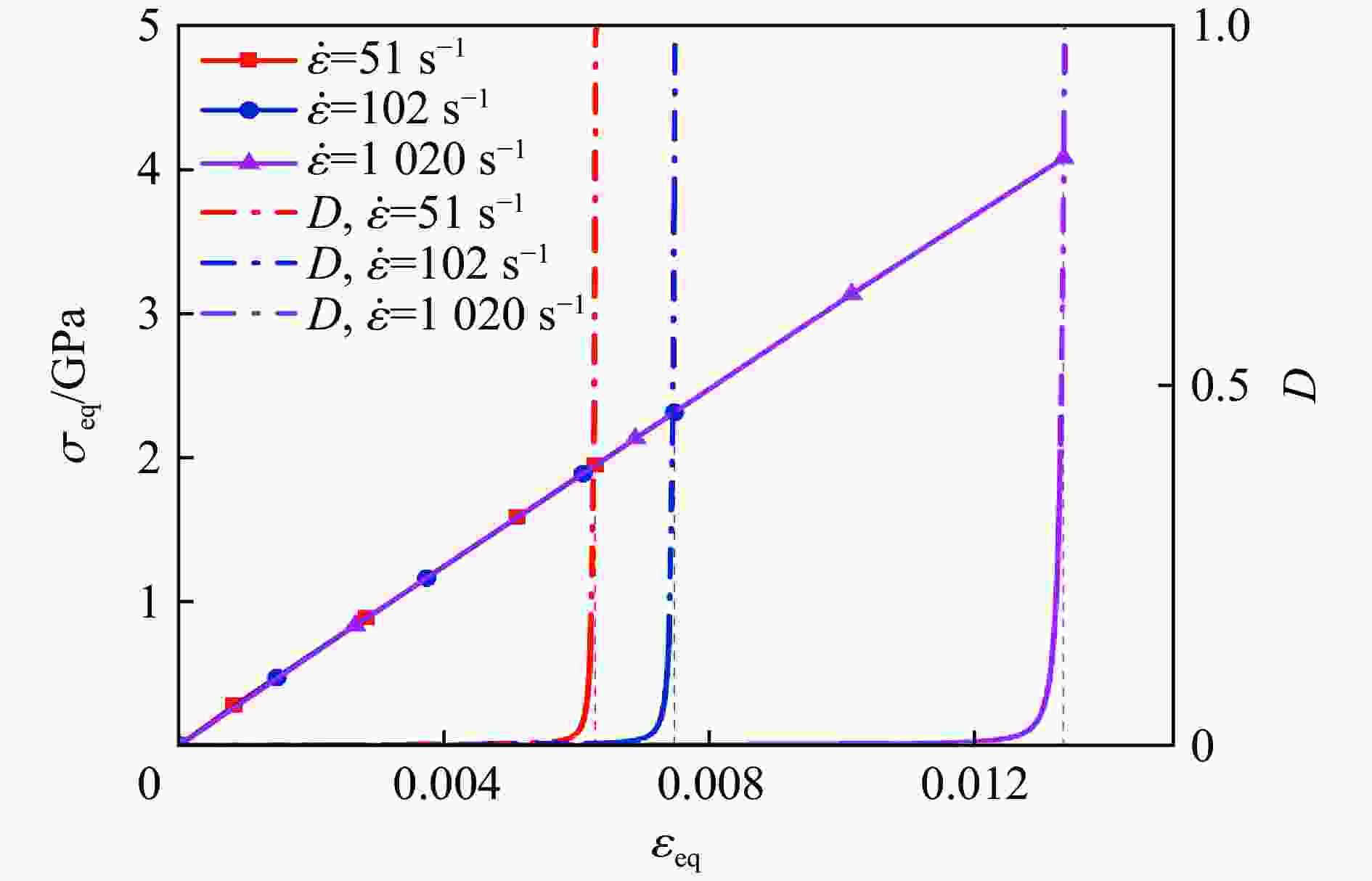

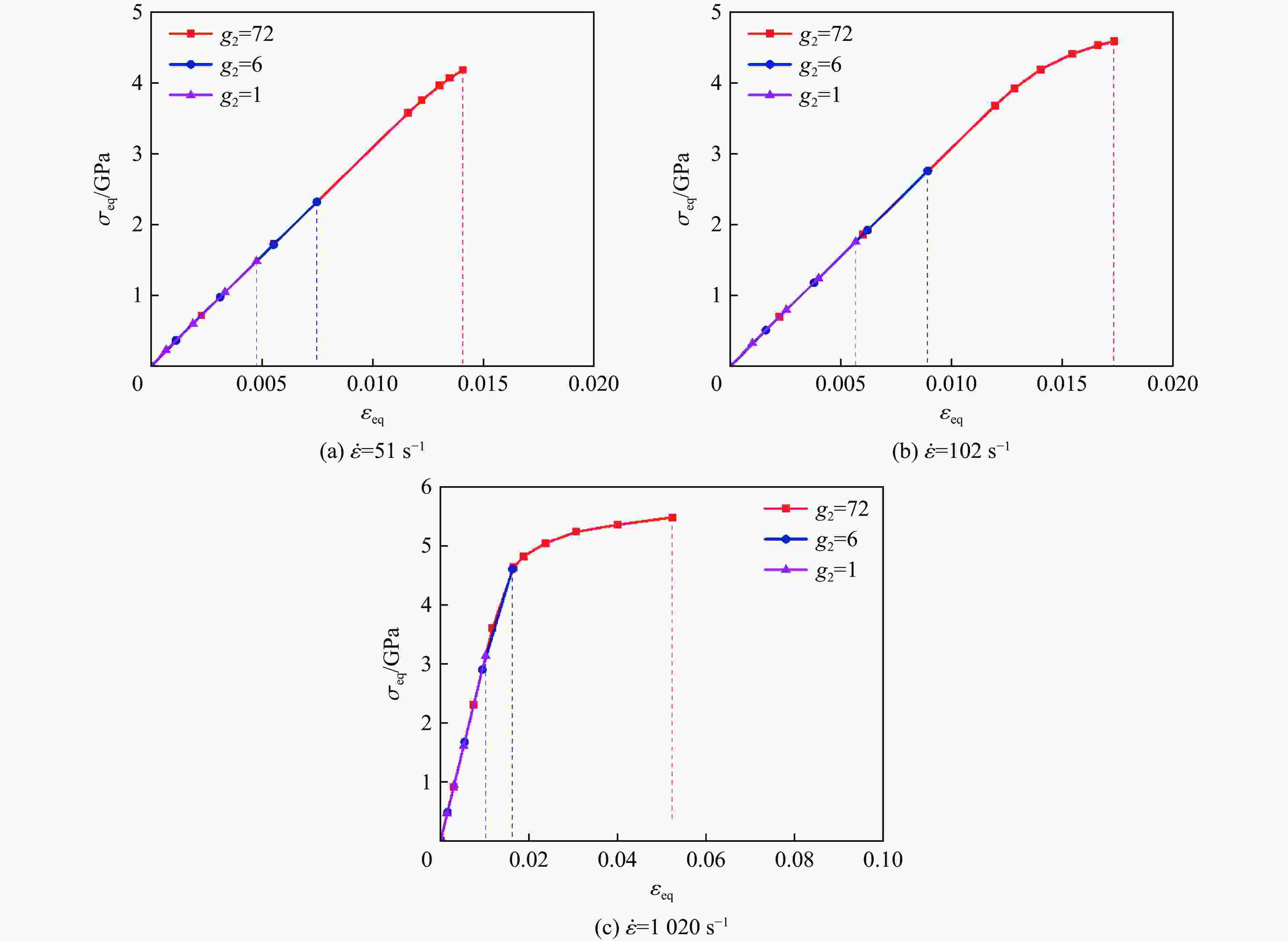

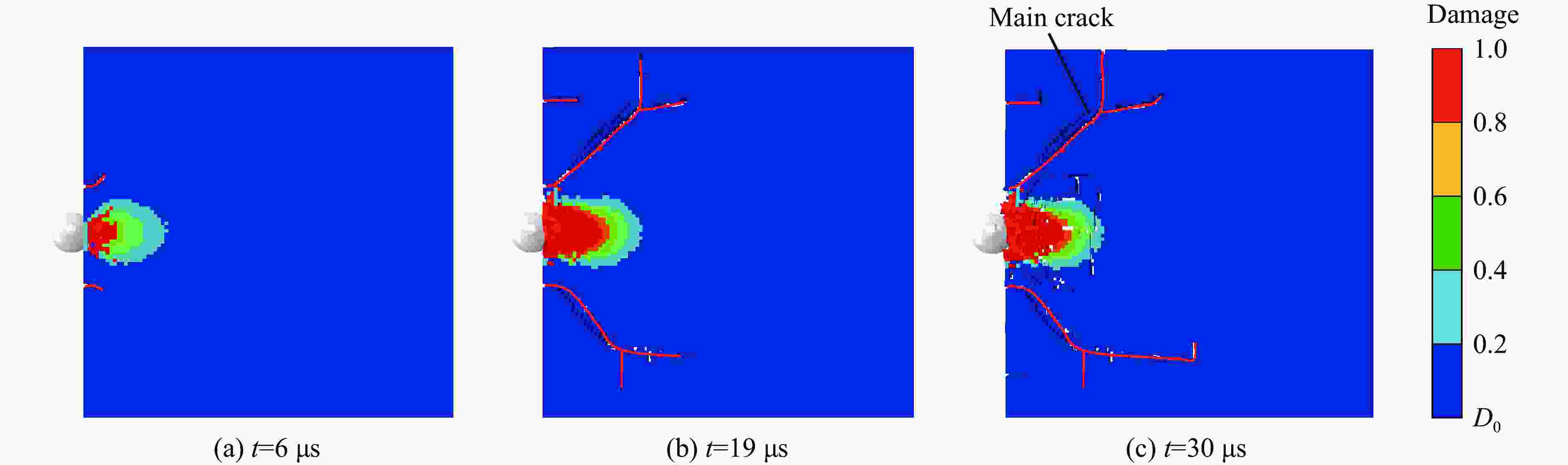

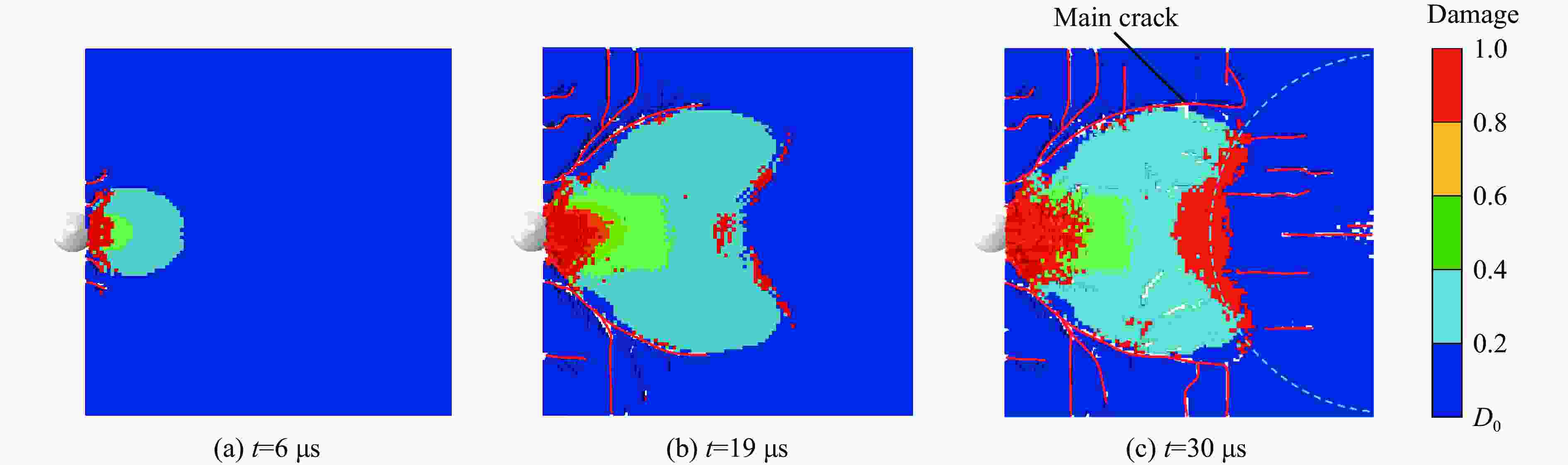

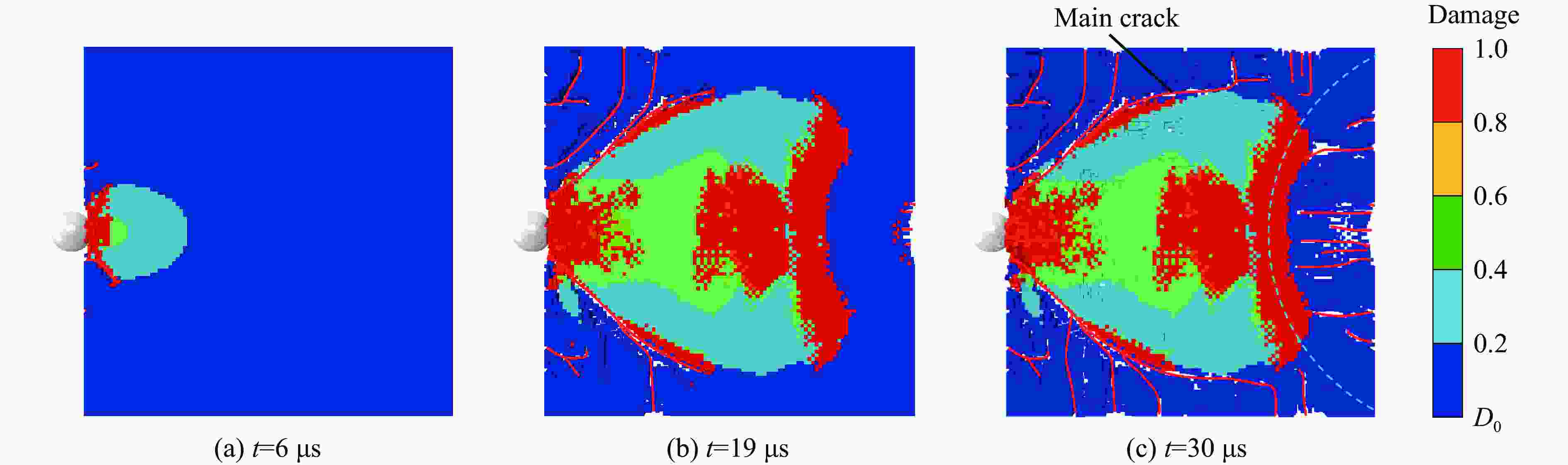

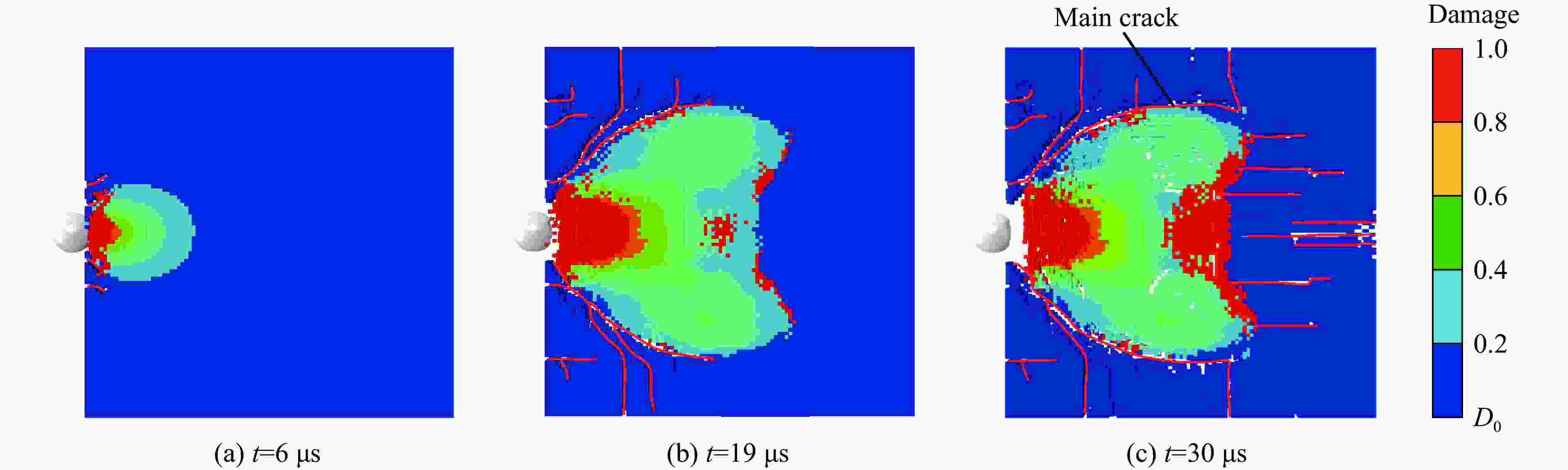

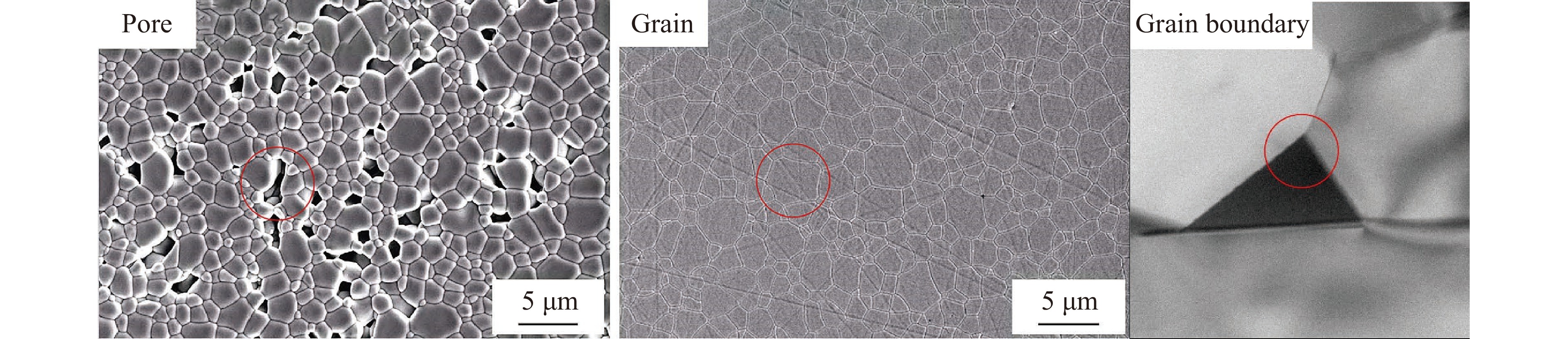

摘要: 为了研究不同微结构陶瓷材料的冲击破坏特征,以从微结构角度出发、描述陶瓷材料非弹性变形和断裂行为的Deshpande-Evan模型为基础构建本构模型,计算了无约束条件下材料的应力状态。为了验证改进模型的有效性,将VUMAT子程序编程方法将与ABAQUS有限元软件相结合,并将其应用于典型陶瓷材料(YAG透明陶瓷)冲击破坏过程的分析模拟。采用改进模型分析应变率、应力三轴度、晶粒尺寸及初始缺陷分布密度对YAG透明陶瓷动态力学行为和损伤演化机制的影响规律。结果表明:随着晶粒尺寸和裂纹分布密度的增加,YAG透明陶瓷破坏程度随之加剧,完全损伤区域面积也随之增加,晶粒尺寸对YAG透明陶瓷宏观破坏特征的影响程度要大于裂纹分布密度;YAG透明陶瓷失效强度以及断裂应变随着晶粒尺寸以及初始缺陷分布密度的增大而减小;随着应变率不断增加,YAG透明陶瓷在不同晶粒尺寸以及初始缺陷分布密度下的峰值应力和断裂应变均随之增加;裂纹扩展速度会随着晶粒尺寸的增加呈现出先增加而后平缓的趋势,裂纹扩展速度与初始缺陷分布密度系数成线性关系。改进模型可以描述YAG透明陶瓷微结构对其宏观破坏特征的影响,为进一步分析微结构对陶瓷材料宏观破坏特征的影响提供支撑。Abstract: In order to study the impact failure characteristics of ceramic materials with different microstructures, a constitutive model was constructed based on the Deshpande-Evan model which describes the inelastic deformation and fracture behavior of ceramic materials from the perspective of microstructure and the stress state of the material is calculated without considering the constraint condition. In order to verify the validity of the improved model, VUMAT subroutine programming method was used to combine it with ABAQUS finite element software, and it was applied to the analysis and simulation of the impact failure process of typical ceramic materials (YAG transparent ceramics). The effects of strain rate, stress triaxiality, grain size and crack distribution density on the dynamic mechanical behavior and damage evolution mechanism of YAG transparent ceramics were analyzed by using the improved model. The results show that with the increase of grain size and crack distribution density, the damage degree of YAG transparent ceramics increases, and the area of complete damage area increases. The influence of grain size on the macroscopic failure characteristics of YAG transparent ceramics is greater than that of crack distribution density. The failure strength and fracture strain of YAG transparent ceramics decrease with the increase of grain and crack distribution density. With the increase of the strain rate, the peak stress and fracture strain of YAG transparent ceramics under the influence of different factors (grain size as well as initial defect distribution density) increase. With the increase of grain size, the crack propagation speed of YAG transparent ceramics increases first and then flattens out, which is linearly related to the crack distribution density coefficient. The improved model can describe the influence of YAG transparent ceramic microstructure on its macroscopic failure characteristics, and provide support for further analysis of the influence of microstructure on the macroscopic failure characteristics of ceramic materials.

-

表 1 YAG透明陶瓷弹性阶段材料参数

Table 1. Material parameters of YAG transparent ceramics in elastic stage

密度/(kg·m3) 剪切模量/GPa 泊松比 $ {\sigma }_{\rm{Y}} $/GPa 4550 113 0.25 1.58 表 2 YAG透明陶瓷塑性阶段材料参数

Table 2. Material parameters of transparent YAG ceramic in plastic stage

$ {\sigma }_{\rm{Y}} $/GPa $ {\varepsilon }_{\rm{Y}} $ $ {\dot{{ \varepsilon }}}_0 $/s−1 $ {\dot{\varepsilon }}_{\rm{t}} $/s−1 n M 1.58 5.6×10−3 1×10−3 1×106 34 0.1 Table 3. Material parameters of YAG transparent ceramics in crack propagation stage

d/μm 摩擦因数 KⅠC/(MPa·m1/2) β γ g1 g2 m $ {\dot{l}}_{0} $/(m·s−1) 100 0.75 1.27 0.45 2 0.5 6 30 0.01 -

[1] 胡泽望, 陈肖朴, 刘欣, 等. 微量SiO2添加对Pr: Lu3Al5O12陶瓷光学及闪烁性能的影响 [J]. 无机材料学报, 2020, 35(7): 796–802. DOI: 10.15541/jim20190418.HU Z W, CHEN X P, LIU X, et al. Trace SiO2 addition on optical and scintillation property of Pr: Lu3Al5O12 ceramics [J]. Journal of Inorganic Materials, 2020, 35(7): 796–802. DOI: 10.15541/jim20190418. [2] 卢绪高. 轧膜成型氮化硅陶瓷的组织结构与导热性能研究 [D]. 哈尔滨: 哈尔滨工业大学, 2019. [3] TAYLOR L M, CHEN E P, KUSZMAUL J S. Microcrack-induced damage accumulation in brittle rock under dynamic loading [J]. Computer Methods in Applied Mechanics and Engineering, 1986, 55(3): 301–320. DOI: 10.1016/0045-7825(86)90057-5. [4] RAJENDRAN A M, KROUPA J L. Impact damage model for ceramic materials [J]. Journal of Applied Physics, 1989, 66(8): 3560–3565. DOI: 10.1063/1.344085. [5] STEINBERG D J. Computer studies of the dynamic strength of ceramics [C]//Proceedings of the 18th International Symposium on Shock Waves. Senda: Springer, 1991: 415–422. DOI: 10.1007/978-3-642-77648-9_64. [6] JOHNSON G R, HOLMQUIST T J. A computational constitutive model for brittle materials subjected to large strains, high strain rates, and high pressures [M]// Shock Wave and High-Strain-Rate Phenomena in Materials. CRC Press, 1992: 1075–1082. DOI: 10.1115/1.4004326. [7] JOHNSON G R, HOLMQUIST T J. An improved computational constitutive model for brittle materials [J]. AIP Conference Proceedings, 1994, 309(1): 981–984. DOI: 10.1063/1.46199. [8] JOHNSON G R, HOLMQUIST T J, BEISSEL S R. Response of aluminum nitride (including a phase change) to large strains, high strain rates, and high pressures [J]. Journal of Applied Physics, 2003, 94(3): 1639–1646. DOI: 10.1063/1.1589177. [9] WILKINS M. Second progress report of light armor program [R]. Livermore: Lawrence Livermore National Laboratory, 1967. DOI: 10.2172/7156835. [10] CHAKRABORTY S, ISLAM R I, SHAW A, et al. A computational framework for modelling impact induced damage in ceramic and ceramic-metal composite structures [J]. Composite Structures, 2017, 164: 263–276. DOI: 10.1016/j.compstruct.2016.12.064. [11] REN H L, ZHUANG X Y, RABCZUK T. Implementation of GTN model in dual-horizon peridynamics [J]. Procedia Engineering, 2017, 197: 224–232. DOI: 10.1016/j.proeng.2017.08.099. [12] 唐瑞涛, 徐柳云, 文鹤鸣, 等. 陶瓷材料宏观动态新本构模型 [J]. 高压物理学报, 2020, 34(4): 044201. DOI: 10.11858/gywlxb.20190863.TANG R T, XU L Y, WEN H M, et al. A macroscopic dynamic constitutive model for ceramic materials [J]. Chinese Journal of High Pressure Physics, 2020, 34(4): 044201. DOI: 10.11858/gywlxb.20190863. [13] RAJENDRAN A M. Modeling the impact behavior of AD85 ceramic under multiaxial loading [J]. International Journal of Impact Engineering, 1994, 15(6): 749–768. DOI: 10.1016/0734-743x(94)90033-h. [14] RAJENDRAN A M, GROVE D J. Modeling the shock response of silicon carbide, boron carbide and titanium diboride [J]. International Journal of Impact Engineering, 1996, 18(6): 611–631. DOI: 10.1016/0734-743x(96)89122-6. [15] ESPINOSA H D, ZAVATTIERI P D, DWIVEDI S K. A finite deformation continuum\discrete model for the description of fragmentation and damage in brittle materials [J]. Journal of the Mechanics and Physics of Solids, 1998, 46(10): 1909–1942. DOI: 10.1016/s0022-5096(98)00027-1. [16] 任会兰, 宁建国. 冲击压缩下准脆性材料含微裂纹损伤的本构模型 [J]. 材料工程, 2007(3): 18–21. DOI: 10.3969/j.issn.1001-4381.2007.03.005.REN H L, NING J G. Micro-cracks damage constitutive model of quasi-brittle materials subjected to shock compression [J]. Journal of Materials Engineering, 2007(3): 18–21. DOI: 10.3969/j.issn.1001-4381.2007.03.005. [17] 任会兰, 宁建国. 强冲击载荷下氧化铝陶瓷的力学特性及本构模型 [J]. 北京理工大学学报, 2007, 27(9): 761–764, 796. DOI: 10.3969/j.issn.1001-0645.2007.09.003.REN H L, NING J G. Mechanical characteristics and constitutive model of alumina ceramic subjected to shock loading [J]. Transactions of Beijing Institute of Technology, 2007, 27(9): 761–764, 796. DOI: 10.3969/j.issn.1001-0645.2007.09.003. [18] ASHBY M F, SAMMIS C G. The damage mechanics of brittle solids in compression [J]. Pure and Applied Geophysics, 1990, 133(3): 489–521. DOI: 10.1007/BF00878002. [19] WANG D, ZHAO J, ZHOU Y H, et al. Extended finite element modeling of crack propagation in ceramic tool materials by considering the microstructural features [J]. Computational Materials Science, 2013, 77: 236–244. DOI: 10.1016/j.commatsci.2013.04.045. [20] VIGLIOTTI A, DESHPANDE V S, PASINI D. Non linear constitutive models for lattice materials [J]. Journal of the Mechanics and Physics of Solids, 2014, 64: 44–60. DOI: 10.1016/j.jmps.2013.10.015. [21] DESHPANDE V S, EVANS A G. Inelastic deformation and energy dissipation in ceramics: a mechanism-based constitutive model [J]. Journal of the Mechanics and Physics of Solids, 2008, 56(10): 3077–3100. DOI: 10.1016/j.jmps.2008.05.002. [22] DESHPANDE V S, GAMBLE E A N, COMPTON B G, et al. A constitutive description of the inelastic response of ceramics [J]. Journal of the American Ceramic Society, 2011, 94(S1): s204–s214. DOI: 10.1111/j.1551-2916.2011.04516.x. [23] LAHIRI S K, SHAW A, RAMACHANDRA L S. On performance of different material models in predicting response of ceramics under high velocity impact [J]. International Journal of Solids and Structures, 2016, 176-177: 96–107. DOI: 10.1016/j.ijsolstr.2019.05.024. [24] GAMBLE E A, COMPTON B G, DESHPANDE V S, et al. Damage development in an armor ceramic under quasi-static indentation [J]. Journal of the American Ceramic Society, 2011, 94(S1): s215–s225. DOI: 10.1111/j.1551-2916.2011.04472.x. [25] ASHBY M F, HALLAM S D. The failure of brittle solids containing small cracks under compressive stress states [J]. Acta Metallurgica, 1986, 34(3): 497–510. DOI: 10.1016/0001-6160(86)90086-6. [26] 韩国庆, 张先锋, 谈梦婷, 等. 边缘冲击(EOI)作用下透明陶瓷破坏特性研究 [J]. 爆炸与冲击, 2022, 42(5): 053102. DOI: 10.11883/bzycj-2021-0292.HAN G Q, ZHANG X F, TAN M T, et al. Failure characteristics of three transparent ceramics materials under the edge-on impact loading [J]. Explosion and Shock Waves, 2022, 42(5): 053102. DOI: 10.11883/bzycj-2021-0292. [27] 马坤, 李名锐, 陈春林, 等. 修正金属本构模型在超高速撞击模拟中的应用 [J]. 爆炸与冲击, 2022, 42(9): 091406. DOI: 10.11883/bzycj-2021-0315.MA K, LI M R, CHEN C L, et al. The application of a modified constitutive model of metals in the simulation of hypervelocity impact [J]. Explosion and Shock Waves, 2022, 42(9): 091406. DOI: 10.11883/bzycj-2021-0315. -

下载:

下载: