Effect of hydrogen ratio on inhibition property of wire mesh to propagation of the flame by methane premixed with hydrogen

-

摘要: 为进一步揭示金属丝网阻抑掺氢甲烷燃烧火焰传播特征的规律,通过实验研究了掺氢比例对不同孔隙密度金属丝网阻火过程的影响。结果表明:随着掺氢比例的增加,金属丝网的阻火难度加大,金属丝网的阻火效果可由成功转为失败,对火焰传播的影响作用可能从抑制转变为促进;当金属丝网阻火失败时,金属丝网会引起火焰褶皱并导致火焰加速,但郁金香形火焰的首现时间有所延迟;随着掺氢比例的增大,火焰穿过金属丝网后的加速现象更为明显;提高金属丝网孔隙密度可提高金属丝网对掺氢甲烷预混火焰的阻火能力,孔隙密度越大,阻火能力越强;60 mpi以上金属丝网能够有效淬熄掺氢甲烷预混火焰。Abstract: In order to further reveal the characteristic of metal mesh to inhibit the flame propagation of hydrogen-methane premixed mixture, hydrogen and methane mixed gas with hydrogen mixing ratio of 0%, 10%, 20% and 30% were selected to conduct the experimental investigation of the effect of hydrogen mixing ratio inhibiting the fire processing through wire mesh with varied size in an explosion pipeline with an inner diameter of 60 mm and a total visible length of 1024 mm. Firstly, the flame propagation process was recorded by a high-speed camera, and the effect of hydrogen mixing ratio on fire resistance of wire mesh with different mesh numbers and the change of flame morphology were analyzed. Secondly, the average velocity of flame front movement was calculated according to the interval of 50 mm, and the flame propagation velocity within the visible area of the pipeline was analyzed. The interaction law between the metal wire mesh and the flame was mainly characterized by the flame propagation velocity on both sides of the metal wire mesh. The results show that with the increase of hydrogen content, the difficulty of flame retardancy of metal wire mesh increases, and the flame retardancy effect of metal wire mesh can transition from success to failure, and the impact on flame propagation may shift from inhibition to promotion. When the wire mesh fails to resist the fire, the wire mesh will cause the flame to fold and cause the flame to accelerate, but the first appearance of the tulip flame is delayed. With the increase of hydrogen mixing ratio, the acceleration phenomenon of flame passing through the wire mesh is more obvious. Increasing the mesh number of wire mesh can improve the fire resistance of wire mesh to hydrogen-methane premixed flame. The larger the mesh number, the stronger the fire resistance. More than 60 mesh wire mesh can effectively quench hydrogen and methane premixed flame.

-

Key words:

- hydrogen-methane /

- flame inhibition /

- wire mesh /

- hydrogen mixing ratio /

- flame propagation velocity

-

近年来,由于化石能源的枯竭和环境污染,全球对新型能源的需求大幅增加。氢气作为理想的清洁能源,因来源广、热值高、无污染等优点在能源领域备受关注[1]。然而,受储运成本的限制,氢气在现有能源供应体系中尚未得到广泛应用。目前,氢能的普遍使用方法是将低浓度的氢气掺入天然气管网中,通过现有的天然气管道实现氢燃料运输;其中,氢气添加比例按照相关标准需低于20%[2]。然而,氢气因其点火能量低、燃烧速度快、爆炸极限范围大等特性,与天然气混合后使掺氢甲烷混合气体的敏感性提升、爆炸强度增加,爆炸危险性大大提高[3-5]。

在运输过程中,掺氢甲烷气体一旦泄漏,失压后空气会流入管道并与掺氢甲烷气体形成爆炸性预混气,当接触点火源时容易出现回火现象从而引起爆炸,造成严重的人员伤亡和经济损失。因此,需要探索有效抑制掺氢甲烷燃烧和爆炸的方法。金属丝网因成本低、易操作、淬火性能优良等[6-7]特点在防火防爆领域受到了广泛关注。有研究指出增加金属丝网层数和孔隙密度[8-9]、体积[10]和丝径[11-12],或减小孔隙率[13]均可有效提高金属丝网的阻火性能。Zhang等[14]开展了金属丝网抑制甲烷/空气混合物爆炸的实验研究,发现多层金属丝网对大容器爆炸强度的影响大于小容器,并且不同层数和孔隙密度的组合对爆炸有不同的防爆效果。陈鹏等[15]通过实验研究了金属丝网对甲烷/空气预混火焰传播过程中压力的影响,发现金属丝网对网前压力波的影响表现为增大超压峰值或吸波效应,而对网后的压力波则表现为增大峰值超压或淬熄火焰。孙玮康等[16]开展了金属丝网对甲烷/空气爆燃火焰超压和温度的影响实验,发现金属丝网能有效抑制火焰超压和温度。Jin等[17-18]在封闭管道中进行了金属丝网抑制预混氢火焰传播动力学的实验,发现金属丝网可以有效抑制火焰前锋速度和最大压力,并且金属丝网的淬火性能随金属丝网体积的增大而增加。Jin等[19]还研究了单层金属丝网对封闭管道中预混甲烷/空气火焰的影响,发现金属丝网对最大压力的衰减作用随孔隙密度的增加而增强,并且抗破坏性对金属丝网的阻火能力具有重要意义。Cheng等[20]通过实验和模拟的方法研究了金属丝网对半封闭管道中预混甲烷/空气火焰传播动力学的影响,发现当火焰通过金属丝网传播时,金属丝网是引起火焰褶皱和加速的关键因素,可能增加甲烷燃烧的风险。

综上所述,以往的研究主要集中在金属丝网对甲烷、氢气单一可燃组分预混气体火焰传播特性的影响,对掺氢甲烷预混气体的阻火研究还有待深入,特别是掺氢比例对金属丝网阻火过程的影响规律尚未揭示清楚。基于此,本文中,选取四种不同掺氢比例的甲烷预混气体,开展不同孔隙密度金属丝网阻火实验,通过分析阻火效果、火焰形态变化及火焰传播速度,揭示掺氢比例对金属丝网阻抑火焰传播的影响规律,以期为提高掺氢甲烷阻火可靠性提供一定的指导和参考。

1. 实验装置及方法

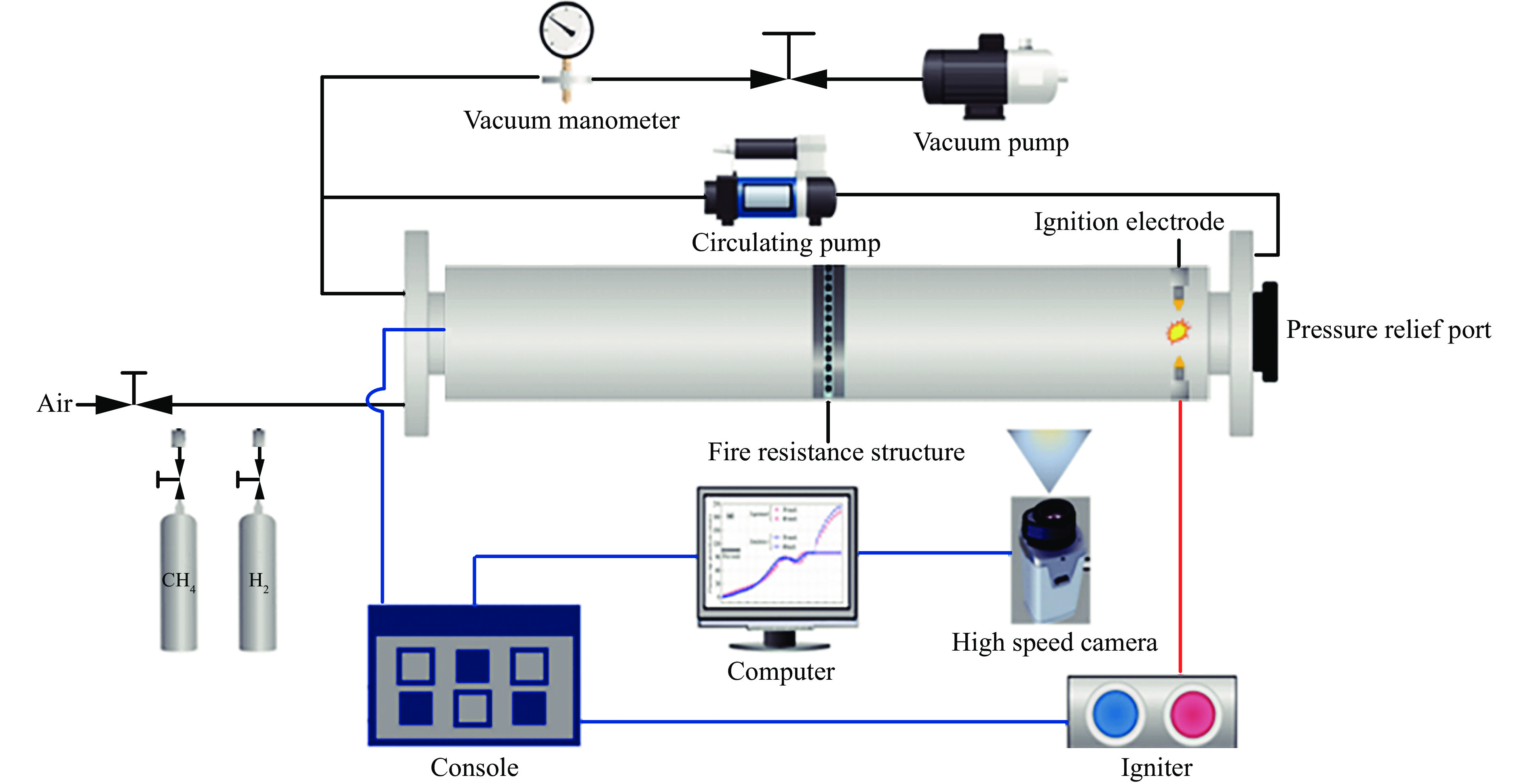

实验装置主要由爆炸管道、自动配气单元、点火控制单元、阻火结构及数据采集系统组成,如图1所示。爆炸管道全长1400 mm,内径60 mm,两端为钢结构,中间为石英玻璃管道,可视部分全长1025 mm。管道右端为点火电极和泄压口,点火采用电火花点火,电极间距为3 mm,点火电弧持续时间为120 ms。采用高速摄像机记录爆炸火焰的发展过程,本实验设置的分辨率为1280×800,拍摄帧率为4000 s−1。实验在常温环境中进行,管内初始压力为101.3 kPa。实验采用道尔顿分压法进行配气,气体循环搅拌时间为300 s,压力数据采样时间间隔为0.2 ms。

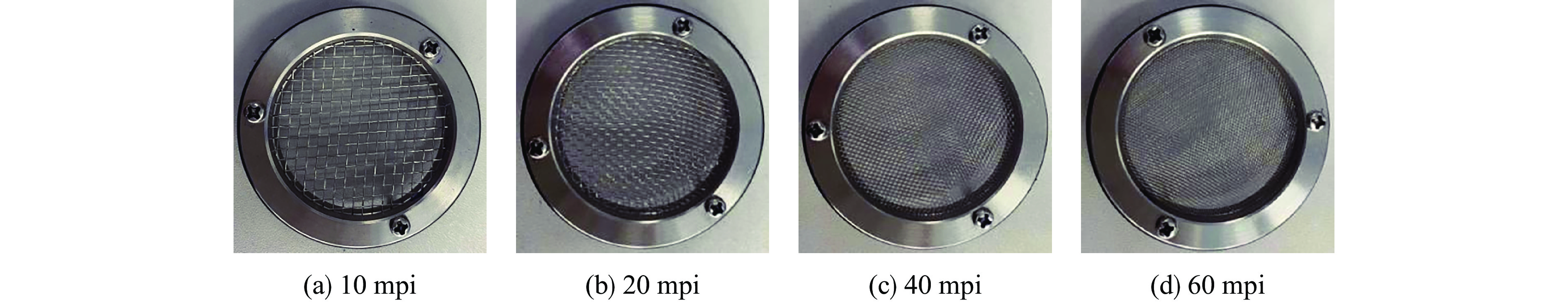

实验采用的阻火结构为304不锈钢金属丝网,如图2所示,其内径为45 mm。通过法兰结构将金属丝网固定在管道内距点火电极550 mm处,法兰盘与管道内壁之间采用橡胶圈密封,以防止其在爆炸压力波和火焰的作用下发生位置偏移。实验使用的金属丝网孔隙密度分别为10、20、40和60目/英寸(meshes per inch, mpi),几何参数如表1所示。

表 1 金属丝网几何参数Table 1. Geometric parameters of wire mesh序号 孔隙密度/mpi 孔径/mm 丝径/mm 1 10 2.3 0.35 2 20 1.1 0.21 3 40 0.5 0.13 4 60 0.3 0.10 根据之前的研究发现,当可燃预混气体的当量比为1时,掺氢甲烷的爆炸危险性最高[21-22]。因此,本实验测试了当量比为1时掺氢甲烷预混气体爆炸火焰动态发展变化过程,其中掺氢比例分别为0%、10%、20%和30%。氢气体积与掺氢甲烷混合气体体积的比值为掺氢比例

,即 φ=VH2VCH4+VH2 (1) 不同掺氢比例的掺氢甲烷预混可燃气体组成成分如表2所示。

表 2 当量比为1时掺氢甲烷混合气体配比Table 2. Mixture ratio of hydrogen and methane when equivalent ratio is 1% 掺氢比例 甲烷体积分数 氢气体积分数 空气体积分数 掺氢比例 甲烷体积分数 氢气体积分数 空气体积分数 0 9.50 0 90.50 20 8.80 2.20 89.00 10 9.18 1.02 89.80 30 8.36 3.58 88.06 2. 实验结果及分析

2.1 掺氢比例对金属丝网阻火效果的影响

金属丝网的阻火效果分为阻火成功和阻火失败两种情况。当火焰在金属丝网处淬熄时,表示阻火成功;反之,则表示阻火失败。不同掺氢比例下,金属丝网对掺氢甲烷预混气体的阻火情况如表3所示,其中,“Y”表示阻火成功,“N”表示阻火失败。由表3可知,40 mpi及以上金属丝网能够淬熄纯甲烷燃烧火焰,但40 mpi金属丝网无法淬熄掺氢甲烷燃烧火焰,60 mpi金属丝网能够淬熄掺氢比例为10%、20%和30%的掺氢甲烷燃烧火焰。由此可见,金属丝网孔隙密度越大,孔径越小,阻火能力越强。当金属丝网孔隙密度一定时,随着掺氢比例的增加,金属丝网阻火效果减弱;对于掺氢比例较高的预混气体燃烧火焰,需要孔隙密度更大的金属丝网才能实现阻火。

表 3 各工况下金属丝网阻火情况Table 3. Fire resistance effect of wire mesh under different working conditions孔隙密度/mpi 阻火效果 孔隙密度/mpi 阻火效果 φ=0% φ=10% φ=20% φ=30% φ=0% φ=10% φ=20% φ=30% 10 N N N N 40 Y N N N 20 N N N N 60 Y Y Y Y 最大试验安全间隙(maximum examination saftey gap, MESG)是反映爆炸性气体混合物传爆能力的重要参数。根据文献[23]提出的燃料比法计算多元混合气体的MESG,得出了掺氢比例为0%、10%、20%和30%的掺氢甲烷可燃气体的MESG,如表4所示。当掺氢比例为0%时,MESG为1.14 mm,与文献[24]附录B中实测结果(1.16±0.02) mm相吻合,表明计算结果准确可靠。随着掺氢比例的增大,掺氢甲烷预混气体的MESG减小。MESG越小,燃爆火焰越难被熄灭。因此,掺氢比例的增加降低了掺氢甲烷可燃气体的MESG,增强了预混火焰的传爆能力,进而增加了金属丝网的阻火难度。

表 4 不同掺氢比例预混气体的最大试验安全间隙Table 4. Maximum examination saftey gap of premixed gas with different ratio of hydrogen掺氢比例/% MESG/mm 掺氢比例/% MESG/mm 0 1.14 20 0.90 10 1.03 30 0.83 2.2 掺氢比例对火焰形态变化的影响

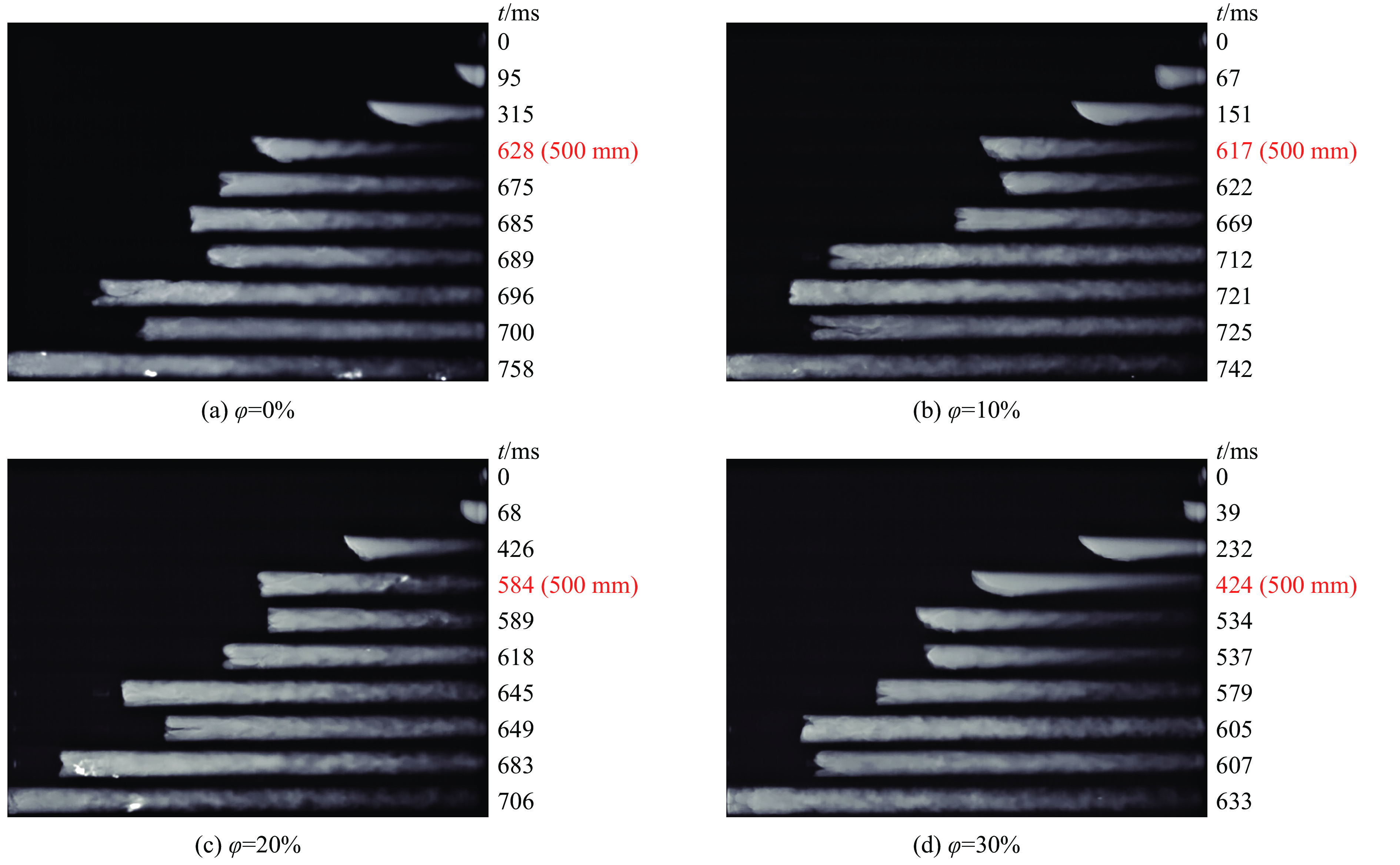

不同比例掺氢甲烷在空管中的火焰传播如图3所示。点火初期,火焰以球形锋面自由传播。然而,由于实验管道两端存在不可视的钢结构,所以未能完整地展示球形火焰形态。随着火焰的传播,火焰锋面被拉伸为椭球形,随即出现指形火焰。随着火焰发展至中后期,经典郁金香形火焰形成,并且呈现出“出现-消失-再现”的规律。郁金香形火焰的形成标志着火焰从层流向湍流的转变[25]。由图3可知,当掺氢比例分别为0%、10%、20%和30%时,郁金香形火焰的首现时间分别为675、669、618和579 ms。随着掺氢比例的增加,郁金香形火焰的首现时间提前。这是因为郁金香形火焰的形成受流场与火焰共同作用的影响。随着掺氢比例的增加,火焰振荡时间提前,火焰抵抗外界扰动能力变差,火焰燃烧不稳定性增加,更容易导致火焰从层流向湍流燃烧的转变。由此可见,当火焰在空管中自由传播时,掺氢甲烷预混火焰均经历了球形、指形和郁金香形三种形态变化。

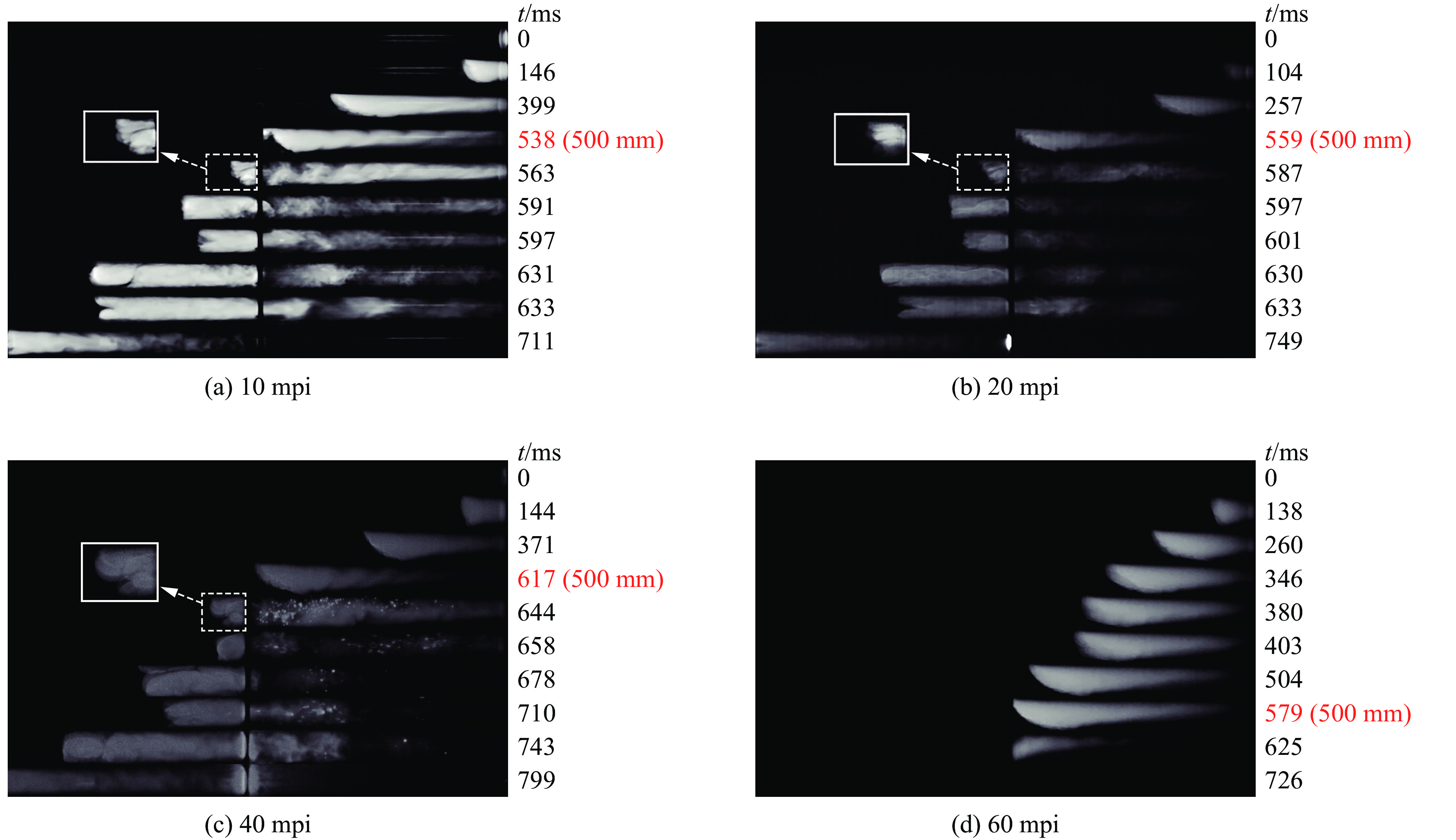

对于添加金属丝网的火焰传播情况,如图4所示,以掺氢比例为20%的预混火焰为例进行分析。如图4(a)~4(c)所示,当金属丝网阻火失败时,呈现出与空管火焰相似的形态演变过程。金属丝网的存在对前期火焰形态变化几乎没有影响,但是火焰穿过金属丝网后,出现了更多的褶皱并对郁金香形火焰的形成产生了影响。当金属丝网孔隙密度为10、20和40 mpi时,郁金香形火焰的首现时间分别为597、633和678 ms。由此可见,金属丝网的存在延迟了郁金香形火焰的首现时间,并且随着金属丝网孔隙密度的增加,郁金香形火焰的首现时间进一步延迟。这是因为金属丝网的存在一定程度上增加了管道内气体流动阻力,降低了压力波的传播速度,火焰锋面受压力波扰动的现象出现较迟,进而延迟了郁金香形火焰的首现时间,且孔隙密度越大,产生的阻力越大,因而延迟越显著。如图4(d)所示,当金属丝网阻火成功时,火焰演变过程表现出与空管火焰发展前期类似的形态,即球形火焰和指形火焰。但是,由于火焰在金属丝网处淬熄,所以整个过程未能形成郁金香形火焰。

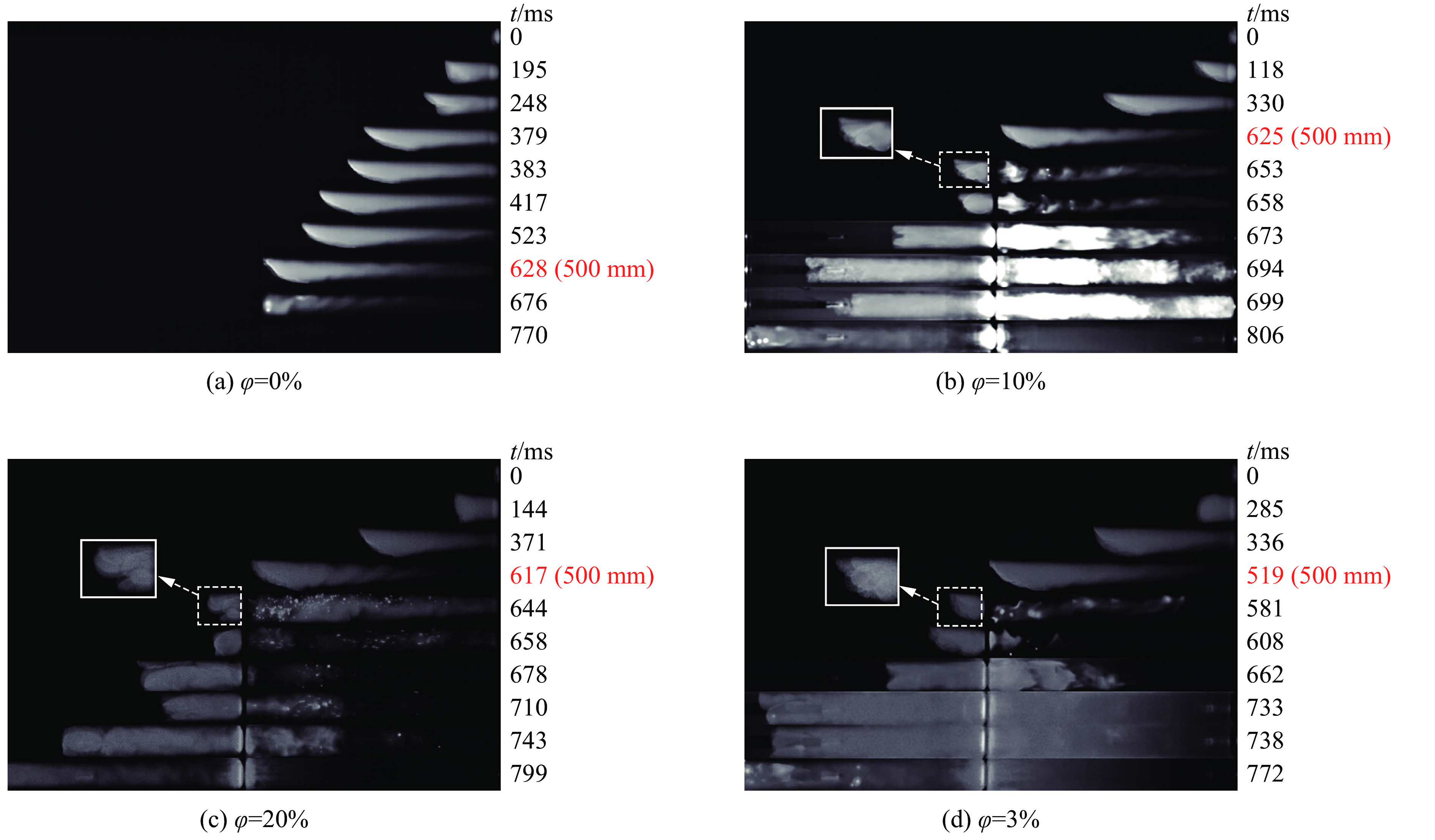

掺氢比例对内置金属丝网管道内火焰形态变化的影响如图5所示,由于掺氢比例对不同孔隙密度的金属丝网阻火成功或失败情况下火焰形态变化的影响基本一致,文中以40 mpi金属丝网为例进行分析。如图5(a)所示,当掺氢比例为0%时,金属丝网的抑制作用对火焰的发展起主导作用,火焰在金属丝网处淬熄。如图5(b)~5(d)所示,当掺氢比例分别为10%、20%和30%时,火焰可以穿过金属丝网并在后期形成郁金香形火焰,郁金香形火焰的首现时间分别为683、678和662 ms。由此可见,当金属丝网阻火失败时,随着掺氢比例的增大,郁金香形火焰的首现时间提前。分析认为,随着掺氢比例的增加,火焰不稳定性提高,导致金属丝网更容易诱导火焰从层流转变为湍流燃烧。然而,与无金属丝网工况相比,掺氢比例为10%、20%和30%时,郁金香形火焰的首现时间均有所延迟,延迟的时间差分别为14、60和83 ms。可见,随着掺氢比例的增加,郁金香形火焰延迟的时间差变大,即延迟的效果越明显。

2.3 掺氢比例对火焰传播速度的影响

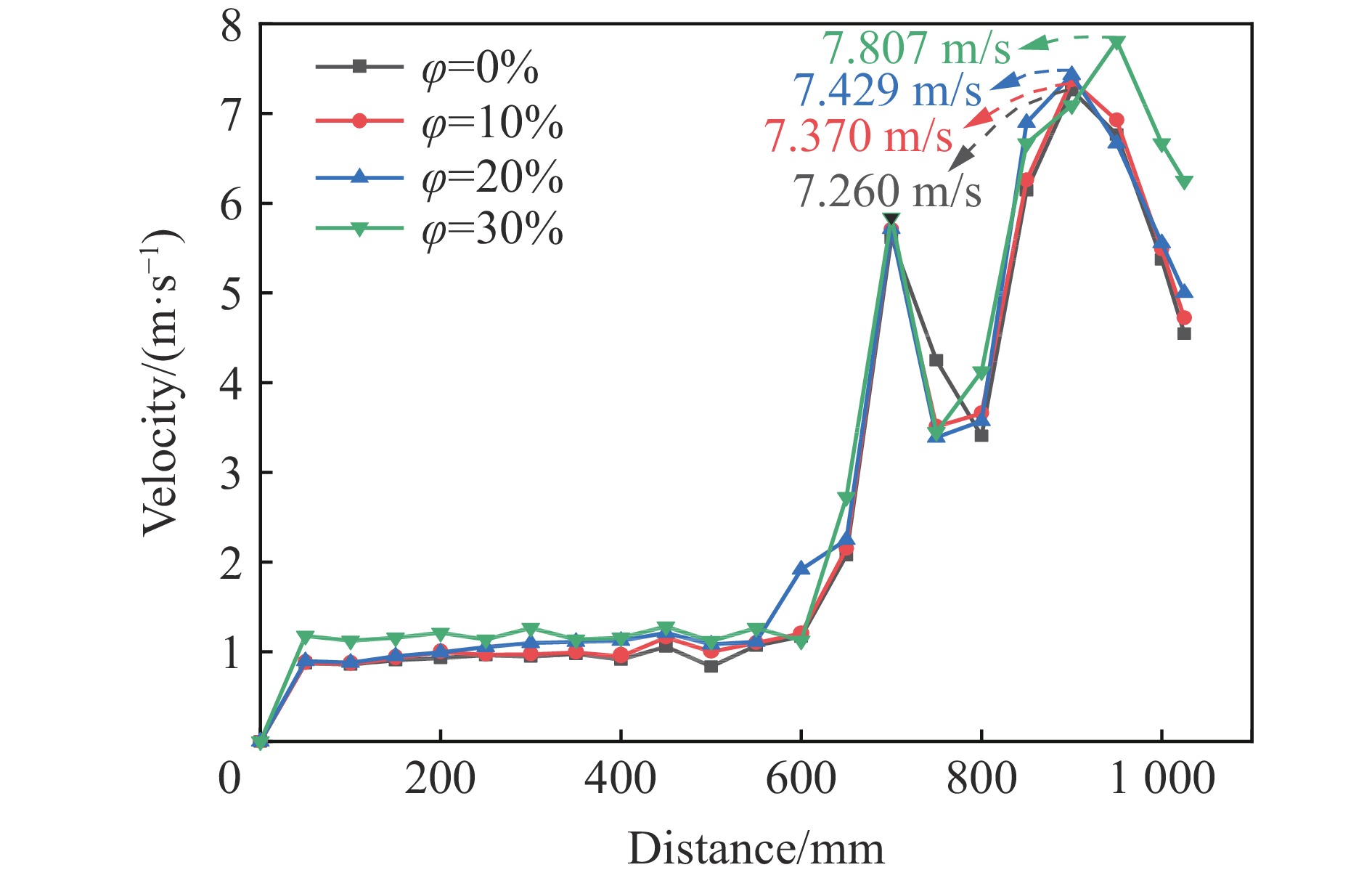

按照每间隔50 mm计算一次火焰锋面移动的平均速度,分析管道可视区域范围内火焰传播速度,得到空管火焰传播速度曲线,如图6所示。从图中可以看出,火焰传播初期以较小的速度(0.8~1.2 m/s)稳定传播,200 mm后出现轻微波动,到达600 mm时火焰传播速度突然骤升,而后出现大幅震荡,900 mm左右时达到速度峰值后逐渐下降。整个火焰传播过程经历了层流燃烧向湍流燃烧的转变,火焰锋面褶皱增加导致表面积的迅速增大是火焰传播速度突然骤升的主要原因,反射压力波引起的气流震荡使得火焰传播出现大幅震荡。后期,混合气体逐渐燃尽、热量损失,火焰传播速度也随之降低。此外,当掺氢比例为0%、10%、20%和30%时,预混火焰最大火焰传播速度分别可达7.260、7.370、7.429和7.807 m/s。由此可见,随着掺氢比例的增加,最大火焰传播速度不断上升。

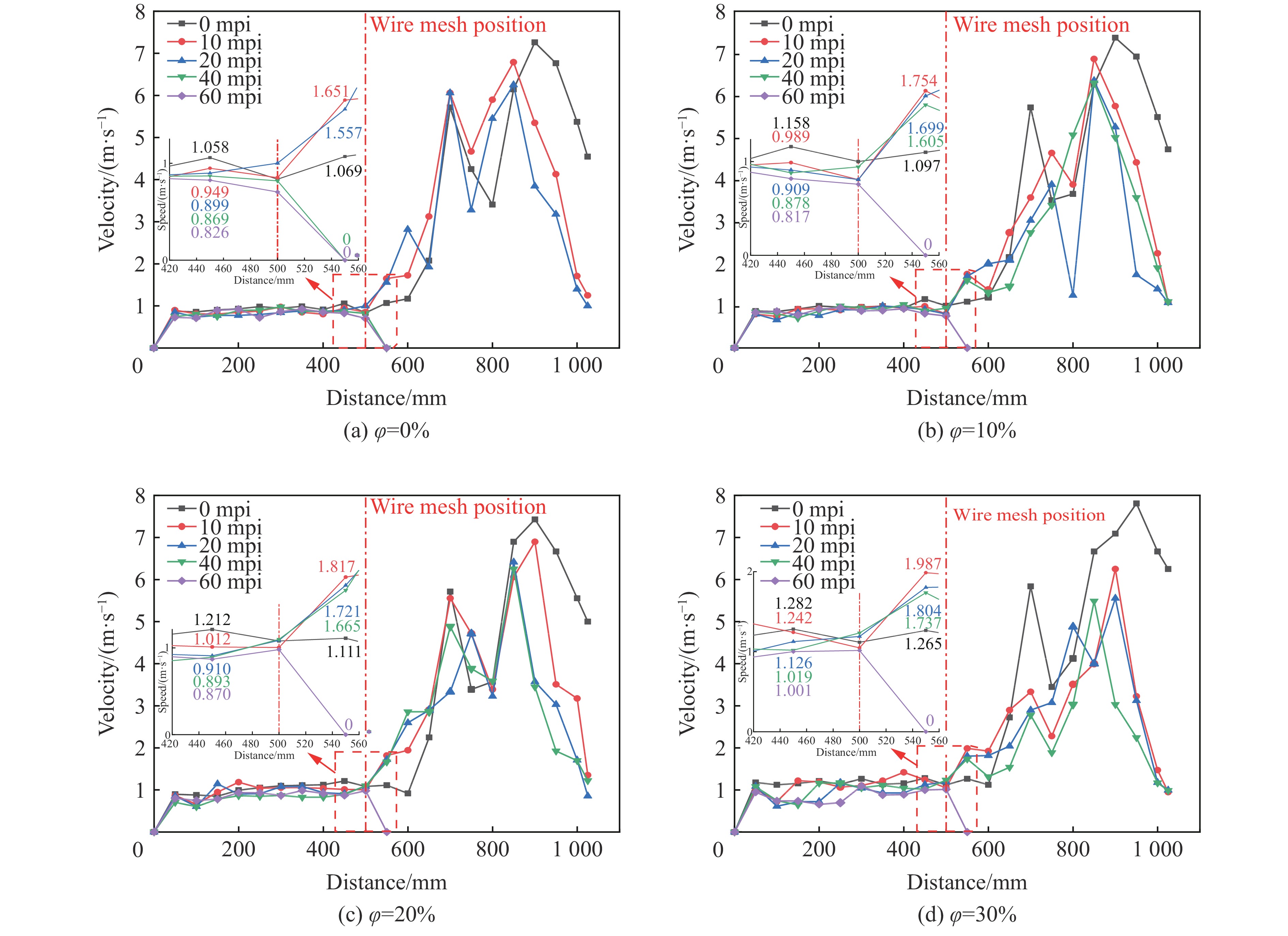

对于添加金属丝网的情况,不同掺氢比例混合气体火焰传播速度随距离的变化曲线如图7所示,其中“0”表示无金属丝网工况,红色虚线表示金属丝网安设位置。当火焰在到达金属丝网前传播时,如图7(a)~7(c)所示,掺氢比例分别为0%、10%和20%的预混火焰传播速度与空管火焰传播速度变化规律基本一致,即金属丝网对火焰传播速度没有明显的抑制作用。然而,当掺氢比例增加到30%时,如图7(d)所示,火焰传播速度与空管工况相比有所降低。当火焰传播至金属丝网附近时,金属丝网两侧火焰传播速度可以有效表征金属丝网与火焰的相互作用规律,选取火焰锋面位置450和550 mm为观测点,对比分析火焰传播速度变化,如图7中的区域放大图片所示,不同掺氢比例时金属丝网孔隙密度对金属丝网两侧火焰传播速度的影响基本一致。以掺氢比例为20%的预混火焰为例(图7(c)),当火焰传播至450 mm时,空管、10、20、40和60 mpi金属丝网管道内的火焰传播速度分别为1.212、1.012、0.910、0.893和0.870 m/s。随着金属丝网孔隙密度的增加,火焰传播速度逐步降低。这是因为靠近金属丝网,气流阻力增大,火焰锋面的传热传质受到影响,导致火焰传播速度下降。同时,随着金属丝网孔隙密度的增加,金属丝网在管道中占据的空间增大,火焰受到的阻力作用增加,金属丝网热量消耗增大,导致金属丝网对火焰的抑制效果增强。与金属丝网阻火成功的情况不同,当金属丝网阻火失败时,与空管火焰传播速度(1.111 m/s)相比,掺氢比例为20%的预混气体在10、20和40目金属丝网作用下,550 mm处的火焰传播速度分别增加为1.817、1.721和1.665 m/s。由此可知,随着金属丝网孔隙密度的增加,穿过金属丝网后的火焰传播速度增幅减小。分析认为,因金属丝网的诱导,火焰直接从层流转变为湍流燃烧,火焰燃烧强度增大,从而增加了火焰传播速度。然而,随着金属丝网孔隙密度的增加,金属丝网导致火焰的热损失效应相应增强,减弱了火焰的加速效应。

值得注意的是,随着掺氢比例的增加,金属丝网两侧火焰传播速度均增大。例如,当管道内设置40 mpi金属丝网时,掺氢比例为0%、10%、20%和30%的预混气体在450 mm处的火焰传播速度分别为0.869、0.879、0.893和1.019 m/s。说明随着掺氢比例的增加,金属丝网对火焰传播的抑制难度加大。同时,在该工况下,当掺氢比例为0%时,金属丝网抑制了火焰的发展,成功阻止了火焰的传播。当掺氢比例增加为10%、20%和30%时,火焰在550 mm处的传播速度分别增加为1.605、1.665和1.737 m/s。由此可知,随着掺氢比例的增加,火焰穿过金属丝网后的传播速度也随之增加。综上所述,金属丝网在阻火成功的临界条件下,随着掺氢比例从0%增加至30%,金属丝网对火焰传播的影响作用从抑制转变为促进。但是,在火焰穿过金属丝网后的传播过程中,与无金属丝网工况相比,火焰传播速度的最大值降低,并且掺氢比例越大,降低幅度越大。

3. 结 论

开展了金属丝网影响掺氢甲烷预混火焰传播的实验研究,主要分析了掺氢比例对不同孔隙密度金属丝网阻火过程的影响规律,得到以下结论:

(1) 掺氢比例是影响金属丝网阻火效果的重要因素;随着掺氢比例的增加,金属丝网的阻火难度加大,容易出现导致阻火失败的情况;增加金属丝网孔隙密度可提高金属丝网对掺氢甲烷预混火焰的阻火能力,孔隙密度越大,阻火能力越强;60 mpi以上金属丝网能够有效淬熄掺氢甲烷预混火焰;

(2) 掺氢比例对火焰形态的影响与金属丝网阻火情况有关;当金属丝网阻火失败时,金属丝网会引起火焰褶皱,并延迟郁金香形火焰的首现时间;掺氢比例越大,火焰褶皱现象越明显,郁金香形火焰延迟的时间差越大;当金属丝网阻火成功时,郁金香形火焰无法形成;

(3) 金属丝网在阻火成功的条件下,随着掺氢比例的增加,对火焰传播的影响作用可能从抑制转变为促进;当火焰穿过金属丝网时,金属丝网会导致火焰传播加速,并且掺氢比例越大,火焰穿过金属丝网后加速现象越明显,火焰传播速度越快。

-

表 1 金属丝网几何参数

Table 1. Geometric parameters of wire mesh

序号 孔隙密度/mpi 孔径/mm 丝径/mm 1 10 2.3 0.35 2 20 1.1 0.21 3 40 0.5 0.13 4 60 0.3 0.10 表 2 当量比为1时掺氢甲烷混合气体配比

Table 2. Mixture ratio of hydrogen and methane when equivalent ratio is 1

% 掺氢比例 甲烷体积分数 氢气体积分数 空气体积分数 掺氢比例 甲烷体积分数 氢气体积分数 空气体积分数 0 9.50 0 90.50 20 8.80 2.20 89.00 10 9.18 1.02 89.80 30 8.36 3.58 88.06 表 3 各工况下金属丝网阻火情况

Table 3. Fire resistance effect of wire mesh under different working conditions

孔隙密度/mpi 阻火效果 孔隙密度/mpi 阻火效果 φ=0% φ=10% φ=20% φ=30% φ=0% φ=10% φ=20% φ=30% 10 N N N N 40 Y N N N 20 N N N N 60 Y Y Y Y 表 4 不同掺氢比例预混气体的最大试验安全间隙

Table 4. Maximum examination saftey gap of premixed gas with different ratio of hydrogen

掺氢比例/% MESG/mm 掺氢比例/% MESG/mm 0 1.14 20 0.90 10 1.03 30 0.83 -

[1] ZOU C N, XIONG B, XUE H Q, et al. The role of new energy in carbon neutral [J]. Petroleum Exploration and Development, 2021, 48(2): 480–491. DOI: 10.1016/S1876-3804(21)60039-3. [2] GONDAL I A, SAHIR M H. Prospects of natural gas pipeline infrastructure in hydrogen transportation [J]. International Journal of Energy Research, 2012, 36(15): 1338–1345. DOI: 10.1002/er.1915. [3] SHEN X B, XIU G L, WU S Z. Experimental study on the explosion characteristics of methane/air mixtures with hydrogen addition [J]. Applied Thermal Engineering, 2017, 120: 741–747. DOI: 10.1016/j.applthermaleng.2017.04.040. [4] 马秋菊, 邵俊程, 王众山, 等. 氢气比例和点火能量对CH4-H2混合气体爆炸强度影响的实验研究 [J]. 高压物理学报, 2020, 34(1): 015201. DOI: 10.11858/gywlxb.20190803.MA Q J, SHAO J C, WANG Z S, et al. Experimental study of the hydrogen proportion and ignition energy effects on the CH4-H2 mixture explosion intensity [J]. Chinese Journal of High Pressure Physics, 2020, 34(1): 015201. DOI: 10.11858/gywlxb.20190803. [5] CAI P, LIU Z Y, LI P L, et al. Effects of fuel component, airflow field and obstacles on explosion characteristics of hydrogen/methane mixtures fuel [J]. Energy, 2023, 265: 126302. DOI: 10.1016/j.energy.2022.126302. [6] PALMER K N. The quenching of flame by wire gauzes [J]. Symposium (International) on Combustion, 1958, 7(1): 497–503. DOI: 10.1016/s0082-0784(58)80084-3. [7] PALMER K N, TONKIN P S. The quenching of flames of various fuels in narrow apertures [J]. Combustion and Flame, 1963, 7: 121–127. DOI: 10.1016/0010-2180(63)90169-X. [8] 喻健良, 孟伟, 王雅杰. 多层丝网结构抑制管内气体爆炸的试验 [J]. 天然气工业, 2005, 25(6): 116–118. DOI: 10.3321/j.issn:1000-0976.2005.06.036.YU J L, MENG W, WANG Y J. Experiment to suppress gas explosion in pipe with structure of multi-layer wire mesh [J]. Natural Gas Industry, 2005, 25(6): 116–118. DOI: 10.3321/j.issn:1000-0976.2005.06.036. [9] CUI Y Y, WANG Z R, ZHOU K B, et al. Effect of wire mesh on double-suppression of CH4/air mixture explosions in a spherical vessel connected to pipelines [J]. Journal of Loss Prevention in the Process Industries, 2017, 45: 69–77. DOI: 10.1016/j.jlp.2016.11.017. [10] 童宇, 刘天生. 金属网对瓦斯爆炸抑制作用的实验研究 [J]. 中北大学学报(自然科学版), 2018, 39(5): 591–594. DOI: 10.3969/j.issn.1673-3193.2018.05.018.TONG Y, LIU T S. Experiment of suppressing the gas explosion with metal mesh [J]. Journal of North University of China (Natural Science Edition), 2018, 39(5): 591–594. DOI: 10.3969/j.issn.1673-3193.2018.05.018. [11] 喻健良, 孟伟, 王雅杰. 评价多层丝网结构阻火性能的试验研究 [J]. 含能材料, 2005, 13(6): 416–420. DOI: 10.3969/j.issn.1006-9941.2005.06.019.YU J L, MENG W, WANG Y J. Appraisal of capability of flame arrest by multi-layer wire mesh structure [J]. Chinese Journal of Energetic Materials, 2005, 13(6): 416–420. DOI: 10.3969/j.issn.1006-9941.2005.06.019. [12] 喻健良, 蔡涛, 李岳, 等. 丝网结构对爆炸气体淬熄的试验研究 [J]. 燃烧科学与技术, 2008, 14(2): 97–100. DOI: 10.3321/j.issn:1006-8740.2008.02.001.YU J L, CAI T, LI Y, et al. Experiment to quench explosive gas with structure of wire mesh [J]. Journal of Combustion Science and Technology, 2008, 14(2): 97–100. DOI: 10.3321/j.issn:1006-8740.2008.02.001. [13] JU X Y, MATSUOKA T, YAMAZAKI T, et al. Effect of single-layer metal wire mesh insertion on the burning behavior of laminar coflow propane/air diffusion flames [J]. Combustion and Flame, 2021, 234: 111612. DOI: 10.1016/j.combustflame.2021.111612. [14] ZHANG S F, WANG Z R, ZUO Q Q, et al. Suppression effect of explosion in linked spherical vessels and pipelines impacted by wire-mesh structure [J]. Process Safety Progress, 2016, 35(1): 68–75. DOI: 10.1002/prs.11728. [15] 陈鹏, 杨永波, 郭实龙, 等. 金属丝网对甲烷/空气预混火焰传播影响的研究 [J]. 中国安全科学学报, 2014, 24(7): 33–36. DOI: 10.16265/j.cnki.issn1003-3033.2014.07.014.CHEN P, YANG Y B, GUO S L, et al. Study on influence of metal mesh on methane/air premixed mixture flame propagation [J]. China Safety Science Journal, 2014, 24(7): 33–36. DOI: 10.16265/j.cnki.issn1003-3033.2014.07.014. [16] 孙玮康, 陈先锋, 冯梦梦, 等. 金属丝网对甲烷/空气爆燃火焰传播特性的影响 [J]. 高压物理学报, 2020, 34(5): 055201. DOI: 10.11858/gywlxb.20200536.SUN W K, CHEN X F, FENG M M, et al. Effect of the wire mesh structure on the flame characteristics of methane/air deflagration [J]. Chinese Journal of High Pressure Physics, 2020, 34(5): 055201. DOI: 10.11858/gywlxb.20200536. [17] JIN K Q, DUAN Q L, CHEN J Y, et al. Experimental study on the influence of multi-layer wire mesh on dynamics of premixed hydrogen-air flame propagation in a closed duct [J]. International Journal of Hydrogen Energy, 2017, 42(21): 14809–14820. DOI: 10.1016/j.ijhydene.2017.03.232. [18] JIN K Q, WANG Q S, DUAN Q L, et al. Effect of metal wire mesh on premixed H2/air flame quenching behaviors in a closed tube [J]. Process Safety and Environmental Protection, 2021, 146: 770–778. DOI: 10.1016/j.psep.2020.12.020. [19] JIN K Q, WANG Q S, DUAN Q L, et al. Effect of single-layer wire mesh on premixed methane/air flame dynamics in a closed pipe [J]. International Journal of Hydrogen Energy, 2020, 45(56): 32664–32675. DOI: 10.1016/j.ijhydene.2020.08.159. [20] CHENG F M, CHANG Z C, LUO Z M, et al. Large eddy simulation and experimental study of the effect of wire mesh on flame behaviours of methane/air explosions in a semi-confined pipe [J]. Journal of Loss Prevention in the Process Industries, 2020, 68: 104258. DOI: 10.1016/j.jlp.2020.104258. [21] 路长, 于子凯, 刘洋, 等. 氢气对预混甲烷/空气燃爆过程的影响 [J]. 安全与环境学报, 2017, 17(6): 2240–2245. DOI: 10.13637/j.issn.1009-6094.2017.06.038.LU C, YU Z K, LIU Y, et al. Impact of hydrogen addition on the premixed methane/air deflagration process [J]. Journal of Safety and Environment, 2017, 17(6): 2240–2245. DOI: 10.13637/j.issn.1009-6094.2017.06.038. [22] 尚融雪, 杨悦, 高俊豪, 等. 掺氢天然气层流火焰传播速度试验研究 [J]. 中国安全科学学报, 2019, 29(11): 103–108. DOI: 10.16265/j.cnki.issn1003-3033.2019.11.017.SHANG R X, YANG Y, GAO J H, et al. Experimental study on laminar flame speed of H2/CH4/air mixtures [J]. China Safety Science Journal, 2019, 29(11): 103–108. DOI: 10.16265/j.cnki.issn1003-3033.2019.11.017. [23] 王晓飞. 石油化工企业爆炸性气体混合物分级计算方法分析 [J]. 炼油技术与工程, 2021, 51(4): 47–50. DOI: 10.3969/j.issn.1002-106X.2021.04.012.WANG X F. Study on grading calculation method of explosive gas mixture in petrochemical enterprises [J]. Petroleum Refinery Engineering, 2021, 51(4): 47–50. DOI: 10.3969/j.issn.1002-106X.2021.04.012. [24] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. GB/T 13347—2010 石油气体管道阻火器 [S]. 北京: 中国标准出版社, 2011.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. GB/T 13347—2010 Flame arresters for petroleum gas pipeline systems [S]. Beijing: Standards Press of China, 2011. [25] 陈先锋, 孙金华, 姚礼殷, 等. Tulip火焰形成过程中的细微结构特性 [J]. 燃烧科学与技术, 2008, 14(4): 350–354. DOI: 10.3321/j.issn:1006-8740.2008.04.012.CHEN X F, SUN J H, YAO L Y, et al. Characteristics of fine structure during tulip flame forming [J]. Journal of Combustion Science and Technology, 2008, 14(4): 350–354. DOI: 10.3321/j.issn:1006-8740.2008.04.012. -

下载:

下载:

下载:

下载: