Elastic compensation for dynamic rigid-plastic solutions of structures

-

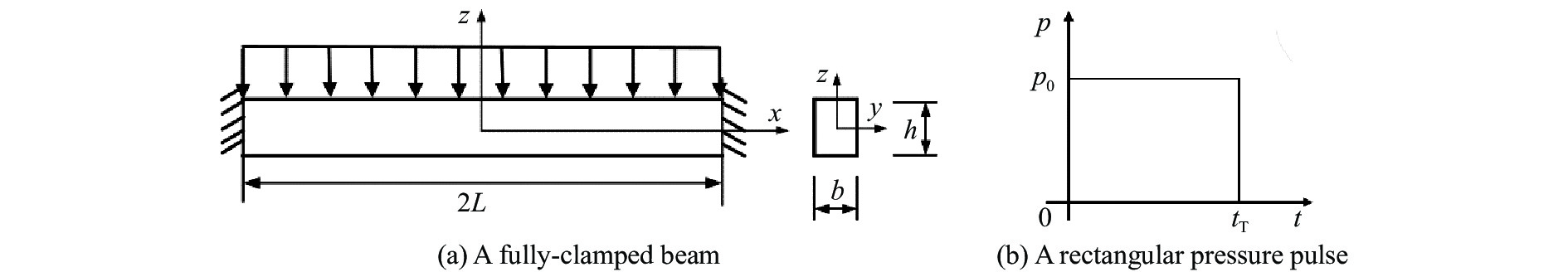

摘要: 近年来,我国学者以膜力因子法和饱和分析方法相结合为理论工具,对梁、板等结构件在脉冲载荷作用下的塑性大变形行为作了全面深入的研究,为脉冲加载下结构的最终挠度提供了优于历史上各种刚塑性近似解的最佳刚塑性预测公式。然而,由于实际工程应用中金属结构弹塑性动力响应的复杂性和数值模拟的局限性,与考虑材料弹性效应的结果相比,刚塑性解对脉冲加载下结构所预测的最终挠度的误差有多大,是一个亟待解决的关键问题。对这个问题的首阶段研究成果厘清了材料弹性对脉冲加载下结构塑性动态大变形的影响,定量评估了由最佳刚塑性理论解与弹塑性数值模拟得到的最终挠度预测结果之间的差异。在此基础上,提出了补偿弹性效应的策略和方法,即:在已有的最佳刚塑性解预测的挠度基础上添加一个补偿项,将补偿项表达为脉冲载荷强度的效应与结构自身刚度的效应分离的变量函数,并尽量减少待定系数/指数的数量,以求表达式的简洁;根据这些原则在金属结构的主要工程应用领域内选定结构刚度和外载参数的变化范围,对固支梁和固支方板的案例实施拟合与补偿,最后得到了对梁和板增添补偿项后的简单而实用的最终挠度预测公式,其相对误差在3%的范围之内,很适合工程设计应用。文末列表给出了符号与公式的一览,并对梁和方板的结果作了综合和比较。Abstract: In recent years, by combining membrane factor method (MFM) and saturation analysis (SA) as a powerful theoretical tool, scholars in China have made comprehensive studies on the large dynamic plastic deformation of beams, plates and other structures under pulse loading, leading to the best rigid-plastic predictions for the final deflection of the pulse-loaded structures, which are superior to the previously proposed various approximate rigid-plastic solutions. However, due to the complexity of the dynamic elastic-plastic response of structures used in engineering and the limitations of numerical simulations, it is critical to clarify how large is the error generated from the rigid-plastic solutions in predicting the final deflection of pulse-loaded structures compared to the result that takes the elastic effect of material into consideration. Our preliminary study on this issue, which has been published in leading international journals, reveals the effect of material’s elasticity on the large dynamic plastic deformation of structures under pulse loading, and quantitatively evaluates the discrepancies between the final deflection predicted by the best theoretical rigid-plastic solutions and that extracted from elastic-plastic numerical simulations. On this basis, the present paper proposes a strategy to compensate for elastic effect; that is, (1) adding a compensation term to the final deflection predicted by the existing best rigid-plastic solution; (2) expressing the compensation term as an elemental function of variables separation to respectively represent the effects of the pulse intensity and the structural stiffness; and (3) adopting minimum number of undetermined coefficients (or power) in the fitting function to achieve concise formulae. Meanwhile, the variation ranges of structural stiffness and dimensionless load parameter are investigated with reference to metallic structures used in their main application fields. Finally, by implementing the fitting and compensation for the cases of fully-clamped beams and square plates, simple and engineer-friendly formulae for predicting the final deflection of beams and plates are eventually obtained. With the compensation terms being added, the rigid-plastic-solution-based predictions on the final deflection of beams and plates possess a relative error within the range of 3%, which are appropriate and suitable for applications in the engineering design stage. A table at the end of the paper summarizes the major notations and formulae, as well as the comparison between the results on beams and square plates.

-

图 8 补偿前(实线)和按式(8)作补偿后(虚线)与弹塑性有限元模拟得到的固支梁最终挠度之间的相对偏差

Figure 8. The relative discrepancies in the final deflection of fully-clamped beams between rigid-plastic predictions (solid lines displaying before compensation, and broken lines displaying after compensation given by Eq.(8)) and elastic-plastic simulation results

表 1 低碳钢和铝合金的材料性质

Table 1. Material properties of mild steel and aluminum alloys

材料 杨氏模量E/GPa 泊松比μ 屈服应力Y/MPa 低碳钢Q235 210 0.3 235 铝合金6061 71 0.3 240 铝合金7075 71 0.3 505 表 2 金属板的半边长与板厚之比 的常用范围

Table 2. Commonly-used ranges of half length-to-plate thickness ratio for metallic plates

工程领域 a/h 船舶海洋结构 10~125 汽车与运载机械 150~900 航空航天结构 80~1500 表 3 主要结果整理及固支梁与固支方板的比较

Table 3. Summary of main results as well as comparison of fully-clamped beams and plates

项目 固支梁(矩形截面) 固支方板 几何参数 长度2L,宽度b,厚度h 边长2a,厚度h 材料参数 杨氏模量E,屈服应力Y 杨氏模量E,泊松比μ,屈服应力Y 塑性极限弯矩 Mp = Ybh2/4 M0 = Yh2/4 准静态坍塌压力 线载荷pY = 4Mp/(bL) = Yh2/L 面载荷pY = 12M0/a2 = 3Yh2/a2 无量纲压力 λ ≡ p0/pY 结构刚度ζ $ {\zeta}_{\text{beam}}\text{≡}\dfrac{{h}}{{L}}\sqrt{\dfrac{{E}}{{Y}}} $ $ {\zeta}_{\text{plate}}\text{≡}\dfrac{{h}}{{a}}\sqrt{\dfrac{{E}}{{Y}({1}-\mu )}} $ 最佳刚塑性解预测的最终挠度 $ {\eta}_{\text{f}}^{\text{rp}}\text{≡}\dfrac{{{w}}_{\text{0f}}^{\text{rp}}}{{h}}={1.10}{ \lambda }{-}{0.414} $ $ {\eta}_{\text{f}}^{\text{rp}}\text{≡}\dfrac{{{w}}_{\text{0f}}^{\text{rp}}}{{h}}={2.16}{ \lambda }{-}{1.456} $ 刚塑性解加上弹性补偿后预测的最终挠度 $ {\eta}_{\text{f}}^{\text{*}}={1.10}{ \lambda }{-}{0.414+} ({-}{0.08}{ \lambda }{+0.29)}{\zeta}^{{-0.9}} $ $ {\eta}_{\text{f}}^{\text{*}}={2.160}{ \lambda }{-}{1.456+} {(0.03}{{ \lambda }}^{2}{-}{0.33}{ \lambda }{+0.85)}{\zeta}^{{-0.4}} $ 弹塑性模拟得到的最终挠度 $ {\eta}_{\text{f}}^{\text{ep}}\text{≡}\dfrac{{{w}}_{\text{0f}}^{\text{ep}}}{{h}} $ 上述二者之间的相对偏差 $ {{D}}_{\eta}^{\text{*}}=\dfrac{{\eta}_{\text{f}}^{\text{*}}-{\eta}_{\text{f}}^{\text{ep}}}{{\eta}_{\text{f}}^{\text{ep}}}{\text{≤}}3\text{%} $ -

[1] JOHNSON W. Impact strength of materials [M]. London: Edward Arnord, 1983. [2] JONES N. Structural impact [M]. 2nd ed. Cambridge: Cambridge University Press, 2011. [3] STRONGE W J, YU T X. Dynamic models for structural plasticity [M]. Berlin: Springer-Verlag, 2012. [4] 余同希, 邱信明. 冲击动力学 [M]. 北京: 清华大学出版社, 2011. [5] SYMONDS P S, FRYE C W G. On the relation between rigid-plastic and elastic-plastic predictions of response to pulse loading [J]. International Journal of Impact Engineering, 1988, 7(2): 139–149. DOI: 10.1016/0734-743X(88)90022-X. [6] YU T X. Elastic effect in the dynamic plastic response of structures [M]//JONES N, WIERZBICKI T. Structural Crashworthiness and Failure. London: Springer-Verlage, 1993: 341–384. DOI: 10.1201/9781482262544. [7] 余同希, 朱凌, 许骏. 结构冲击动力学进展(2010−2020) [J]. 爆炸与冲击, 2021, 41(12): 121401. DOI: 10.11883/bzycj-2021-0113.YU T X, ZHU L, XU J. Progress in structural impact dynamics during 2010−2020 [J]. Explosion and Shock Waves, 2021, 41(12): 121401. DOI: 10.11883/bzycj-2021-0113. [8] 余同希, 朱凌, 陈发良. 饱和冲量与膜力因子法: 强动载荷下结构塑性大变形的分析和预测方法 [M]//陈建康, 白树林. 材料的非线性力学性能研究进展. 北京: 机械工业出版社, 2021: 17–29. [9] 余同希, 田岚仁, 朱凌. 强脉冲载荷作用下结构塑性大变形的最大挠度直接预测 [J]. 力学学报, 2023, 55(5): 1113–1123. DOI: 10.6052/0459-1879-22-607.YU T X, TIAN L R, ZHU L. Direct prediction of maximum deflection for plastically deformed structures under intense dynamic pulse [J]. Chinese Journal of Theoretical and Applied Mechanics, 2023, 55(5): 1113–1123. DOI: 10.6052/0459-1879-22-607. [10] 朱凌, 田岚仁, 李德聪, 等. 饱和冲量及其等效方法在舱室内爆炸中的应用 [J]. 中国舰船研究, 2021, 16(2): 99–107. DOI: 10.19693/j.issn.1673-3185.01876.ZHU L, TIAN L R, LI D C, et al. Saturated impulse and application of saturation equivalent method in cabin explosion [J]. Chinese Journal of Ship Research, 2021, 16(2): 99–107. DOI: 10.19693/j.issn.1673-3185.01876. [11] TIAN L R, CHEN F L, ZHU L, et al. Saturated analysis of pulse-loaded beams based on Membrane Factor Method [J]. International Journal of Impact Engineering, 2019, 131: 17–26. DOI: 10.1016/j.ijimpeng.2019.04.021. [12] TIAN L R, CHEN F L, ZHU L, et al. Large deformation of square plates under pulse loading by the combination of Saturated Analysis and Membrane Factor Method [J]. International Journal of Impact Engineering, 2020, 140: 103546. DOI: 10.1016/j.ijimpeng.2020.103546. [13] HU Q J, ZHU L, YU T X. Elastic effects on the dynamic plastic deflection of pulse-loaded beams [J]. International Journal of Impact Engineering, 2023, 176: 104550. DOI: 10.1016/j.ijimpeng.2023.104550. [14] HU Q J, ZHU L, YU T X. Elastic effect on the final deflection of rigid-plastic square plates under pulse loading [J]. Thin-Walled Structures, 2023, 193: 111238. DOI: 10.1016/j.tws.2023.111238. [15] YOUNGDAHL C K. Correlation parameters for eliminating the effect of pulse shape on dynamic plastic deformation [J]. Journal of Applied Mechanics, 1970, 37(3): 744–752. DOI: 10.1115/1.3408605. [16] YOUNGDAHL C K. Influence of pulse shape on the final plastic deformation of a circular plate [J]. International Journal of Solids and Structures, 1971, 7(9): 1127–1142. DOI: 10.1016/0020-7683(71)90057-6. [17] ZHU L, TIAN L R, CHEN F L, et al. A new equivalent method for complex-shaped pulse loading based on saturation analysis and membrane factor method [J]. International Journal of Impact Engineering, 2021, 158: 104018. DOI: 10.1016/j.ijimpeng.2021.104018. [18] CHEN F L, TIAN L R, YU T X, et al. Complete solution of large plastic deformation of square plates under exponentially decaying pulse loading [J]. Acta Mechanica Solida Sinica, 2021, 34(6): 922–936. DOI: 10.1007/s10338-021-00280-6. -

下载:

下载: