Microstructure and properties of copper coating prepared by explosive compaction-coating

-

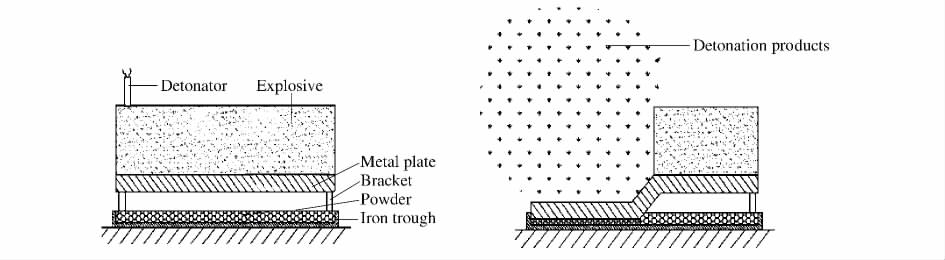

摘要: 利用爆炸压涂技术在铜基板上制备了较大面积的铜涂层,详细阐述了爆炸压涂技术的工艺。利用光学显微镜、扫描电镜观察了铜涂层的微观组织结构,涂层的厚度为280μm,用截线法在涂层的显微结构图上测得其孔隙率为约2%,利用显微硬度计测量了涂层的显微硬度hV0.05=114,还利用能谱分析测量了粉末和涂层中各元素的质量分数,实验前后元素的组成成分基本没有发生变化。爆炸压涂制备的铜涂层具有较好的均匀性和致密性,铜粉末在形成涂层的过程中不会发生氧化现象。Abstract: The explosive compaction-coating technology was introduced in detail and was used to prepare the large-area copper coating.And the surface morphology, element content and thickness of the prepared copper coating were investigated by means of optical microscope, scanning electron microscopy and energy dispersion spectrum.The porosity of the copper coating was measured by the quantitative line method in its SEM photograph.The hardness of the copper coating was observed by a microhardness tester.The thickness of the copper coating was 280μm, the porosity was about 2%, the average microhardness was about 114HV0.05, and the element content remained roughly constant before and after the experiment.The results show that the prepared copper coating has excellent uniformity and compactness and no oxidation of the copper powder can occur during the process of the copper coating formation.

-

Key words:

- mechanics of explosion /

- porosity /

- explosive compaction-coating /

- copper coating /

- oxidation

-

表 1 涂层和铜板的显微硬度

Table 1. Microhardness of coating and copper plate

No. hV0.05, coating hV0.05, plate 1 117 114 2 107 121 3 114 118 4 119 114 平均 114 117 表 2 铜粉末和涂层的元素组成

Table 2. Element composition of powder and coating

元素 wpower/% wcoating/% C 0.37 0.49 O 3.53 4.48 Cu 96.11 95.03 -

[1] Kim J H, Yang H S, Baik K H, et al. Development and properties of nanostructured thermal spray coatings[J]. Current Applied Physics, 2006, 6(6): 1002-1006. doi: 10.1016/j.cap.2005.07.006 [2] Matthews S, James B, Hyland M. The role of microstructure in the mechanism of high velocity erosion of Cr3C2-NiCr thermal spray coatings: As-sprayed coatings[J]. Surface and Coatings Technology, 2009, 203(8): 1086-1093. doi: 10.1016/j.surfcoat.2008.10.005 [3] Klinkov S V, Kosarev V F, Sova A A, et al. Deposition of multicomponent coatings by cold spray[J]. Surface and Coatings Technology, 2008, 202(4): 5858-5862. http://www.sciencedirect.com/science/article/pii/S0257897208005835 [4] Yue T M, Huang K J, Man H C. Laser cladding of Al2O3 coating on aluminium alloy by thermite reactions[J]. Surface and Coatings Technology, 2005, 194(2/3): 232-237. http://www.sciencedirect.com/science/article/pii/S0257897204009120 [5] Izumi H, Machida K, Iguchi M, et al. Zinc coatings on Sm2Fe17Nx powder by photoinduced chemical vapour deposition method[J]. Journal of Alloys and Compounds, 1997, 261(1/2): 304-307. [6] 赵铮, 陶钢.双金属复合板的新制备工艺:爆炸压涂[J].材料开发与应用, 2008, 23(5): 48-51. http://www.cnki.com.cn/Article/CJFDTotal-CLKY200805012.htmZhao Zheng, Tao Gang. Spray technology for preparation of double metal clad plate: Explosive compaction[J]. Development and Application of Materials, 2008, 23(5): 48-51. http://www.cnki.com.cn/Article/CJFDTotal-CLKY200805012.htm [7] 赵铮, 杜长星, 陶钢, 等.板-粉双层复合材料的爆炸压涂制备技术[J].材料导报, 2009, 23(7): 95-97. http://www.cnki.com.cn/Article/CJFDTotal-CLDB200913028.htmZhao Zheng, Du Chang-xing, Tao Gang, et al. Explosive compact-coating preparation technology of plate-powder double layer composites[J]. Materials Review, 2009, 23(7): 95-97. http://www.cnki.com.cn/Article/CJFDTotal-CLDB200913028.htm [8] 李晓杰, 莫非, 闫鸿浩, 等.爆炸焊接斜碰撞过程的数值模拟[J].高压物理学报, 2011, 25(2): 173-176. http://www.cqvip.com/Main/Detail.aspx?id=37468621Li Xiao-jie, Mo Fei, Yan Hong-hao, et al. Numerical simulation of the oblique collision in explosive welding[J]. Chinese Journal of High Pressure Physics, 2011, 25(2): 173-176. http://www.cqvip.com/Main/Detail.aspx?id=37468621 [9] 张越举, 李晓杰, 赵铮, 等.纳米γ-Al2O3陶瓷粉末的预热爆炸压实实验研究[J].爆炸与冲击, 2008, 28(3): 220-223. http://www.cqvip.com/Main/Detail.aspx?id=27842270Zhang Yue-ju, Li Xiao-jie, Zhao Zheng, et al. On the preheated explosive consolidation of nanometerγ-Al2O3 ceramic powders[J]. Explosion and Shock Waves, 2008, 28(3): 220-223. http://www.cqvip.com/Main/Detail.aspx?id=27842270 [10] Du C X, Zhao Z, Tao G. Explosive compaction-coating manufacture large area coat[J]. Advanced Materials Research, 2011, 189: 1014-1017. http://www.scientific.net/AMR.189-193.1014 [11] Diaz P, Edirisinghe M J, Ralph B. Microstructural changes and phase transformations in a plasma-sprayed zirconia-yttria-titania thermal barrier coating[J]. Surface and Coatings Technology, 1996, 82(3): 284-290. doi: 10.1016/0257-8972(95)02721-1 [12] 陈辉, 郑涛, 代双贺.钢基冷喷铜涂层与轧制覆铜板性能对比[J].沈阳建筑大学学报:自然科学版, 2010, 26(1): 180-183. http://d.wanfangdata.com.cn/periodical/syjzgcxyxb201001034Chen Hui, Zheng Tao, Dai Shuang-he. Properties comparison between steel-based cold-sprayed copper coating and copper clad laminate[J]. Journal of Shenyang Jianzhu University: Natural Science, 2010, 26(1): 180-183. http://d.wanfangdata.com.cn/periodical/syjzgcxyxb201001034 [13] Seo D, Ogawa K, Sakaguchi K, et al. Parameter study influencing thermal conductivity of annealed pure copper coatings deposited by selective cold spray processes[J]. Surface and Coatings Technology, 2012, 206(8/9): 2316-2324. http://www.sciencedirect.com/science/article/pii/S0257897211010036 [14] 郭辉华, 周香林, 巫湘坤, 等.几种金属基板上冷喷涂铜涂层的试验与模拟[J].材料热处理学报, 2009, 30(6): 158-163. http://d.wanfangdata.com.cn/Periodical/jsrclxb200906035Guo Hui-hua, Zhou Xiang-lin, Wu Xiang-kun, et al. Preparation and simulation of cold sprayed copper coating on metal substrate[J]. Transactions of Materials and Heat Treatment, 2009, 30(6): 158-163. http://d.wanfangdata.com.cn/Periodical/jsrclxb200906035 [15] Sharma R K, Bhatnagar M C, Sharma G L. Mechanism of highly sensitive and fast response Cr doped TiO2 oxygen gas sensor[J]. Sensors and Actuators B: Chemical, 1997, 45(3): 209-215. doi: 10.1016/S0925-4005(97)00295-5 -

下载:

下载: