Energy release characteristics of composite charge in confined space

-

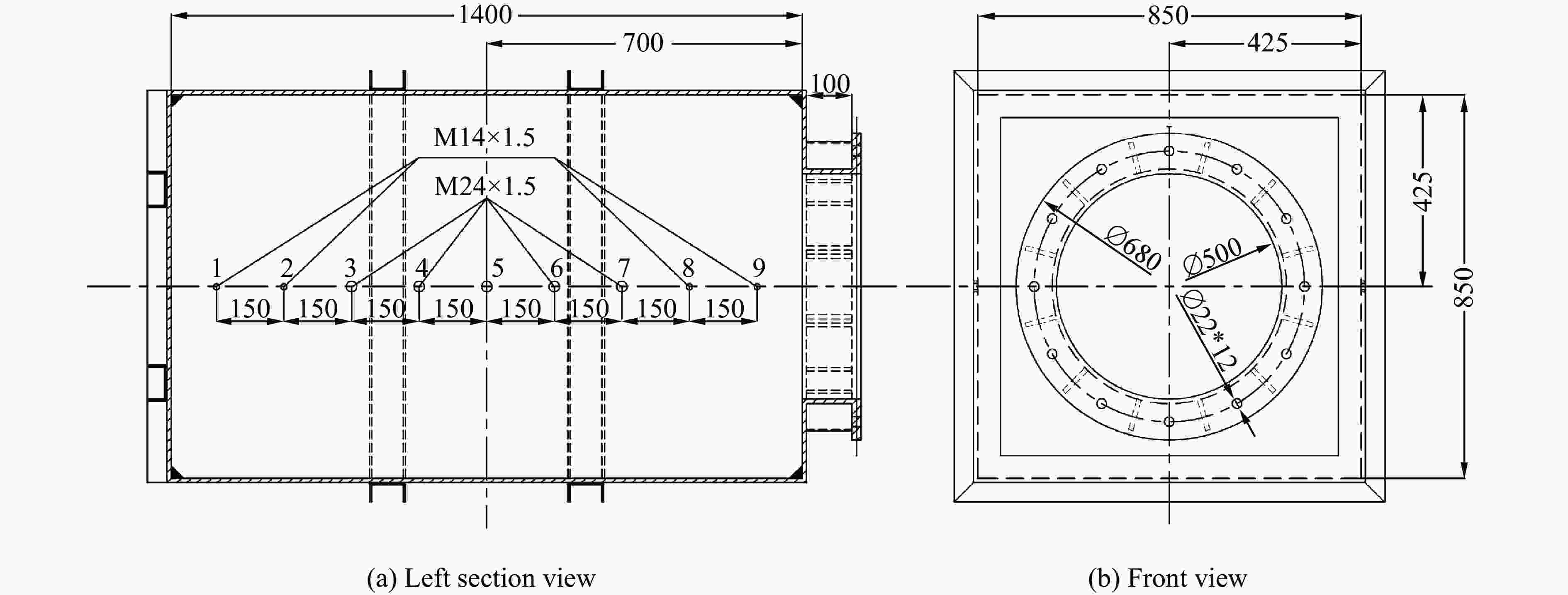

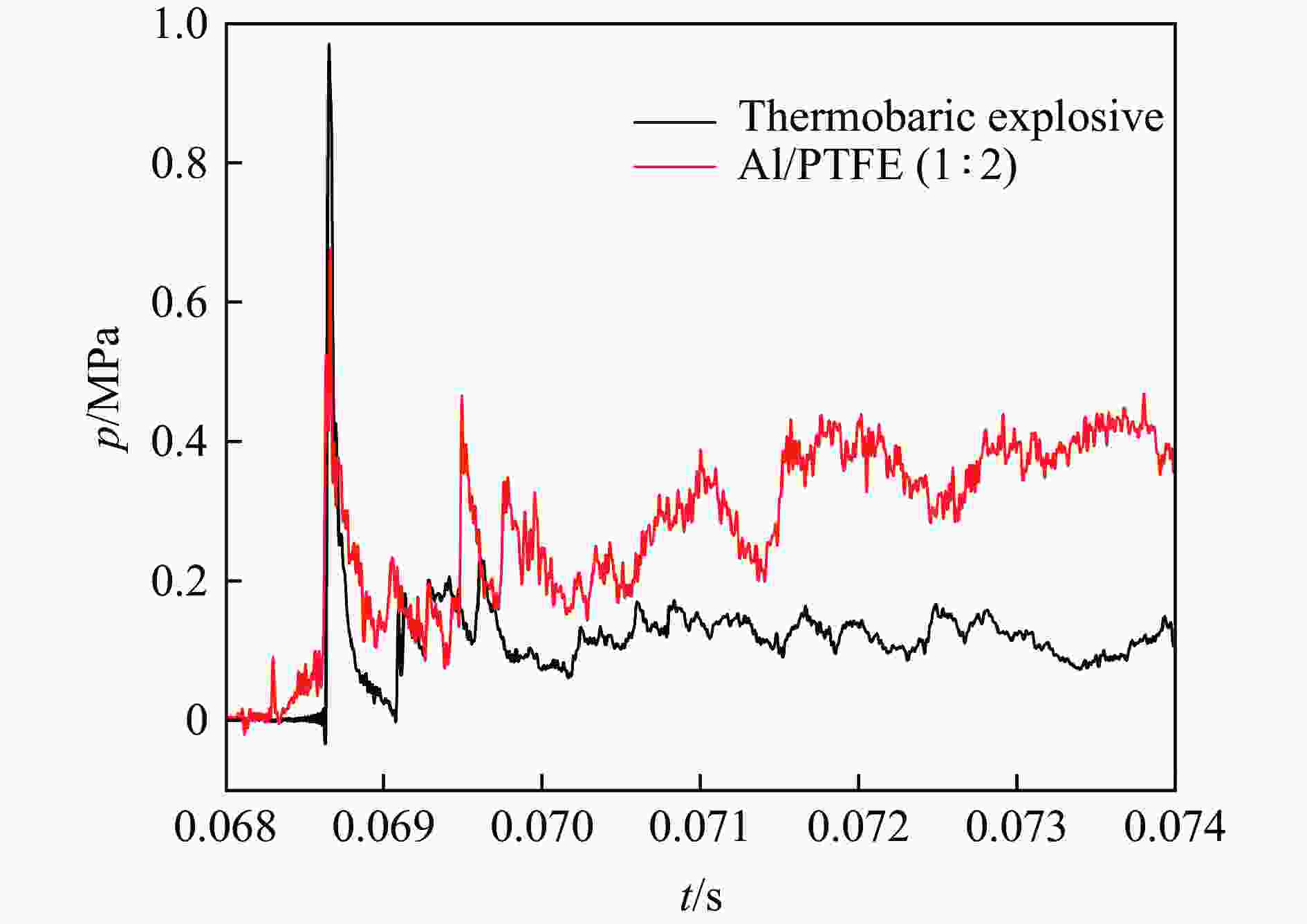

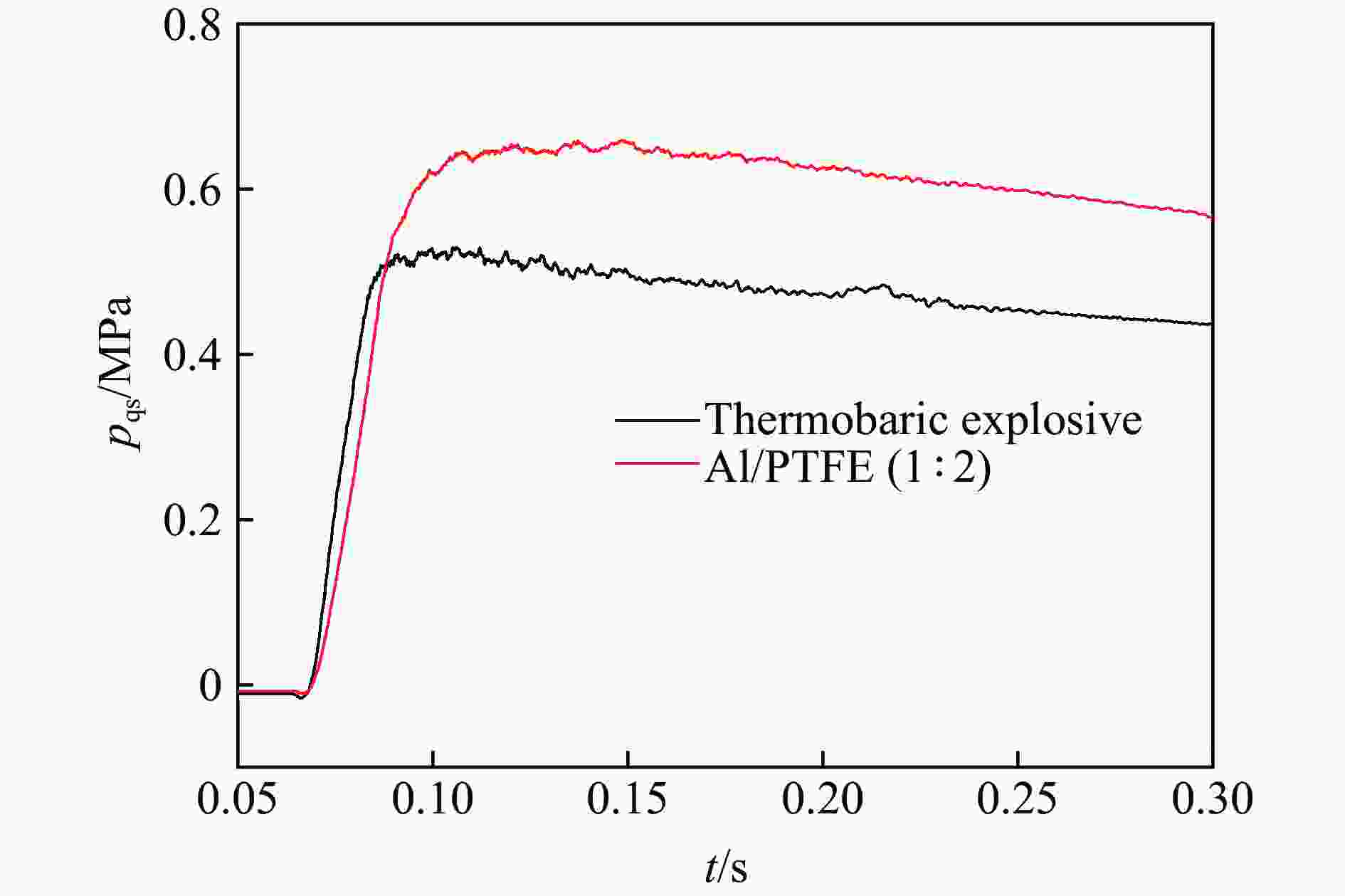

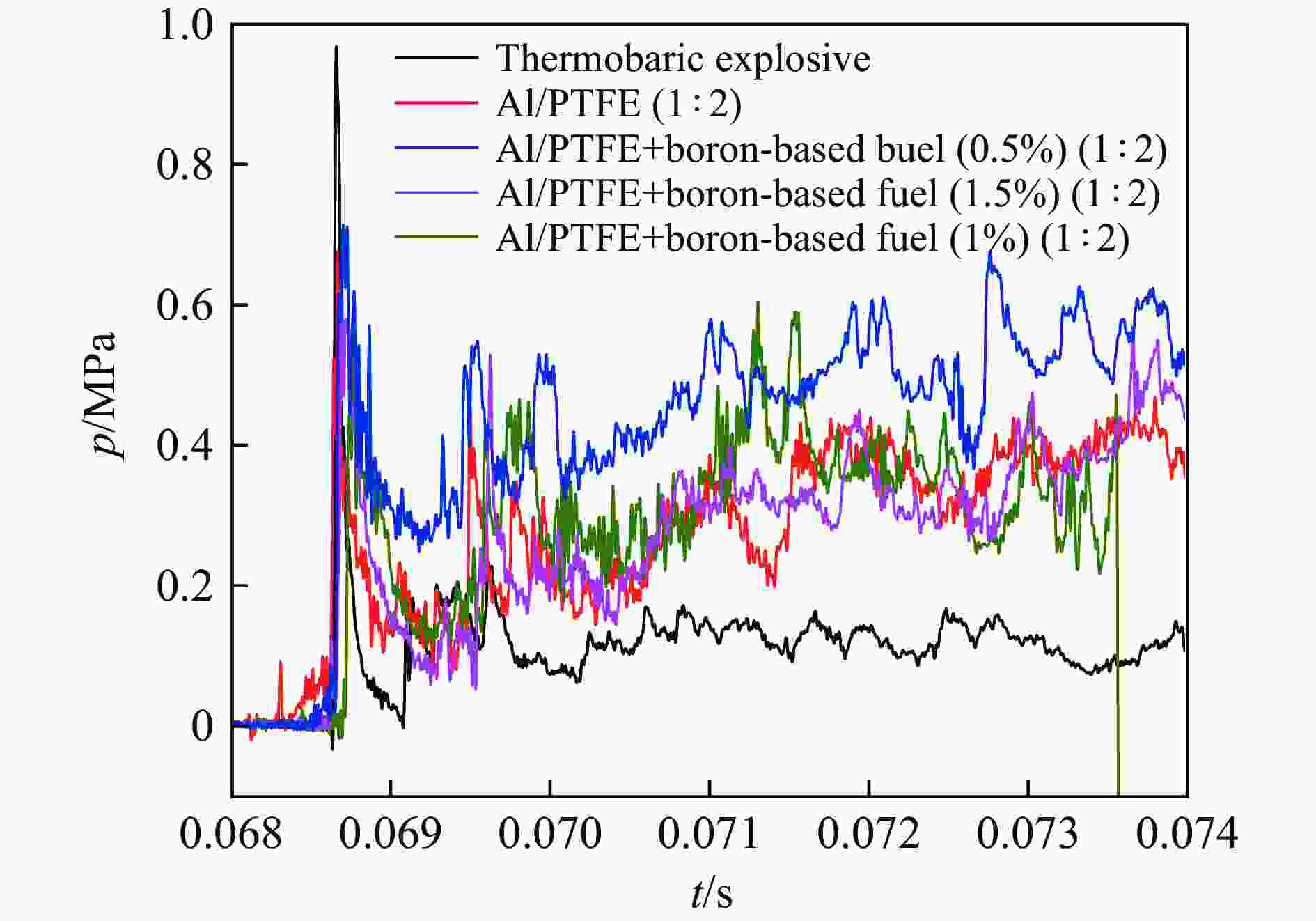

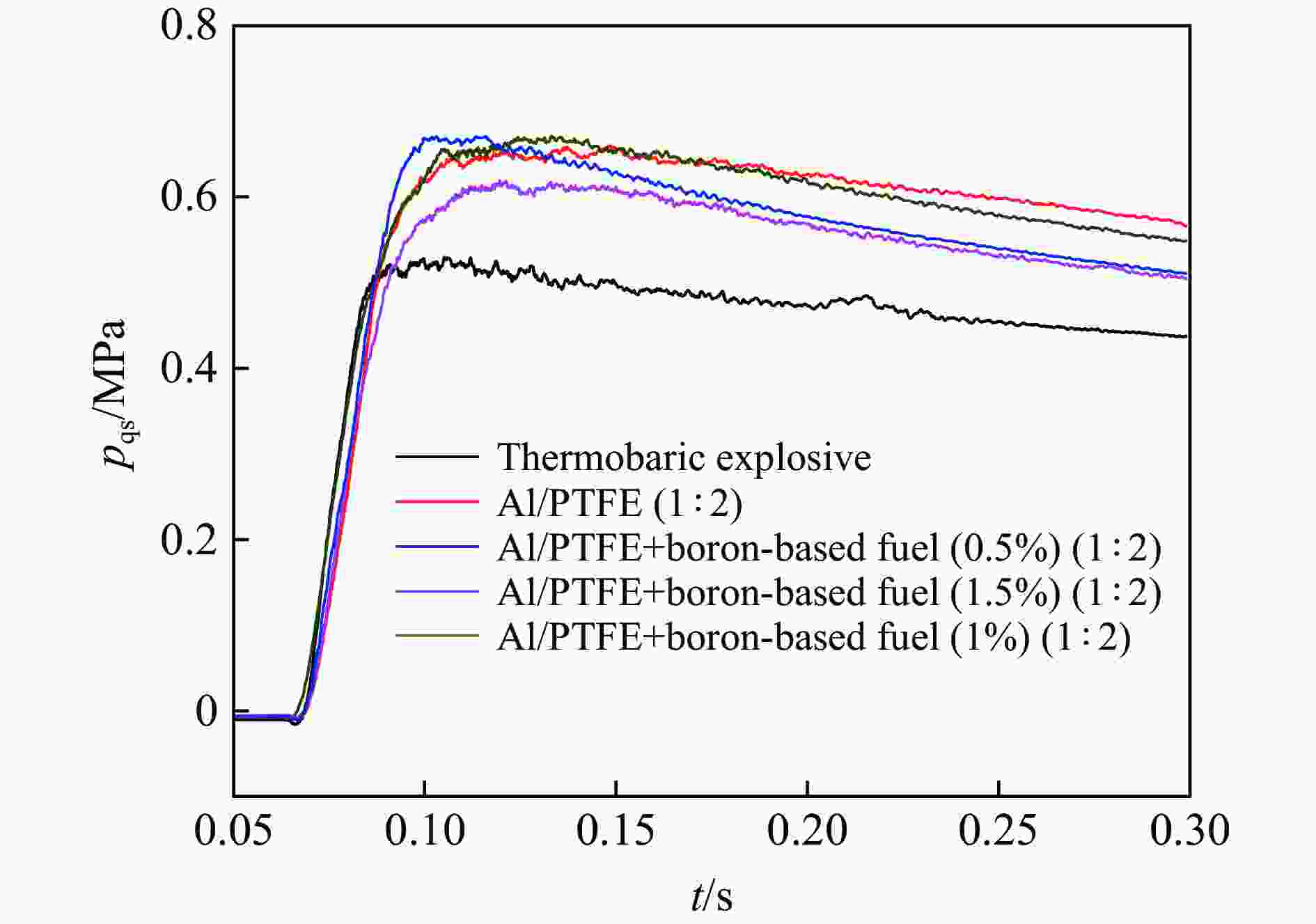

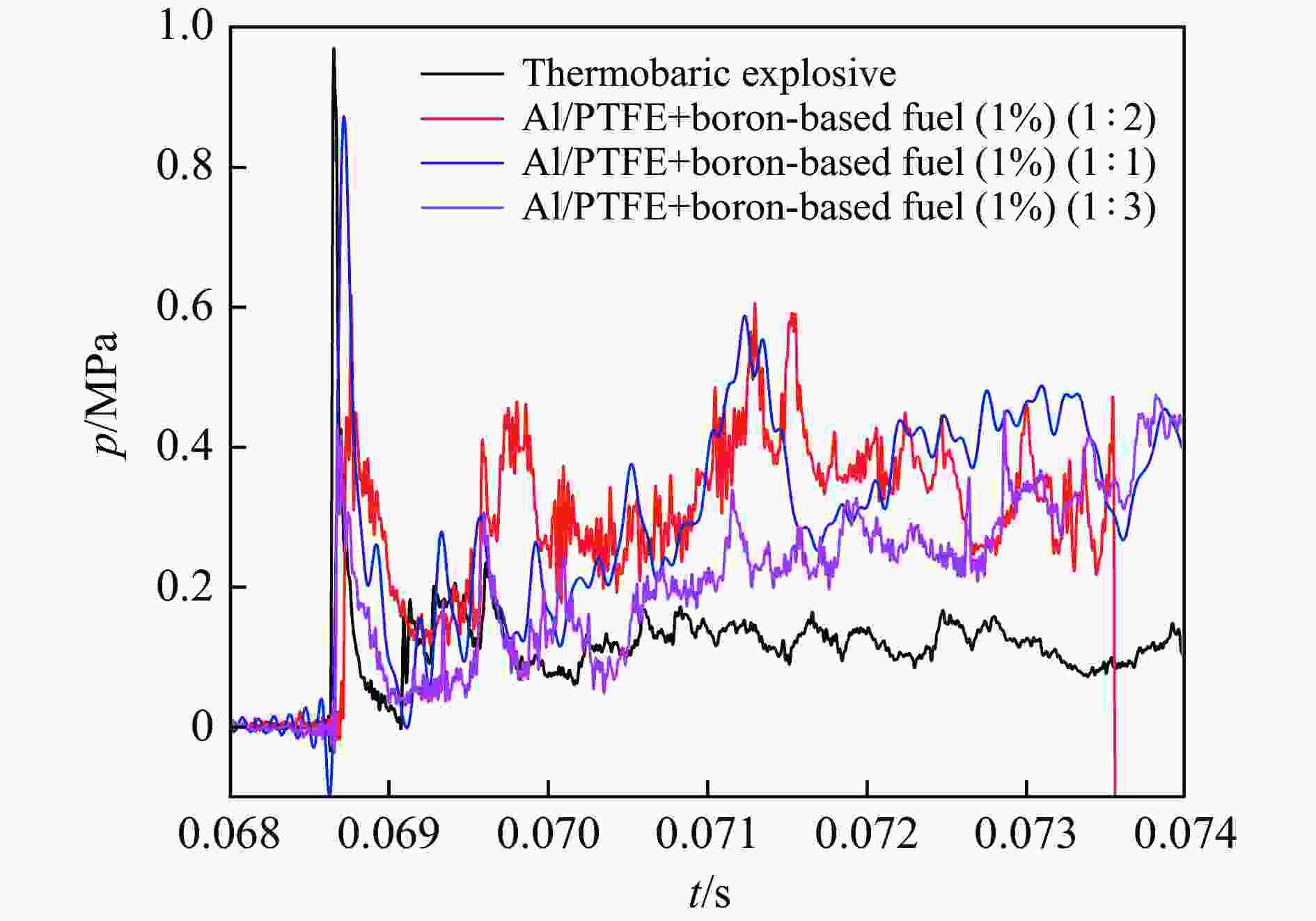

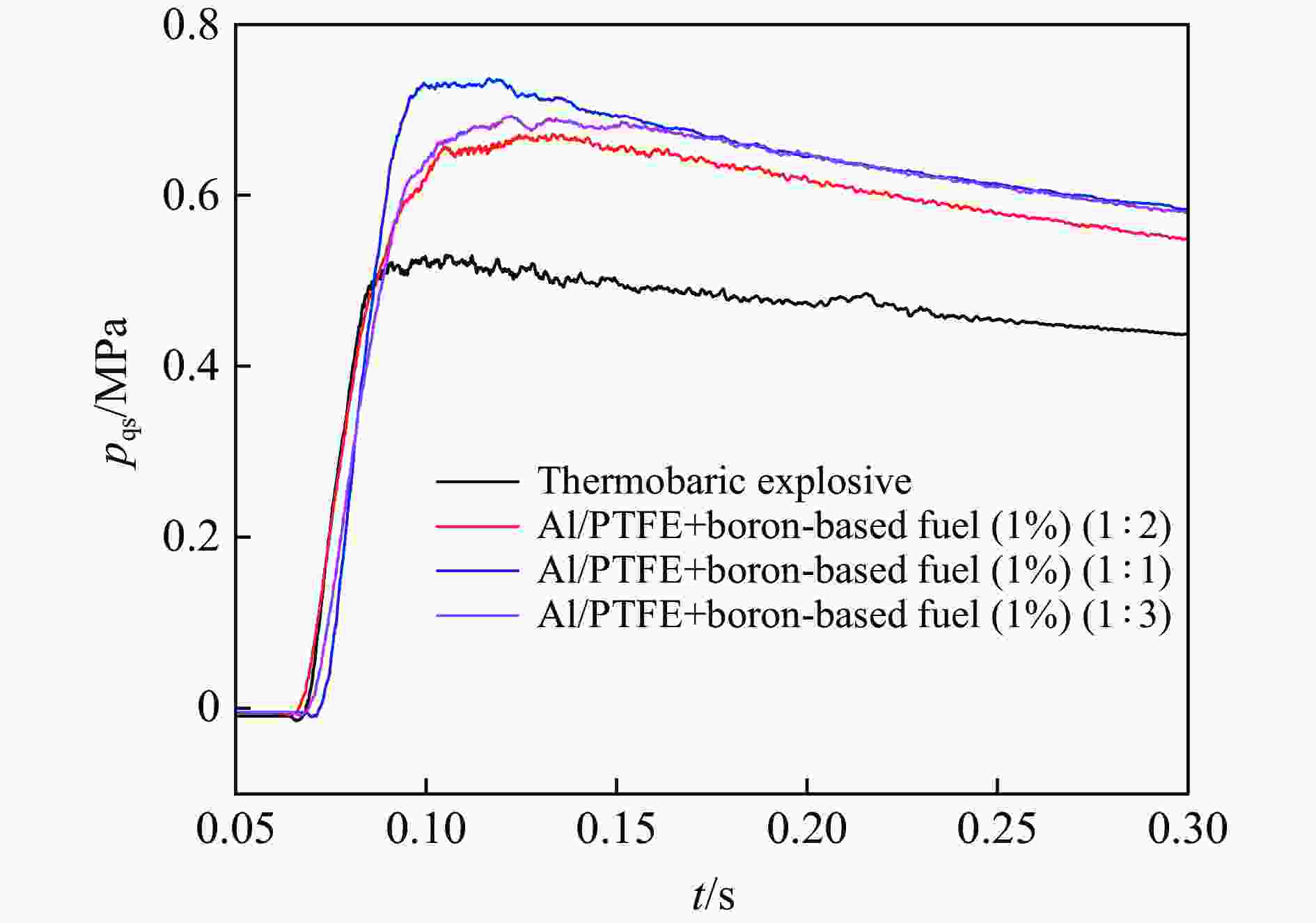

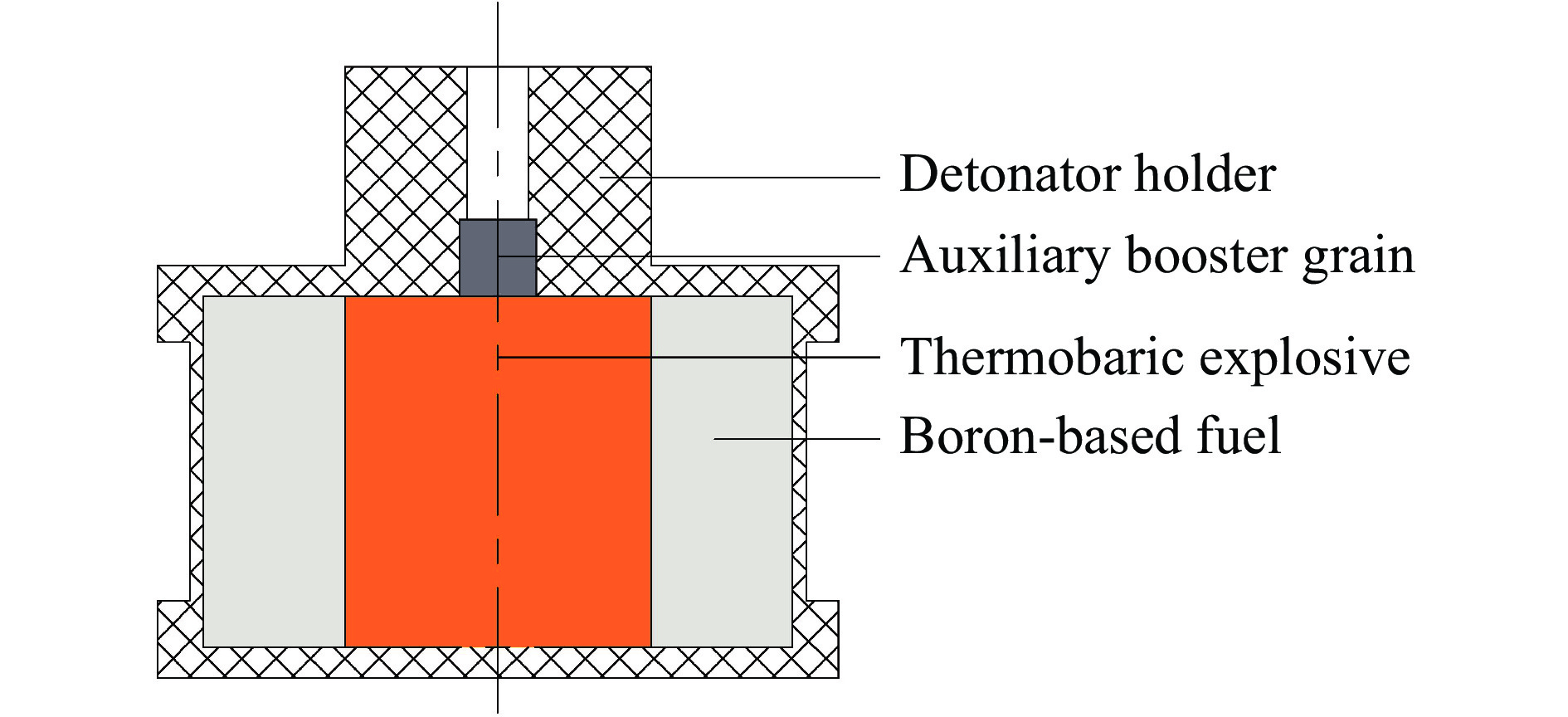

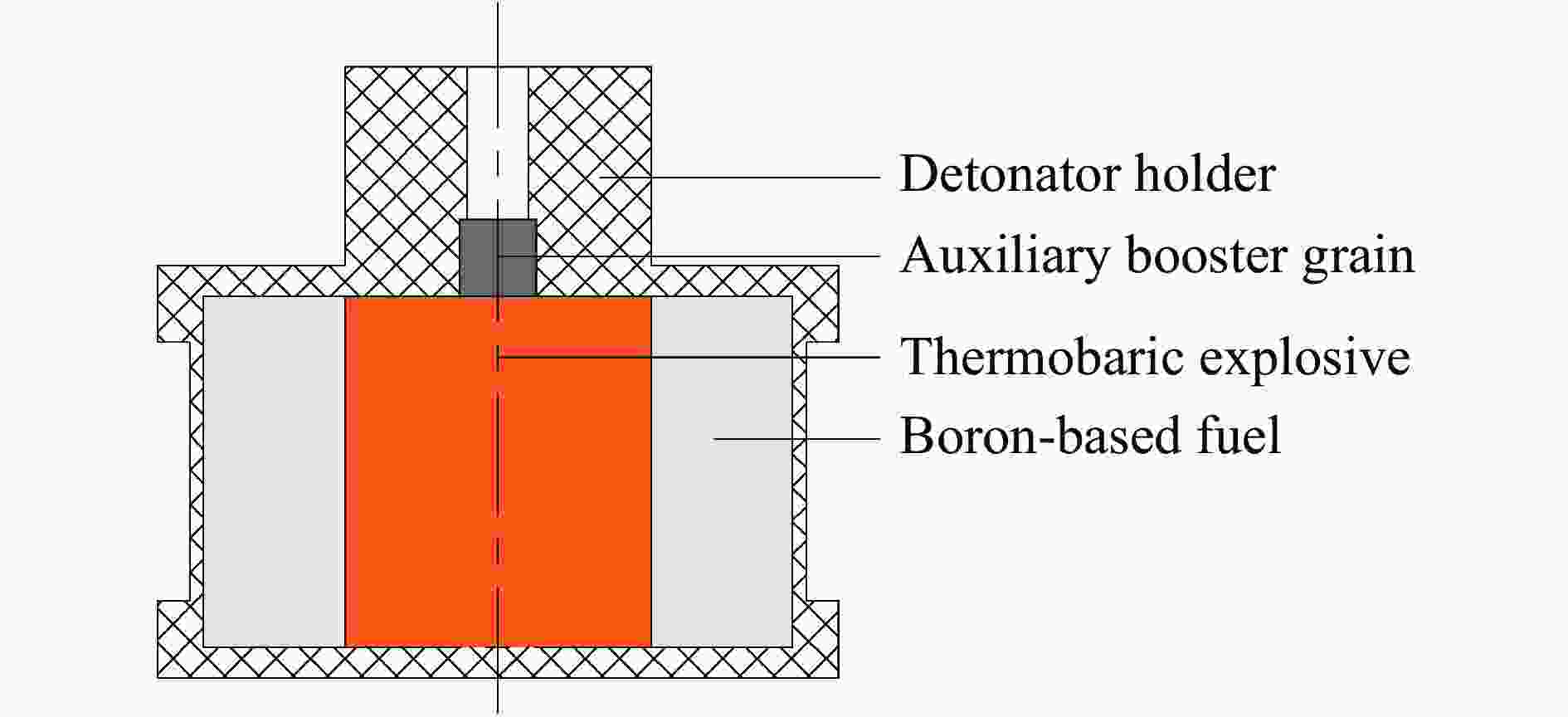

摘要: 为研究密闭空间中复合装药能量的释放特性,设计了一种同轴复合装药,其内层为温压炸药,外层为不同组分的混合燃料,混合燃料主要由铝/聚四氟乙烯(Al/PTFE)活性材料或硼基燃料组成,利用密闭爆炸装置开展了复合装药内爆炸试验,获取了壁面冲击波超压和准静态压力。试验结果表明:相同质量、不同硼基燃料含量的复合装药在密闭空间内爆炸,产生的准静态压力随着硼基燃料含量的增加呈现先升高后降低的趋势,硼基燃料分解产物参与二次反应的最佳体积分数在1.0%左右;对于复合装药,密闭空间中氧气含量有限,当参与二次反应的物质浓度达到一定阈值,无论是提高点火能量还是提高反应物浓度,准静态压力都无法获得高效提升,能量利用率没有提高。Abstract: In order to study the energy release characteristics of composite charge in confined space, a type of coaxial composite charge was designed with the inner layer of thermobaric explosive and the outer layer of mixed fuel of different components. And the mixed fuel was mainly composed of Al/PTFE active material or boron-based fuel. Al/PTFE active material can undergo a detonation-like reaction and provide energy for the shock wave, but its reaction products are all solid. The lack of gaseous medium is not conducive to shock wave propagation. However, boron-based fuel can decompose to produce gas under detonation loading, which can make up for the shortcomings of Al/PTFE active material. The mixed fuel formulations were designed and the content of boron-based fuel in different formulations was determined. The internal explosion test of composite charge was carried out by using sealed explosion device. The shock wave overpressure on the device wall and the quasi-static pressure were obtained, which can be used to evaluate the implosion power of the composite charges. The effects of boron-fuel content, secondary ignition energy and reactant concentration on the post-combustion reaction and energy release characteristics of the composite charges were investigated by using the method of implosion power evaluation. The experimental results show that the quasi-static pressure of the composite charge with the same mass but different boron-based fuel content increases first and then decreases with the increase of boron-based fuel content, and the optimal volume fraction of boron-based fuel decomposition products participating in the secondary reaction is about 1.0%. For the composite charge, because the oxygen content in the confined space is limited, when the concentration of substances involved in the secondary reaction reaches a certain threshold, the quasi-static pressure cannot be effectively improved by increasing the ignition energy or the reactant concentration, and the energy utilization rate is not improved.

-

Key words:

- composite charge /

- internal explosion /

- quasi static pressure /

- Al/PTFE /

- boron-based fuel

-

表 1 试验样品状态

Table 1. Test sample status

试样 内层材料 内层质量/g 外层材料 外层质量/g 内外层质量比 总质量/g 1 温压炸药 50 温压炸药 100 1∶2 150 2 温压炸药 50 Al/PTFE 100 1∶2 150 3 温压炸药 50 Al/PTFE+硼基燃料(0.5%) 100 1∶2 150 4 温压炸药 50 Al/PTFE+硼基燃料(1.5%) 100 1∶2 150 5 温压炸药 50 Al/PTFE+硼基燃料(1%) 100 1∶2 150 6 温压炸药 100 Al/PTFE+硼基燃料(1%) 100 1∶1 200 7 温压炸药 50 Al/PTFE+硼基燃料(1%) 150 1∶3 200 注:表中的0.5%、1.5%和1%为硼基燃料的分解产物在爆炸装置内爆炸产物中的体积分数,在后文中能够以此推算硼基燃料的质量。 表 2 内爆试验结果

Table 2. Internal explosion test results

试样 外层材料 冲击波超压峰值/

MPa冲击波冲量/

(MPa·s)准静态压力峰值/

MPa准静态压力/

MPa准静压上升速率/

(MPa·s−1)1 温压炸药 0.970 0.0006 0.529 0.501 20.95 2 Al/PTFE(1∶2) 0.677 0.0015 0.659 0.642 15.77 3 Al/PTFE+硼基燃料(0.5%)(1∶2) 0.715 0.0023 0.670 0.627 19.62 4 Al/PTFE+硼基燃料(1.5%)(1∶2) 0.630 0.0014 0.619 0.593 13.42 5 Al/PTFE+硼基燃料(1%)(1∶2) 0.618 0.0015 0.671 0.646 17.35 6 Al/PTFE+硼基燃料(1%)(1∶1) 0.873 0.0016 0.736 0.693 25.59 7 Al/PTFE+硼基燃料(1%)(1∶3) 0.432 0.0010 0.692 0.667 14.63 -

[1] 胡宏伟, 宋浦, 赵省向, 等. 有限空间内部爆炸研究进展 [J]. 含能材料, 2013, 21(4): 539–546. DOI: 10.3969/j.issn.1006-9941.2013.04.026.HU H W, SONG P, ZHAO S X, et al. Progress in explosion in confined space [J]. Chinese Journal of Energetic Materials, 2013, 21(4): 539–546. DOI: 10.3969/j.issn.1006-9941.2013.04.026. [2] 焦晓龙, 赵鹏铎, 姚养无, 等. 基于仿真与量纲分析的不同药量TNT内爆下多舱室结构毁伤规律研究 [J]. 爆炸与冲击, 2020, 40(8): 085101. DOI: 10.11883/bzyjc-2019-0438.JIAO X L, ZHAO P D, YAO Y W, et al. Regulation of different quantity TNT blasting in multi-cabin structure based on simulation and dimensional analysis [J]. Explosion and Shock Waves, 2020, 40(8): 085101. DOI: 10.11883/bzyjc-2019-0438. [3] 李芝绒, 张玉磊, 袁建飞, 等. 内部爆炸薄圆板的变形及有效载荷 [J]. 爆炸与冲击, 2020, 40(11): 113101. DOI: 10.11883/bzycj-2020-0045.LI Z R, ZHANG Y L, YUAN J F, et al. Deformation and payload of thin circular plates subjected to internal explosion [J]. Explosion and Shock Waves, 2020, 40(11): 113101. DOI: 10.11883/bzycj-2020-0045. [4] WEIBULL H R W. Pressures recorded in partially closed chambers at explosion of TNT charges [J]. Annals of the New York Academy of Sciences, 1968, 152(1): 357–361. DOI: 10.1111/j.1749-6632.1968.tb11987.x. [5] CARLSON R W. Confinement of an explosion by a steel vessel: LA-390 [R]. Los Alamos: LANL, 1945. [6] MOIR D C. Safety analysis of the M-2 confinement systems: LA-TM-264 [R]. Los Alamos: LANL, 1979. [7] 钟巍, 田宙. 等压假设下考虑化学反应动力学影响的约束爆炸准静态压力的计算 [J]. 爆炸与冲击, 2013, 33(4): 375–380. DOI: 10.3969/j.issn.1001-1455.2013.04.007.ZHONG W, TIAN Z. Calculation of quasi-static pressures for confined explosions considering chemical reactions under isobaric assumption [J]. Explosion and Shock Waves, 2013, 33(4): 375–380. DOI: 10.3969/j.issn.1001-1455.2013.04.007. [8] AMES R G, DROTAR J T, SILBER J, et al. Quantitative distinction between detonation and after burn energy deposition using pressure-time histories in enclosed explosions [C]//Proceedings of the 13th International Detonation Symposium. Norfolk, Virginia: Office of Naval Research, 2006: 253–262. [9] 张玉磊, 李芝绒, 蒋海燕, 等. 温压炸药内爆炸压力特性及威力试验研究 [J]. 兵工学报, 2018, 39(7): 1333–1338. DOI: 10.3969/j.issn.1000-1093.2018.07.011.ZHANG Y L, LI Z R, JIANG H Y, et al. Experimental study of the characteristics of internal explosion pressure and power of thermobaric explosive [J]. Acta Armamentarii, 2018, 39(7): 1333–1338. DOI: 10.3969/j.issn.1000-1093.2018.07.011. [10] 王梓昂, 翟红波, 李芝绒, 等. 不同炸药在圆筒装置内爆炸冲击波载荷传播规律与分布特性 [J]. 弹箭与制导学报, 2019, 39(1): 11–14,20. DOI: 10.15892/j.cnki.djzdxb.2019.01.003.WANG Z A, ZHAI H B, LI Z R, et al. Study on propagation rules and distribution characteristics of explosion shock wave loading on different explosives inside cylindrical device [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2019, 39(1): 11–14,20. DOI: 10.15892/j.cnki.djzdxb.2019.01.003. [11] 金朋刚, 郭炜, 王建灵, 等. 不同粒度铝粉在HMX基炸药中的能量释放特性 [J]. 含能材料, 2015, 23(10): 989–993. DOI: 10.11943/j.issn.1006-9941.2015.10.013.JIN P G, GUO W, WANG J L, et al. Energy releasing characteristics of aluminum powder in HMX-based explosives [J]. Chinese Journal of Energetic Materials, 2015, 23(10): 989–993. DOI: 10.11943/j.issn.1006-9941.2015.10.013. [12] 陈昊, 陶钢, 蒲元. 温压药在有限空间内爆炸冲击波的实验研究及数值模拟 [J]. 火炸药学报, 2009, 32(5): 41–45,57. DOI: 10.3969/j.issn.1007-7812.2009.05.012.CHEN H, TAO G, PU Y. Experiment study and numerical simulation of shock wave generated by thermobaric column exploding in limited space [J]. Chinese Journal of Explosives and Propellants, 2009, 32(5): 41–45,57. DOI: 10.3969/j.issn.1007-7812.2009.05.012. [13] 刘欣, 顾文彬, 蔡星会, 等. 圆柱形爆炸容器的内壁爆炸载荷 [J]. 爆炸与冲击, 2022, 42(2): 022201. DOI: 10.11883/bzycj-2021-0209.LIU X, GU W B, CAI X H, et al. Blast loads on the inner wall of cylindrical explosion containment vessel [J]. Explosion and Shock Waves, 2022, 42(2): 022201. DOI: 10.11883/bzycj-2021-0209. [14] 李芝绒, 翟红波, 闫潇敏, 等. 一种温压内爆炸准静态压力测量方法研究 [J]. 传感技术学报, 2016, 29(2): 208–212. DOI: 10.3969/j.issn.1004-1699.2016.02.010.LI Z R, ZHAI H B, YAN X M, et al. Test method research for the quas-static pressure on inside-explosive [J]. Chinese Journal of Sensors and Actuators, 2016, 29(2): 208–212. DOI: 10.3969/j.issn.1004-1699.2016.02.010. [15] 李尚青, 李芝绒, 张玉磊, 等. 炸药在预制条形孔圆筒装置内爆炸威力的评价方法 [J]. 火炸药学报, 2020, 43(3): 341–344,350. DOI: 10.14077/j.issn.1007-7812.201902015.LI S Q, LI Z R, ZHANG Y L, et al. An evaluation method of internal blast power in a perforated cylinder device [J]. Chinese Journal of Explosives and Propellants, 2020, 43(3): 341–344,350. DOI: 10.14077/j.issn.1007-7812.201902015. [16] 陈坤, 肖伟, 韩志伟, 等. 铝粉粒径对HMX基温压炸药在密闭空间爆炸参数的影响 [J]. 火炸药学报, 2020, 43(3): 298–302,307. DOI: 10.14077/j.issn.1007-7812.201909018.CHEN K, XIAO W, HAN Z W, et al. Effect of aluminum particle size on the explosion parameters of HMX-based thermobaric explosives in confined space [J]. Chinese Journal of Explosives and Propellants, 2020, 43(3): 298–302,307. DOI: 10.14077/j.issn.1007-7812.201909018. [17] 李凌峰, 王辉, 韩秀凤, 等. Al/PTFE与炸药组合装药的爆炸释能特性 [J]. 火炸药学报, 2023, 46(1): 69–75. DOI: 10.14077/j.issn.1007-7812.202205006.LI L F, WANG H, HAN X F, et al. Explosive energy release characteristics of composite charges with Al/PTFE and explosives [J]. Chinese Journal of Explosives and Propellants, 2023, 46(1): 69–75. DOI: 10.14077/j.issn.1007-7812.202205006. [18] 陶俊, 王晓峰. 金属-氟聚物机械活化含能材料的研究进展 [J]. 火炸药学报, 2017, 40(5): 8–14. DOI: 10.14077/j.issn.1007-7812.2017.05.022.TAO J, WANG X F. Research progress in metal-fluoropolymer mechanical activation energetic composites [J]. Chinese Journal of Explosives and Propellants, 2017, 40(5): 8–14. DOI: 10.14077/j.issn.1007-7812.2017.05.022. [19] 张玉磊, 苏健军, 李芝绒, 等. TNT内爆炸准静态压力特性 [J]. 爆炸与冲击, 2018, 38(6): 1429–1434. DOI: 10.11883/bzycj-2017-0170.ZHANG Y L, SU J J, LI Z R, et al. Quasi-static pressure characteristic of TNT’s internal explosion [J]. Explosion and Shock Waves, 2018, 38(6): 1429–1434. DOI: 10.11883/bzycj-2017-0170. -

下载:

下载: